Abstract

The obtained results of experimental studies on the influence of the physical and mechanical properties of an elastoplastic material (clods of soil and potato tubers) on the factors of its destruction when interacting with an absolutely solid body (separating working body) established that an increase in the density of a soil clod leads to an increase in the effort expended on dynamic destruction, regardless of the size fraction. Within one fractional group, the increase in force from the minimum value necessary for the destruction of the soil clod in the density range from 1300 to 1700 kg/m3 is on average 56–67 N. However, there is a tendency to increase the effort to destroy the soil clod with an increase in the size fraction, including identical density, by 7–8 N, which is 4–5% of the initial value of the destruction force of a given density. The greatest destruction of soil clods is provided at a moisture content of 22–24%, which should be explained by the formation of the physical ripeness of the leached chernozem. In addition, a decrease in soil moisture leads to a more intense adhesion of soil particles to each other and, consequently, to an increase in the force on the soil clod to destroy it.

1. Introduction

The values of the external forces that ensure the destruction of soil clods are limited by the condition of tuber damage. Thus, the average compressive hardness of tubers before the appearance of visible damage varies within 481–750 N.

The hardness of soil clods is from 196 N to 1860 N, which is much more than the allowable indicators of tubers. Therefore, when potato harvesters operate on soils of medium and especially heavy mechanical composition, a significant proportion of soil clods remain undestroyed. Undestroyed soil clods cannot be simply removed because there are tubers inside the clods, and some of the tubers are stuck to the soil clods, which is facilitated by soil “glue” composed of organic and mineral colloids, various salts, and silty substances. To release the tubers from lumps, modern potato harvesters are forced to utilize sorting workers or to perform this work at sorting stations.

The main soil parameters that adequately characterize its properties are moisture and density. All studies on the destruction of soil clods are based on the condition of minimal damage to potato tubers (within the limits of agrotechnical requirements).

Based on this postulate, Russian and world sciences have come to the conclusion that the magnitude of the differences in the working bodies of potato harvesters should not exceed 30–40 cm and potato tubers. Therefore, according to statistics, a soil lump with a tuber will fall on the separating working body with the tuber down in fifty percent of cases and will damage the tuber.

In order to increase the completeness of the separation of the heap components and the performance of secondary separation devices, namely tine humps, they began to install various kinds of separation intensifiers in their design, the designs of which are considered in the works of N.V. Byshova, S.G. Borycheva, G.K. Rembalovich, El-Rahman, and Dai F [1,2].

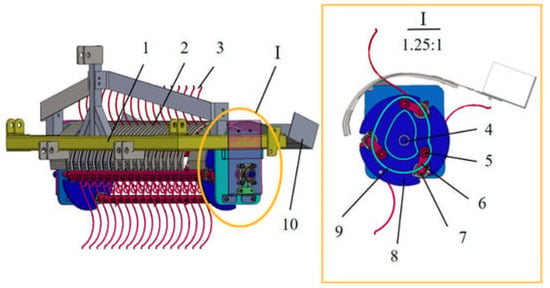

For example, a team of scientists led by Lihe Wang developed a design of a potato harvester with spring fingers (Figure 1), the design of which helps to solve the problem of manually picking potatoes with high labor intensity and low production efficiency; the researchers have conducted a significant amount of research and achieved good application results [3].

Figure 1.

Schematic diagram of the complete device of the pick-up: 1—frame; 2—curved body; 3—pushing gear; 4—spindle; 5—roller; 6—crank handle; 7—spring-finger shaft; 8—roller disk; 9—inner and outer cams; 10—a box for collecting potatoes.

Shi et al. [4] designed a small potato harvester with a 30 kW tractor using a picking shovel combined with a spring-pin conveyor chain to pick potatoes and a potato lifter and a potato picker to separate the potatoes from the soil and collect the potato blocks; however, the level of damaged potatoes and the level of contamination were higher than the relevant national industry standards. Xiao et al. [5] developed a small potato picking and grading machine using a roller-type secondary potato grading device to achieve the combined potato harvesting, sorting, and collecting of potato blocks, but the number of sorting levels did not meet the actual sorting requirements, and the collection efficiency was low. Hu et al. [6] developed an integrated potato harvester and sorter using a cam mechanism and a wheel mechanism vibration-damping arm to achieve the horizontal and vertical vibration of the screening part, thereby achieving the goal of two-monopoly potato harvesting and three-stage harvesting; however, the size of the whole machine increased, which caused a little problem when turning the machine.

When developing separators for harvesters, it is of great importance to study the variability of the mixture, i.e., its individual physical signs in the process of separation. Insufficient knowledge of the physical and mechanical properties of the separated products leads to a decrease in the quality of cleaning and an increase in the injury rate of potato tubers.

Studies on the orientation of a solid lump of soil with a tuber stuck to it during free fall, in order to destroy the soil lump without damaging the potato tuber, have not been found in world scientific practice.

The creation and implementation of machines of a new, intelligent type are defining components of the strategy for the development of agricultural engineering in the Russian Federation [7,8,9]. The effectiveness and efficiency of harvesting directly depend on the optimal solution to the problem of controlling the technological process of machine harvesting of root crops and onions [10,11,12]. When solving many of the problems related to the improvement of technological processes and working bodies of agricultural machines, the main goal is to increase the yield of agricultural crops and improve the quality of harvesting the grown crop [13,14,15]. Therefore, it is necessary to develop a methodology and algorithm for performing actions to study the effect of tuber injury when interacting with a cleaning device as well as to assess the effect of the separation process on the tribological properties of soil clods.

2. Materials and Methods

2.1. Studying the Tribological Properties Methodology to an Elastoplastic Material in Interaction with an Absolutely Rigid Body

For this research, a laboratory setup was developed, a general view of which is shown in Figure 2.

Figure 2.

Laboratory setup for studying the tribological properties of an elastoplastic material when interacting with an absolutely solid body: 1—frame; 2—container for preliminary placement of a heap; 3—separating rod elevator; 4—a tray for collecting impurities; 5—tarpaulin of separated products; 6—electric motor; 7—single-stage gearbox; 8—frequency converter; 9—chain transmission; 10—support racks.

The study of the separation process was carried out on the laboratory setup shown in Figure 1. The speed of the drive shaft of the rod elevator drive was changed through the gearbox by a chain transmission from an AC electric motor installed on the support platform by changing the frequency of the current with a frequency converter. The gaps between the bars of the elevator were set steplessly with the help of thrust bolts without removing the bar. Cloths of a bar elevator with different variants of the bar spacing changed during the research [13,14,15]. The studies were carried out in laboratory conditions on leached chernozem with soil moisture W = 19%. When evaluating the operation of root and tuber harvesters, an assessment is made of the physical and mechanical properties of the soil and the fractional composition of soil impurities. However, it is known that, in terms of the physical and mechanical properties and types of soil with other things being equal, soil separation is performed unevenly even within the length of the studied accounting plot. In this case, the research does not allow us to take into account all the factors influencing the separation process because some have not been fully studied, others have not been fully studied at all, and there are no methods for their determination. Therefore, it is necessary to ensure the development of a comprehensive indicator that takes into account the known factors that affect soil separation. This indicator is the “soil separating ability index” , which expresses the amount of soil, the state under consideration, capable of passing through a constant working area of the separating surface per unit time:

where is the mass of the soil sample, kg; and is the separation time of the studied soil sample, s.

This indicator can also be expressed by the time during which a sample of soil with a certain constant weight under study will pass through the separating surface. When studying the fractional composition of the soil, it is necessary to use sieve analysis. However, the use of this method distorts the natural state of the soil in view of the violation of the integrity of the soil layer and the interconnection of individual soil aggregates; therefore, the soil aggregates are destroyed by passing through the sieve holes of the device. As a result, this method is unacceptable for studying the fractional composition of the soil.

To take soil samples from the surface of potato cultivation in this study, a sampler was used with a design developed in Ulyanovsk State Agrarian University “Device for determining the density of the soil”, the novelty of the technical solution of which is confirmed by the patents of the Russian Federation No. 55478, No. 149064, and No. 149065. In this case, sampling from the bed is carried out by an intake when cutting out a certain volume of soil without violating the coherence and integrity of the soil structure. The sample is subjected to fractional analysis on the classifier (Figure 3), where the soil clods are separated by size.

Figure 3.

The device of the classifier of the state of the soil.

One of the three linear dimensions of the soil clod is chosen as the basis—length, width, and thickness. Based on the obtained data on the fractional composition of soil clods, graphic dependences are constructed, represented by variation curves. The classifier (Figure 3) consists of a body that includes eight sections of the accepted number of size fractions of soil clods. A wedge-shaped adjustable slot is located on the top cover of the classifier. The method for determining the fractional composition of the soil is carried out as follows. When disassembling a soil sample, it is necessary to install each soil clod in a wedge-shaped slot; the soil clod is distributed over a section corresponding to the measured value (width, length, or thickness) after passing into the lower collection tank of soil fractions [16,17,18,19]. Therefore, excluding additional measurements, the soil sample is divided into classes.

The evaluation of the separating ability of an elastoplastic material, depending on their physical and mechanical properties, is carried out on the installation shown in Figure 3 according to the following algorithm:

- It is necessary to extract the soil sample with a sampling tool without disturbing the natural state of the soil.

- Perform the determination of the fractional composition of the soil on the developed classifier.

- Determine the moisture content of the soil sample with the thermostatic-weight method or resistance-type moisture meter.

- Carry out the supply of the tuberous heap to the rod elevator continuously from the tank for preliminary placement of the heap with an intensity of 20–48 kg/s by adjusting the angle of inclination of the tank relative to the horizon.

2.2. Methodology for Conducting Research on the Dynamic Impact on Soil Clods

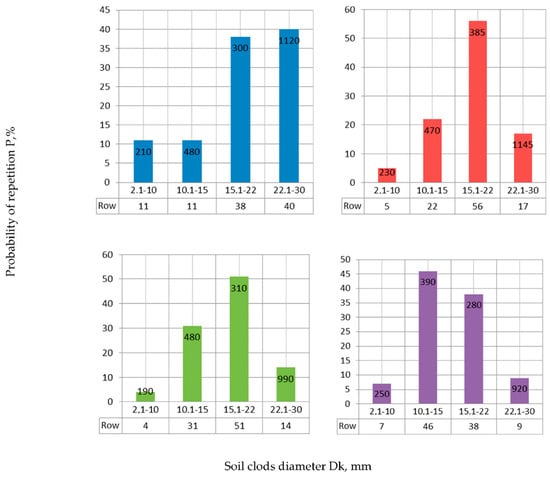

The methodology for conducting research on the dynamic impact on soil clods consists of performing sequential operations and is as follows. The soil sampling for research on the dynamic impact of the destruction of soil clods was carried out from the bunker of the combine harvester brand «Bolko S» with the distribution of dimensional characteristics of the shedding heap of soil clods presented in the diagrams of Figure 4.

Figure 4.

Fractional composition and mass of soil clods.

During each experiment of the selected fraction (Figure 4), 50 soil clods were selected with subsequent loading of the soil heap together with the software tool “Electronic Potato Tuber Log“ through the passage window formed between the blade 2 and the end of the drum 3 (Figure 5).

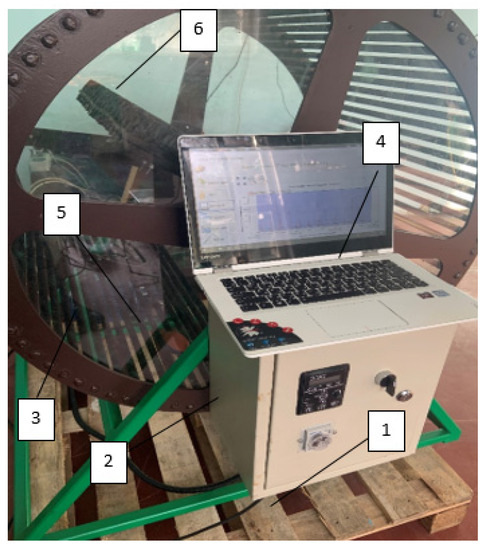

Figure 5.

General view of the laboratory installation for assessing the dynamic impact on soil clods: 1—support platform; 2—control cabinet; 3—drum; 4—personal computer; 5—data recorder; 6—finger slide.

It should be noted that the studies on the dynamic destruction of soil clods of all the selected fractions were carried out at soil moisture W = 30%, the value of which corresponds to the maximum value of static destruction of 288.7 N.

In addition, taking into account the research of Kamaletdinov R.R., it is known that soil clods with a density of 1600–1700 kg/m3 are destroyed under a static compression of 1300–1400 kg/m3 at a moisture content of 22–24%; therefore, soil samples were chosen with the following densities: 1300, 1400, 1500, 1600, and 1700 kg/m3.

Further, the rotational speed of the bar drum 3 was set using the control cabinet 2 while fixing the force impact of the data recorder 5 while visualizing the obtained values on the personal computer 4. Turning off the rotation of the bar drum 3 was performed at 90% destruction of the soil clods, i.e., when shedding destroyed the soil clods through the slotted holes of the drum bars [20,21,22]. After a series of experiments, the sequence of actions was repeated for each of the studied fractions of the soil clods: 10.1–15 mm, 15.1–22 mm, and 22.1–30 mm of the corresponding density.

2.3. Methodology of Soil Viscosity Determination

In addition, due to the fact that, at present, the working surface of the separators of the harvester is coated with polymer-composite materials in order to avoid damage to commercial products, it is necessary to determine the viscosity of various types of soil on the working surface of modern separators of potato harvesters [23].

This circumstance is due to the fact that the earlier studies by N.V. Byshova [1] were aimed at determining the viscosity of the soil in relation to a metal plate in view of the fact that, in the design of the cleaning devices for the primary separation of the harvesting machine of the samples of the 20th century, metal bars were used as the working surface of bar elevators. The results of the studies presented by the scientists above indicate that viscosity depends on the composition of the soil and its moisture content. The methodology for conducting studies of soil viscosity is carried out as follows.

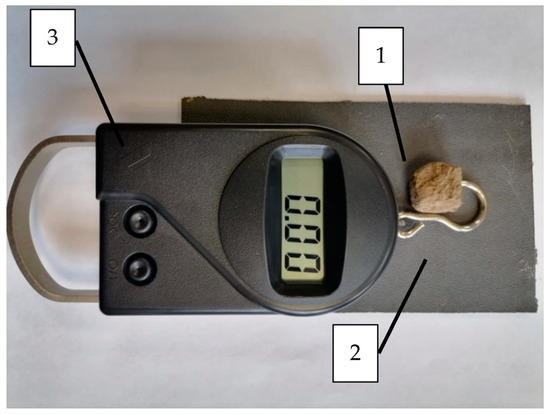

Soil samples (made in the form of a cube with an edge length of 3 cm) most suitable for potato cultivation (chernozem, sandy loam, and light loam) were prepared to the required soil moisture when it was fixed with a moisture meter “Soil Moisture meter MC-7828 Soil” (Figure 6) to the state: W = 10, 15, 20, 25, and 30%.

Figure 6.

General view of the moisture meter “Soil Moisture meter MC-7828 Soil”.

Next, the prepared samples 1 were installed on a plate 2 composed of a polymer material (Stern-PVC coating), 10 × 10 cm in size, with their fixation by the locking element of the adhesionometer 3 (Figure 7) and determining the limiting force of sticking of wet soil to the plate with digital control of the AMC-2.

Figure 7.

General view of experimental studies of soil viscosity: 1—soil sample; 2—polymer plate; 3—adhesion meter AMC-2.

Technical characteristics of the moisture meter and adhesion meter are presented in Table 1 and Table 2.

Table 1.

Technical characteristics of the moisture meter “Soil Moisture meter MC-7828 Soil”.

Table 2.

Technical characteristics of the electronic adhesive meter AMTs-2.

3. Results and Discussion

3.1. Results of Studies on Soil Viscosity

The results of soil viscosity studies are presented in Table 3.

Table 3.

Results of studies of soil viscosity.

The experiments were carried out in triplicate for each type of soil (Table 4).

Table 4.

Results of statistical processing of experimental studies.

The reliability of the conducted studies was assessed with the calculated value of the mathematical expectation , the normal law of distribution:

Student’s distribution quantile:

3.2. Results of Studies on Dynamic Effects on Soil Clods

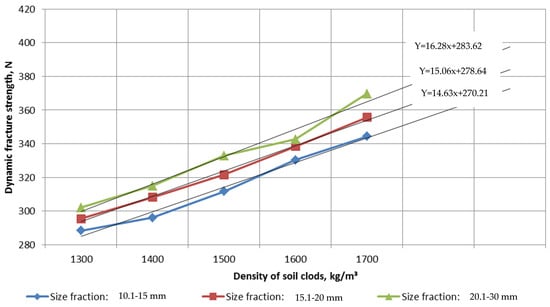

The results of the experimental studies of the dynamic impact on soil clods are presented as well as in the form of a graphical dependence in Figure 8.

Figure 8.

Dependence of the dynamic destruction of soil clods on density and fractions, standard error 1.12; error variance, 1.16.

The research results presented in Figure 8 indicate that an increase in the density of the soil clod leads to an increase in the effort expended on dynamic destruction, regardless of the size fraction.

Within one fractional group, the increase in force from the minimum value necessary for the destruction of the soil clod in the density range from 1300 to 1700 kg/m3 averages 56–67 N.

However, there is a tendency to increase the force for the destruction of the soil clod with an increase in the size fraction, including identical density, by 7–8 N, which is 4–5% of the initial value of the destruction force of a given density.

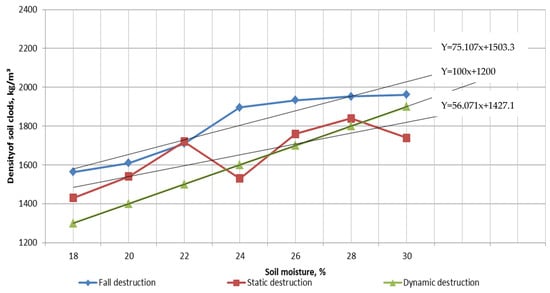

Figure 9 shows the normalized boundaries of the destruction of the soil clods of the studied density and moisture at static (soil hardness tester «Wile Soil») and dynamic (simulator of dynamic impact) impacts without limiting the injury rate of tubers.

Figure 9.

The dependence of the destruction of soil clods on density and moisture, standard error 1.08; error variance, 1.14.

The p-values of the models for dynamic clod breaking were less than 0.01, and the p-values for misfit conditions were greater than 0.05. The coefficients of determination of dynamic clod breakage versus density and fractions (Figure 8) were 0.9214 and 0.9643 for clod breakup versus density and moisture content (Figure 9), respectively, indicating that the optimized model was extremely significant and a good fit, and the model is reliable.

3.3. Results of Studies of the Movement of Potato Tubers of Various Varieties on the Surface of the Separating Devices of the Harvester When Interacting with Soil Impurities

To determine the empirical dependence of the movement of potato tubers of various varieties on the surface of the separating devices of a harvesting machine when interacting with soil impurities of varying physical and mechanical composition, it is necessary to conduct studies to determine the time spent by marketable products of potato tubers on the separating surface of a rod elevator, which leads to an increase in the quality of cleaning tubers in the view of increasing the intervals for a discrete comparison of soil impurities with the slotted holes of the rod elevator. The studies were carried out on the laboratory setup shown in Figure 2.

The research methodology involves the formation of the required fractional composition of the tuberous heap with different varieties of potato tubers: varieties “Red Scarlet”, ”Gala”, and “Nevsky” with a ratio of soil moisture in the range of 20 and 25% on chernozem soils and light loam.

The fractional composition of the tuberous heap consisted of soil, potato tubers, and plant impurities, and the mass ratio of the components in the heap by weight was 4:1:0.5, respectively.

Next, the separating rod elevator was switched on by connecting the electric motor to the AC network, and we achieved a translational speed of the web from 1.2 to 1.6 m/s, fixed the time of passage of the entire mass of tubers onto the tarpaulin of the separated products, and recorded the completeness of cleaning from mechanical impurities.

The choice of this range of speed of the rod elevator is due to the prevention of unloading of the tuberous heap on the surface of the rod elevator directly during combine harvesting, since in order to eliminate this negative impact, it is necessary to exceed this component over the forward speed of the harvester by 1.2 times.

The mass of the heap was calculated with the formula:

where is the supply of the tuberous heap, kg/s; and is the translational speed of the rod elevator, m/s.

In accordance with the research program, the purpose of the experiment was to determine the completeness of the separation of the heap of potatoes and damage to the tubers P.

Determining the completeness of the separation for each second of the presence of tubers on the rod elevator, the extraction of soil from the tray 4 for collecting impurities was determined (Figure 10). Damage to the tubers was determined by fixing and removing them from the tarpaulin 5 of the separated products when determining the studied indicator according to the formulas below. The completeness of separation of a heap of root crops and potatoes is determined with the formula:

where is the mass of soil impurities in the initial heap, kg; and is the mass of non-isolated soil impurities, kg.

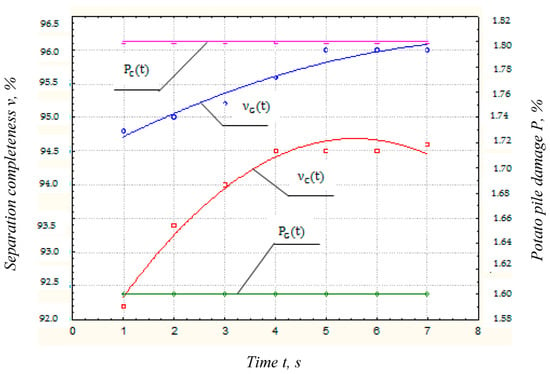

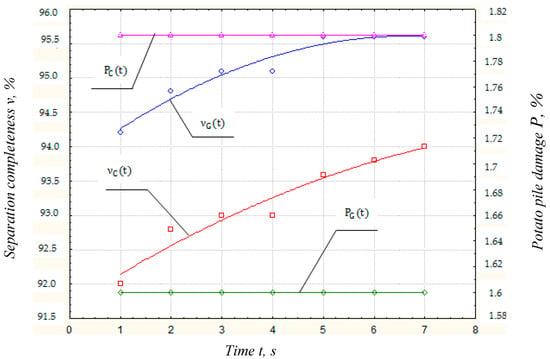

Figure 10.

Dependence of the completeness of separation ν, % and damage to tubers P, % on the time of exposure of potato tubers of the Gala variety on the separating surface at soil moisture W = 20% (chernozem and loam): standard error 1.14; error variance, 1.24.

Damage on a functioning element of a machine for harvesting root crops and potatoes is determined with the formula:

where is the mass of damaged standard potato tubers in a heap, kg; and is the mass of the total number of potato tubers in a heap, kg.

The pattern of movement of the components of the tuberous heap of potato variety “Gala” on the separating surface at soil moisture W = 20% is determined with the system of expressions:

According to the empirical dependence presented, it follows that the completeness of cleaning during the heap separation process changes according to a quadratic dependence in view of the sifting of soil particles on the working surface of the elevator when the damage to potato tubers for the studied varieties changes from 1.6 to 1.8%, which is due to colloidal adhesion particles of black earth soil with elevator bars and, consequently, less damage.

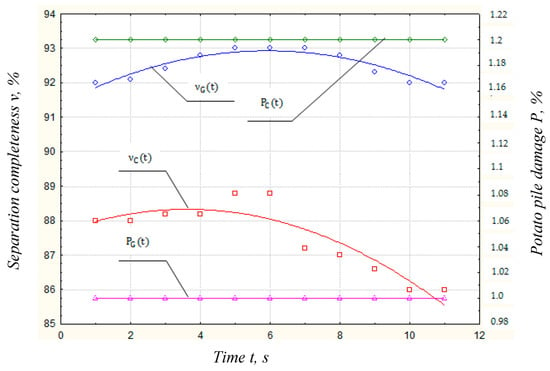

In the dependence of the movement of a heap of potato tubers of the Gala variety with a soil moisture content of not more than 25%, shown in Figure 11, this allows us to conclude that the time for the gathering of potato tubers increases according to the pattern of changes in cleaning quality indicators:

Figure 11.

Dependence of the completeness of separation ν, % and damage to tubers P, % on the time of exposure of potato tubers of the Gala variety on the separating surface at soil moisture W = 25% (chernozem and loam): standard error 1.14; error variance, 1.23.

The empirical dependence of the change in the quality indicators of the cleaning of the tuberous heap, represented by expression (8) in terms of the completeness of separation, has a parabolic dependence; the amount of damage to the tubers remains constant throughout the process (Figure 12).

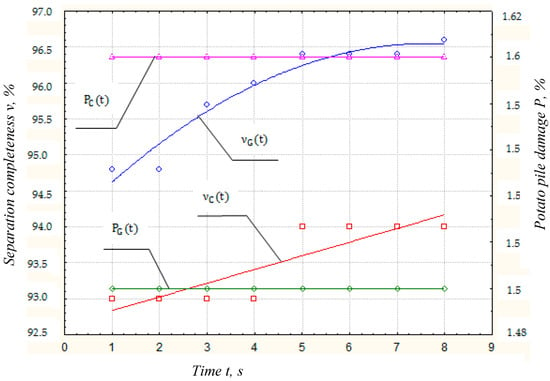

Figure 12.

The dependence of the completeness of separation ν, % and damage to tubers P, % on the time of exposure of potato tubers of the “Nevsky” variety on the separating surface at soil moisture W = 20% (chernozem and loam): standard error 1.15; error variance, 1.26.

The change in the residence time of the separated tuberous heap on the cleaning device is due to a decrease in the coefficient of friction of potato tubers with the working surface of the separated device in view of the excellent size and mass characteristics of potato tubers of the Nevsky variety and, consequently, a change in the quality indicators of cleaning and movement of tubers in accordance with the empirical dependence:

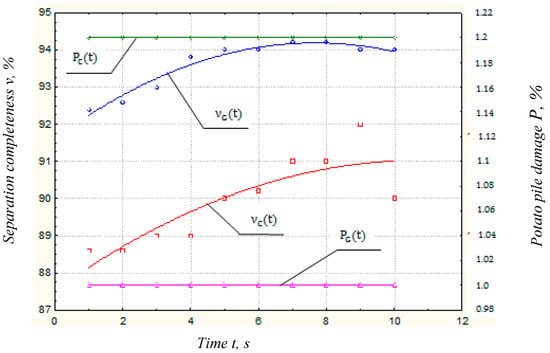

The graphical dependence of the movement of potato tubers of the Nevsky variety on the separating surface at soil moisture W = 25% (chernozem and loam) is shown in Figure 13.

Figure 13.

Dependence of the completeness of separation ν, % and damage to tubers P, % on the time of exposure of potato tubers of the “Nevsky” variety on the separating surface at soil moisture W = 25% (chernozem and loam): standard error 1.12; error variance, 1.22.

Interpretation of the graphs shown in Figure 13 allows us to conclude that the decrease in the completeness of separation of potato tubers of the Nevsky variety from loamy soils is on average lower than from chernozems by 4–6%, which is explained by the increased adhesion of soil particles both with potato tubers and directly with the bars of the elevator.

This leads to a decrease in the coefficient of rolling friction between the tubers and the working surface of the web and, as a result, to a decrease in their movement and the quality of cleaning, the dependence of which is represented by the expression (10):

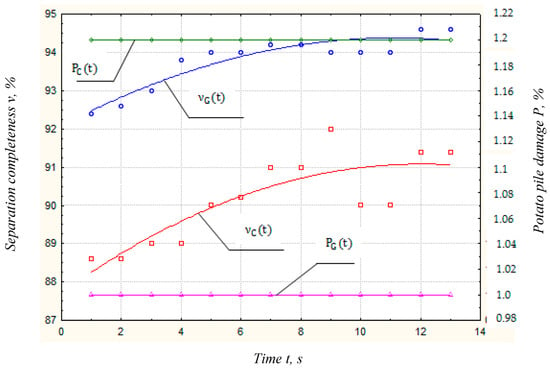

Changes in the quality indicators of cleaning potato tubers of the “Red” variety “Scarlet“ display the graphic dependence shown in Figure 14, which allows us to conclude that the change in the size and mass characteristics of potato tubers and their varietal affiliation (“Nevsky”, “Gala” and “Red Scarlet”) under identical soil harvesting conditions (physical and mechanical soil properties) leads to a wide range of variation in the quality indicators of cleaning commercial products from mechanical impurities.

Figure 14.

Dependence of the completeness of separation ν, % and damage to tubers P, % on the exposure time of potato tubers of the Red Scarlet variety on the separating surface at soil moisture W = 20% (chernozem and loam): standard error 1.15; error variance, 1.23.

The pattern of changes in the quality indicators of cleaning potato tubers of the variety “Red Scarlet“ at a soil moisture content of 20% is determined with the system of expressions (11):

However, even within the same variety “Red Scarlet“ with a change in soil moisture up to 25%, there is a tendency to increase the time for potato tubers to leave the separating surface up to 13 s, which is 5 s more than at 20% soil moisture and also 6 s higher than the time spent by the varieties “Gala” and “Nevsky” at the studied values of soil moisture (Figure 15).

Figure 15.

Dependence of the completeness of separation ν, % and damage to tubers P, % on the exposure time of potato tubers of the Red Scarlet variety on the separating surface at soil moisture W = 25% (chernozem and loam): standard error 1.12; error variance, 1.19.

The empirical dependence of the change in the quality indicators of cleaning potato tubers on the completeness of separation has a pronounced identical dependence on various physical and mechanical properties of the soil with a fundamental difference in the completeness of separation of chernozem soils by 4% higher than loamy soils:

The descent of potato tubers of the studied varieties from the rod elevator at identical forward speeds and different properties of mechanical impurities at different time intervals is due to the processes of soil interaction with the working surface of the cleaning devices, and in one case, the soil acts as a “conductive” material (soil moisture W = 25%), and the tubers slide over its surface due to sticking of the inter-bar spacing; the separation quality deteriorates.

In another case, the soil performs the function of a “conductor” until the moment of the greatest passage through the grates of the elevator (soil moisture W = 20%)—the quality of separation increases in accordance with the increase in damage to the potato tubers and a decrease in the passage time of the separated mass.

In addition, the change in the time of convergence from the rod elevator of the tubers of the varieties “Red Scarlet“, “Gala”, and “Nevsky” with identical physical and mechanical properties of the soil and the parameters of the movement of the canvas is due to differences in their size–mass characteristics, the values of which are presented above.

4. Conclusions

The results of the experimental studies on the influence of the physical and mechanical properties of an elastoplastic material (clods of soil and potato tubers) on the factors of its destruction when interacting with an absolutely solid body (separating working body) were obtained, and it is established that an increase in the density of a soil clod leads to an increase in the effort expended to dynamic fracture regardless of the size fraction. Within one fractional group, the increase in force from the minimum value necessary for the destruction of the soil clod in the density range from 1300 to 1700 kg/m3 is on average 56–67 N. However, there is a tendency to increase the effort to destroy the soil clod with an increase in the size fraction, including identical density, by 7–8 N, which is 4–5% of the initial value of the destruction force of a given density.

The greatest destruction of soil clods is provided at a moisture content of 22–24%, which should be explained by the formation of the physical ripeness of the leached chernozem. In addition, a decrease in soil moisture leads to a more intense adhesion of soil particles to each other and, consequently, to an increase in the force on the soil clod to destroy it.

- On heavy soils with high humidity, the use of destructive devices using the static compression method is also impractical. In addition, due to the fact that the size and shape of tubers are significant factors in the design of separation devices, which should include the length (Lc), height (Hc), and thickness (Tk) of the tuber, studies of the size–mass characteristics of tubers were carried out on potatoes of three different varieties: “Red Scarlet”, “Nevsky”, and “Gala”.

- An empirical dependence of the movement of potato tubers of various varieties on the surface of the separating devices of a harvesting machine was obtained when interacting with soil impurities that varied in physical and mechanical composition. It was found that the change in the time of convergence from the rod elevator of tubers of the varieties “Gala” and “Nevsky” with identical physical and mechanical soil properties and web movement parameters is due to differences in their size and mass characteristics, and it was also found that the descent of potato tubers of the studied varieties from the rod elevator at identical forward speeds and different properties of mechanical impurities at different time intervals is due to the processes of soil interaction with the working surface of the cleaning devices.

Author Contributions

Conceptualization, A.S., A.D. and O.D.; methodology, A.A. and M.G.; software, N.S. and M.G.; validation, A.S.; investigation, A.S.; resources, M.M.; writing—original draft preparation, M.G.; writing–review and editing, A.S.; project administration, A.S.; funding acquisition, N.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was carried out with the financial support of the Russian Science Foundation of the 2022 contest “Conducting research by scientific groups led by young scientists” of the Presidential Program of research projects implemented by leading scientists, including young scientists No. 22-76-10002.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors without undue reservation.

Conflicts of Interest

The authors declare they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Byshov, N.V.; Yakutin, N.N.; Koveshnikov, R.Y.; Rodionov, V.V.; Serzhantov, N.V.; Smirnov, P.S. Modernization of the KST-1.4 digger. Bull. Ryazan State Agrotechnol. Univ. Named V.I. P.A. Kostychev 2016, 75–78. Available online: http://vestnik.rgatu.ru/archive/2016_2.pdf (accessed on 27 July 2023).

- Dai, F.; Guo, X.H.; Zhao, W.Y.; Xin, S.L.; Liu, X.L.; Wu, Z.W. Design and experiment of canvas belt combined operation machine for potato digging and plastic film collecting. Trans. CSAM 2018, 3, 104–113. [Google Scholar]

- Wang, L.; Liu, F.; Wang, Q.; Zhou, J.; Fan, X.; Li, J.; Zhao, X.; Xie, S. Design of a Spring-Finger Potato Picker and an Experimental Study of Its Picking Performance. Agriculture 2023, 13, 945. [Google Scholar] [CrossRef]

- Shi, Y.; Yan, S.; Zhu, R.; Li, J.; Huang, S.; Liu, Y. Development and experiment of a small potato picker. Arid Reg. Agric. Res. 2016, 4, 287–298, 287–291+298. [Google Scholar]

- Xiao, W.; Gao, Y.; Chen, H.; Zhang, Y. Design and experiment of small potato picking and grading machine. Agric. Mech. Res. 2019, 12, 130–134. [Google Scholar]

- Hu, Q.; Xiao, W. Design and test of an integrated potato picking and grading harvester. Agric. Mech. Res. 2021, 11, 110–114. [Google Scholar]

- Dorokhov, A.; Didmanidze, O.; Aksenov, A.; Sibirev, A.; Sazonov, N.; Mosyakov, M.; Godyaeva, M. The Results of Studies on the Assessment of the Destruction of Soil Clods during Combine Harvesting of Potatoes. Agriculture 2022, 12, 2024. [Google Scholar] [CrossRef]

- Dorokhov, A.; Aksenov, A.; Sibirev, A.; Mosyakov, M.; Sazonov, N.; Godyaeva, M. Evaluation of Comparative Field Studies for Root and Onion Harvester with Variable Angle Conveyor. Agriculture 2023, 13, 572. [Google Scholar] [CrossRef]

- Dorokhov, A.S.; Sibirev, A.V.; Aksenov, A.G. Results of field studies on the separation of a heap of onion sets on a bar ele-vator with asymmetrically installed shakers. Eng. Technol. Syst. 2020, 1, 133–149. [Google Scholar]

- Bentini, M.; Caprara, C.; Martelli, R. Harvesting damage to potato tubers by analysis of impacts recorded with an instrumented sphere. Biosyst. Eng. 2006, 94, 75–85. [Google Scholar] [CrossRef]

- Akdemir, B.; Ulger, P.; Arin, S. Mechanized panting and harvesting of onion. Agric. Mech. Asia 1993, 24, 23–26. [Google Scholar]

- Mendoza, F.; Lu, R.; Cen, H. Grading of apples based on firmness and soluble solids content using Vis/SWNIR spectroscopy and spectral scattering techniques. J. Food Eng. 2014, 125, 59–68. [Google Scholar] [CrossRef]

- Böl, M.; Seydewitz, R.; Leichsenring, K.; Sewerin, F. A phenomenological model for the inelastic stress–strain response of a potato tuber. J. Mech. Phys. Solids 2020, 137, 94–103. [Google Scholar] [CrossRef]

- Pasaman, B.; Zakharchuk, V. The determination of the parameters of a plowshare-rotorting potato digger. ECOTECHMOD Int. Q. J. 2012, 1, 43–47. [Google Scholar]

- El-Rahman, A.; Magda, M. Development and performance evaluation of a simple grading machine suitable for onion sets. J. Soil Sci. Agric. Eng. Mansoura Univ. 2011, 2, 213–226. [Google Scholar] [CrossRef]

- Khura, T.; Mani, I.; Srivastava, A. Design and development of tractor-drawn onion (Allium cepa) harvester. Indian J. Agric. Sci. 2011, 6, 528–532. [Google Scholar]

- Indraja, D.; Ajkhilesh, J.; Vishal, P.; Amarsingh, P.; Ashutosh, D. A Review paper based on Design and Development of An Onion Harvesting Machine. J. Inf. Comput. Sci. 2019, 9, 333–337. [Google Scholar]

- Bachche, S. Deliberation on Design Strategies of Automatic Harvesting Systems: A Survey. Robotics 2015, 4, 194–222. [Google Scholar] [CrossRef]

- Bachche, S.; Oka, K. Modeling and performance testing of end-effector for sweet pepper harvesting robot. J. Robot. Mechatron. 2013, 25, 705–717. [Google Scholar] [CrossRef]

- Xiong, P.Y.; Lin, X.; Wang, Y.; Shen, S.B. Simulation of southern potato grader based on adams. INMATEH—Agric. Eng. 2016, 1, 5–13. [Google Scholar]

- Leblicq, T.; Smeets, B.; Vanmaercke, S.; Ramon, H.; Saeys, W. A discrete element approach for modelling bendable crop stems. Comput. Electron. Agric. 2016, 124, 141–149. [Google Scholar] [CrossRef]

- Zheng, W.X.; Lü, Z.Q.; Lu, Y.; Liu, Z.D.; Cheng, X.X. Shear properties test of sweet potato vine in mature period. Int. Agric. Eng. J. 2017, 26, 204–212. [Google Scholar]

- Zeng, L.; Cao, Y.; Zhong, X.; Wang, W.; Huang, W. Design of stem-leaf separation device for sugar canes. China Southern Agric. Mach. 2021, 52, 36–38. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).