Parameters Optimization and Performance Evaluation Model of Air-Assisted Electrostatic Sprayer for Citrus Orchards

Abstract

1. Introduction

2. Materials and Methods

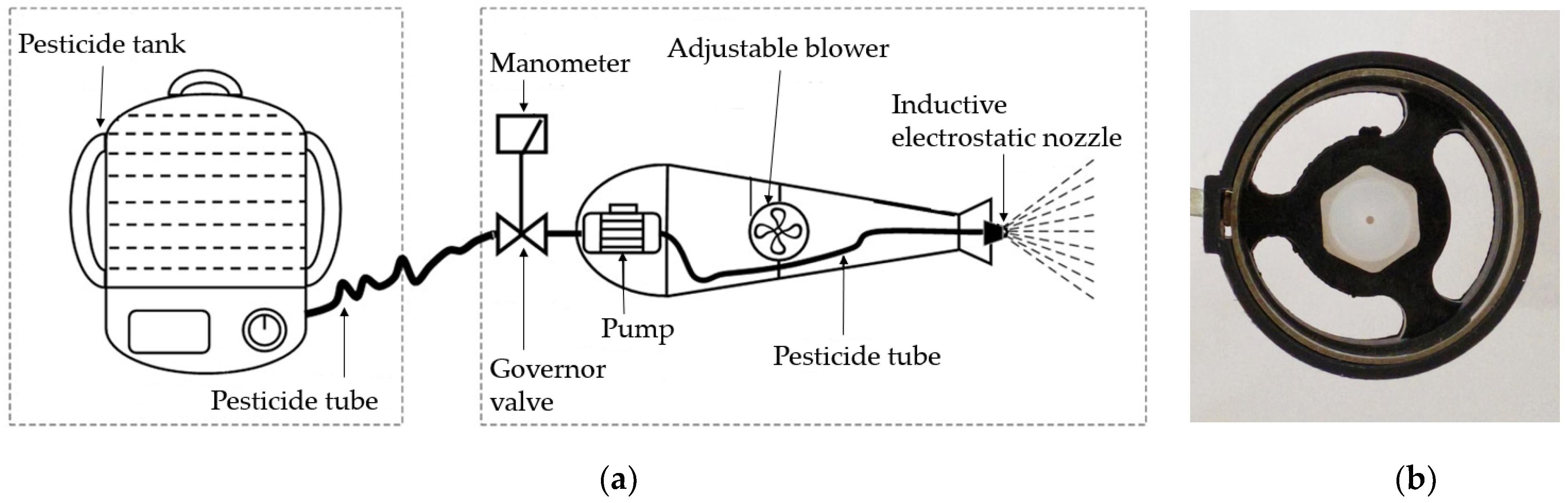

2.1. Air-Assisted Electrostatic Sprayer Design

2.2. Orthogonal Experiment Design

2.3. Measurement of CMR

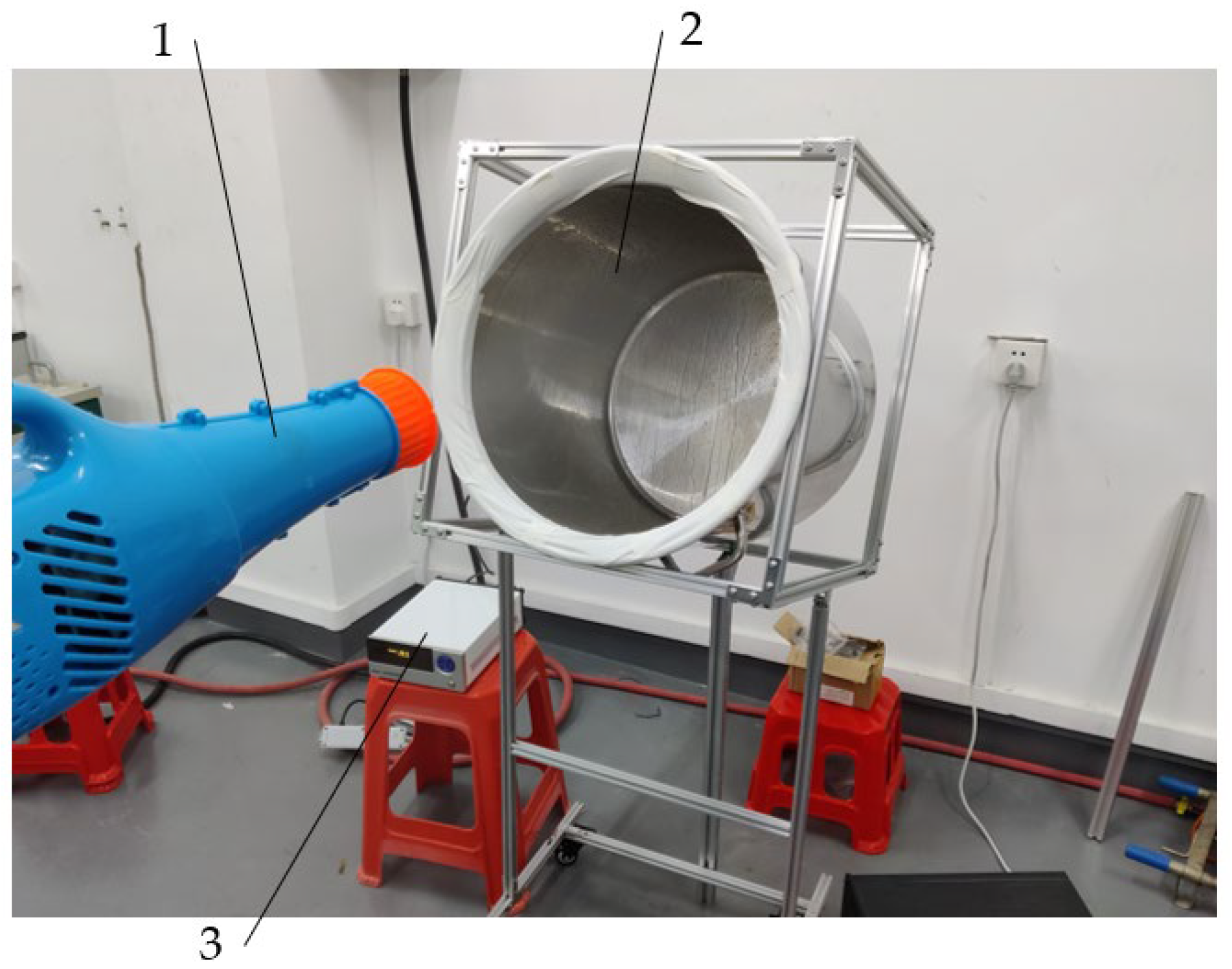

2.4. Measurement of the Droplet Size

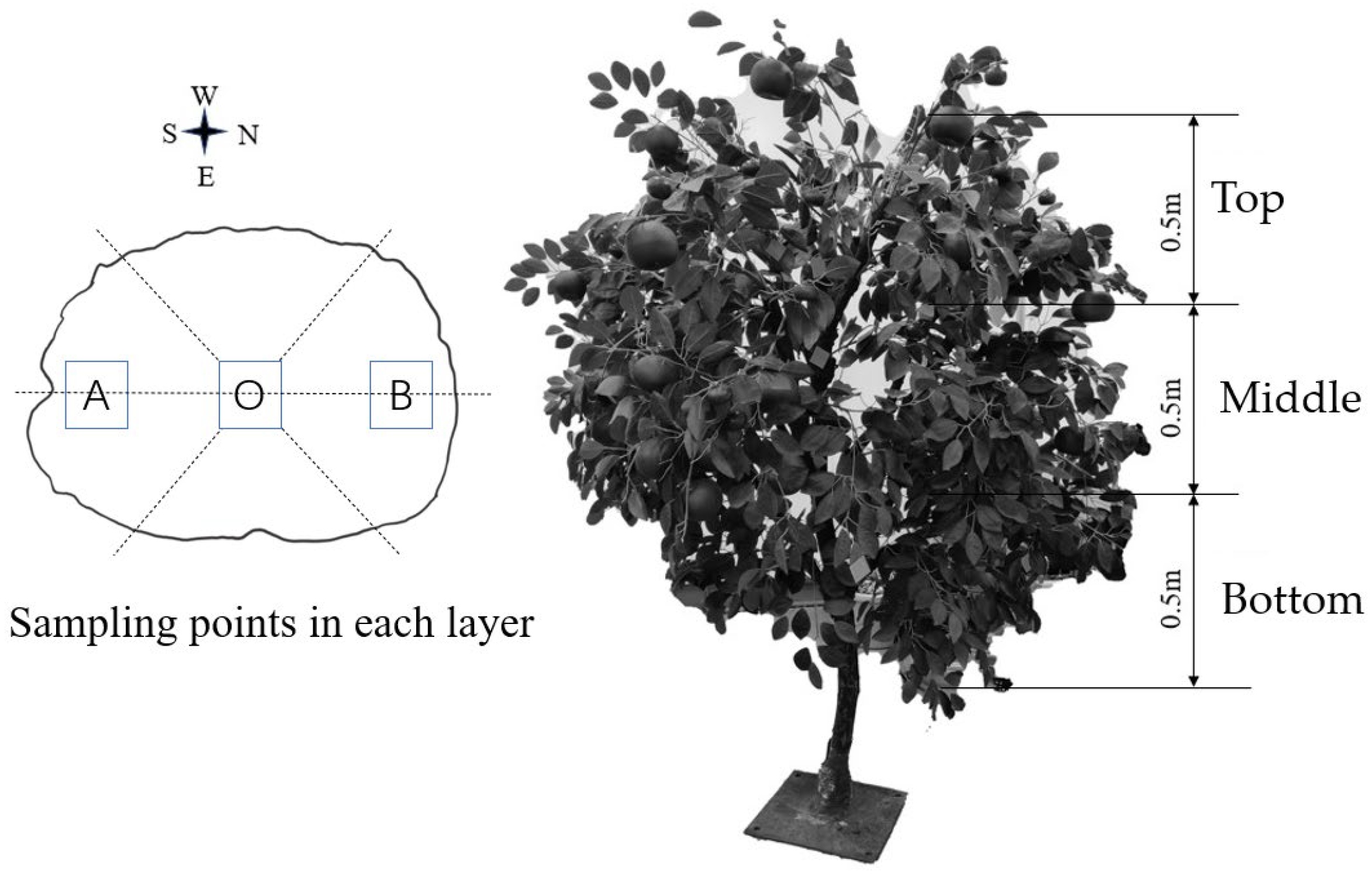

2.5. Measurement of the Spray Coverage

2.6. Field Tests in a Citrus Orchard with Different Cultivation Patterns

2.7. Spray Performance Comprehensive Evaluation Model

- Indexes conversion; In the comprehensive evaluation model, all the indexes should be dimensionless. Here, the equalization method was used to convert the indexes to dimensionless indexes. In addition, negative indexes (i.e., water consumption, CV) were converted to positive indicators using the reciprocal method.

- Weight determination; The subjective weight method (SWM) and objective weight method (OWM) were used to determine the weight of the indexes [29]. Here, the subjective weight values were 1/5 and the values of objective weight were calculated based on the CV of the comprehensive evaluation indexes, as shown in Equations (6) and (7).where is the coefficient of variation of index , refers to the field tests data of the three sprayers under different cultivation patterns, is the mean value of index for three sprayers, and is the weight of index .

- Model construction; The multi-indicator comprehensive evaluation model usually includes a linear weighted model or nonlinear weighted model. In this paper, the linear weighted method was used to construct the model.

3. Results and Discussion

3.1. Analysis of the Orthogonal Experiment and Optimal Level of Spray Parameters

3.2. Analysis of Field Tests

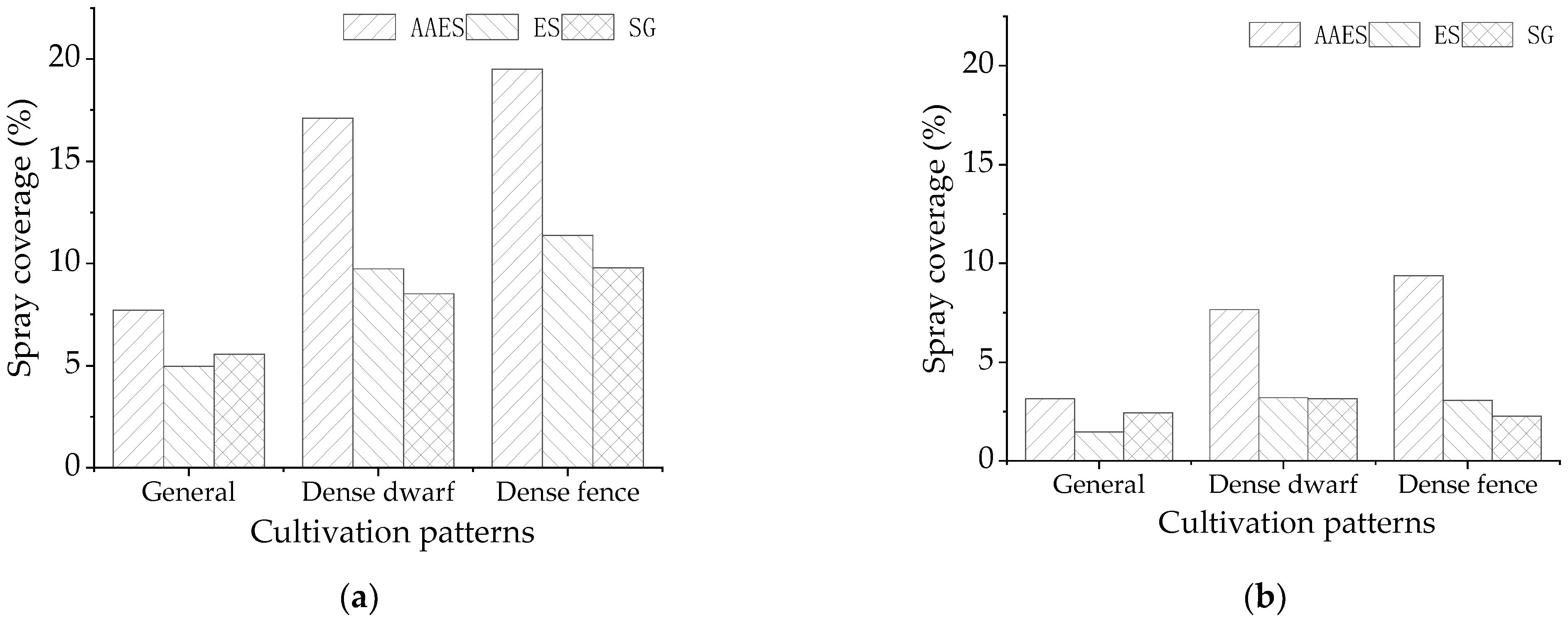

3.2.1. Spray Coverage for AAES under Different Cultivation Patterns

3.2.2. Comparison of Spray Coverage for Sprayers

3.3. Comprehensive Evaluation Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, C.; Hou, J.; Huang, M.; Hu, M.; Deng, L.; Zeng, K.; Yao, S. A comprehensive review of segment drying (vesicle granulation and collapse) in citrus fruit: Current state and future directions. Sci. Hortic. 2023, 309, 111683. [Google Scholar] [CrossRef]

- Xiao, Y.; Dutt, M.; Ma, H.; Xiao, C.; Tong, Z.; Wang, Z.; He, X.; Sun, Z.; Qiu, W. Establishment of an efficient root mediated genetic transformation method for gene function verification in citrus. Sci. Hortic. 2023, 321, 112298. [Google Scholar] [CrossRef]

- Ma, C.; Li, G.; Li, X.; Huang, Y.; Song, J.; Yang, S. Development of multi-orientation automatic spraying device for citrus orchards in hilly and mountainous areas. Trans. Chin. Soc. Agric. Eng. 2019, 35, 31–41. [Google Scholar] [CrossRef]

- Wang, S.; Wang, W.; Lei, X.; Wang, S.; Li, X.; Norton, T. Canopy Segmentation Method for Determining the Spray Deposition Rate in Orchards. Agronomy 2022, 12, 1195. [Google Scholar] [CrossRef]

- An, Q.; Li, D.; Wu, Y.; Pan, C. Deposition and distribution of myclobutanil and tebuconazole in a semidwarf apple orchard by hand-held gun and air-assisted sprayer application. Pest. Manag. Sci. 2020, 76, 4123–4130. [Google Scholar] [CrossRef]

- Sánchez-Hermosilla, J.; Rincón, V.J.; Páez, F.C.; Pérez-Alonso, J.; Callejón-Ferre, Á. Evaluation of the Effect of Different Hand-Held Sprayer Types on a Greenhouse Pepper Crop. Agriculture 2021, 11, 532. [Google Scholar] [CrossRef]

- Sánchez-Hermosilla, J.; Pérez-Alonso, J.; Martínez-Carricondo, P.; Carvajal-Ramírez, F.; Agüera-Vega, F. Evaluation of Electrostatic Spraying Equipment in a Greenhouse Pepper Crop. Horticulturae 2022, 8, 541. [Google Scholar] [CrossRef]

- Salcedo, R.; Llop, J.; Campos, J.; Costas, M.; Gallart, M.; Ortega, P.; Gil, E. Evaluation of leaf deposit quality between electrostatic and conventional multi-row sprayers in a trellised vineyard. Crop Prot. 2020, 127, 104964. [Google Scholar] [CrossRef]

- Salcedo, R.; Sánchez, E.; Zhu, H.; Fàbregas, X.; García-Ruiz, F.; Gil, E. Evaluation of an electrostatic spray charge system implemented in three conventional orchard sprayers used on a commercial apple trees plantation. Crop Prot. 2023, 167, 106212. [Google Scholar] [CrossRef]

- Patel, M.K.; Khanchi, A.; Chauhan, A.; Kumar, A.; Akkireddi, S.R.K.; Jangra, A.; Kanawade, R.; Manivannan, N.; Mitchell, G.R. Real-time measurement of droplet size and its distribution of an air-induced air-assisted electrostatic nozzle. J. Electrost. 2022, 115, 103665. [Google Scholar] [CrossRef]

- Gan-Mor, S.; Ronen, B.; Ohaliav, K. The effect of air velocity and proximity on the charging of sprays from conventional hydraulic nozzles. Biosyst. Eng. 2014, 121, 200–208. [Google Scholar] [CrossRef]

- Cross, J.V.; Walklate, P.J.; Murray, R.A.; Richardson, G.M. Spray deposits and losses in different sized apple trees from an axial fan orchard sprayer: 3. Effects of air volumetric flow rate. Crop Prot. 2003, 22, 381–394. [Google Scholar] [CrossRef]

- Wang, X.; Feng, Y.; Fu, W.; Qi, J.; Song, J. Simple decision-making model for orchard air-assisted spraying airflow. Int. J. Agr. Biol. Eng. 2023, 16, 23–29. [Google Scholar] [CrossRef]

- Ru, Y.; Hu, C.; Chen, X.; Yang, F.; Zhang, C.; Li, J.; Fang, S. Droplet Penetration Model Based on Canopy Porosity for Spraying Applications. Agriculture 2023, 13, 339. [Google Scholar] [CrossRef]

- Hu, Q.; Dian, X.; Gong, Z.; Zhang, J.; Hu, C.; Liu, Y. Analyzing fruit quality of Newhall navel oranges with different cultiva-tion patterns. J. Huazhong Agric. Univ. 2022, 41, 108–115. [Google Scholar]

- Patel, M.K.; Praveen, B.; Sahoo, H.K.; Patel, B.; Kumar, A.; Singh, M.; Nayak, M.K.; Rajan, P. An advance air-induced air-assisted electrostatic nozzle with enhanced performance. Comput. Electron. Agr. 2017, 135, 280–288. [Google Scholar] [CrossRef]

- Salcedo, R.; Zhu, H.; Ozkan, E.; Falchieri, D.; Zhang, Z.; Wei, Z. Reducing ground and airborne drift losses in young apple orchards with PWM-controlled spray systems. Comput. Electron. Agr. 2021, 189, 106389. [Google Scholar] [CrossRef]

- Miranda-Fuentes, A.; Rodríguez-Lizana, A.; Cuenca, A.; González-Sánchez, E.J.; Blanco-Roldán, G.L.; Gil-Ribes, J.A. Improving plant protection product applications in traditional and intensive olive orchards through the development of new prototype air-assisted sprayers. Crop Prot. 2017, 94, 44–58. [Google Scholar] [CrossRef]

- Hu, H.; Kaizu, Y.; Huang, J.; Furuhashi, K.; Zhang, H.; Xiao, X.; Li, M.; Imou, K. Design and performance test of a novel UAV air-assisted electrostatic centrifugal spraying system. Int. J. Agr. Biol. Eng. 2022, 15, 34–40. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, X.; Lan, Y.; Wang, L.; Lu, X.; Yan, K.; Deng, J.; Zeng, W. Development and Prospect of UAV-Based Aerial Electrostatic Spray Technology in China. Appl. Sci. 2021, 11, 4071. [Google Scholar] [CrossRef]

- Dai, S.; Zhang, J.; Jia, W.; Ou, M.; Zhou, H.; Dong, X.; Chen, H.; Wang, M.; Chen, Y.; Yang, S. Experimental Study on the Droplet Size and Charge-to-Mass Ratio of an Air-Assisted Electrostatic Nozzle. Agriculture 2022, 12, 889. [Google Scholar] [CrossRef]

- Ma, X.; Guo, L.; Wen, Z.; Wei, Y.; Xiao, R.; Zeng, H. Atomization characteristics of multi-nozzle electrostatic spray and field experiment. Trans. Chin. Soc. Agric. Eng. 2020, 36, 73–82. [Google Scholar] [CrossRef]

- Liu, X.; Doub, W.H.; Guo, C. Evaluation of droplet velocity and size from nasal spray devices using phase Doppler anemometry (PDA). Int. J. Pharmaceut. 2010, 388, 82–87. [Google Scholar] [CrossRef]

- Lodwik, D.; Pietrzyk, J.; Malesa, W. Analysis of Volume Distribution and Evaluation of the Spraying Spectrum in Terms of Spraying Quality. Appl. Sci. 2020, 10, 2395. [Google Scholar] [CrossRef]

- Chen, S.; Lan, Y.; Zhou, Z.; Ouyang, F.; Wang, G.; Huang, X.; Deng, X.; Cheng, S. Effect of Droplet Size Parameters on Droplet Deposition and Drift of Aerial Spraying by Using Plant Protection UAV. Agronomy 2020, 10, 195. [Google Scholar] [CrossRef]

- Miranda-Fuentes, A.; Marucco, P.; Gonzalez-Sanchez, E.J.; Gil, E.; Grella, M.; Balsari, P. Developing strategies to reduce spray drift in pneumatic spraying in vineyards: Assessment of the parameters affecting droplet size in pneumatic spraying. Sci. Total Environ. 2018, 616, 805–815. [Google Scholar] [CrossRef]

- Musiu, E.M.; Qi, L.; Wu, Y. Spray deposition and distribution on the targets and losses to the ground as affected by application volume rate, airflow rate and target position. Crop Prot. 2019, 116, 170–180. [Google Scholar] [CrossRef]

- Salcedo, R.; Zhu, H.; Jeon, H.; Ozkan, E.; Wei, Z.; Gil, E. Characterisation of activation pressure, flowrate and spray angle for hollow-cone nozzles controlled by pulse width modulation. Biosyst. Eng. 2022, 218, 139–152. [Google Scholar] [CrossRef]

- Wang, T.; Lee, H. Developing a fuzzy TOPSIS approach based on subjective weights and objective weights. Expert. Syst. Appl. 2009, 36, 8980–8985. [Google Scholar] [CrossRef]

- Xu, Y.; Tan, L.; Cao, S.; Qu, W. Multiparameter and multiobjective optimization design of centrifugal pump based on orthogonal method. Proc. Inst. Mech. Eng. Part. C J. Mech. Eng. Sci. 2017, 231, 2569–2579. [Google Scholar] [CrossRef]

- Zheng, Y.; Chen, B.; Lyu, H.; Kang, F.; Jiang, F. Research progress of orchard plant protection mechanization technology and equipment in China. Trans. Chin. Soc. Agric. Eng. 2020, 36, 110–124. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Cerruto, E. Spray deposition in “tendone” vineyards when using a pneumatic electrostatic sprayer. Crop Prot. 2015, 68, 1–11. [Google Scholar] [CrossRef]

- McCoy, M.L.; Hoheisel, G.; Khot, L.R.; Moyer, M.M. Assessment of Three Commercial Over-the-Row Sprayer Technologies in Eastern Washington Vineyards. Am. J. Enol. Viticult. 2021, 72, 217–229. [Google Scholar] [CrossRef]

- Zhou, L.; Zhang, L.; Xue, X.; Ding, W.; Shun, Z.; Zhou, Q.; Cui, F. Design and experiment of 3WQ-400 double air-assisted electrostatic orchard sprayer. Trans. Chin. Soc. Agric. Eng. 2016, 32, 45–53. [Google Scholar] [CrossRef]

- Dai, S.; Ou, M.; Du, W.; Yang, X.; Dong, X.; Jiang, L.; Zhang, T.; Ding, S.; Jia, W. Effects of sprayer speed, spray distance, and nozzle arrangement angle on low-flow air-assisted spray deposition. Front. Plant Sci. 2023, 14, 1184244. [Google Scholar] [CrossRef]

- Rocamora, M.C.; Val, L.; Pérez, M. PM—Power and Machinery. Biosyst. Eng. 2002, 81, 385–393. [Google Scholar] [CrossRef]

- Brentjes, A.; Jansen, B.; Pozarlik, A.K. Spray characteristics of an air-assisted electrostatic atomiser. J. Electrost. 2022, 115, 103654. [Google Scholar] [CrossRef]

| Test Number | Factor | ||

|---|---|---|---|

| Spray Pressure A/(MPa) | Applied Voltage B/(kV) | Air Flow Velocity C/(m/s) | |

| 1 | 0.3 | 3 | 6 |

| 2 | 0.3 | 6 | 8 |

| 3 | 0.3 | 9 | 10 |

| 4 | 0.5 | 3 | 8 |

| 5 | 0.5 | 6 | 10 |

| 6 | 0.5 | 9 | 6 |

| 7 | 0.7 | 3 | 10 |

| 8 | 0.7 | 6 | 6 |

| 9 | 0.7 | 9 | 8 |

| Spray Application Parameters | AAES | ES | SG |

|---|---|---|---|

| Flow rate (L·min−1) | 1.59 | 1.59 | 2.36 |

| Spray angle (Degrees) | 64.8 | 55.5 | 55.9 |

| Maximum spray distance (m) | 3.7 | 1.9 | 1.6 |

| Water consumption (L·ha−1) | 406 | 954 | 1665 |

| Cultivation Pattern | Row Spacing (m) | Plant Spacing (m) | Canopy Width (m) | Tree Height (m) |

|---|---|---|---|---|

| General | 3 | 1.3 | 1.7 ± 0.4 | 1.8 ± 0.4 |

| Dense dwarf | 4 | 1.5 | 1.4 ± 0.2 | 1.1 ± 0.3 |

| Dense fence | 4.5 | 1 | 0.7 ± 0.3 | 1.9 ± 0.2 |

| Index | Value | Spray Pressure A/(MPa) | Applied Voltage B/(kV) | Air Flow Velocity C/(m/s) |

|---|---|---|---|---|

| CMR (mC·kg−1) | 0.169 | 0.071 | 0.165 | |

| 0.168 | 0.186 | 0.142 | ||

| 0.146 | 0.224 | 0.174 | ||

| 0.023 | 0.153 | 0.032 | ||

| VMD (μm) | 240.23 | 218.37 | 221.00 | |

| 208.54 | 215.07 | 229.88 | ||

| 196.74 | 212.07 | 194.63 | ||

| 43.49 | 6.30 | 35.26 | ||

| RS | 0.85 | 0.88 | 0.79 | |

| 0.85 | 0.86 | 0.85 | ||

| 0.90 | 0.85 | 0.96 | ||

| 0.05 | 0.03 | 0.17 | ||

| spray coverage (%) | 11.46 | 12.58 | 13.43 | |

| 14.04 | 14.5 | 13.96 | ||

| 17.36 | 15.72 | 15.48 | ||

| 5.90 | 3.14 | 2.05 |

| Analysis Method | CMR | VMD | RS | Spray Coverage |

|---|---|---|---|---|

| Range analysis | A1B3C3 | A3B3C3 | A1B3C1 | A3B3C3 |

| Layer | Leaf Surface | Cultivation Pattern | ||

|---|---|---|---|---|

| General | Dense Dwarf | Dense Fence | ||

| Top | Adaxial | 11.91 | 9.42 | 15.69 |

| Abaxial | 4.85 | 3.39 | 6.94 | |

| Middle | Adaxial | 9.52 | 19.03 | 20.20 |

| Abaxial | 2.88 | 12.56 | 11.92 | |

| Bottom | Adaxial | 1.69 | 22.87 | 22.6 |

| Abaxial | 1.68 | 7.03 | 9.29 | |

| Mean spray coverage | Adaxial | 7.71 | 17.11 | 19.50 |

| Abaxial | 3.14 | 7.66 | 9.38 | |

| CV between layers | Adaxial | 56.64 | 33.10 | 14.69 |

| Abaxial | 41.66 | 49.22 | 21.68 | |

| Cultivation Pattern | Sprayer | I1 | I2 | I3 | I4 | I5 |

|---|---|---|---|---|---|---|

| General | AAES | 1.80 | 1.27 | 1.34 | 0.98 | 0.58 |

| ES | 0.76 | 0.82 | 0.62 | 1.03 | 2.08 | |

| BS | 0.44 | 0.91 | 1.04 | 0.98 | 0.34 | |

| Dense dwarf | AAES | 1.80 | 1.45 | 1.64 | 0.84 | 0.85 |

| ES | 0.76 | 0.83 | 0.69 | 0.69 | 0.89 | |

| BS | 0.44 | 0.72 | 0.67 | 1.46 | 1.25 | |

| Dense fence | AAES | 1.80 | 1.44 | 1.91 | 1.14 | 1.51 |

| ES | 0.76 | 0.84 | 0.63 | 0.41 | 0.65 | |

| BS | 0.44 | 0.72 | 0.46 | 1.45 | 0.84 |

| Cultivation Pattern | Sprayer | SWM Evaluation Index | SWM Rank | OWM Evaluation Index | OWM Rank |

|---|---|---|---|---|---|

| General | AAES | 1.19 | 1 | 1.19 | 1 |

| ES | 1.06 | 2 | 0.90 | 2 | |

| BS | 0.74 | 3 | 0.79 | 3 | |

| Dense dwarf | AAES | 1.32 | 1 | 1.37 | 1 |

| ES | 0.77 | 3 | 0.76 | 3 | |

| BS | 0.91 | 2 | 0.90 | 2 | |

| Dense fence | AAES | 1.56 | 1 | 1.66 | 1 |

| ES | 0.66 | 3 | 0.67 | 2 | |

| BS | 0.78 | 2 | 0.79 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, X.; Zeng, K.; Li, N.; Luo, Q.; Ji, Y.; Li, Z.; Lyu, S.; Song, S. Parameters Optimization and Performance Evaluation Model of Air-Assisted Electrostatic Sprayer for Citrus Orchards. Agriculture 2023, 13, 1498. https://doi.org/10.3390/agriculture13081498

Xue X, Zeng K, Li N, Luo Q, Ji Y, Li Z, Lyu S, Song S. Parameters Optimization and Performance Evaluation Model of Air-Assisted Electrostatic Sprayer for Citrus Orchards. Agriculture. 2023; 13(8):1498. https://doi.org/10.3390/agriculture13081498

Chicago/Turabian StyleXue, Xiuyun, Kaixiang Zeng, Nengchao Li, Qin Luo, Yihang Ji, Zhen Li, Shilei Lyu, and Shuran Song. 2023. "Parameters Optimization and Performance Evaluation Model of Air-Assisted Electrostatic Sprayer for Citrus Orchards" Agriculture 13, no. 8: 1498. https://doi.org/10.3390/agriculture13081498

APA StyleXue, X., Zeng, K., Li, N., Luo, Q., Ji, Y., Li, Z., Lyu, S., & Song, S. (2023). Parameters Optimization and Performance Evaluation Model of Air-Assisted Electrostatic Sprayer for Citrus Orchards. Agriculture, 13(8), 1498. https://doi.org/10.3390/agriculture13081498