Enhancing Agricultural Biogas Desulfurization: Improving Cost-Efficiency and Robustness Through Micro-Aeration with Psychrophilic Anaerobic Liquid/Solid Media

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Set-Up

2.1.1. Liquid Inoculum as Biodesulfurization Medium (Phase 1)

2.1.2. Solid-Inoculum as Biodesulfurization Medium (Phase-2)

2.2. Sampling and Analytical Procedures

3. Results and Discussion

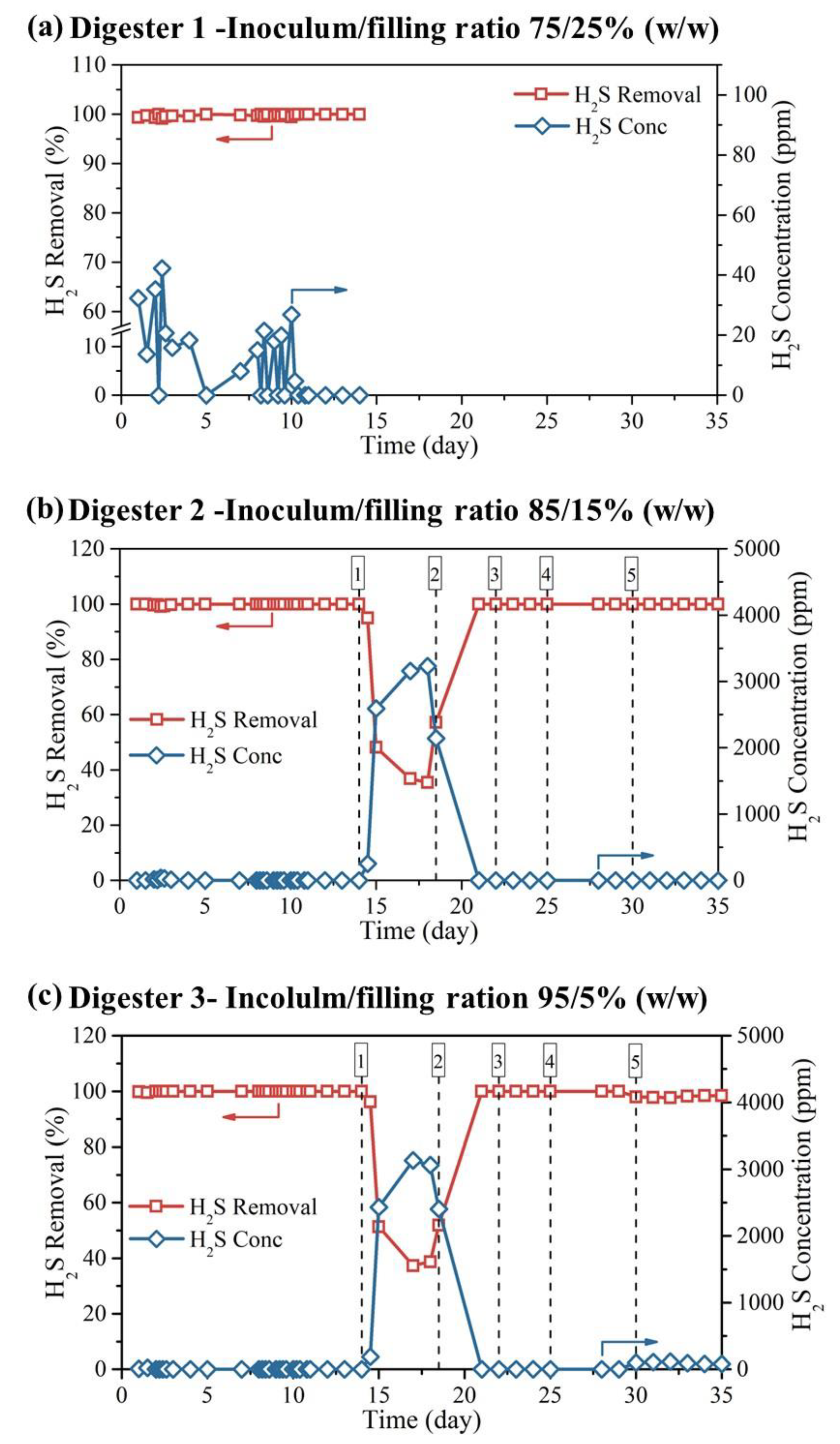

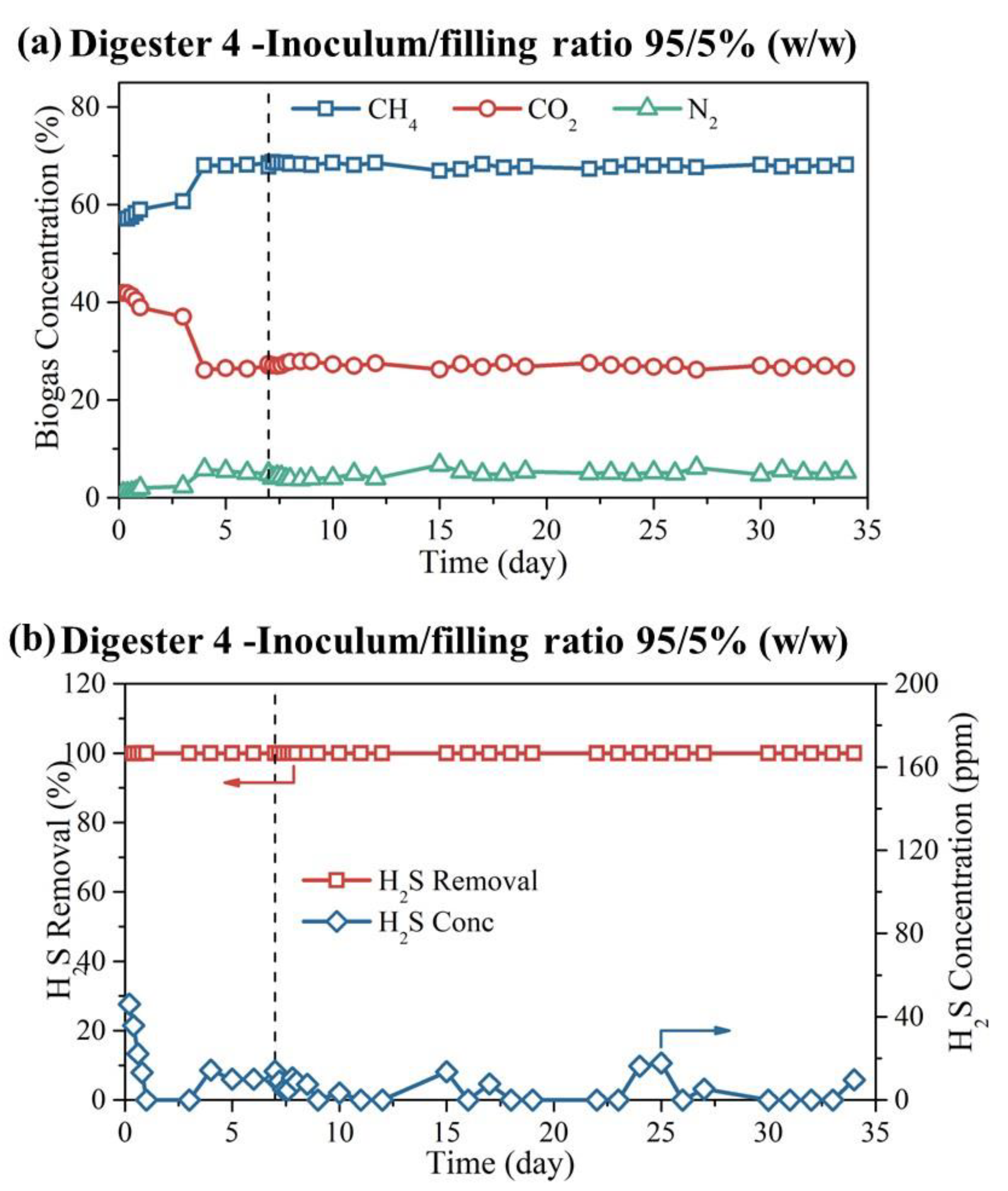

3.1. Liquid-Inoculum as Biodesulfurization Medium (Phase 1)

3.2. Solid-Inoculum as Biodesulfurization Medium (Phase 2)

3.2.1. Determination of Adequate Structural Mix and O2 Concentrations

3.2.2. Validation of Experimental Results and Determination of H2S Removal Saturation Limit

4. Comparative Assessment and Recommendations

4.1. A Summary of Desulfurization Studies

| Type of Waste or Substrate | Reactor Type | Method/Set-Up | Capacity of Reactor, (L, Working Volume) | Operating Conditions | Biodesulfurization Efficiency (%) | Key Remarks | References | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Operating Temperature (°C) | pH | Chemical Added to Raise H2S Concentration | HRT (Days) | Air Flow Rate (L/d) or O2 Concentration (%) | Air/O2 Dose Point | ORP Set Point (mV) | H2S Concentration (ppm) | |||||||

| In-situ Desulfurization (within the Anaerobic Digester) | ||||||||||||||

| Synthetic brewery wastewater | UASB and micro aerated UASB | UASB (control) and UMSB (micro aerobic USAB) | 2.7 | 37 | 7.0–7.6 | Na2SO4 | 0.3 | 1 (air flow) | n.a. | UASB −450 mV UMSB −425 mV | 5850 | 73% | Sulfur removed in the form of inorganic suspended solids and partly accumulated on head space wall and G-L-S separator. | [19] |

| Municipal WWTP 1 | Anaerobic digesters | Digester P—1600 m3 2 Digester M—2600 m3 2 | n.a. | n.a. | n.a. | n.a. | P—24,000 (air flow) M—8160 (air flow) | Dosing in sludge recirculation stream (in liquid phase) | n.a. | P—2438 M—507 | Dig P—87.9% Dig M—96.0% | Air can be used instead of pure oxygen (no decrease in methane content due to nitrogen dilution when air was used). | [18] | |

| Municipal WWTP | CSTRs | Reactor R1 mixed with Sludge Recirculation (SR) R2 mixed with Biogas Recirculation (BR) | 200 | 35 ± 1 | 7.1–7.3 | Na2SO4 | 20 | 2.5 3 (O2 flow) | R1—SR and head space R2—feed sludge and head space | −510 mV | R1—14,437 R2—12,926 | >98% | Similar biodesulfurization efficiencies were achieved regardless of dosing point. BR can be used to remove dissolved sulfide from liquid. | [26] |

| WWTP | CSTRs | Reactor S1 with Sludge Recirculation (SR) Reactor S2 with Biogas Recirculation (BR) | 200 | 35 ± 1 | n.a. | Na2SO4 | 20 | S1—4.7 (O2 flow) S2—4.5 (O2 flow) | SR, feed sludge | n.a. | S1—9318 S2—10,361 | >99% | SR and BR as mixing methods show the same biodesulfurization efficiencies. BR reduced dissolved sulfide concentration by 10 times (compared to SR). | [27] |

| Animal waste (Chicken manure) | CSTRs | In situ desulfurization | 10 | 37 | 7.7–8.1 | n.a. | 40 | 0.12–0.36 (air flow) | Head space | n.a. | 5500 | 68–99% | Single-pulse air injection gave the lowest removal efficiency (68%) and for continuous air injection, an increase in air dose increased the biodesulfurization efficiency. Micro-aeration enhanced sulfide-oxidising bacteria and increased soluble iron concentration, which had a positive effect on methane yield. | [21] |

| Municipal WWTP | Anaerobic Digesters | ORP used to regulate oxygen injection | 50 | 35.0 ± 0.2 | 6.9–7.1 | Mg·SO4·7H2O | 20 | 12.1 (O2 flow) | Liquid sludge phase | −320 to −270 mV (baseline −485 mV) | 6000 | >99% | To obtain a suitable micro-aerobic condition, ORP can be used as a regulating parameter. | [29] |

| Municipal WWTP | CSTR | Robustness study on a pilot-plant digester (variations in sulfur load and in oxygen rate studied) | 200 | 35 ± 1 | 7.2–7.4 | Na2SO4 | 20 | 3.6 4 (O2 flow) | Head space | n.a. | n.a. | n.a. | The biodesulfurization process showed quick recovery from variations in sulfur load, O2 supply and from opening the digester for head space cleaning to remove accumulated sulfur. | [30] |

| Synthetic WW | Continuous-flow anaerobic reactor | Reactor was operated under anaerobic condition until stabilization after which micro-aeration commenced | 2.8 | n.a. | n.a. | Na2SO4 | 0.5 | 0.29 (air flow) | Head space | n.a. | 0.15 5 | 93 | Methane production was reduced due to nitrogen dilution by air. Micro-aeration was technically and economically more feasible than traditional caustic washing for H2S removal. | [31] |

| WWTP | n.a. | Micro-aeration using air or oxygen | 200 | 35 ± 1 | 7.2–7.4 | Na2SO4 | 20 | 2.9 (O2 flow) | Head space | −510 to −480 mV | 10,392 | >99 | Methane in biogas was reduced due to nitrogen dilution when air was used for micro-aeration. | [32] |

| Ex-situ Desulfurization Unit | ||||||||||||||

| Municipal WWTP | Sulfide Oxidizing Unit (SOU) | 1 L (SOU)—connected to output of AD (92 L volume) along with ORP and pH control units | n.a. | 25 ± 2 | 7.1 | Na2SO4 | 20 | 1.4 (air flow) | n.a. | −200 mV | 2170 | >99% | Constant pH along with ORP controlled aeration can prevent oxygen overdosing. | [16] |

| Animal manure and energy crops | Fixed-bed trickling bioreactor (FBTB) | External desulfurization unit consisted of FBTB and carbon filter installed between secondary digester and CHP unit | n.a. | 35–37 | n.a. | No | n.a. | O2 content 0.5% and 2% in biogas | Biogas supply pipeline | n.a. | 500–600 | 98% | Highest removal efficiency obtained at 30–40 °C. Here, 35 °C was observed as the optimum temperature range for sulfate-reducing bacteria. | [25] |

| Animal waste (swine, dairy) | Biodesulfurization reactor | Phase 1—liquid inoculum as biodesulfurization medium Phase 2—solid inoculum as biodesulfurization medium | Liquid inoculum digester—15 Solid inoculum digester—10 | 20 ± 1 | n.a. | No | n.a. | O2 concentration in biogas 0.5% to 1% | n.a. | n.a. | 1000–4000 | Phase 1—94% Phase 2—99.8% | Volume of solid inoculum (Phase 2) required was at least half of the liquid inoculum needed. Use of diffusers (required in the case of liquid medium) can be neglected. | Present study |

4.2. Liquid vs. Solid Biodesulfurization Medium

4.3. Solid Medium: Footprint and Cost-Benefit Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lyng, K.-A.; Bjerkestrand, M.; Stensgård, A.; Callewaert, P.; Hanssen, O. Optimising Anaerobic Digestion of Manure Resources at a Regional Level. Sustainability 2018, 10, 286. [Google Scholar] [CrossRef]

- Massé, D.I.; Rajagopal, R.; Singh, G. Technical and Operational Feasibility of Psychrophilic Anaerobic Digestion Biotechnology for Processing Ammonia-Rich Waste. Appl. Energy 2014, 120, 49–55. [Google Scholar] [CrossRef]

- Nguyen, L.N.; Kumar, J.; Vu, M.T.; Mohammed, J.A.H.; Pathak, N.; Commault, A.S.; Sutherland, D.; Zdarta, J.; Tyagi, V.K.; Nghiem, L.D. Biomethane Production from Anaerobic Co-Digestion at Wastewater Treatment Plants: A Critical Review on Development and Innovations in Biogas Upgrading Techniques. Sci. Total Environ. 2021, 765, 142753. [Google Scholar] [CrossRef] [PubMed]

- Vu, H.P.; Nguyen, L.N.; Wang, Q.; Ngo, H.H.; Liu, Q.; Zhang, X.; Nghiem, L.D. Hydrogen Sulphide Management in Anaerobic Digestion: A Critical Review on Input Control, Process Regulation, and Post-Treatment. Bioresour. Technol. 2022, 346, 126634. [Google Scholar] [CrossRef]

- EPA, United States Environmental Protection Agency [WWW Document], 2023. AgSTAR. Available online: https://www.epa.gov/agstar/agstar-data-and-trends (accessed on 11 March 2024).

- IEA. Bioenergy Task 37, Country Report Summaries; IEA: Paris, France, 2019. [Google Scholar]

- IEA. Biogas Production and Utilisation; IEA: Paris, France, 2005. [Google Scholar]

- Wang, X.; Lu, X.; Yang, G.; Feng, Y.; Ren, G.; Han, X. Development Process and Probable Future Transformations of Rural Biogas in China. Renew. Sustain. Energy Rev. 2016, 55, 703–712. [Google Scholar] [CrossRef]

- Li, Y.; Alaimo, C.P.; Kim, M.; Kado, N.Y.; Peppers, J.; Xue, J.; Wan, C.; Green, P.G.; Zhang, R.; Jenkins, B.M.; et al. Composition and Toxicity of Biogas Produced from Different Feedstocks in California. Environ. Sci. Technol. 2019, 53, 11569–11579. [Google Scholar] [CrossRef]

- Muñoz, R.; Meier, L.; Diaz, I.; Jeison, D. A Review on the State-of-the-Art of Physical/Chemical and Biological Technologies for Biogas Upgrading. Rev. Environ. Sci. Biotechnol. 2015, 14, 727–759. [Google Scholar] [CrossRef]

- Vikrant, K.; Kailasa, S.K.; Tsang, D.C.W.; Lee, S.S.; Kumar, P.; Giri, B.S.; Singh, R.S.; Kim, K.-H. Biofiltration of Hydrogen Sulfide: Trends and Challenges. J. Clean. Prod. 2018, 187, 131–147. [Google Scholar] [CrossRef]

- Noyola, A.; Morgan-Sagastume, J.M.; López-Hernández, J.E. Treatment of Biogas Produced in Anaerobic Reactors for Domestic Wastewater: Odor Control and Energy/Resource Recovery. Rev. Environ. Sci. Biotechnol. 2006, 5, 93–114. [Google Scholar] [CrossRef]

- Leitao, R.; Vanhaandel, A.; Zeeman, G.; Lettinga, G. The Effects of Operational and Environmental Variations on Anaerobic Wastewater Treatment Systems: A Review. Bioresour. Technol. 2006, 97, 1105–1118. [Google Scholar] [CrossRef]

- Haghighatafshar, S. Management of Hydrogen Sulfide in Anaerobic Digestion of Enzyme Pretreated Marine Macro-Algae. Master’s Thesis, Lund University, Lund, Sweden, 2012. [Google Scholar]

- Choudhury, A.; Shelford, T.; Felton, G.; Gooch, C.; Lansing, S. Evaluation of Hydrogen Sulfide Scrubbing Systems for Anaerobic Digesters on Two U.S. Dairy Farms. Energies 2019, 12, 4605. [Google Scholar] [CrossRef]

- Duangmanee, T. Micro-Aeration for Hydrogen Sulfide Removal from Biogas. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2009. [Google Scholar]

- Pudi, A.; Rezaei, M.; Signorini, V.; Andersson, M.P.; Baschetti, M.G.; Mansouri, S.S. Hydrogen Sulfide Capture and Removal Technologies: A Comprehensive Review of Recent Developments and Emerging Trends. Sep. Purif. Technol. 2022, 298, 121448. [Google Scholar] [CrossRef]

- Jeníček, P.; Horejš, J.; Pokorná-Krayzelová, L.; Bindzar, J.; Bartáček, J. Simple Biogas Desulfurization by Microaeration—Full Scale Experience. Anaerobe 2017, 46, 41–45. [Google Scholar] [CrossRef]

- Krayzelova, L.; Bartacek, J.; Kolesarova, N.; Jenicek, P. Microaeration for Hydrogen Sulfide Removal in UASB Reactor. Bioresour. Technol. 2014, 172, 297–302. [Google Scholar] [CrossRef]

- Ghimire, A.; Gyawali, R.; Lens, P.N.L.; Lohani, S.P. Technologies for Removal of Hydrogen Sulfide (H2S) from Biogas. In Emerging Technologies and Biological Systems for Biogas Upgrading; Elsevier: Amsterdam, The Netherlands, 2021; pp. 295–320. ISBN 978-0-12-822808-1. [Google Scholar]

- Song, Y.; Mahdy, A.; Hou, Z.; Lin, M.; Stinner, W.; Qiao, W.; Dong, R. Air Supplement as a Stimulation Approach for the In Situ Desulfurization and Methanization Enhancement of Anaerobic Digestion of Chicken Manure. Energy Fuels 2020, 34, 12606–12615. [Google Scholar] [CrossRef]

- Tian, G.; Xi, J.; Yeung, M.; Ren, G. Characteristics and Mechanisms of H2S Production in Anaerobic Digestion of Food Waste. Sci. Total Environ. 2020, 724, 137977. [Google Scholar] [CrossRef]

- Krayzelova, L.; Bartacek, J.; Díaz, I.; Jeison, D.; Volcke, E.I.P.; Jenicek, P. Microaeration for Hydrogen Sulfide Removal during Anaerobic Treatment: A Review. Rev. Environ. Sci. Biotechnol. 2015, 14, 703–725. [Google Scholar] [CrossRef]

- Eaton, A.D.; Clesceri, L.S.; Greenberg, A.E. Standard Methods for the Examination of Water and Wastewater; American Public Health Association (APHA): Washington, DC, USA, 2005. [Google Scholar]

- Naegele, H.-J.; Merkle, J.L.W.; Lemmer, A.; Jungbluth, T.; Bogenrieder, C. Effects of Temperature, pH and O2 on the Removal of Hydrogen Sulfide from Biogas by External Biological Desulfurization in a Full Scale Fixed-Bed Trickling Bioreactor (FBTB). Int. J. Agric. Biol. Eng. 2013, 6, 69–81. [Google Scholar] [CrossRef]

- Díaz, I.; Pérez, S.I.; Ferrero, E.M.; Fdz-Polanco, M. Effect of Oxygen Dosing Point and Mixing on the Microaerobic Removal of Hydrogen Sulphide in Sludge Digesters. Bioresour. Technol. 2011, 102, 3768–3775. [Google Scholar] [CrossRef]

- Fdz.-Polanco, M.; Díaz, I.; Pérez, S.I.; Lopes, A.C.; Fdz.-Polanco, F. Hydrogen Sulphide Removal in the Anaerobic Digestion of Sludge by Micro-Aerobic Processes: Pilot Plant Experience. Water Sci. Technol. 2009, 60, 3045–3050. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Tsapekos, P.; Alfaro, N.; Díaz, I.; Fdz-Polanco, M.; Rafiee, S.; Angelidaki, I. A Review on Prospects and Challenges of Biological H2S Removal from Biogas with Focus on Biotrickling Filtration and Microaerobic Desulfurization. Biofuel Res. J. 2017, 4, 741–750. [Google Scholar] [CrossRef]

- Nghiem, L.D.; Manassa, P.; Dawson, M.; Fitzgerald, S.K. Oxidation Reduction Potential as a Parameter to Regulate Micro-Oxygen Injection into Anaerobic Digester for Reducing Hydrogen Sulphide Concentration in Biogas. Bioresour. Technol. 2014, 173, 443–447. [Google Scholar] [CrossRef] [PubMed]

- Díaz, I.; Fdz-Polanco, M. Robustness of the Microaerobic Removal of Hydrogen Sulfide from Biogas. Water Sci. Technol. 2012, 65, 1368–1374. [Google Scholar] [CrossRef] [PubMed]

- Sousa, M.R.; Oliveira, C.J.S.; Lopes, A.C.; Rodríguez, E.R.; Holanda, G.B.M.; Landim, P.G.C.; Firmino, P.I.M.; Dos Santos, A.B. Technical, Economical, and Microbiological Aspects of the Microaerobic Process on H2S Removal for Low Sulfate Concentration Wastewaters. Appl. Biochem. Biotechnol. 2016, 180, 1386–1400. [Google Scholar] [CrossRef]

- Díaz, I.; Lopes, A.C.; Pérez, S.I.; Fdz-Polanco, M. Performance Evaluation of Oxygen, Air and Nitrate for the Microaerobic Removal of Hydrogen Sulphide in Biogas from Sludge Digestion. Bioresour. Technol. 2010, 101, 7724–7730. [Google Scholar] [CrossRef]

- Mulbry, W.; Selmer, K.; Lansing, S. Effect of Liquid Surface Area on Hydrogen Sulfide Oxidation during Micro-Aeration in Dairy Manure Digesters. PLoS ONE 2017, 12, e0185738. [Google Scholar] [CrossRef]

- Di Costanzo, N.; Di Capua, F.; Cesaro, A.; Carraturo, F.; Salamone, M.; Guida, M.; Esposito, G.; Giordano, A. Headspace Micro-Oxygenation as a Strategy for Efficient Biogas Desulfurization and Biomethane Generation in a Centralized Sewage Sludge Digestion Plant. Biomass Bioenergy 2024, 183, 107151. [Google Scholar] [CrossRef]

| Parameter | 15-L Active Volume Bioreactor | 250-L Active Volume Bioreactor |

|---|---|---|

| Gas Composition (Inlet) | ||

| CH4 (Methane) | 65–70% | 65–70% |

| CO2 (Carbon Dioxide) | 25–30% | 25–30% |

| N2 (Nitrogen) | <1% | <1% |

| O2 (Oxygen) | 1% O2-to-biogas | 1% O2-to-biogas |

| Gas Composition (Outlet) | ||

| CH4 (Methane) | 65–70% | 65–70% |

| CO2 (Carbon Dioxide) | 25–30% | 25–30% |

| N2 (Nitrogen) | <1% | <1% |

| O2 (Oxygen) | ND | ND |

| Other Values (Outlet) | ||

| H2S Concentration | Reduced from ~1000–4000 ppm (inlet) to <50 ppm (outlet) | Similar rate observed |

| Elemental Sulfur (S0) | Accumulation rate: ~2.4 mg S₀/Linoculum/h | Similar rate observed |

| COD (Chemical Oxygen Demand) | Initial: ~4000 mg/L, reduced during operation (~15%) | Same as 40 L (~12%, reduction rate) |

| Total Solids (TS) | ~3.5–4.0%, reduced during operation (10–16%) | Similar rate observed (~12%, reduction rate) |

| Volatile Solids (VS) | ~2.8–3.2%, reduced during operation (7–10%) | Similar rate observed (~8%, reduction rate) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajagopal, R.; Goyette, B. Enhancing Agricultural Biogas Desulfurization: Improving Cost-Efficiency and Robustness Through Micro-Aeration with Psychrophilic Anaerobic Liquid/Solid Media. Agriculture 2024, 14, 2113. https://doi.org/10.3390/agriculture14122113

Rajagopal R, Goyette B. Enhancing Agricultural Biogas Desulfurization: Improving Cost-Efficiency and Robustness Through Micro-Aeration with Psychrophilic Anaerobic Liquid/Solid Media. Agriculture. 2024; 14(12):2113. https://doi.org/10.3390/agriculture14122113

Chicago/Turabian StyleRajagopal, Rajinikanth, and Bernard Goyette. 2024. "Enhancing Agricultural Biogas Desulfurization: Improving Cost-Efficiency and Robustness Through Micro-Aeration with Psychrophilic Anaerobic Liquid/Solid Media" Agriculture 14, no. 12: 2113. https://doi.org/10.3390/agriculture14122113

APA StyleRajagopal, R., & Goyette, B. (2024). Enhancing Agricultural Biogas Desulfurization: Improving Cost-Efficiency and Robustness Through Micro-Aeration with Psychrophilic Anaerobic Liquid/Solid Media. Agriculture, 14(12), 2113. https://doi.org/10.3390/agriculture14122113