Parametric Design and Genetic Algorithm Optimization of a Natural Light Stereoscopic Cultivation Frame

Abstract

:1. Introduction

2. Materials and Methods

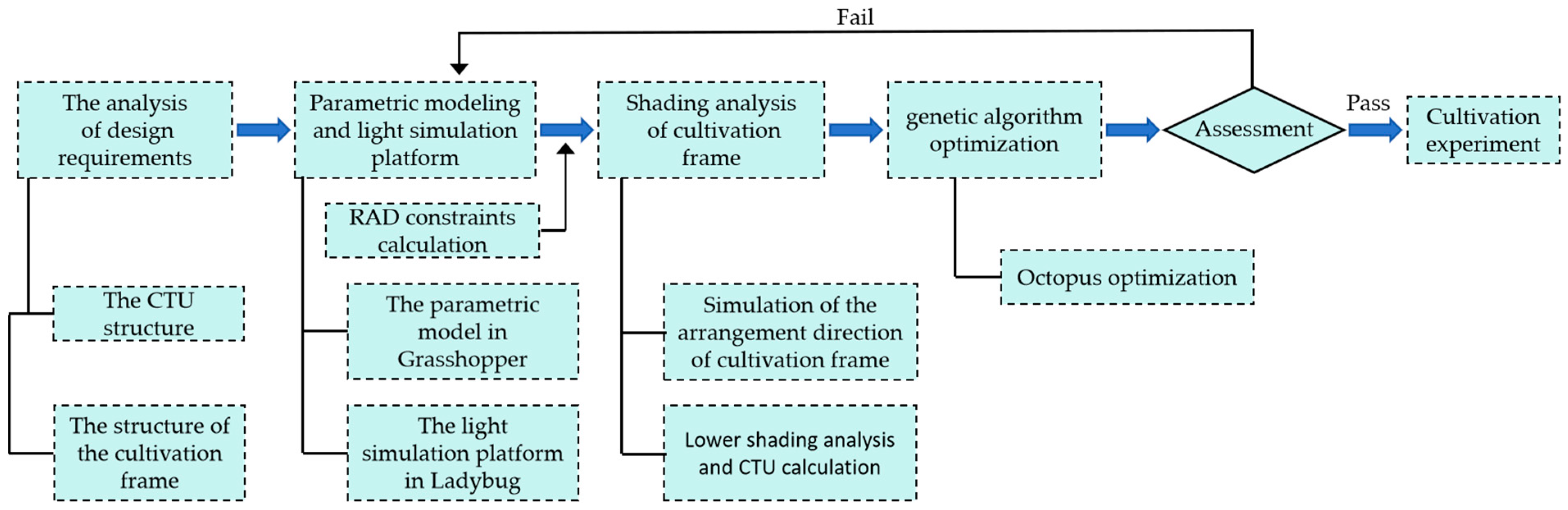

2.1. Research Processes

2.2. The Software and Design Requirement Analysis

2.2.1. Software

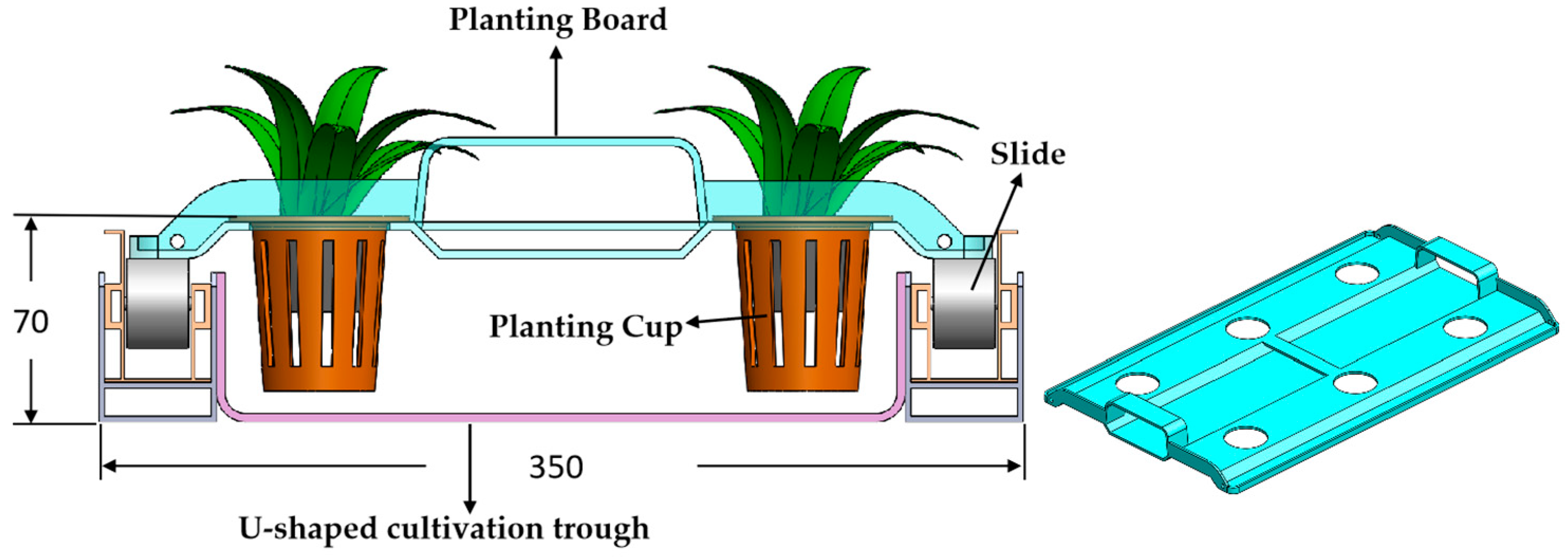

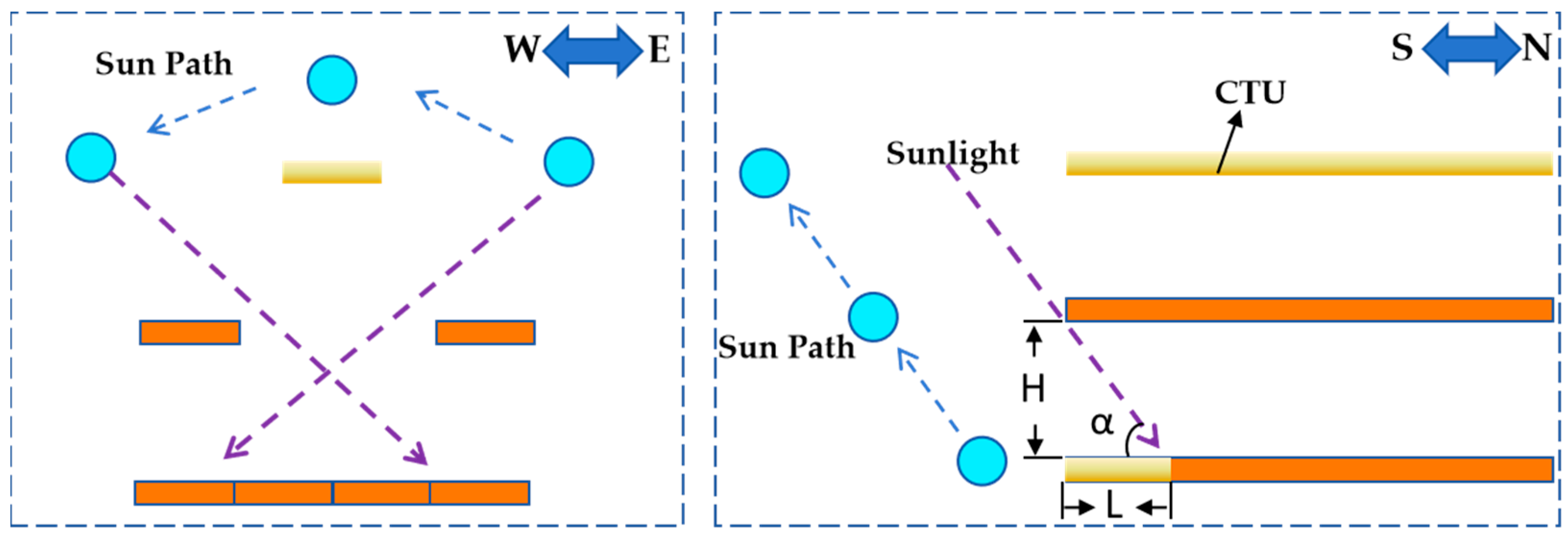

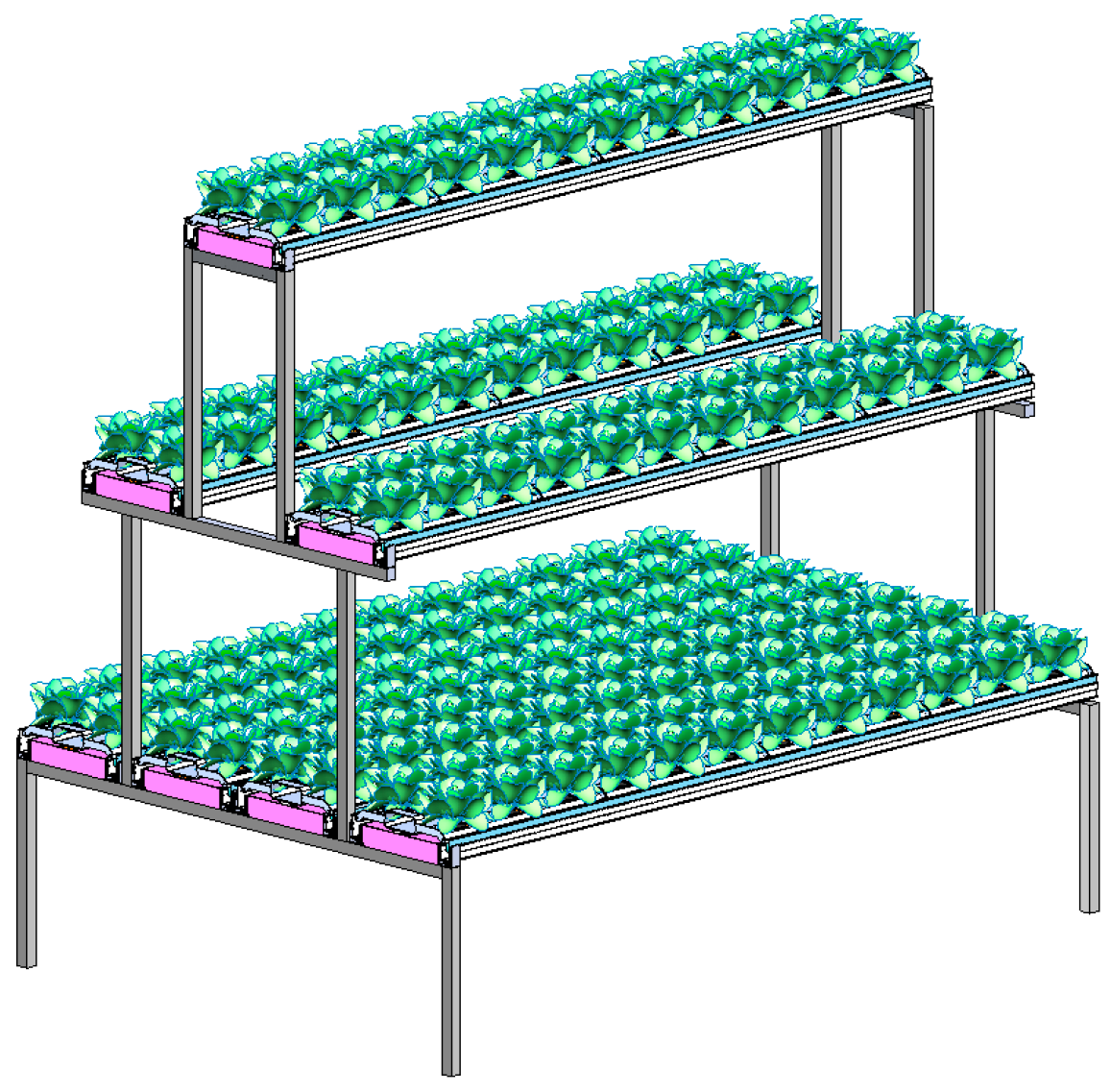

2.2.2. The CTU Structure and the Cultivation Frame Parameter Design Requirements

- The cultivation frame should have 3 layers, the layer height is over 300 mm, the number of CTUs in the lower layer is 4 groups, and the overall width is 1400 mm.

- The height of the cultivation frame should not exceed 2 m, and the between-group distance of the cultivation frame is 500 mm.

- The width of the middle and upper layers should not exceed the width of the bottom layer.

2.3. Establishment of the Parametric Model

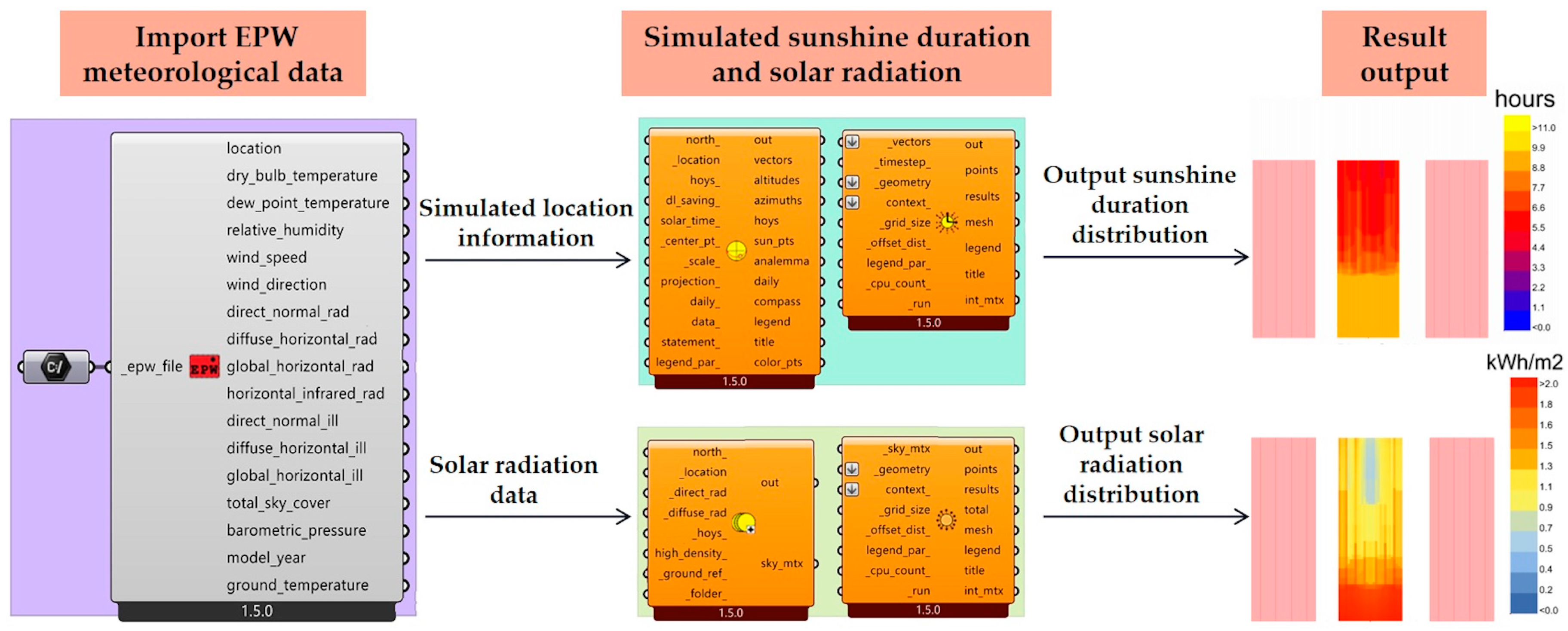

2.4. Establishment of the Light Simulation Platform

2.5. Calculation of the Solar Radiation Condition

2.6. Genetic Algorithm

2.7. Cultivation Experiment

3. Results and Discussion

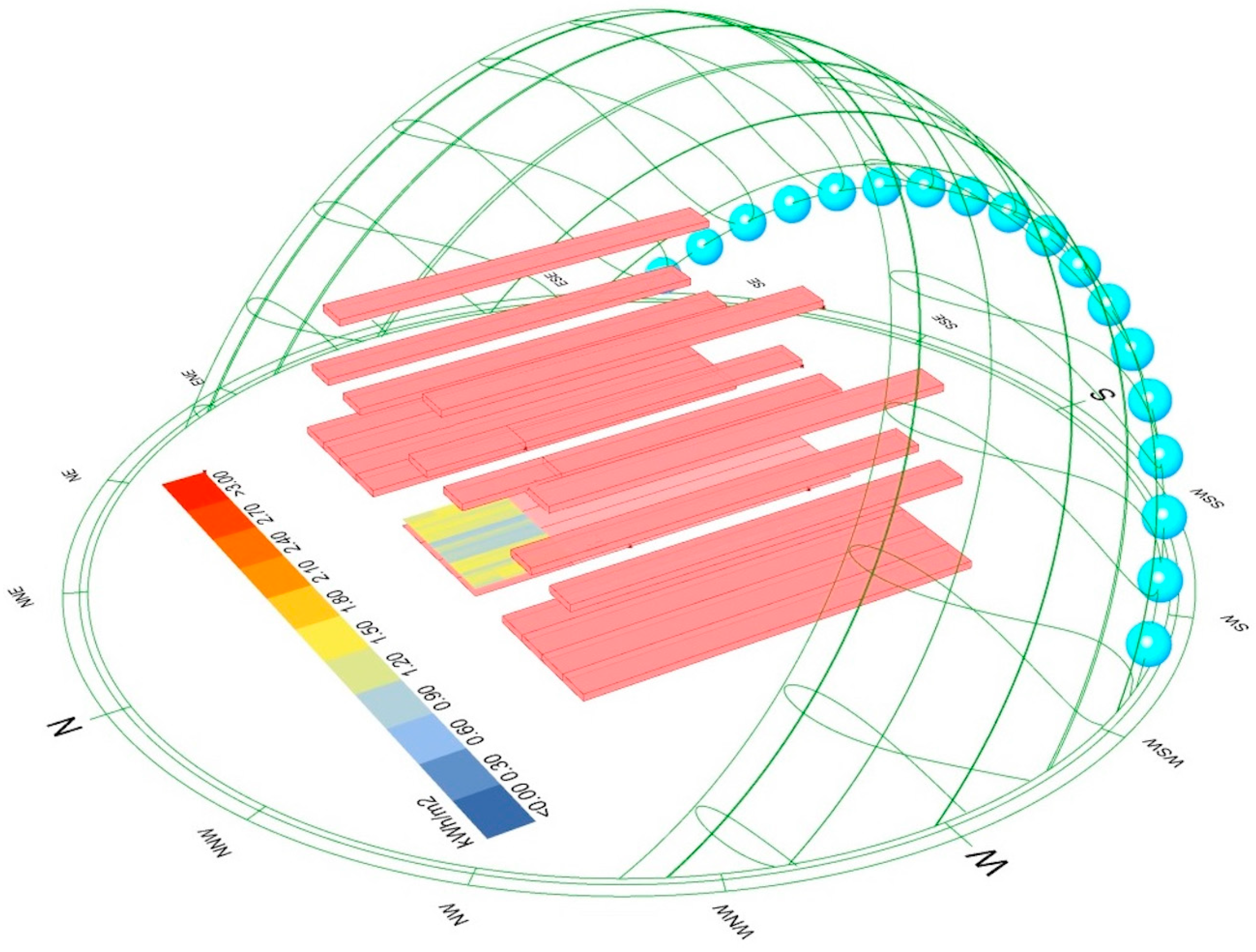

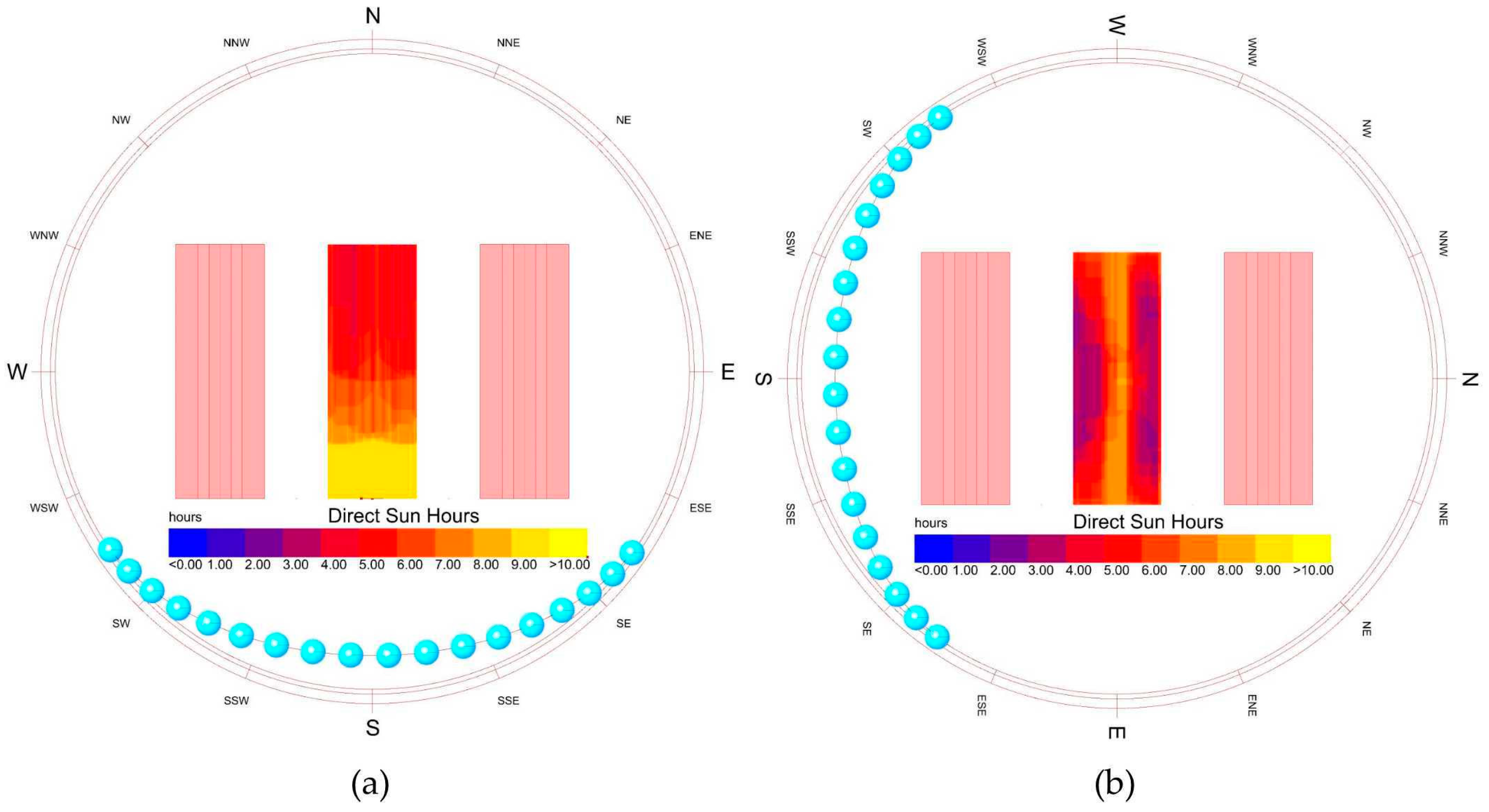

3.1. Analysis of the Arrangement Direction of the Cultivation Frame

3.2. Analysis of the Influence of the Number of CTUs and the Layer Height on the Shading of the Lower Layer under a Single Shading Layer

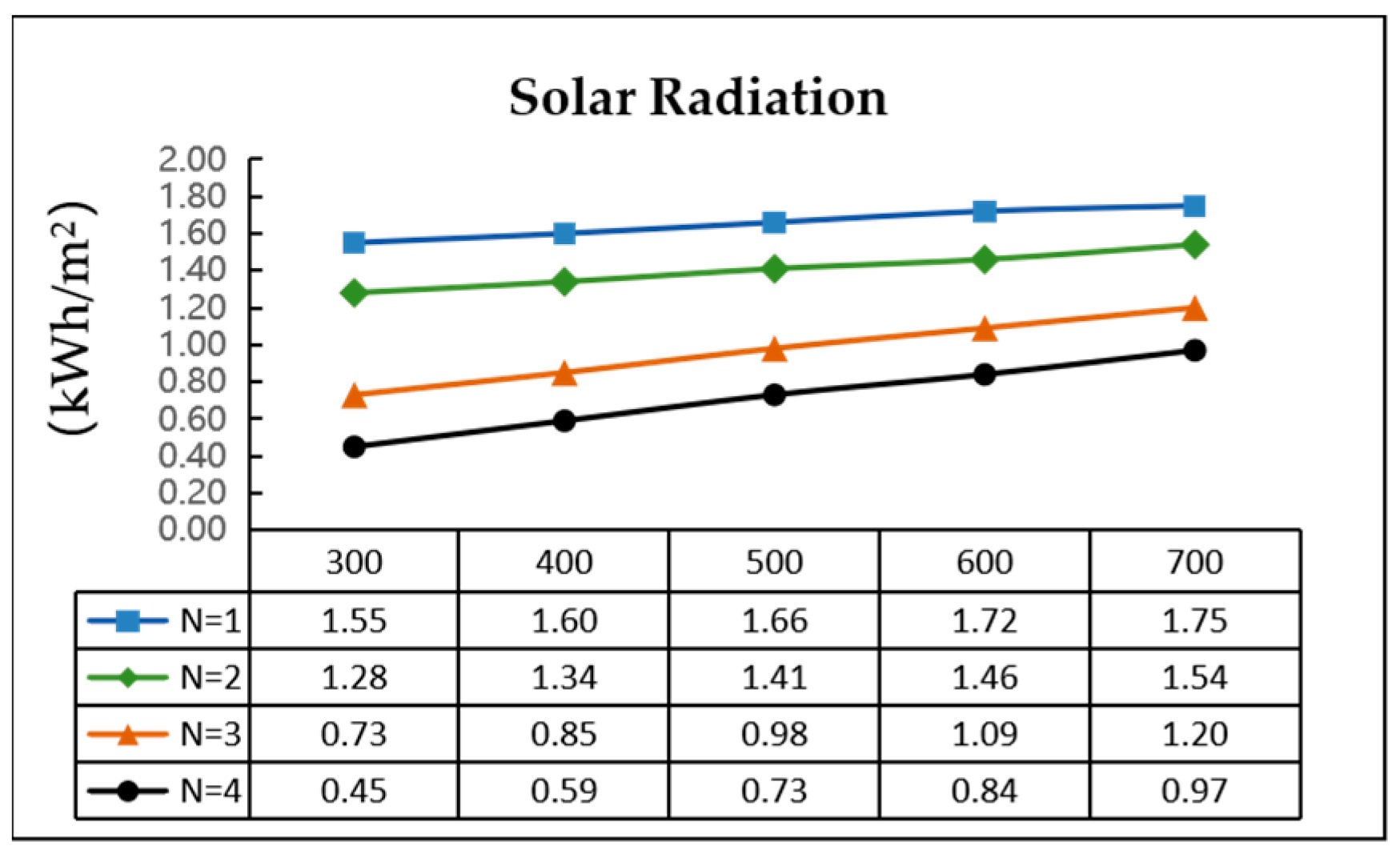

3.2.1. Simulation Calculation of Lower Layer Solar Radiation

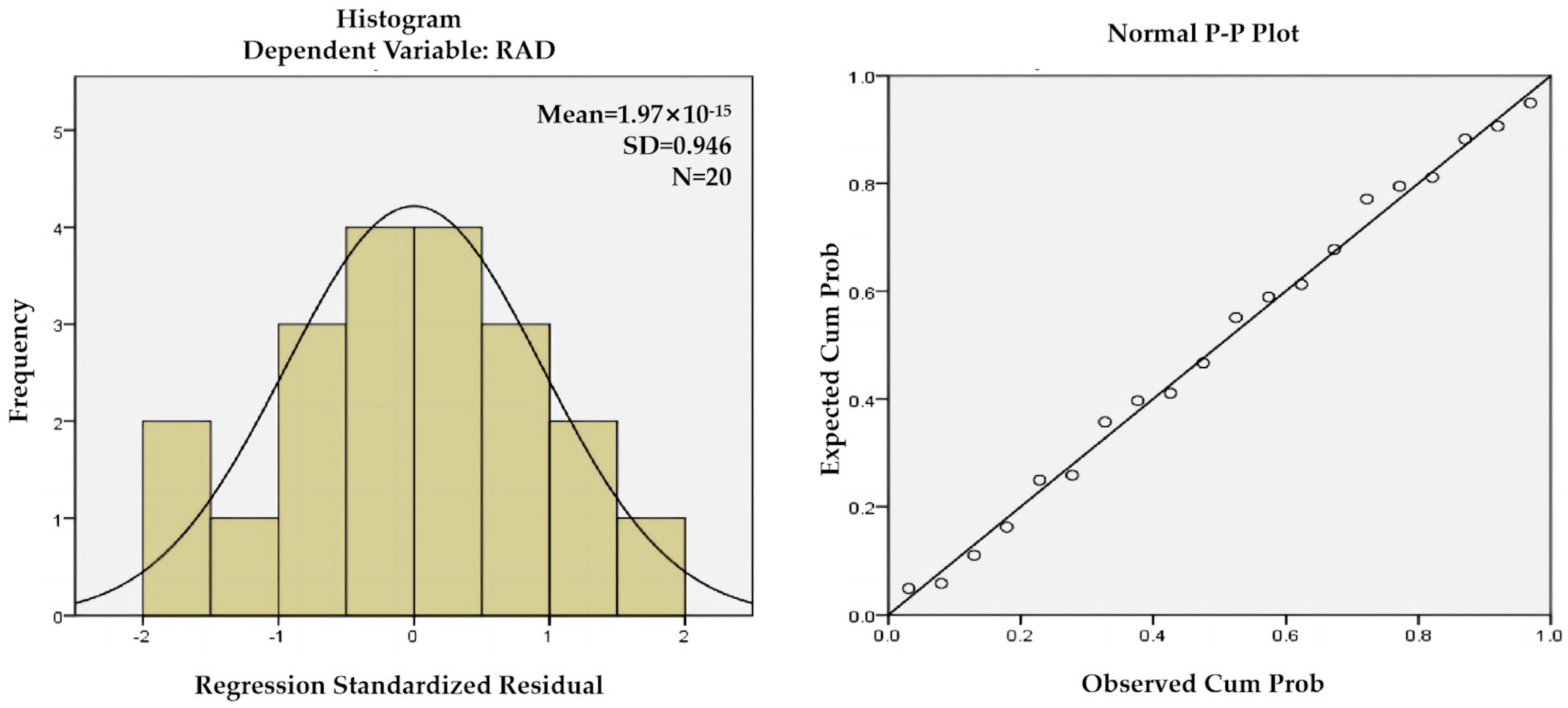

3.2.2. Regression Model Construction and Determination of the Maximum Number of CTUs of the Shading Layers

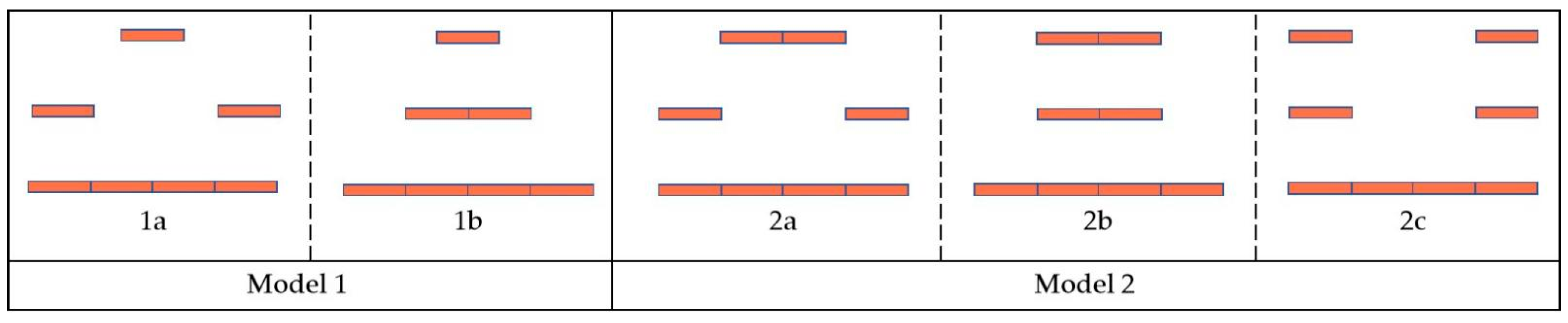

3.3. Simulation Solution for the Number of CTUs in the Upper Layer

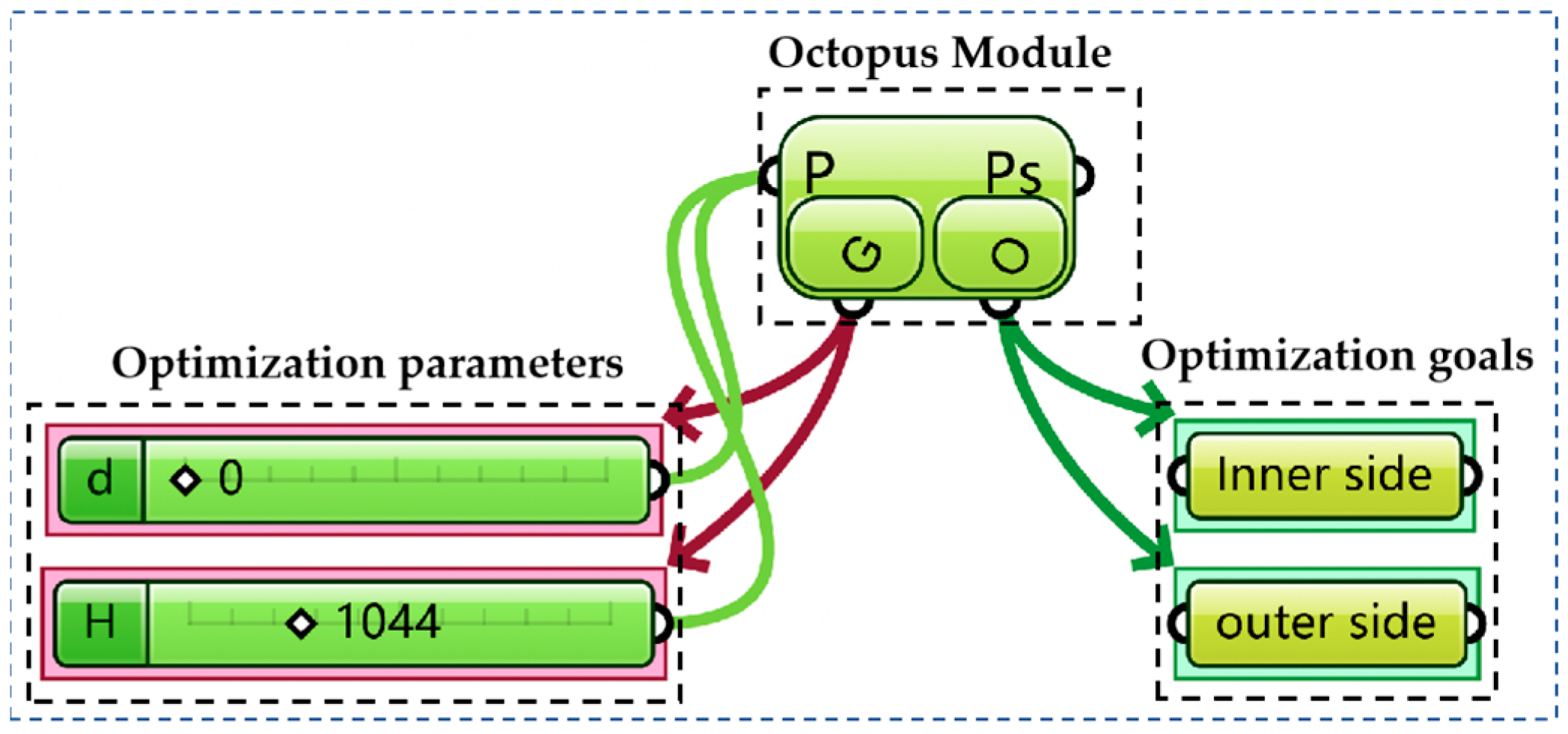

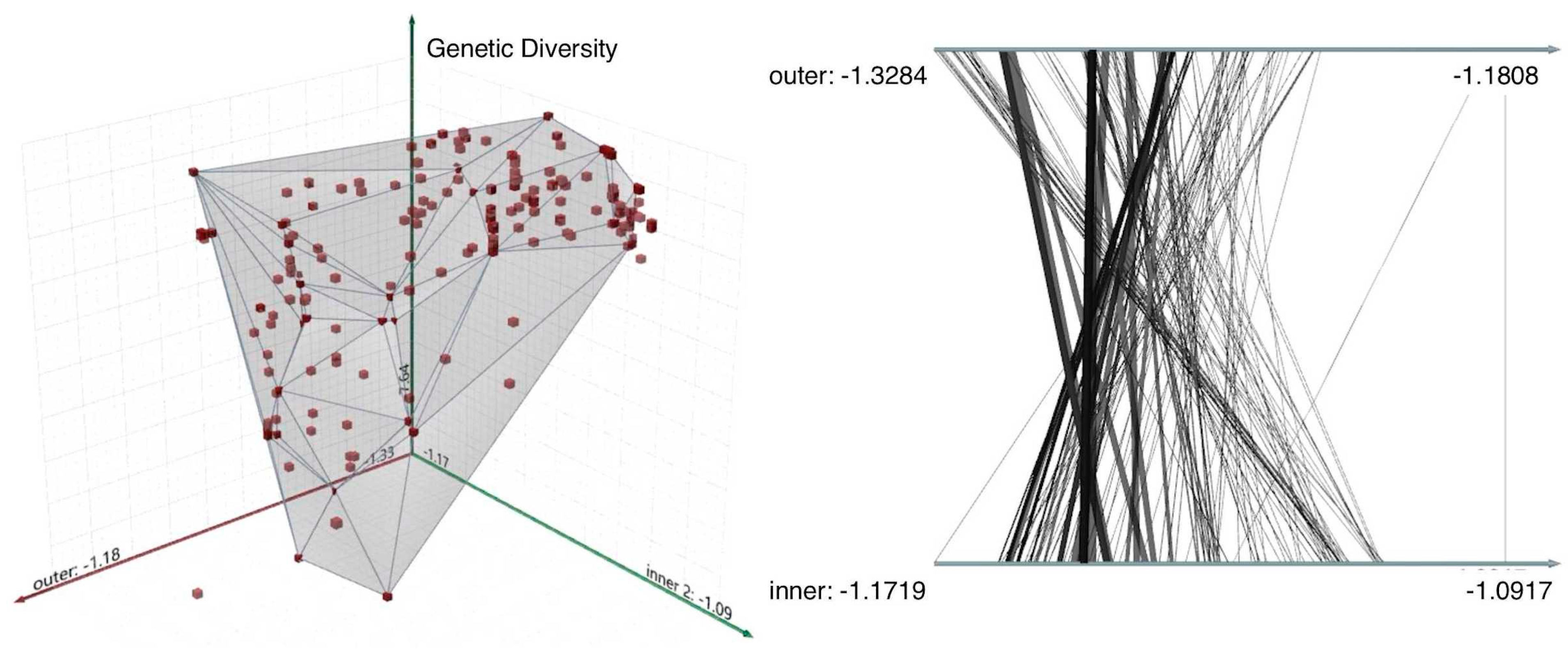

3.4. Optimization of the Cultivation Frame Structure Using Octopus

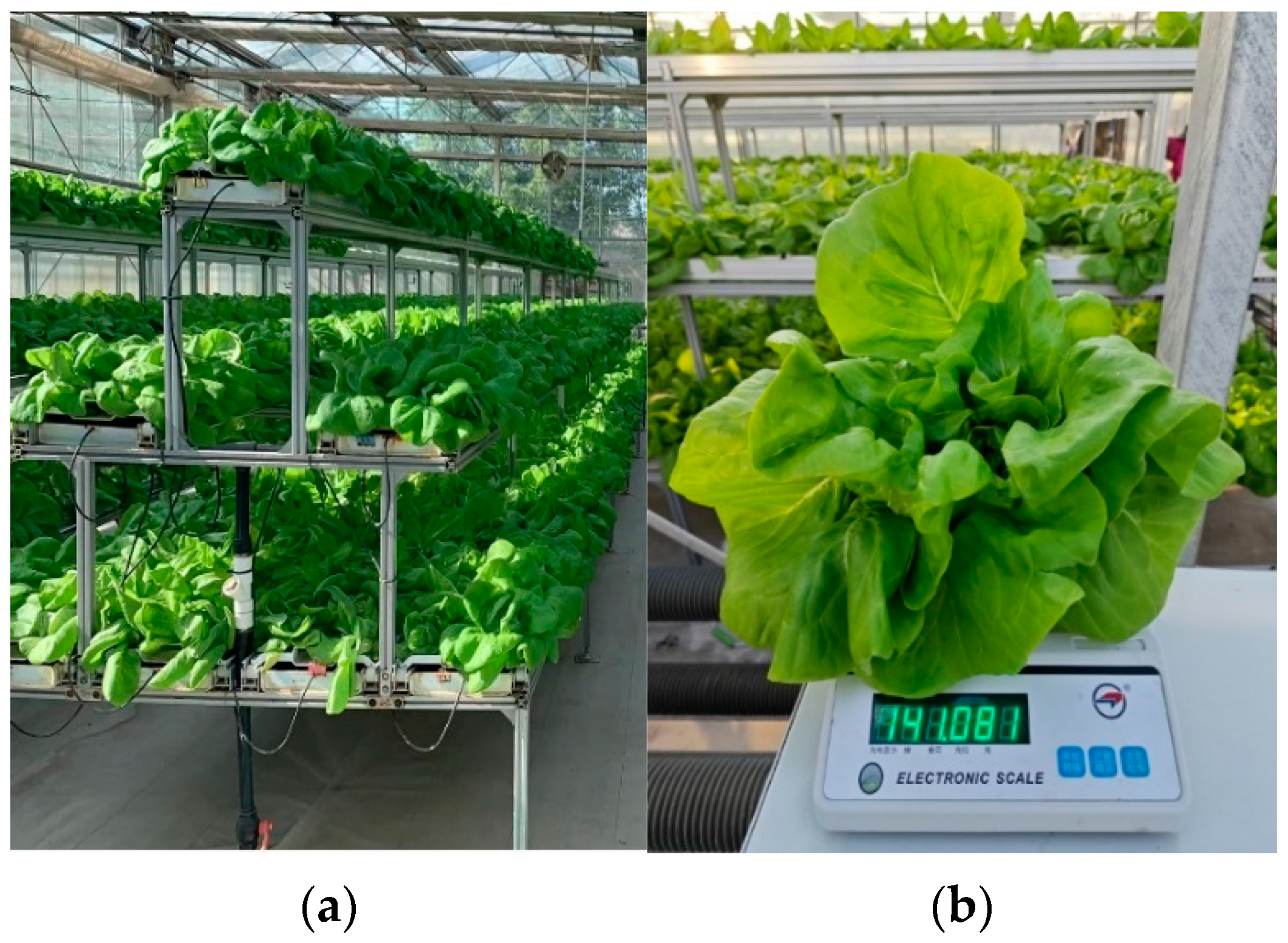

3.5. Lettuce Cultivation Experiment

4. Conclusions

- Novel optimization methods for the structure design of VF cultivation frames were explored. By harnessing parametric modeling and light simulation techniques, our research introduced innovative approaches to designing and optimizing VF frames. The pivotal findings underscore the remarkable capability of these methods to swiftly and precisely simulate light characteristics across diverse frame structures. Notably, parametric modeling emerges as a key facilitator, streamlining design modifications with unprecedented convenience. These innovative methods provide technical support for the construction of VF cultivation systems, effectively reducing the design costs and design cycle of VF. This paper’s primary contributions lie in expanding the technical toolkit for VF design and catalyzing practical advancements that propel the field toward enhanced sustainability and cost-effectiveness.

- We designed a NLSCF to reduce supplementary lighting energy consumption in VF. This study fully considered the structural design requirements of the cultivation frame and the lighting needs of the lower layers. Through a combination of parametric modeling, light simulation, and genetic algorithm optimization, the structure of the cultivation frame was designed and optimized. Therefore, the NLSCF could meet the lighting design requirements for the middle and lower layers, even under no supplementary lighting conditions. The optimized structure consisted of four sets of CTUs for the lower layer, two sets for the middle layer, and one set for the upper layer, with a layer height of 685 mm and a spacing of 350 mm between CTUs.

- We conducted cultivation experiments to validate the NLSCF. The results of lettuce cultivation under natural light verification experiments showed that the yields of the middle and lower layers could reach from 82.9% to 92.6% of the upper layer. Based on the simulated design, the practical effect of not requiring supplementary lighting was effectively verified.

- Although the above research results provide a solution to reduce supplementary lighting energy consumption in VF, the planting density of the cultivation frame is lower than that of a plant factory. Further studies may apply the structural design methods and genetic algorithm to increase the height and number of layers of the cultivation frame and combine lifting and transporting equipment to achieve the goal of increasing planting density. The NLSCF system may also benefit from better light intensity range management, including avoiding photo saturation and photoinhibition and optimizing light distribution among layers.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- SharathKumar, M.; Heuvelink, E.; Marcelis, L.F.M. Vertical Farming: Moving from Genetic to Environmental Modification. Trends Plant Sci. 2020, 25, 724–727. [Google Scholar] [CrossRef] [PubMed]

- Van Gerrewey, T.; Boon, N.; Geelen, D. Vertical Farming: The Only Way Is Up? Agronomy 2021, 12, 2. [Google Scholar] [CrossRef]

- Sambo, P.; Nicoletto, C.; Giro, A.; Pii, Y.; Valentinuzzi, F.; Mimmo, T.; Lugli, P.; Orzes, G.; Mazzetto, F.; Astolfi, S.; et al. Hydroponic Solutions for Soilless Production Systems: Issues and Opportunities in a Smart Agriculture Perspective. Front. Plant Sci. 2019, 10, 923. [Google Scholar] [CrossRef] [PubMed]

- Benke, K.; Tomkins, B. Future Food-Production Systems: Vertical Farming and Controlled-Environment Agriculture. Sustain. Sci. Pract. Policy 2017, 13, 13–26. [Google Scholar] [CrossRef]

- Beacham, A.M.; Vickers, L.H.; Monaghan, J.M. Vertical Farming: A Summary of Approaches to Growing Skywards. J. Hortic. Sci. Biotechnol. 2019, 94, 277–283. [Google Scholar] [CrossRef]

- Montes Rivera, M.; Escalante-Garcia, N.; Dena-Aguilar, J.A.; Olvera-Gonzalez, E.; Vacas-Jacques, P. Feature Selection to Predict LED Light Energy Consumption with Specific Light Recipes in Closed Plant Production Systems. Appl. Sci. 2022, 12, 5901. [Google Scholar] [CrossRef]

- Pennisi, G.; Pistillo, A.; Orsini, F.; Cellini, A.; Spinelli, F.; Nicola, S.; Fernandez, J.A.; Crepaldi, A.; Gianquinto, G.; Marcelis, L.F.M. Optimal Light Intensity for Sustainable Water and Energy Use in Indoor Cultivation of Lettuce and Basil under Red and Blue LEDs. Sci. Hortic. 2020, 272, 109508. [Google Scholar] [CrossRef]

- Smirnov, A.A.; Semenova, N.A.; Dorokhov, A.S.; Proshkin, Y.A.; Godyaeva, M.M.; Vodeneev, V.; Sukhov, V.; Panchenko, V.; Chilingaryan, N.O. Influence of Pulsed, Scanning and Constant (16- and 24-h) Modes of LED Irradiation on the Physiological, Biochemical and Morphometric Parameters of Lettuce Plants (Lactuca sativa L.) While Cultivated in Vertical Farms. Agriculture 2022, 12, 1988. [Google Scholar] [CrossRef]

- Zhang, Y.; Kacira, M. Analysis of Climate Uniformity in Indoor Plant Factory System with Computational Fluid Dynamics (CFD). Biosyst. Eng. 2022, 220, 73–86. [Google Scholar] [CrossRef]

- Yeo, U.-H.; Lee, S.-Y.; Park, S.-J.; Kim, J.-G.; Cho, J.-H.; Decano-Valentin, C.; Kim, R.-W.; Lee, I.-B. Rooftop Greenhouse: (2) Analysis of Thermal Energy Loads of a Building-Integrated Rooftop Greenhouse (BiRTG) for Urban Agriculture. Agriculture 2022, 12, 787. [Google Scholar] [CrossRef]

- Graamans, L.; Baeza, E.; van den Dobbelsteen, A.; Tsafaras, I.; Stanghellini, C. Plant Factories versus Greenhouses: Comparison of Resource Use Efficiency. Agric. Syst. 2018, 160, 31–43. [Google Scholar] [CrossRef]

- Avgoustaki, D.D.; Xydis, G. Energy Cost Reduction by Shifting Electricity Demand in Indoor Vertical Farms with Artificial Lighting. Biosyst. Eng. 2021, 211, 219–229. [Google Scholar] [CrossRef]

- Hosseini, H.; Mozafari, V.; Roosta, H.R.; Shirani, H.; van de Vlasakker, P.C.H.; Farhangi, M. Nutrient Use in Vertical Farming: Optimal Electrical Conductivity of Nutrient Solution for Growth of Lettuce and Basil in Hydroponic Cultivation. Horticulturae 2021, 7, 283. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Göçer, F.; Uztürk, D. A Novel Pythagorean Fuzzy Set Integrated Choquet Integral Approach for Vertical Farming Technology Assessment. Comput. Ind. Eng. 2021, 158, 107384. [Google Scholar] [CrossRef]

- Rengasamy, N.; Othman, R.Y.; Che, H.S.; Harikrishna, J.A. Artificial Lighting Photoperiod Manipulation Approach to Improve Productivity and Energy Use Efficacies of Plant Factory Cultivated Stevia Rebaudiana. Agronomy 2022, 12, 1787. [Google Scholar] [CrossRef]

- Watawana, B.; Isaksson, M. Design and Simulations of a Self-Assembling Autonomous Vertical Farm for Urban Farming. Agriculture 2023, 13, 112. [Google Scholar] [CrossRef]

- Zhang, Y.; Kacira, M. Comparison of Energy Use Efficiency of Greenhouse and Indoor Plant Factory System. Eur. J. Hortic. Sci. 2020, 85, 310–320. [Google Scholar] [CrossRef]

- Weidner, T.; Yang, A.; Hamm, M.W. Energy Optimisation of Plant Factories and Greenhouses for Different Climatic Conditions. Energy Convers. Manag. 2021, 243, 114336. [Google Scholar] [CrossRef]

- Jürkenbeck, K.; Heumann, A.; Spiller, A. Sustainability Matters: Consumer Acceptance of Different Vertical Farming Systems. Sustainability 2019, 11, 4052. [Google Scholar] [CrossRef]

- Wang, C.; Song, W.; Zhao, S.; Qu, S. Effect of different combinations of H-type cultivation frame on light and strawberry growth and yield. Trans. Chin. Soc. Agric. Eng. 2017, 33, 234–239. [Google Scholar] [CrossRef]

- Liao, P.; Liu, P.; Wang, Y.; Huang, C.; Lan, L.; Yang, Y.; Cui, X. Stereoscopic Cultivation of Panax Notoginseng: A New Approach to Overcome the Continuous Cropping Obstacle. Ind. Crops Prod. 2018, 126, 38–47. [Google Scholar] [CrossRef]

- Kempler, C. ’Out-of-season’ greenhouse production of raspberry and strawberry. Acta Hortic. 2004, 633, 459–465. [Google Scholar] [CrossRef]

- Lin, X.; Luo, Y.; Wang, H. Effect of light and temperature on strawberry in stereoscopic culture system. J. China Agric. Univ. 2014, 19, 67–73. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, P.; Zhang, B.; Wang, J.; Song, S.; Wang, H. Light and temperature and their effects on photosynthesis characteristics of stereoscopic cultivation in strawberry. J. China Agric. Univ. 2011, 16, 42–48. [Google Scholar]

- Wang, C.; Sun, W.; Zhao, S.; Qu, M. Sun-tracking multi-layer stereo-cultivation system improving light and temperature environment and increasing yield for strawberry. Trans. Chin. Soc. Agric. Eng. 2017, 33, 187–194. [Google Scholar] [CrossRef]

- Goharian, A.; Daneshjoo, K.; Yeganeh, M. Standardization of Methodology for Optimizing the Well Aperture as Device (Reflector) for Light-Wells; A Novel Approach Using Honeybee & Ladybug Plugins. Energy Rep. 2022, 8, 3096–3114. [Google Scholar] [CrossRef]

- Eltaweel, A.; Su, Y. Controlling Venetian Blinds Based on Parametric Design; via Implementing Grasshopper’s Plugins: A Case Study of an Office Building in Cairo. Energy Build. 2017, 139, 31–43. [Google Scholar] [CrossRef]

- Saito, K.; Ishigami, Y.; Goto, E. Evaluation of the Light Environment of a Plant Factory with Artificial Light by Using an Optical Simulation. Agronomy 2020, 10, 1663. [Google Scholar] [CrossRef]

- Jung, D.H.; Lee, J.W.; Kang, W.H.; Hwang, I.H.; Son, J.E. Estimation of Whole Plant Photosynthetic Rate of Irwin Mango under Artificial and Natural Lights Using a Three-Dimensional Plant Model and Ray-Tracing. Int. J. Mol. Sci. 2018, 19, 152. [Google Scholar] [CrossRef]

- Badji, A.; Benseddik, A.; Bensaha, H.; Boukhelifa, A.; Hasrane, I. Design, Technology, and Management of Greenhouse: A Review. J. Clean. Prod. 2022, 373, 133753. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, Q.; Liu, P.; Liang, R.; Fu, Z. A Parameterized Design Method for Building a Shading System Based on Climate Adaptability. Atmosphere 2022, 13, 1244. [Google Scholar] [CrossRef]

- Viršilė, A.; Brazaitytė, A.; Vaštakaitė-Kairienė, V.; Miliauskienė, J.; Jankauskienė, J.; Novičkovas, A.; Samuolienė, G. Lighting Intensity and Photoperiod Serves Tailoring Nitrate Assimilation Indices in Red and Green Baby Leaf Lettuce. J. Sci. Food Agric. 2019, 99, 6608–6619. [Google Scholar] [CrossRef] [PubMed]

- Yan, Z.; He, D.; Niu, G.; Zhai, H. Evaluation of Growth and Quality of Hydroponic Lettuce at Harvest as Affected by the Light Intensity, Photoperiod and Light Quality at Seedling Stage. Sci. Hortic. 2019, 248, 138–144. [Google Scholar] [CrossRef]

- Eaton, M.; Harbick, K.; Shelford, T.; Mattson, N. Modeling Natural Light Availability in Skyscraper Farms. Agronomy 2021, 11, 1684. [Google Scholar] [CrossRef]

- Torres, A.P.; Lopez, R. Measuring Daily Light Integral in a Greenhouse. Purdue Extension. Ho-238-W. 2012. 1–10. Available online: https://mdc.itap.purdue.edu/item.asp?itemID=19338 (accessed on 29 July 2023).

- Maraveas, C. Environmental Sustainability of Greenhouse Covering Materials. Sustainability 2019, 11, 6129. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, W. A Study on Parametric Design Method for Optimization of Daylight in Commercial Building’s Atrium in Cold Regions. Sustainability 2022, 14, 7667. [Google Scholar] [CrossRef]

- Lei, C.; Engeseth, N.J. Comparison of Growth Characteristics, Functional Qualities, and Texture of Hydroponically Grown and Soil-Grown Lettuce. LWT 2021, 150, 111931. [Google Scholar] [CrossRef]

- Kwack, Y.; Kim, K.K.; Hwang, H.; Chun, C. Growth and Quality of Sprouts of Six Vegetables Cultivated under Different Light Intensity and Quality. Hortic. Environ. Biotechnol. 2015, 56, 437–443. [Google Scholar] [CrossRef]

- Chaichana, C.; Man, A.; Wicharuck, S.; Mona, Y.; Rinchumphu, D. Modelling of Annual Sunlight Availability on Vertical Shelves: A Case Study in Thailand. Energy Rep. 2022, 8, 1136–1143. [Google Scholar] [CrossRef]

- Lee, Y.Y.; Yik, J.; Koay, E.H.H.; Lau, H.H. Application of Light Redirecting Panels to Improve Sunlight Utilization in Multi-Tiered Vertical Farming Systems. Clean Technol. Environ. Policy 2023. [Google Scholar] [CrossRef]

- Fang, H.; Cheng, R.; Wu, G.; Tong, Y.; Liu, Q. Effects of multi-layer three-dimensional cultivation combined with artificial lighting on lettuce yield and quality in Greenhouse. J. China Agric. Univ. 2021, 26, 147–154. [Google Scholar] [CrossRef]

- Barbieri, F.; Barbi, S.; Bertacchini, A.; Montorsi, M. Combined Effects of Different LED Light Recipes and Slow-Release Fertilizers on Baby Leaf Lettuce Growth for Vertical Farming: Modeling through DoE. Appl. Sci. 2023, 13, 8687. [Google Scholar] [CrossRef]

- Farhangi, H.; Mozafari, V.; Roosta, H.R.; Shirani, H.; Farhangi, M. Optimizing Growth Conditions in Vertical Farming: Enhancing Lettuce and Basil Cultivation through the Application of the Taguchi Method. Sci. Rep. 2023, 13, 6717. [Google Scholar] [CrossRef] [PubMed]

| Optimization Variable | Constraint Condition |

|---|---|

| d | [0 mm, 700 mm] |

| H | [300 mm, 700 mm] |

| Optimization Parameters | Value |

|---|---|

| Elitism | 0.5 |

| Mutation Probability | 0.1 |

| Mutation Rate | 0.9 |

| Crossover Rate | 0.8 |

| Population Size | 100 |

| Max Generation | 0 |

| Record interval | 1 |

| Save interval | 0 |

| Model | B | t | p | Collinearity Statistics | |

|---|---|---|---|---|---|

| Tolerance | VIF | ||||

| (Constant) | 1.547 | 23.597 | <0.001 | ||

| N | −0.326 | −23.880 | <0.001 | 1 | 1 |

| H | 0.001 | 8.419 | <0.001 | 1 | 1 |

| Model | The Average Solar Radiation of the Lower Layer (kWh·m−2) | The Average Solar Radiation of the Middle Layer (kWh·m−2) | Minimum Layer Height (mm) | The Total Height of the Cultivation Frame (mm) |

|---|---|---|---|---|

| 1a | 1.19 | 1.69 | 1020 | 2650 |

| 1b | 1.19 | 1.64 | 670 | 1950 |

| 2a | 1.19 | 1.49 | 1130 | 2870 |

| 2b | 1.19 | 1.21 | 1080 | 2770 |

| 2c | 1.19 | 1.24 | 1110 | 2830 |

| Variable | Fresh Weight (g) | Plant Width (cm) | Plant Height (cm) |

|---|---|---|---|

| The upper layer | 140.68 ± 6.84 a | 29.33 ± 2.38 a | 20.47 ± 1.95 a |

| The middle layer | 130.33 ± 11.63 ab | 28.97 ± 1.95 a | 18.46 ± 1.22 ab |

| The inner side of the lower layer | 116.56 ± 9.40 b | 29.27 ± 2.08 a | 16.46 ± 1.94 b |

| The outer side of the lower layer | 125.27 ± 7.51 ab | 25.66 ± 2.37 a | 17.20 ± 1.40 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, D.; Zheng, W.; Wei, X.; Guo, W.; Zhao, Q.; Gao, G. Parametric Design and Genetic Algorithm Optimization of a Natural Light Stereoscopic Cultivation Frame. Agriculture 2024, 14, 84. https://doi.org/10.3390/agriculture14010084

Jia D, Zheng W, Wei X, Guo W, Zhao Q, Gao G. Parametric Design and Genetic Algorithm Optimization of a Natural Light Stereoscopic Cultivation Frame. Agriculture. 2024; 14(1):84. https://doi.org/10.3390/agriculture14010084

Chicago/Turabian StyleJia, Dongdong, Wengang Zheng, Xiaoming Wei, Wenzhong Guo, Qian Zhao, and Guohua Gao. 2024. "Parametric Design and Genetic Algorithm Optimization of a Natural Light Stereoscopic Cultivation Frame" Agriculture 14, no. 1: 84. https://doi.org/10.3390/agriculture14010084

APA StyleJia, D., Zheng, W., Wei, X., Guo, W., Zhao, Q., & Gao, G. (2024). Parametric Design and Genetic Algorithm Optimization of a Natural Light Stereoscopic Cultivation Frame. Agriculture, 14(1), 84. https://doi.org/10.3390/agriculture14010084