Research and Experimentation on Sparse–Dense Interphase Curved-Tooth Sorghum Threshing Technology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Composition and Working Principle of Sorghum Threshing Device

2.2. Threshing System Design

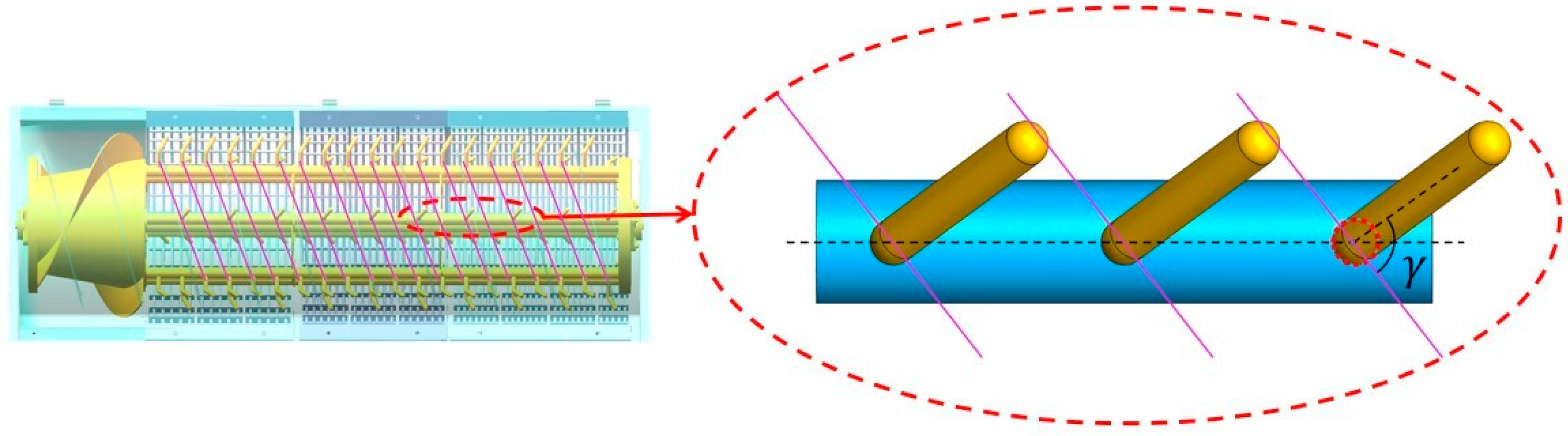

2.2.1. Overall Distribution of Threshing Elements

2.2.2. Determination of Key Parameters of Threshing Drums

- Determination of the number of threshing elements

- Determination of the number of tooth plates

- Determination of the number of helical heads

- Determination of threshing drum diameter

- Determination of threshing drum length

- Determination of threshing element spacing

2.2.3. Determination of the Structure of the Threshing Element

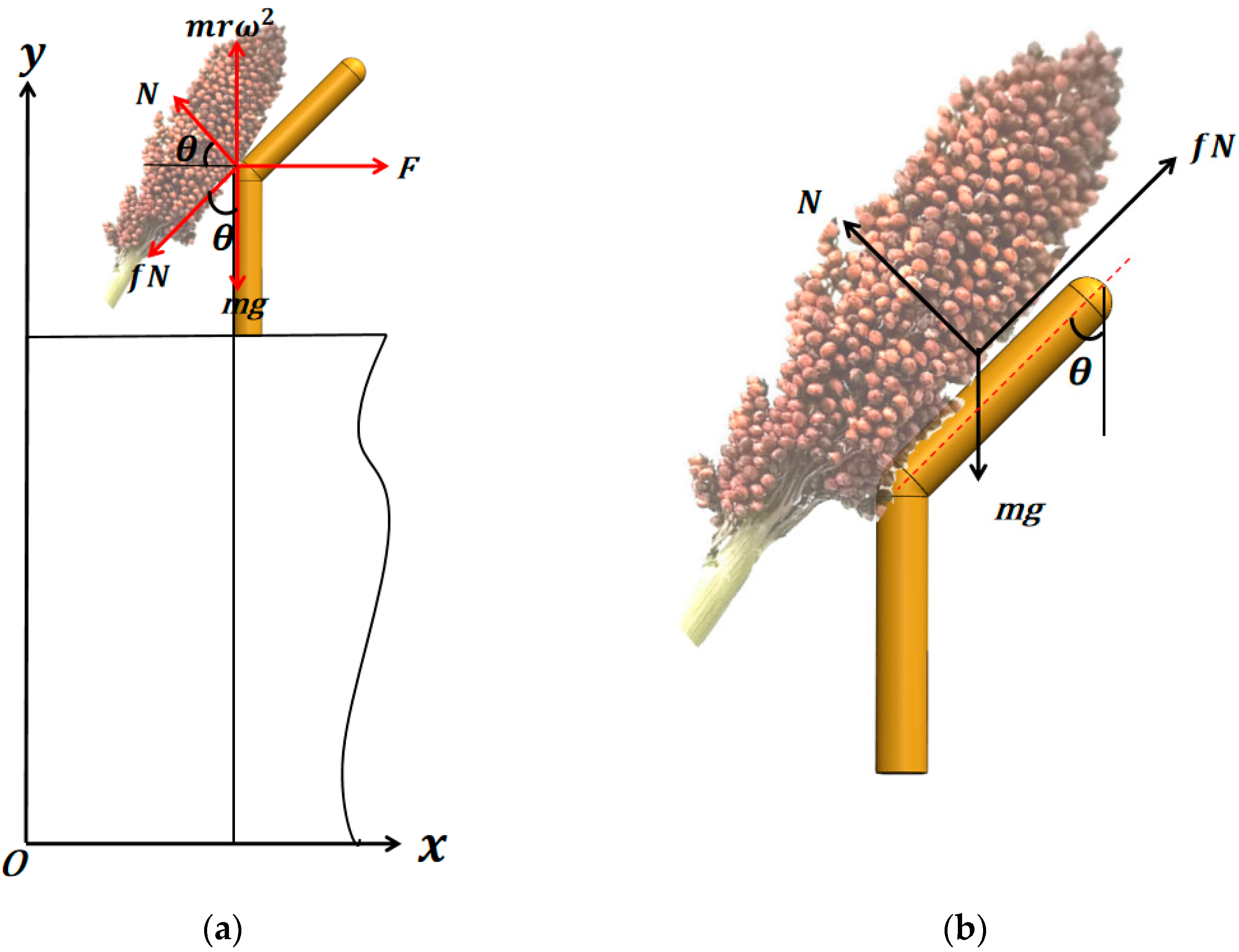

2.2.4. Mounting Angle of the Threshing Element

2.3. Field Trials

2.3.1. Test Conditions and Methods

- Test conditions

- Test methods

2.3.2. Pilot Program

2.3.3. Parameter Optimization and Validation Tests

3. Results

3.1. Analysis of Orthogonal Test Results

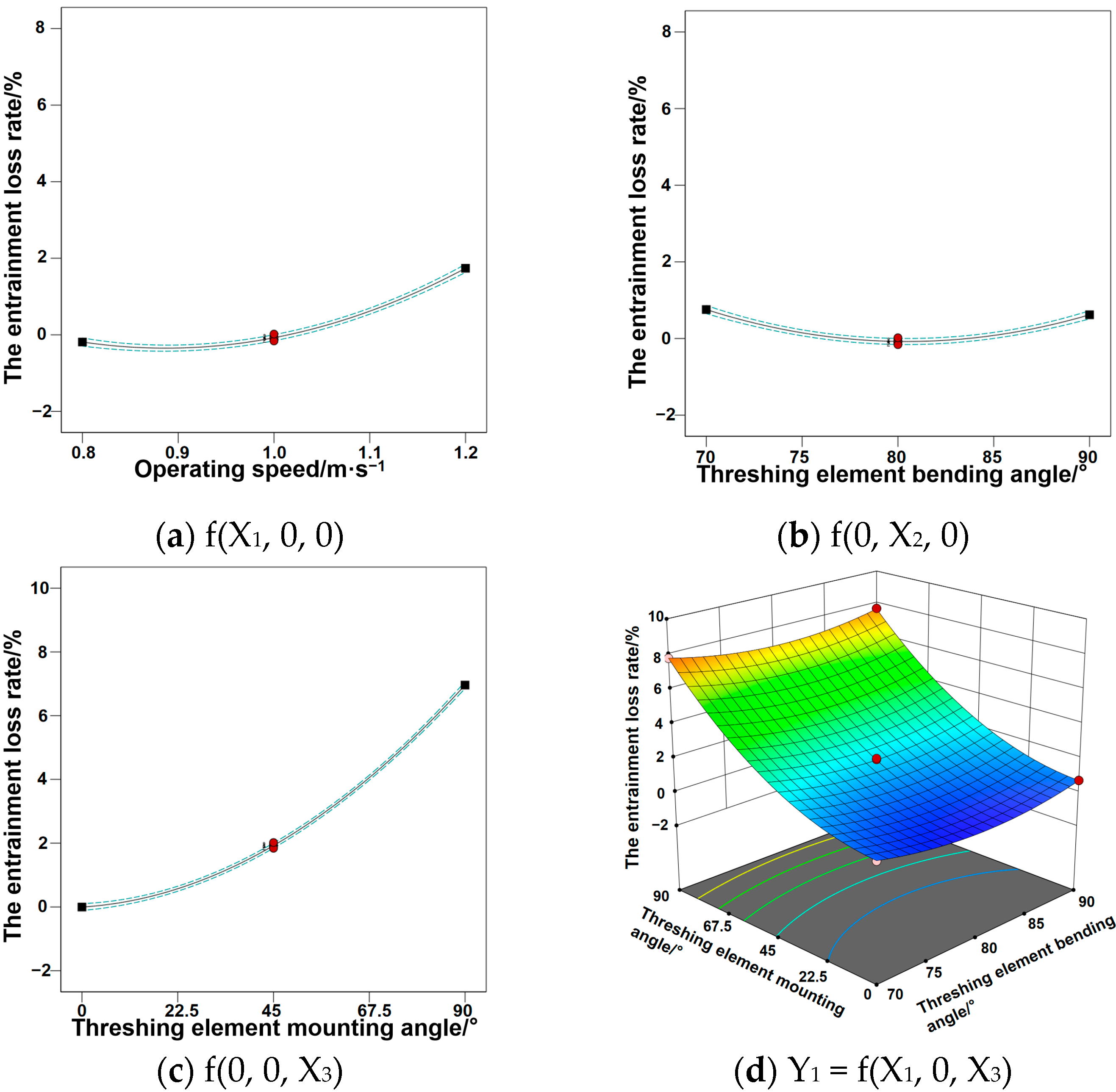

3.1.1. Analysis of Variance for the Entrainment Loss Rate

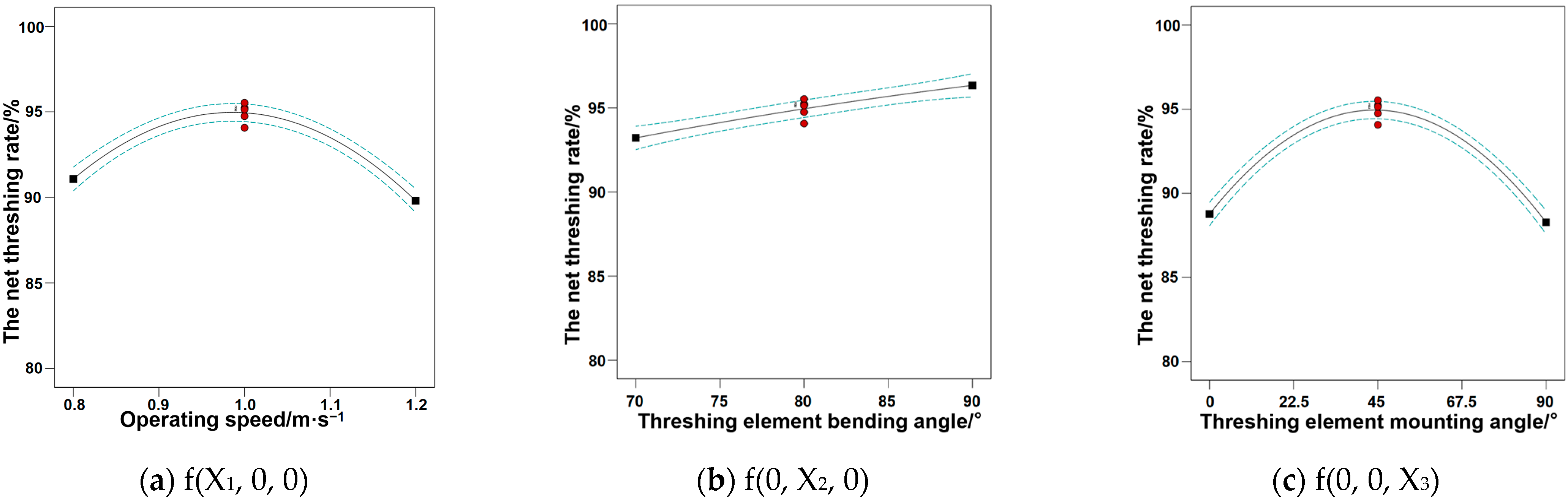

3.1.2. Analysis of Variance for the Net Threshing Rate

3.2. Parameter Optimization and Validation Test Results

4. Discussion

5. Conclusions

- We developed end-bending rod teeth for a sparse-dense threshing drum, determined the overall distribution structure of the threshing element, and identified the key parameters of the threshing drum. We established the structure of the threshing element with straight rod teeth bent backward at half of their height, setting the bending angle of the threshing element in the range of 69.5° to 90° and the mounting angle of the threshing element in the range of 0° to 90°. This effectively reduces the impact load of the threshing rod teeth on the sorghum, improves the smoothness of the crop sliding off the threshing element, enhances the integrity of the stalk, and improves the conditions for the seeds to cross the draft layer, facilitating the separation of the threshed seeds from the draft grass, thereby helping to reduce the impurity rate of the seeds.

- Orthogonal tests were carried out using the sparse-dense interphase threshing drum as the research object, selecting operating speed, bending angle of the threshing element, and mounting angle of the threshing element as test factors, with the entrainment loss rate and the net threshing rate as assessment indicators for a three-factor, three-level test. The optimal parameter range was derived as follows: an operating speed of 0.9~1.1 m/s, an element bending angle of 80~85°, and an element mounting angle of 22.5~45°.

- Design-export was used to establish a mathematical regression model between the factors and the two indicators, resulting in the following optimized parameters: when the operating speed is 1.0 m·s−1, the bending angle of the threshing element is 80°, and the mounting angle of the threshing element is 45°, the entrainment loss rate is 1.89%, and the net threshing rate is 95.53%.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Nagy, R.; Kun-Nemes, A.; Szőllősi, E.; Molnár, P.B.; Cziáky, Z.; Murányi, E.; Sipos, P.; Remenyik, J. Physiological potential of different Sorghum bicolor varieties depending on their bioactive characteristics and antioxidant potential as well as different extraction methods. Heliyon 2024, 10, e35807. [Google Scholar] [CrossRef] [PubMed]

- Cao, W.; Sun, C.; Liu, R.; Yin, R.; Wu, X. Comparison of the effects of five pretreatment methods on enhancing the enzymatic digestibility and ethanol production from sweet sorghum bagasse. Bioresour. Technol. 2012, 111, 215–221. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Qiu, S.; Yuan, X.; Cui, Q.; Wu, C. Tensile Characteristics of Sorghum Spikelet and Grains. Agric. Eng. 2021, 11, 119–124. [Google Scholar]

- Wang, L.; Hu, C.; Guo, W.; He, X.; Wang, X.; Jian, J.; Hou, S. The effects of moisture content and loading orientation on some physical andmechanical properties of tiger nut. Am. J. Biochem. Biotechnol. 2021, 17, 109–117. [Google Scholar] [CrossRef]

- He, Q.; Wang, Q.; Geng, D.; Li, D.; Niu, L.; Ma, J.; Zhang, C.; Ming, J.; Ni, L. Design and Experiment of Grain Lifter for Sorghum Harvester. Appl. Sci. 2023, 13, 13168. [Google Scholar] [CrossRef]

- Wu, L.; Chen, D.; Xu, X.; Wu, Y. Experimental Design and Validation of an Adjustable Straw Guide Structure for a Grain Combine Harvester Thresher Based on a Material Movement Model. Appl. Sci. 2023, 13, 8476. [Google Scholar] [CrossRef]

- Astanakulov, K.D.; Umirov, A.T.; Sultanbekova, P.S.; Alpamyssova, G.B. Determination of working indicators of New Holland TS-5060 combine for soy bean harvesting. IOP Conf. Ser. Earth Environ. Sci. 2021, 839, 052048. [Google Scholar] [CrossRef]

- GRAIN. IMC completes harvesting winter wheat, threshing 122,000 tonnes. In Interfax: Russia & CIS Food & Agriculture Weekly; Interfax: Moscow, Russia, 2021. [Google Scholar]

- Rogovskii, I.L.; Martiniuk, D.I.; Voinash, S.A.; Luchinovich, A.A.; Sokolova, V.A.; Ivanov, A.M.; Churakov, A.V. Modeling the throughput capacity of threshing-separating apparatus of grain harvester’s combines. IOP Conf. Ser. Earth Environ. Sci. 2021, 677, 042098. [Google Scholar] [CrossRef]

- Camolese, H.; Baio, F.; Alves, C. Quantitative and Qualitative Losses from Harvesters with Radial and Axial Threshing Systems Depending on Grain Moisture. Rev. Bras. Eng. Biossist. 2015, 9, 21–29. [Google Scholar]

- Chaturvedi, S.; Rathore, F.; Pandey, S. A Modification and development of threshing unit for minor millets. Bhartiya Krishi Anusandhan Patrika 2018, 33, 195–199. [Google Scholar] [CrossRef]

- Powar, R.V.; Aware, V.V.; Shahare, P.U. Optimizing operational parameters of finger millet threshing drum using RSM. J. Food Sci. Technol. 2019, 56, 3481–3491. [Google Scholar] [CrossRef] [PubMed]

- Ryadnov, A.I.; Fedorova, O.A.; Sharipov, R.V.; Baril, V.A. Sorghum harvester work quality assessment. Conf. Ser. Earth Environ. Sci. 2021, 786, 012030. [Google Scholar] [CrossRef]

- Tang, Z.; Li, Y.; Xu, L.; Zhao, Z.; Li, H. Effects of different threshing components on grain threshing and separating by tangential-axial test device. Trans. CSAE 2011, 27, 93–97. [Google Scholar]

- Li, Y.; Li, H.; Xu, L. Comparative experiments on threshing performance between short-rasp-bar tooth cylinder and spike tooth cylinder. Trans. CSAE 2008, 24, 139–142. [Google Scholar]

- Kang, D.; Wu, C.; Liang, S.; Tang, Q. Design and test of threshing device of millet combine harvester. J. China Agric. Univ. 2017, 22, 135–143. [Google Scholar]

- Li, X.; Wang, W.; Zhao, G.; Sun, C.; Hu, P.; Ji, J. Design and Experiment of Longitudinal Axial Flow Double Flexible Rolling and Kneading Threshing Device for Millet. Trans. Chin. Soc. Agric. Mach. 2021, 52, 113–123. [Google Scholar]

- Wang, F.; Liu, Y.; Li, Y.; Ji, K. Research and Experiment on Variable-Diameter Threshing Drum with Movable Radial Plates for Combine Harvester. Agriculture 2023, 13, 1487. [Google Scholar] [CrossRef]

- Pan, C.B.; Zhang, J.L.; Wang, G.M.; Wang, C.; Zhong, N.Q.; Pan, Z.P. Botanical characteristics and biomass of hongyingzi sorghum. Tillage Cultiv. 2022, 42, 37–41. [Google Scholar]

- Liu, W.; Zhou, Y.; Xu, H.; Fu, J.; Zhang, N.; Xie, G.; Zhang, G. Optimization and experiments of the drum longitudinal axial threshing cylinder with rod tooth for rice. Trans. Chin. Soc. Agric. Eng. 2023, 39, 34–45. [Google Scholar]

- Barnwal, P.; Kadam, D.M.; Singh, K. Influence of moisture content on physical properties of maize. Int. Agrophys. 2012, 26, 331–334. [Google Scholar] [CrossRef]

- Khazaei, J.; Shahbazi, F.; Massah, J. Evaluation and modeling of physical and physiological damage to wheat seeds under successive impact loadings: Mathematical and neural networks modeling. Crop. Sci. 2008, 48, 1532–1544. [Google Scholar] [CrossRef]

- Jin, C.; Kang, Y.; Guo, H.; Wang, T.; Yin, X. Experimental research on the influence of threshing roller structures on the quality of mechanically-harvested soybeans. Trans. Chin. Soc. Agric. Eng. 2021, 37, 49–58. [Google Scholar]

- Duanyang, G.; Daolin, Z. Threshing device. In New Agricultural Mechanics, 1st ed.; Duanyang, G., Daolin, Z., Eds.; National Defense Industry Press: Beijing, China, 2011; Volume 11, pp. 267–268. [Google Scholar]

- Teng, Y.J.; Chen, Y.P.; Jin, C.Q.; Yin, X. Design and test on the type of spiral cylinder⁃segmented concave threshing system the type of spiral cylinder-segmented concave threshing system. In Proceedings of the 2019 ASABE Annual International Meeting 1900700, Boston, MA, USA, 7–10 July 2019. [Google Scholar]

- Liang, S.N.; Jin, C.Q.; Zhang, F.F.; Kang, D.; Hu, M.J. Design and experiment of 4LZG-3.0 millet combine harvester. Trans. Chin. Soc. Agric. Eng. 2015, 31, 31–38. [Google Scholar]

- Sandhiya, D.P.; Eindhuja, M.; Giridharan, K.; Kamali, K.; Sakthi, V.S. Design and Development of Sesame Threshing Unit. Sci. Hub Appl. Res. Eng. Inf. Technol. 2022, 2, 19–26. [Google Scholar]

- Gurracho, B.A.; Bedie, A.F.; Tola, Y.B.; Habtegabriel, S.A.; Forsio, S.F. Design, Manufacturing and Testing of Composite Type Cylinder Sorghum Thresher. East Afr. J. Sci. 2024, 18, 1–14. [Google Scholar] [CrossRef]

- Xin, P.L.; Wan, T.Z.; Wen, Z.W.; Yu, H. Design and Test of Longitudinal Axial Flow Staggered Millet Flexible Threshing Device. Agriculture 2022, 12, 1179. [Google Scholar] [CrossRef]

- Fulani, A.U.; Kuje, J.Y.; Mohammed, B.I. Effect of Moisture Content on Performance of a Locally Fabricated Cowpea Thresher. J. Eng. Appl. Sci. 2013, 5, 1–15. [Google Scholar]

| Level | Experimental Factors | ||

|---|---|---|---|

| Operating Speed X1/m·s−1 | Threshing Element Bending Angle X2/° | Threshing Element Mounting Angle X3/° | |

| 1 | 0.8 | 70 | 0 |

| 2 | 1.0 | 80 | 45 |

| 3 | 1.2 | 90 | 90 |

| No. | X1 | X2 | X3 | The Entrainment Loss Rate Y1/% | The Net Threshing Rate Y2/% |

|---|---|---|---|---|---|

| 1 | 0.8 | 70 | 45 | 2.62 | 89.21 |

| 2 | 1.2 | 90 | 45 | 4.47 | 91.37 |

| 3 | 1.0 | 90 | 0 | 0.71 | 89.73 |

| 4 | 1.0 | 80 | 45 | 1.92 | 94.75 |

| 5 | 1.2 | 70 | 45 | 4.63 | 88.18 |

| 6 | 1.2 | 80 | 0 | 1.67 | 83.84 |

| 7 | 0.8 | 80 | 0 | 0.05 | 85.03 |

| 8 | 0.8 | 80 | 90 | 6.78 | 84.56 |

| 9 | 1.0 | 70 | 90 | 7.80 | 86.49 |

| 10 | 1.0 | 80 | 45 | 2.02 | 95.24 |

| 11 | 1.0 | 70 | 0 | 0.79 | 87.13 |

| 12 | 1.0 | 80 | 45 | 1.95 | 94.07 |

| 13 | 1.2 | 80 | 90 | 8.82 | 82.64 |

| 14 | 1.0 | 80 | 45 | 1.84 | 95.14 |

| 15 | 1.0 | 90 | 90 | 7.67 | 90.07 |

| 16 | 0.8 | 90 | 45 | 2.44 | 92.32 |

| 17 | 1.0 | 80 | 45 | 1.89 | 95.53 |

| Source of Variation | Sum of Squares | Degrees of Freedom | Mean Square | F | p |

|---|---|---|---|---|---|

| mold | 121.71 | 9 | 13.52 | 2409.09 | <0.0001 ** |

| X1 | 7.41 | 1 | 7.41 | 1320.24 | <0.0001 ** |

| X2 | 0.0378 | 1 | 0.0378 | 6.74 | 0.0357 * |

| X3 | 96.95 | 1 | 96.95 | 17,271.15 | <0.0001 ** |

| X1X2 | 0.0001 | 1 | 0.0001 | 0.0178 | 0.8976 |

| X1X3 | 0.0441 | 1 | 0.0441 | 7.86 | 0.0264 * |

| X2X3 | 0.0006 | 1 | 0.0006 | 0.1113 | 0.7484 |

| X12 | 3.05 | 1 | 3.05 | 544.15 | <0.0001 ** |

| X22 | 2.46 | 1 | 2.46 | 438.09 | <0.0001 ** |

| X32 | 10.17 | 1 | 10.17 | 1811.92 | <0.0001 ** |

| Residual | 0.0393 | 7 | 0.0056 | ||

| Incoherent | 0.0212 | 3 | 0.0071 | 1.56 | 0.3308 |

| Pure error | 0.0181 | 4 | 0.0045 | ||

| Inaccuracies | 121.75 | 16 |

| Source of Variation | Sum of Squares | Degrees of Freedom | Mean Square | F | p |

|---|---|---|---|---|---|

| mold | 298.86 | 9 | 33.21 | 139.44 | <0.0001 ** |

| X1 | 3.24 | 1 | 3.24 | 13.60 | 0.0078 ** |

| X2 | 19.47 | 1 | 19.47 | 81.76 | <0.0001 ** |

| X3 | 0.4851 | 1 | 0.4851 | 2.04 | 0.1965 |

| X1X2 | 0.0016 | 1 | 0.0016 | 0.0067 | 0.9370 |

| X1X3 | 0.1332 | 1 | 0.1332 | 0.5595 | 0.4789 |

| X2X3 | 0.2401 | 1 | 0.2401 | 1.01 | 0.3488 |

| X12 | 85.52 | 1 | 85.52 | 359.12 | <0.0001 ** |

| X22 | 0.1206 | 1 | 0.1206 | 0.5065 | 0.4997 |

| X32 | 173.64 | 1 | 173.64 | 729.16 | <0.0001 ** |

| Residual | 1.67 | 7 | 0.2381 | ||

| Incoherent | 0.3960 | 3 | 0.1320 | 0.4155 | 0.7518 |

| Pure error | 1.27 | 4 | 0.3177 | ||

| Inaccuracies | 300.53 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, J.; He, Q.; Geng, D.; Niu, L.; Cui, Y.; Yu, Q.; Yin, J.; Wang, Y.; Ni, L. Research and Experimentation on Sparse–Dense Interphase Curved-Tooth Sorghum Threshing Technology. Agriculture 2024, 14, 1722. https://doi.org/10.3390/agriculture14101722

Ma J, He Q, Geng D, Niu L, Cui Y, Yu Q, Yin J, Wang Y, Ni L. Research and Experimentation on Sparse–Dense Interphase Curved-Tooth Sorghum Threshing Technology. Agriculture. 2024; 14(10):1722. https://doi.org/10.3390/agriculture14101722

Chicago/Turabian StyleMa, Jie, Qinghao He, Duanyang Geng, Lin Niu, Yipeng Cui, Qiming Yu, Jianning Yin, Yang Wang, and Lei Ni. 2024. "Research and Experimentation on Sparse–Dense Interphase Curved-Tooth Sorghum Threshing Technology" Agriculture 14, no. 10: 1722. https://doi.org/10.3390/agriculture14101722

APA StyleMa, J., He, Q., Geng, D., Niu, L., Cui, Y., Yu, Q., Yin, J., Wang, Y., & Ni, L. (2024). Research and Experimentation on Sparse–Dense Interphase Curved-Tooth Sorghum Threshing Technology. Agriculture, 14(10), 1722. https://doi.org/10.3390/agriculture14101722