Abstract

The dessert banana is a popular fruit worldwide, but its ripening process is greatly accelerated by high temperatures, which eventually leads to an unpleasant taste and the appearance of spots on the skin of the fruits. To slow down the ripening of bananas, expensive strategies are used, which are usually not practical for conventional farmers in less developed countries. In this study, we try to find a less costly alternative. Therefore, the effects of coatings of lemon peel extract (2.5%, 5%, and 10%), calcium chloride (4%), and glycerol (2%) on the shelf life and postharvest quality of the banana fruit (Cavendish) stored at 19–22 °C and 40–60% relative humidity were investigated. Treatment with a mixture of 2.5% lemon peel extract and 2% glycerol resulted in an extension of the shelf life of the dessert banana by up to 6 days and no detectable fungal infestation. The coating solution is an effective alternative to extend the shelf life and reduce quality losses in bananas.

1. Introduction

Bananas are among the most well-known and frequently consumed fruits worldwide. It is valued for its convenient size, ease of transport, and sweet and savory taste. However, aside from their delicious flavor, bananas are also very nutritious and have numerous health benefits. The Cavendish banana variety is the fifth largest agricultural commodity in the world trade after cereals, cassava, sweet potato, and yams and the fourth most important foodstuff in the world after rice, wheat, and milk [1]. Banana plays an important socioeconomic role in developing countries from tropical and subtropical zones, especially in east, central, and west African countries, Southeast Asia, Central and South America, and the Caribbean [2]. Cavendish banana production is currently dominated by Indonesia, with the Philippines in second place. The Philippines produced roughly 7.5 million tonnes of bananas in 2020, compared to Indonesia’s production of over 11 million tonnes. With 2.3 million, 1.5 million, and 1.1 million tonnes of Cavendish bananas produced in 2020, the United Nations Organization for Food and Agriculture reports that Ivory Coast, Ghana, and Cameroon are Africa’s top producers of the variety [3].

Banana is a rich source of vitamins A, B, and C, manganese, potassium, and fibers. In addition, 100 g of banana contains approximately 89 kcal calories, 74 g water, 1.1 g protein, 0.3 g lipid, 21.8 g carbohydrate, 2 g fiber, 1 mg sodium, 385 mg potassium, 8 mg calcium, 30 mg magnesium, 0.4 mg iron, 22 mg phosphorous, 11.7 mg ascorbic acid, 40 µg thiamin, 70 µg riboflavin, 610 µg niacin, 80–600 µg pantothenic acid, 470 µg pyridoxine, and 23 µg folic acid [4].

Banana is a climacteric fruit that ripens quickly after harvesting. Thus, it is a perishable fruit and has a very short lifespan between harvest and the onset of deterioration [5]. It is estimated that post-harvest losses in bananas can differ based on several variables, including the variety of bananas, the storage conditions, and the handling methods. In developing countries, post-harvest loss of bananas reaches 30% or higher because of the poor storing and handling conditions, which are frequently unsatisfactory, while post-harvest losses are often lower in developed countries with stronger handling and storage infrastructure, averaging around 5–10% [3]. Many storage methods have been developed to increase the time and distance between harvest and marketing for commodities. For example, the fruit is usually harvested when mature and unripe for commercial use and refrigerated during transportation to the importing nations. Upon arrival at their destination, the green bananas are held in modified atmospheric rooms at the distribution centers, where they are treated with chemicals like ethylene gas before selling [6]. By lowering the metabolic rate, minimizing peel degreening, and preventing fruit degradation, several other preservation techniques have been investigated, such as regulated and controlled atmospheres [7]. Similarly, low oxygen pre-treatment for two days can prevent bananas from ripening during storage and shipping [8]. To preserve the color and texture of post-harvest bananas, chemicals are frequently used to delay ripening [9]. Edible coatings [10] and the combinations of chemical dipping with edible coatings [11] are also used. Small farmers in developing countries rely on the natural ripening of bananas, which can be considered unsustainable and unprofitable as these processes are very costly. Because of inadequate storage and ripening conditions, many ripe bananas are lost or spoiled.

Among all the methods of fruit preservation currently in use, the use of edible coatings is a popular practice that helps preserve the nutrients of food, particularly fruits, and vegetables, and offers long shelf lives [12]. Edible coatings help preserve volatile flavor components, slow down microbial growth, delay dehydration, reduce respiration, improve textural quality, and prolong the shelf life of perishable food products [13]. The antioxidant and antifungal qualities of the coating solution give it the ability to delay ripening and senescence. According to recent studies, fruit seeds and peels may potentially have antioxidant capabilities. Examples include mango seed kernels [14], pomegranate peels [15], wampee peels [16], and grape seeds and peels [17]. In the past ten years, several researchers have suggested that citrus waste might be utilized as a natural source of antioxidants [18]. The wealth of this information is invaluable particularly when considering the context of sub-Saharan Countries such as Cameroon, where it has been observed that 76% of oranges and 60% of lemons are wasted due to failure to sell, mechanical damage during transportation, storage conditions, inappropriate used packaging material, and poor hygiene [19]. This led us to use lemon peel as the basis for our coating solution. However, using glycerol as a plasticizer, calcium chloride has been widely used as a preservative and firming agent for whole and fresh-cut goods. The use of calcium chloride has also been linked to fruit firmness, stress tolerance, ripening, and senescence [20]. There is little information about the combined effect of lemon peel extract and calcium chloride on banana fruits. Therefore, the objective of this study was to find an alternative solution to extend the shelf life of bananas by using a combination of lemon peel extract, glycerol, and calcium chloride as an edible coating solution and study their effect on the physicochemical and biochemical qualities of the dessert banana fruit.

2. Materials and Methods

2.1. Chemicals and Reagents

The standards lutein, alpha-carotene, beta-carotene, sucrose, fructose, and glucose were obtained from Sigma-Aldrich (Darmstadt, Germany); acetone, acetonitrile, n-hexane, ethanol (EtOH), methanol (MeOH), methyl tert-butyl ether (MTBE), calcium chloride (CaCl2), and glycerol were purchased from Merck (Darmstadt, Germany). H2O and acetonitrile were of liquid chromatography grade.

2.2. Plant Materials

Sample Preparation and Storage

Lemon fruits were acquired from a private plantation in Foumbot, Cameroon, which is located in the western part of the country. After removing all the fruits with physiological and physical abnormalities, such as those that were rotten and immature, the fruits were immersed for around 2 h in water containing sodium hypochlorite (230 µL·L−1) for disinfection. After that, they were rinsed with fresh tap water and the fruit’s peels were removed using a sharp knife. They were crushed with a conventional grinder after they had completely dried in the shade, producing a lemon peel powder, and were transported to the Fraunhofer Institute for Process Engineering and Packaging IVV, department of Optimization of the Quality and Shelf-life of Foods, where the experiments were carried out.

Seven hundred banana fruits from Costa Rica were purchased fresh from a local supermarket in Germany. They were in the greenest stage conceivable (stage 1), as indicated by a greenness of level 1. After being delivered to the laboratory, healthy fruits were selected, disassembled, thoroughly washed with fresh tap water, and dried for about two hours under ambient temperature (21–24 °C).

2.3. Coatings and Storage Conditions

The different coatings were made of different concentrations of lemon peel extract (0%, 2.5%, 5%, and 10%) which were obtained from the powder using ethanol and distilled water as solvents (CH3CH2OH/H2O, 1/1 v/v), calcium chloride (4%), and glycerol (2%). The pH of the solution was adjusted to pH 5.6 using 0.1 mol·L−1 sodium hydroxide. Bananas (54 per treatment) were dipped into the prepared coating solution for 3 min and allowed to dry for 1 h. Uncoated bananas, representing control samples (T0), were immersed in distilled water for the same period. The storage room, which was a purpose-built environmental chamber for food storage, was equipped with LED (light-emitting diodes, manufactured by Sylvania Luxine Plus, Erlangen, Germany) light to simulate daylight (F30W/865-T8). The temperature and relative humidity were controlled throughout the storage period. The temperature of the storage room was automatically recorded via an internal system and ranged from 19–22 °C, and the relative humidity was recorded using an Efento sensor (Krakow, Poland), ranging from 40 to 60% and controlled using an air humidifier (PHILIPS, Amsterdam, The Netherlands). The coated and uncoated bananas were stored for a period of 13 d and quality parameters were recorded at 4-d intervals. Visual observations were made for a further 7 d.

2.4. Experimental Design

Nine edible coating solutions were prepared, and the used concentrations in this investigation were determined through prior experiments conducted in our laboratory, undertaken as a preparatory phase preceding the development of our experimental design: T0 = control sample with only distilled water, T1 = distilled water + glycerol (2%), T2 = glycerol (2%) + 2.5% lemon peel extract, T3 = glycerol (2%) and 5% lemon peel extract, T4 = glycerol (2%) + 10% lemon peel extract, T5 = 4% calcium chloride (CaCl2), T6 = glycerol (2%) + CaCl2 (4%), T7 = glycerol (2%), CaCl2 (4%) and 2.5% lemon peel extract, T8 = glycerol (2%), CaCl2 (4%) and 5% lemon peel extract, and T9 = glycerol (2%), CaCl2 (4%), and 10% lemon peel extract. These treatments were arranged in a completely randomized design (CRD) with three replications. Eighteen banana fruits were used and replicated three times, for a total of 54 fruits were used for each treatment.

2.5. Weight Loss

The weight of each banana finger was measured using an analytical balance (Sartorius Lab Instruments, GmbH & Co., KG, Göttingen, Germany). The fruit weights were recorded at 4-d intervals throughout the storage period, and the cumulative weight loss was determined using the formula below:

where WL represents the weight loss in percentage and IM and FM represent the initial mass and the final mass in g, respectively.

2.6. Firmness

The fruit’s textural properties were measured using the texture analyzer (Model TA-XT, Stable Micro System Ltd., Surrey, UK). The data were recorded using the EXPONENT 6.2.3.0 software. The firmness of the fruit’s flesh was measured by punching the sample, resulting in a plot of strength vs. time. Compression force measurement mode, pre-test speed of 1.5 mm·s−1, test speed of 1.0 mm·s−1, post-test speed of 10 mm·s−1, trigger-auto type of 2 kg, and data acquisition speed were the working circumstances used to measure the firmness value. The accessories used were a 5 mm cylindrical probe (P/5) and a heavy platform (HDP/90). Triple readings were taken and recorded at three separate locations (the middle part, stem end, and distal end) on the fruit while resting on the texture analyzer’s platform. The average data in kilogram-force (Kgf) were used.

2.7. Color Analysis

A method described by [21] was used with modifications. A D90 digital Nikon camera and a 35 mm F/2 D Nikon prime lens (Tokyo, Japan) were used for color analysis. Digital photos were captured under controlled LED illumination using a DigiEye imaging system (VeriVide Limited, Enderby, Leicester, UK) with the help of DigiEye software version 2.8.0.3. The VeriVide D65 fluorescent tubes are located in the illumination box, which is a lighting cabinet with light having similar characteristics to natural daylight. Before any measurement, the system was calibrated using a white uniform board Digitizer Calibration Pack (version number 4.0) from the Digieye service Pack. Five banana fruits per replicate (i.e., 15 banana fruits per treatment) were placed on the surface of an additional rectangular blue plate in the box. The surface of the plate containing the fruits was illuminated by the mirrors. The blue background of the collected images was removed, and the fruit color was analyzed using ImageJ version 1.53K (http://imagej.nih.gov/ij (accessed on 26 November 2022)); the results were expressed in RBG (Red-Blue-Green) values and then converted into La*b* values using Python. These La*b* values determined the total color difference using the formula below:

where ΔL represents the change in lightness, L2* and L1* are the lightness values of the two compared samples, a2 and a1 are the red-green color values of the two compared samples, b2, and b1 are the yellow-blue color values of the two compared samples. The notation—(+ = lighter; − = darker), (+ = redder, − = greener), (+ = yellow, − = bluer)—describes the positive and negative changes in lightness (ΔL), red-green (Δa), and yellow-blue (Δb) color values.

ΔE = [(ΔL)2 + (Δa*)2 + (Δb*)2]½

ΔE = [(L2 − L1)2 + (a2 − a1)2 + (b2 − b1)2]½

2.8. Decay Percentage

The percentage of decay or rot was determined through visual observation on day 20. The survey focused on fruits that were rotten due to physiological and/or microbiological disorders, and the percentage was estimated using the following formula:

Percentage of decay (%) = (number of decayed fruits) × 100/(Total number of fruits in the treatment)

2.9. Total Soluble Sugar, Titratable Acidity, and pH

A 5 g sample of the banana pulp was prepared from 3 fruits (equal parts of fruit flesh were collected from the middle and both ends of each fruit) and homogenized with ultra-turrax and 15 mL of MQ water. The plant material was centrifuged for 10 min at 3000 rpm. Total soluble sugar was determined using a digital refractometer (Atago, Pocket Brix-Acidity Meter, Tokyo, Japan). A volume of 45 mL of MQ water was used to dilute and homogenize 5 mL of the fruit juice. The pH was measured using a digital pH meter (EC-30-PH PHOENIX instrument from ProfiLab24 GmbH, Berlin, Germany). By titrating the diluted fruit juice using a magnetic stirrer in the presence of phenolphthalein, the titratable acidity was determined and calculated using the following formula:

where the volume of NaOH (in mL) is the volume of sodium hydroxide solution (in milliliters) used to neutralize the acidity in the juice sample during the titration process, 0.1 is the normality of the sodium hydroxide (NaOH) solution and represents its concentration, 0.064 is the citric acid milliequivalent factor, and total juice volume (in mL) is the volume of the juice sample used in the titration (before the addition of NaOH).

Titratable Acidity (TA) = (Volume of NaOH (in mL) × 0.1 (normality of NaOH) × 0.064)/(Total juice volume in mL) × 100

2.10. Sugar Analysis

Ten grams of the banana pulp from each treatment were ground, diluted, and centrifuged at 13,000 rpm for 10 min. The supernatant was collected, dried via lyophilization, and kept at −4 °C for further analysis. The HPLC system used for analysis was equipped with an S5200 autosampler and a pump 1000 Smartline with Manager 5000 (Göbel Instrumentelle Analytik GmbH, Hallertau, Germany). The detector was an evaporative light scattering detector (ELSD; PL-ELS 2100, Polymer Laboratories GmbH, Darmstadt, Germany). The column (Grace GmbH, Worms, Germany) was Allsphere Amino 250 × 4.6 mm, 5 µm. MilliQ water (ultrapure water) was utilized as eluent A (20%) and acetonitrile as eluent B (80%). The flow rate was 1.0 mL·min−1 at 30 °C. The parameters for the ELSD were Evap: 80, Neb: 45, Gas: 1.6, Pmt: 6, Smth: 1, and LED: 100. The data management system was Geminix III software, version 1.10.3.9 (Göbel Instrumentelle Analytik). Sucrose, glucose, and fructose standards were used for identification and quantification.

2.11. Carotenoids Analysis

Ten grams of banana pulp were extracted using ethanol/n-hexane (4:3 v/v). After centrifugation at 13,500 rpm for 10 min, the yellow supernatant was collected and re-extracted with the same solvent until it had become colorless. The supernatants were combined and dried under reduced pressure using a rotatory evaporator. The residues were dissolved with n-hexane and redried. One hundred µL of ethyl acetate was added to the dried samples, vortexed, and centrifuged at 10,000 rpm. The analysis was carried out on the Agilent Technologies 1260 Infinity HPLC (Agilent, Waldbronn, Germany) equipped with a column size of 250 × 4.6 mm (RP-18; YMC Co., Ltd., Kyoto, Japan). The eluents were methanol (eluent A: 20%) and tert.-butyl methyl ether (eluent B: 80%). Carotenoids were detected at 440 nm. The injection volume was10 µL, and the flow rate was 1 mL·min−1. The signals were converted and recorded via the OpenLab software version 2.4. Identification and quantification of individual carotenoids were carried out by comparing retention times and UV/Vis absorption with those of authentic standards.

2.12. Statistical Analysis

With treatment and storage time as sources of variation, all quantitative parameter data were subjected to a one-way ANOVA using R version 4.1.2 (1 November 2021) statistical analysis software with its cross-platform development environment—Rstudio. Data were expressed as mean plus standard deviation (SD) from the three replicates. Tukey tests, performed at a significance level of p < 0.05, were used to find differences between treatments.

3. Results and Discussion

3.1. Weight Loss

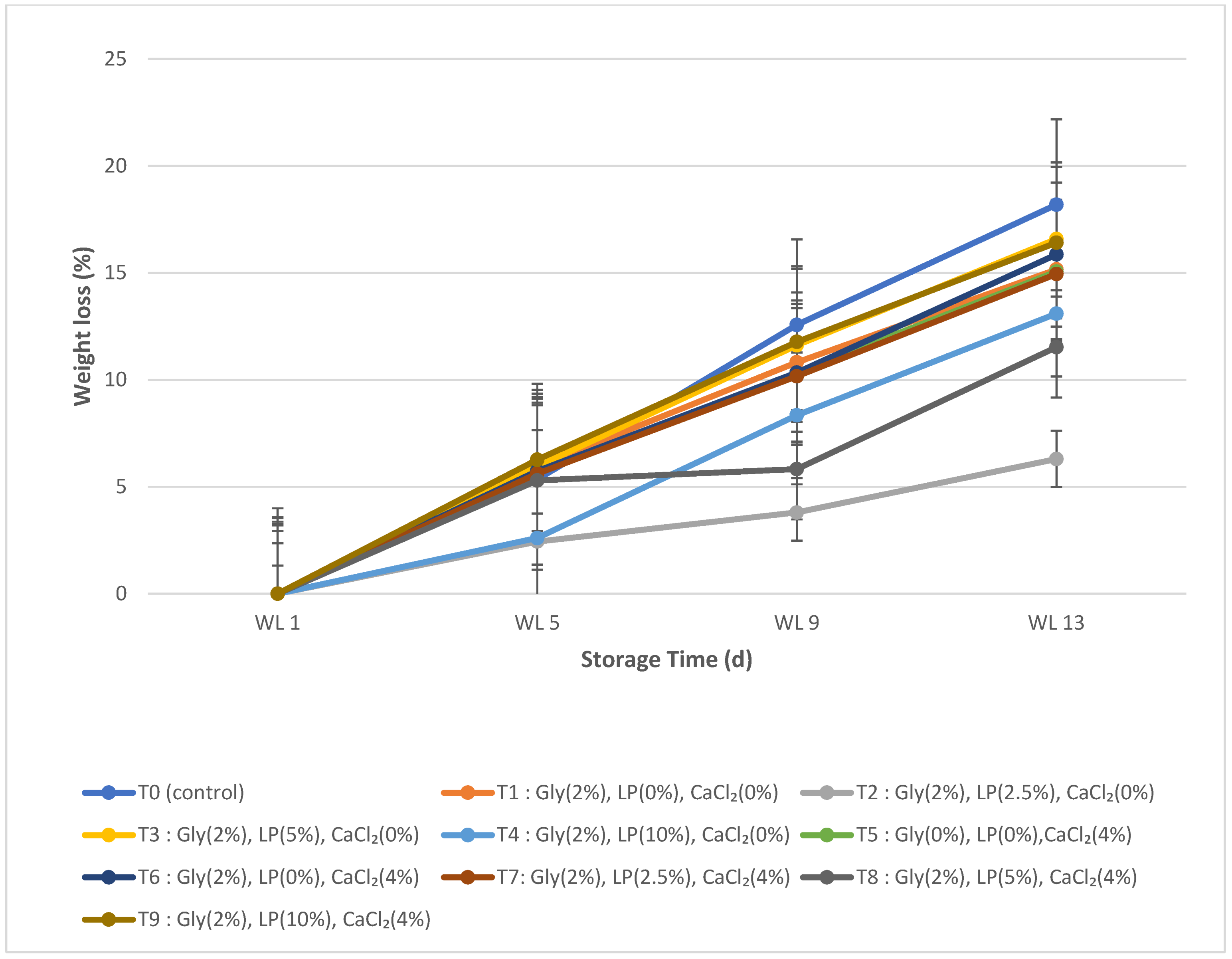

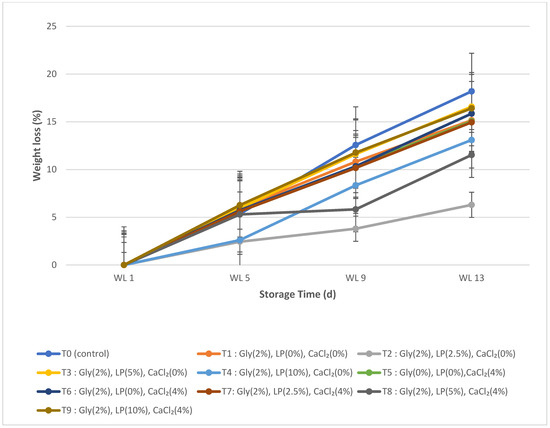

Due to physiological changes and water loss, banana fruits lose weight during storage. Therefore, the influence of edible coatings on the physiological weight loss (PWL) of banana fruits during storage was studied (Figure 1). As the storage time increased, the weight loss in all the treatments also increased as a result of the normal ripening process, which is related to the increase in the respiration rate and thus, the loss of water content in the fruits. On the first day (day 1) after coating, no (0%) physiological weight loss was recorded in both coated and non-coated banana fruits, meaning that the application of the edible coating formulation had no immediate effect on the water content of the banana. The physiological weight loss values varied from 2.4% to 6.2% on day 5, where some treatments exhibited noticeable differences in PWL compared to the control T0. T1 and T9 showed higher PWL values of 6.1% and 6.4%, respectively, indicating that the coating might have limited effectiveness in reducing PWL at this time point, but T2 demonstrated a high reduction in PWL, with a value of 4.9%, suggesting that the coating formulation in T2 has a positive impact on preserving banana weight during this period. On day 9, all treatments displayed a noticeable reduction in PWL compared to the control T0. T2, T3, and T6 showed a high reduction in PWL, with values of 5.2%, 7.6%, and 4.9%, respectively. The results indicate that the effect of the edible coating becomes more evident with increasing storage time. On day 13, when all the fruits were ripe, a high value of WL was observed in all treatments in comparison to the control T0 (2.3%), which was already at the senescent phase. T2 continued to show the greatest reduction in WL at 4.9%, implying that the formulation has an influence on fruit respiration and enables them to produce less water vapor, thus preserving fruit from weight loss. The main cause of physiological weight loss for fruit and vegetables is transpiration, which is influenced by the difference in water vapor pressure between the fruit and the atmosphere [22]. Then, the increased rate of fruit respiration (where a carbon atom is lost from the fruit in each cycle) during storage, the hastened evaporation from the fruit surface, and the burning of the fruit surface tissue were the causes of the greater weight loss in the treated fruit [23]. Similar observations on weight loss have been made by [24]. Furthermore, edible coatings act as a semipermeable barrier against oxygen, carbon dioxide, moisture, and solute movement, thus lowering respiration, water loss, and oxidation reaction rate [25]. The effectiveness of a coating on water retention depends on its concentration [26]. Our results are not consistent with [27], who reported that improving pore blockage and forming a thicker layer on the skin of pear offered a better defense against the friction damage from the brushes and were the main ways by which increasing coating concentration (and deposit on the skin) reduced fruit drying time.

Figure 1.

Influence of different edible coating formulations on the weight loss of the banana fruits during storage at 19–22 °C and 40–60% relative humidity. Where WL 1, WL 5, WL 9 and WL 13 represent the weight loss value on day 1, 5, 9 and 13. Each data point consisted of 10 fruits repeated three times.

3.2. Texture Analysis

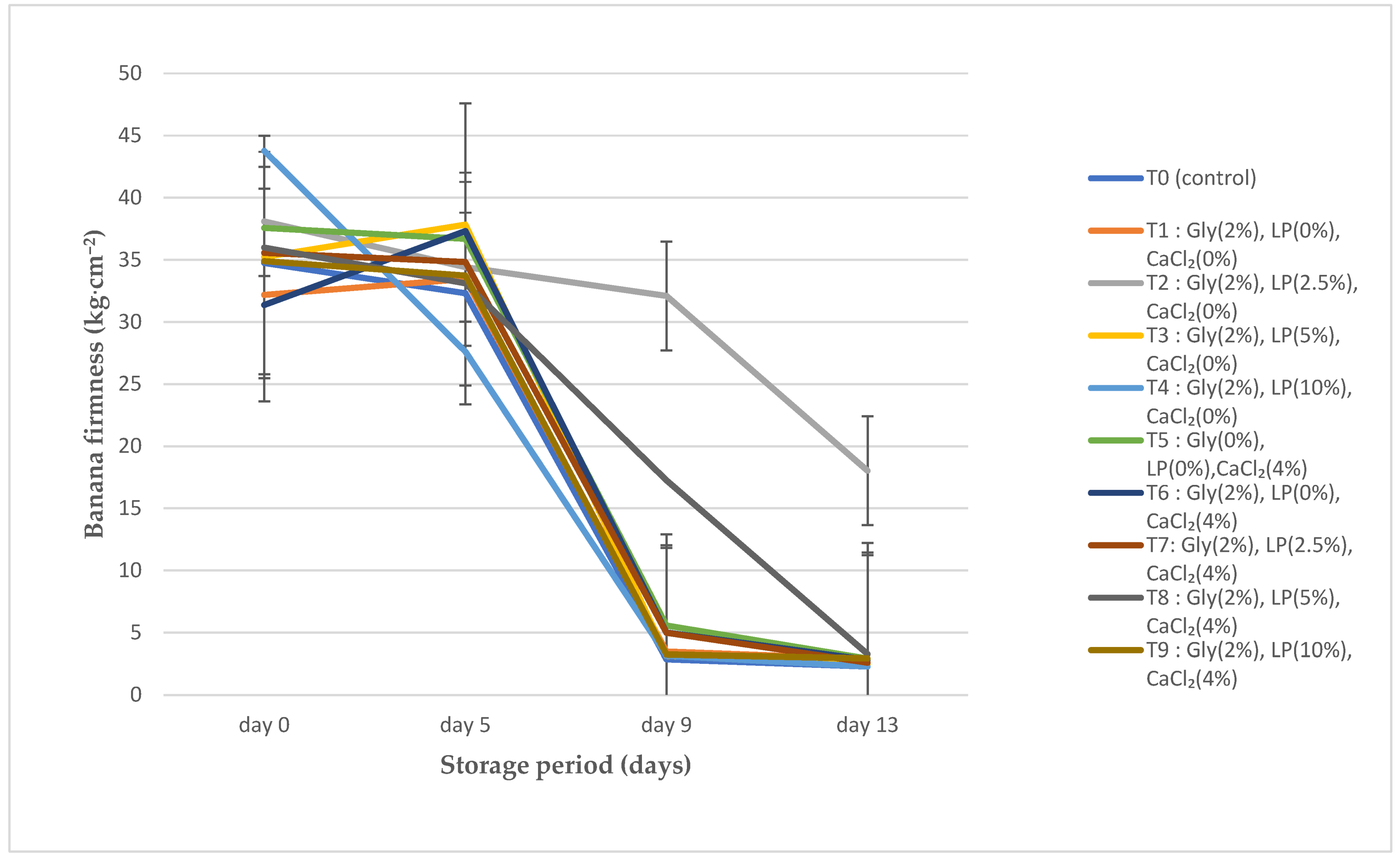

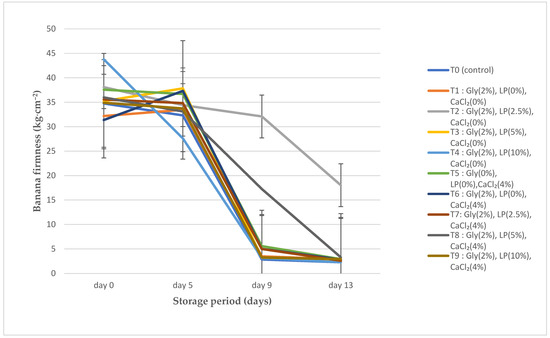

The changes in texture or firmness of the banana fruit with and without coating during the storage period are shown in Figure 2. All treatments showed comparable firmness values (p > 0.05) after one day of storage, which is not surprising given that all fruit was purchased from the same company, implying that the fruit was handled under the same conditions. This result for d = 1 also shows that different coating formulations have no direct influence on the fruit’s firmness. Significant firmness changes between treatments were observed after 9 days of storage (p < 0.05). In comparison to other treatments, T2 had the highest firmness value (32.1 ± 3.2 Kg·cm−2), followed by T8 (15. 3 ± 19.4 Kg·cm−2), indicating improved firmness preservation. The lowest value measured (2.6 ± 0.3 Kg·cm−2) was observed for T9, showing a considerable loss of firmness during storage. At d = 13, there were still differences between the treatments in the firmness values, which ranged from 2.3 Kg·cm−2 to 9.6 Kg·cm−2. However, there were no significant variations between the treatments (p > 0.05). The firmness of fruits is crucial in determining how resistant they are to mechanical injury. The different treatments of the samples affected how well the firmness was preserved during storage. The results thus demonstrate the impact of the concentration of lemon peel extract (LPE) on the firmness of bananas during storage. T2 had the lowest change in firmness. We speculate that the amount of lemon peel powder contained in T2 was optimized to enhance the fruit’s resistance to physical damage, reducing the risk of bruising or other injuries during handling and transportation. Another potential explanation is the dose-response efficiency of the formulation T2, which could have also provided a protective layer on the surface of the banana, helping to preserve the integrity of the cellular structures, which contributes to the overall firmness and texture of the banana during storage. However, bananas treated with CaCl2 alone (T5) were also firmer than untreated fruits (T0) after 9 and 13 days of storage. This result is consistent with the recent observation that banana fruits treated with CaCl2 have a slower rate of deterioration and loss of texture [28]. In addition, CaCl2 treatment has been proven to effectively retain the firmness of chili pepper [29]. However, others reported that CaCl2 solution accelerates the ripening process of bananas [30]. Fruit softening and textural changes are brought on by the depolymerization and solubilization of peptic cell walls, middle lamella constituents, cell structure degradation [24,31], and the movement of water from the peel to the pulp due to the process called osmosis [32].

Figure 2.

Influence of different edible coating formulations on the firmness of the banana fruits during storage at 19–22 °C and 40–60% relative humidity. Each data point consisted of 3 fruits repeated three times and on each fruit, 3 values were obtained respectively from the middle and both ends of the fruits; the vertical bar represents the standard errors of their means.

3.3. Colour Analysis

The La*b* color space offers insightful information about the samples’ color properties. In this study, the change in La*b* values over time was studied for various treatments in comparison to the control (T0) (Table 1). On day 1, all treatments showed comparable L* values in comparison to the control (T0), showing that there were no appreciable variations in the samples’ lightness. The a* and b* values were also similar to T0, indicating that there were no significant differences in the red-green and yellow-blue color components. The day 5 analysis showed that T1 had a considerably higher a* value than T0 (p < 0.05). T1 showed a shift towards a more intense red or green hue compared to T0, with an average a* value of 91.6 ± 0.5. The L and b* values between treatments did not show any discernible variations at this time. On day 9, when compared to T0, T2 had significantly lower L levels (p < 0.05). T2 had a darker appearance than T0, with an average L value of 90.3 ± 1.3. Furthermore, b values in T2 were considerably lower than in T0 (p < 0.05) and showed a trend towards a more vivid blue or yellow color with an average b value of 12.4 ± 0.1. The values between treatments did not show any discernible variations at this period. However, when compared to the other treatments, T6 displayed a considerably higher b value at day 9 (7.5 ± 0.1). This suggests that the yellow color of T6 was more pronounced. However, treatment T2 was greener than the other treatments on day 13. This can be concluded by the lower a* value of T2 (6.5 ± 4.5) on day 13 in comparison to the other treatments. The CIELAB color space’s green-red axis is represented by the* value, where negative values denote greener hues. As a result, T2 had a greener appearance on day 13 than the other treatments. The results show that T3, T4, T9, and T2 effectively retained the most chlorophyll content (green color) of the fruit, while the other coated fruits are yellow due to the carotenoid content of the fruit’s peel. The green hue of the banana peel gradually fades during ripening as a result of the thylakoid membrane breaking and the chlorophyll being degraded by chlorophyllase and oxidase enzymes, revealing yellow carotenoid pigments [33]. LPE could effectively retain the green color of banana fruit, while the combination of LPE and CaCl2 could reduce this effect. This is well observed in T8, with a 5% concentration of LPE in combination with CaCl2 (4%), which had a lower effect on the retention of green color during the storage time compared to T3 with 5% LPE concentration without CaCl2, which represents a stronger effect on the green color retention. However, during storage, L values decreased for both coated and uncoated samples, possibly as a result of surface moisture loss, which could have resulted in the darker hue observed [34]. Similar results were obtained in the study of an edible coating based on various concentrations of quince seed gum on banana slices at 4 °C and 40 °C [35].

Table 1.

Effect of edible coating formulations on the color of banana storage at 19–22 °C and 40–60% relative humidity.

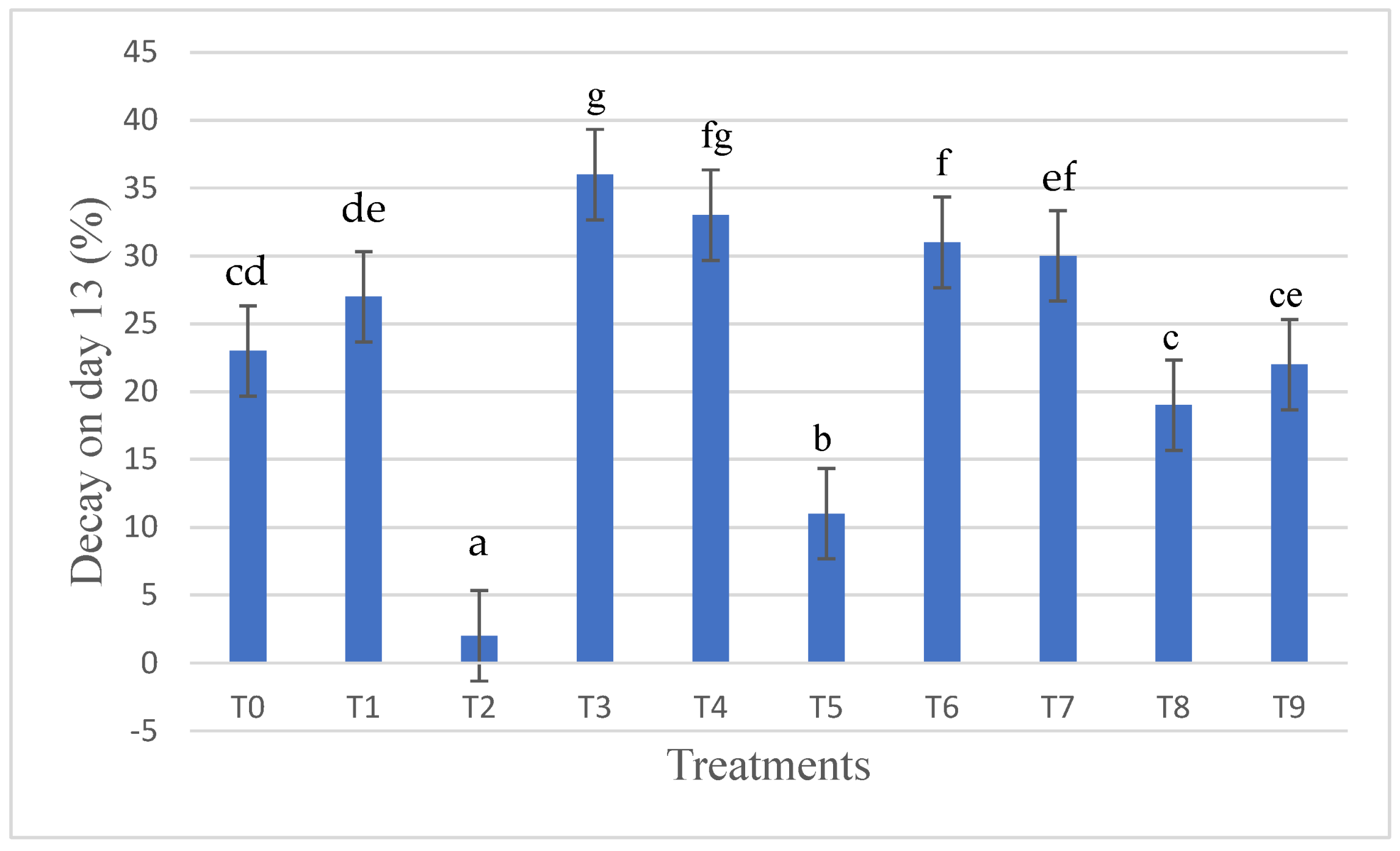

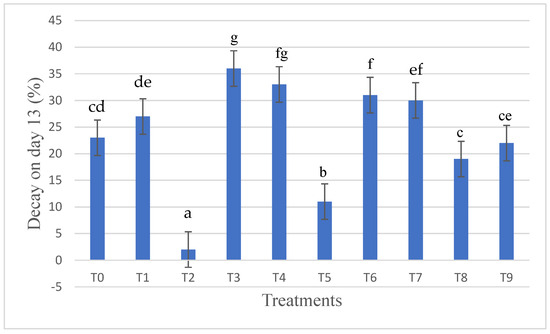

3.4. Decay Percentage

The bananas that showed decay after day 13 were counted and expressed as a percentage (Figure 3). T2 showed the lowest number of damaged bananas with a decay percentage of 2.3 ± 0.6%, compared to the other treatments. A low concentration of LPE (2.5%) had a strong positive effect on the shelf life of the bananas, while a high concentration of LPE (5% and 10%) accelerated the deterioration of the fruits, e.g., T3 (34.4 ± 1.5%) and T4 (31.3 ± 1.5%), respectively. This low decay percentage observed in the formulation T2 could have happened because of the low weight loss and high firmness value recorded, implying a delay or disorder in the metabolism of the normal ripening process and as a result, preventing the fruits from rotting. The first symptoms of dark coloration and overripe appearance were also perceived as an increase in banana respiration and microbial activity. We equally assumed that T2 provided a balance in a dose-response efficiency in its formulation as low (0%) and high (5% and 10%) concentrations of lemon peel powder had very high decay percentages and then decreased in their visual quality, while the percentage of lemon peel powder in T2 was optimal, allowing the fruits to preserve their quality. Similar observations were made by [36]. However, some researchers [26] reported that the high concentration used in the coating formulation forms a very thick layer on the fruit surface, which contributes to more clogging of the skin pores, exposing the fruit to anaerobic respiration that develops an odd taste, which is also a sign of premature decay in fruits. Similarly, CaCl2 treatment (T5) reduced the decay of banana in comparison with the control (T0) as only 11.0 ± 1% of the fruits were spoiled compared to T6 (31.6 ± 2.0%), T7 (28 ± 2%), T8 (19.3 ± 2.5%), and T9 (23.6 ± 2.0%). The reduction in the decay of the fruits after the application of LPE as an edible coating on the surface of fruits could be explained by the antifungal effect of lemon peel. The effect of the essential oils of lemon, mandarin, grapefruit, and orange on the growth of molds commonly associated with food spoilage has already been shown [37].

Figure 3.

Decay percentage of coated and uncoated bananas on day 20, where T0 = control sample with only distilled water, T1 = distilled water + glycerol (2%), T2 = glycerol (2%) + 2.5% lemon peel powder, T3 = glycerol (2%) and 5% lemon peel powder, T4 = glycerol (2%) + 10% lemon peel powder, T5 = 4% calcium chloride (CaCl2), T6 = glycerol (2%) + CaCl2 (4%), T7 = glycerol (2%), CaCl2 (4%) and 2.5% lemon peel powder, T8 = glycerol (2%), CaCl2 (4%) and 5% lemon peel powder, and T9 = glycerol (2%), CaCl2 (4%), and 10% lemon peel powder.

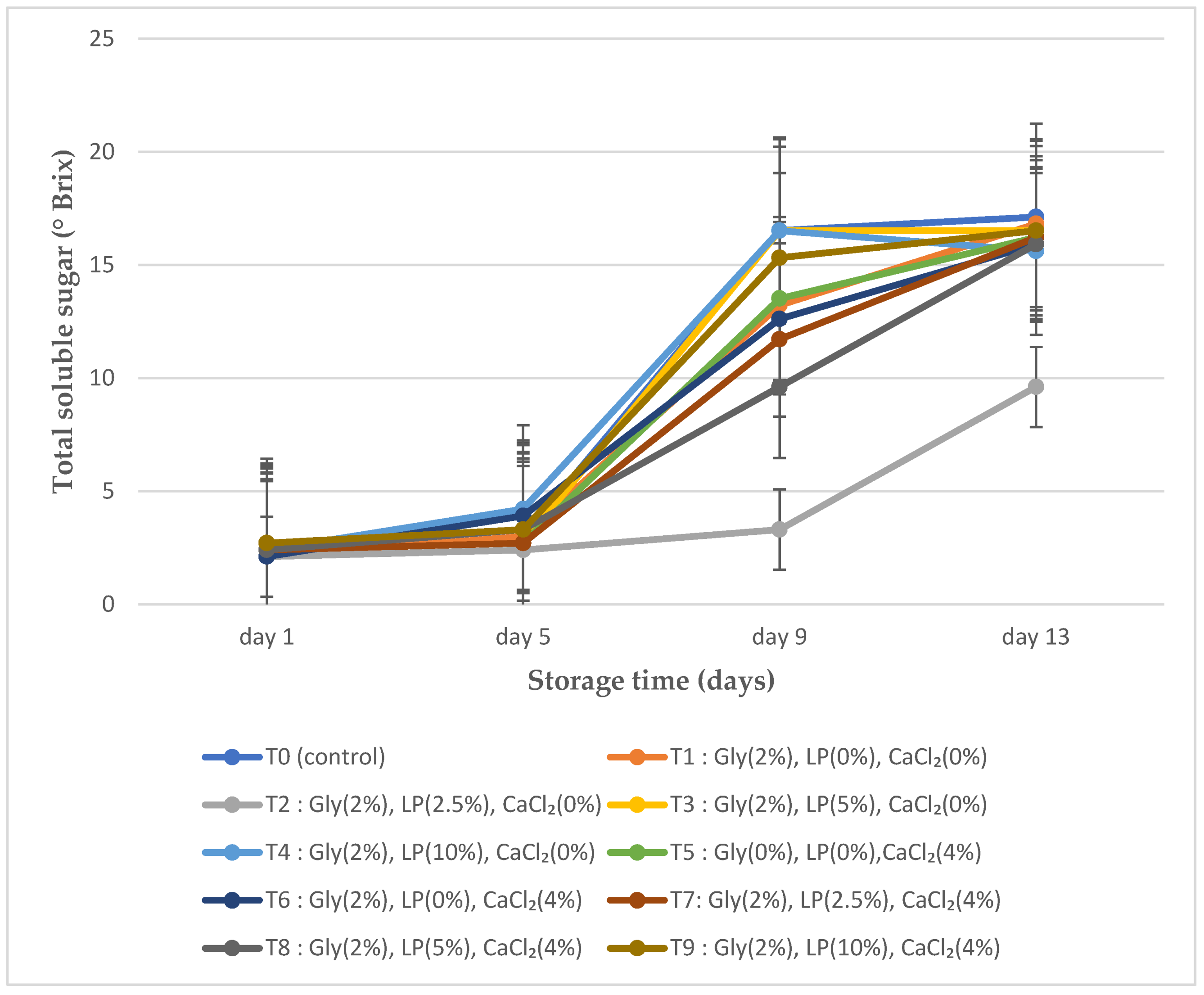

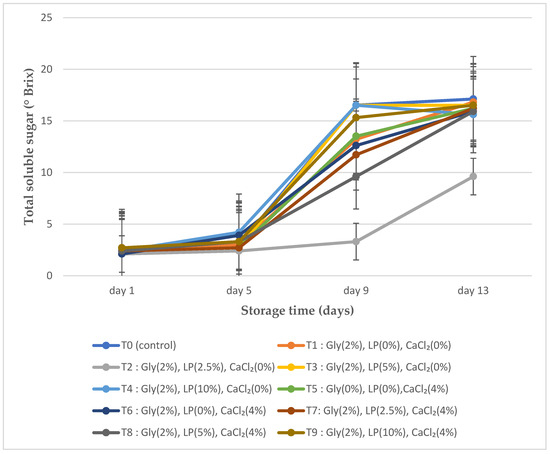

3.5. Total Soluble Sugar

The total soluble sugar (TSS, ° Brix) of the coated and uncoated bananas was determined during storage (Figure 4). All treatments had TSS values between 2.1 and 2.1% Brix after an initial storage period of 1 day. The TSS values significantly differed between the treatments after the 5-day storage period. In comparison to other treatments, T0, T1, T4, T8, and T9 exhibited higher TSS values (ranging from 3.0 to 3.4° Brix), indicating a faster ripening of these bananas in comparison with the fruits treated differently. The TSS readings continued to deviate when the storage duration increased. TSS values for T0, T3, and T4 showed the highest values, with 16.8 ± 0.2, 16.6 ± 0.1, and 16.5 ± 0.1° Brix, respectively on day 9. Similarly, results differed significantly on day 13. TSS values for T0 were highest at 17.8 ± 0.1° Brix, indicating that all other treatments slowed the ripening process. These results of the effect of edible coatings are similar to those obtained on strawberries [38] and bananas [39]. The T2 treatment was found to be the most effective in retaining TSS during the storage period. This could be because only a moderate concentration of lemon peel is required for the effective preservation of the banana fruit. High concentrations also had an effect on the titratable acidity during the ripening process of the bananas but not enough to make the coating effective. Similarly, the effect of CaCl2 was not significant enough to maintain TSS compared to other edible coating formulations. The coating film on the surface of the banana reduces the internal respiration rate and vital processes, which reduces the ripening process and keeps the TSS value low. Physiologically, the noticeable general increase of TSS over the storage time is due to the breakdown of starch into soluble sugars [40]. Similar results have been reported in another study [24].

Figure 4.

Influence of different edible coating formulations on the titratable acidity of the banana fruits during storage at 19–22 °C and 40–60% relative humidity, where T0 = control sample with only distilled water, T1 = distilled water + glycerol (2%), T2 = glycerol (2%) + 2.5% lemon peel powder, T3 = glycerol (2%) and 5% lemon peel powder, T4 = glycerol (2%) + 10% lemon peel powder, T5 = 4% calcium chloride (CaCl2), T6 = glycerol (2%) + CaCl2 (4%), T7 = glycerol (2%), CaCl2 (4%) and 2.5% lemon peel powder, T8 = glycerol (2%), CaCl2 (4%) and 5% lemon peel powder, and T9 = glycerol (2%), CaCl2 (4%), and 10% lemon peel powder. Each data point was a pooled sample of fresh material from 3 fruits repeated thrice and the vertical bar represents the standard errors of their means.

3.6. Titratable Acidity, and pH

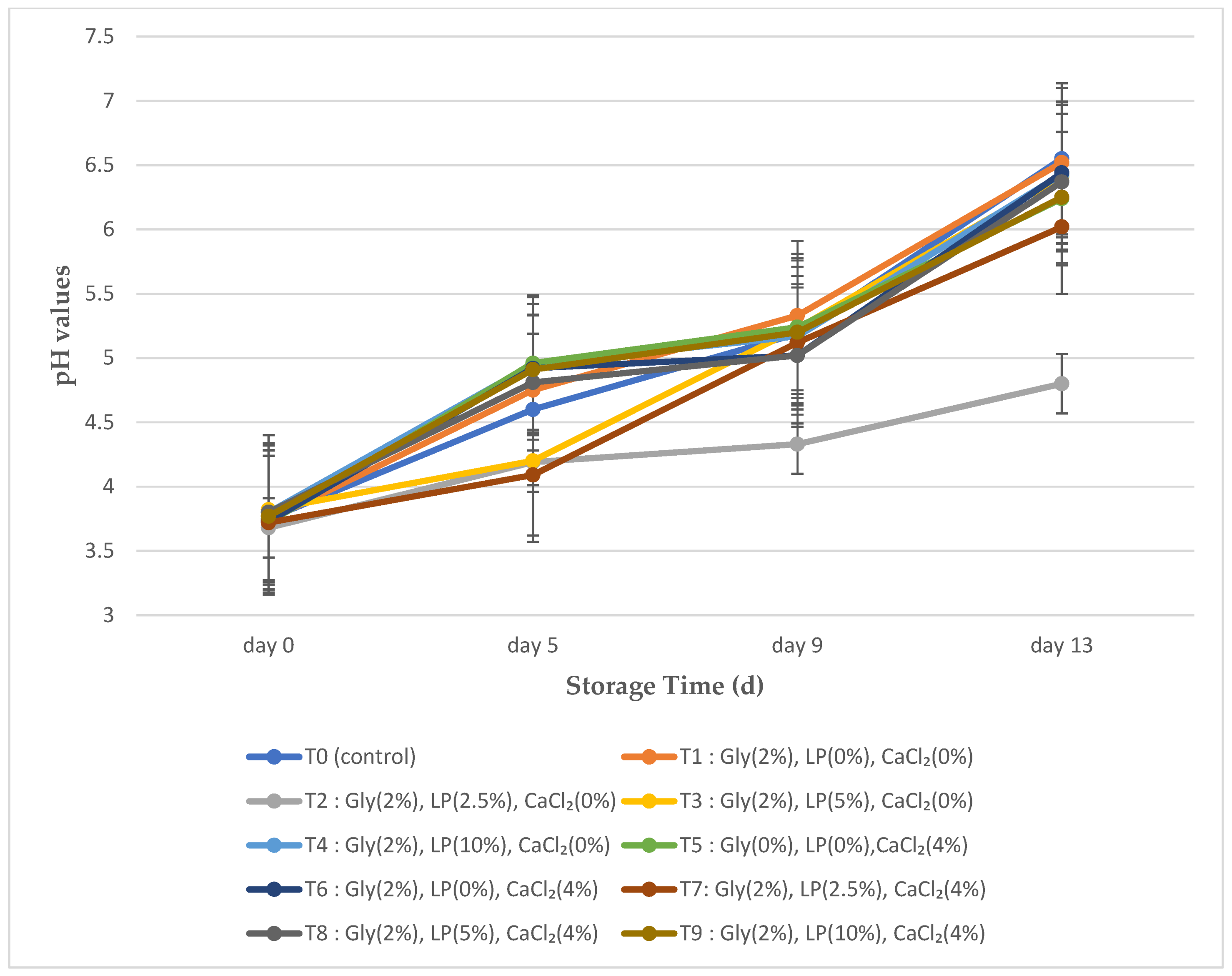

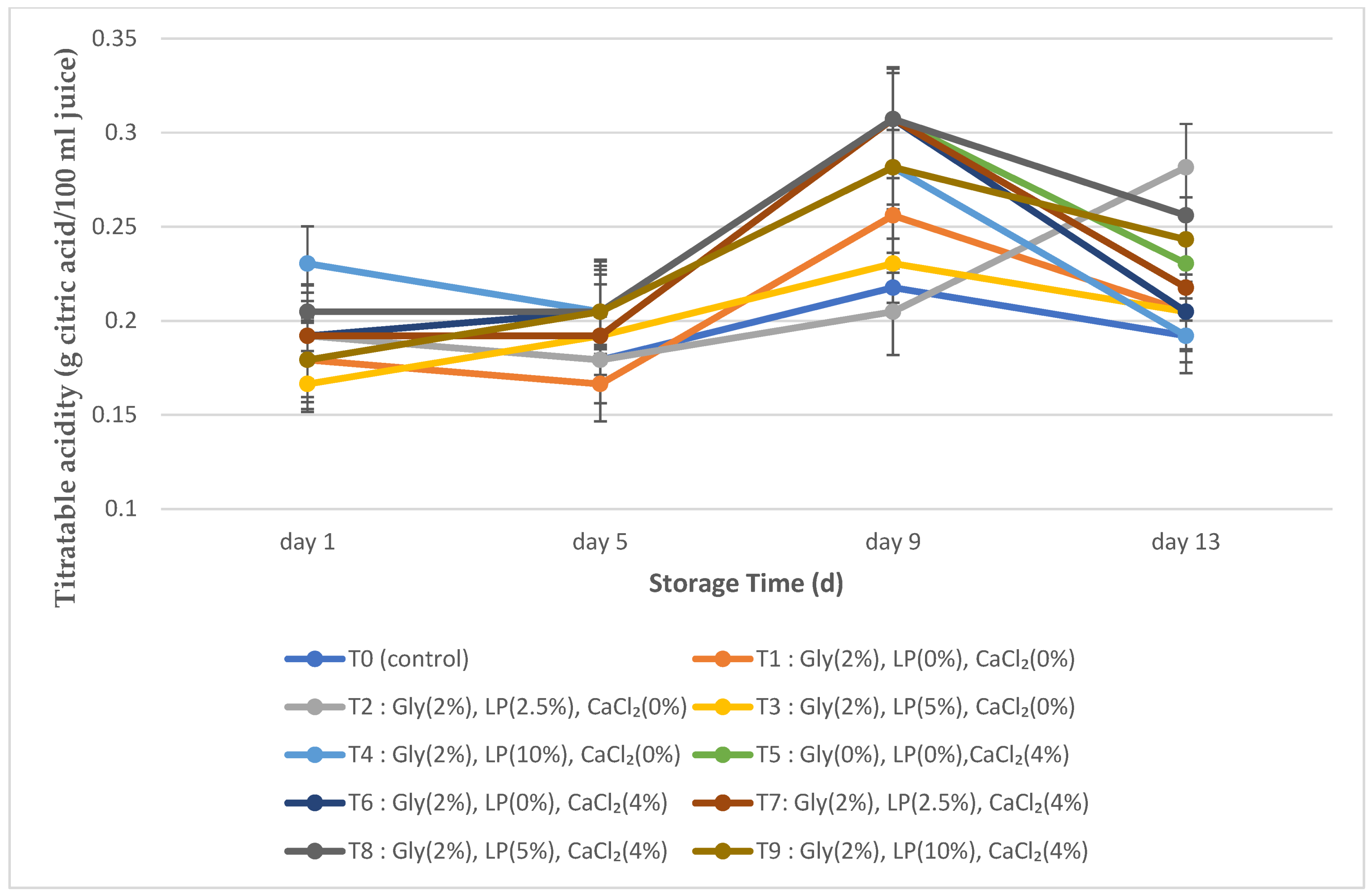

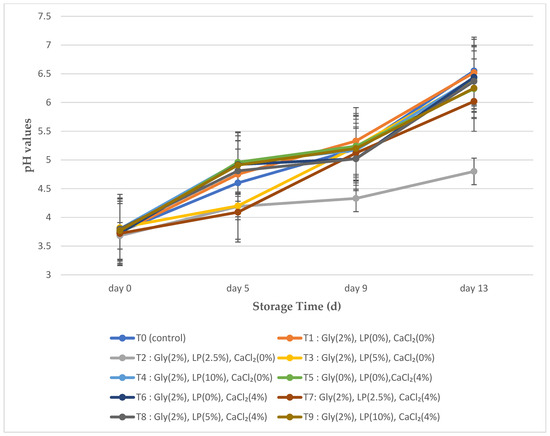

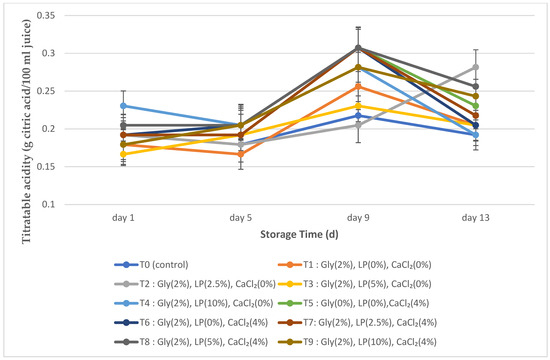

The changes in the pH of control and treated banana fruits during the storage period were determined (Figure 5). The pH increased as the storage time increased. On day 1, there was no difference between the pH of the coated and the control fruits, whose value varied between 3.7 and 3.8. By day 9 and 13, the pH values increased uniformly and T2 showed the lowest pH throughout the storage period, with values of 4.3 and 4.8 on days 9 and 13, respectively, while the control sample had values of 5.2 and 6.6 on days 9 and 13, respectively. No significant differences were found in the other formulations compared to the control samples. The TA gradually decreased as the storage time increased (Figure 6). On the first day, the TA values for all treatments, including the control, were almost identical. This could be because the fruits were all handled under the same storage conditions. We can conclude from this observation that the different formulations had no direct influence on the TA value of the fruits. On day 5, we observed a general decrease in the TA value for all treatments, but with a small slope value for T2. This observation was even more pronounced on day 9, where T2 had a TA value of 0.24 g citric acid/100 mL juice, while the other treatments, including the control (T0 = 0.23 g citric acid/100 mL juice), had a TA value between 0.192 and 0.2048 g citric acid/100 mL juice. By day 13, the values of TA for all the treatments were higher than the control, and in particular, T2 was higher than all the other treatments. This indicates that T2, which contained a moderate amount of lemon peel, was effective in maintaining the titratable acidity by reducing the metabolic activity and lowering the respiration in the fruits. Lemon concentration plays an important role in the formation of organic acids during the ripening process of bananas, which are very crucial for their final flavor. Organic acids, such as citric or malic acid are considered to be the primary substrates for the respiration process [41]. Edible coatings reduce the rate of respiration and may therefore delay the utilization of these organic acids [42]. In contrast to the results of [43], there was a direct relationship between pH and titratable acidity in different samples. These results are in accordance with the results obtained on bananas coated with chitosan alone and with a combination of chitosan and gibberellic acid [25].

Figure 5.

Influence of different edible coating formulations on the pH of the banana fruits during storage at 19–22 °C and 40–60% relative humidity. Each data point was a pooled sample of fresh material from 3 fruits repeated thrice and the vertical bar represents the standard errors of their means.

Figure 6.

Influence of different edible coating formulations on the titratable acidity of the banana fruits during storage at 19–22 °C and 40–60% relative humidity. Storage conditions T0–T9 are described in detail in the Materials and Methods section (experimental design). Each data point was a pooled sample of fresh material from 3 fruits repeated thrice and the vertical bar represents the standard errors of their means.

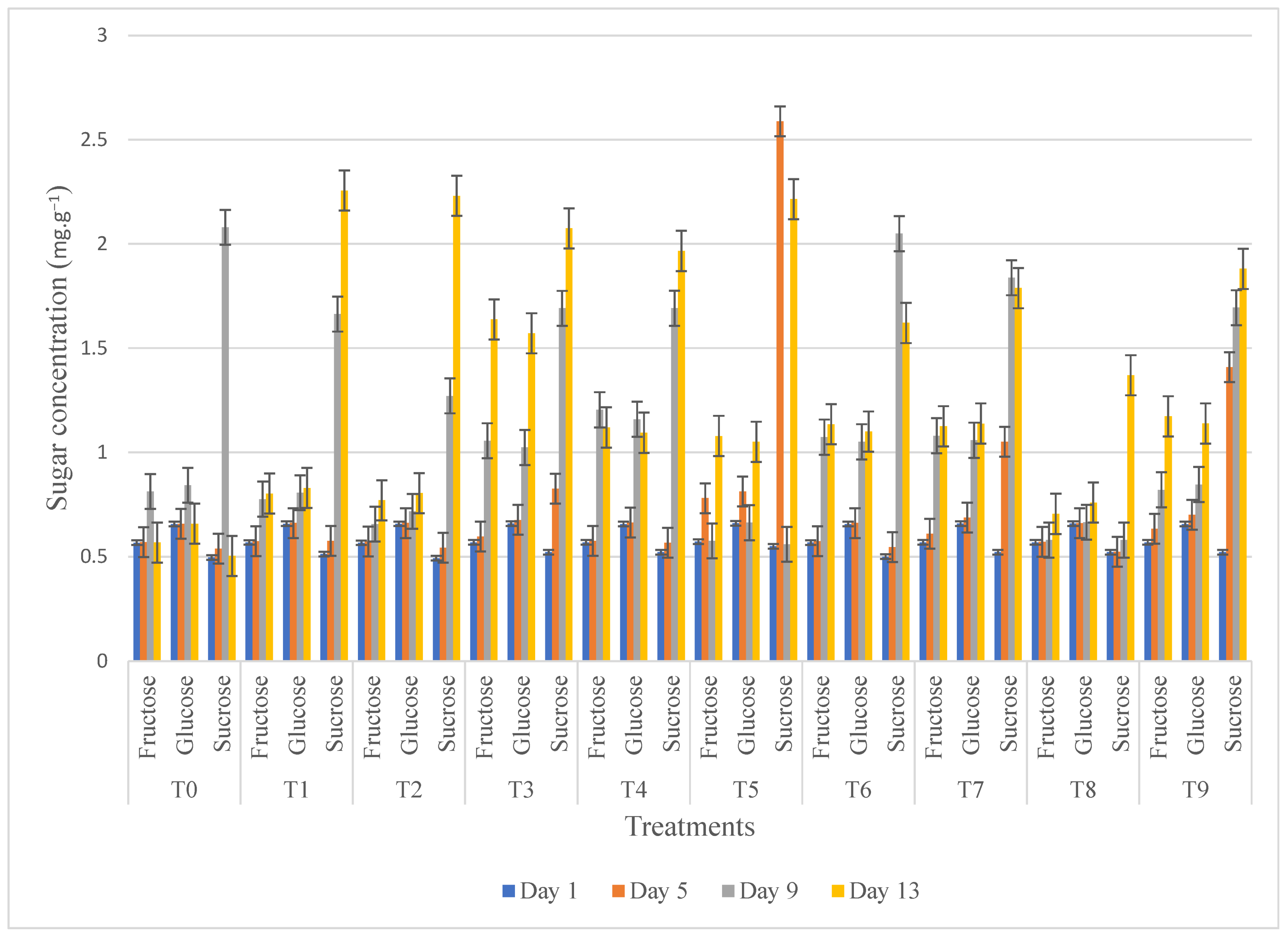

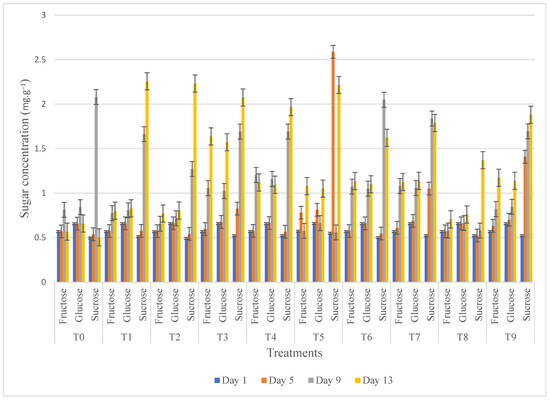

3.7. Influence of Different Edible Formulation Coatings on the Sugar Content of the Banana

Glucose, fructose, and sucrose are the main sugars in bananas during ripening, and these sugars increase in concentration during ripening [44]. The concentration of these sugars in coated and uncoated bananas was determined during the storage period (Figure 7). In general, the sugar content increased as the storage time increased. The concentrations were not significantly different from each other up to the first 9 days of storage. By day 9, the highest sucrose concentration was in T0 (2.1 mg·g−1), T6 (2.0 mg·g−1), and T7 (1.8 mg·g−1), while the lowest sucrose concentration was in T8 (0.8 mg·g−1), and T2 (1.3 mg·g−1). The sucrose concentration of T0 dropped to 0.7 mg·g−1 on day 13, while the sucrose content increased in all the coated samples. T1, T2, and T5 showed the highest sucrose concentrations on day 13, with 2.3 mg·g−1, 2.2 mg·g−1, and 2.2 mg·g−1, respectively. The fructose concentrations were higher in most of the coated fruits compared to the control samples. By day 9, the concentration of fructose and glucose were highest in T4 (1.2 mg·g−1 and 1.2 mg·g−1, respectively), T7 (1.8 mg·g−1 and 1.1 mg·g−1, respectively), T6 (1.1 mg·g−1 and 1.1 mg·g−1, respectively), and T3 (1.1 mg·g−1 and 1.1 mg·g−1, respectively), while the lowest content was observed in T2 (0.7 mg·g−1 and 0.7 mg·g−1, respectively). T0 had 0.8 mg·g−1 and 0.8 mg·g−1 of fructose and glucose, respectively. T0 fructose and glucose concentrations dropped to 0.7 mg·g−1 and 0.7 mg·g−1, respectively, on day 13, while the concentration of sugars in the coated fruits continued to increase. However, among the coated fruits, low fructose-glucose content was found in T8 (0.9 mg·g−1 and 1.1 mg·g−1, respectively), T1 (0.8 mg·g−1 and 0.8 mg·g−1, respectively), and T2 (0.8 mg·g−1 and 0.8 mg·g−1, respectively). A complicated regulatory process changes the metabolism during banana ripening, from starch synthesis to starch breakdown, resulting in the accumulation of soluble sugars, primarily sucrose, which significantly affects the taste and flavor of the fruit. This conversion of starch into sucrose appears to be responsible for sweetening the pulp and providing energy for metabolic processes that lead to the development of other quality characteristics of ripe bananas, such as color change, synthesis of volatile compounds, and even softening of the pulp, which greatly affects the quality of the finished fruit [45]. In all the samples, a higher concentration of sucrose than fructose and glucose was detected. In fact, during the ripening process, glucose and fructose are formed from sucrose molecules. When the climacteric peak is reached, this sucrose concentration starts decreasing under the effect of saccharolytic enzymes, while fructose and glucose concentrations increase. Several authors have tracked the concentration of starch, sucrose, glucose, and fructose as well as the activities of various enzymes involved in the synthesis of sucrose [46]. In the control sample T0, a typical natural ripening was observed (Figure 5), as demonstrated by the degradation of sucrose on day 13, while all the coated samples showed a high sucrose content on day 13. From an organoleptic point of view, the coated fruits could be sweeter because the total content of sweet-tasting sugars is higher in the coated fruit samples, which is an important criterion for consumer acceptance.

Figure 7.

The concentration of sugars in coated and non-coated bananas during the storage period at 19–22 °C and 40–60% relative humidity, where T0 = control sample with only distilled water, T1 = distilled water + glycerol (2%), T2 = glycerol (2%) + 2.5% lemon peel powder, T3 = glycerol (2%) and 5% lemon peel powder, T4 = glycerol (2%) + 10% lemon peel powder, T5 = 4% calcium chloride (CaCl2), T6 = glycerol (2%) + CaCl2 (4%), T7 = glycerol (2%), CaCl2 (4%) and 2.5% lemon peel powder, T8 = glycerol (2%), CaCl2 (4%) and 5% lemon peel powder, and T9 = glycerol (2%), CaCl2 (4%), and 10% lemon peel powder. Each data point was a pooled sample of fresh material from 3 fruits repeated thrice and the vertical bar represents the standard errors of their means.

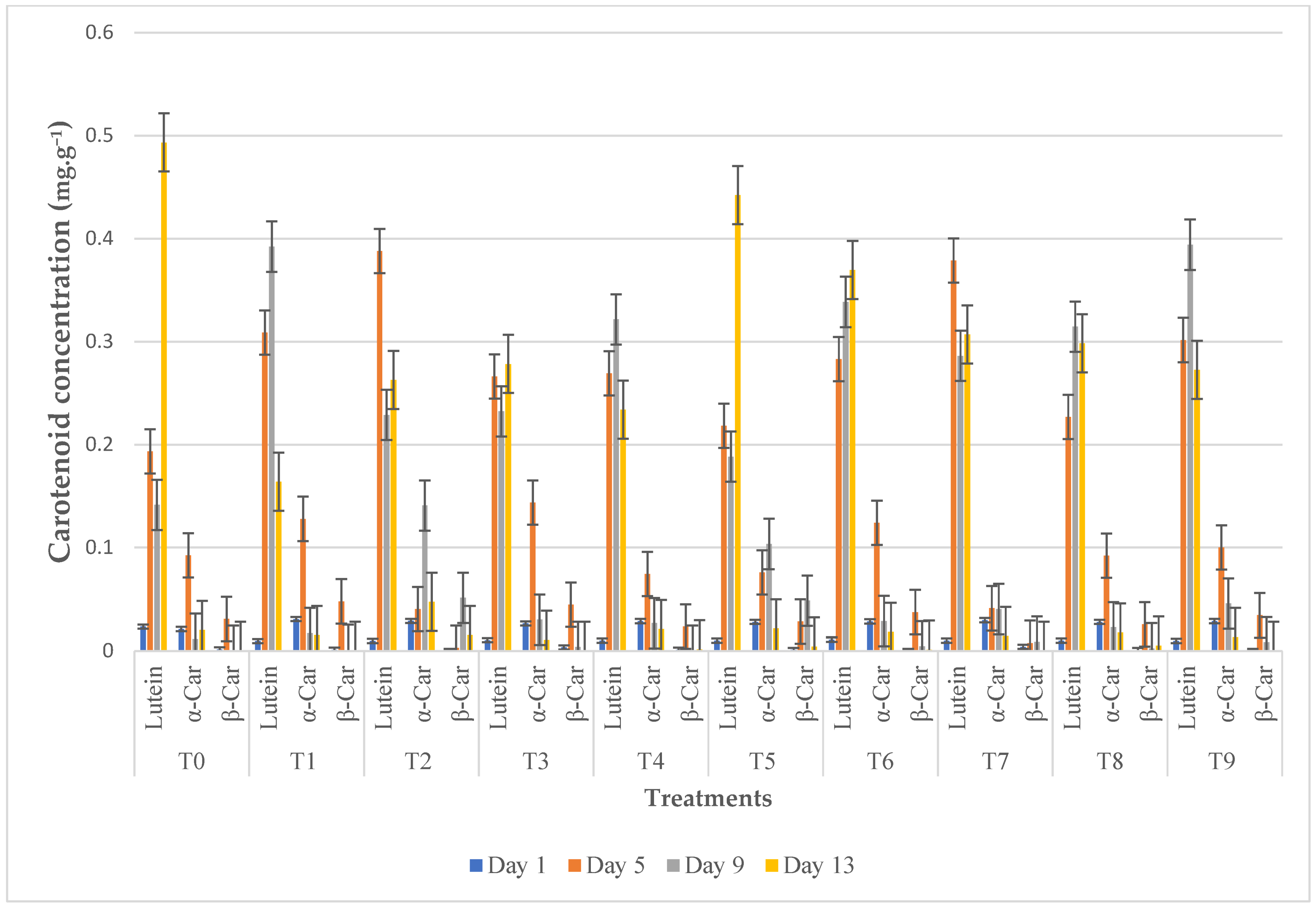

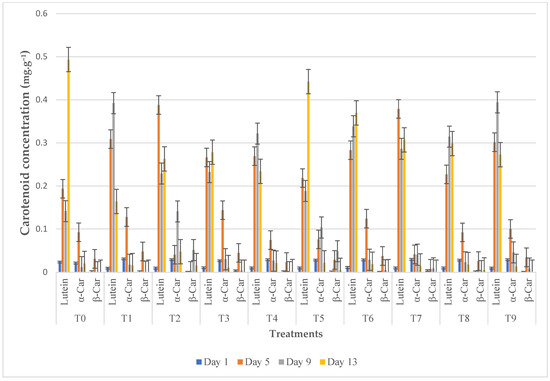

3.8. Influence of Different Edible Formulation Coatings on the Carotenoid Contents of the Banana

The distinctive yellow color of ripe banana peels is solely the result of chlorophyll breakdown, which obscures the yellow hue of unripe bananas. As a result, the carotenoid content in bananas changes as fruit ripening and maturation proceed. The concentration of carotenoids (lutein and alpha- and beta-carotene) obtained from the calibration curve calculations using high-performance liquid chromatography (HPLC) was analyzed in the coated and non-coated bananas during the storage period (Figure 8). The concentration of carotenoids increased with increasing storage time. Lutein was the major carotenoid, followed by alpha- and beta-carotene. A large difference in carotenoid concentration was observed particularly on day 5 of the storage time, when all the treated banana fruits had a higher lutein concentration compared to the control samples, which had a concentration of 0.2 mg·g−1. The highest concentration was detected in T1 (0.3 mg·g−1), T2 (0.38 mg·g−1), T7 (0.37 mg·g−1), and T9 (0.30 mg·g−1), while the alpha- and beta- carotene content remained low. On day 9, alpha- and beta-carotene concentrations were particularly high in T2, with 0.14 mg·g−1 and 0.05 mg·g−1, respectively. In the control, beta-carotene was not detected on day 9. The highest concentration of lutein was found in the control sample T0, with 0.5 mg·g−1 on day 13. Fruits like bananas produce a large amount of carotenoids, which are produced from terpenoids as the chloroplast to chromoplast transition occurs [47]. During the ripening process, the fruit color changes due to the production of carotenoids and the destruction of chlorophylls. Similar to regular ripening, the highest level of lutein content was found in T0 and T5 compared to the other coated samples on day 13. This indicates that T0 and T5 may be in a more advanced stage of the ripening process; thus, coating delays the ripening of the banana.

Figure 8.

Concentration of carotenoids in coated and non-coated bananas during the storage period at 19–22 °C and 40–60% relative humidity, where T0 = control sample with only distilled water, T1 = distilled water + glycerol (2%), T2 = glycerol (2%) + 2.5% lemon peel powder, T3 = glycerol (2%) and 5% lemon peel powder, T4 = glycerol (2%) + 10% lemon peel powder, T5 = 4% calcium chloride (CaCl2), T6 = glycerol (2%) + CaCl2 (4%), T7 = glycerol (2%), CaCl2 (4%) and 2.5% lemon peel powder, T8 = glycerol (2%), CaCl2 (4%) and 5% lemon peel powder, and T9 = glycerol (2%), CaCl2 (4%), and 10% lemon peel powder. Each data point was a pooled sample of fresh material from 3 fruits repeated thrice and the vertical bar represents the standard errors of their means.

4. Conclusions

Our results suggest that banana fruits coated with lemon peel extract-based formulations post-harvest retain significant fruit chlorophyll content despite a reduction in fruit firmness. The addition of CaCl2 in the formulation reduced the effect of the lemon peel extract but was not enough to be considered important. The use of a concentration of 2.5% lemon peel extract in the formulation of an edible coating for the post-harvest preservation of bananas showed significant retention of color, sugar, firmness, and carotenoids of the fruit, which are very important parameters for quality control, as shown by treatment T2 throughout the storage period. On the other hand, a high percentage of lemon peel extract (in this case, 10% in T3) in the edible coating solution applied to the surface of bananas caused the fruit to ripen very quickly compared to the control samples. These data provide significant and helpful information for maintaining the quality of bananas in fresh produce post-harvest management industries. The findings of this research contribute significantly to the income improvement for farmers, processors, and distributors to market bananas in developing and emerging countries and toward the use of plastic-free packaging in the fruits and vegetable industries.

Author Contributions

E.-I.N.T.: Conceptualization, investigation, methodology, analysis, writing—original draft, and writing review and editing. W.S.: Supervision, conceptualization, investigation, methodology, analysis, resources, writing—review and editing, and validation. V.F.N.: supervision, methodology, project administration, and visualization. J.A.-N.: supervision, project administration, conceptualization, investigation, and methodology. P.M.: conceptualization, methodology, and analysis. T.T.: conceptualization, methodology, formal analysis, software, and data curation. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the DAAD (Deutscher Akademischer Austauschdienst) and the Professorship Biotechnology of Natural Products.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Acknowledgments

Thomas Hoffmann, Anja Forstner, Mechthild Mayershofer, and Sadiq Mareai are acknowledged for their technical support.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

LPE: Lemon peel extract

References

- Picq, V.; Ramillon, J.M.; Balanzat, E. Swift heavy ions on polymers: Hydrocarbon gas release. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms. 1998, 146, 496–503. [Google Scholar] [CrossRef]

- Karamura, D.; Frison, E.; Karamura, D.A.; Sharrock, S. Banana production systems in eastern and southern Africa. Banan. Food Secur. 1998, 401, 412. [Google Scholar]

- FAO. Brief to The State of Food Security and Nutrition in the World 2023; FAO: Rome, Italy, 2023. [Google Scholar] [CrossRef]

- Aurore, G.; Parfait, B.; Fahrasmane, L. Bananas, raw materials for making processed food products. Trends Food Sci. Technol. 2009, 20, 78–91. [Google Scholar] [CrossRef]

- Dwivany, F.M.; Aprilyandi, A.N.; Suendo, V.; Sukriandi, N. Carrageenan edible coating application prolongs Cavendish banana shelf life. Int. J. Food Sci. 2020, 2020, 8861610. [Google Scholar] [CrossRef]

- Ahmed, Z.F.R.; Palta, J.P. A Postharvest Dip Treatment with of Banana Fruit. HortScience 2015, 50, 1035–1040. [Google Scholar] [CrossRef]

- Songe, J.; Fan, L.; Forney, C.; Campbell-Palmer, L.; Fillmore, S. Effect of hexanal vapor to control postharvest decay and extend shelf-life of highbush blueberry fruit during controlled atmosphere storage. Can. J. Plant Sci. 2010, 90, 359–366. [Google Scholar] [CrossRef]

- Imahori, Y.; Yamamoto, K.; Tanaka, H.; Bai, J. Residual effects of low oxygen storage of mature green fruit on ripening processes and ester biosynthesis during ripening in bananas. Postharvest Biol. Technol. 2013, 77, 19–27. [Google Scholar] [CrossRef]

- Silva, V.D.M.; Arquelau, P.B.F.; Silva, M.R.; Augusti, R.; Meloc, J.O.F.; Fantea, C.A. Use of Paper Spray-Mass Spectrometry to Determine the Chemical Profile of Ripe Banana Peel Flour and Evaluation of Its Physicochemical and Antioxidant Properties. Quim. Nova 2020, 43, 579–585. [Google Scholar] [CrossRef]

- Aghofack-Nguemezi, J.; Fuchs, C.; Yeh, S.Y.; Huang, F.C.; Hoffmann, T.; Schwab, W. An oxygenase inhibitor study in Solanum lycopersicum combined with metabolite profiling analysis revealed a potent peroxygenase inactivator. J. Exp. Bot. 2011, 62, 1313–1323. [Google Scholar] [CrossRef][Green Version]

- Aghofack-Nguemezi, J.; Hoffmann, T.; Schwab, W. Effects of bio-based coatings on the ripening and quality attributes of tomato (Solanum lycopersicum) fruits. J. Sci. Food Agric. 2019, 99, 1842–1849. [Google Scholar] [CrossRef]

- Ghasemzadeh, R.; Karbassi, A.; Ghoddousi, H.B. Application of Edible Coating for Improvement of Quality and Shelf-life of Raisins. World Appl. Sci. J. 2008, 3, 82–87. [Google Scholar]

- Debeaufort, F.; Quezada-Gallo, J.A.; Voilley, A. Edible Films and Coatings: Tomorrow’s Packagings: A Review. Crit. Rev. Food Sci. Nutr. 1998, 38, 299–313. [Google Scholar] [CrossRef]

- Kabuki, T.; Nakajima, H.; Arai, M.; Ueda, S.; Kuwabara, Y.; Dosako, S. Characterization of novel antimicrobial compounds from mango (Mangifera indica L.) kernel seeds. Food Chem. 2000, 71, 61–66. [Google Scholar] [CrossRef]

- Chidambara Murthy, K.N.; Jayaprakasha, G.K.; Singh, R.P. Studies on antioxidant activity of pomegranate (Punica granatum) peel extract using in vivo models. J. Agric. Food Chem. 2002, 50, 4791–4795. [Google Scholar] [CrossRef] [PubMed]

- Prasad, K.N.; Xie, H.; Hao, J.; Yang, B.; Qiu, S.; Wei, X.; Chen, F.; Jiang, Y. Antioxidant and anticancer activities of 8-hydroxypsoralen isolated from wampee [Clausena lansium (Lour.) Skeels] peel. Food Chem. 2010, 118, 62–66. [Google Scholar] [CrossRef]

- Negro, C.; Tommasi, L.; Miceli, A. Phenolic compounds and antioxidant activity from red grape marc extracts. Bioresour. Technol. 2003, 87, 41–44. [Google Scholar] [CrossRef] [PubMed]

- Manthey, J.A.; Grohmann, K.; Guthrie, N. Biological properties of citrus flavonoids pertaining to cancer and inflammation. Curr. Med. Chem. 2001, 8, 135–153. [Google Scholar] [CrossRef] [PubMed]

- Silapeux, A.G.K.; Ponka, R.; Frazzoli, C.; Fokou, E. Waste of fresh fruits in Yaoundé, Cameroon: Challenges for retailers and impacts on consumer health. Agriculture 2021, 11, 89. [Google Scholar] [CrossRef]

- Martín-Diana, A.B.; Rico, D.; Frías, J.M.; Barat, J.M.; Henehan, G.T.M.; Barry-Ryan, C. Calcium for extending the shelf life of fresh whole and minimally processed fruits and vegetables: A review. Trends Food Sci. Technol. 2007, 18, 210–218. [Google Scholar] [CrossRef]

- Pathare, P.B.; Opara, U.L.; Al-Said, F.A.J. Colour Measurement and Analysis in Fresh and Processed Foods: A Review. Food Bioprocess. Technol. 2013, 6, 36–60. [Google Scholar] [CrossRef]

- Momin, M.; Jamir, A.; Ankalagi, N.; Henny, T.; Devi, O. Edible coatings in fruits and vegetables: A brief review. Pharma Innov. J. 2021, 10, 71–78. [Google Scholar]

- Kulkarni, S.G.; Kudachikar, V.B.; Keshava Prakash, M.N. Studies on physico-chemical changes during artificial ripening of banana (Musa sp) variety “Robusta”. J. Food Sci. Technol. 2011, 48, 730–734. [Google Scholar] [CrossRef]

- Kaka, A.K. Effect of hot water treatments and storage period on the quality attributes of banana (Musa sp.) fruit. Pure Appl. Biol. 2019, 8, 363–371. [Google Scholar] [CrossRef]

- Gol, N.B.; Ramana Rao, T.V. Banana fruit ripening as influenced by edible coatings. Int. J. Fruit. Sci. 2011, 11, 119–135. [Google Scholar] [CrossRef]

- Lufu, R.; Ambaw, A.; Opara, U.L. Water loss of fresh fruit: Influencing pre-harvest, harvest and postharvest factors. Sci. Hortic. 2020, 272, 109519. [Google Scholar] [CrossRef]

- Amarante, C.; Banks, N.H.; Ganesh, S. Effects of coating concentration, ripening stage, water status and fruit temperature on pear susceptibility to friction discolouration. Postharvest Biol. Technol. 2001, 21, 283–290. [Google Scholar] [CrossRef]

- Minh, N.P. Effectiveness of CaCl2 treatment on quality attributes of banana fruit during storage. Plant Sci. Today 2022, 9, 206–214. [Google Scholar] [CrossRef]

- Tunde-Akintunde, T.Y. Effect of pretreatment on drying time and quality of chilli pepper. J. Food Process. Preserv. 2010, 34, 595–608. [Google Scholar] [CrossRef]

- Wills, R.B.H.; Tirmazi, S.I.H.; Scott, K.J. Effect of postharvest application of calcium on ripening rates of pears and bananas. J. Hortic. Sci. 1982, 57, 431–435. [Google Scholar] [CrossRef]

- Maduwanthi, S.D.T.; Marapana, R.A.U.J. Induced ripening agents and their effect on fruit quality of banana. Int. J. Food Sci. 2019, 2019. [Google Scholar] [CrossRef] [PubMed]

- Newilah, G.N.; Tomekpe, K.; Fokou, E.; Etoa, F.X. Physicochemical Changes during Ripening of Bananas Grown in Cameroon. Fresh Prod. 2009, 3, 64–70. [Google Scholar]

- Özdemir, I.S. Effect of light treatment on the ripening of banana fruit during postharvest handling. Fruits 2016, 71, 115–122. [Google Scholar] [CrossRef]

- Perdones, A.; Sánchez-González, L.; Chiralt, A.; Vargas, M. Effect of chitosan-lemon essential oil coatings on storage-keeping quality of strawberry. Postharvest Biol. Technol. 2012, 70, 32–41. [Google Scholar] [CrossRef]

- Farahmandfar, R.; Asnaashari, M.; Amraie, M.; Salehi, M. Color and weight changes of fresh-cut banana slices coated by quince seed gum: Effect of concentration, storage temperature and duration. Iran. Food Sci. Technol. Res. J. 2019, 14, 75–85. [Google Scholar] [CrossRef]

- Nunes, C.N.; Emond, J.P. Relationship between Weight Loss and Visual Quality of Fruits and Vegetables. Proc. Fla. State Hort. Soc. 2007, 120, 235–245. [Google Scholar]

- Viuda-Martos, M.; Ruiz-Navajas, Y.; Fernández-López, J.; Pérez-Álvarez, J. Antifungal activity of lemon (Citrus lemon L.), mandarin (Citrus reticulata L.), grapefruit (Citrus paradisi L.) and orange (Citrus sinensis L.) essential oils. Food Control 2008, 19, 1130–1138. [Google Scholar] [CrossRef]

- Amal, S.H.; El-Mogy, M.M.; Aboul-Anean, H.E.; Alsanius, B.W. Improving Strawberry Fruit Storability by Edible Coating as a Carrier of Thymol or Calcium Chloride. J. Hortic. Sci. Ornam. Plants 2010, 2, 88–97. [Google Scholar]

- Rahman, M.; Hossain, T.B.; Hossain, M.S.; Sattar, S.; Das, P.C. Effect of banana peel extract on storage stability of banana cv. Sagar. Food Res. 2020, 4, 488–494. [Google Scholar] [CrossRef]

- Reyes, M.E.Q.; Nishijima, W.; Paull, R.E. Control of crown rot in “Santa Catarina Prata” and “Williams” banana with hot water treatments. Postharvest Biol. Technol. 1998, 14, 71–75. [Google Scholar] [CrossRef]

- Yaman, Ö.; Bayoindirli, L. Effects of an edible coating and cold storage on shelf-life and quality of cherries. LWT 2002, 35, 146–150. [Google Scholar] [CrossRef]

- Maqbool, M.; Ali, A.; Alderson, P.G.; Zahid, N.; Siddiqui, Y. Effect of a novel edible composite coating based on gum arabic and chitosan on biochemical and physiological responses of banana fruits during cold storage. J. Agric. Food Chem. 2011, 59, 5474–5482. [Google Scholar] [CrossRef] [PubMed]

- Bico, S.L.S.; Raposo, M.F.J.; Morais, R.M.S.C.; Morais, A.M.M.B. Combined effects of chemical dip and/or carrageenan coating and/or controlled atmosphere on quality of fresh-cut banana. Food Control 2009, 20, 508–514. [Google Scholar] [CrossRef]

- Zhu, X.; Li, Q.; Li, J.; Luo, J.; Chen, W.; Li, X. Comparative study of volatile compounds in the fruit of two banana cultivars at different ripening stages. Molecules 2018, 23, 2456. [Google Scholar] [CrossRef] [PubMed]

- Cordenunsi-Lysenko, B.R.; Nascimento, J.R.O.; Castro-Alves, V.C.; Purgatto, E.; Fabi, J.P.; Peroni-Okyta, F.H.G. The starch is (not) just another brick in the wall: The primary metabolism of sugars during banana ripening. Front. Plant Sci. 2019, 10, 391. [Google Scholar] [CrossRef] [PubMed]

- Emaga, T.H.; Wathelet, B.; Paquot, M.; Emaga, T.H. Changements texturaux et biochimiques des fruits du bananier au cours de la maturation. Leur influence sur la préservation de la qualité du fruit et la maîtrise de la maturation. Biotechnol. Agron. Soc. Environ. 2008, 12, 1335–1342. [Google Scholar]

- Bouzayen, M.; Latché, A.; Nath, P.; Pech, J.C. Open Archive TOULOUSE Archive Ouverte (OATAO) Mechanism of Fruit Ripening. Dev. Biol. 2010, 1. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).