An Environmental and Economic Analysis of Strawberry Production in Southern Italy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Systems Description

- Conventional (SC), growing on rows made ex novo and managed during the production cycle according to the ordinary cultivation techniques;

- Integrated (SI), growing on rows made ex novo and managed during the production cycle according to the integrated cultivation techniques [35];

- Organics (SO1, SO2), growing on rows made ex novo and managed during the production cycle according to the organic cultivation techniques [36].

- Replanted Strawberry Crop treated with Compost Tea (RSC + CT)—strawberry plants were grown on rows already used in the previous production cycle. Ordinary cultivation techniques were carried out supplemented by seven root applications (through fertigation) of CT produced on farms;

- Replanted Strawberry Crop without Compost Tea application (RSC)—strawberry plants were grown on rows already used in the previous production cycle. Ordinary cultivation techniques were performed;

- Not Replanted Strawberry Crop treated with Compost Tea (NRSC + CT)—strawberry plants were grown on rows made ex novo. Furthermore, in this case, the ordinary cultivation techniques were implemented during the production cycle and supplemented by seven root applications (via fertigation) of CT produced on farms;

- Not Replanted Strawberry Crop without Compost Tea application (NRSC)—Strawberry plants were grown on ex novo rows and managed during the production cycle according to ordinary cultivation techniques.

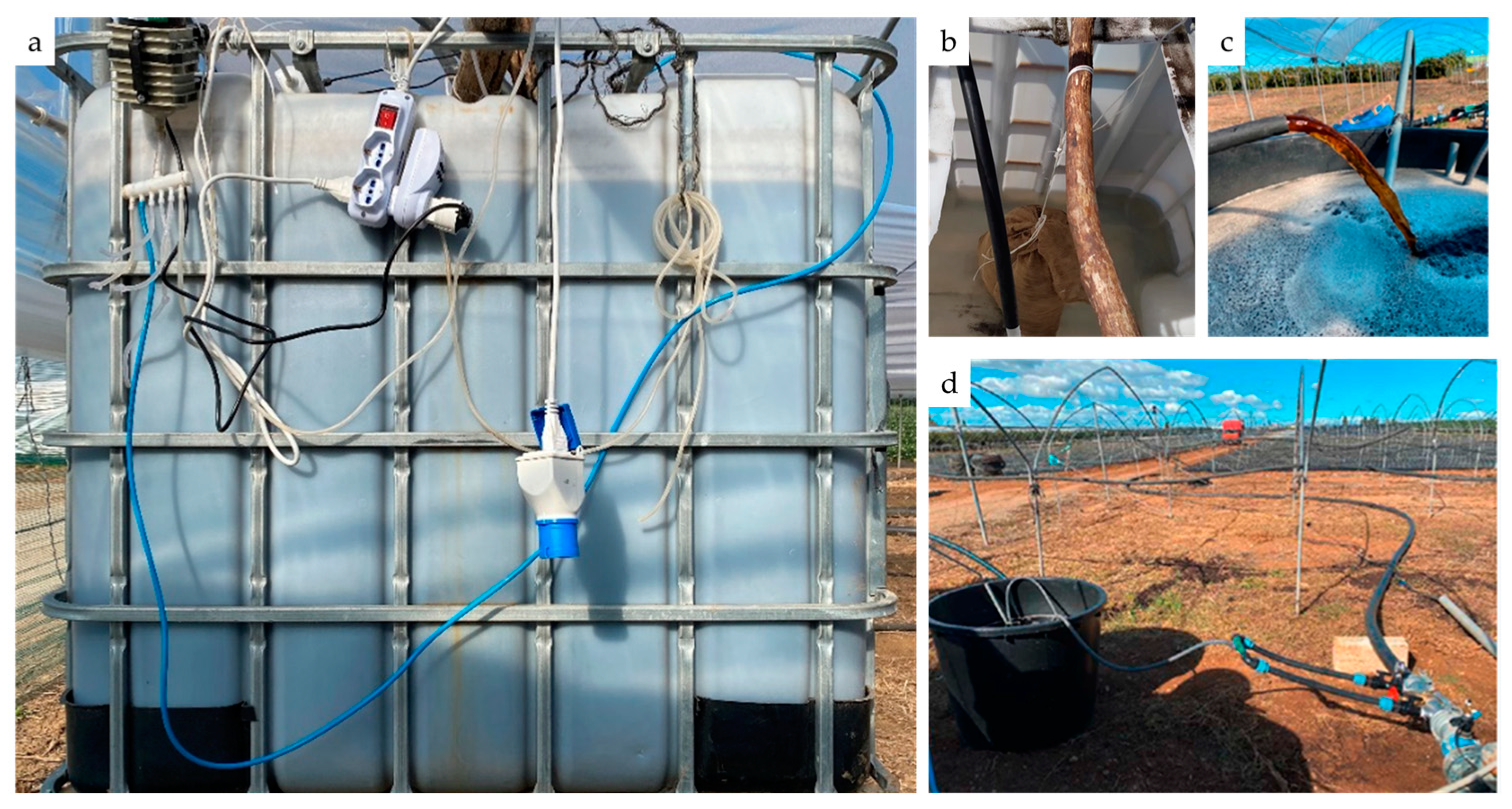

2.2. Compost Tea Production and Characterization

2.3. Environmental Analysis

2.4. Economic Analysis

2.5. Statistical Analysis

3. Results

3.1. Characterization and Biostimulative Action of the Compost Tea Used

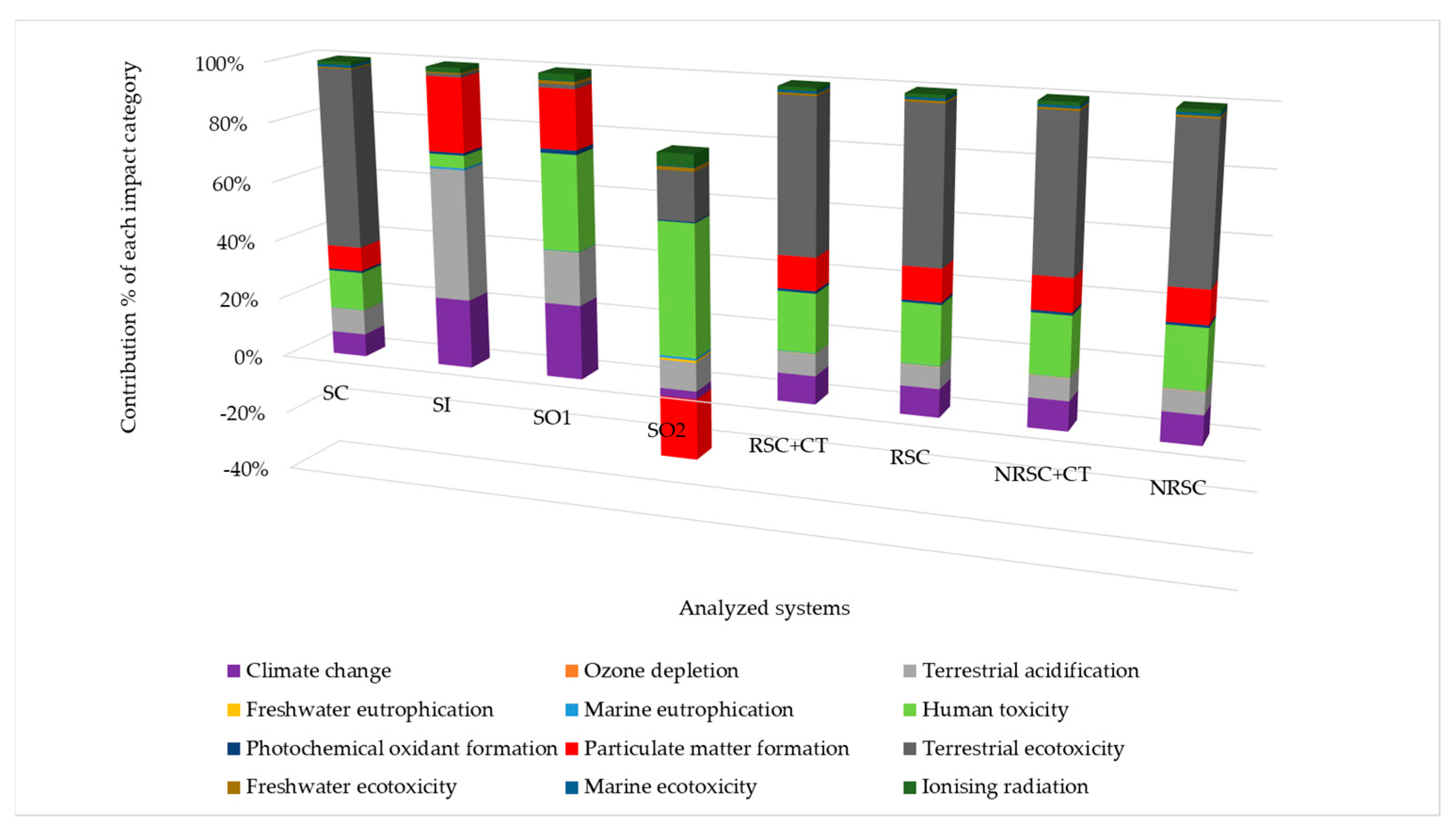

3.2. Environmental Impacts

3.3. Economic Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ISTAT. Censimento Agricoltura. 2020. Available online: https://www.istat.it/it/censimenti/agricoltura/7-censimento-generale (accessed on 15 May 2023).

- ISMEA. Scheda di Settore FRUTTA FRESCA. 2023. Available online: https://www.ismeamercati.it/ortofrutta/frutta (accessed on 20 May 2023).

- Tabatabaie, S.M.; Murthy, G.S. Cradle to farm gate life cycle assessment of strawberry production in the United States. J. Clean. Prod. 2016, 127, 548–554. [Google Scholar] [CrossRef]

- Markovitz, G.; Calvo, H.G. Number of Consumers Adopting Green Habits due to Climate Concern Is Falling, Survey Finds. 2021. Available online: https://www.weforum.org/press/2021/11/number-of-consumers-adopting-green-habits-due-to-climate-concern-is-falling-survey-finds (accessed on 18 August 2023).

- Pergola, M.; Persiani, P.; Pastore, V.; Palese, A.M.; D’Adamo, C.; De Falco, E.; Celano, G. Sustainability Assessment of the Green Compost Production Chain from Agricultural Waste: A Case Study in Southern Italy. Agronomy 2020, 10, 230. [Google Scholar] [CrossRef]

- Pergola, M.; Persiani, A.; Palese, A.M.; Di Meo, V.; Pastore, V.; D’Adamo, C.; Celano, G. Composting: The way for a sustainable agriculture. Appl. Soil Ecol. 2018, 123, 744–750. [Google Scholar] [CrossRef]

- Palese, A.M.; Pane, C.; Villecco, D.; Zaccardelli, M.; Altieri, G.; Celano, G. Effects of Organic Additives on Chemical, Mi-crobiological and Plant Pathogen Suppressive Properties of Aerated Municipal Waste Compost Teas. Appl. Sci. 2021, 11, 7402. [Google Scholar] [CrossRef]

- De Corato, U. Agricultural waste recycling in horticultural intensive farming systems by on-farm composting and com-post-based tea application improves soil quality and plant health: A review under the perspective of a circular economy. Sci. Total Environ. 2020, 738, 139840. [Google Scholar] [CrossRef]

- Hargreaves, J.C.; Adl, M.S.; Warman, P.R. Are compost teas an effective nutrient amendment in the cultivation of strawberries? Soil and plant tissue effects. J. Sci. Food Agric. 2009, 89, 390–397. [Google Scholar] [CrossRef]

- Arancon, N.Q.; Edwards, C.A.; Bierman, P.; Welch, C.; Metzger, J.D. Influences of vermicomposts on field strawberries: 1. Effects on growth and yields. Bioresour. Technol. 2004, 93, 145–153. [Google Scholar] [CrossRef] [PubMed]

- Duffy, B.; Sarreal, C.; Stevenson, R.; Ravva, S.; Stanker, L. Regrowth of pathogenic bacteria in compost teas and risk of transmission to strawberry plants. In Proceedings of 2002 International Symposium: Composting and Compost Utilization; Michel, F.C., Jr., Rynk, R.F., Hoitink, H.A.J., Eds.; The JG Press, Inc.: Emmaus, PA, USA, 2002; pp. 1142–1149. [Google Scholar]

- Hargreaves, J.C.; Adl, M.S.; Warman, P.R. The Effects of Municipal Solid Waste Compost and Compost Tea on Mineral Element Uptake and Fruit Quality of Strawberries. Compost. Sci. Util. 2013, 17, 2. [Google Scholar] [CrossRef]

- Welke, S.E. The effect of compost extract on the yield of strawberries and the severity of Botrytis cinerea. J. Sustain. Agric. 2005, 25, 57–67. [Google Scholar] [CrossRef]

- Pergola, M.; Palese, A.M.; Persiani, A.; De Francesco, P.; Cirillo, C.; Giacca, G.M.; Maffia, A.; Celano, G. Mediterranean Cropping Systems: The Importance of Their Economic and Environmental Sustainability. Adv. Environ. Eng. Res. 2021, 2, 4. [Google Scholar] [CrossRef]

- De Backer, E.; Aertsens, J.; Vergucht, S.; Steurbaut, W. Assessing the ecological soundness of organic and conventional agriculture by means of life cycle assessment (LCA): A case study of leek production. Br. Food J. 2009, 10, 1028–1061. [Google Scholar] [CrossRef]

- Haas, G.; Wetterich, F.; Geier, U. Life cycle assessment framework in agriculture on the farm level. Int. J. Life Cycle Assess. 2000, 5, 345–348. [Google Scholar] [CrossRef]

- Brentrup, F.; Küsters, J.; Kuhlmann, H.; Lammel, J. Application of the life cycle assessment methodology to agricultural production: An example of sugar beet production with different forms of nitrogen fertilizers. Eur. J. Agron. 2001, 14, 221–233. [Google Scholar] [CrossRef]

- Cederberg, C. Life Cycle Assessment (LCA) of Animal Production. Ph.D. Thesis, Department of Applied Environmental Science, Göteborg University, Göteborg, Sweden, 2002. [Google Scholar]

- Brentrup, F.; Küsters, J.; Kuhlmann, H.; Lammel, J. Environmental impact assessment of agricultural production systems using the life cycle assessment methodology: I. theoretical concept of a LCA method tailored to crop production. Eur. J. Agron. 2004, 20, 247–264. [Google Scholar] [CrossRef]

- Stern, S.; Sonesson, U.; Gunnarsson, S.; Öborn, I.; Kumm, K.I.; Nybrant, T. Sustainable development of food production: A case study on scenarios for pig production. Ambio 2005, 34, 402–407. [Google Scholar] [CrossRef]

- Charles, R.; Jolliet, O.; Gaillard, G.; Pellet, D. Environmental analysis of intensity level in wheat crop production using life cycle assessment. Agric. Ecosyst. Environ. 2006, 113, 216–225. [Google Scholar] [CrossRef]

- Canals, L.M.; Burnip, G.M.; Cowell, S.J. Evaluation of the environmental impacts of apple production using life cycle assessment (LCA): Case study in New Zealand. Agric. Ecosyst. Environ. 2006, 114, 226–238. [Google Scholar] [CrossRef]

- Galafton, C.; Maga, D.; Sonnemann, G.; Thonemann, N. Life cycle assessment of different strawberry production methods in Germany with a particular focus on plastic emissions. Int. J. Life Cycle Assess. 2023, 28, 611–625. [Google Scholar] [CrossRef]

- Clark, S.; Mousavi-Avval, S.H. Global Warming Potential of Organic Strawberry Production under Unheated High Tunnels in Kentucky, USA. Sustainability 2022, 14, 1778. [Google Scholar] [CrossRef]

- Parajuli, R.; Matlock, M.D.; Thoma, G. Environmental life cycle impact assessment of fresh California strawberries: A full supply chain perspective. Clean. Responsible Consum. 2022, 6, 100073. [Google Scholar] [CrossRef]

- Bakari, Z.; Ghadraoui, A.E.; Boujelben, N.; Del Bubba, M.; Elleuch, B. Assessment of the impact of irrigation with treated wastewater at different dilutions on growth, quality parameters and contamination transfer in strawberry fruits and soil: Health risk assessment. Sci. Hortic. 2022, 297, 110942. [Google Scholar] [CrossRef]

- Ilari, A.; Toscano, G.; Boakye-Yiadom, K.A.; Duca, D.; Foppa Pedretti, E. Life Cycle Assessment of Protected Strawberry Productions in Central Italy. Sustainability 2021, 13, 4879. [Google Scholar] [CrossRef]

- Legua, P.; Hernández, F.; Tozzi, F.; Martínez-Font, R.; Jorquera, D.; Rosique Jiménez, C.; Giordani, E.; Martínez-Nicolás, J.J.; Melgarejo, P. Application of LCA Methodology to the Production of Strawberry on Substrates with Peat and Sediments from Ports. Sustainability 2021, 13, 6323. [Google Scholar] [CrossRef]

- Romero-Gámez, M.; Suárez-Rey, E. Environmental footprint of cultivating strawberry in Spain. Int. J. Life Cycle Assess. 2020, 25, 719–732. [Google Scholar] [CrossRef]

- Valiante, D.; Sirtori, I.; Cossa, S.; Corengia, L.; Pedretti, M.; Cavallaro, L.; Vignoli, L.; Galvagni, A.; Gomarasca, S.; Pesce, G.R.; et al. Environmental impact of strawberry production in Italy and Switzerland with different cultivation practices. Sci. Total Environ. 2019, 664, 249–261. [Google Scholar] [CrossRef]

- Girgenti, V.; Peano, C.; Baudino, C.; Tecco, N. From “farm to fork” strawberry system: Current realities and potential in-novative scenarios from life cycle assessment of non-renewable energy use and greenhouse gas emissions. Sci. Total Environ. 2014, 473, 48–53. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Rafiee, S.; Mousazadeh, H. Environmental impact assessment of open field and greenhouse strawberry production. Eur. J. Agron. 2013, 50, 29–37. [Google Scholar] [CrossRef]

- Gunady, M.G.A.; Biswas, W.; Solah, V.A.; James, A.P. Evaluating the global warming potential of the fresh produce supply chain for strawberries, romaine/cos lettuces (Lactuca sativa), and button mushrooms (Agaricus bisporus) in Western Australia using life cycle assessment (LCA). J. Clean. Prod. 2012, 28, 81–87. [Google Scholar] [CrossRef]

- Williams, A.; Pell, E.; Webb, J.; Moorhouse, E.; Audsley, E. Strawberry and tomato production for the UK compared between the UK and Spain. In Proceedings of the 6th International Conference on LCA in the Agri-Food Sector, Zürich, Switzerland, 12–14 November 2008; pp. 254–414. [Google Scholar]

- Ministero delle Politiche. Agricole Alimentari e Forestali, Gruppo Difesa Integrata; Decree of Ministry of Agricultural, Food and Forestry Policies, No. 2722; Istituto Superiore per la Protezione e la Ricerca Ambientale: Rome, Italy, 2008; Available online: https://indicatori-pan-fitosanitari.isprambiente.it/sites/indicatori-panfitosanitari.isprambiente.it/files/pdf/LINEE%20GUIDA%20PRODUZIONE%20INTEGRATA_DIFESA%20FITOSANITARIA%20CONTROLLO%20INFESTANTI.pdf (accessed on 9 February 2018).

- Commission Regulation (EC) No 889/2008 of 5 September 2008 Laying Down Detailed Rules for the Implementation of Council Regulation (EC) No 834/2007 on Organic Production and Labelling of Organic Products with Regard to Organic Production, Labelling and Control. Available online: https://eur-lex.europa.eu/eli/reg/2008/889/oj (accessed on 5 May 2023).

- Persiani, A.; Pergola, M.; Pastore, V.; Palese, A.M. Compostaggio Aziendale per la Produzione di Ammendante Verde Compostato. Notiziario Regionale di Agricoltura Sostenibile-Nuova Edizione–Agrifoglio. n. 52 Ottobre 2015. Available online: https://www.researchgate.net/publication/282646718_Compostaggio_aziendale_per_la_produzione_di_ammendante_verde_compostato (accessed on 5 May 2023).

- Pergola, M.; Piccolo, A.; Palese, A.M.; Ingrao, C.; Di Meo, V.; Celano, G. A combined assessment of the energy, economic and environmental issues associated with on-farm manure composting processes: Two case studies in South of Italy. J. Clean. Prod. 2018, 172, 3969–3981. [Google Scholar] [CrossRef]

- ANPA. Methods of Compost Analysis; Handbooks and Guidelines; 3/2001; Stampa SPEED srl.: Rome, Italy, 2001; p. 135. [Google Scholar]

- Pane, C.; Spaccini, R.; Piccolo, A.; Celano, G.; Zaccardelli, M. Disease suppressiveness of agricultural green waste composts as related to chemical and bio-based properties shaped by different on-farm composting methods. Biol. Control 2019, 137, 104026. [Google Scholar] [CrossRef]

- Scher, F.M.; Baker, R. Effect of Pseudomonas putida and a synthetic iron chelator on induction of soil suppressiveness to Fusarium Wilt pathogens. Phytopathology 1982, 72, 1567–1573. [Google Scholar] [CrossRef]

- Sadfi, N.; Cherif, M.; Fliss, I.; Boudabbous, A.; Antoun, H. Evaluation of bacterial isolates from salty soils and Bacillus thurigiensis strains for the biocontrol of Fusarium dry rot of potato tubers. J. Plant Pathol. 2001, 83, 101–118. [Google Scholar]

- EN ISO 14044; Environmental Management, Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- EN ISO 14040; Environmental Management, Life Cycle Assessment—Principles and Framework. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- Maffia, A.; Pergola, M.; Palese, A.M.; Celano, G. Environmental impact assessment of organic vs. integrated olive-oil systems in Mediterranean context. Agronomy. 2020, 10, 416. [Google Scholar] [CrossRef]

- Pergola, M.; Persiani, A.; Pastore, V.; Palese, A.M.; Arous, A.; Celano, G. A comprehensive life cycle assessment (LCA) of three apricot orchard systems located in Metapontino area (Southern Italy). J. Clean Prod. 2017, 142, 4059–4071. [Google Scholar] [CrossRef]

- Cerutti, A.K.; Bagliani, M.; Beccaro, G.L.; Peano, C.; Bounous, G. Comparison of LCA and EFA for the environmental account of fruit production systems: A case study in Northern Italy. In Proceedings of the LCA Food 2010, Bari, Italy, 22–24 September 2010; Università di Bari: Bari, Italy, 2010. [Google Scholar]

- Seda, M.; Assumpeió, A.; Muñoz, P. Analyzing the influence of functional unit in agricultural LCA. In Proceedings of the LCA Food 2010, Bari, Italy, 22–24 September 2010. [Google Scholar]

- Brentrup, F.; Küsters, J.; Lammel, J.; Kuhlmann, H. Methods to estimate on-field nitrogen emissions from crop production as an input to LCA studies in the agricultural sector. Int. J. Life Cycle Assess. 2000, 5, 349–357. [Google Scholar] [CrossRef]

- IPCC. Guidelines for National Greenhouse Gas Inventories; Institute for Global Environmental Strategies (IGES) for the IPCC: Geneva, Switzerland, 2006; Volume 11. [Google Scholar]

- Hauschild, M.Z. Estimating pesticide emissions for LCA of agricultural products. In Agricultural Data for Life Cycle Assessments; Agricultural Economics Research Institute: Hague, The Netherlands, 2000; pp. 64–79. [Google Scholar]

- Ecoinvent Version 3. 2016. Available online: https://ecoinvent.org/the-ecoinvent-database/data-releases/ecoinvent-3--3/ (accessed on 15 April 2023).

- de Bruyn, S.; Bijleveld, M.; de Graaff, L.; Schep, E.; Schroten, A.; Vergeer, R.; Ahdour, S. Environmental Prices Handbook, EU28 version; Publication Code: 18.7N54.125; CE Delft: Delft, The Netherlands, 2018; Available online: https://cedelft.eu/publications/environmental-prices-handbook-eu28-version/ (accessed on 10 May 2023).

- RIVM; CML; PRé Consultants and the Radboud University Nijmegen on behalf of the Dutch Ministry of Infrastructure and the Environment. ReCiPe. Available online: https://www.rivm.nl/en/life-cycle-assessment-lca/downloads (accessed on 1 June 2023).

- ISMEA. Banca Dati Prezzi—Origine. 2023. Available online: https://www.ismeamercati.it/flex/cm/pages/ServeBLOB.php/L/IT/IDPagina/12378 (accessed on 2 May 2023).

- Palese, A.M.; Pergola, M.; Favia, M.; Xiloyannis, C.; Celano, G. A sustainable model for the management of olive orchards located in semi-arid marginal areas: Some remarks and indications for policy makers. Environ. Sci. Policy 2013, 27, 81–90. [Google Scholar] [CrossRef]

- Mordini, M.; Nemecek, T.; Gaillard, G. Carbon & Water Footprint of Oranges and Strawberries. A Literature Review; Agroscope Reckenholz-Tänikon Research Station ART: Zurich, Switzerland, 2009; Available online: https://saiplatform.org/uploads/Library/WG%20Fruit%20-%20ART%20Final%20Report.pdf (accessed on 10 June 2023).

- Peano, C.; Baudino, C.; Tecco, N.; Girgenti, V. Green marketing tools for fruit growers associated groups: Application of the Life Cycle Assessment (LCA) for strawberries and berry fruits ecobranding in northern Italy. J. Clean. Prod. 2015, 104, 59–67. [Google Scholar] [CrossRef]

- Maraseni, T.N.; Cockfield, G.; Maroulis, J. An assessment of greenhouse gas emissions: Implications for the Australian cotton industry. J. Agric. Sci. 2010, 148, 501–510. [Google Scholar] [CrossRef]

- da Silva, T.M.; Giuggioli, N.R.; Peano, C. Modelling strawberry quality in a longitudinal study under the marketing concept of branding. Heliyon 2021, 7, 06165. [Google Scholar]

- Banaeian, N.; Omid, M.; Ahmadi, H. Energy and economic analysis of greenhouse strawberry production in Tehran province of Iran. Energ. Convers. Manag. 2011, 52, 1020–1025. [Google Scholar] [CrossRef]

| Orchard | SC | SI | SO1 | SO2 | RSC + CT | RSC | NRSC+ CT | NRSC |

|---|---|---|---|---|---|---|---|---|

| Characteristics | ||||||||

| Cultivar | Melissa, Sabrina, Flaminia, Nabila | Melissa, Sabrina | Melissa | Sabrina, Marinbella, Savana | Sabrosa, Rossetta | |||

| Planting density (plants ha−1) | 75,000 (0.35 m × 0.20 m) | 99,500 (0.30 m × 0.30 m) | 99,500 (0.30 m × 0.30 m) | 70,000 (0.20 m × 0.30 m) | 75,000 (0.20 m × 0.30 m) | |||

| Soil texture | Sandy—silty | Sandy | ||||||

| Cultivation system | Conventional under greenhouse | Integrated under greenhouse | Organic under greenhouse | Organic under greenhouse | Integrated under greenhouse | |||

| Irrigation | Drip line | Localized | Drip line | |||||

| Fertilization | Mineral | Mineral/Organic | Mineral/organic/green manure | Green manure/Organic | Mineral + Organic | Mineral | Mineral + Organic | Mineral |

| Soil management/Weed control | Not applied | Not applied | Not applied | Manual | Glyphosate | |||

| Soil disinfestation/Disease control | Conventional products | Organic products | Organic products | Solarization/Biological fight | Conventional products | |||

| Harvesting method | Manual | |||||||

| Parameters | Values (% DW) | Parameters | Values (mg kg DW−1) |

|---|---|---|---|

| Ashes | 61.80 | N-NH4 | 167.00 |

| CaCO3 | 7.63 | N-NO3 | 478.00 |

| C | 20.56 | Ni | 37.31 |

| Total N | 1.55 | Cr | 66.28 |

| H | 3.27 | Zn | 140.72 |

| HA-C | 5.29 | B | 85.44 |

| FA-C | 1.31 | Mn | 705.78 |

| Humic-C | 6.60 | Cu | 114.86 |

| P | 0.62 | Parameters | Values (mS cm−1) |

| C/P | 33.20 | Conductivity | 3.95 |

| S | 0.61 | Parameters | Values |

| Ca | 5.11 | pH | 10.70 |

| K | 3.18 | C/N | 13.30 |

| Na | 1.73 | ||

| Mg | 1.17 | ||

| Fe | 2.07 |

| SC | SI | SO1 | SO2 | RSC + CT | RSC | NRSC + CT | NRSC | |

|---|---|---|---|---|---|---|---|---|

| Fertilizers (kg ha−1) | ||||||||

| Agristart magnum | 76 | 76 | 76 | 76 | ||||

| Simple phosphate mineral fertilizer | 55 | 55 | 55 | 55 | ||||

| Simple mineral nitrogen fertilizer | 83 | 83 | 83 | 83 | ||||

| Simple mineral potassium fertilizer | 107 | 107 | 107 | 107 | ||||

| Vegetable/organic fertilizer | 1500 | |||||||

| Calcium nitrate | 30 | 550 | ||||||

| Potassium nitrate | 25 | 350 | ||||||

| Ammonium nitrate | 300 | 50 | ||||||

| Magnesium nitrate | 100 | |||||||

| Urea | 75 | 450 | ||||||

| Magnesium sulfate | 250 | 2300 | ||||||

| Potassium sulfate | 2326 | |||||||

| Ammonium sulfate | 200 | |||||||

| Hydromix | 25 | 1290 | ||||||

| Resolvine 500 | 15 | 65 | ||||||

| Siapton | 40 | 6265 | ||||||

| Fertildung stallatico | 20 | |||||||

| Auxine e citochinine | 1584 | |||||||

| Solubordf | 11 | |||||||

| Partner 700 | 30 | |||||||

| Nutrimix | 10 | |||||||

| Novatecsolub | 150 | |||||||

| Maxiron | 8 | |||||||

| Fosfoman | 120 | |||||||

| Calcio bio | 10 | |||||||

| Biocal | 4 | |||||||

| Bioup | 0.5 | |||||||

| Chelated iron | 1 | |||||||

| N | 85 | 85 | ||||||

| P2O5 | 45 | 45 | ||||||

| K2O | 90 | 90 | ||||||

| Mg | 8 | 8 | ||||||

| (L ha−1) | ||||||||

| Lisofert biogarder | 42 | |||||||

| (m3 ha−1) | ||||||||

| Compost tea | 15.68 | 15.68 | ||||||

| Chemicals (kg ha−1) | ||||||||

| Affirm | 1.5 | 1.5 | 1.5 | 1.5 | ||||

| Laser | 0.25 | 0.25 | 0.25 | 0.25 | ||||

| Ortiva | 1 | 1 | 1 | 1 | ||||

| Topas | 1 | 1 | 1 | 1 | ||||

| Dargonis | 0.6 | 0.6 | 0.6 | 0.6 | ||||

| Nimrod | 1 | 1 | 1 | 1 | ||||

| Signum | 3 | |||||||

| Copper oxychloride | 4.2 | 4.2 | ||||||

| Metaldeide | 5 | |||||||

| Sulfur | 4 | 4 | ||||||

| (L ha−1) | ||||||||

| Epik | 2 | 2 | 2 | 2 | ||||

| Roundup | 5 | 5 | 5 | 5 | ||||

| Chloropicrin | 180 | |||||||

| Dichloropropene | 240 | |||||||

| Piretrine | 4.6 | 4.6 | ||||||

| Spinosad | 0.4 | 0.4 | ||||||

| Piraclostobin | 3 | 3 | ||||||

| Clofentezine | 0.3 | |||||||

| Pirimetalin | 2 | |||||||

| Micronized sulfur | 1.2 | |||||||

| Iron structures (kg ha−1year−1) | 678 | 807 | 807 | 870 | 610 | 610 | 1219 | 1219 |

| Plastics (films, pipes, containers) (kg ha−1year−1) | 1900 | 3402 | 2578 | 1352 | 2150 | 2150 | 2300 | 2300 |

| Human labor (h ha–1) | 4063 | 6150 | 3192 | 788 | 266 | 259 | 287 | 280 |

| Machinery (h ha–1) | 52 | 51 | 35 | 22 | 74 | 74 | 100 | 100 |

| Diesel (kg ha–1) | 234 | 201 | 201 | 179 | 46 | 46 | 69 | 69 |

| Water (mc ha−1) | 1440 | 3000 | 3000 | 1133 | 9000 | 9000 | 9000 | 9000 |

| OUTPUT—Strawberries average yield (kg ha−1) | 38,000 | 43,550 | 24,000 | 52,500 | 47,850 | 41,250 | 52,200 | 45,000 |

| Items | Value | Comment |

|---|---|---|

| Escherichia coli | Absent | |

| pH | 8.21 | |

| EC (μs cm−1) | 2645 | Need of dilution before the use |

| Yeasts (c.f.u. mL−1) | 2.53 × 107 | Action in biocontrol |

| Molds (c.f.u. mL−1) | 4.00 × 105 | Filamentous fungi |

| Bacillus (c.f.u. mL−1) | 4.33 × 105 | Antagonistic bacteria. Action in biocontrol |

| Pseudomonas (c.f.u. mL−1) | 9.67 × 104 | Antagonistic bacteria. Action in biocontrol |

| Total bacteria (c.f.u. mL−1) | 3.66 × 105 |

| Dilution | Root Length (R, mm) | Aerial Part Length (A, mm) | A/R |

|---|---|---|---|

| Ctrl | 25.37 | 24.07 | 0.95 |

| CT as it is | 16.88 | 32.05 * | 1.90 |

| 1:10 | 22.06 | 30.33 * | 1.37 |

| 1:100 | 24.04 | 23.33 | 0.97 |

| 1:1000 | 20.25 | 20.29 | 1.00 |

| 1:10,000 | 22.07 | 18.17 | 0.82 |

| 1:100,000 | 21.18 | 17.26 | 0.81 |

| Impact Category | Unit | SC | SI | SO1 | SO2 | RSC + CT | RSC | NRSC + CT | NRSC |

|---|---|---|---|---|---|---|---|---|---|

| Climate change | kg CO2 eq | 7461 | 9617 | 9116 | −972 | 11,068 | 10,996 | 11,431 | 11,359 |

| Ozone depletion | kg CFC-11 eq | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Terrestrial acidification | kg SO2 eq | 60 | 138 | 49 | 26 | 63 | 63 | 64 | 64 |

| Freshwater eutrophication | kg P eq | 3 | 0 | 1 | 7 | 6 | 6 | 6 | 6 |

| Marine eutrophication | kg N eq | 4 | 5 | 2 | 5 | 6 | 6 | 4 | 4 |

| Human toxicity | kg 1,4-DB eq | 7949 | 1118 | 7389 | 9983 | 14,641 | 14,633 | 14,545 | 14,537 |

| Photochemical oxidant formation | kg NMVOC | 33 | 17 | 26 | 7 | 49 | 47 | 52 | 49 |

| Particulate matter formation | kg PM10 eq | 11 | 15 | 10 | −10 | 18 | 18 | 18 | 18 |

| Terrestrial ecotoxicity | kg 1,4-DB eq | 380 | 3 | 3 | 37 | 393 | 392 | 389 | 389 |

| Freshwater ecotoxicity | kg 1,4-DB eq | 654 | 289 | 585 | 664 | 1261 | 1260 | 1232 | 1231 |

| Marine ecotoxicity | kg 1,4-DB eq | 6132 | 251 | 517 | 610 | 6546 | 6546 | 6540 | 6540 |

| Ionizing radiation | kBq U235 eq | 1328 | 771 | 968 | 1815 | 1701 | 1685 | 1689 | 1673 |

| Water depletion | m3 | 1627 | 3125 | 3123 | 3334 | 9088 | 9085 | 9095 | 9092 |

| Metal depletion | kg Fe eq | −1045 | −3003 | 8313 | −6508 | −57 | −58 | −251 | −252 |

| Fossil depletion | kg oil eq | 4687 | 6128 | 5727 | 2087 | 5069 | 5064 | 5434 | 5429 |

| Impact Category | Unit | SC | SI | SO1 | SO2 | RSC + CT | RSC | NRSC + CT | NRSC |

|---|---|---|---|---|---|---|---|---|---|

| Total | EUR2015 | 5508 | 2368 | 2086 | 1098 | 6798 | 6781 | 6780 | 6763 |

| Climate change | EUR2015 | 422 | 544 | 516 | −55 | 626 | 622 | 647 | 643 |

| Ozone depletion | EUR2015 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Terrestrial acidification | EUR2015 | 450 | 1033 | 365 | 194 | 473 | 470 | 482 | 478 |

| Freshwater eutrophication | EUR2015 | 6 | 1 | 3 | 13 | 11 | 11 | 10 | 10 |

| Marine eutrophication | EUR2015 | 11 | 16 | 7 | 16 | 19 | 19 | 13 | 13 |

| Human toxicity | EUR2015 | 711 | 100 | 661 | 892 | 1309 | 1308 | 1300 | 1300 |

| Photochemical oxidant formation | EUR2015 | 38 | 19 | 30 | 8 | 56 | 54 | 59 | 56 |

| Particulate matter formation | EUR2015 | 436 | 583 | 408 | −409 | 719 | 715 | 720 | 716 |

| Terrestrial ecotoxicity | EUR2015 | 3304 | 24 | 28 | 325 | 3412 | 3411 | 3378 | 3377 |

| Freshwater ecotoxicity | EUR2015 | 24 | 10 | 21 | 24 | 46 | 45 | 44 | 44 |

| Marine ecotoxicity | EUR2015 | 45 | 2 | 4 | 5 | 48 | 48 | 48 | 48 |

| Ionizing radiation | EUR2015 | 61 | 36 | 45 | 84 | 78 | 78 | 78 | 77 |

| Impact Category | Unit | SC | SI | SO1 | SO2 | RSC + CT | RSC | NRSC + CT | NRSC |

|---|---|---|---|---|---|---|---|---|---|

| Climate change | kg CO2 eq | 0.196 | 0.221 | 0.380 | −0.019 | 0.231 | 0.267 | 0.219 | 0.252 |

| Ozone depletion | kg CFC-11 eq | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| Terrestrial acidification | kg SO2 eq | 0.002 | 0.003 | 0.002 | 0.000 | 0.001 | 0.002 | 0.001 | 0.001 |

| Freshwater eutrophication | kg P eq | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| Marine eutrophication | kg N eq | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| Human toxicity | kg 1,4-DB eq | 0.209 | 0.026 | 0.308 | 0.190 | 0.306 | 0.355 | 0.279 | 0.323 |

| Photochemical oxidant formation | kg NMVOC | 0.001 | 0.000 | 0.001 | 0.000 | 0.001 | 0.001 | 0.001 | 0.001 |

| Particulate matter formation | kg PM10 eq | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| Terrestrial ecotoxicity | kg 1,4-DB eq | 0.010 | 0.000 | 0.000 | 0.001 | 0.008 | 0.010 | 0.007 | 0.009 |

| Freshwater ecotoxicity | kg 1,4-DB eq | 0.017 | 0.007 | 0.024 | 0.013 | 0.026 | 0.031 | 0.024 | 0.027 |

| Marine ecotoxicity | kg 1,4-DB eq | 0.161 | 0.006 | 0.022 | 0.012 | 0.137 | 0.159 | 0.125 | 0.145 |

| Ionizing radiation | kBq U235 eq | 0.035 | 0.018 | 0.040 | 0.035 | 0.036 | 0.041 | 0.032 | 0.037 |

| Water depletion | m3 | 0.043 | 0.072 | 0.130 | 0.064 | 0.190 | 0.220 | 0.174 | 0.202 |

| Metal depletion | kg Fe eq | −0.027 | −0.069 | 0.346 | −0.124 | −0.001 | −0.001 | −0.005 | −0.006 |

| Fossil depletion | kg oil eq | 0.123 | 0.141 | 0.239 | 0.040 | 0.106 | 0.123 | 0.104 | 0.121 |

| Impact Category | Unit | SC | SI | SO1 | SO2 | RSC + CT | RSC | NRSC + CT | NRSC |

|---|---|---|---|---|---|---|---|---|---|

| Total | EUR2015 | 0.145 | 0.054 | 0.087 | 0.021 | 0.142 | 0.164 | 0.130 | 0.150 |

| Climate change | EUR2015 | 0.011 | 0.012 | 0.021 | −0.001 | 0.013 | 0.015 | 0.012 | 0.014 |

| Ozone depletion | EUR2015 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| Terrestrial acidification | EUR2015 | 0.012 | 0.024 | 0.015 | 0.004 | 0.010 | 0.011 | 0.009 | 0.011 |

| Freshwater eutrophication | EUR2015 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| Marine eutrophication | EUR2015 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| Human toxicity | EUR2015 | 0.019 | 0.002 | 0.028 | 0.017 | 0.027 | 0.032 | 0.025 | 0.029 |

| Photochemical oxidant formation | EUR2015 | 0.001 | 0.000 | 0.001 | 0.000 | 0.001 | 0.001 | 0.001 | 0.001 |

| Particulate matter formation | EUR2015 | 0.011 | 0.013 | 0.017 | −0.008 | 0.015 | 0.017 | 0.014 | 0.016 |

| Terrestrial ecotoxicity | EUR2015 | 0.087 | 0.001 | 0.001 | 0.006 | 0.071 | 0.083 | 0.065 | 0.075 |

| Freshwater ecotoxicity | EUR2015 | 0.001 | 0.000 | 0.001 | 0.000 | 0.001 | 0.001 | 0.001 | 0.001 |

| Marine ecotoxicity | EUR2015 | 0.001 | 0.000 | 0.000 | 0.000 | 0.001 | 0.001 | 0.001 | 0.001 |

| Ionizing radiation | EUR2015 | 0.002 | 0.001 | 0.002 | 0.002 | 0.002 | 0.002 | 0.001 | 0.002 |

| SC | SI | SO1 | SO2 | RSC + CT | RSC | NRSC + CT | NRSC | |

|---|---|---|---|---|---|---|---|---|

| Average yield (kg) | 38,000 | 43,550 | 24,000 | 52,500 | 47,850 | 41,250 | 52,200 | 45,000 |

| Average price (€) [2] | 2.49 | 2.74 | 2.74 | 2.63 | 3.76 | 3.76 | 3.76 | 3.76 |

| Total Output (€) | 94,620 | 119,327 | 65,760 | 138,075 | 179,916 | 155,100 | 196,272 | 169,200 |

| Variable production costs (€) | 70,130 | 85,403 | 113,345 | 94,949 | 53,214 | 53,064 | 57,381 | 57,231 |

| Gross profit (€) | 24,490 | 33,924 | −47,585 | 43,126 | 126,702 | 102,036 | 138,891 | 111,969 |

| SC | SI | SO1 | SO2 | RSC + CT | RSC | NRSC + CT | NRSC | |

|---|---|---|---|---|---|---|---|---|

| Soil preparation (€) | 3936 | 97 | 97 | 2249 | 8077 | 8077 | 8153 | 8153 |

| Plantation, irrigation system, and supporting structures installation (€) | 19,257 | 23,418 | 23,418 | 11,863 | 12,997 | 12,997 | 15,208 | 15,208 |

| Irrigation and Fertigation (€) | 951 | 5166 | 44,625 | 1189 | 13,391 | 13,391 | 13,391 | 13,391 |

| Weed and diseases control (€) | 346 | 1030 | 2739 | 12,000 | 651 | 651 | 651 | 651 |

| Compost tea production and distribution (€) | 0 | 0 | 0 | 0 | 150 | 0 | 150 | 0 |

| Harvesting (€) | 44,377 | 54,391 | 41,466 | 64,507 | 15,948 | 15,948 | 18,028 | 18,028 |

| Explant and other manual operations (€) | 1262 | 1300 | 1000 | 3142 | 2000 | 2000 | 1800 | 1800 |

| System | Variable Costs | Environmental Cost | Total Cost | Total Output | Gross Profit |

|---|---|---|---|---|---|

| SO1 | 4.72 | 0.09 | 4.81 | 2.74 | −2.07 |

| SC | 1.85 | 0.14 | 1.99 | 2.49 | 0.50 |

| SI | 1.96 | 0.05 | 2.02 | 2.74 | 0.72 |

| SO2 | 1.81 | 0.02 | 1.83 | 2.63 | 0.80 |

| RSC | 1.29 | 0.16 | 1.45 | 3.76 | 2.31 |

| NRSC | 1.27 | 0.15 | 1.42 | 3.76 | 2.34 |

| RSC + CT | 1.11 | 0.14 | 1.25 | 3.76 | 2.51 |

| NRSC + CT | 1.10 | 0.13 | 1.23 | 3.76 | 2.53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pergola, M.; Maffia, A.; Carlucci, G.; Persiani, A.; Palese, A.M.; Zaccardelli, M.; Altieri, G.; Celano, G. An Environmental and Economic Analysis of Strawberry Production in Southern Italy. Agriculture 2023, 13, 1705. https://doi.org/10.3390/agriculture13091705

Pergola M, Maffia A, Carlucci G, Persiani A, Palese AM, Zaccardelli M, Altieri G, Celano G. An Environmental and Economic Analysis of Strawberry Production in Southern Italy. Agriculture. 2023; 13(9):1705. https://doi.org/10.3390/agriculture13091705

Chicago/Turabian StylePergola, Maria, Angela Maffia, Giuseppe Carlucci, Alessandro Persiani, Assunta Maria Palese, Massimo Zaccardelli, Gessica Altieri, and Giuseppe Celano. 2023. "An Environmental and Economic Analysis of Strawberry Production in Southern Italy" Agriculture 13, no. 9: 1705. https://doi.org/10.3390/agriculture13091705

APA StylePergola, M., Maffia, A., Carlucci, G., Persiani, A., Palese, A. M., Zaccardelli, M., Altieri, G., & Celano, G. (2023). An Environmental and Economic Analysis of Strawberry Production in Southern Italy. Agriculture, 13(9), 1705. https://doi.org/10.3390/agriculture13091705