Theoretical Calculations and Experimental Studies of Power Loss in Dual-Clutch Transmission of Agricultural Tractors

Abstract

:1. Introduction

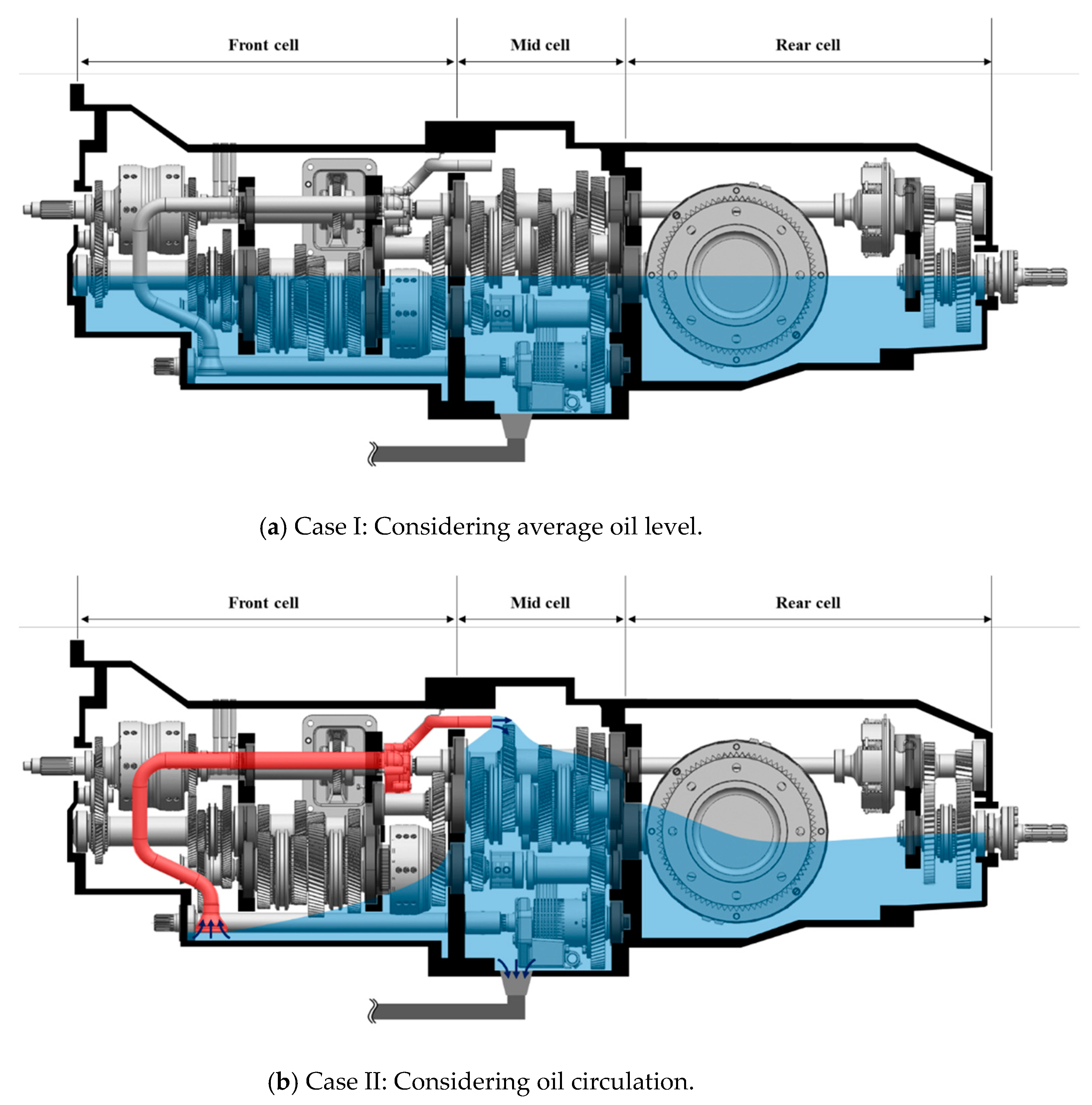

2. Materials and Methods

2.1. DCTs for Agricultural Tractors

2.2. Power Loss Calculations

2.2.1. Power Losses of the Gear and Shaft

2.2.2. Power Loss of the Bearing

2.2.3. Power Loss of the Clutch and Brake

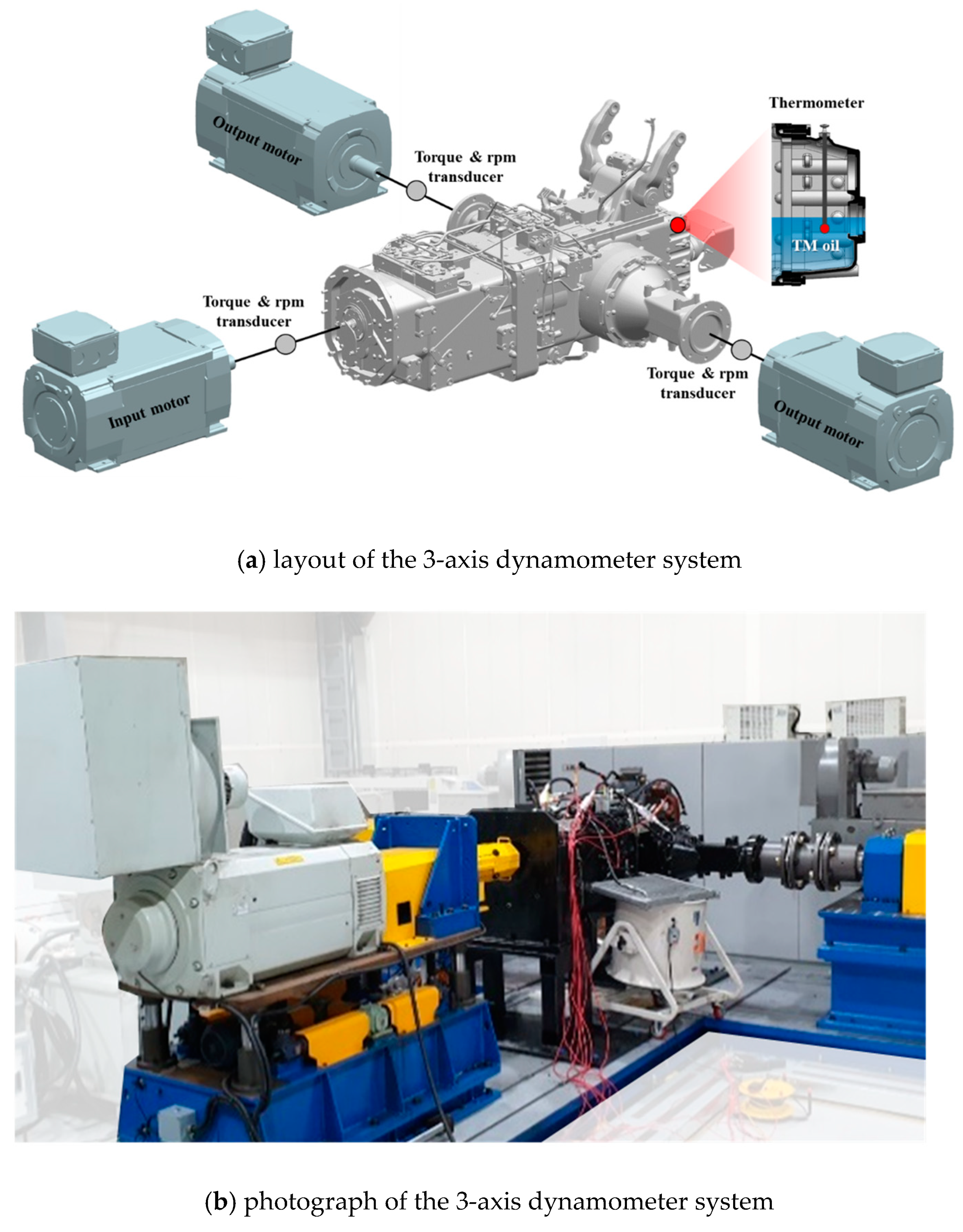

2.3. Power Loss Measurement of DCT

3. Results

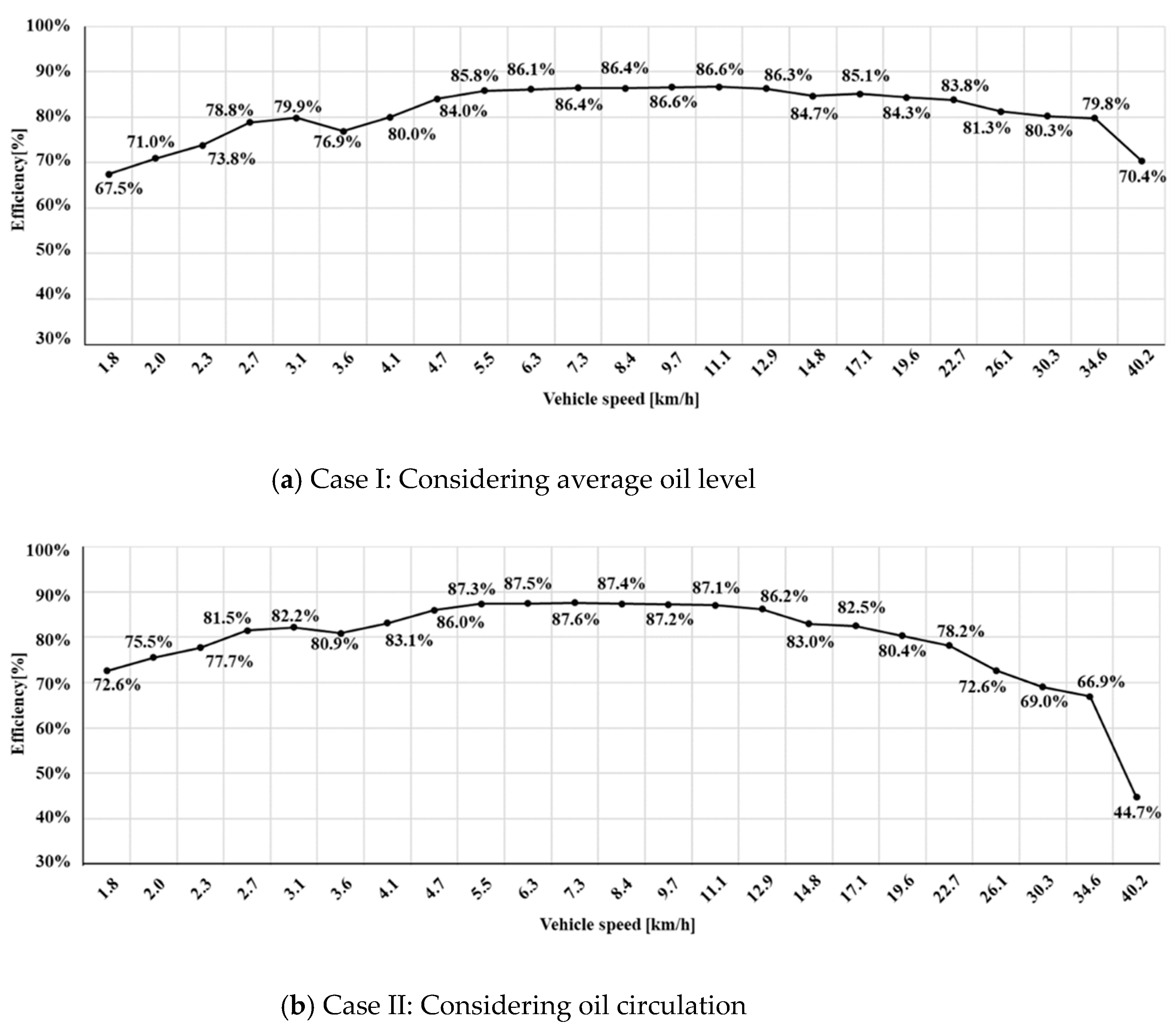

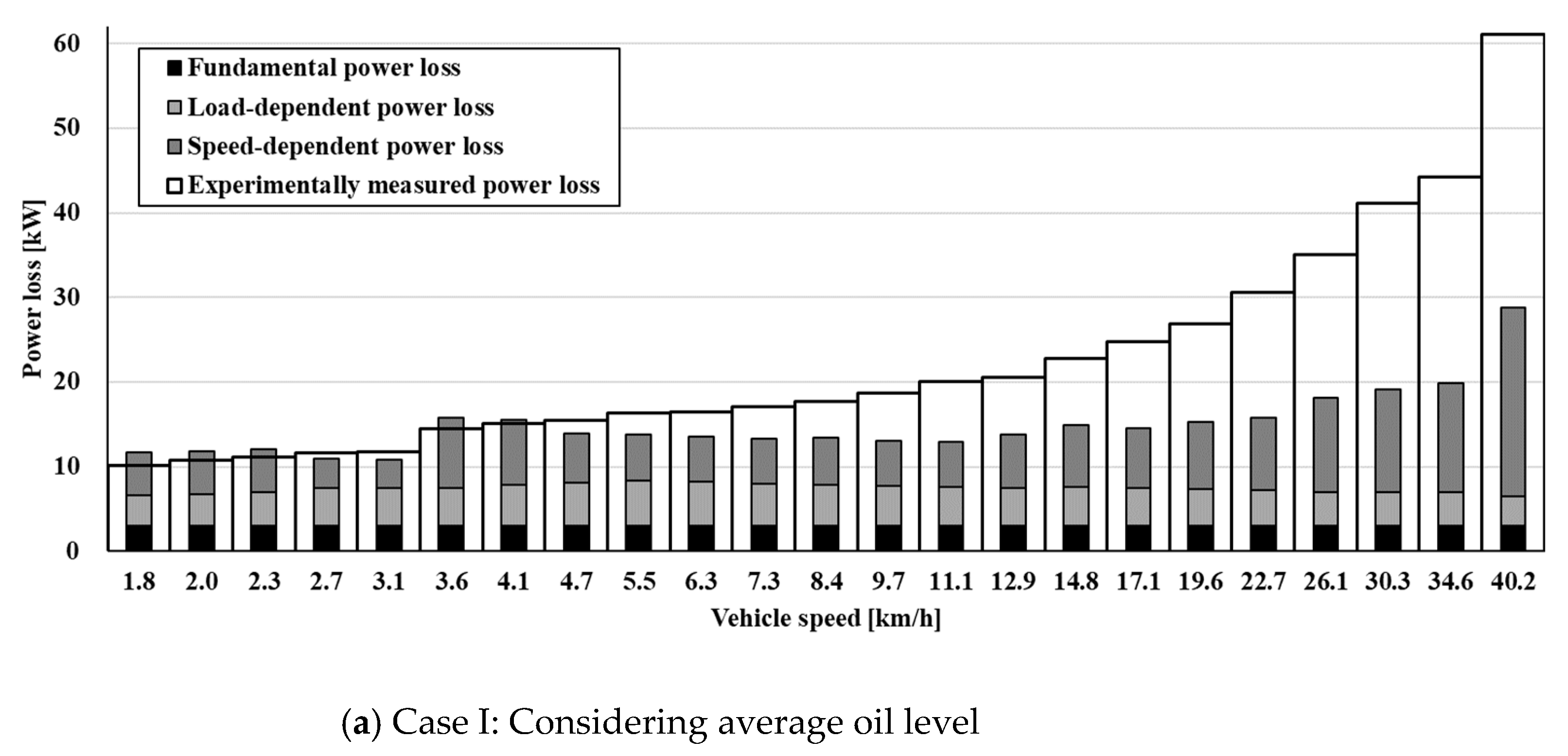

3.1. Theoretical Power Loss Calculations

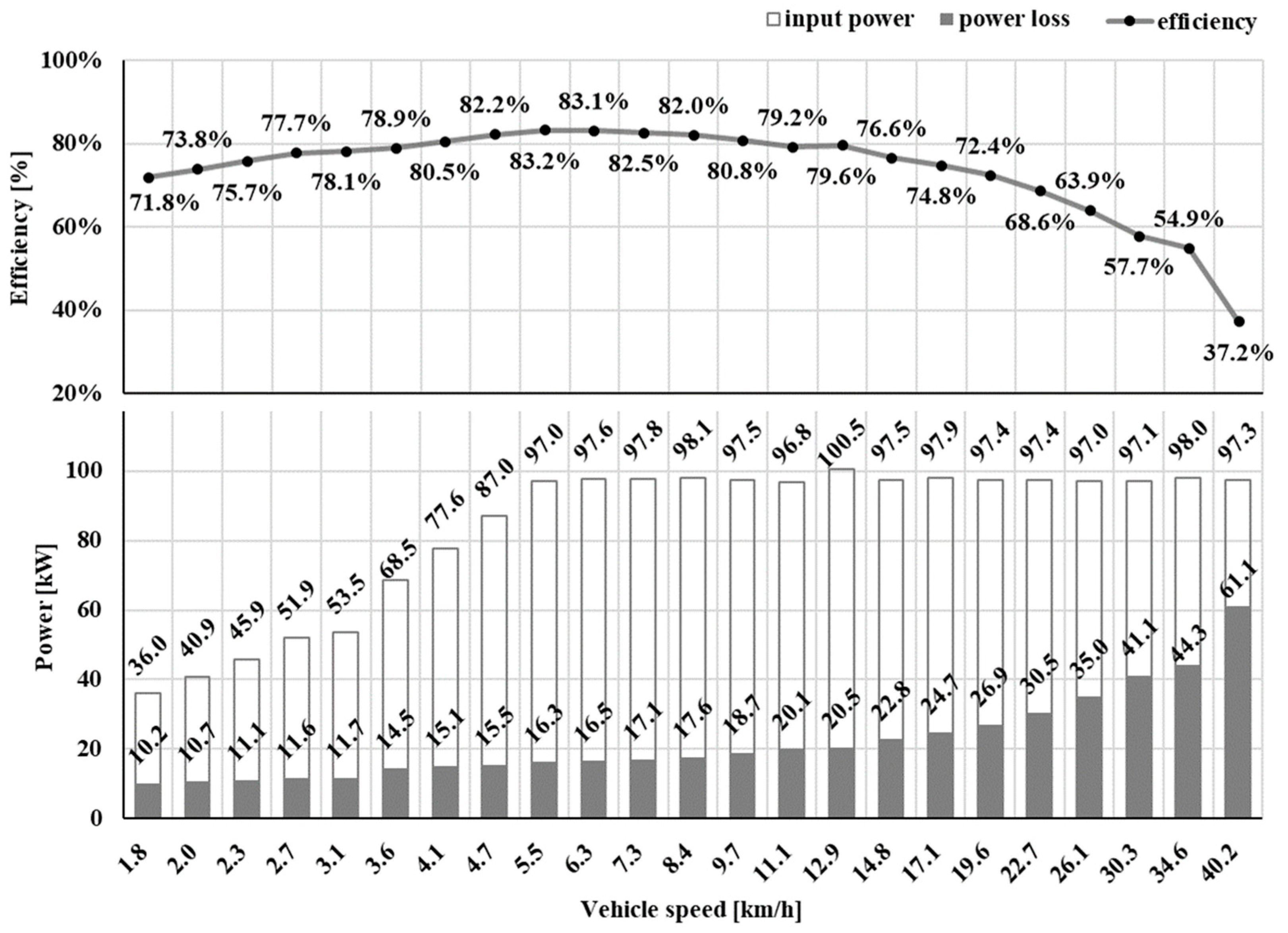

3.2. Experimental Studies of Power Loss

4. Discussion

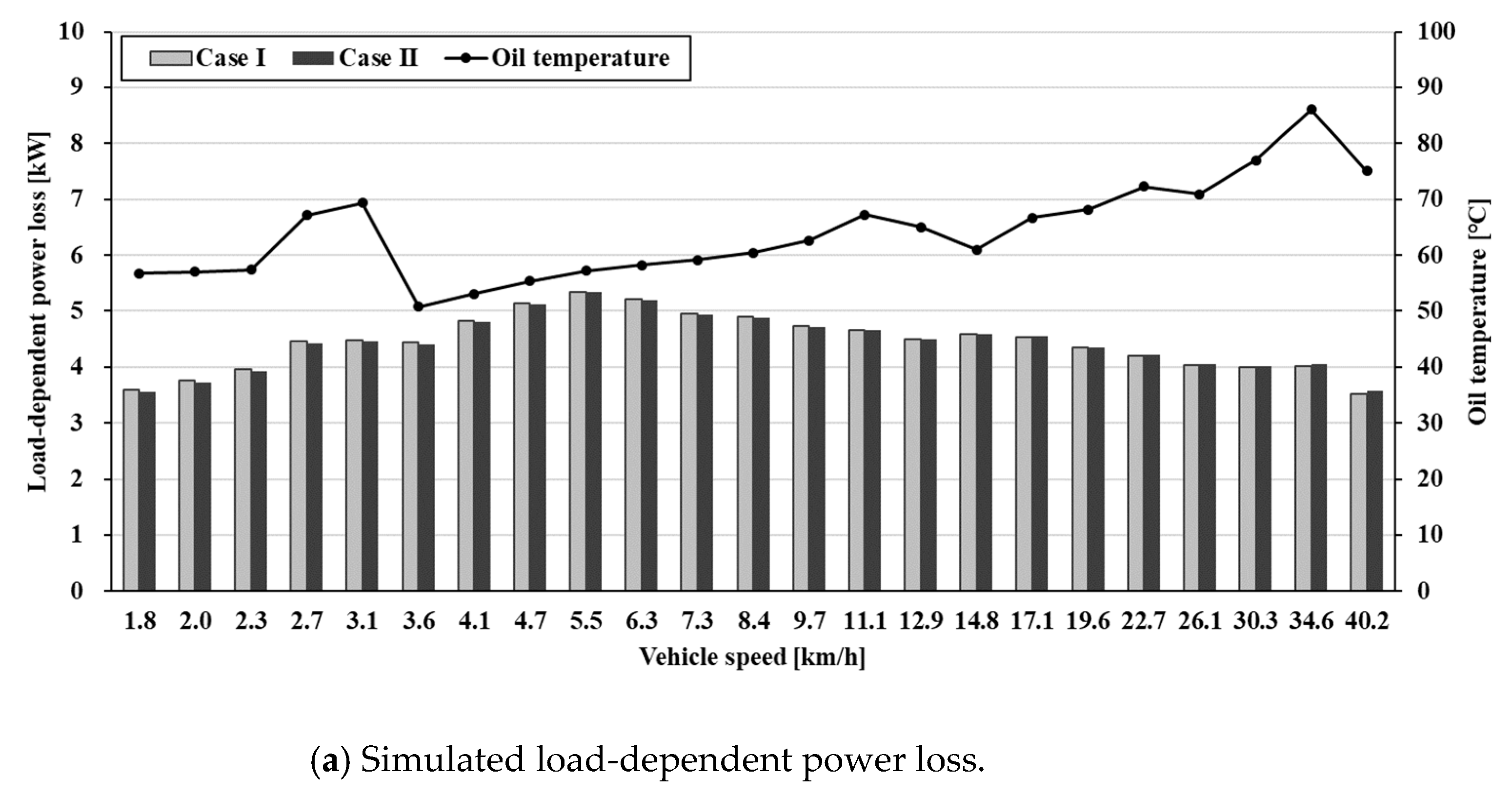

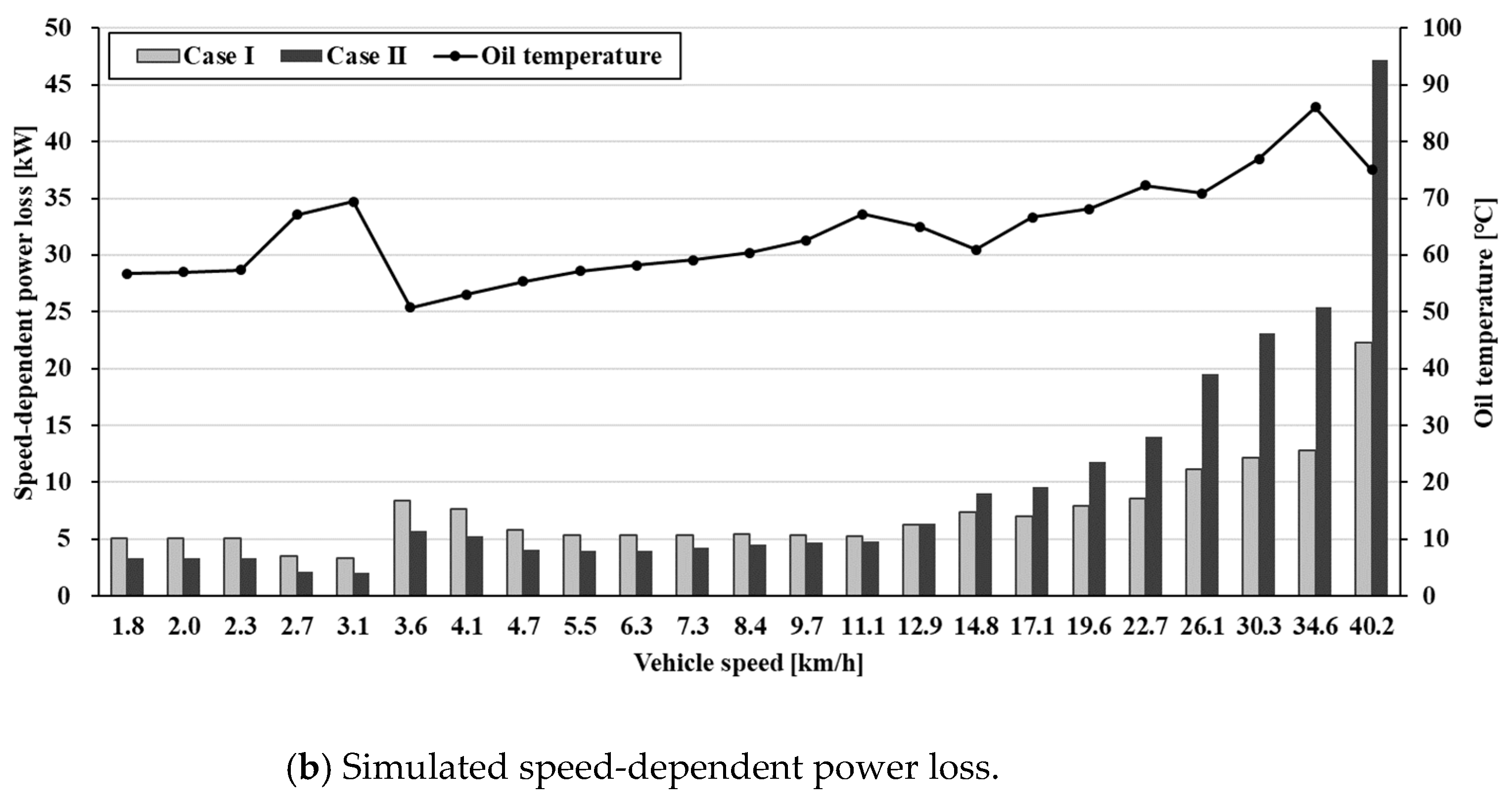

Comparison between Theoretical Calculations and Experimental Studies

5. Conclusions

- We calculated the power loss for each gear shift stage of a DCT applied to agricultural tractors using the ISO standard and the viscous fluid theory. The components accounting for the largest portion of the total power loss were the gears and bearings, with the efficiency calculated to be highest at 5.5 km/h, the fastest speed in the max. traction force range.

- We confirmed that the theoretical calculation results of power loss in Case II were more consistent with the test results compared to Case I. Additionally, while the load-dependent power loss was not significantly affected by the oil level, the speed-dependent power loss was affected by the locally varying oil level owing to oil circulation.

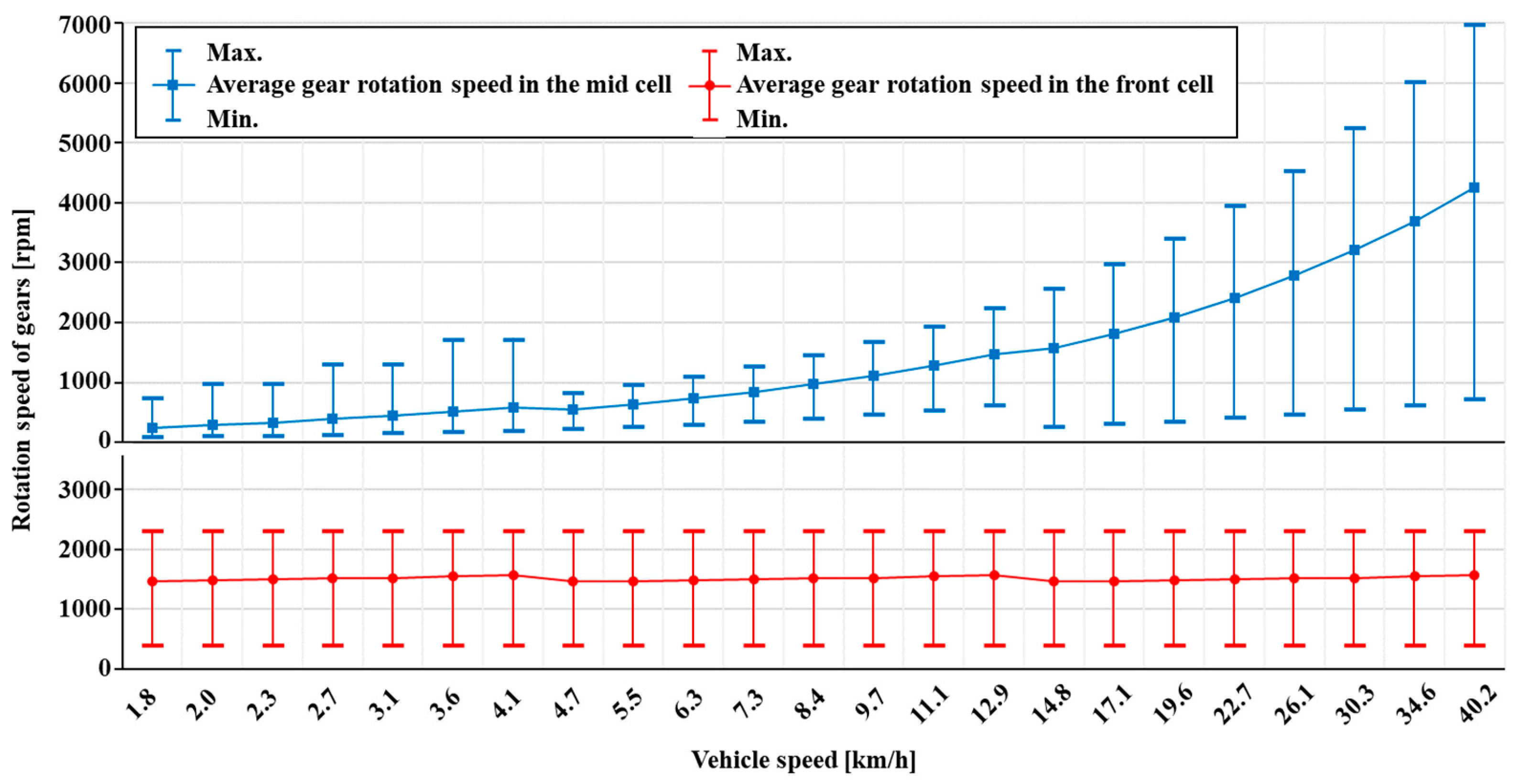

- The transmission components closer to the engine exhibited smaller speed deviations for each gear step, while the gears of the transmission components closer to the output shaft exhibited greater rotation speed and speed deviation between gears at higher gear steps. Owing to these driving characteristics, when the oil level in the cell closer to the output shaft rose, the power loss was lower at low-speed gear shift stages, while it increased sharply at high-speed gear steps.

- Thus, we confirmed that, to predict the efficiency of agricultural transmissions, the oil level reflecting the transmission structure characteristics, oil circulation, and the operating characteristics of the transmission component—such as rotation speed and deviation—must be considered.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Total power loss, kW | |

| Fundamental power loss of the hydraulic pump, kW | |

| Load-dependent power loss of the gear, kW | |

| Speed-dependent power loss of the gear, kW | |

| Load-dependent power loss of the bearing, kW | |

| Speed-dependent power loss of the bearing, kW | |

| Speed-dependent power loss of the shaft, kW | |

| Speed-dependent power loss of the clutch, kW | |

| Speed-dependent power loss of the brake, kW | |

| Mesh coefficient of friction | |

| Mesh mechanical advantage | |

| Pinion torque, Nm | |

| Pinion rotation speed, rpm | |

| Operating helix angle/mean spiral angle, degrees | |

| Gear windage and churning losses associated with smooth outside diameters, kW | |

| Gear windage and churning losses associated with smooth sides of the disc, kW | |

| Gear windage and churning losses associated with tooth surfaces, kW | |

| Gear dip factor | |

| Kinematic oil viscosity, m2/s | |

| Rotating speed, rpm | |

| Length of element for gearing windage and churning, mm | |

| Arrangement constant | |

| Total face width, mm | |

| Roughness factor for gear teeth | |

| Load-independent frictional moment, Nm | |

| Bearing load-dependent torque, Nm | |

| Cylindrical roller bearing axial load-dependent moment, Nm | |

| Frictional moment of seals, Nm | |

| Clutch torque loss, Nm | |

| Percentage value of the groove area to the friction material area | |

| Torque loss due to oil film in continuous section, Nm | |

| Torque loss due to oil film in ruptured section, Nm | |

| Torque loss due to mist in ruptured section, Nm | |

| Critical radius, m | |

| Inner radius of the disk, m | |

| Outer radius of the disk, m | |

| Number of friction surfaces | |

| Fluid absolute viscosity, Pa⋅s | |

| Absolute viscosity of mist, Pa⋅s | |

| Difference in clutch rotation speed, rad/s | |

| Clearance between plate and disc, m | |

| Critical radius square, m2 | |

| Angle of the area of brake caliper, rad |

References

- Ueka, Y.; Yamashita, J.; Sato, K.; Doi, Y. Study on the development of the electric tractor: Specifications and traveling and tilling performance of a prototype electric tractor. Eng. Agric. Environ. Food 2013, 6, 160–164. [Google Scholar] [CrossRef]

- Vogt, H.H.; de Melo, R.R.; Daher, S.; Schmuelling, B.; Antunes, F.L.M.; dos Santos, P.A.; Albiero, D. Electric tractor system for family farming: Increased autonomy and economic feasibility for an energy transition. J. Energy Storage 2021, 40, 102744. [Google Scholar] [CrossRef]

- Moreda, G.P.; Muñoz-García, M.A.; Barreiro, P.J. High voltage electrification of tractor and agricultural machinery—A review. Energy Convers. Manag. 2016, 115, 117–131. [Google Scholar] [CrossRef]

- Martini, V.; Mocera, F.; Somà, A. Numerical Investigation of a Fuel Cell-Powered Agricultural Tractor. Energies 2022, 15, 8818. [Google Scholar] [CrossRef]

- Yang, H.; Sun, Y.; Xia, C.; Zhang, H. Research on Energy Management Strategy of Fuel Cell Electric Tractor Based on Multi-Algorithm Fusion and Optimization. Energies 2022, 15, 6389. [Google Scholar] [CrossRef]

- Hosseinzadeh-bandbafha, H.; Rafiee, S.; Ghobadian, B.; Mohammadi, P. Exergetic, economic, and environmental life cycle assessment analyses of a heavy-duty tractor diesel engine fueled with diesel–biodiesel-bioethanol blends. Energy Convers. Manag. 2021, 241, 114300. [Google Scholar] [CrossRef]

- Madovi, O.; Hoffrichter, A.; Little, N.; Foster, S.N.; Isaac, R. Feasibility of hydrogen fuel cell technology for railway intercity services: A case study for the Piedmont in North Carolina. Railw. Eng. Sci. 2021, 29, 258–270. [Google Scholar] [CrossRef]

- Bergthorson, J.M. Recyclable metal fuels for clean and compact zero-carbon power. Prog. Energy Combust. Sci. 2018, 68, 169–196. [Google Scholar] [CrossRef]

- Kim, W.-S.; Kim, Y.-J.; Kim, Y.-S.; Baek, S.-M.; Baek, S.-Y.; Lee, D.-H.; Nam, K.-C.; Kim, T.-B.; Lee, H.-J. Development of Control System for Automated Manual Transmission of 45-kW Agricultural Tractor. Appl. Sci. 2020, 10, 2930. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Lee, H. Motor position control algorithm for an automated manual transmission of the agricultural tractor. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 229, 3341–3349. [Google Scholar] [CrossRef]

- Brenninger, M.M. Fendt Vario CVT in Agricultural Tractors. SAE Tech. Pap. 2007. [CrossRef]

- Tanelli, M.; Panzani, G.; Savaresi, S.M.; Pirola, C. Transmission control for power-shift agricultural tractors: Design and end-of-line automatic tuning. Mechatronics 2011, 21, 285–297. [Google Scholar] [CrossRef]

- Pahlovy, S.A.; Mahmud, S.F.; Kubota, M.; Ogawa, M.; Takakura, N. Prediction of Drag Torque in a Disengaged Wet Clutch of Automatic Transmission by Analytical Modeling. Tribol. Online 2016, 11, 121–129. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Y.; Liu, E.A.; Hill, J.; Zou, Q. An Improved Hydrodynamic Model for Open Wet Transmission Clutches. J. Fluids Eng. 2007, 129, 333–337. [Google Scholar] [CrossRef]

- Shen, Y.; Liu, Z.; Rinderknecht, S. Modelling of Power Losses of Transmission Synchronizers in Neutral Position. SAE Tech. Pap. 2018. [CrossRef]

- Fernandes, C.M.; Marques, P.M.; Martins, R.C.; Seabra, J.H. Gearbox power loss. Part I: Losses in rolling bearings. Tribol. Int. 2015, 88, 298–308. [Google Scholar] [CrossRef]

- Seetharaman, S.; Kahraman, A.; Moorhead, M.D.; Petry-Johnson, T.T. Oil Churning Power Losses of a Gear Pair: Experiments and Model Validation. J. Tribol. 2009, 131, 022202. [Google Scholar] [CrossRef]

- Hu, X.; Jiang, Y.; Luo, C.; Feng, L.; Dai, Y. Churning power losses of a gearbox with spiral bevel geared transmission. Tribol. Int. 2019, 129, 398–406. [Google Scholar] [CrossRef]

- Diab, Y.; Ville, F.; Velex, P. Prediction of Power Losses Due to Tooth Friction in Gears. Tribol. Trans. 2006, 49, 260–270. [Google Scholar] [CrossRef]

- Fernandes, C.M.; Marques, P.M.; Martins, R.C.; Seabra, J.H. Gearbox power loss. Part II: Friction losses in gears. Tribol. Int. 2015, 88, 309–316. [Google Scholar] [CrossRef]

- Vacca, F.; De Pinto, S.; Karci, A.E.H.; Gruber, P.; Viotto, F.; Cavallino, C.; Rossi, J.; Sorniotti, A. On the Energy Efficiency of Dual Clutch Transmissions and Automated Manual Transmissions. Energies 2017, 10, 1562. [Google Scholar] [CrossRef] [Green Version]

- Habermehl, C.; Jacobs, G.; Neumann, S. A modeling method for gear transmission efficiency in transient operating conditions. Mech. Mach. Theory 2020, 153. [Google Scholar] [CrossRef]

- Strapasson, L.; Zimmermann, G.G.; Jasper, S.P.; Savi, D.; Sobenko, L.R. Energy efficiency of agricultural tractors equipped with continuously variable and full powershift transmission systems. Eng. Agrícola 2022, 42. [Google Scholar] [CrossRef]

- Molari, G.; Sedoni, E. Experimental evaluation of power losses in a power-shift agricultural tractor transmission. Biosyst. Eng. 2008, 100, 177–183. [Google Scholar] [CrossRef]

- Moon, S.P.; Moon, S.G.; Kim, J.S.; Sohn, J.H.; Kim, Y.J.; Kim, S.C. Transmission efficiency of dual-clutch transmission in agricultural tractors. J. Drive Control 2022, 19, 43–50. [Google Scholar]

- ISO/TR 14179-1; Gears-Thermal Capacity-Part 1: Rating Gear Drives with Thermal Equilibrium at 95 °C Sump Temperature. International Standard: Geneva, Switzerland, 2001.

- Park, K.; Kang, M.; Lee, J.; Son, W.C.; Harianto, J.; Kahraman, A. Development of an Analysis Program to Predict Efficiency of Automotive Power Transmission and Its Applications. SAE Tech. Pap. 2018. [CrossRef]

| Power Loss | Component |

|---|---|

| Fundamental power loss | ] |

| Load-dependent power loss | ] |

| Speed-dependent power loss | ] |

| Component | Specifications |

|---|---|

| Input motor | Rated voltage: 360 V, rated speed: 3090 rpm, rated power: 282 kW |

| Output motor | Rated voltage: 360 V, rated speed: 1800 rpm, rated power: 246 kW |

| Torque and rpm sensor | Nominal torque: 30 kNm, nominal rotational speed: 4000 rpm Magnetic rotational speed measuring system: 1024 pulses/revolution |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, H.-J.; Park, Y.-J.; Kim, S.-C.; Choi, C. Theoretical Calculations and Experimental Studies of Power Loss in Dual-Clutch Transmission of Agricultural Tractors. Agriculture 2023, 13, 1225. https://doi.org/10.3390/agriculture13061225

Ahn H-J, Park Y-J, Kim S-C, Choi C. Theoretical Calculations and Experimental Studies of Power Loss in Dual-Clutch Transmission of Agricultural Tractors. Agriculture. 2023; 13(6):1225. https://doi.org/10.3390/agriculture13061225

Chicago/Turabian StyleAhn, Hyoung-Jong, Young-Jun Park, Su-Chul Kim, and Chanho Choi. 2023. "Theoretical Calculations and Experimental Studies of Power Loss in Dual-Clutch Transmission of Agricultural Tractors" Agriculture 13, no. 6: 1225. https://doi.org/10.3390/agriculture13061225

APA StyleAhn, H.-J., Park, Y.-J., Kim, S.-C., & Choi, C. (2023). Theoretical Calculations and Experimental Studies of Power Loss in Dual-Clutch Transmission of Agricultural Tractors. Agriculture, 13(6), 1225. https://doi.org/10.3390/agriculture13061225