Live Pig-Weight Learning and Prediction Method Based on a Multilayer RBF Network

Abstract

:1. Introduction

2. Material and Methods

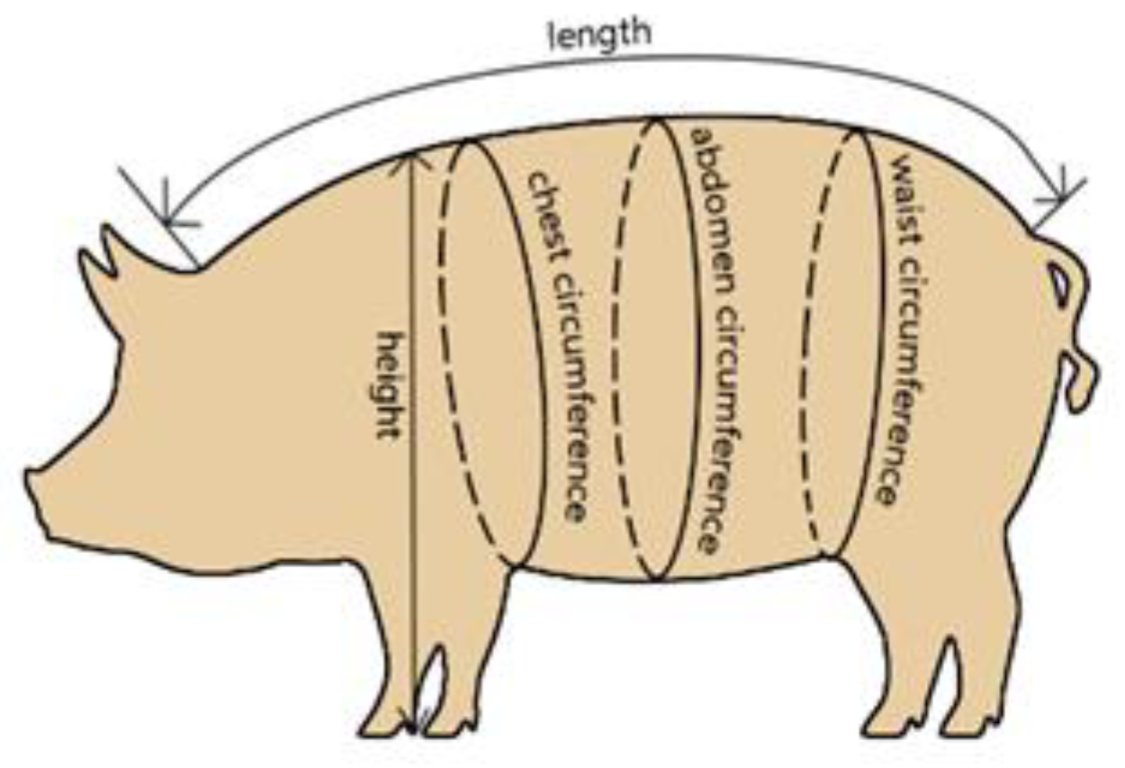

2.1. Data

2.2. Data Preprocessing

2.3. RBF Network Structure

2.4. The Model of Deep Learning Network Framework in This Paper

2.5. BP network and Machine Learning Algorithms

3. Result

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Alsahaf, A.; Azzopardi, G.; Ducro, B.; Hanenberg, E.; Veerkamp, R.F.; Petkov, N. Prediction of Slaughter Age in Pigs and Assessment of the Predictive Value of Phenotypic and Genetic Information Using Random Forest. J. Anim. Sci. 2018, 96, 4935–4943. [Google Scholar] [CrossRef]

- Sharp, J.R.; Turner, M.J.B. Automatic Weight Monitoring of Pigs—Part II: Analysis of Results From Trial Work of Mk II In-Pen Pig Weigher; National Institute of Agricultural Engineering Divisional Note DN: Silsoe, UK, 1985; p. 1267. [Google Scholar]

- Brandl, N.; Jørgensen, E. Determination of Live Weight of Pigs from Dimensions Measured Using Image Analysis. Comput. Electron. Agric. 1996, 15, 57–72. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, W.; Winter, P.; Walker, L.T. Non-contact sensing of hog weights by machine vision. Appl. Eng. Agric. 2006, 22, 577–582. [Google Scholar] [CrossRef]

- Tscharke, M.; Banhazi, T.M. Growth Recorded Automatically and Continuously by a Machine Vision System for Finisher Pigs. Aust. J. Multi-Discip. Eng. 2013, 10, 70–80. [Google Scholar] [CrossRef] [Green Version]

- Song, X.; Bokkers, E.A.M.; van der Tol, P.P.J.; Groot Koerkamp, P.W.G.; van Mourik, S. Automated Body Weight Prediction of Dairy Cows Using 3-Dimensional Vision. J. Dairy Sci. 2018, 101, 4448–4459. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kashiha, M.; Bahr, C.; Ott, S.; Moons, C.P.H.; Niewold, T.A.; Ödberg, F.O.; Berckmans, D. Weight Estimation of Pigs Using Top-View Image Processing. In Image Analysis and Recognition; Campilho, A., Kamel, M., Eds.; Lecture Notes in Computer Science; Springer International Publishing: Cham, Switzerland, 2014; Volume 8814, pp. 496–503. [Google Scholar] [CrossRef]

- White, R.P.; Schofield, C.P.; Green, D.M.; Parsons, D.J.; Whittemore, C.T. The Effectiveness of a Visual Image Analysis (VIA) System for Monitoring the Performance of Growing/Finishing Pigs. Anim. Sci. 2004, 78, 409–418. [Google Scholar] [CrossRef] [Green Version]

- Minagawa, H.; Murakami, T. A hands-off method to estimate pig weight by light projection and image analysis. In Livestock Environment VI, Proceedings of the 6th International Symposium 2001, Louisville, KY, USA, 21–23 May 2001; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2001. [Google Scholar] [CrossRef]

- Minagawa, H. Stereo Photogrammetric Errors in Determining the Surface Area of a Small Pig Model with Non-Metric Cameras. J. Agric. Meteorol. 1995, 51, 335–343. [Google Scholar] [CrossRef]

- Li, Z.; Luo, C.; Teng, G.; Liu, T. Estimation of Pig Weight by Machine Vision: A Review. Computer and Computing Technologies in Agriculture VII. CCTA 2013. IFIP Adv. Inf. Commun. Technol. 2014, 420, 42–49. [Google Scholar] [CrossRef]

- Kongsro, J. Estimation of Pig Weight Using a Microsoft Kinect Prototype Imaging System. Comput. Electron. Agric. 2014, 109, 32–35. [Google Scholar] [CrossRef]

- Shi, C.; Teng, G.; Li, Z. An Approach of Pig Weight Estimation Using Binocular Stereo System Based on LabVIEW. Comput. Electron. Agric. 2016, 129, 37–43. [Google Scholar] [CrossRef]

- Pezzuolo, A.; Guarino, M.; Sartori, L.; González, L.A.; Marinello, F. On-Barn Pig Weight Estimation Based on Body Measurements by a Kinect v1 Depth Camera. Comput. Electron. Agric. 2018, 148, 29–36. [Google Scholar] [CrossRef]

- Kaewtapee, C.; Rakangtong, C.; Bunchasak, C. Pig Weight Estimation Using Image Processing and Artificial Neural Networks. JOAAT 2019, 6, 253–256. [Google Scholar] [CrossRef]

- Tasdemir, S.; Ozkan, I.A. Ann approach for estimation of cow weight depending on photogrammetric body dimensions. Int. J. Eng. Geosci. 2019, 4, 36–44. [Google Scholar] [CrossRef] [Green Version]

- Bhatt, C.; Hassanien, A.E.; Shah, N.A.; Thik, J. Barqi breed sheep weight estimation based on neural network with regression. arXiv 2018, arXiv:1807.10568. [Google Scholar] [CrossRef]

- Spoliansky, R.; Edan, Y.; Parmet, Y.; Halachmi, I. Development of Automatic Body Condition Scoring Using a Low-Cost 3-Dimensional Kinect Camera. J. Dairy Sci. 2016, 99, 7714–7725. [Google Scholar] [CrossRef] [Green Version]

- Haile-Mariam, M.; Gonzalez-Recio, O.; Pryce, J.E. Prediction of Liveweight of Cows from Type Traits and Its Relationship with Production and Fitness Traits. J. Dairy Sci. 2014, 97, 3173–3189. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jensen, D.B.; Dominiak, K.N.; Pedersen, L.J. Automatic estimation of slaughter pig live weight using convolutional neural networks. In Proceedings of the II International Conference on Agro Big Data and Decision Support Systems in Agriculture, Lleida, Spain, 12–14 July 2018. [Google Scholar]

- Cang, Y.; He, H.; Qiao, Y. An Intelligent Pig Weights Estimate Method Based on Deep Learning in Sow Stall Environments. IEEE Access 2019, 7, 164867–164875. [Google Scholar] [CrossRef]

- Huma, Z.E.; Iqbal, F. Predicting the Body Weight of Balochi Sheep Using a Machine Learning Approach. Turk. J. Vet. Anim. Sci. 2019, 43, 500–506. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, W.; Winter, P.; Walker, L. Walk-through Weighing of Pigs Using Machine Vision and an Artificial Neural Network. Biosyst. Eng. 2008, 100, 117–125. [Google Scholar] [CrossRef]

- He, Y.; Tiezzi, F.; Howard, J.; Maltecca, C. Predicting Body Weight in Growing Pigs from Feeding Behavior Data Using Machine Learning Algorithms. Comput. Electron. Agric. 2021, 184, 106085. [Google Scholar] [CrossRef]

- Walugembe, M.; Nadiope, G.; Stock, J.D.; Stalder, K.J.; Rothschild, M.F. Prediction of Live Body Weight Using Various Body Measurements in Ugandan Village Pigs. Development 2014, 26, 5. [Google Scholar]

- Use Heart Girth to Estimate the Weight of Finishing Pigs. Available online: https://www.thepigsite.com/articles/use-heart-girth-to-estimate-the-weight-of-finishing-pigs (accessed on 8 January 2023.).

- Maruyama, M.; Girosi, F.; Poggio, T. A Connection Between GRBF and MLP; Laboratory Massachusetts Institute of Technology: Cambridge, MA, USA, 1992. [Google Scholar]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-learn: Machine Learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- Chen, T.; Guestrin, C. XGBoost: A Scalable Tree Boosting System. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; pp. 785–794. [Google Scholar] [CrossRef] [Green Version]

- Breiman, L. Stacked Regressions. Mach. Learn. 1996, 24, 49–64. [Google Scholar] [CrossRef]

| Serial Number | Body Length (cm) | Height (cm) | Chest Circumference (cm) | Abdomen Circumference (cm) | Waist Circumference (cm) | Body Weight (kg) |

|---|---|---|---|---|---|---|

| 1 | 121 | 67 | 105 | 115 | 103 | 117.5 |

| 2 | 120 | 69 | 107 | 118 | 105 | 113.7 |

| 3 | 117 | 64 | 103 | 111 | 104 | 105.6 |

| 4 | 125 | 69 | 108 | 120 | 107 | 120.0 |

| 5 | 126 | 65 | 111 | 123 | 110 | 120.3 |

| Algorithm | On Training Dataset | On Testing Dataset | ||||||

|---|---|---|---|---|---|---|---|---|

| R2 | MAE | RMSE | MAPE | R2 | MAE | RMSE | MAPE | |

| RandomForestRegressor | 0.59 | 2.01 | 6.44 | 1.82 | 0.38 | 2.05 | 6.55 | 1.85 |

| ExtraTreesRegressor | 0.65 | 1.95 | 5.82 | 1.76 | 0.43 | 1.96 | 5.99 | 1.78 |

| KNeighborsRegressor | 0.71 | 1.83 | 5.25 | 1.65 | 0.48 | 1.99 | 6.27 | 1.81 |

| GradientBoostingRegressor | 0.69 | 1.88 | 5.67 | 1.71 | 0.53 | 1.92 | 5.76 | 1.73 |

| XGBRegressor | 0.74 | 1.77 | 4.89 | 1.59 | 0.53 | 1.91 | 5.97 | 1.73 |

| CatBoostRegressor | 0.70 | 1.88 | 5.61 | 1.70 | 0.54 | 1.89 | 5.67 | 1.71 |

| BayesianRidge | 0.54 | 2.18 | 7.66 | 1.99 | 0.44 | 2.24 | 7.75 | 2.02 |

| BP Network | 0.52 | 2.10 | 6.58 | 1.91 | 0.43 | 2.26 | 8.07 | 2.03 |

| Multilayer RBF network | 0.72 | 1.68 | 5.03 | 1.53 | 0.63 | 1.85 | 5.74 | 1.68 |

| Algorithm | R2 | MAE | RMSE | MAPE | ||||

|---|---|---|---|---|---|---|---|---|

| Mean | SD | Mean | SD | Mean | SD | Mean | SD | |

| Multilayer RBF network | 0.66 | 0.037 | 1.95 | 0.012 | 6.15 | 0.069 | 1.71 | 0.011 |

| Breed and Gender | On Training Dataset | On Testing Dataset | ||||||

|---|---|---|---|---|---|---|---|---|

| R2 | MAE | RMSE | MAPE | R2 | MAE | RMSE | MAPE | |

| Duroc boar | 0.89 | 1.08 | 2.08 | 0.95 | 0.85 | 1.40 | 3.48 | 1.23 |

| Duroc sow | 0.84 | 1.05 | 2.02 | 0.96 | 0.79 | 1.20 | 2.77 | 1.10 |

| Duroc boars and sows mixed | 0.72 | 1.68 | 5.03 | 1.53 | 0.63 | 1.85 | 5.74 | 1.68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Liang, Y.; Huang, H.; Huang, Q.; Gu, W.; Liang, H. Live Pig-Weight Learning and Prediction Method Based on a Multilayer RBF Network. Agriculture 2023, 13, 253. https://doi.org/10.3390/agriculture13020253

Chen H, Liang Y, Huang H, Huang Q, Gu W, Liang H. Live Pig-Weight Learning and Prediction Method Based on a Multilayer RBF Network. Agriculture. 2023; 13(2):253. https://doi.org/10.3390/agriculture13020253

Chicago/Turabian StyleChen, Haoming, Yun Liang, Hao Huang, Qiong Huang, Wei Gu, and Hao Liang. 2023. "Live Pig-Weight Learning and Prediction Method Based on a Multilayer RBF Network" Agriculture 13, no. 2: 253. https://doi.org/10.3390/agriculture13020253