Production of Sweet Sorghum Bio-Feedstock on Technosol Using Municipal Sewage Sludge Treated with Flocculant, in Ukraine

Abstract

:1. Introduction

2. Materials and Methods

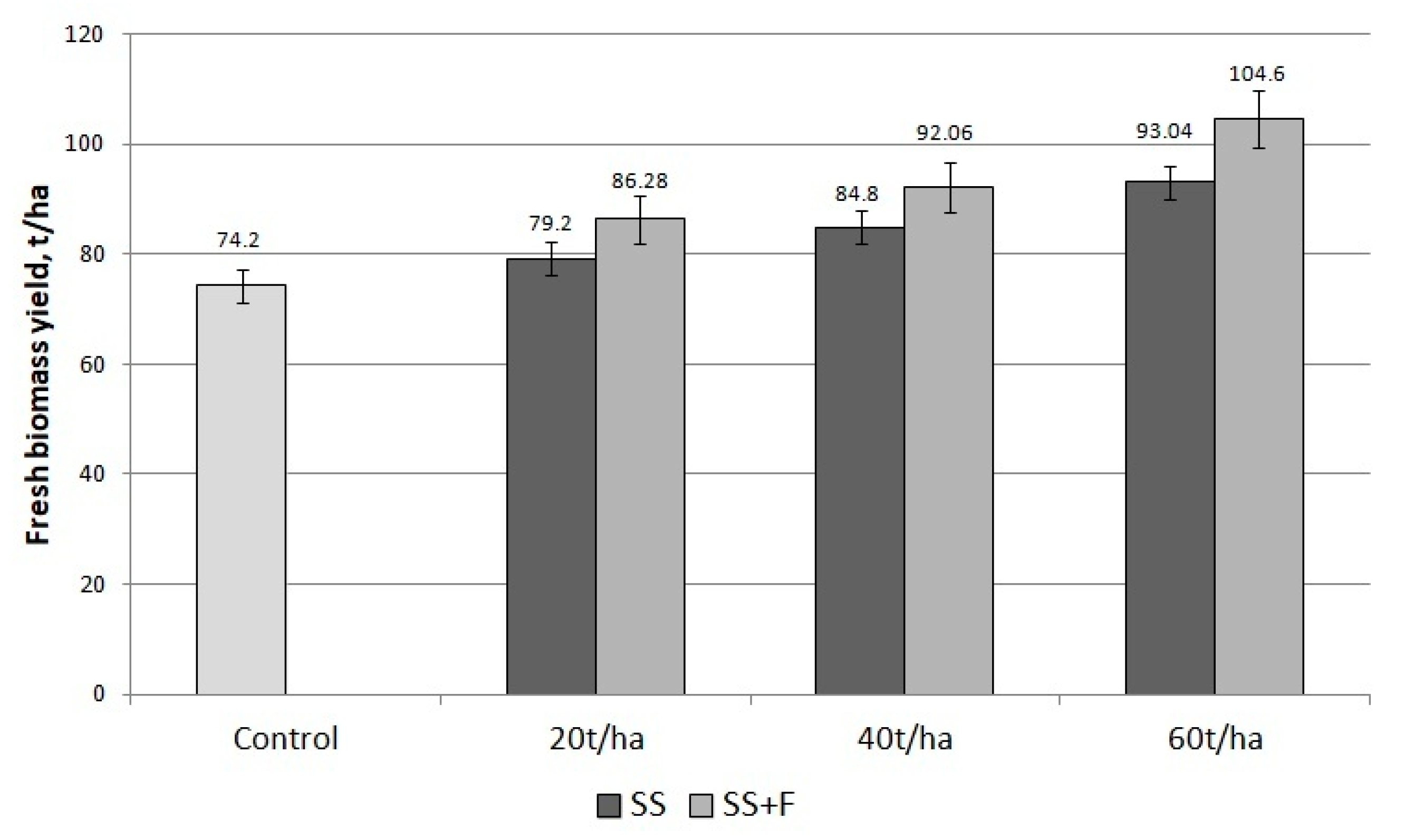

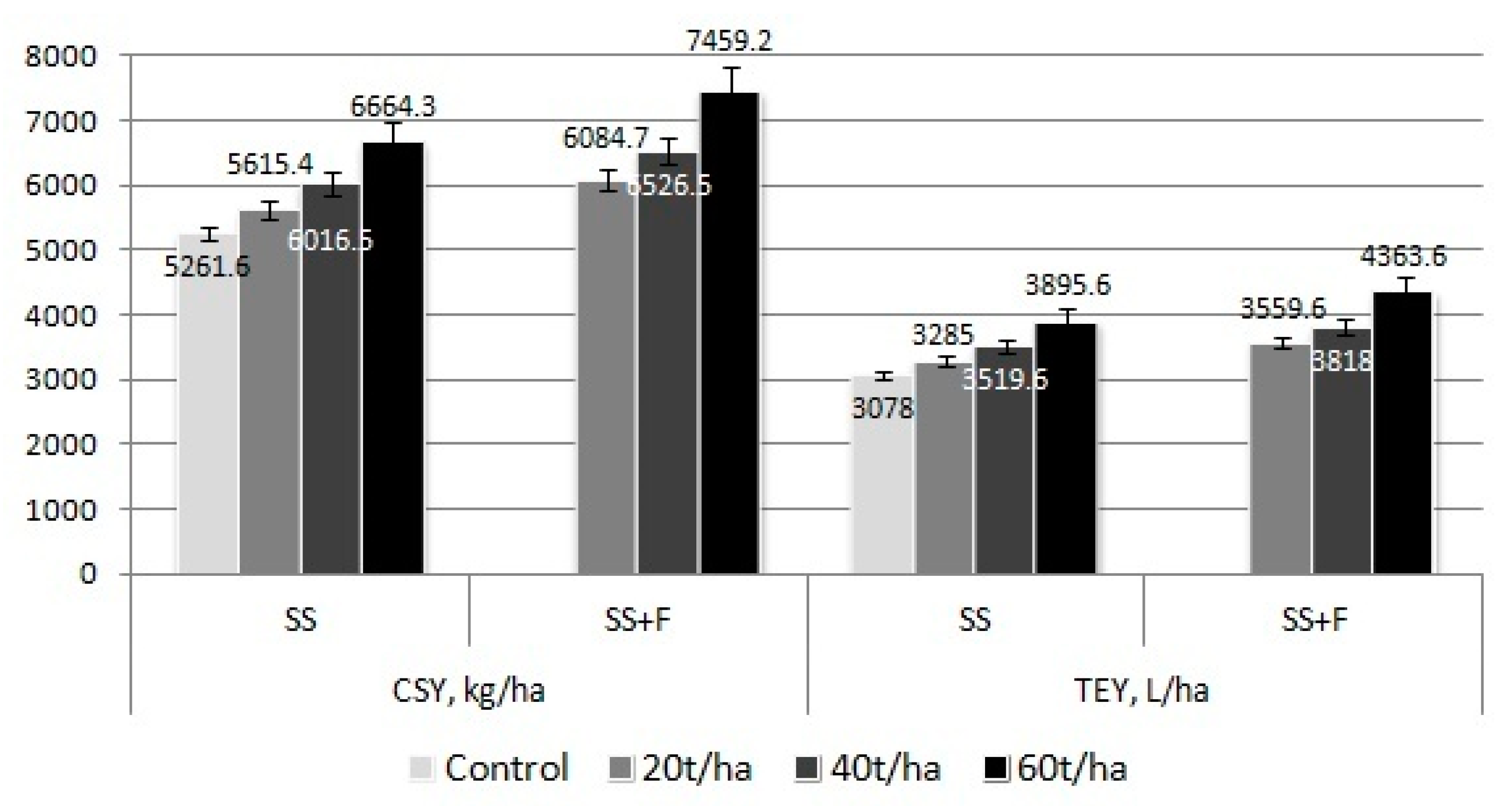

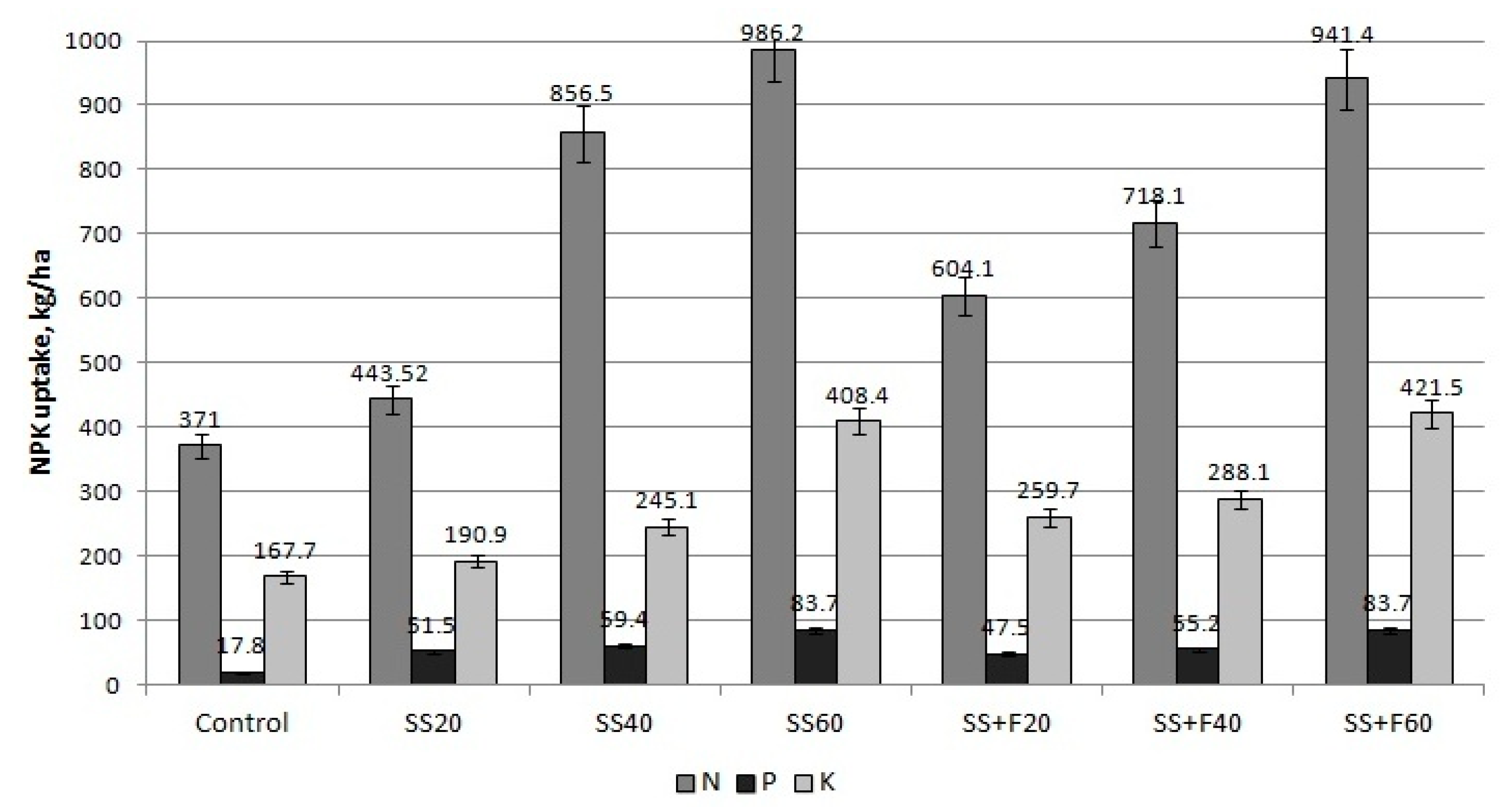

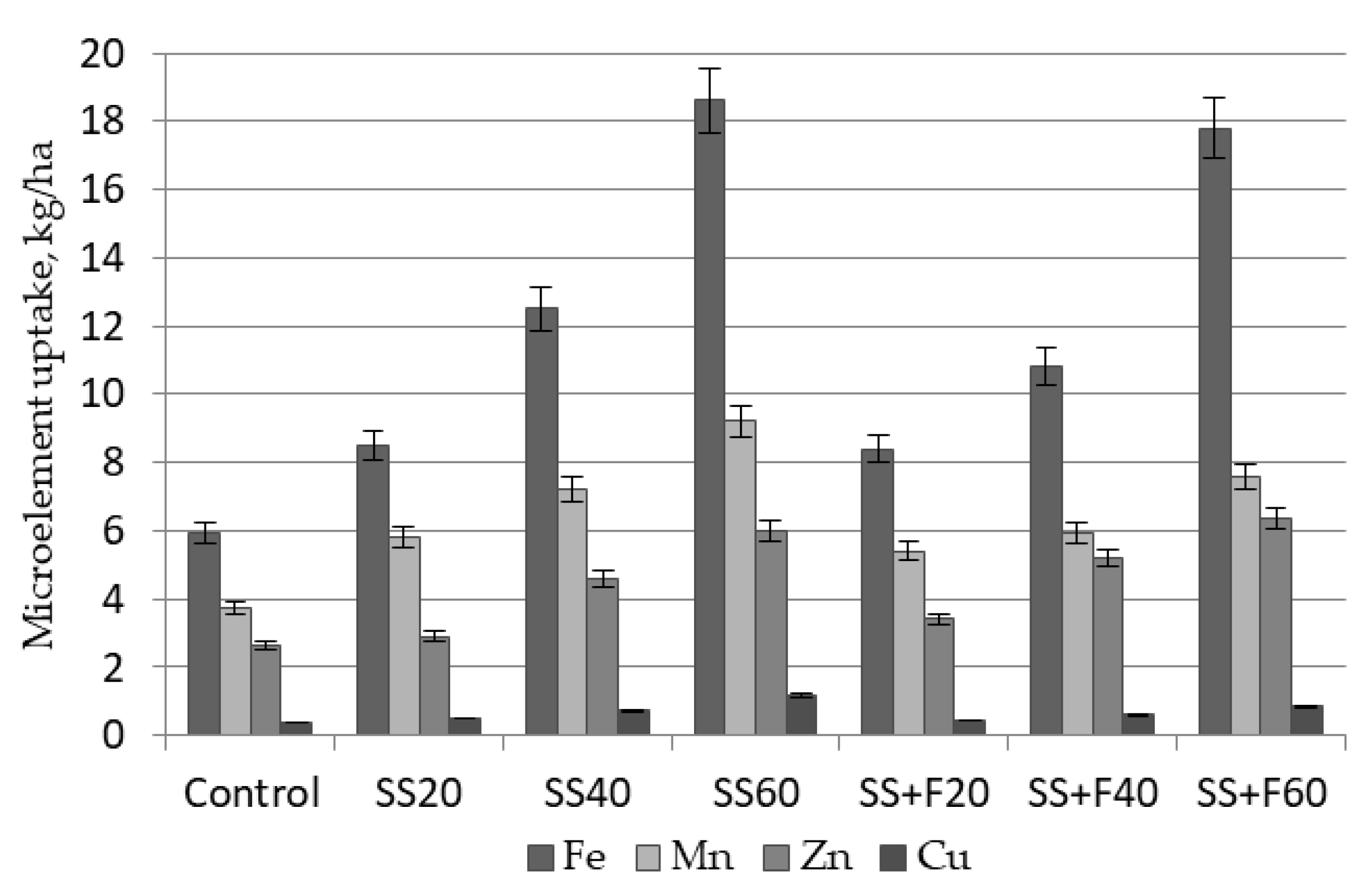

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kołodziej, B.; Antonkiewicz, J.; Stachyra, M.; Bielińska, E.J.; Wiśniewski, J.; Luchowska, K.; Kwiatkowski, C. Use of sewage sludge in bioenergy production—A case study on the effects on sorghum biomass production. Eur. J. Agron. 2015, 69, 63–74. [Google Scholar] [CrossRef]

- Melo, W.J.; Melo, G.M.P.; Melo, V.P.; Yada, M.M.; Carlos, R.S.; Silva, E.G. Sorghum growth in soil treated with sewage sludge from the textile industry. WIT Trans. Ecol. Environ. 2015, 196, 233–241. [Google Scholar] [CrossRef]

- Shashoug, M.; Abdalla, M.; Elhadi, E.; Rezig, F. Response of fodder sorghum (Sorghum bicolor (L.) to sewage sludge treatment and irrigation intervals in a dryland condition. Eurasian J. Soil Sci. 2017, 6, 144–153. [Google Scholar] [CrossRef]

- Cheng, H.; Hu, Y. Municipal solid waste (MSW) as a renewable source of energy: Current and future practices in China. Bioresour. Technol. 2010, 101, 3816–3824. [Google Scholar] [CrossRef]

- Kominko, H.; Gorazda, K.; Wzorek, Z. The possibility of organo-mineral fertilizer production from sewage sludge. Waste Biomass Valorization 2017, 8, 1781–1791. [Google Scholar] [CrossRef]

- Przydatek, G.; Wota, A.K. Analysis of the comprehensive management of sewage sludge in Poland. J. Mater. Cycles Waste Manag. 2020, 22, 80–88. [Google Scholar] [CrossRef]

- Glab, L.; Sowinski, J. Sustainable production of sweet sorghum as a bioenergy crop using biosolids taking into account greenhouse gas emissions. Sustainability 2019, 11, 3033. [Google Scholar] [CrossRef]

- Maucieri, C.; Nicoletto, C.; Caruso, C.; Sambo, P.; Borin, M. Effects of digestate solid fraction fertilisation on yield and soil carbon dioxide emission in a horticulture succession. Ital. J. Agron. 2017, 12, 116–123. [Google Scholar] [CrossRef]

- Singh, R.P.; Agrawal, M. Potential benefits and risks of land application of sewage sludge. Waste Manag. 2008, 28, 347–358. [Google Scholar] [CrossRef]

- Kacprzak, M.; Neczaj, E.; Fijałkowski, K.; Grobelak, A.; Grosser, A.; Worwag, M.; Singh, B.R. Sewage sludge disposal strategies for sustainable development. Environ. Res. 2017, 156, 39–46. [Google Scholar] [CrossRef]

- Ungureanu, N.; Vlăduț, V.; Voicu, G. Water scarcity and wastewater reuse in crop irrigation. Sustainability 2020, 12, 9055. [Google Scholar] [CrossRef]

- Izydorczyk, G.; Mikula, K.; Skrzypczak, D.; Trzaska, K.; Witek-Krowiak, A.; Chojnacka, K. Agricultural and non-agricultural directions of bio-based sewage sludge valorization by chemical conditioning. Environ. Sci. Pollut. Res. 2021, 28, 47725–47740. [Google Scholar] [CrossRef] [PubMed]

- Carrere, H.; Dumas, C.; Battimelli, A.; Batstone, D.J.; Delgenès, J.P.; Steyer, J.P.; Ferrer, I. Pretreatment methods to improve sludge anaerobic degradability: A review. J. Hazard Mater. 2010, 183, 1–15. [Google Scholar] [CrossRef]

- Zhou, J.; Parker, W.; Laha, S. Biosolids and sludge management. Water Environ. Res. 2007, 79, 1496–1527. [Google Scholar] [CrossRef]

- Malovanyy, M.; Shandrovych, V.; Malovanyy, A.; Polyuzhyn, I. Comparative analysis of the effectiveness of regulation of aeration depending on the quantitative characteristics of treated sewage water. J. Chem. 2016, 2016, 6874806. [Google Scholar] [CrossRef]

- Di Bonito, M. Sewage sludge in Europe and in the UK. Environmental impact and improved standards for recycling and recovery to land. In Environmental Geochemistry; De Vivo, B., Belkin, H.E., Lima, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2008; pp. 251–286. [Google Scholar] [CrossRef]

- Liang, Y.; Wang, R.; Sun, W.; Sun, Y. Advances in chemical conditioning of residual activated sludge in China. Water 2023, 15, 345. [Google Scholar] [CrossRef]

- Getmanenko, V.A.; Skrylnyk, Y.V. Scientific-organizational and normative-legal aspects of recovery of sediments of communal sewage (on an instance of European experience). Agrovisnyk 2017, 2, 43–49. [Google Scholar] [CrossRef]

- Dhar, B.R.; Nakhla, G.; Ray, M.B. Techno-economic evaluation of ultrasound and thermal pretreatments for enhanced anaerobic digestion of municipal waste activated sludge. Waste Manag. 2012, 32, 542–549. [Google Scholar] [CrossRef]

- Liu, J.B.; Yu, D.W.; Zhang, J.; Yang, M.; Wang, Y.W.; Wei, Y.S.; Tong, J. Rheological properties of sewage sludge during enhanced anaerobic digestion with microwave-H2O2 pretreatment. Water Res. 2016, 98, 98–108. [Google Scholar] [CrossRef]

- Ruiz-Hernando, M.; Simon, F.X.; Labanda, J.; Llorens, J. Effect of ultrasound, thermal and alkali treatments on the rheological profile and water distribution of waste activated sludge. Chem. Eng. J. 2014, 255, 14–22. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, J.K.; Yu, W.B.; Luo, S.; Peng, L.; Shen, X.X.; Shi, Y.F.; Zhang, S.N.; Song, J.; Ye, N.; et al. Mechanism of red mud combined with Fenton’s reagent in sewage sludge conditioning. Water Res. 2014, 59, 239–247. [Google Scholar] [CrossRef] [PubMed]

- Tyagi, V.K.; Lo, S.-L. Sludge: A waste or renewable source for energy and resources recovery? Sustain. Energy Rev. 2013, 25, 708–728. [Google Scholar] [CrossRef]

- Devi, P.; Saroha, A.K. Utilization of sludge based adsorbents for the removal of various pollutants: A review. Sci. Total Environ. 2017, 578, 16–33. [Google Scholar] [CrossRef] [PubMed]

- Svirenko, L.; Bondar, V. Sludge treatment for application in agriculture should be the option number one for Ukraine. Linnaeus Eco-Tech 2010, 10, 356–362. [Google Scholar] [CrossRef]

- Vankovych, D.; Bota, O.; Malovanyy, M.; Odusha, M.; Tymchuk, I.; Sachnyk, I.; Shkvirko, O.; Garasymchuk, V. Assessment of the prospects of application of sewage sludge from lviv wastewater treatment plants for the purpose of conducting the biological reclamation. J. Ecol. Eng. 2021, 22, 134–143. [Google Scholar] [CrossRef]

- Chernysh, Y.; Balintova, M.; Plyatsuk, L.; Holub, M.; Demcak, S. The Influence of phosphogypsum addition on phosphorus release in biochemical treatment of sewage sludge. Int. J. Environ. Res. Public Health 2018, 15, 1269. [Google Scholar] [CrossRef] [PubMed]

- Lopushnyak, V.; Hrytsulyak, H.; Voloshyn, Y.; Lopushniak, H.; Baran, B. Bioaccumulation and translocation of heavy metals in plants artichoke during sewage sediment in podzols soils. EEET 2022, 23, 178–187. [Google Scholar] [CrossRef]

- Anbu Clemensis, A.C.; Martinez-Garcia, G.; Edyvean, R.G.J. Chemical precipitation of aerobically treated olive mill wastewater. Desalin. Water Treat. 2012, 16, 39–44. [Google Scholar] [CrossRef]

- Meyn, T.; Altmann, J.; Leiknes, T. In-line coagulation prior to ceramic microfiltration for surface water treatment—Minimisation of flocculation pre-treatment. Desalin. Water Treat. 2012, 42, 163–176. [Google Scholar] [CrossRef]

- Ștefan, V.; Simion, M.A.; Popa, L.; Nedelcu, A.; Ciupercă, R. Pre-treatment of industrial waste water with hydrocarbon separators. In Proceedings of the 18th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 22–24 May 2019. [Google Scholar] [CrossRef]

- Lee, C.S.; Robinson, J.; Chong, M.F. A review on application of flocculants in wastewater treatment. Process Saf. Environ. 2014, 92, 489–508. [Google Scholar] [CrossRef]

- Yang, R.; Li, H.J.; Huang, W.; Yang, H.; Li, A.M. A review on chitosan-based flocculants and their applications in water treatment. Water Res. 2016, 95, 59–89. [Google Scholar] [CrossRef]

- Bratby, J. Coagulation and Flocculation in Water and Wastewater Treatment, 3rd ed.; IWA Publishing: London, UK, 2016. [Google Scholar]

- Chang, Q. Flocculation in Water Treatment, 2nd ed.; Chemical Industry Press: Beijing, China, 2011. [Google Scholar]

- Wei, H.; Gao, B.; Ren, J.; Li, A.; Yang, H. Coagulation/flocculation in dewatering of sludge: A review. Water Res. 2018, 143, 608–631. [Google Scholar] [CrossRef]

- Wang, X.; Chen, T.; Ge, Y.; Jia, Y. Studies on land application of sewage sludge and its limiting factors. J. Hazard. Mater. 2008, 160, 554–558. [Google Scholar] [CrossRef]

- Hudcová, H.; Vymazal, J.; Rozkošný, M. Present restrictions of sewage sludge application in agriculture within the European Union. Soil Water Res. 2019, 14, 104–120. [Google Scholar] [CrossRef]

- Moffat, A.J.; Armstrong, A.T.; Ockleston, J. The optimization of sewage sludge and effluent disposal on energy crops of short rotation hybrid poplar. Biomass Bioenergy 2001, 20, 161–169. [Google Scholar] [CrossRef]

- Lag-Brotons, A.; Gómez, I.; Navarro-Pedreño, J.; Mayoral, A.M.; Curt, M.D. Sewage sludge compost use in bioenergy production—A case study on the effects on Cynara cardunculus L energy crop. J. Clean Prod. 2014, 79, 32–40. [Google Scholar] [CrossRef]

- Gudulas, K.; Michailidou-Notara, P.; Notaras, E.; Papadimitriou, C.; Samaras, P. Management of Sludge from Municipal Wastewater Treatment Plants in the Regions of Thessaly and West Macedonia, Greece. In Proceedings of the International Conference on Environmental Management, Engineering, Planning and Economics, Skiathos, Greece, 24–28 June 2007; Kungolos, A., Aravossis, K., Karagiannidis, A., Samaras, P., Eds.; GRAFIMA: Belgrado, Serbia, 2007; pp. 1249–1254. [Google Scholar]

- Golia, E.; Angelaki, A.; Giannoulis, K.; Skoufogianni, E.; Bartzialis, D.; Cavalaris, C.; Vleioras, S. Evaluation of soil properties, irrigation and solid waste application levels on Cu and Zn uptake by industrial hemp. Agron. Res. 2021, 19, 92–99. [Google Scholar] [CrossRef]

- Choi, Y.H.; Moon, Y.H.; Ahn, S.H.; Yoon, Y.M.; Cha, Y.L.; Koo, B.C.; Kim, W.S. Characteristics of sweet sorghum germplasm for bioethanol production in reclaimed soil. Korean J. Crop Sci. 2012, 57, 384–388. [Google Scholar] [CrossRef]

- Kim, S.; Ryu, J.H.; Paik, C.H.; Lee, S.H.; Oh, Y.Y.; Lee, J.T. Characteristics of emergence and growth of sorghum at various soil salinities and seeding methods in reclaimed soil. Korean J. Crop Sci. 2017, 62, 233–240. [Google Scholar]

- Zhu, Y.; Song, X.; Wang, X.; Chen, W.; Niu, X. The yield increase and land improvement effects of different sorghum/wild soybean intercropping patterns on reclaimed coastal salt pans. J. Soils Sediments 2022, 22, 731–744. [Google Scholar] [CrossRef]

- Dumitru, I.; Voicea, I.; Vlăduț, V.; Găgeanu, I.; Oprescu, R.; Persu, C.; Ungureanu, N.; Bălan, V. Technology for cultivating bicolor sorghum for food and energetic purposes. In Proceedings of the 7th International Conference on Thermal Equipment, Renewable Energy and Rural Development (TE-RE-RD), Drobeta Turnu Severin, Romania, 31 May–2 June 2018; pp. 239–244. [Google Scholar]

- Caba, I.; Laza, E.; Vlăduț, V.; Marin, E.; Ungureanu, N.; Biriș, S.Ș.; Găgeanu, I.; Voicea, I.; Isticioaia, S.; Olan, M.; et al. Sweet sorghum—An alternative for Romanian farmers in the conditions of the current climate change. In Proceedings of the International Symposium ISB-INMATEH—Agricultural and Mechanical Engineering, Bucharest, Romania, 1–3 November 2018; pp. 945–954. [Google Scholar]

- Nenciu, F.; Vlăduț, V. Studies on the perspectives of replacing the classic energy plants with Jerusalem artichoke and Sweet Sorghum, analyzing the impact on the conservation of ecosystems. IOP Conf. Ser. Earth Environ. Sci. 2021, 635, 012002. [Google Scholar] [CrossRef]

- Sipos, B.; Réczey, J.; Somorai, Z. Sweet sorghum as feedstock for ethanol production: Enzymatic hydrolysis of steam-pretreated bagasse. Appl. Biochem. Biotechnol. 2009, 153, 151–162. [Google Scholar] [CrossRef]

- Rakhmetov, D.B.; Vergun, O.; Blum, Y.B.; Rakhmetova, S.O.; Fishchenko, V.V. Biochemical composition of plant raw material of sweet sorghum (Sorghum saccharatum (L.) Moench) genotype. Plants J. 2018, 79, 83–90. [Google Scholar] [CrossRef]

- Nghiem, N.P.; Toht, M.J. Pretreatment of sweet sorghum bagasse for ethanol production using Na2CO3 obtained by NaOH absorption of CO2 generated in sweet sorghum juice ethanol fermentation. Fermentation 2019, 5, 91. [Google Scholar] [CrossRef]

- Nenciu, F.; Paraschiv, M.; Kuncser, R.; Stan, C.; Cocârță, D.; Vlăduț, V. High-grade chemicals and biofuels produced from marginal lands using an integrated approach of alcoholic fermentation and pyrolysis of sweet sorghum biomass residues. Sustainability 2022, 14, 402. [Google Scholar] [CrossRef]

- Akdeniz, H.; Yilmaz, I.; Bozkurt, M.A.; Keskin, B. The effects of sewage sludge and nitrogen applications on grain sorghum grown (Sorghum vulgare L.) in Van-Turkey. Pol. J. Environ. Stud. 2006, 15, 19–26. [Google Scholar]

- Eid, E.M.; Shaltout, K.H.; Alamri, S.A.; Alrumman, S.A.; Hussain, A.A.; Sewelam, N.; Ragab, G.A. Monitored sewage sludge application improves soil quality, enhances plant growth, and provides evidence for metal remediation by Sorghum bicolor L. J. Soil Sci. Plant Nutr. 2021, 21, 2325–2338. [Google Scholar] [CrossRef]

- Börjesson, G.; Kätterer, T. Soil fertility effects of repeated application of sewage sludge in two 30-year-old field experiments. Nutr. Cycl. Agroecosyst. 2018, 112, 369–385. [Google Scholar] [CrossRef]

- Kharytonov, M.M.; Martynova, N.V.; Babenko, M.G.; Rula, I.V. Environmentally Compatible Utilization of Reclaimed Minelands for Sustainable Production Food and Bioenergy Feedstock; Publishing House “Baltija Publishing”: Riga, Latvia, 2020; pp. 625–658. [Google Scholar]

- Kharytonov, M.M.; Gonchar, N.V.; Gavryushenko, O.O.; Mytsyk, O.O. Ecological Assessment of the State of Rocks in the of Reclamation Process in the Nikopol Manganese ore Basin. In Resource-Saving Technologies of Raw-Material Base Development in Mineral Mining and Processing; Universitas Publishing: Petroșani, Romania, 2020; pp. 392–413. [Google Scholar]

- Dokuchaev Soil Institute. Agrochemical Methods of Soil Investigation. Edited by USSR Academy of Science, 4th ed.; Science Publishers: Moscow, Russia, 1965; 436p. (In Russian) [Google Scholar]

- Ekefre, D.E.; Mahapatra, A.K.; Latimore, M., Jr.; Bellmer, D.D.; Jena, U.; Whitehead, G.J.; Williams, A.L. Evaluation of three cultivars of sweet sorghum as feedstocks for ethanol production in the Southeast United States. Heliyon 2017, 3, e00490. [Google Scholar] [CrossRef]

- Thomas, R.L.; Sheard, R.W.; Mayer, J.R. Comparison of conventional and automated procedures for nitrogen, phosphorus and potassium analysis of plant material using a single digestion. Agron. J. 1967, 59, 240–243. [Google Scholar] [CrossRef]

- Kharytonov, M.; Martynova, N.; Babenko, M.; Rula, I.; Gumentyk, M.; Bagorka, M.; Pashova, V. The production of biofuel feedstock on reclaimed lands based on sweet sorghum biomass. Agric. For. 2019, 65, 233–240. [Google Scholar] [CrossRef]

- Kharytonov, M.; Martynova, N.; Babenko, M.; Honchar, N.; Sytnyk, S.; Sereda, V. Sweet sorghum cultivation in black soil and phytomeliorated rocks in Ukraine. Acta Tech. Corviniensis-Bull. Eng. 2021, 14, 103–106. [Google Scholar]

- Boumalek, W.; Kettab, A.; Bensacia, N.; Bruzzoniti, M.C.; Othman, D.B.; Mandi, L.; Chabaca, M.N.; Benziada, S. Specification of sewage sludge arising from a domestic wastewater treatment plant for agricultural uses. Desalin. Water Treat. 2019, 143, 178–183. [Google Scholar] [CrossRef]

- Arlo, L.; Beretta, A.; Szogi, A.; del Pino, A. Biomass production, metal and nutrient content in sorghum plants grown on soils amended with sewage sludge. Helyon 2022, 8, e08658. [Google Scholar] [CrossRef]

- Al-Jaloud, A.A. Effect of sewage sludge on germination, growth and biomass yield of sorghum in calcareous soils. Pak. J. Biol. Sci. 1999, 2, 494–497. [Google Scholar] [CrossRef]

- Zuo, W.; Gu, C.; Zhang, W.; Xu, K.; Wang, Y.; Bai, Y.; Dai, Q. Sewage sludge amendment improved soil properties and sweet sorghum yield and quality in a newly reclaimed mudflat land. Sci. Total Environ. 2019, 654, 541–549. [Google Scholar] [CrossRef]

| Parameter | Content | |

|---|---|---|

| Sewage Sludge | Sewage Sludge with Flocculant | |

| Mass fraction of moisture (%) | 15.99 ± 0.27 | 29.12 ± 0.31 |

| Mass fraction of dry matter (%) | 84.01 ± 0.41 | 70.88 ± 0.39 |

| Mass fraction of ash (%) | 50.75 ± 0.36 | 30.25 ± 0.28 |

| Mass fraction of organic matter (%) | 49.25 ± 0.31 | 69.75 ± 0.86 |

| Mass fraction of total carbon, C (g/kg) | 222.0 ± 2.19 | 354.0 ± 4.57 |

| Mass fraction of total nitrogen, N (g/kg) | 26.6 ± 0.28 | 38.6 ± 0.47 |

| Mass fraction of total phosphorus, P2O5 (g/kg) | 26.2 ± 0.27 | 12.0 ± 0.21 |

| Mass fraction of total potassium, K2O (g/kg) | 4.3 ± 0.10 | 4.1 ± 0.09 |

| Mass fraction of copper, Cu (mg/kg) | 195.2 ± 1.92 | 98.6 ± 0.53 |

| Mass fraction of iron, Fe (mg/kg) | 20,019.5 ± 18.44 | 17,535.4 ± 16.86 |

| Mass fraction of manganese, Mn (mg/kg) | 420.0 ± 3.51 | 125.1 ± 2.52 |

| Mass fraction of zinc, Zn (mg/kg) | 875.9 ± 9.82 | 557.5 ± 7.39 |

| Mass fraction of cobalt, Co (mg/kg) | 3.0 ± 0.11 | 2.5 ± 0.08 |

| Mass fraction of nickel, Ni (mg/kg) | 4.7 ± 0.15 | 4.0 ± 0.09 |

| Mass fraction of lead, Pb (mg/kg) | 2.1 ± 0.08 | 1.5 ± 0.06 |

| Mass fraction of chromium, Cr (mg/kg) | 3.5 ± 0.09 | 2.2 ± 0.08 |

| Mass fraction of cadmium, Cd (mg/kg) | 1.4 ± 0.05 | 1.3 ± 0.05 |

| Ratio C:N | 8.3 | 9.2 |

| pH | 6.6 ± 0.13 | 6.6 ± 0.14 |

| Characteristic | SS | SS + F | |||||

|---|---|---|---|---|---|---|---|

| Control | 20 t/ha | 40 t/ha | 60 t/ha | 20 t/ha | 40 t/ha | 60 t/ha | |

| Humus (%) | 1.19 ± 0.03 | 1.71 ± 0.06 | 1.86 ± 0.08 | 1.96 ± 0.08 | 1.60 ± 0.07 | 1.66 ± 0.06 | 2.14 ± 0.08 |

| Mass fraction of dry matter (%) | 96.6 ± 2.10 | 96.7 ± 1.90 | 96.9 ± 2.61 | 96.8 ± 2.5 | 97.2 ± 1.80 | 97.2 ± 1.87 | 97.0 ± 2.12 |

| Total carbon (%) | 0.69 ± 0.04 | 0.99 ± 0.06 | 1.08 ± 0.08 | 1.14 ± 0.09 | 0.93 ± 0.06 | 0.96 ± 0.05 | 1.24 ± 0.09 |

| Mass fraction of nitrogen (mg/kg) | 65.1 ± 1.80 | 80.0 ± 2.32 | 90.9 ± 2.48 | 103.8 ± 3.1 | 80.2 ± 2.30 | 92.2 ± 2.71 | 111.0 ± 3.60 |

| Mass fraction of mobile phosphorus, P2O5 (mg/kg) | 42.2 ± 1.31 | 160.1 ± 2.61 | 188.1 ± 2.90 | 214.2 ± 3.1 | 139.0 ± 2.11 | 176.1 ± 2.60 | 225.7 ± 2.81 |

| Mass fraction of exchangeable potassium, K2O (mg/kg) | 206.5 ± 1.89 | 220.0 ± 2.50 | 226.6 ± 2.71 | 370.8 ± 3.8 | 227.2 ± 2.30 | 247.8 ± 2.52 | 350.2 ± 3.50 |

| Parameter | SS | SS + F | |||||

|---|---|---|---|---|---|---|---|

| Control | 20 t/ha | 40 t/ha | 60 t/ha | 20 t/ha | 40 t/ha | 60 t/ha | |

| Mass fraction of dry matter (%) | 89.5 ± 1.61 | 89.6 ± 1.80 | 90.0 ± 2.11 | 89.6 ± 1.62 | 89.8 ± 1.69 | 90.0 ± 1.80 | 89.8 ± 1.53 |

| Total nitrogen (%) | 0.50 ± 0.13 | 0.70 ± 0.11 | 1.01 ± 0.10 | 1.06 ± 0.11 | 0.56 ± 0.14 | 0.78 ± 0.10 | 0.90 ± 0.10 |

| Total phosphorus (%) | 0.024 ± 0.004 | 0.065 ± 0.005 | 0.07 ± 0.006 | 0.09 ± 0.008 | 0.055 ± 0.005 | 0.06 ± 0.006 | 0.08 ± 0.007 |

| Total potassium (%) | 0.226 ± 0.06 | 0.241 ± 0.07 | 0.289 ± 0.09 | 0.439 ± 0.11 | 0.301 ± 0.09 | 0.313 ± 0.08 | 0.405 ± 0.09 |

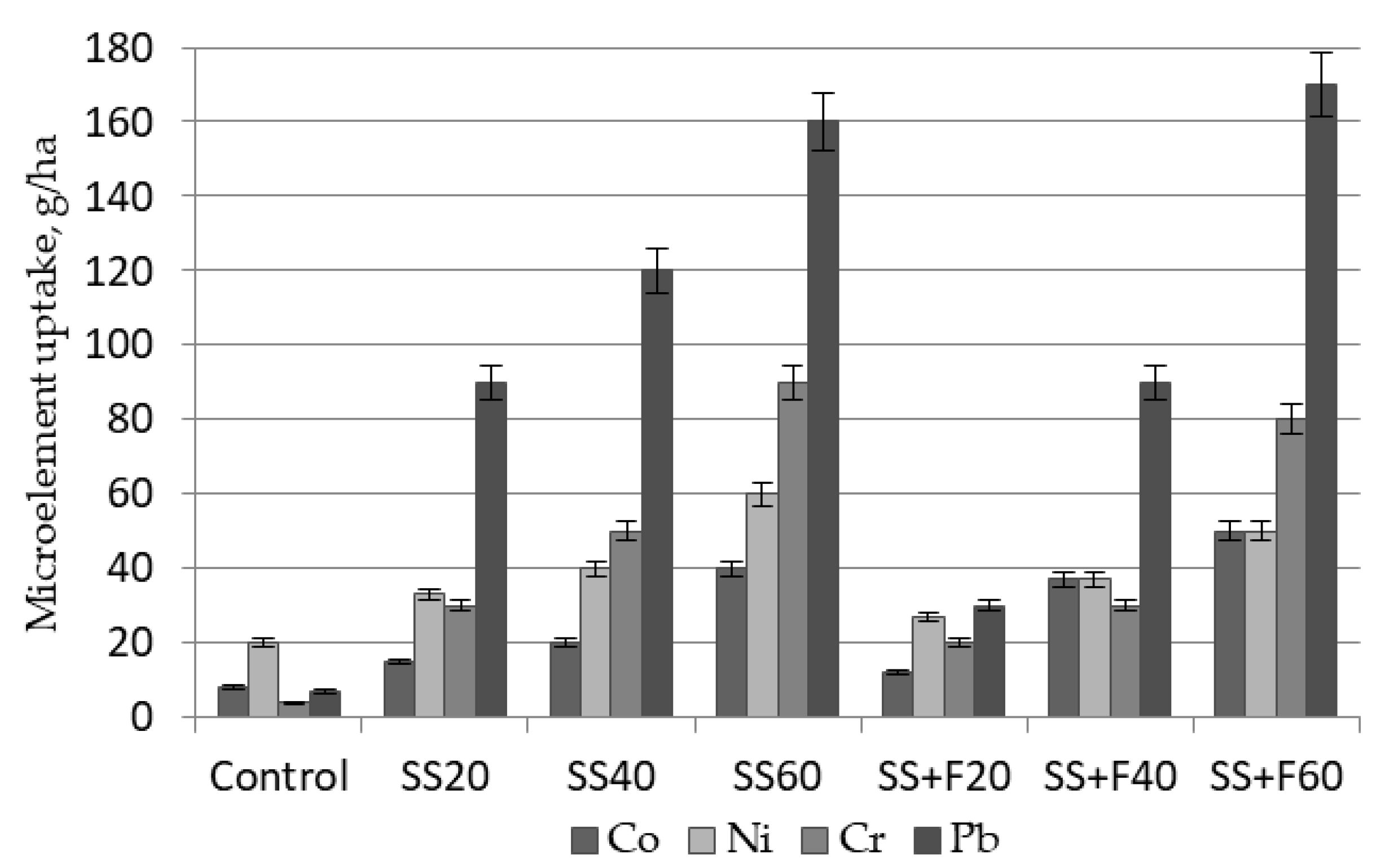

| Elements | SS | SS + F | |||||

|---|---|---|---|---|---|---|---|

| Control | 20 t/ha | 40 t/ha | 60 t/ha | 20 t/ha | 40 t/ha | 60 t/ha | |

| Fe | 80.2 ± 2.11 | 107.3 ± 3.63 | 147.9 ± 3.80 | 199.7 ± 3.72 | 97.3 ± 2.51 | 111.7 ± 3.80 | 169.9 ± 3.84 |

| Mn | 50.2 ± 1.23 | 73.6 ± 1.81 | 85.3 ± 1.83 | 99.1 ± 1.95 | 62.6 ± 1.37 | 64.4 ± 1.42 | 72.4 ± 1.45 |

| Cu | 5.1 ± 0.40 | 6.38 ± 0.41 | 8.46 ± 0.51 | 12.36 ± 0.53 | 5.11 ± 0.38 | 6.41 ± 0.42 | 8.18 ± 0.48 |

| Zn | 35.4 ± 0.65 | 36.19 ± 0.67 | 54.28 ± 0.72 | 64.55 ± 0.76 | 39.70 ± 0.63 | 56.94 ± 0.70 | 60.86 ± 0.75 |

| Co | 0.11 ± 0.01 | 0.19 ± 0.01 | 0.30 ± 0.01 | 0.49 ± 0.02 | 0.14 ± 0.01 | 0.40 ± 0.01 | 0.46 ± 0.02 |

| Ni | 0.29 ± 0.02 | 0.42 ± 0.02 | 0.54 ± 0.02 | 0.61 ± 0.03 | 0.32 ± 0.02 | 0.40 ± 0.02 | 0.51 ± 0.02 |

| Cr | 0.06 ± 0.006 | 0.34 ± 0.01 | 0.63 ± 0.03 | 1.0 ± 0.11 | 0.30 ± 0.02 | 0.34 ± 0.02 | 0.76 ± 0.03 |

| Pb | 0.1 ± 0.008 | 1.18 ± 0.1 | 1.43 ± 0.04 | 1.71 ± 0.05 | 0.41 ± 0.02 | 0.94 ± 0.03 | 1.62 ± 0.06 |

| Cd | 0.01 ± 0.002 | 0.05 ± 0.003 | 0.06 ± 0.003 | 0.08 ± 0.004 | 0.03 ± 0.001 | 0.05 ± 0.002 | 0.06 ± 0.003 |

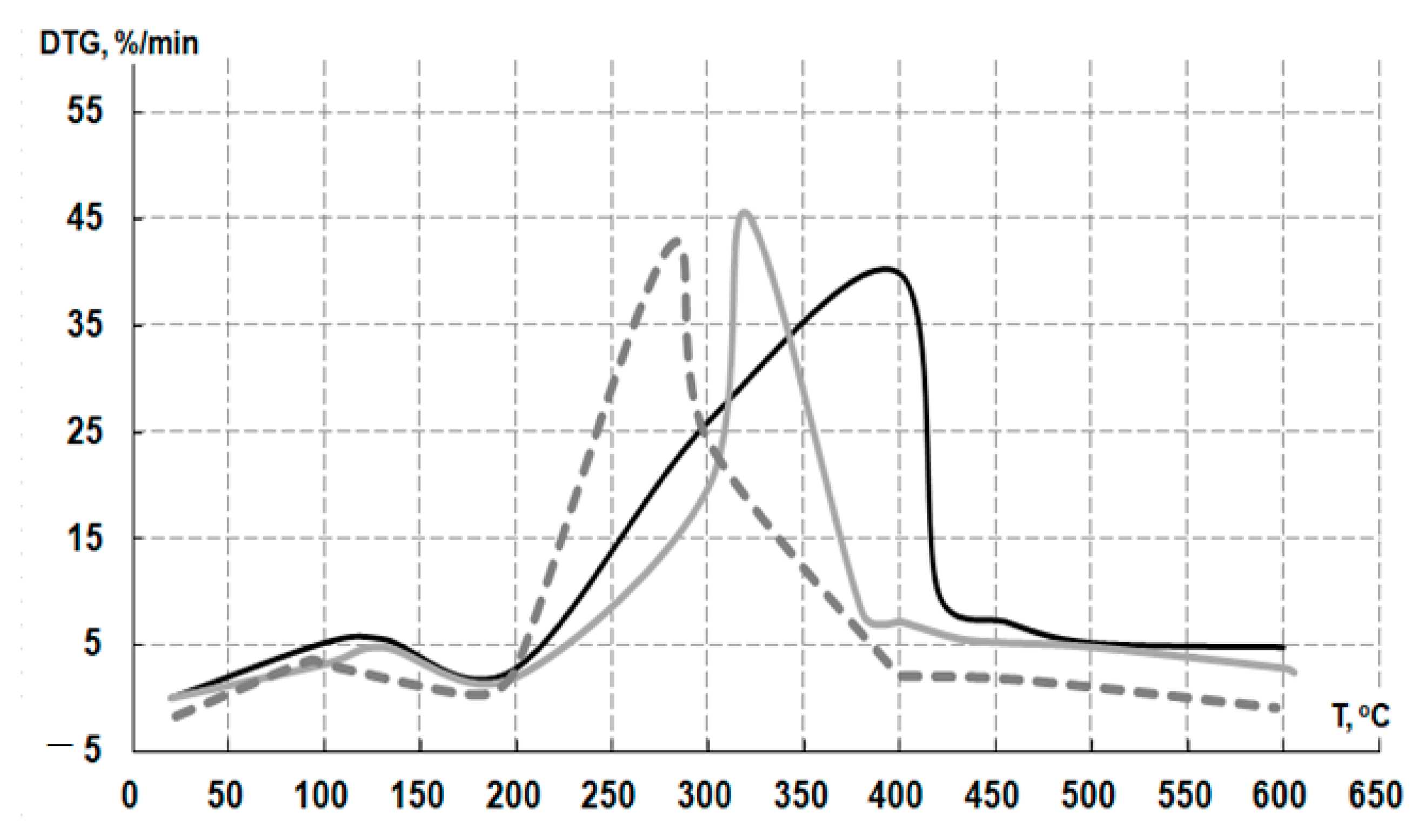

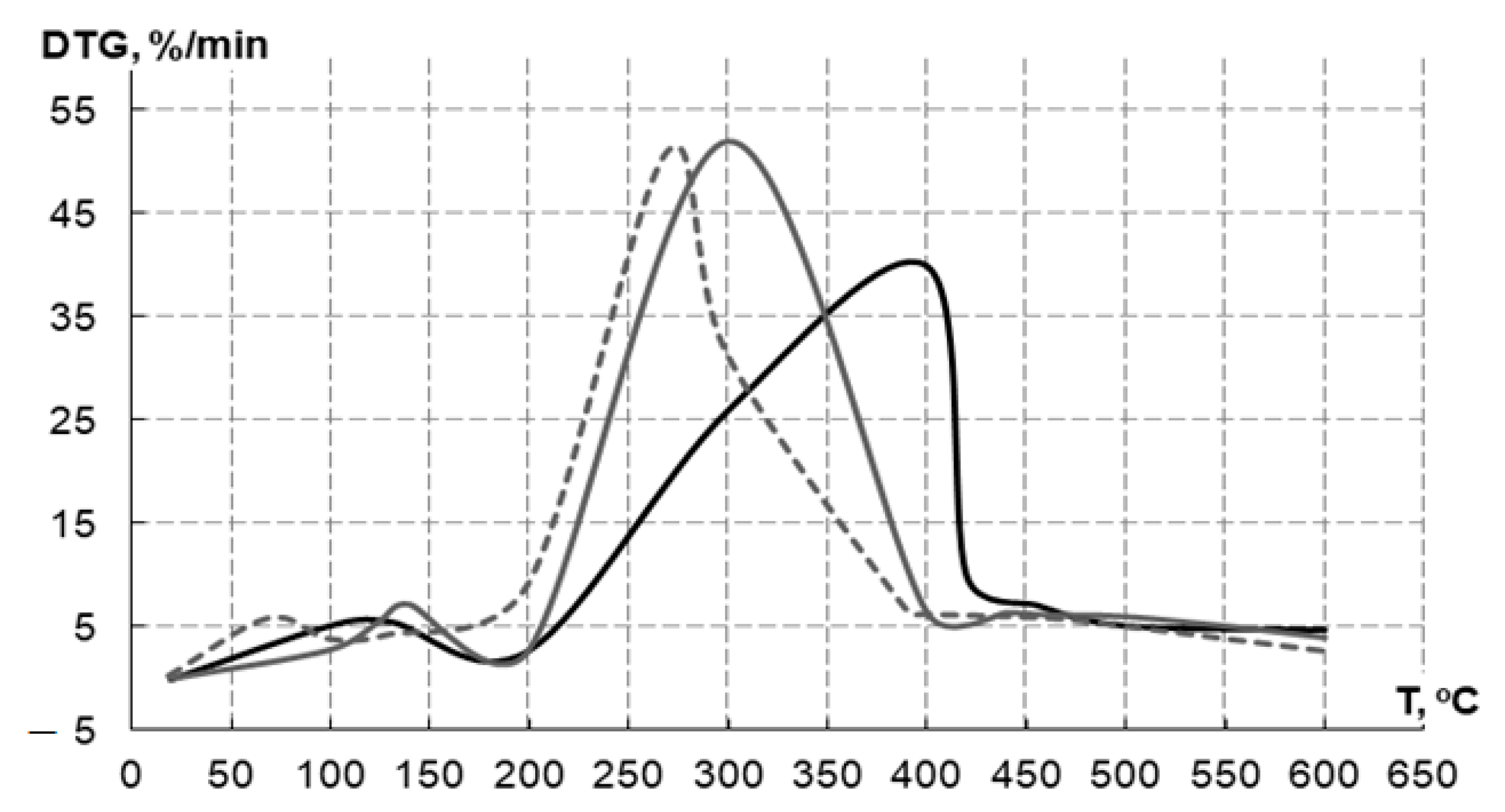

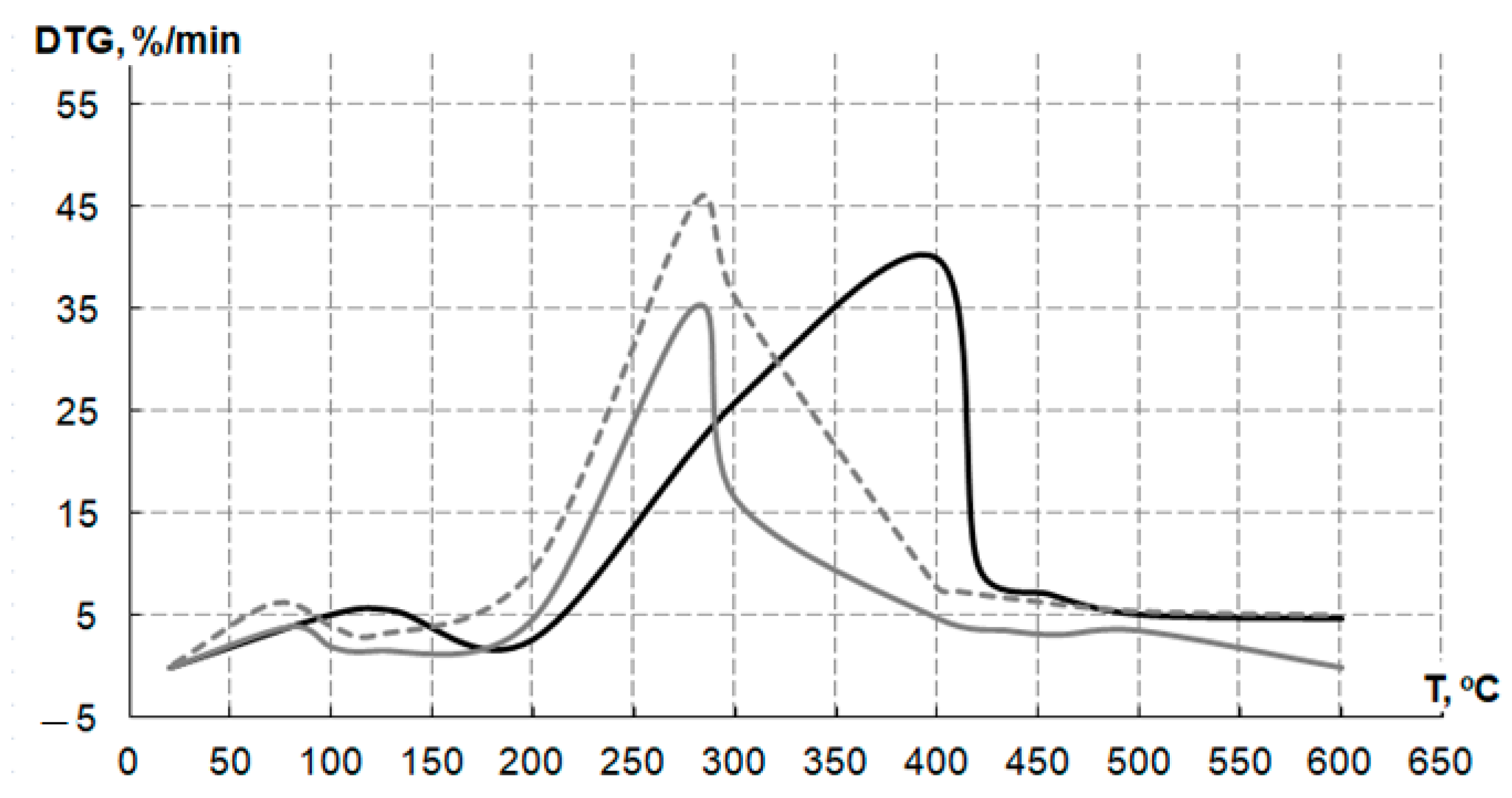

| Treatment | Stage | Interval (°C) | Peak (°C) | Maximum Rate (%/min) | Mass Loss (%) | Share of Residual Mass (%) |

|---|---|---|---|---|---|---|

| Control | I | 30–170 | 110 | 5.3 ± 0.20 | 6.8 ± 0.22 | 3.6 ± 0.16 |

| II | 170–420 | 390 | 40.0 ± 0.45 | 65.4 ± 0.54 | ||

| III | 420–600 | 460 | 7.6 ± 0.36 | 24.2 ± 0.43 | ||

| SS20 | I | 30–170 | 120 | 5.1 ± 0.18 | 5.4 ± 0.18 | 2.6 ± 0.13 |

| II | 170–380 | 320 | 45.6 ± 0.48 | 60.8 ± 0.51 | ||

| III | 380–605 | 400 | 6.2 ± 0.21 | 31.2 ± 0.33 | ||

| SS40 | I | 30–180 | 130 | 8.1 ± 0.35 | 6.4 ± 0.18 | 1.9 ± 0.11 |

| II | 180–410 | 300 | 53.2 ± 0.47 | 68.6 ± 0.59 | ||

| III | 410–600 | 440 | 6.9 ± 0.20 | 23.1 ± 0.39 | ||

| SS60 | I | 30–170 | 95 | 4.6 ± 0.18 | 4.9 ± 0.19 | 1.4 ± 0.09 |

| II | 170–410 | 290 | 35.1 ± 0.46 | 65.8 ± 0.59 | ||

| III | 410–600 | 470 | 4.7 ± 0.18 | 27.9 ± 0.48 | ||

| SS20 + F | I | 30–170 | 95 | 5,0 ± 0.21 | 8,1 ± 0.25 | 1.2 ± 0.09 |

| II | 170–400 | 290 | 44.6 ± 0.41 | 52.5 ± 0.46 | ||

| III | 400–600 | 440 | 4.3 ± 0.16 | 38.2 ± 0.41 | ||

| SS40 + F | I | 30–160 | 80 | 5.5 ± 0.18 | 9.9 ± 0.19 | 1.1 ± 0.08 |

| II | 160–390 | 290 | 50.8 ± 0.39 | 63.6 ± 0.58 | ||

| III | 390–600 | 450 | 5.2 ± 0.15 | 25.4 ± 0.47 | ||

| SS60 + F | I | 30–150 | 95 | 5.1 ± 0.15 | 8.1 ± 0.16 | 1.1 ± 0.08 |

| II | 150–410 | 280 | 45.6 ± 0.36 | 65.1 ± 0.68 | ||

| III | 410–600 | 470 | 7.1 ± 0.26 | 25.7 ± 0.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kharytonov, M.; Martynova, N.; Babenko, M.; Rula, I.; Ungureanu, N.; Ștefan, V. Production of Sweet Sorghum Bio-Feedstock on Technosol Using Municipal Sewage Sludge Treated with Flocculant, in Ukraine. Agriculture 2023, 13, 1129. https://doi.org/10.3390/agriculture13061129

Kharytonov M, Martynova N, Babenko M, Rula I, Ungureanu N, Ștefan V. Production of Sweet Sorghum Bio-Feedstock on Technosol Using Municipal Sewage Sludge Treated with Flocculant, in Ukraine. Agriculture. 2023; 13(6):1129. https://doi.org/10.3390/agriculture13061129

Chicago/Turabian StyleKharytonov, Mykola, Nadia Martynova, Mykhailo Babenko, Iryna Rula, Nicoleta Ungureanu, and Vasilica Ștefan. 2023. "Production of Sweet Sorghum Bio-Feedstock on Technosol Using Municipal Sewage Sludge Treated with Flocculant, in Ukraine" Agriculture 13, no. 6: 1129. https://doi.org/10.3390/agriculture13061129