Design and Test of a Crawler-Type Tiger-Nut Combine Harvester

Abstract

:1. Introduction

2. Structure and Working Principle

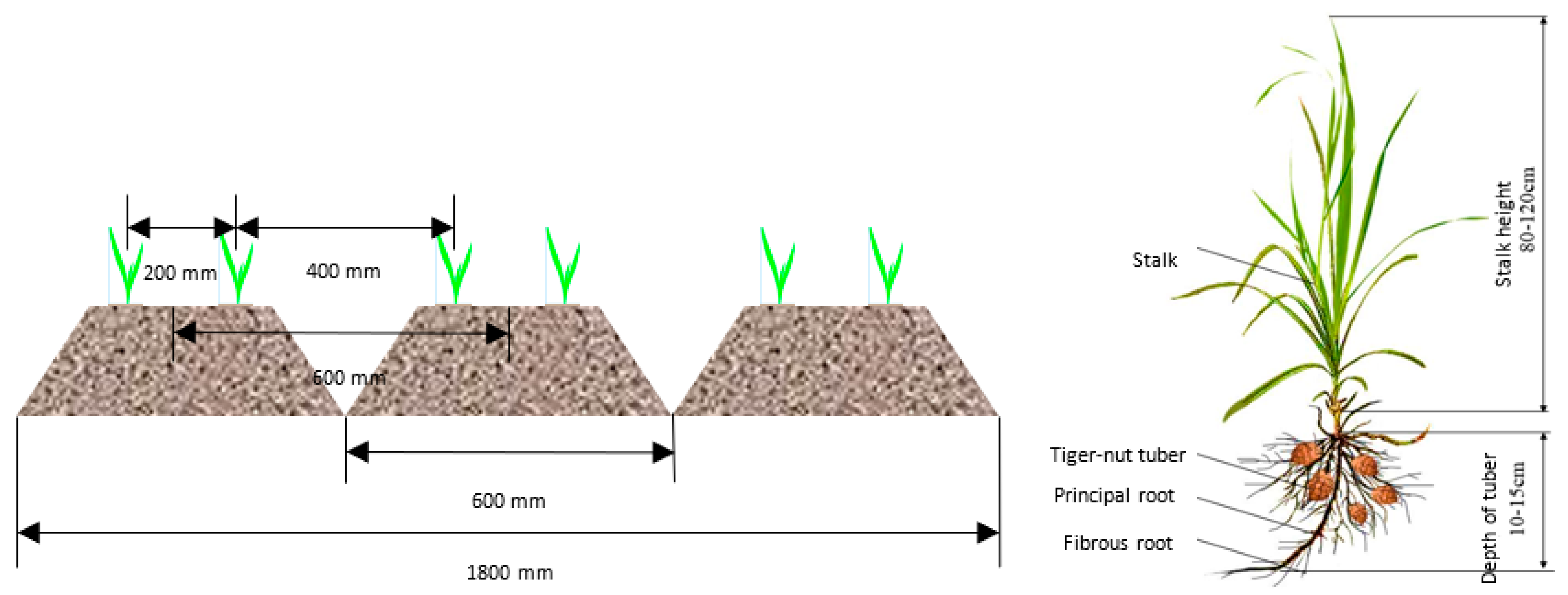

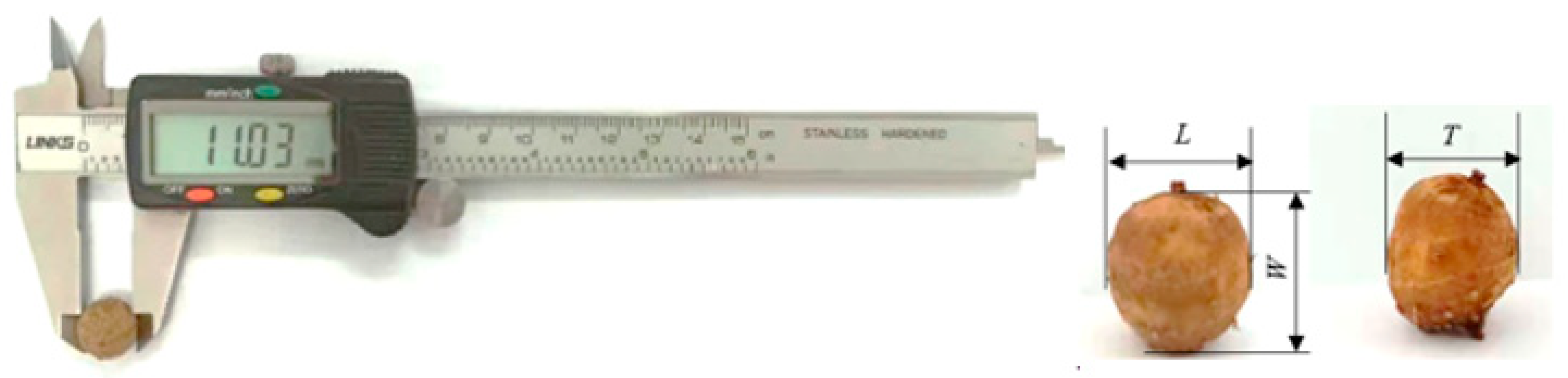

2.1. Planting of Tiger Nuts

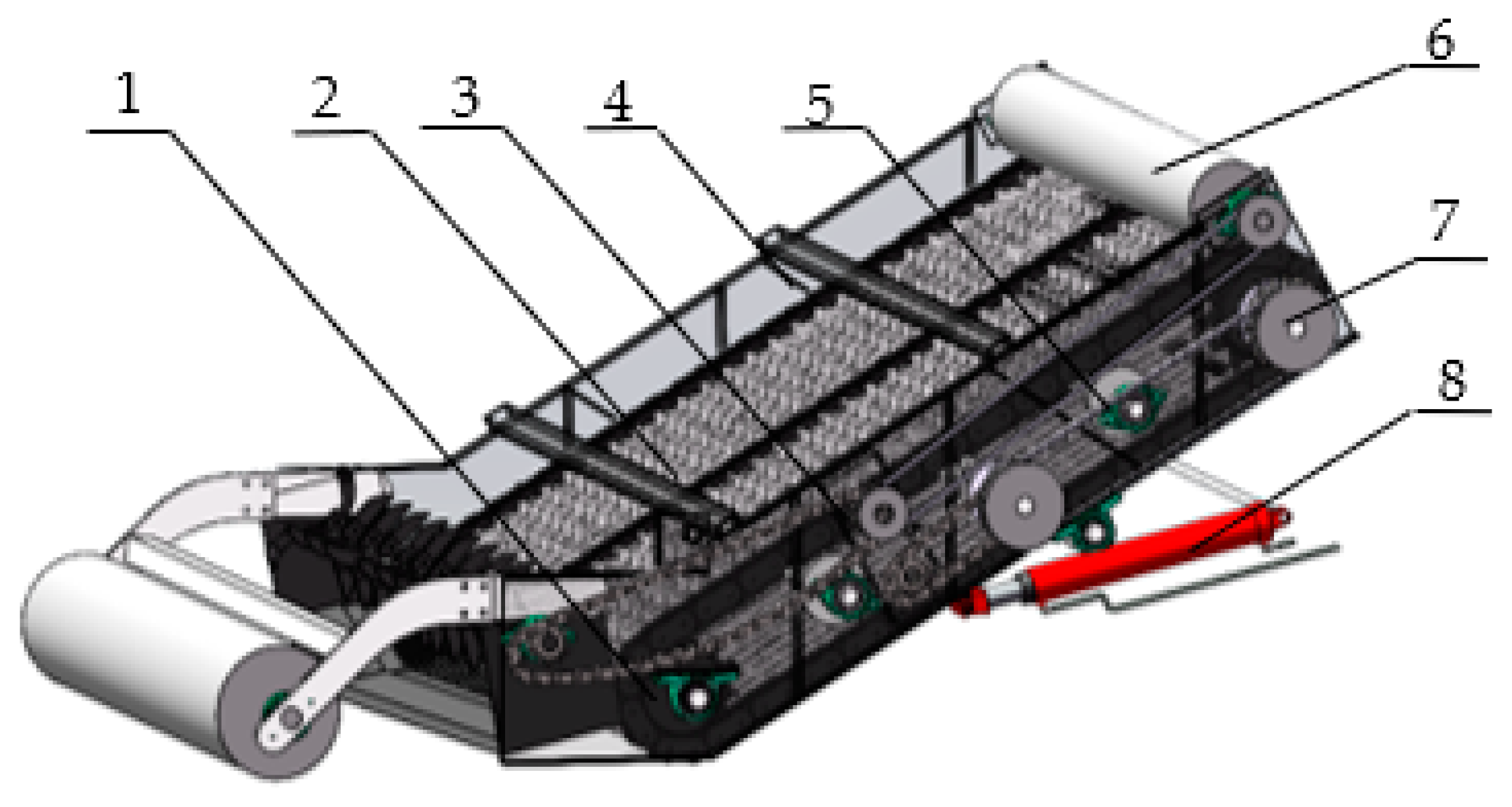

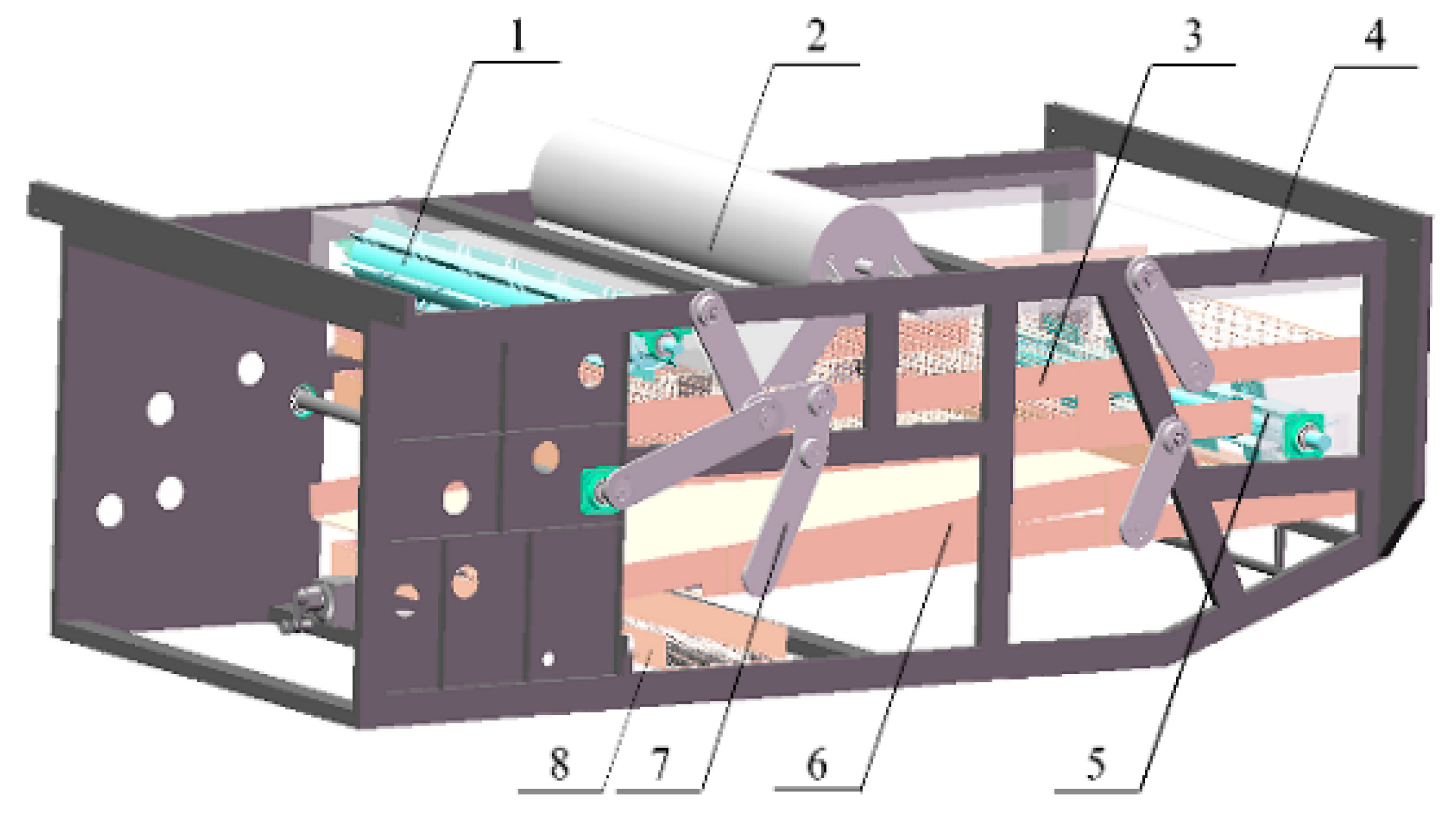

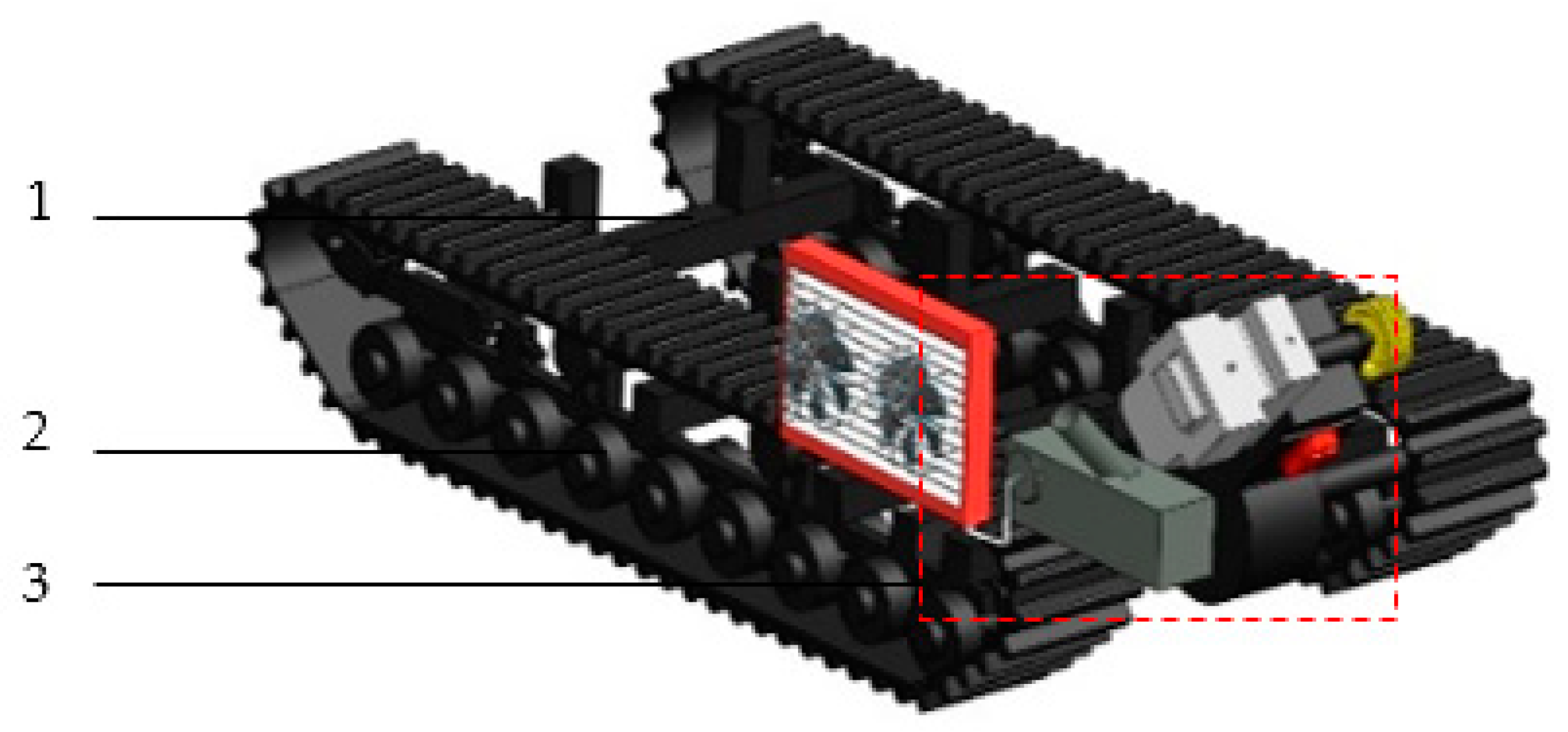

2.2. The Structure

2.3. Working Principle

3. Design of Key Devices

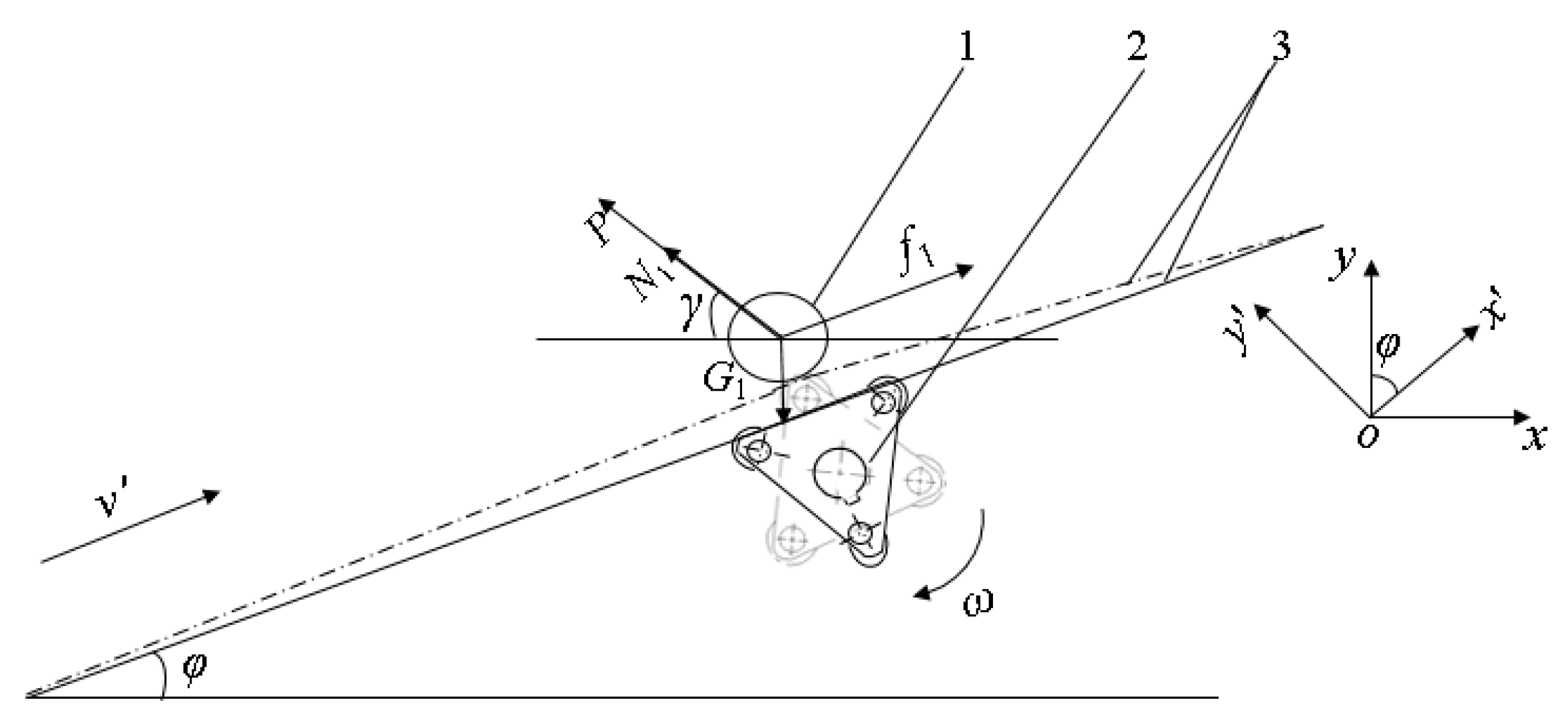

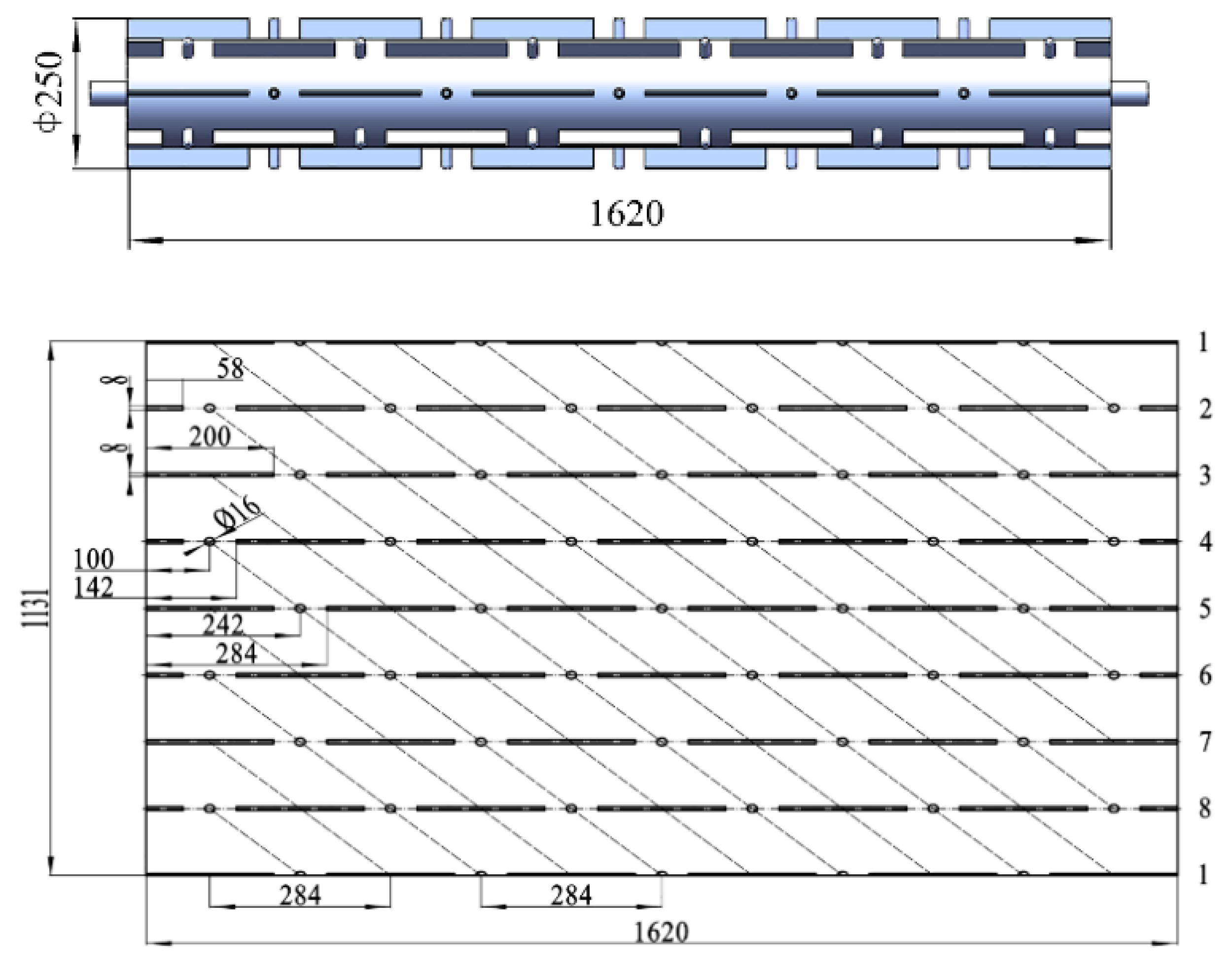

3.1. Design of the Digging and Hoisting Devices

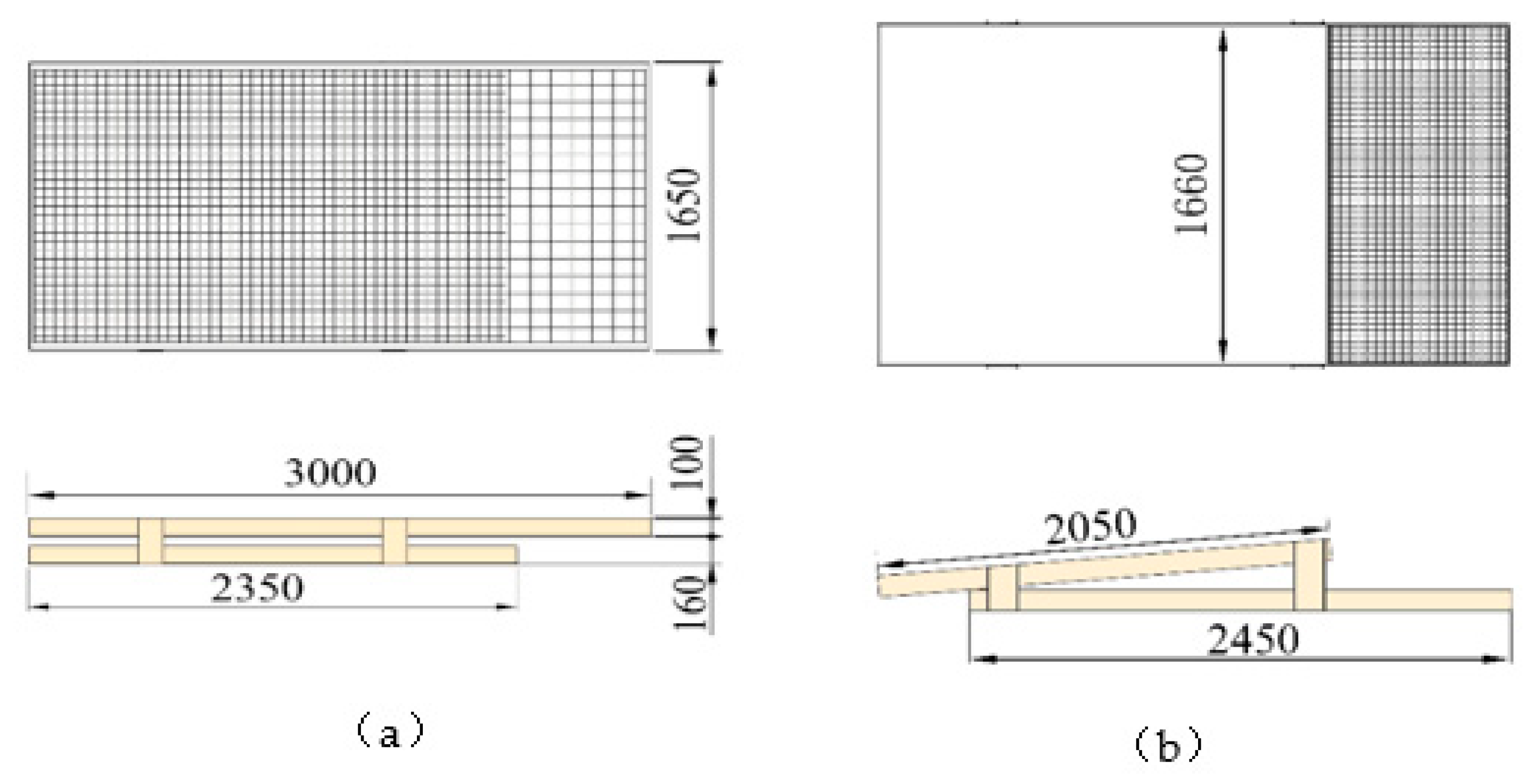

3.2. Design of the Tuber Picking and Screening Devices

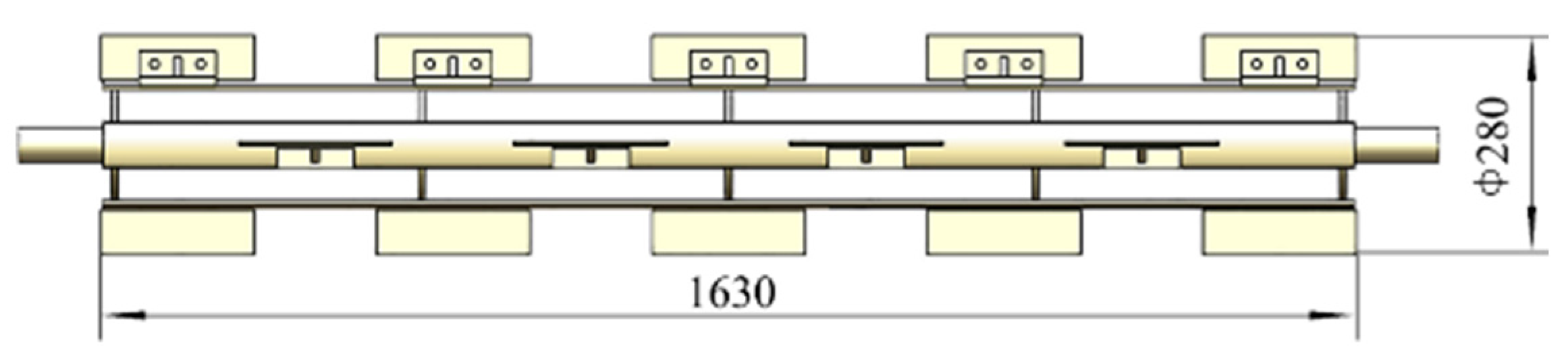

3.3. Design of the Crawler Devices

4. Simulation Tests

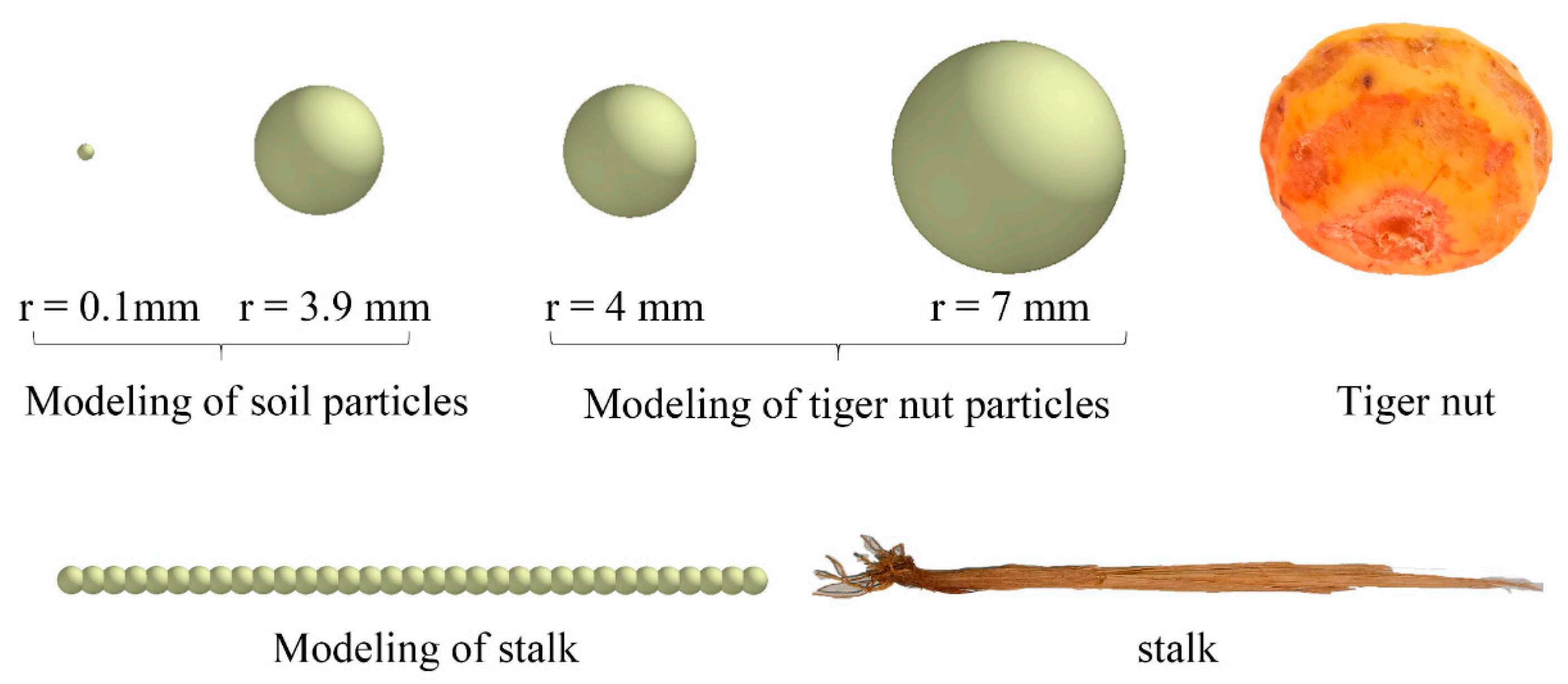

4.1. Establishment of the Simulation Models

4.2. Setting the Simulation Parameters

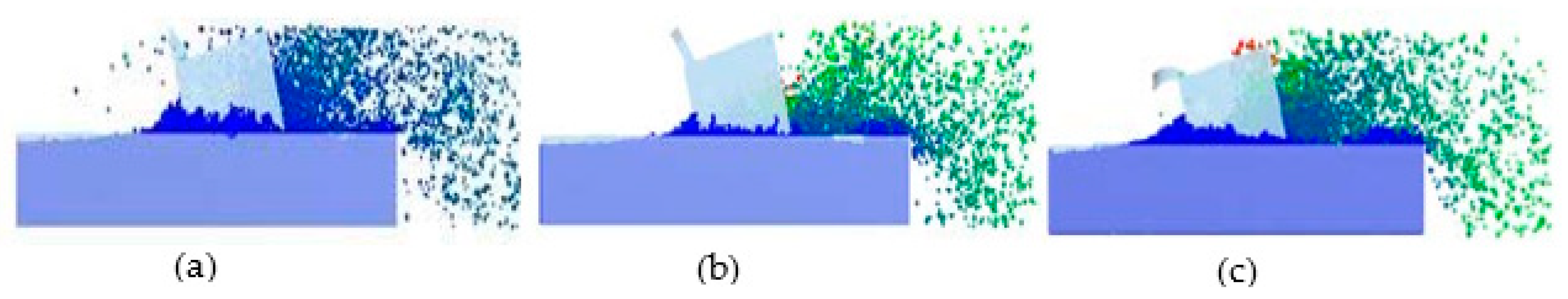

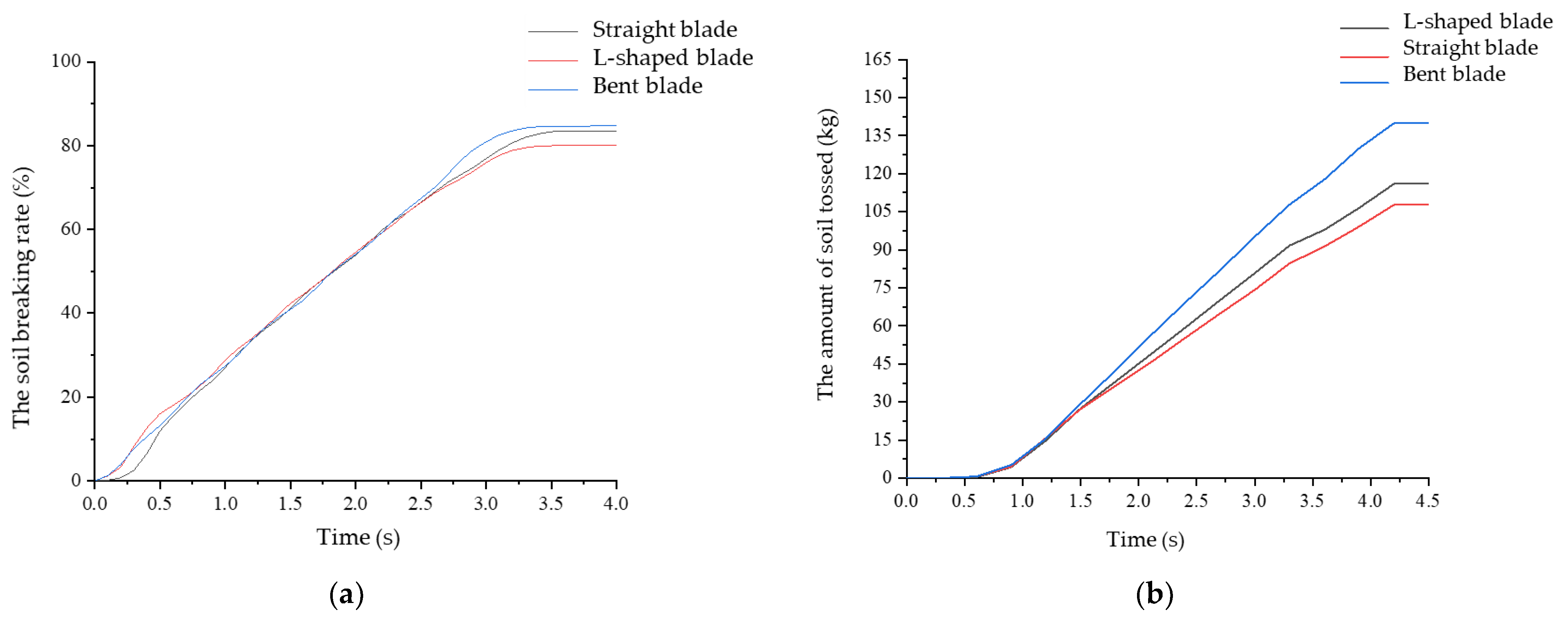

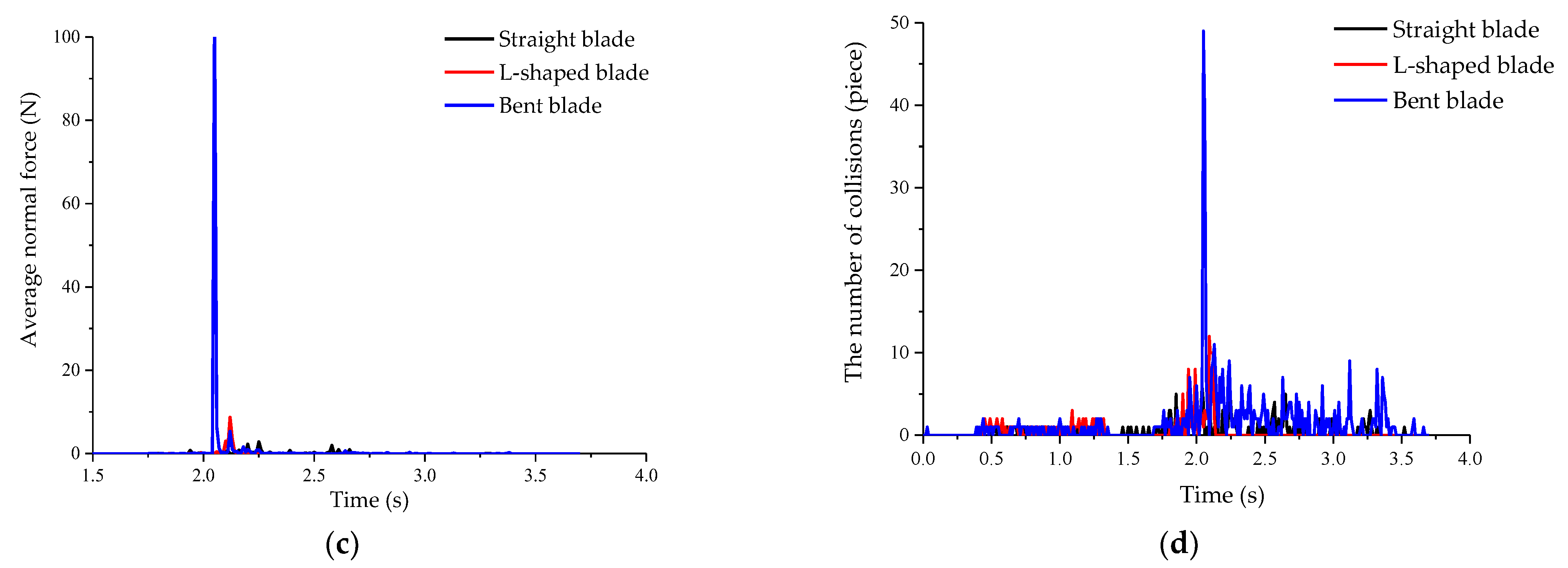

4.3. Determination of the Type of Soil-Breaking Blades

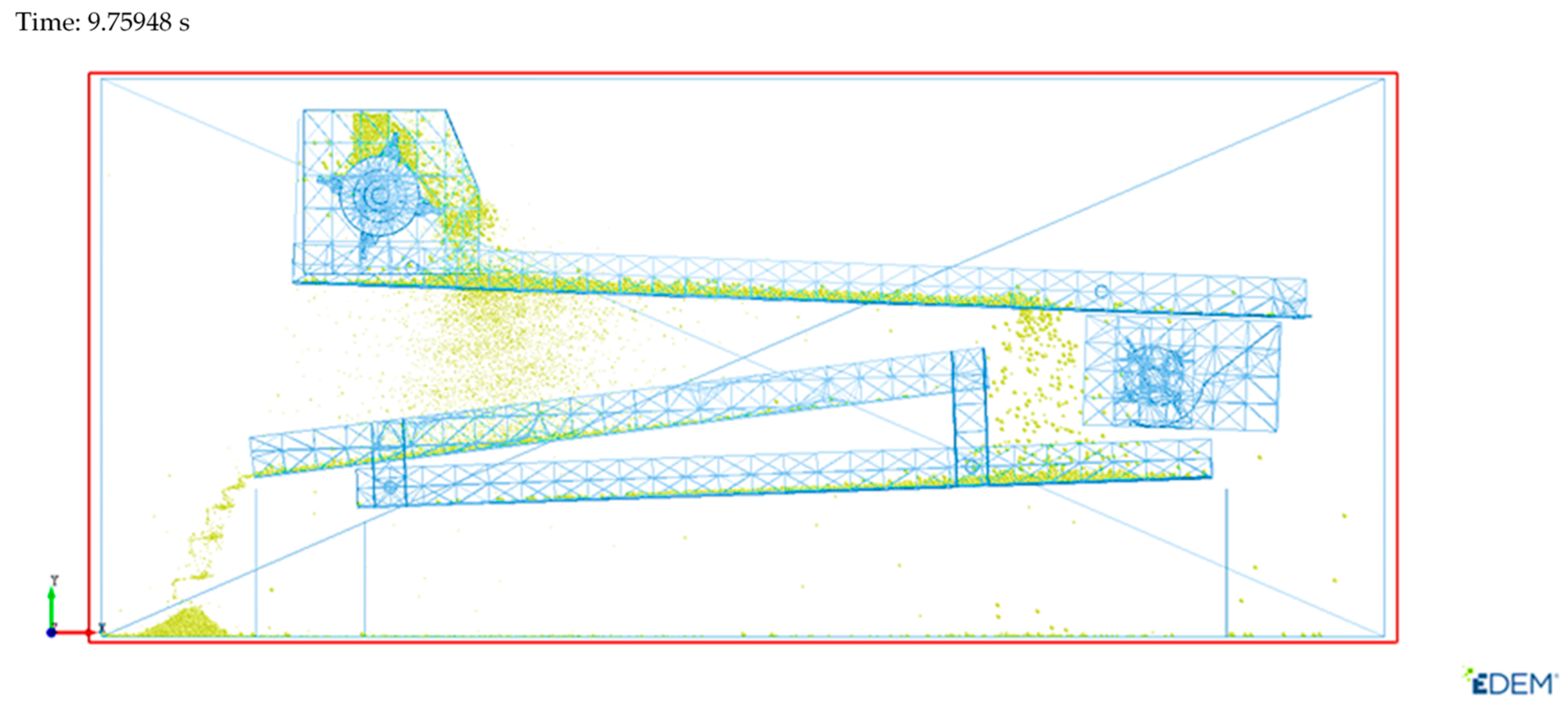

4.4. Simulation and Verification of the Digging and Elevation Process

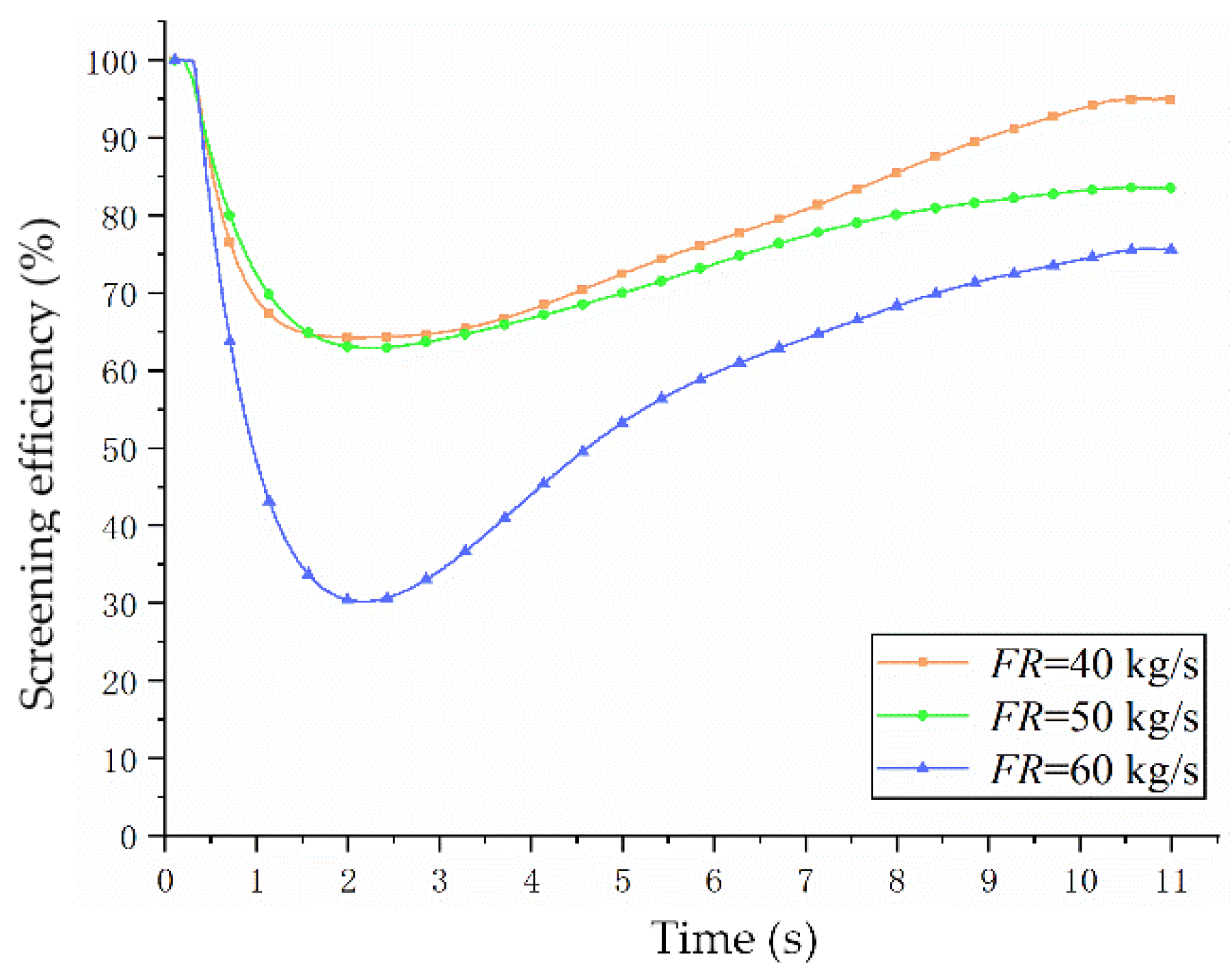

4.5. Simulation and Verification of the Tuber Picking and Screening Process

5. Field Tests

5.1. Test Conditions

5.2. Test Methods

5.3. Test Results

6. Discussion

- (1)

- The developed tiger-nut harvester is specific for tiger nuts planted in sandy loam in Xinzheng City; subsequent research should explore the optimization of key devices under different soil structures and consider the applicability and reliability of the machinery in different working environments, so as to meet the requirement of improving the overall applicability and universality;

- (2)

- The developed harvester is based on traditional design to meet the design requirements. An intelligent control system will be studied in future research to develop an adaptive control system with sensing, decision-making, and control functions, to realize the intelligent harvesting of tiger nuts.

7. Conclusions

- (1)

- The designed tiger-nut combine harvester is self-propelled; it consists of digging and hoisting devices, a tuber picking and screening device, and crawler devices. It can achieve one-pass integrated harvesting of tiger nuts including the digging, soil removal, picking, screening, and collection thereof, which improves harvesting efficiency and quality and compensates for shortcomings of mechanized harvesting of tiger nuts in China;

- (2)

- The key devices comprising the harvester were theoretically designed, and the combination of straight and bent blades was determined to serve as the soil-breaking blades through simulation analysis of the soil-breaking rate, tossing performance, and tuber damage arising from the use of different types of blades. The stress state of tiger nuts in the elevation process was studied. Results show that when the hoisting angle is 15°, the normal elevation of tiger nuts is ensured when the elevation speed ranges between 0.63 and 0.81 m/s. The principle of the tuber picking and screening process was analyzed to facilitate the design of the tuber picking drum, double-deck heterodromous vibrating screens, and soil-crushing guide roller. The screening area of the whole harvester reaches 13.6 m2. By calculating and evaluating the supporting capacity of the tracks, the crawler devices were designed on the premise of meeting the requirement for a specific ground contact pressure. The motion and screening efficiency curves of tiger-nut tubers on the hoisting devices were obtained through discrete element simulation. The results indicate that the law of motion conforms to the objective law, thus verifying the rationality of the theoretical design;

- (3)

- Field tests of the prototype show that the harvest rate, impurity rate, and harvesting efficiency of the designed harvester are 98.14%, 3.24%, and 0.216 ha/h when the digging depth is 130 mm. The whole harvester works in a stable manner and various indices all meet the technological requirements imposed by tiger-nut growers in China.

8. Patent

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, H.Y.; Wang, L.H.; Liu, Y.Y. Development status of olea bean products. Farm Prod. Process. 2021, 14, 97–99. [Google Scholar] [CrossRef]

- Adel, A.M.; Awad, A.M.; Mohamed, H.H.; Iryna, S. Chemical composition, physicochemical properties and fatty acid profile of Tiger Nut (Cyperus esculentus) seed oil as affected by different preparation methods. Int. Food Res. J. 2015, 22, 1931–1938. Available online: https://www.proquest.com/scholarly-journals/chemical-composition-physicochemical-properties/docview/1705545904/se-2?accountid=43822 (accessed on 13 November 2022).

- Guo, T.T.; Wan, C.T.; Huang, F.H.; Wei, C.L.; Hu, Z.H. Research progress on the main nutritional components and physiological functions of tiger nut (Cyperus esculentus L.). Chin. J. Oil Crop Sci. 2021, 43, 1174–1180. [Google Scholar] [CrossRef]

- Follak, S.; Belz, R.; Bohren, C.; De Castro, O.; Del Guacchio, E.; Pascual-Seva, N.; Schwarz, M.; Verloove, F.; Essl, F. Biological flora of Central Europe: Cyperus esculentus L. Perspect. Plant Ecol. Evol. Syst. 2016, 23, 33–51. [Google Scholar] [CrossRef]

- Shi, X. Cyperus esculentus L.; China Agricultural Science and Technology Press: Beijing, China, 2020. [Google Scholar]

- Li, Z.J.; Wang, J.; Liu, H.; Wang, P.; Wu, X.T.; Ma, C.M.; Zhang, D.J. Status of development of Cyperus esculentus industry and Its suggestion. Mod. Agric. Sci. Technol. 2022, 08, 225–231. [Google Scholar]

- Wang, R.Y.; Wang, X.S.; Xiang, H. A multi-purpose novel oil crop—Cyperus beans. China Oils Fats 2019, 44, 1–4. [Google Scholar]

- Yang, X.D.; Li, Z.Y. Tigernut industry in China: Current status of development, potential and adaptive suggestions. Chin. J. Oil Crop Sci. 2022, 44, 712–717. [Google Scholar] [CrossRef]

- Wang, R.Y.; Zheng, Z.A.; Gao, L.; Jiang, D.L.; Zhang, Z.M. Current situation and countermeasures of mechanized harvesting technology of traditional Chinese medicine agriculture. J. Agric. Mech. Res. 2022, 44, 1–7. [Google Scholar] [CrossRef]

- Li, T.; Zhou, J.; Xu, W.Y.; Zhang, H.; Liu, C.G.; Jiang, W. Design and test of auto-follow row system employed in root and stem crops harvester. Trans. Chin. Soc. Agric. Mach. 2019, 50, 102–110. [Google Scholar]

- Liu, X.M.; Liu, Z.H.; Liang, Y.; Xiao, S.P. Development of multifunctional harvesting machine based on modular theory. Chin. Agric. Mech. 2012, 5, 47–50. [Google Scholar]

- Zhao, Y.Q.; Li, B.J.; Meng, L.; Wang, L.; Bi, T.; Jian, J.M.; Hou, S.L. Optimal design of mechanical harvesting and separation system for Tiger Nut. J. Agric. Mech. Res. 2022, 44, 51–56. [Google Scholar] [CrossRef]

- Zhang, H.M.; Zhou, Z.; Lv, Z.J.; Wang, W.Z.; He, H.; Lv, Y.L. Kinematic analysis and testing of vibratory sieving mechanism for Cyperus esculentus L. harvester. Chin. Agric. Mech. 2021, 42, 92–99. [Google Scholar] [CrossRef]

- He, X.N.; Zhang, X.J.; Zhao, Z.; Shang, S.Q.; Wang, D.W.; Yuan, X.W. Design and test of resistance-reducing excavation device of Cyperus edulis based on discrete element method. Trans. Chin. Soc. Agric. Mach. 2021, 52, 124–133. [Google Scholar]

- He, X.N.; Zhang, X.J.; Zhao, Z.; Shang, S.Q.; Wang, D.W.; Yang, S. Design and optimization tests of reverse spin-throwing Cyperus edulis starting device. Trans. Chin. Soc. Agric. Mach. 2022, 53, 34–43. [Google Scholar]

- Zhang, S.L.; Wang, X.S.; Zhang, D.C. A kind of traction type Cyperus esculentus harvester. CN: 216313995U, 19 April 2022. [Google Scholar]

- An, S.G. Design and Experiment of Threshing and Separating Device for Cyperus esculentus; Shihezi University: Xinjiang, China, 2022. [Google Scholar]

- Zhu, H.; Wang, D.W.; He, X.N.; Shang, S.Q.; Zhao, Z.; Wang, H.Q.; Tan, Y.; Shi, Y.X. Study on plant crushing and soil throwing performance of bionic rotary blades in Cyperus esculentus harvesting. Machines 2022, 10, 562. [Google Scholar] [CrossRef]

- Zhao, Z.; He, X.N.; Wang, D.W.; Shang, S.Q.; Xu, N.; Zhu, H.; Xia, C.; Zheng, X.W. Design and test of the anti-rotation throwing device of the Cyperus Edulis combine harvester. J. Agric. Mech. Res. 2023, 45, 172–176+182. [Google Scholar] [CrossRef]

- Satch, C.S. Exploration of Chufa (Cyperus esculentus L. var. sativus Boeck) as a Novel Specialty Crop for the Northeastern United States. Master’s thesis, Rutgers University, Graduate School, Fredericton, NB, Canada, 2016. [Google Scholar] [CrossRef]

- Zhao, Y.G.; Zou, X.L.; Zhang, Y.; Han, Z.K.; Zeng, L.; Zhang, X.K. High oil and high yielding varieties of Cyperus esculentus in oilseed 1. China Seed Ind. 2019, 06, 96–97. [Google Scholar] [CrossRef]

- Guo, H.Q. Design and Experimental Study of Key Components of Cyperus Esculentus Seeder. Master’s Thesis, Henan Agricultural University, Zhengzhou, China, 2022. [Google Scholar] [CrossRef]

- He, X.; Lv, Y.L.; Wang, W.Z.; Zhou, Z.; He, H.; Guo, H.Q. Effects of moisture content on physical and mechanical properties of Cyperus esculentus. J. Chin. Agric. Mech. 2022, 43, 80–85. [Google Scholar] [CrossRef]

- Chinese Academy of Agricultural Mechanization Sciences. Agricultural Machinery Design Manual; China Agricultural Science and Technology Press: Beijing, China, 2007. [Google Scholar]

- Lv, Y.L. Design and Experiment of Excavating and Hoisting Device of Cyperus Esculentus Harvester. Master’s Thesis, Henan Agricultural University, Zhengzhou, China, 2022. [Google Scholar] [CrossRef]

- Yao, C.X.; Yuan, J.N.; Pan, J.K. Design and simulation analysis of the terrain adaptive chassis’s walking system of rubber track combine harvester. Chin. Agric. Mech. 2020, 41, 107–113. [Google Scholar] [CrossRef]

- Hu, K.; Zhang, W.Y.; Li, K.; Liu, H.J.; Qi, B. Multi-body dynamics modeling and experiment of triangular tracked chassis with high ground clearance. Trans. Chin. Soc. Agric. Mach. 2021, 52, 386–394. [Google Scholar]

- He, X.; Lv, Y.; Qu, Z.; Wang, W.; Zhou, Z.; He, H. Parameters optimization and test of caterpillar self-propelled tiger nut harvester hoisting device. Agriculture 2022, 12, 1060. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, Z.; Qu, Z.; Li, Z.; Wang, W. Simulation and experiment of sieving process of sieving device for tiger nut harvester. Agriculture 2022, 12, 1680. [Google Scholar] [CrossRef]

- Zhang, R.; Han, D.L.; Ji, Q.L.; He, Y.; Li, J.Q. Calibration methods of sandy soil parameters in simulation of discrete element method. Trans. Chin. Soc. Agric. Mach. 2017, 48, 49–56. [Google Scholar]

- Qiao, Y.C.; Yi, J.G.; Yuan, Y.W. Simulation of flat ridge process based on EDEM/FEM coupling algorithm. J. Hebei Agric. Univ. 2020, 43, 127–132. [Google Scholar] [CrossRef]

- Qi, J.T.; An, S.G.; Kan, Z.; Meng, H.W.; Li, Y.P.; Zhao, X.Y. Discrete element-based calibration of simulation parameters of Cyperus esculentus L. (tiger nut) planted in sandy soil. J. Food Process. Preserv. 2021, 45, e15631. [Google Scholar] [CrossRef]

- Hao, J.J.; Long, S.F.; Li, H.; Jia, Y.L.; Ma, Z.K.; Zhao, J.G. Development of discrete element model and calibration of simulation parameters for mechanically-harvested yam. Trans. Chin. Soc. Agric. Eng. 2019, 35, 34–42. [Google Scholar]

- Zhang, S.; Fu, J.; Zhang, R.; Zhang, Y.; Yuan, H. Experimental study on the mechanical properties of friction, collision and compression of tiger nut tubers. Agriculture 2022, 12, 65. [Google Scholar] [CrossRef]

- Ji, L.L.; Xie, H.X.; Yang, H.G.; Wei, H.; Yan, J.C.; Shen, H.Y. Simulation analysis of potato dry soil cleaning device based on EDEM-Recurdyn coupling. J. Chin. Agric. Mech. 2021, 42, 109–115. [Google Scholar] [CrossRef]

- GB/T 5262-2008; Agricultural Machinery Test Conditions General Provisions for the Determination of Methods. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of the People’s Republic of China: Beijing, China.

- Zheng, S.Y.; Kang, Q.H.; Zhao, J.T.; Pan, W.Y. Technical research and test of rootstock traditional Chinese medicine harvester. Agric. Mach. Qual. Superv. 2022, 3, 21+25. Available online: http://www.lninfo.com.cn:8088/ShowDetail.aspx?d=1016&id=QKC20222022050900045200 (accessed on 13 November 2022).

- NY/T 3481-2019; Root and Stem Chinese Herbal Medicine Harvesting Machine Quality Evaluation Technical Specification. Gansu Agricultural Mechanization Technology Extension Station: Gansu, China.

- Wang, Z.C.; Li, S.S.; Qi, Z.X.; Zhang, W.Q. Current situation of Cyperus esculentus industry mechanization development in China and construction of whole industrial chain equipment system. Agric. Eng. 2022, 12, 5–10. [Google Scholar] [CrossRef]

- Lu, Z.; He, L.; Zhang, J.; Ren, J.; Cheng, Y.; Zhang, D.; Shi, G.; Chen, L.; Zhao, X. The Current Situation, Problems and Suggestions on the Development of Cyperus esculentus L. (tiger nut) Industry. Mod. Agric. 2019, 6, 11+13. [Google Scholar] [CrossRef]

- Sao, Y.M. Design and Experimental Study on Low Damage Thresher Equipment of Corn Grain Harvester. Master’s Thesis, Anhui Science and Technology University, Chuzhou, China, 2020. [Google Scholar] [CrossRef]

- Zhang, Z.Z.; Xie, F.P.; Tian, L.Q.; Liu, D.W.; Wang, X.S.; Li, X. Current situation and development trend of threshing and separating system of international grain combine harvester. J. Chin. Agric. Mech. 2021, 42, 20–29. [Google Scholar] [CrossRef]

| Project | Maximum Size | Minimum Value | Mean Value | Standard Deviation |

|---|---|---|---|---|

| L(mm) | 14.68 | 8.65 | 11.499 | 1.387 |

| W(mm) | 13.59 | 6.61 | 10.044 | 1.351 |

| T(mm) | 14.43 | 7.32 | 11.565 | 1.550 |

| Item | Value |

|---|---|

| Machine size (mm) | 6800 × 2500 × 3200 |

| Engine power (kW) | 140 |

| Digging depth (mm) | 0~200 |

| Number of ridge harvested | 3 |

| Working width (mm) | 1800 |

| Driving speed (m/s) | 0.23~0.33 |

| Harvesting efficiency (ha/h) | 0.15~0.22 |

| Impurity rate (%) | ≤5 |

| Harvest rate (%) | ≥95 |

| Item (mm) | Value |

|---|---|

| The length of ground contact of tracks | 2200 |

| The width of tracks | 400 |

| The total length of tracks | 5670 |

| The pitch diameter of the driving wheel | 120 |

| The pitch diameter of the support wheel | 100 |

| The pitch diameter of the guide wheel | 110 |

| The pitch diameter of the carrier roller | 45 |

| Materials | Collision Recovery Coefficient | Static Friction Coefficient | Dynamic Friction Coefficient |

|---|---|---|---|

| Tiger nut-Tiger nut | 0.48 | 0.10 | 0.34 |

| Tiger nut-Soil particle | 0.49 | 0.25 | 0.42 |

| Tiger nut-Soil particle | 0.62 | 0.07 | 0.25 |

| Tiger nut-Stalk | 0.35 | 0.02 | 0.32 |

| Soil particle-Soil particle | 0.14 | 0.27 | 0.56 |

| Soil particle-Steel | 0.15 | 0.36 | 0.50 |

| Soil particle-Stalk | 0.11 | 0.09 | 0.21 |

| Stalk-Stalk | 0.26 | 0.01 | 0.32 |

| Stalk-Steel | 0.43 | 0.03 | 0.45 |

| Materials | Poisson Ratio | Density (kg/m3) | Shear Modulus (MPa) |

|---|---|---|---|

| Tiger nut | 0.18 | 1230 | 4 |

| Soil particle | 0.26 | 1179 | 1.1 |

| Steel | 0.27 | 7850 | 8 × 104 |

| Stalk | 0.42 | 241 | 1.0 |

| Serial Number | Harvesting Efficiency (ha/h) | Harvest Rate (%) | Impurity Rate (%) |

|---|---|---|---|

| 1 | 0.208 | 98.37 | 3.38 |

| 2 | 0.216 | 98.30 | 3.11 |

| 3 | 0.201 | 99.21 | 2.79 |

| 4 | 0.230 | 97.45 | 3.57 |

| 5 | 0.225 | 97.37 | 3.35 |

| Average | 0.216 | 98.14 | 3.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, Z.; Han, M.; Lv, Y.; Zhou, Z.; Lv, Z.; Wang, W.; He, X. Design and Test of a Crawler-Type Tiger-Nut Combine Harvester. Agriculture 2023, 13, 277. https://doi.org/10.3390/agriculture13020277

Qu Z, Han M, Lv Y, Zhou Z, Lv Z, Wang W, He X. Design and Test of a Crawler-Type Tiger-Nut Combine Harvester. Agriculture. 2023; 13(2):277. https://doi.org/10.3390/agriculture13020277

Chicago/Turabian StyleQu, Zhe, Minghui Han, Yanliu Lv, Zheng Zhou, Zhijun Lv, Wanzhang Wang, and Xun He. 2023. "Design and Test of a Crawler-Type Tiger-Nut Combine Harvester" Agriculture 13, no. 2: 277. https://doi.org/10.3390/agriculture13020277

APA StyleQu, Z., Han, M., Lv, Y., Zhou, Z., Lv, Z., Wang, W., & He, X. (2023). Design and Test of a Crawler-Type Tiger-Nut Combine Harvester. Agriculture, 13(2), 277. https://doi.org/10.3390/agriculture13020277