Impact of Biochar Dose and Origin on Winter Wheat Grain Quality and Quantity

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

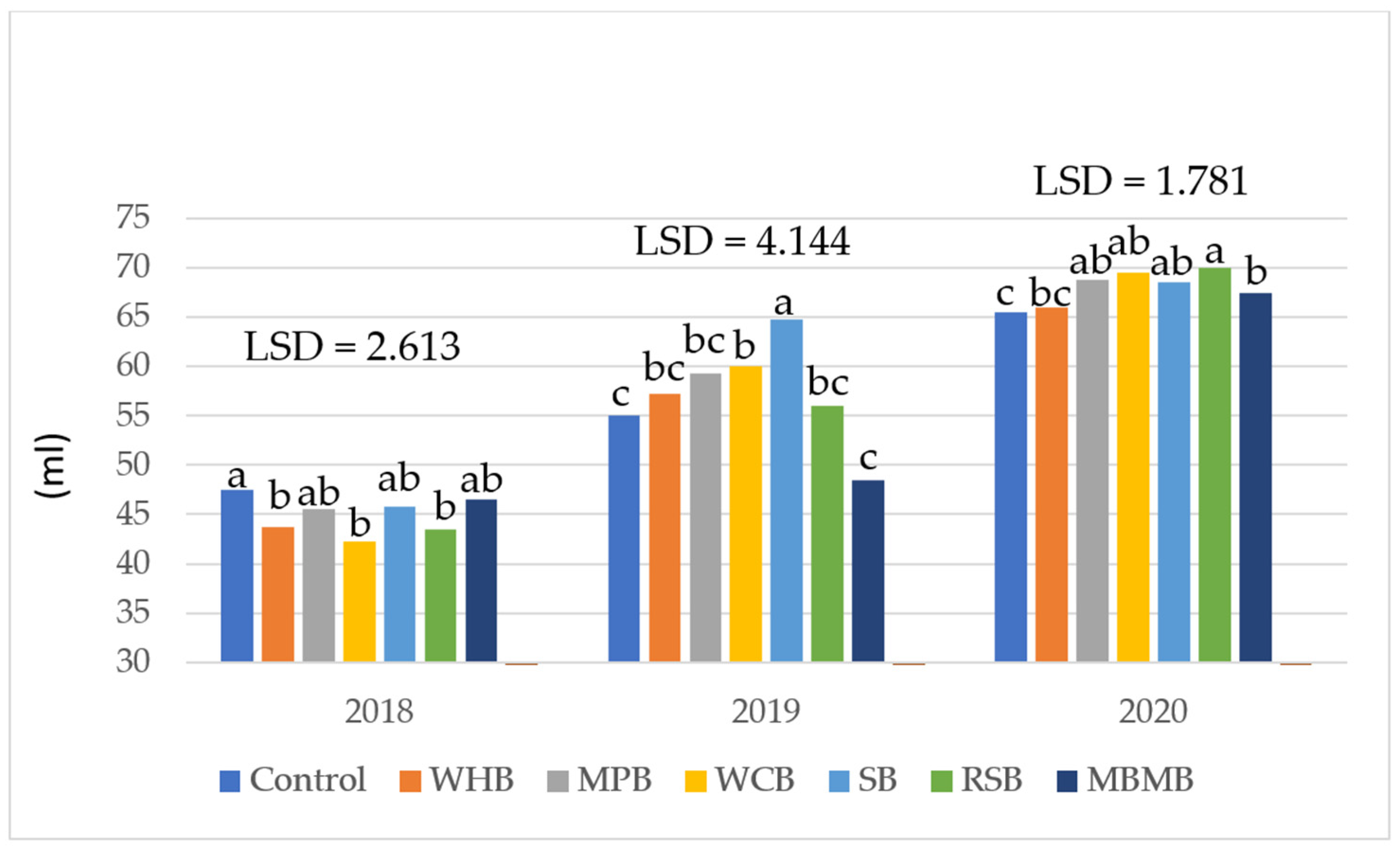

3.1. Winter Wheat Yields

3.2. Grain Characteristics

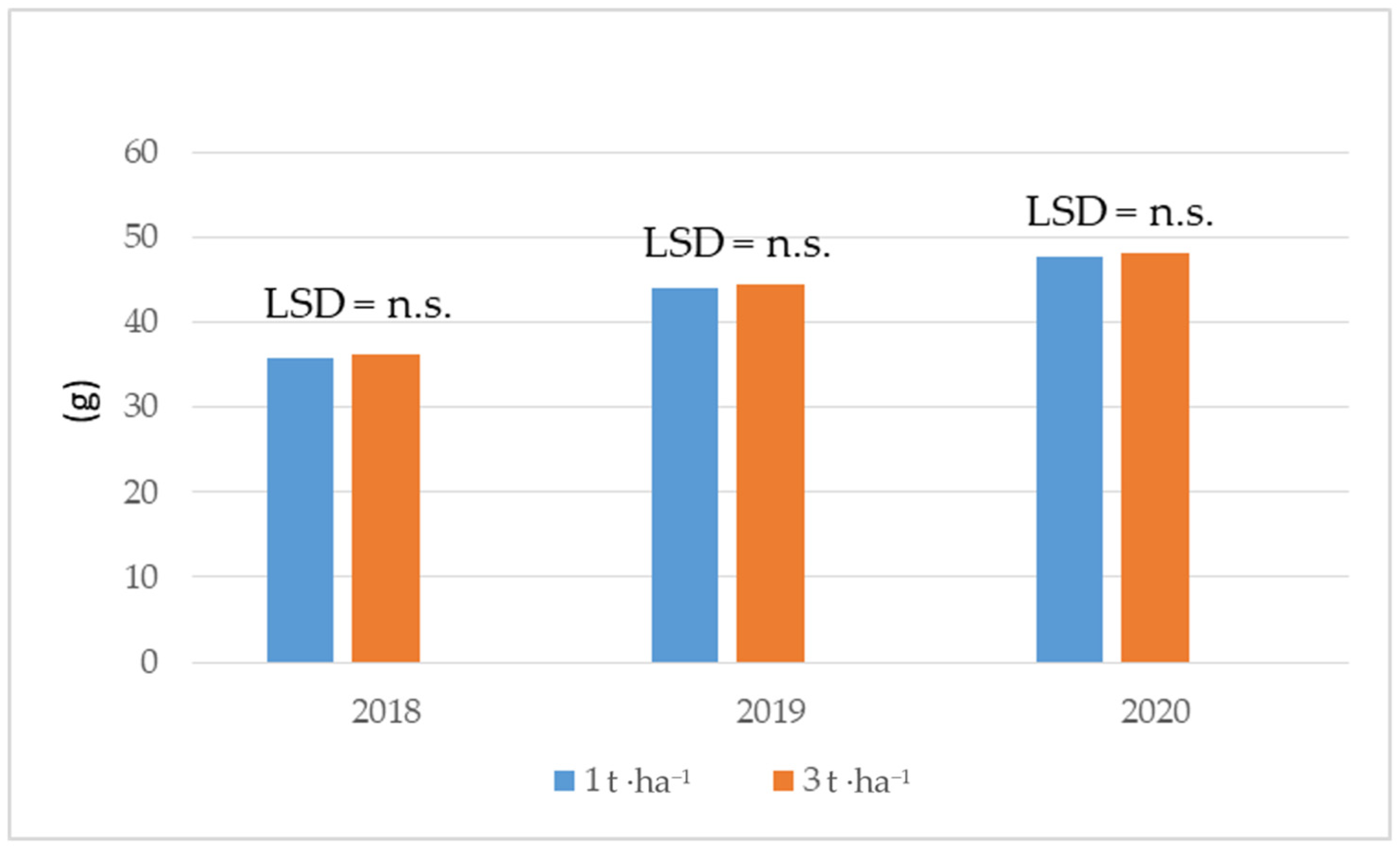

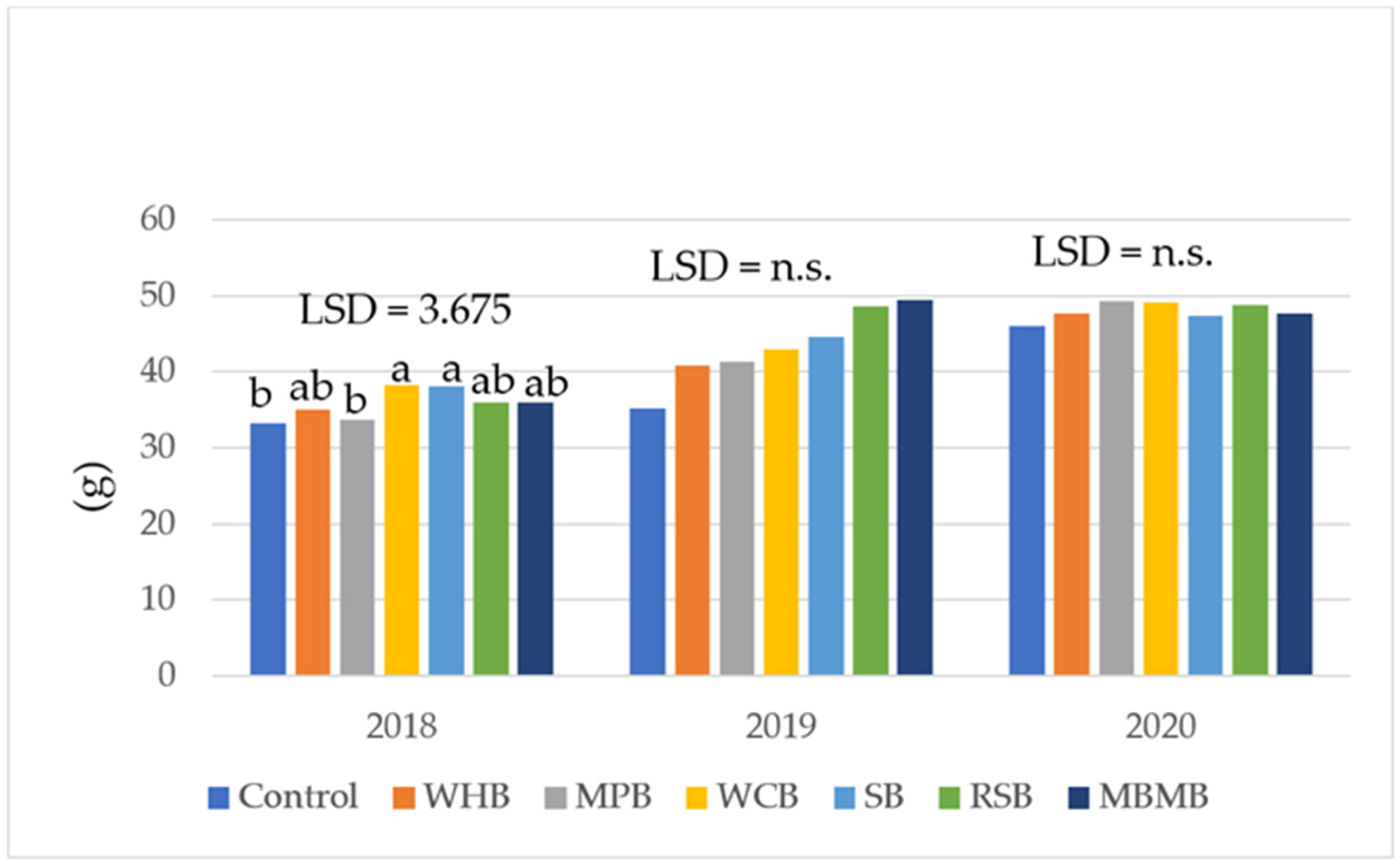

3.2.1. Mass of Thousand Grains

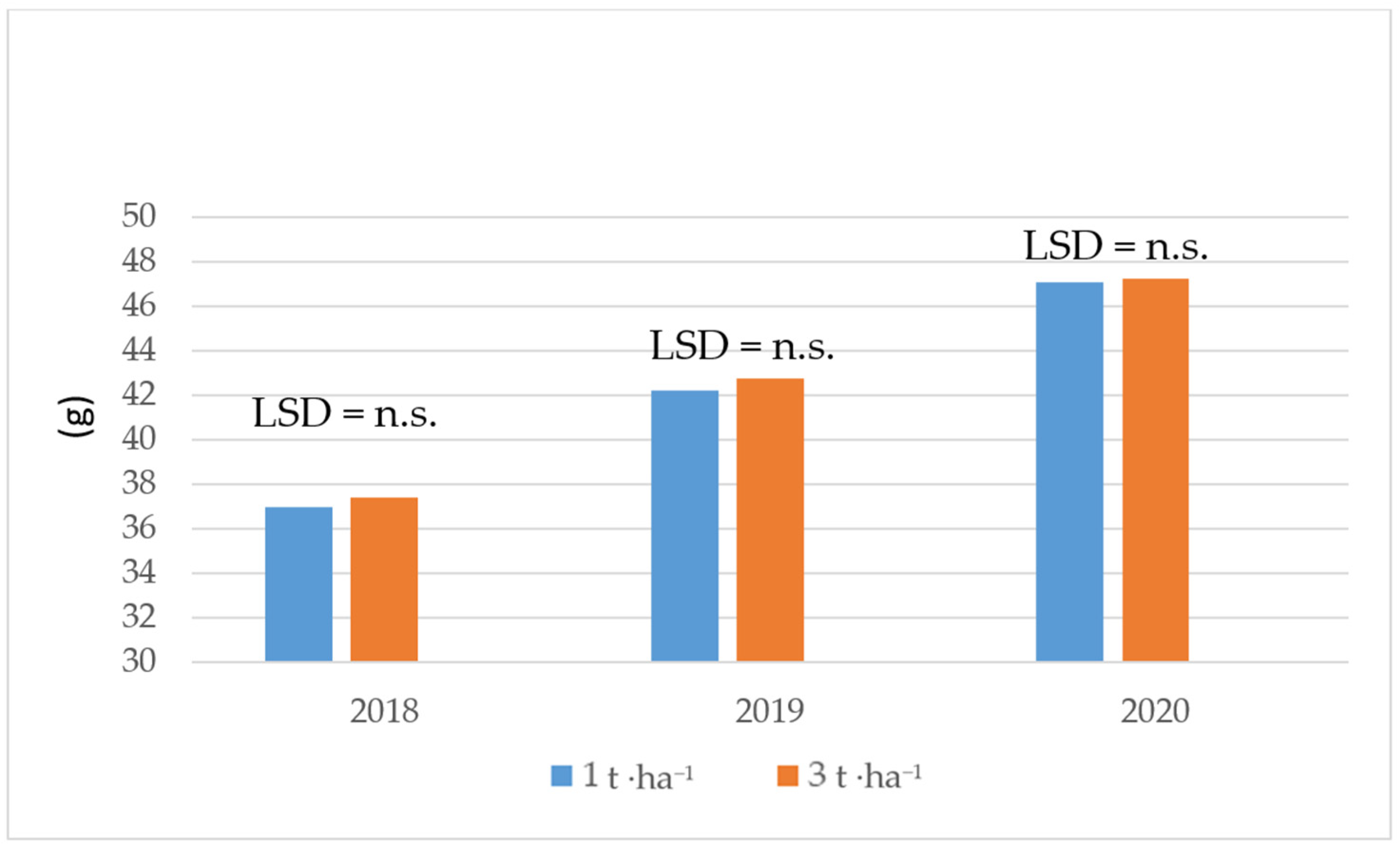

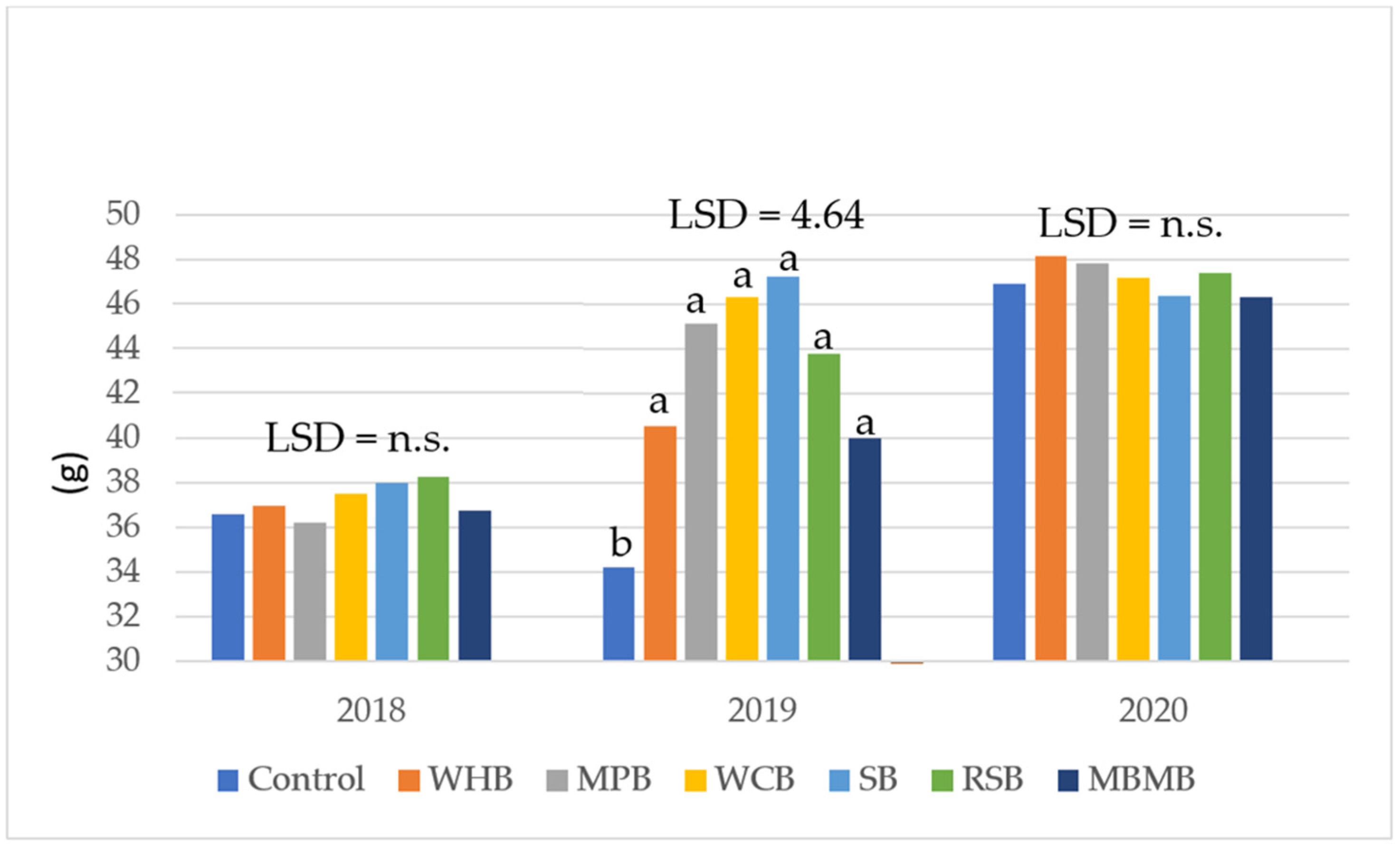

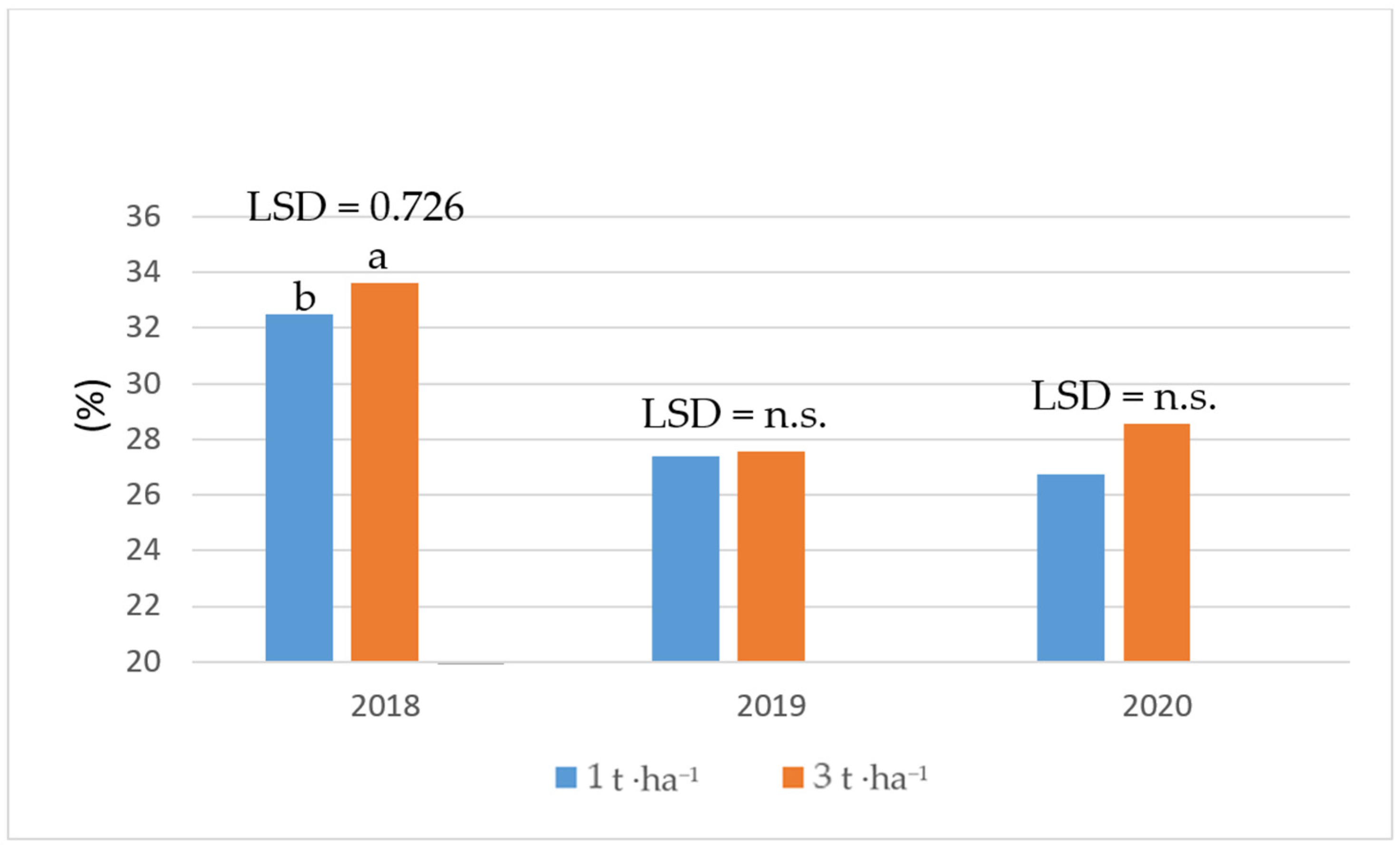

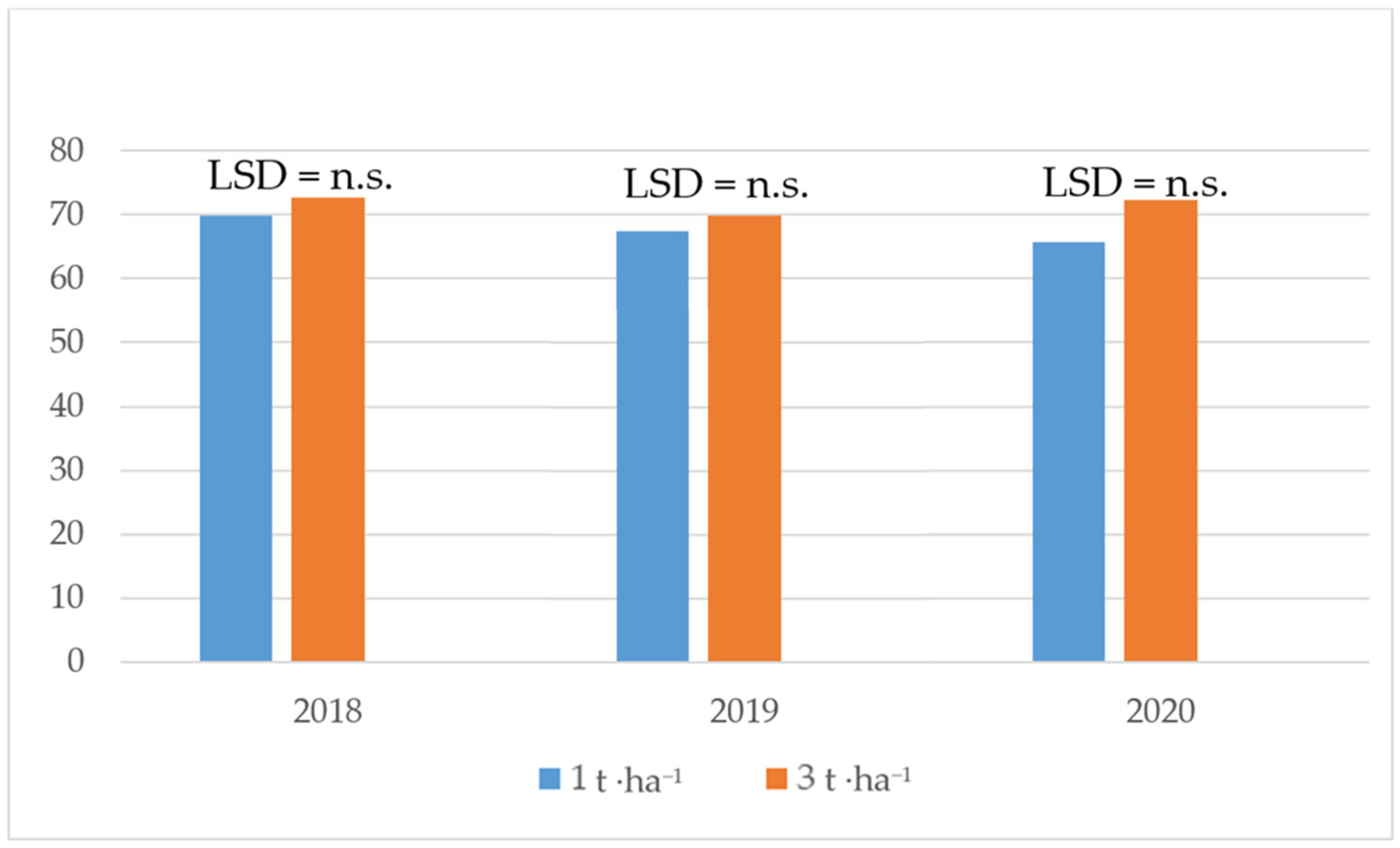

3.2.2. Wet Gluten Content and Gluten Index

3.2.3. Grain Falling Number and Sedimentation Index

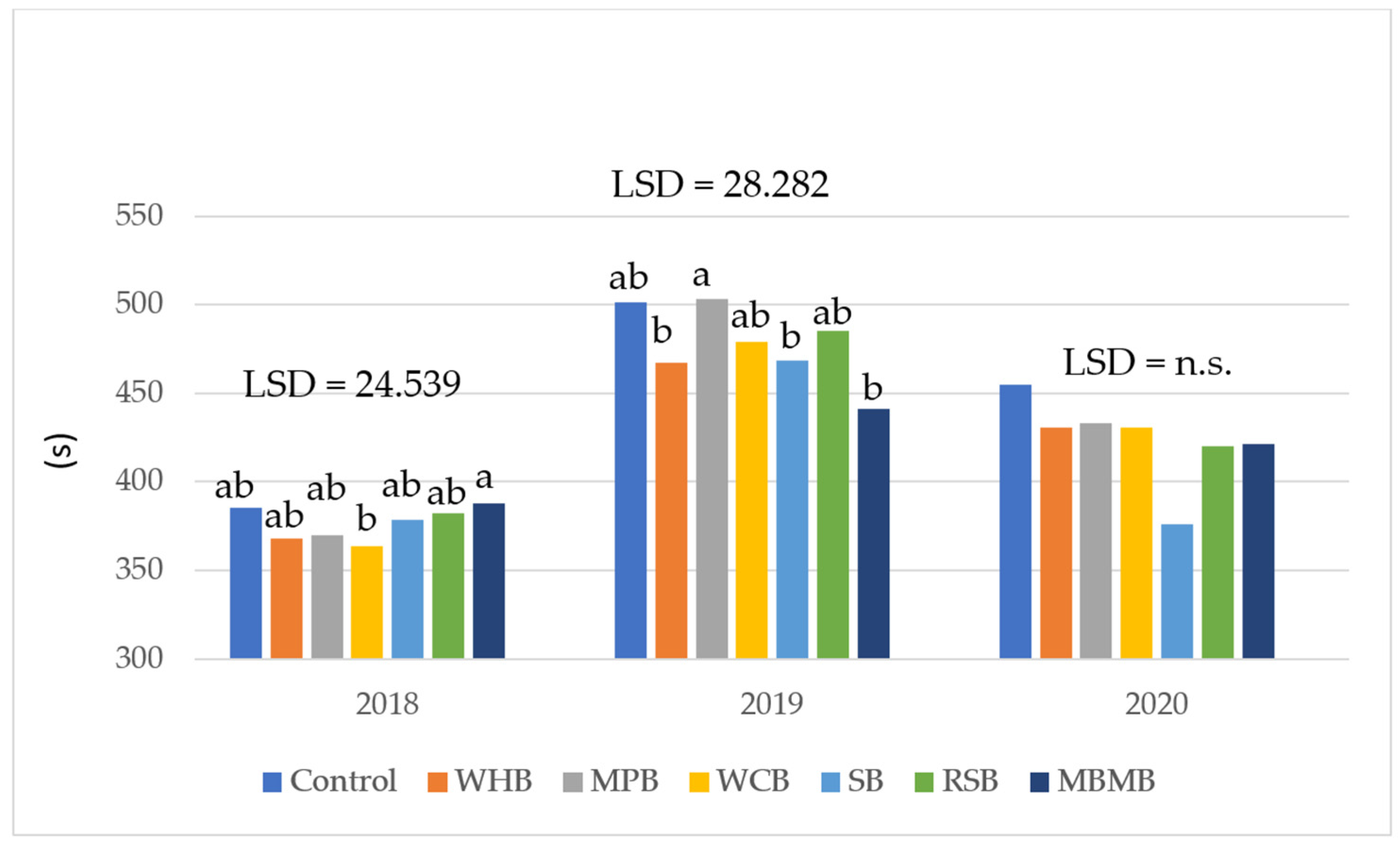

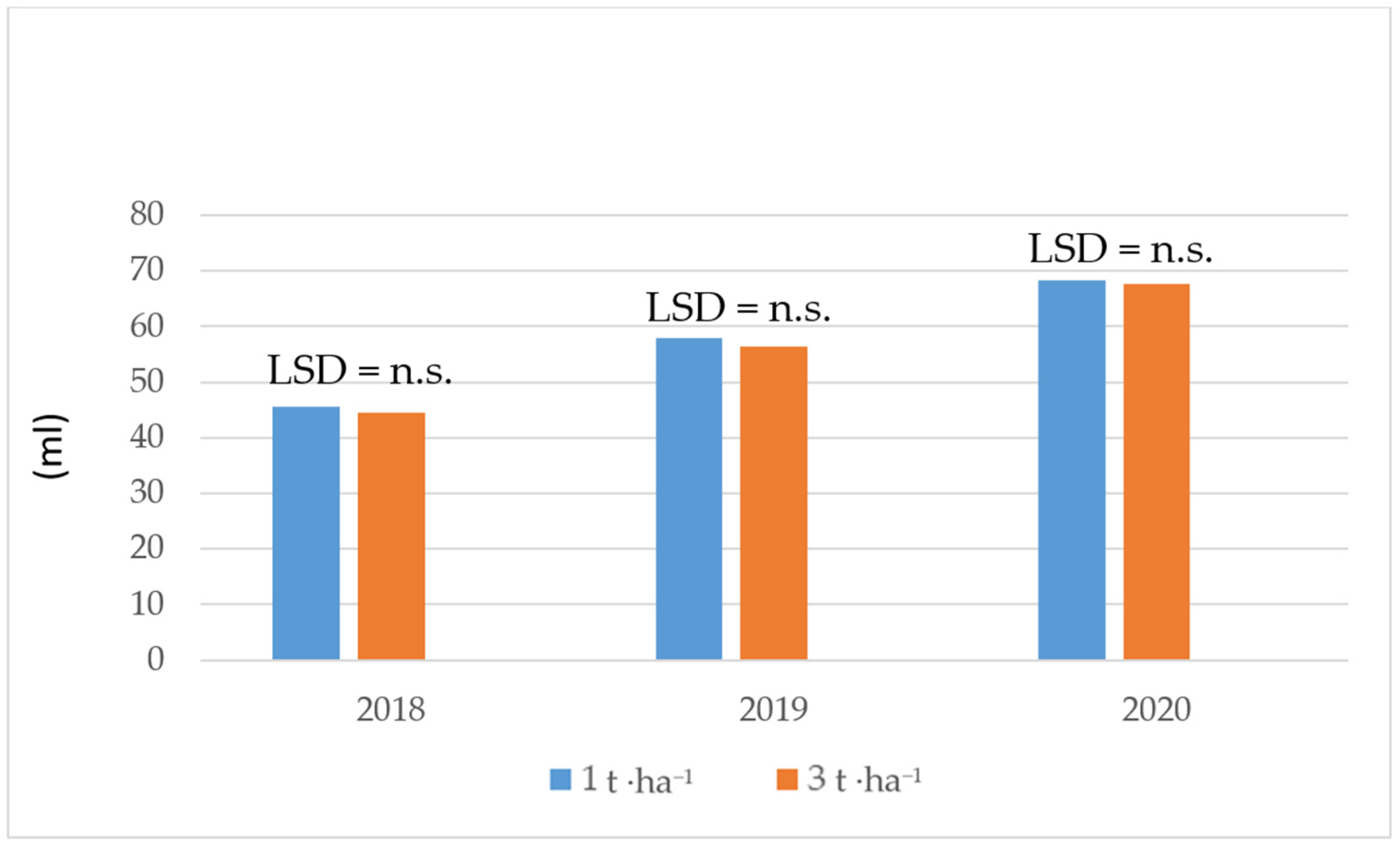

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Dijk, M.; Morley, T.; Rau, M.L.; Saghai, Y. A meta-analysis of projected global food demand and population at risk of hunger for the period 2010–2050. Nat. Food 2021, 2, 494–501. [Google Scholar] [CrossRef] [PubMed]

- Noel, S. Economics of Land Degradation Initiative: Report for Policy and Decision Makers_Reaping Economic and Environmental Benefits from Sustainable Land Management; ELD Initiative and Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH: Bonn, Germany, 2015; ISBN 978-92-808-6063-4. [Google Scholar]

- Dorling, D. World population prospects at the UN: Our numbers are not our problem? In The Struggle for Social Sustainability; Policy Press: Bristol, UK, 2021; pp. 129–154. [Google Scholar] [CrossRef]

- Ladha, J.; Pathak, H.; Krupnik, T.; Six, J.; van Kessel, C. Efficiency of fertilizer nitrogen in cereal production: Retrospects and prospects. Adv. Agron. 2005, 87, 85–156. [Google Scholar] [CrossRef]

- Anioł, A. Wpływ biotechnologii i procesów globalizacji w gospodarce na hodowlę roślin i wspierające ten sektor badania naukowe. Biul. IHAR 2010, 256, 3–13. [Google Scholar] [CrossRef]

- Maron, P.A.; Lemanceau, P. Soil as a support of biodiversity and functions. In Soil Carbon: Science, Management and Policy for Multiple Benefits; CABI: Wallingford, UK, 2015; pp. 141–153. [Google Scholar] [CrossRef]

- Adhikari, K.; Hartemink, A.E. Linking soils to ecosystem services—A global review. Geoderma 2016, 262, 101–111. [Google Scholar] [CrossRef]

- Alhameid, A.; Tobin, C.; Maiga, A.; Kumar, S.; Osborne, S.; Schumacher, T. Intensified agroecosystems and changes in soil carbon dynamics. In Soil Health and Intensification of Agroecosytems; Academic Press: Cambridge, MA, USA, 2017; pp. 195–214. [Google Scholar] [CrossRef]

- Garratt, M.P.; Bommarco, R.; Kleijn, D.; Martin, E.; Mortimer, S.R.; Redlich, S.; Senapathi, D.; Steffan-Dewenter, I.; Świtek, S.; Takács, V.; et al. Enhancing soil organic matter as a route to the ecological intensification of European arable systems. Ecosystems 2018, 21, 1404–1415. [Google Scholar] [CrossRef]

- Bahuguna, A.; Sharma, S.; Yadav, J. Effect of different organic sources on physical, chemical and biological properties of soil in inceptisols of Varanasi. Int. J. Plant Soil Sc. 2021, 33, 41–52. [Google Scholar] [CrossRef]

- Wyzinska, M.; Smreczak, B. The influence of type and rate of biochar on productivity of winter wheat. In Proceedings of the 2019 International Conference “Engineering for Rural Development”, Jelgava, Latvia, 22–24 May 2019; pp. 594–599. [Google Scholar] [CrossRef]

- European Green Deal. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions the European Green Deal. Publications Office of the European Union; COM/2019/640 Final. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM:2019:640:FIN (accessed on 20 November 2023).

- EBC. European Biochar Certificate—Guidelines for a Sustainable Production of Biochar; European Biochar Foundation (EBC): Arbaz, Switzerland, 2012–2022; Available online: http://european-biochar.org (accessed on 20 November 2023).

- Malińska, K. Prawne i jakościowe aspekty dotyczące wymagań dla biowęgla. Inżynieria Ochr. Sr. 2015, 18, 359–371. [Google Scholar]

- Bis, Z. Biowęgiel–powrót do przeszłości, szansa dla przyszłości. Czysta Energia 2012, 6, 28–31. [Google Scholar]

- Sanchez, M.E.; Lindao, E.; Margaleff, D.; Martinez, O.; Moran, A. Pyrolysis of agricultural residues from rape and sunflower: Production and characterization of bio-fuels and biochar soil management. J. Anal. Appl. Pyrolysis 2009, 85, 142–144. [Google Scholar] [CrossRef]

- Kwapinski, W.; Byrne, C.M.P.; Kryachko, E.; Wolfram, P.; Adley, C.; Leahy, J.J.; Novotny, E.H.; Hayes, M.H.B. Biochar from Biomass and Waste. Waste Biomass Valorization 2010, 1, 177–189. [Google Scholar] [CrossRef]

- Ibarrola, R.; Shackely, S.; Hammond, J. Pyrolysis biochar systems for recovering biodegradable materials: A life cycle carbon assessment. Waste Manag. 2012, 32, 859–868. [Google Scholar] [CrossRef] [PubMed]

- Song, W.; Guo, M. Quality variations of poultry litter biochar generated at different pyrolysis temperatures. J. Anal. Appl. Pyrolysis 2012, 94, 138–145. [Google Scholar] [CrossRef]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar physicochemical properties: Pyrolysis temperature and feedstock kind effects. Rev. Environ. Sci. Biotechnol. 2020, 19, 191–215. [Google Scholar] [CrossRef]

- Dai, Z.; Xiong, X.; Zhu, H.; Xu, H.; Leng, P.; Li, J.; Tang, C.; Xu, J. Association of biochar properties with changes in soil bacterial, fungal and fauna communities and nutrient cycling processes. Biochar 2021, 3, 239–254. [Google Scholar] [CrossRef]

- Razzaghi, F.; Obour, P.B.; Arthur, E. Does biochar improve soil water retention? A systematic review and meta-analysis. Geoderma 2020, 361, 114055. [Google Scholar] [CrossRef]

- Hossain, M.Z.; Bahar, M.M.; Sarkar, B.; Donne, S.W.; Ok, Y.S.; Palansooriya, K.N.; Kirkham, M.B.; Chowdhury, S.; Bolan, N. Biochar and its importance on nutrient dynamics in soil and plant. Biochar 2020, 2, 379–420. [Google Scholar] [CrossRef]

- Różyło, K.; Świeca, M.; Gawlik-Dziki, U.; Stefaniuk, M.; Oleszczuk, P. The potential of biochar for reducing the negative effects of soil contamination on the phytochemical properties and heavy metal accumulation in wheat grain. Agric. Food Sci. 2017, 26, 34–46. [Google Scholar] [CrossRef]

- Medyńska-Juraszek, A.; Rivier, P.A.; Rasse, D.; Joner, E.J. Biochar affects heavy metal uptake in plants through interactions in the rhizosphere. Appl. Sci. 2020, 10, 5105. [Google Scholar] [CrossRef]

- Nkoh, J.N.; Ajibade, F.O.; Atakpa, E.O.; Abdulaha-Al Baquy, M.; Mia, S.; Odii, E.C.; Xu, R. Reduction of heavy metal uptake from polluted soils and associated health risks through biochar amendment: A critical synthesis. J. Hazard. Mater. Adv. 2022, 6, 100086. [Google Scholar] [CrossRef]

- Różewicz, M.; Grabiński, J.; Wyzińska, M. Wpływ metody strip-till na plonowanie i jakośc ziarna pszenicy ozimej w zależności od odmiany i zakresu uprawy pożniwnej Część II. Jakość ziarna. Agron. Sci. 2023, 78, 19–28. [Google Scholar] [CrossRef]

- PN-68/R-74017; Cereals and Pulses—Determinationa of the Mass Od 1000 Grains. Polish Committee for Standardization: Warsaw, Poland, 1968.

- PN-EN ISO 3093:2010; Wheat, Rye and Flours Derived from Them—Durum Wheat and Semolina. Determination of Falling Number by the Hagberg-Perten Method. Polish Committee for Standardization: Warsaw, Poland, 2010.

- PN-A-74042-03:1993/Az1:1996; Cereal Grains and Cereal Products—Determination of Wet Gluten by Mechanical Equipment. Wheat Flour. Polish Committee for Standardization: Warsaw, Poland, 1996.

- PN-EN ISO 5529:2010; Wheat—Determination of Sedimentation Rate. Zeleny Test. Polish Committee for Standardization: Warsaw, Poland, 2010.

- Lilli, M.A.; Paranychianakis, N.V.; Lionoudakis, K.; Saru, M.L.; Voutsadaki, S.; Kritikaki, A.; Komnitsas, K.; Nikolaidis, N.P. Characterization and Risk Assessment of Different-Origin Biochars Applied in Agricultural Experiments. Sustainability 2023, 15, 9036. [Google Scholar] [CrossRef]

- Gebremedhin, G.H.; Halieselassie, B.; Berhe, D.; Belay, T. Effect of biochar on yield and yield components of wheat and post-harvest soil properties in Tigray, Ethiopia. J. Fertil. Pestic. 2015, 6, 2. [Google Scholar] [CrossRef]

- Khan, M.A.; Basir, A.; Fahad, S.; Adnan, M.; Saleem, M.H.; Iqbal, A.; Al-Huqail, A.A.; Alosaimi, A.A.; Saud, S.; Liu, K.; et al. Biochar optimizes wheat quality, yield, and nitrogen acquisition in low fertile calcareous soil treated with organic and mineral nitrogen fertilizers. Front. Plant Sci. 2022, 13, 879788. [Google Scholar] [CrossRef] [PubMed]

- Akhtar, S.S.; Andersen, M.N.; Liu, F. Residual effects of biochar on improving growth, physiology and yield of wheat under salt stress. Agric. Water Manag. 2015, 158, 61–68. [Google Scholar] [CrossRef]

- Ali, K.; Wang, X.; Riaz, M.; Islam, B.; Khan, Z.H.; Shah, F.; Munsif, F.; Haq, S.I.U. Biochar: An eco-friendly approach to improve wheat yield and associated soil properties on sustainable basis. Pak. J. Bot. 2019, 51, 1255–1261. [Google Scholar] [CrossRef]

- Dawar, K.; Fahad, S.; Alam, S.S.; Khan, S.A.; Dawar, A.; Younis, U.; Danish, S.; Datta, R.; Dick, R.P. Influence of variable biochar concentration on yield-scaled nitrous oxide emissions, Wheat yield and nitrogen use efficiency. Sci. Rep. 2021, 11, 16774. [Google Scholar] [CrossRef] [PubMed]

- Khan, Z.; Rahman, M.H.U.; Haider, G.; Amir, R.; Ikram, R.M.; Ahmad, S.; Schofield, H.K.; Riaz, B.; Iqbal, R.; Fahad, S.; et al. Chemical and biological enhancement effects of biochar on wheat growth and yield under arid field conditions. Sustainability 2021, 13, 5890. [Google Scholar] [CrossRef]

- Zhu, X.; Chen, L.; Kong, X.; Bao, S.; Wu, S.; Fang, L.; Shen, Y. Biochar alters the morphology of plant roots to enable optimized and reduced nitrogen fertilizer applications. Plant Soil 2023, 492, 655–673. [Google Scholar] [CrossRef]

- Billah, M.M.; Ahmad, W.; Ali, M.; Khan, F. Effect of biochar particle size and biofertilizers on lentil (Lense culinarous M.) yield and available fractions of soil nutrients. Soil Environ. 2018, 37, 143–151. [Google Scholar]

- Litke, L.; Gaile, Z.; Ruža, A. Effect of nitrogen fertilization on winter wheat yield and yield quality. Agron. Res. 2018, 16, 500–509. [Google Scholar] [CrossRef]

- Selivanovskaya, S.; Galitskaya, P.; Mukharamova, S.; Gordeev, A.; Kanunnikov, K. Biochar From Chicken Manure Enriched With Iodine. In Proceedings of the 19th International Multidisciplinary Scientific GeoConference SGEM, Albena, Bulgaria, 28 June–6 July 2019; pp. 59–66. [Google Scholar] [CrossRef]

- Shahzad, K.; Abid, M.; Sintim, H.Y.; Hussain, S.; Nasim, W. Tillage and biochar effects on wheat productivity under arid conditions. Crop Sci. 2019, 59, 1191–1199. [Google Scholar] [CrossRef]

- Kraska, P.; Andruszczak, S.; Oleszczuk, P.; Świeca, M.; Kwiecińska-Poppe, E.; Gierasimiuk, P.; Różyło, K.; Pałys, E. The content of elements and quality parameters of winter rye grain as influenced by biochar-amended soil. Zemdirbyste-Agric. 2018, 105, 11–20. [Google Scholar] [CrossRef]

- Gooding, M.J.; Kettlewell, P.S.; Davies, W.P.; Hocking, T.J. Effects of spring nitrogen fertilizer on the Hagberg falling number of grain from breadmaking varieties of winter wheat. J. Agric. Sci. 1986, 107, 475–477. [Google Scholar] [CrossRef]

- Silva, R.R.; Zucareli, C.; Fonseca IC, D.B.; Riede, C.R.; Gazola, D. Nitrogen management, cultivars and growing environments on wheat grain quality. Rev. Bras. Eng. Agrícola Ambient. 2019, 23, 826–832. [Google Scholar] [CrossRef]

- Barnard, A.; Smith, M.F. Determination of the influence of climate on falling number of winter wheat in the dryland production areas of the Free State Province of South Africa. Euphytica 2012, 188, 15–24. [Google Scholar] [CrossRef]

- Hrušková, M.; Škodová, V.; Blažek, J. Wheat sedimentation values and falling number. Czech J. Food Sci. 2004, 22, 51. [Google Scholar] [CrossRef]

- Knapowski, T.; Ralcewicz, M.; Spychaj-Fabisiak, E.; Ložek, O. Ocena jakości ziarna pszenicy ozimej uprawianej w warunkach zróżnicowanego nawożenia azotem. Fragm. Agron. 2010, 27, 73–80. [Google Scholar]

- Murawska, B.; Spychaj-Fabisiak, E.; Keutgen, A.; Wszelaczyńske, E.; Pobereży, J. Cechy technologiczne badanych odmian ziarna pszenicy ozimej uprawianych w warunkach Polski i Wielkiej Brytanii. Inżynieria Apar. Chem. 2014, 2, 96–98. [Google Scholar]

- Liana, A.; Alda, S.; Fora, C.; Diana, M.; Gogoasa, I.; Bordean, D.; Cârciu, G.; Cristea, T. Climatic conditions influence on the variation of quality indicators of some Romanian and foreign winter wheat cultivars. J. Hortic. For. Biotechnol. 2012, 16, 68–72. [Google Scholar]

- Stepien, A.; Wojtkowiak, K. Evaluation of the effect of different levels of nitrogen and manganese fertiliser on the yield, macronutrient content and technological properties of winter wheat. J. Elementol. 2019, 24, 661–675. [Google Scholar] [CrossRef]

- Nematian, M.; Keske, C.; Ng’ombe, J.N. A techno-economic analysis of biochar production and the bioeconomy for orchard biomass. Waste Manag. 2021, 135, 467–477. [Google Scholar] [CrossRef]

| Type of Biochar | Total Carbon (%) | N (%) | S (%) | P (%) | pH | Pyrolysis Temperature (°C) | Time of Pyrolysis (min) |

|---|---|---|---|---|---|---|---|

| WHB | 70.8 | 3.9 | 0.074 | 0.320 | 8.50 | 550 | nd 1 |

| MPB | 63.5 | 1.8 | 0.890 | 0.095 | 10.00 | 600 | nd |

| WCB | 67.6 | 2.4 | <0.100 | 0.330 | 6.79 | 500 | 4–7 |

| SB | 42.6 | 3.6 | 0.224 | 4.420 | 6.78 | 550 | 240 |

| RSB | 70.5 | 1.2 | 0.146 | 0.260 | 9.65 | 550 | 180 |

| MBMB | 75.6 | 1.9 | 0.136 | 0.120 | 8.32 | 550 | 240 |

| Month | 2017/2018 | 2018/2019 | 2019/2020 | 1981–2010 |

|---|---|---|---|---|

| IX | 14.1 | 15.5 | 14.4 | 13.3 |

| X | 9.5 | 10.0 | 10.8 | 8.0 |

| XI | 4.5 | 4.2 | 6.4 | 2.7 |

| XII | 2.4 | 0.9 | 3.1 | −1.4 |

| I | 0.6 | −2.4 | 1.7 | −3.3 |

| II | −3.5 | 2.9 | 3.4 | −2.3 |

| III | 0.3 | 5.7 | 4.7 | 1.6 |

| IV | 13.9 | 10.0 | 8.9 | 8.7 |

| V | 17.7 | 13.9 | 11.9 | 14.5 |

| VI | 19.6 | 22.7 | 19.1 | 17.2 |

| VII | 21.0 | 19.4 | 19.3 | 19.5 |

| VIII | 21.1 | 20.4 | 20.3 | 17.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wyzińska, M.; Berbeć, A.K.; Grabiński, J. Impact of Biochar Dose and Origin on Winter Wheat Grain Quality and Quantity. Agriculture 2024, 14, 39. https://doi.org/10.3390/agriculture14010039

Wyzińska M, Berbeć AK, Grabiński J. Impact of Biochar Dose and Origin on Winter Wheat Grain Quality and Quantity. Agriculture. 2024; 14(1):39. https://doi.org/10.3390/agriculture14010039

Chicago/Turabian StyleWyzińska, Marta, Adam Kleofas Berbeć, and Jerzy Grabiński. 2024. "Impact of Biochar Dose and Origin on Winter Wheat Grain Quality and Quantity" Agriculture 14, no. 1: 39. https://doi.org/10.3390/agriculture14010039