Analysis and Experimental of Seeding Process of Pneumatic Split Seeder for Cotton

Abstract

:1. Introduction

2. Analysis of the Structure and Pneumatic Seed Delivery Process of the Split Seed Dispenser

2.1. Structure and Working Principle of the Split Seed Rower

2.2. Pneumatic Conveying Seed Process Analysis

2.2.1. Pipeline Airflow Resistance and Pressure Loss Analysis

2.2.2. Pressure Loss Calculation for Each Section

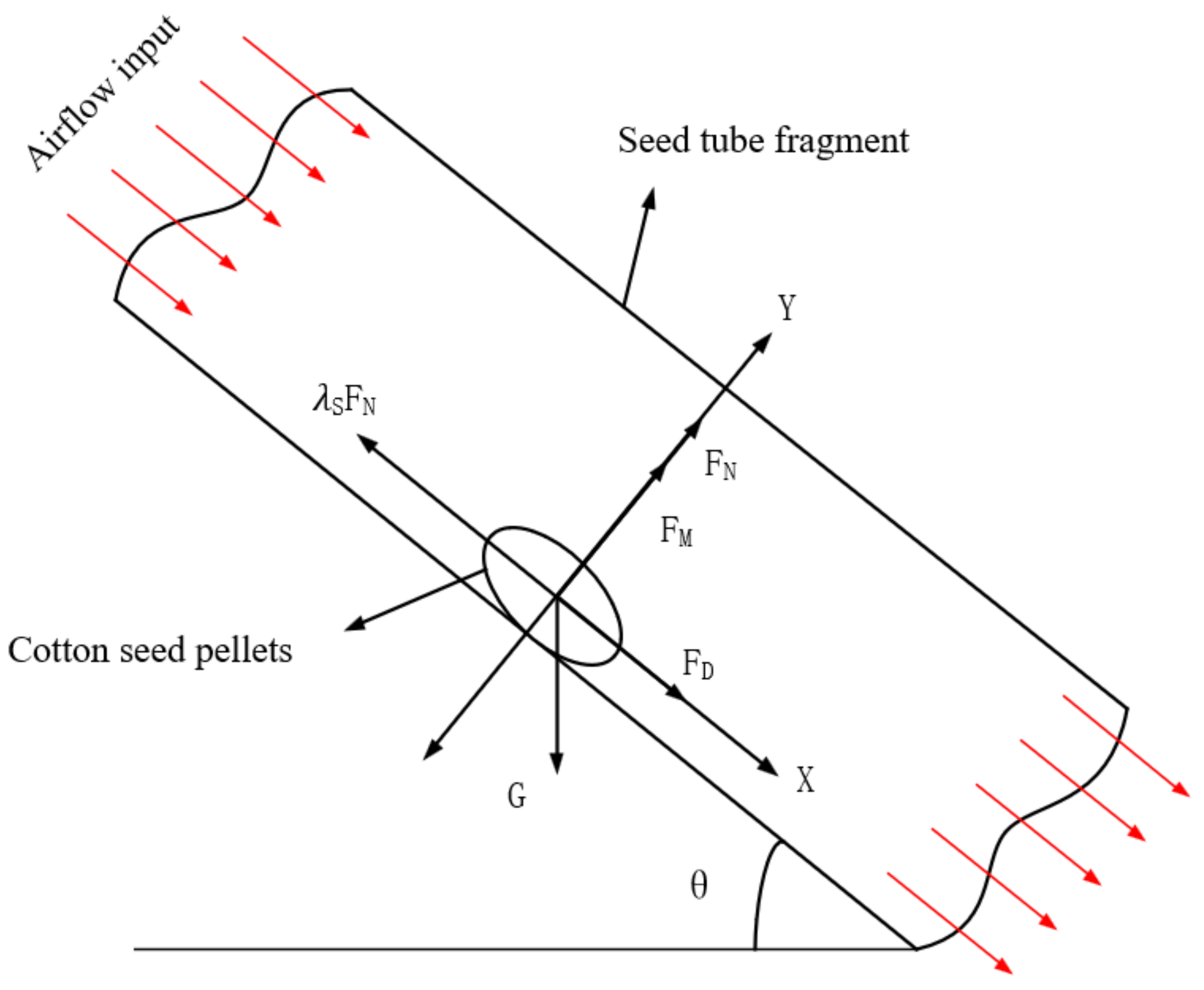

2.2.3. Force Analysis of Cotton Seeds

3. Simulation Analysis of Seed Delivery and Seeding

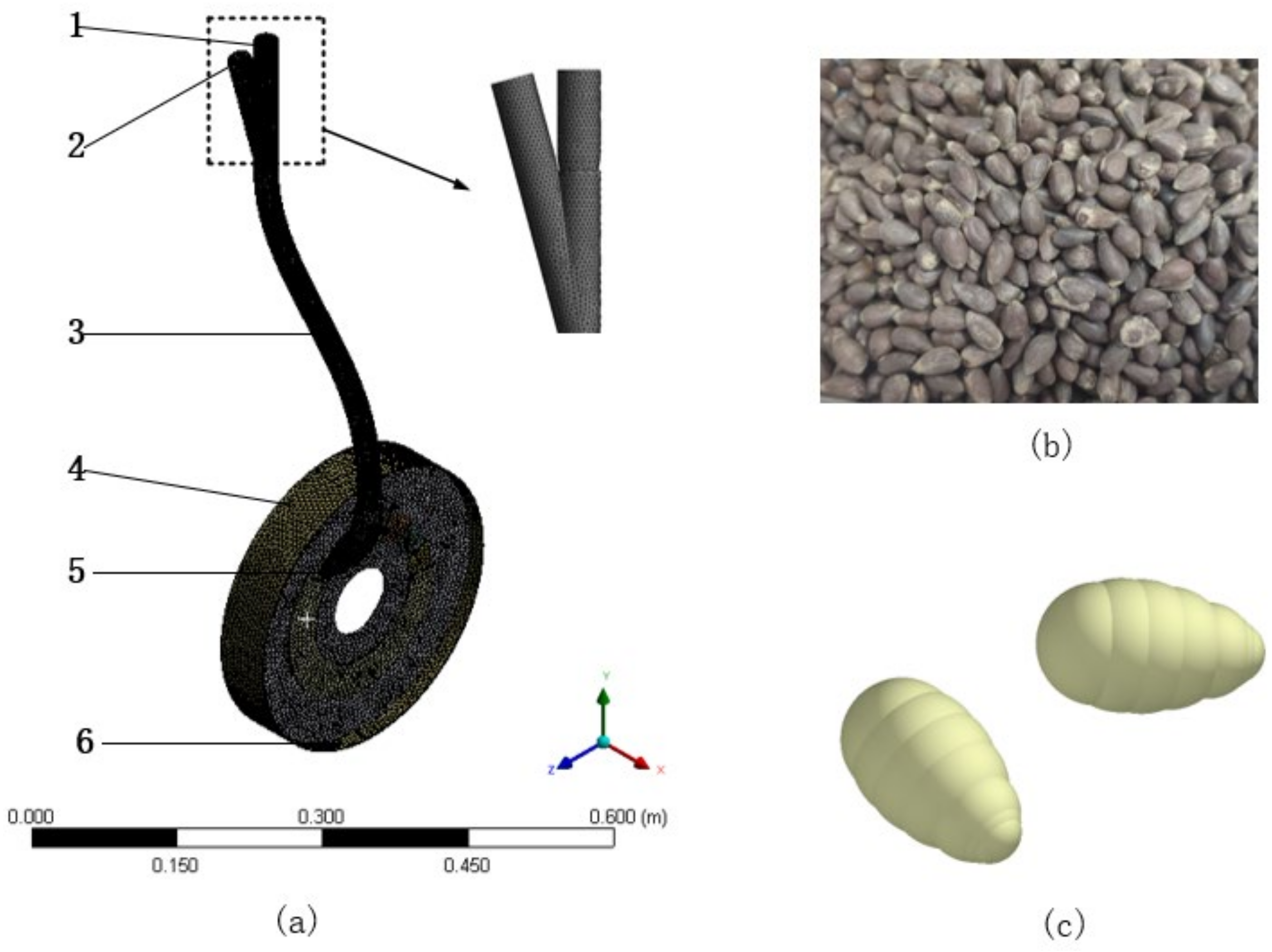

3.1. Simulation Model

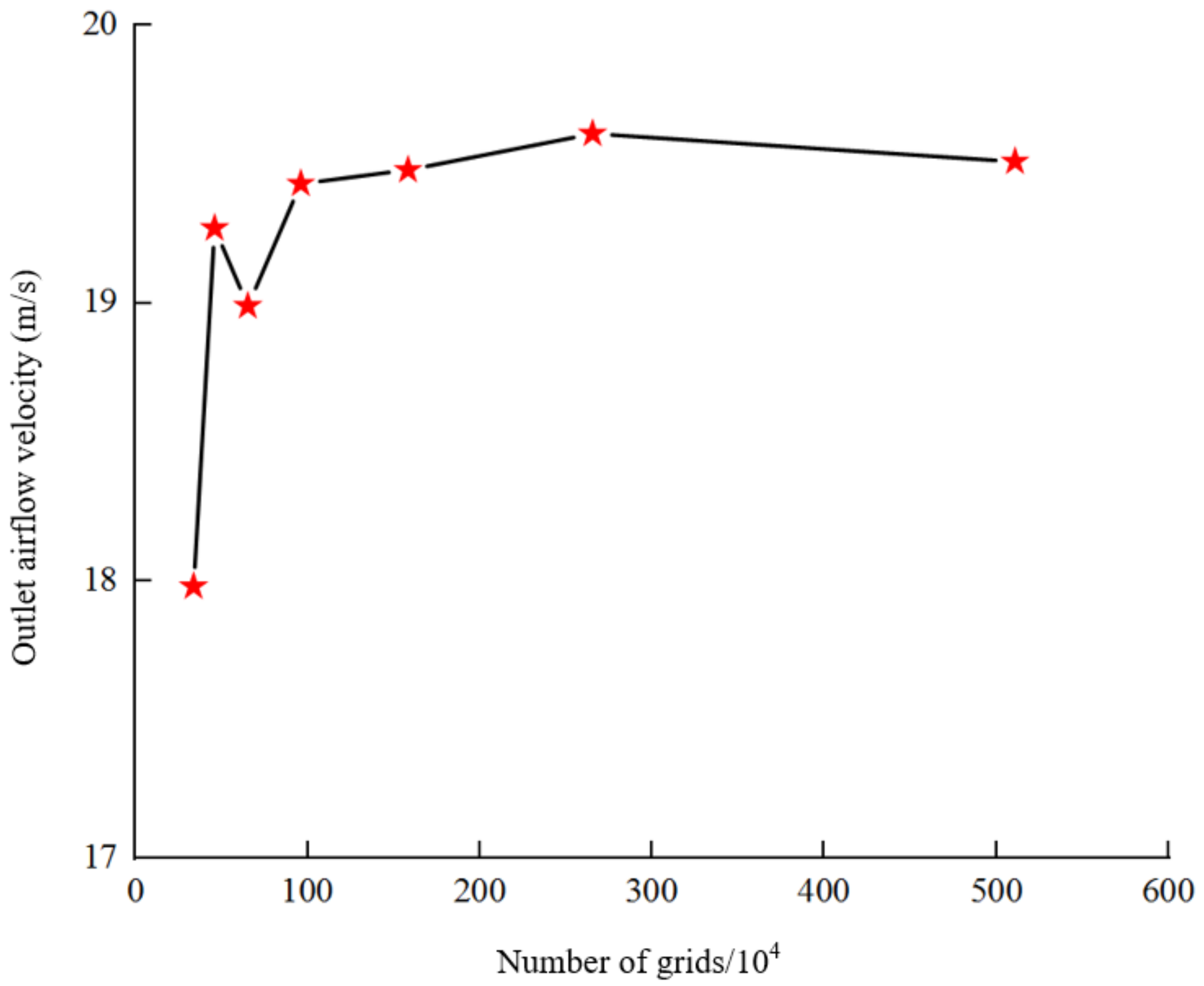

3.2. Grid Irrelevance Verification

3.3. Simulation Test Design

3.3.1. Fluent-Based Simulation Tests

3.3.2. EDEM-Based Simulation Test

3.3.3. FLUENT-EDEM Based Coupling Simulation Test

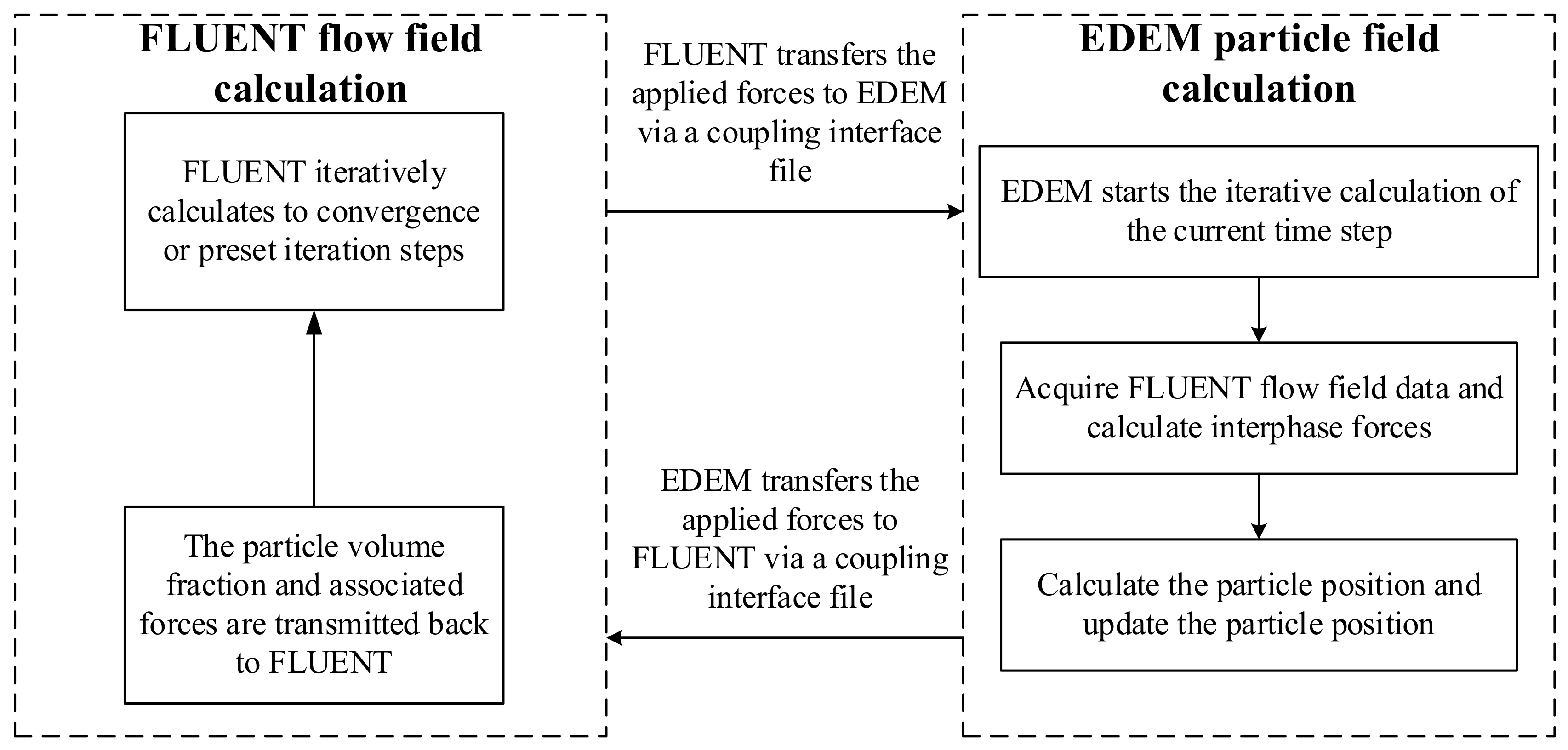

3.4. Coupling Simulation Process

3.5. Simulation Parameter Setting

3.6. Simulation Results and Analysis

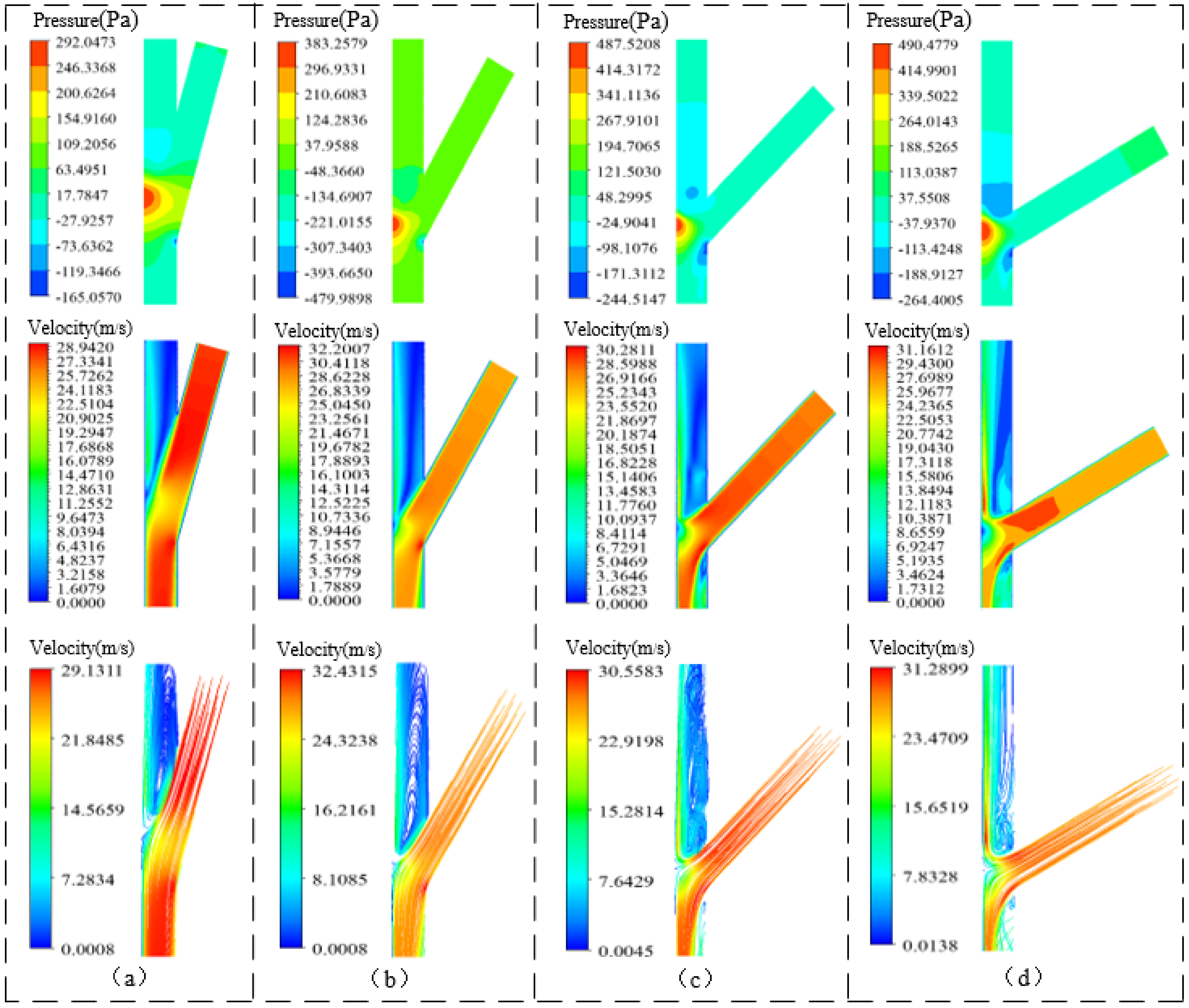

3.6.1. Influence of Seed Delivery Tube Joint Angle on Airflow Field

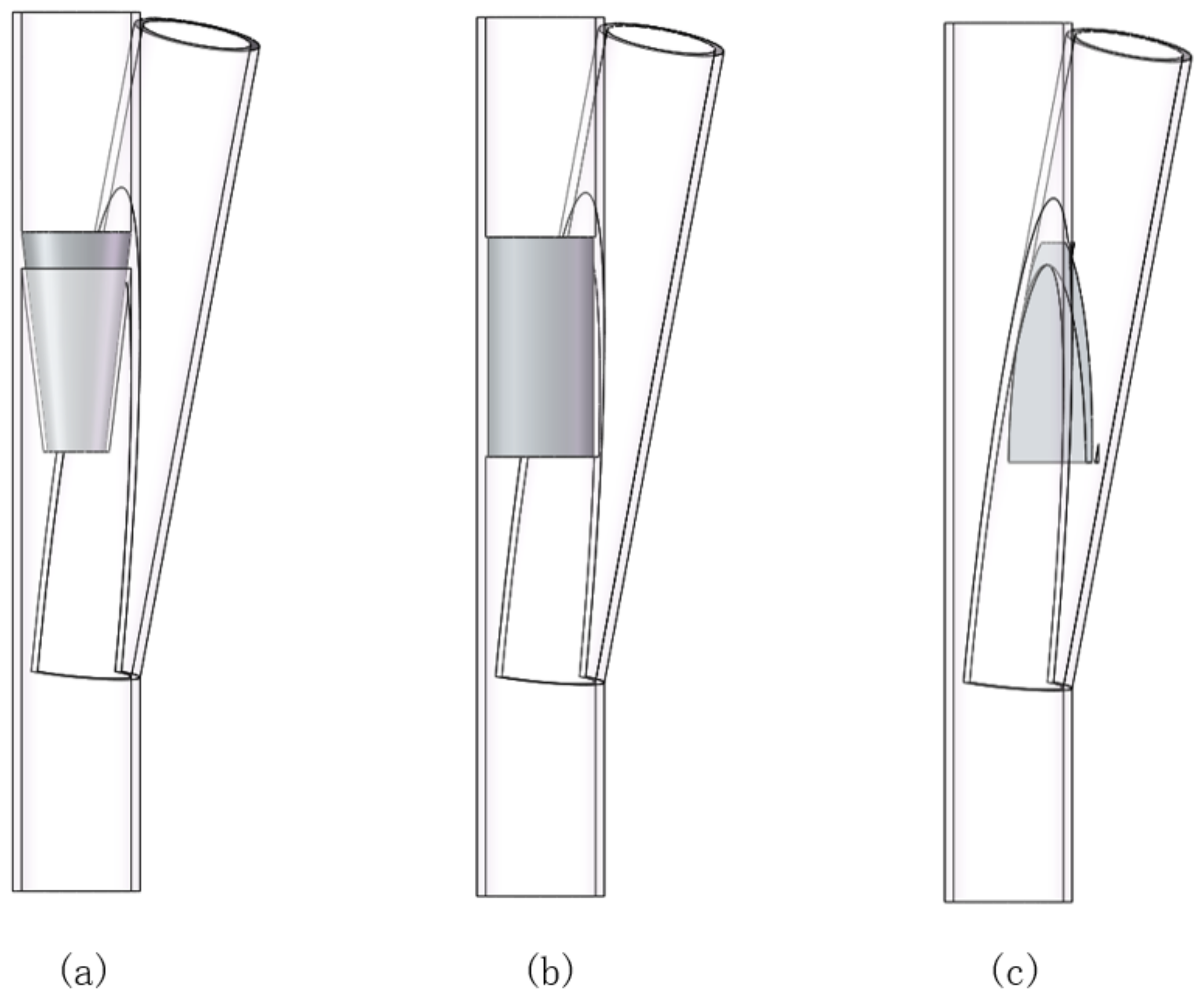

3.6.2. Influence of the Diversion Structure of the Seed Delivery Pipe Joint on the Airflow Field

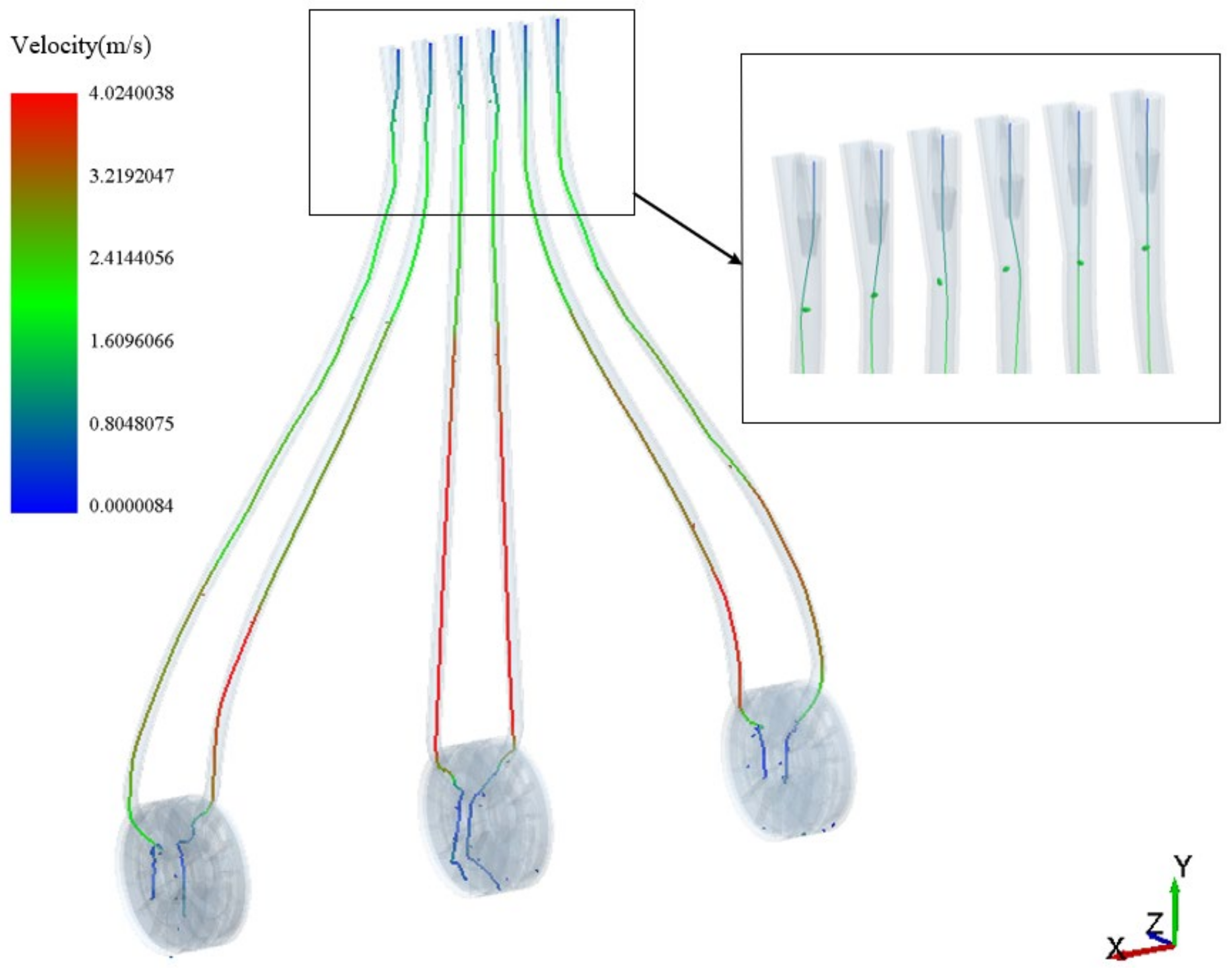

3.6.3. Overall Seeding Analysis

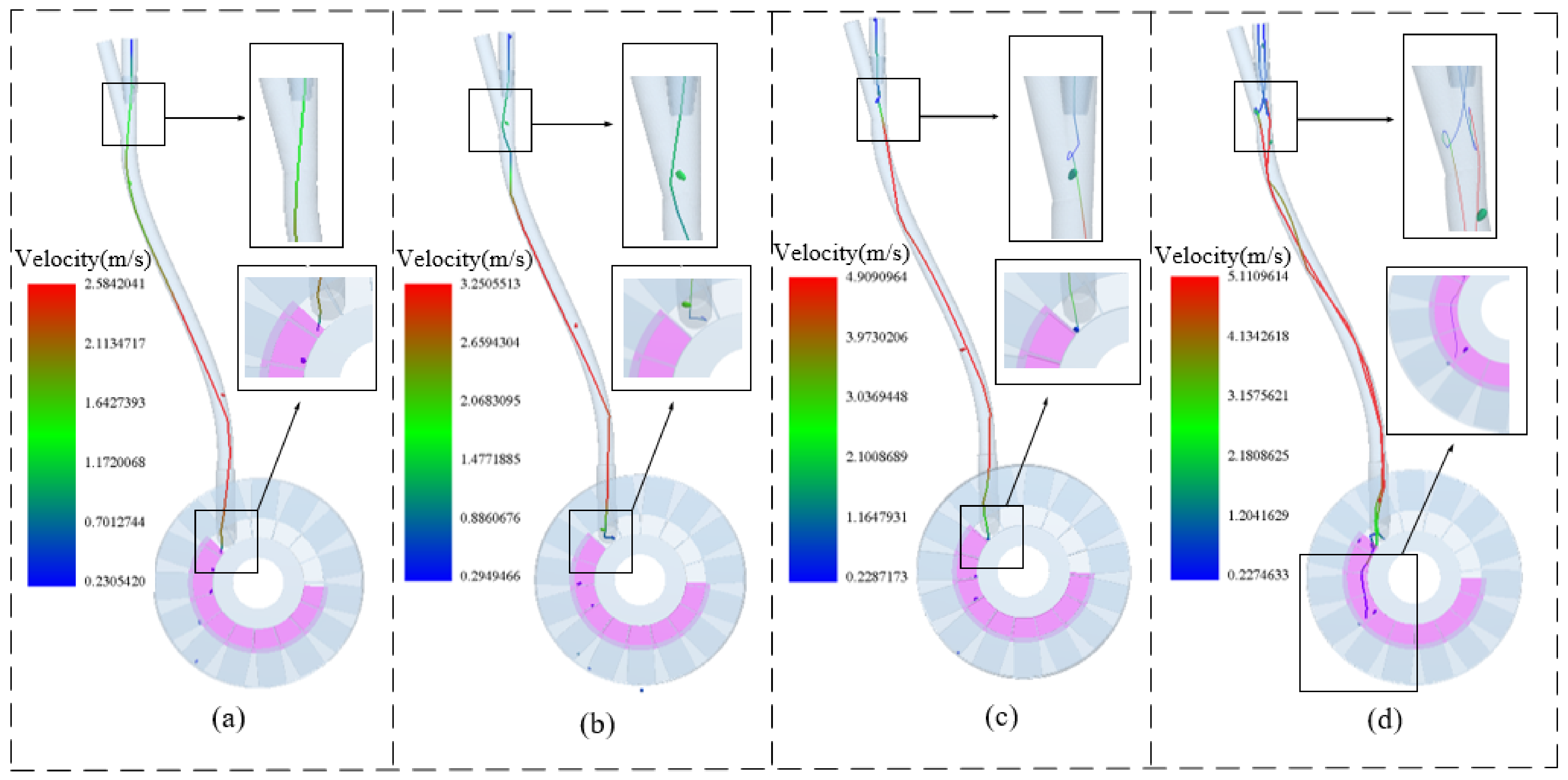

3.6.4. Analysis of Cotton Seed Transport Process under Different Cavity Seeder Speed

3.6.5. Analysis of Cotton Seed Transport Process under Different Seed Delivery Positive Pressure

3.6.6. Influence of Working Parameters on Seeding Effect

4. Bench Test Verification

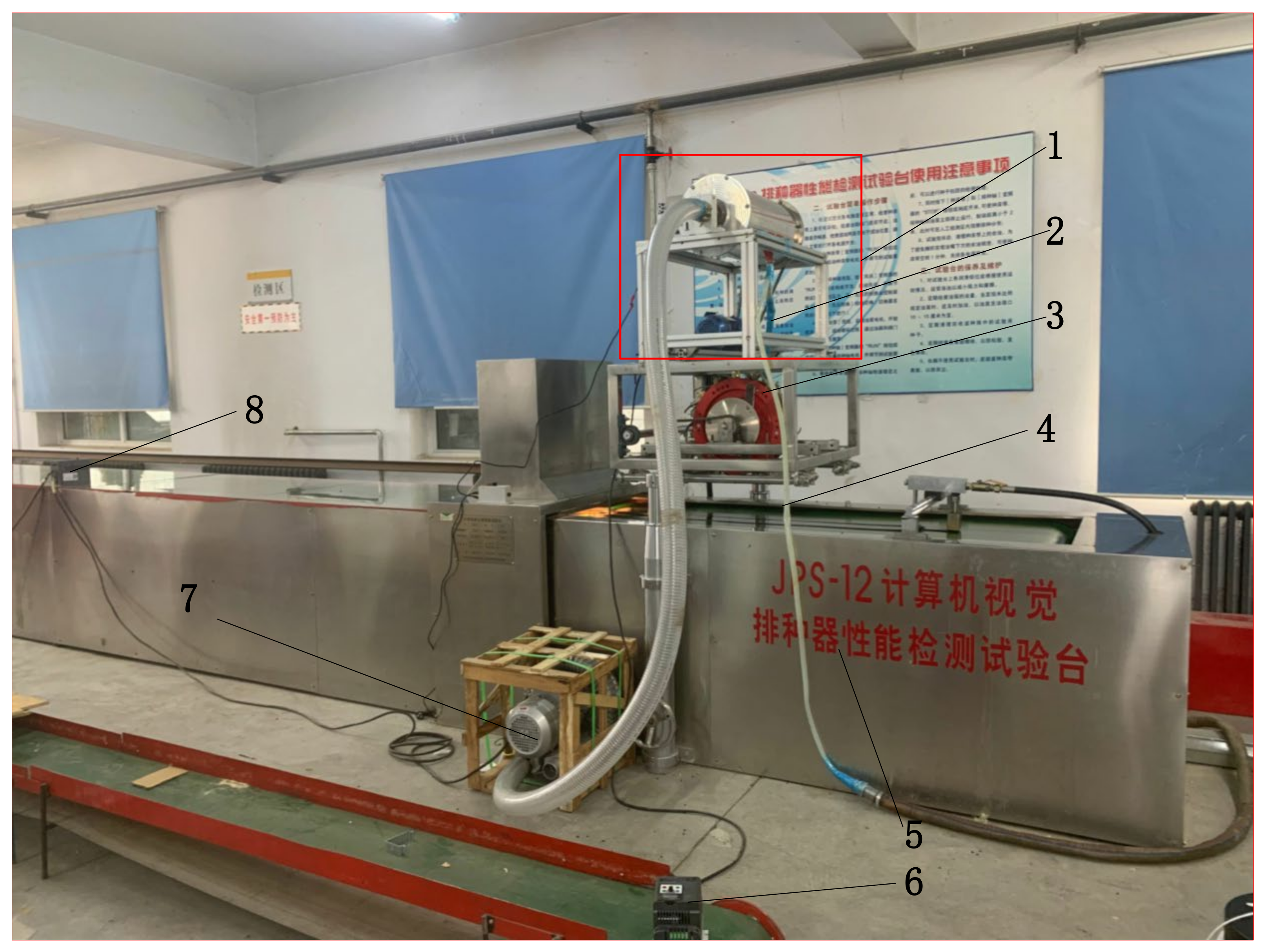

4.1. Experimental Design and Methodology

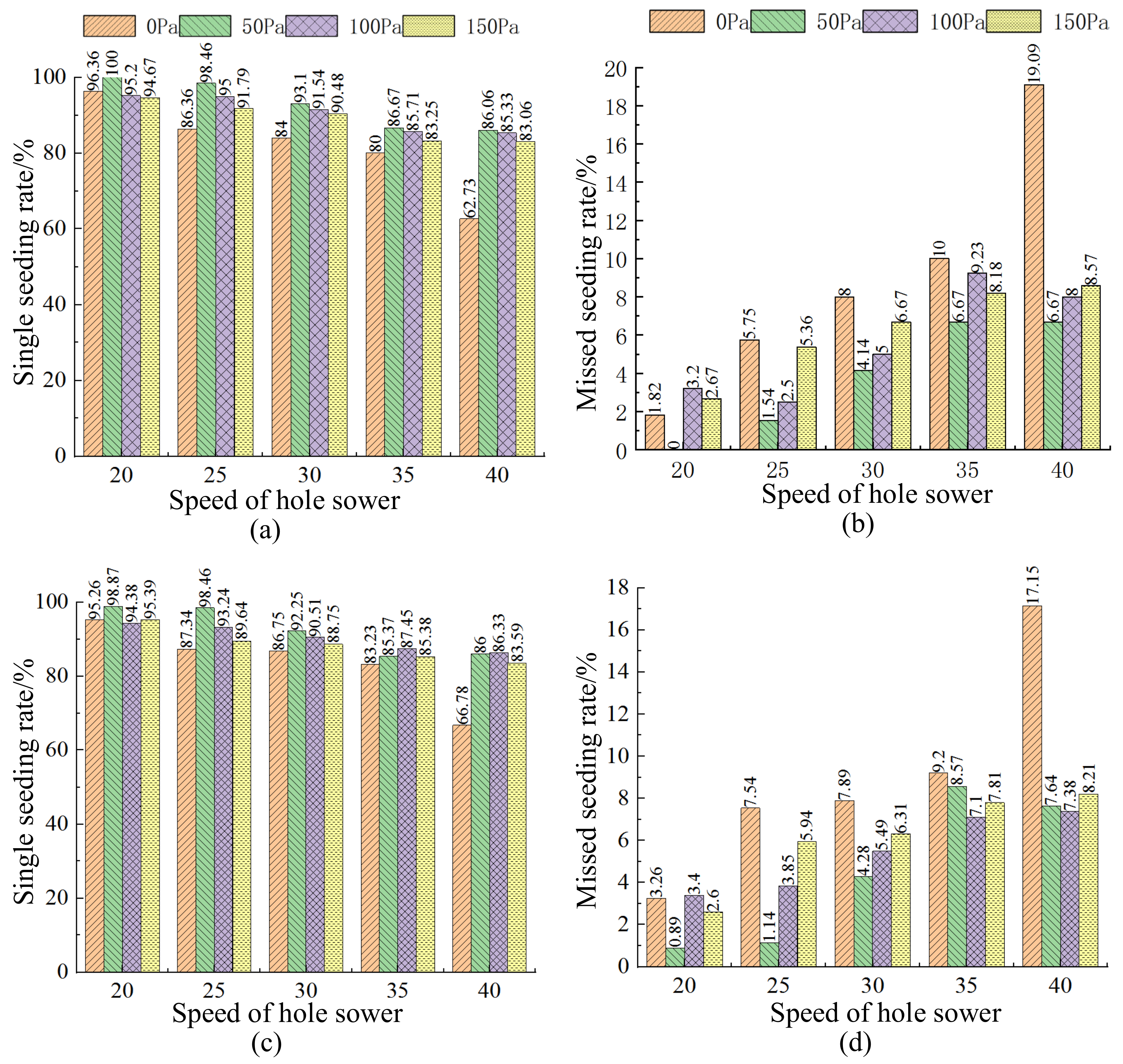

4.2. Test Results and Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Han, D.; Zhang, D.; Jing, H.; Yang, L.; Cui, T.; Ding, Y.; Wang, Z.; Wang, Y.; Zhang, T. DEM-CFD coupling simulation and optimization of an inside-filling air-blowing maize precision seed-metering device. Comput. Electron. Agric. 2018, 150, 426–438. [Google Scholar] [CrossRef]

- Mandal, S.; Kumar, G.P.; Tanna, H.; Kumar, A. Design and evaluation of a pneumatic metering mechanism for power tiller operated precision planter. Curr. Sci. A Fortn. J. Res. 2018, 115, 1106–1114. [Google Scholar] [CrossRef]

- Xue, P.; Xia, X.; Gao, P.; Ren, D.; Hao, Y.; Zheng, Z.; Zhang, J.; Zhu, R.; Hu, B.; Huang, Y. Double-Setting Seed-Metering Device for Precision Planting of Soybean at High Speeds. Trans. ASABE 2019, 62, 187–196. [Google Scholar] [CrossRef]

- Lu, B.; Ni, X.; Li, S.; Li, K.; Qi, Q. Simulation and Experimental Study of a Split High-Speed Precision Seeding System. Agriculture 2022, 12, 1037. [Google Scholar] [CrossRef]

- Liao, Y.; You, Y.; Hui, Y.; Zhang, X.; Wang, D. Mixed Seeds of Oat and Vetch Based on DEM-Fluent Coupling Motion Simulation in a Venturi Tube. Processes 2023, 11, 1095. [Google Scholar] [CrossRef]

- Kocher, M.F.; Coleman, J.M.; Smith, J.A.; Kachman, S.D. Corn seed spacing uniformity as affected by seed tube condition. Appl. Eng. Agric. 2011, 27, 177–183. [Google Scholar] [CrossRef]

- Wang, B.; Liao, Q.; Wang, L.; Shu, C.; Cao, M.; Du, W. Design and Test of Air-Assisted Seed-Guiding Device of Precision Hill-Seeding Centralized Seed-Metering Device for Sesame. Agriculture 2023, 13, 393. [Google Scholar] [CrossRef]

- Yatskul, A.; Lemiere, J.P. Establishing the conveying parameters required for the air-seeders. Biosyst. Eng. 2018, 166, 1–12. [Google Scholar] [CrossRef]

- Qin, J. Development of One-Step Centralized Type Pneumatic Seeding System. Master’s Thesis, Shandong Agricultural University, Tai’an, China, 2005. [Google Scholar]

- Sun, Q. Study and Test Analysis of One-Stepseed-Centralized Pneumatic Drill. Master’s Thesis, Shandong Agricultural University, Tai’an, China, 2003. [Google Scholar]

- He, Y. Study on the structure and airflow parameters of airflow seed delivery tube. J. Xihua Univ. Nat. Sci. 1982, 13, 24–31+61. [Google Scholar]

- Li, Y.; Liu, R.; Liu, C.; Liu, L. Simulation and Test of Seed Velocity Coupling in Seed Tube of Pneumutic Seed Metering Device. Trans. Chin. Soc. Agric. Mach. 2021, 52, 54–61+133. [Google Scholar]

- Li, Y.; Liu, Y.; Liu, L. Distribution Mechanism of Airflow in Seed Tube of Different Lengths in Pneumatic Seeder. Trans. Chin. Soc. Agric. Mach. 2020, 51, 55–64. [Google Scholar]

- Endrerud, H.C. Influence of Tube Configuration on Seed Delivery to a Coulter. J. Agric. Eng. Res. 1999, 74, 177–184. [Google Scholar] [CrossRef]

- Qi, Q.; Ni, X.; Kang, S.; Lu, B.; Hu, B. Test on cotton seed pneumatic delivery performance of centralized seed-metering device. J. Gansu Agric. Univ. 2021, 56, 187–192+200. [Google Scholar] [CrossRef]

- Cheng, L.; Mou, X.; Pen, Z. Application of discrete element method in agricultural engineering. Agric. Eng. 2021, 11, 29–34. [Google Scholar]

- Din, l.; Yang, L.; Wu, D.; Li, D.; Zhang, D.; Liu, S. Simulation and Experiment of Corn Air Suction Seed Metering Device Based on DEM-CFD Coupling Method. Trans. Chin. Soc. Agric. Mach. 2018, 49, 48–57. [Google Scholar]

- Zhang, X. Research on computer simulation technology and its application in agricultural engineering. China Rice 2021, 27, 150. [Google Scholar]

- Zhen, Z.; Ma, X.; Cao, X.; Li, Z.; Wang, X. Critical review of applications of discrete element method in agricultural engineering. Trans. Chin. Soc. Agric. Mach. 2021, 52, 1–20. [Google Scholar]

- Zhao, X.; Xu, L.; Wang, Y.; Li, C. Directional Adsorption Characteristics of Corn Seed Based on Fluent and High-speed Photography. Trans. Chin. Soc. Agric. Mach. 2014, 45, 103–109+128. [Google Scholar]

- Lei, X.; Hu, H.; Wu, W.; Liu, H.; Liu, L.; Yang, W.; Zhou, Z.; Ren, W. Seed motion characteristics and seeding performance of a centralised seed metering system for rapeseed investigated by DEM simulation and bench testing. Biosyst. Eng. 2021, 203, 22–33. [Google Scholar] [CrossRef]

- Han, D.; Zhang, D.; Yang, L.; Li, K.; Zhang, T.; Wang, Y.; Cui, T. EDEM-CFD simulation and experiment of working performance of inside-filling air-blowing seed metering device in maize. Trans. Chin. Soc. Agric. Eng. 2017, 33, 23–31. [Google Scholar]

- Lei, X.; Liao, Y.; Zhang, W.; Li, S.; Wang, D.; Liao, Q. Simulation and Experiment of Gas-Solid Flow in Seed Conveying Tube for Rapeseed and Wheat. Trans. Chin. Soc. Agric. Mach. 2017, 33, 67–75. [Google Scholar]

- Gao, X.; Xu, Y.; Yang, L.; Zhang, D.; Li, Y.; Cui, T. Simulation and Experiment of Uniformity of Venturi Feeding Tube Based on DEM-CFD Coupling. Trans. Chin. Soc. Agric. Mach. 2018, 49, 92–100. [Google Scholar]

- Lei, X.; Liao, Y.; Li, Z.; Cao, X.; Li, S.; Wei, Y.; Liao, Q. Design and experiment of seed feeding device in air-assisted centralized metering device for rapeseed and wheat. Trans. Chin. Soc. Agric. Eng. 2015, 31, 10–18. [Google Scholar]

- Wang, L.; Liao, Y.; Wan, X.; Wang, B.; Hu, Q.; Liao, Q. Design and Test on Mixing Component of Air-assisted Centralized Metering Device for Rapeseed and Wheat. Trans. Chin. Soc. Agric. Mach. 2022, 53, 68–79+97. [Google Scholar]

- Li, Y.; ZHAO, J.; ZHAO, J.; LIU, L.; LIU, R. Biomimetic Design and Experiment of Distributor of Pneumatic Seeding System Based on Crucian Curve. Trans. Chin. Soc. Agric. Mach. 2022, 53, 80–87. [Google Scholar]

- Wang, L.; Liao, Y.; Wan, X.; Xiao, W.; Wang, B.; Liao, Q. Design and Test on Distributor Device of Air-assisted Centralized Metering Device for Rapeseed and Wheat. Trans. Chin. Soc. Agric. Mach. 2021, 52, 43–53. [Google Scholar]

- Zou, Y.; Hao, X.; He, R. Numerical simulation and experiment of air distribution seed-metering device based on coupled EDEM-Fluent. J. South China Agric. Univ. 2017, 38, 110–116. [Google Scholar]

- Kumar, N.; Upadhyay, G.; Choudhary, S.; Patel, B.; Naresh; Chhokar, R.S.; Gill, S.C. Resource Conserving Mechanization Technologies for Dryland Agriculture. In Enhancing Resilience of Dryland Agriculture Under Changing Climate: Interdisciplinary and Convergence Approaches; Naorem, A., Machiwal, D., Eds.; Springer Nature Singapore: Singapore, 2023; pp. 657–688. [Google Scholar]

- Chang, J.; Zhang, X. Design and test of one-step centralized type pneumatic seeding system. Trans. Chin. Soc. Agric. Eng. 2011, 27, 136–141. [Google Scholar]

- Qi, B.; Zhang, D.; Cui, T. Design and experiment of centralized pneumatic seed metering device for maize. Trans. Chin. Soc. Agric. Eng. 2013, 29, 8–15. [Google Scholar]

- Wang, G.; Xia, X.; Zhu, Q.; Yu, H.; Huang, D. Design and experiment of soybean high-speed precision vacuum seed metering with auxiliary filling structure based on DEM-CFD. J. Jilin Univ. Eng. Technol. Ed. 2022, 52, 1208–1221. [Google Scholar] [CrossRef]

- GB/T 6973-2005; Testing Methods of Single Seed Drills (Precision Drills). China Standard Publishing House: Beijing, China, 2005.

- Bai, S.; Yuan, Y.; Niu, K.; Zhou, L.; Zhao, B.; Wei, L.; Liu, L.; Xiong, S.; Shi, Z.; Ma, Y.; et al. Simulation Parameter Calibration and Experimental Study of a Discrete Element Model of Cotton Precision Seed Metering. Agriculture 2022, 12, 870. [Google Scholar] [CrossRef]

| Projects | Properties | Numerical Value |

|---|---|---|

| Cotton seeds | Triaxial dimension (mm × mm × mm) | 6.94 × 5.19 × 4.82 |

| Density/(kg·m−3) | 664.6 | |

| Poisson’s ratio | 0.25 | |

| Elastic modulus/Pa | 1.0 × 106 | |

| ABS Plastic | Density/(kg·m−3) | 1180 |

| Poisson’s ratio | 0.5 | |

| Elastic modulus/Pa | 1.77 × 106 | |

| Cotton seed-cotton seed | Collision recovery coefficient | 0.3 |

| coefficient of static friction | 0.56 | |

| coefficient of rolling friction | 0.15 | |

| ABS Plastic-cotton seed | Collision recovery coefficient | 0.6 |

| coefficient of static friction | 0.48 | |

| coefficient of rolling friction | 0.1 |

| Pipe Angle (°) | Outlet Air Pressure (Pa) | Outlet Air Flow Velocity (m/s) | Cotton Seed Inlet Airflow Pressure (Pa) | Cotton Seed Inlet Air Flow Rate (m/s) | Pressure Loss (Pa) | Air Flow into PORT Speed (m/s) |

|---|---|---|---|---|---|---|

| 15 | 417.63 | 25.93 | 6.37 | 2.30 | 76.00 | 28.00 |

| 30 | 411.27 | 25.60 | 7.47 | 2.60 | 81.26 | 27.79 |

| 45 | 353.62 | 23.33 | 21.97 | 4.81 | 124.41 | 27.46 |

| 60 | 277.52 | 19.98 | 44.96 | 7.69 | 177.52 | 27.04 |

| Type of the Seed Diversion Tube Joint | Outlet Air Pressure (Pa) | Outlet Air Flow Velocity (m/s) | Cotton Seed Inlet Air Flow Pressure (Pa) | Cotton Seed Inlet Air Flow Rate (m/s) | Pressure Loss (Pa) | Air Flow into Port Speed (m/s) |

|---|---|---|---|---|---|---|

| No diversion | 417.63 | 25.93 | 6.37 | 2.30 | 76.00 | 28.00 |

| Vertical plate diversion | 155.06 | 14.51 | −0.06 | −6.19 | 345.00 | 15.54 |

| Cylindrical diversion | 250.09 | 18.47 | −0.03 | −3.27 | 249.74 | 15.18 |

| Round table diversion | 386.78 | 24.95 | 0.01 | 0.12 | 113.21 | 25.05 |

| Speed of Cavity Seeder (rev/min) | Positive Pressure (Pa) | Single Seeding Rate/% | Missed Seeding Rate/% | Multiple Seeding Rate/% |

|---|---|---|---|---|

| 20 | 0 | 80.36 | 10.54 | 9.10 |

| 50 | 89.54 | 6.43 | 4.03 | |

| 100 | 88.92 | 6.78 | 4.30 | |

| 150 | 85.34 | 8.33 | 6.33 | |

| 30 | 0 | 77.82 | 13.09 | 9.09 |

| 50 | 88.76 | 7.26 | 3.98 | |

| 100 | 86.59 | 7.75 | 5.66 | |

| 150 | 83.21 | 8.93 | 7.86 | |

| 40 | 0 | 70.65 | 16.53 | 12.82 |

| 50 | 87.32 | 7.38 | 5.30 | |

| 100 | 86.12 | 7.94 | 5.94 | |

| 150 | 80.64 | 9.86 | 9.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, K.; Li, S.; Ni, X.; Lu, B.; Zhao, B. Analysis and Experimental of Seeding Process of Pneumatic Split Seeder for Cotton. Agriculture 2023, 13, 1050. https://doi.org/10.3390/agriculture13051050

Li K, Li S, Ni X, Lu B, Zhao B. Analysis and Experimental of Seeding Process of Pneumatic Split Seeder for Cotton. Agriculture. 2023; 13(5):1050. https://doi.org/10.3390/agriculture13051050

Chicago/Turabian StyleLi, Kezhi, Shufeng Li, Xiangdong Ni, Bo Lu, and Binqiang Zhao. 2023. "Analysis and Experimental of Seeding Process of Pneumatic Split Seeder for Cotton" Agriculture 13, no. 5: 1050. https://doi.org/10.3390/agriculture13051050