1. Introduction

Brazil is projected to contribute around a third of the world’s coffee production, solidifying its position as the leading producer and exporter of coffee [

1,

2]. The arabica coffee (

Coffea arabica L.) comprises approximately 70% of Brazil’s coffee output, with Minas Gerais standing out as the state with the highest production volume [

2]. These statistics underscore the significant economic and social significance of the coffee industry in Brazil.

The regional climate and terrain characteristics of Minas Gerais state provide favorable conditions for coffee production. However, the high productive potential of coffee in these areas necessitates adequate monitoring and the use of technology to ensure high yields. In this context, precision agriculture has become intrinsic to coffee cultivation. Within coffee farming, this approach is known as precision coffee farming, characterized by a collection of methods and technologies that consider the spatial characteristics of both soil and plants, helping coffee growers manage their crops to improve the final product’s quality and maximize income [

2]. However, this technology cannot be implemented without the farmer’s knowledge of the field, and agricultural practices developed across generations are also crucial for successful coffee growing.

Among the different phases of the coffee production cycle, establishing the crop in the field is essential. Therefore, it is important to produce quality seedlings and ensure adequate monitoring after transplanting to ensure a good crop establishment in the field. In this context, conducting studies to evaluate the production of coffee seedlings in different containers, as well as the response of the seedlings after implantation in the field, becomes necessary.

The utilization of different containers for coffee seedling production has been the focus of research studies. Conventional polyethylene bags have some disadvantages, such as potential disintegration, susceptibility to nematode infection, taproot coiling, high substrate demand, and low efficiency in the nursery phase, necessitating a large area and manual planting. Consequently, root trainers and perforated bags have emerged as alternative options. In addition to overcoming the aforementioned disadvantages, both alternatives enable mechanical planting, among other benefits. However, farmers harbor concerns about certain factors, like seedling survival, creating resistance to change due to the high manual labor cost associated with replanting [

3,

4,

5]. Studies on containers for coffee seedling production have been conducted, most of which have shown superior results in higher-volume containers without necessarily indicating an effect from the container material [

6,

7]. However, the majority of these studies evaluated the nursery phase, with only a few assessing the performance post-transplanting.

One of the approaches integrated into precision agriculture is remote sensing, defined as the acquisition of information about objects on the Earth’s surface without physical contact [

8,

9]. Due to the well-defined spectral response of plants and their characteristic interaction with electromagnetic radiation, remote sensors find application in agriculture for monitoring purposes. However, there is a lack of studies related to coffee cultivation post-transplanting of seedlings in the field, as coffee is a perennial, complex crop with diverse phenological phases. Furthermore, the emergence of Unmanned Aerial Vehicles (UAV) equipped with remote sensors exacerbates this gap, as UAV images offer higher spatiotemporal resolution compared to satellite images [

10]. The challenges related to acquiring spectral information at an appropriate temporal resolution and the expenses associated with obtaining high spatial resolution imagery have been successfully addressed with UAVs [

11].

Various studies have employed remote sensing to assess coffee plants, monitor diseases and water stress, and establish correlations among other biotic and abiotic factors using vegetation indices (VIs) measured by orbital sensors [

12,

13,

14]. Others have utilized multispectral cameras coupled to UAVs to evaluate fruit ripening, seedling mortality, and correlations between field measurements and aerial images [

15,

16,

17,

18,

19,

20,

21,

22,

23]. However, no studies have utilized remote sensing and UAVs to monitor farming practices, specifically the response of coffee seedlings transplanted in different containers.

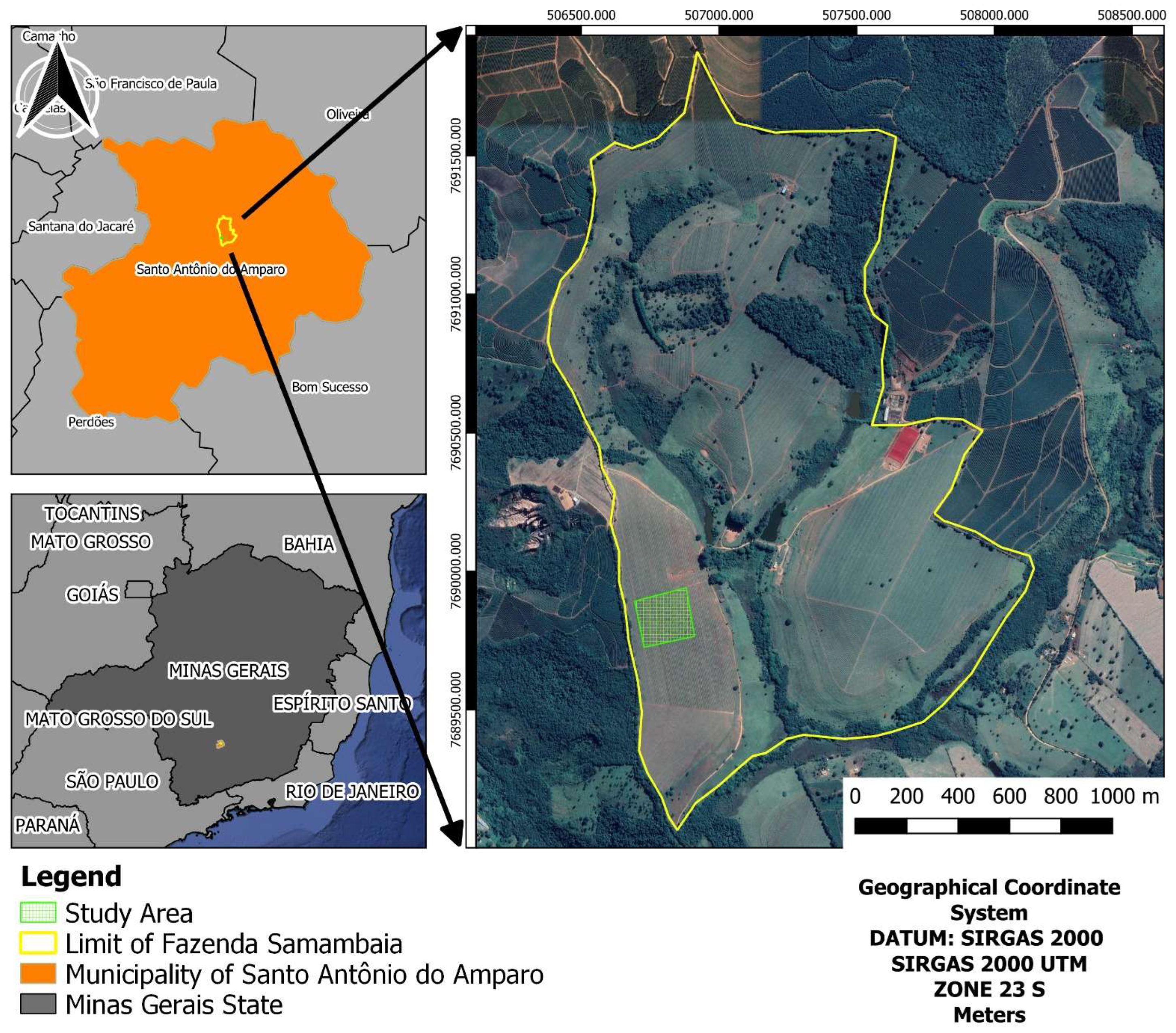

To address this gap, a comparative study was conducted, examining indices obtained from aerial imagery in conjunction with field-collected data, including crop growth variables. The study involved graphical analysis of variations over time, correlation analysis, and development of linear models. Within this scope, the study aimed to evaluate the response of coffee plants grown in different containers (root trainers and perforated bags) after transplantation to the field, using VIs generated from multispectral images acquired by UAVs.

4. Discussion

This manuscript contributes relevant information that, alongside other studies, can be utilized as a basis for monitoring coffee plants and evaluating them post-transplantation in the field. Additionally, this study offers insights into choosing the optimal container for producing high-quality seedlings with better survival rates in the field. The results presented here are pivotal for planning and decision-making among coffee producers. The utilization of UAV and the integrated multispectral sensor proved efficient in monitoring the effects of transplanting seedlings from different containers.

Coffee growth variables showed a progressive increase throughout the cycle. This temporal variation correlates with augmented dry matter and leaf emissions, stabilizing in September. According to [

52], when estimating LAI using equations, an average of 0.27 for coffee seedlings after 15 months was assessed; this is a value similar to those found in this study. Moreover, similar temporal variations in LAI, as reported by [

43] in assessments of evapotranspiration and crop coefficients during coffee plant growth, were observed. Notably, a significant reduction in chlorophyll values occurred during the rainy season (January), consistent with [

53], who state that under water stress, chloroplasts increase CO

2 assimilation to uphold plant physiological functions, thereby heightening the content of photosynthetic pigments due to reduced leaf water content, consequently elevating chlorophyll meter sensor readings during these periods.

The variations in coffee growth variables corresponded to fluctuations in vegetation indices, which mirror the plant’s response. These indices decline during the dry season and rise during the rainy season. The dry season, overlapping with winter, a period of stress where photoassimilates prioritize root growth overshoots, explains the drop in VI values [

54,

55,

56].

The findings of this study corroborate with [

57], which assessed temporal changes in the wood biomass of Arabica coffee plants using Landsat-5 images, revealing the lowest values of NDVI, soil-adjusted vegetation index (SAVI), and field-measured LAI in August and September. Similar water deficit effects were noted in [

58], where a decrease in NDVI values was observed using a moderate-resolution imaging spectroradiometer (MODIS) sensor for coffee plants grown under full sunlight. Additionally, Ref. [

59] reported the lowest crop coefficient values in June, July, and August, coinciding with the dormancy phase of coffee plants characterized by reduced vegetative activity.

Some indices, such as MCARI1 and MSAVI2, exhibited higher values in November compared to January. These indices might be more responsive to flowering in this experimental area, corroborating with [

60], which also observed increased biomass and consequent index elevation from mid-October onward.

The temporal dynamics of VIs calculated in this study agree with the findings from [

60], where NDVI measured using a MODIS sensor evaluated coffee plants’ temporal changes during seedling production, growth, and pruning, proposing an agrometeorological–spectral monitoring model. Similar trends in coffee plant variations using VIs have been reported in other studies [

57,

58,

61]. Hence, even during seedling growth and initial months after transplantation, coffee plants exhibit response patterns associated with their phenological phases, as described by [

62]. Young coffee plants demonstrate distinct responses compared to mature trees, particularly in the first 3 years, where most photoassimilates drive plant growth, resulting in lower biomass and, subsequently, lower VI values [

60,

63], as observed in the results of this study.

Most vegetation indices exhibited a similar temporal variation, decreasing from May with the lowest values reached in September. Similar VI responses were documented by [

58,

60,

61], aligning with the coffee phenology proposed by [

62]. Notably, NDRE demonstrated distinct behavior compared to other indices, showing a more linear variation over time with no decrease in September or only a slight drop in January. This pattern reflects the dynamics of growth variables. NDRE, commonly associated with ripeness and vegetation pigments, including chlorophyll (strongly linked to vegetative vigor), is widely used in crop monitoring. The consistent increase in this index from September onwards suggests a correlation with the phenological behavior of coffee plants, which experience heightened growth and ripening after that month.

Based on the results presented, no significant differences were found for most studied coffee growth variables across the evaluated treatments. These findings agree with the values observed in the temporal analysis. Many studies on coffee plants grown in different containers focus on seedlings in the nursery stage and do not assess performance after transplanting. In addition to measuring differences between container materials, most studies, like [

3,

5], evaluate the effects of volume and substrate. They generally identify better results in polyethylene bags or root trainers with larger volumes and commercial substrates compared to mineral soil.

In a study examining coffee plants after transplanting in the field [

6], seedlings grown in polyethylene bags and in 50 and 120 mL root trainers using different substrates were evaluated. Considering the studies cited in the previous paragraph, which found no significant differences between coffee seedlings grown in polyethylene bags and those in 120 mL root trainers, it can be concluded that 180 mL root trainers (as used in this research) could be a viable alternative to perforated bags. However, container volume should be carefully considered, as opting for root trainers with lower volumes may result in less substrate and compromise root development.

In the correlation analysis, strong correlations were observed between all variables except for chlorophyll. The weak correlations observed between chlorophyll levels and most calculated VIs in this research could be attributed to random leaf sampling. Even within a single coffee tree, leaves that are more exposed might suffer from burning and chlorosis during cooler periods or endure harsher conditions in hot summers. However, leaves positioned inside the canopy area may be more protected from such factors or receive reduced solar radiation, potentially affecting the behavior of their photosynthetic pigments.

All vegetation indices demonstrated a correlation with growth measures exceeding 0.70, indicating that VIs can be a viable option for estimating certain coffee growth variables using this approach. Moreover, the variables that exhibited higher values both when growing seedlings in perforated bags and when growing seedlings in root trainers in the canopy planar area were calculated by vectorization (cm2), NDVI, and NDRE. However, the latter resulted in the lowest correlation value, with crown diameter among the studied VIs.

Considering the observed relationship between growth variables and vegetation indices, the generated models yielded favorable results for the studied treatments. Consequently, it is possible to use and recommend such linear models for estimating the coffee leaf area. In the literature, some studies have developed linear models to estimate crop-growth parameters such as height, diameter, and LAI, combining these measures, with results similar to the findings of this study. For instance, Ref. [

63] reported R

2 values close to 0.8 and 0.9 for maize and potatoes, respectively, when using their models to estimate LAI based on SAVI, MSA-VI, the transformed soil-adjusted vegetation index (TSAVI), and the perpendicular vegetation index (PVI) derived from QuickBird satellite images. However, in sorghum, R

2 values of 0.85 and 0.81 were observed when estimating LAI using NDVI and EVI, respectively, from multispectral images acquired by UAV [

64].

Studies on perennial crops have reported good R

2 values and correlations between growth variables measured and those measured by UAV, particularly involving forest species [

65,

66]. In coffee cultivation, a similar UAV approach was undertaken by [

19], with high R

2 values for height and diameter (0.87 and 0.95, respectively), which were variables used to calculate LAI. However, there is still a scarcity of studies employing VIs to estimate this variable in coffee plants. This may be attributed to the saturation of indices such as NDVI when LAI reaches higher values [

67]. According to [

68], no significant results were obtained when using NDVI, SAVI, green vegetation index (GVI), and ratio vegetation index (RVI) to estimate LAI, although they reported a good correlation of the parameter with the blue and green spectral bands. Additionally, Ref. [

69] achieved an R² of 0.78 for LAI based on the NDVI measured using a MODIS sensor after several calibrations and adjustments. However, various VIs were calculated in this study, and the coffee plants were young, implying that their LAI values were low. Consequently, the R

2 values of the proposed models are considered good in regression models.

An important point to highlight is related to the possible existence of autocorrelation in the data due to temporal analysis. In this study, this fact was not a limiting factor since the objective was to characterize the variations over time and observe the existing correlations between the variables studied. Other studies also conducted monitoring and evaluation of plant response over time and did not observe problems with autocorrelation in the analysis [

19,

70]. In future studies, especially those with long time series that require temporal analysis, the use of autocorrelation analysis may be necessary and recommended.

Studying the response and survival of coffee seedlings in the field becomes crucial, primarily due to the high investment and need for a robust establishment of the crop. In this context, coffee seedlings transplanted from perforated polyethylene bags exhibited a higher survival rate than seedlings produced in root trainers, as indicated by the lower number of dead seedlings in the field. This difference may primarily be attributed to the volume of substrate, which is considerably lower in the root trainers than in the perforated polyethylene bags tested in this study, affecting not only the nutrition of the plants but also their ability to retain water during higher temperatures.

The literature lacks studies utilizing vegetation indices and Unmanned Aerial Vehicles for this approach, with agronomic studies typically relying on in situ field measurements. For instance, Ref. [

71] evaluated the survival of Topázio cultivar coffee seedlings produced in plastic bags and 120 mL and 50 mL root trainers after transplanting, comparing conventional to no-till planting, where dry Brachiaria was managed on the soil, previously planted between rows. The study observed that seedlings grown in plastic bags exhibited a higher survival rate than those grown in root trainers 138 days after planting (DAP). However, the difference for the root trainer with a higher volume (120 mL) was significantly smaller in conventional planting in dystrophic red–yellow argisol. In no-till planting, a clear difference in seedling survival was observed from 30 days after planting, with percentages reaching 100%, 91.62%, and 40.62% for plastic bags and 120 mL and 50 mL root trainers, respectively, after 138 days.

Another study by [

71] focused on seedling survival in different planting seasons for the Acaiá Cerrado cultivar, grown in plastic bags and 120 mL root trainers in different soil types. On all dates, seedlings produced in perforated bags demonstrated a higher survival rate. However, in seasons with unfavorable climatic conditions, the percentage of seedling survival after transplanting from root trainers reached its lowest value (12.50%), in contrast to 90% for seedlings grown in plastic bags in dystrophic red latosol. In dystrophic red–yellow argisol, the difference in seedling survival was lower (97.50% for plastic bags versus 67.50% for root trainers), also highlighting the impact of soil factors. Therefore, substrate volume emerged as a critical factor for seedling survival in periods of stress for coffee plants.

While the increase in seedling survival in perforated bags corroborates with the findings of the present study, the difference in the percentage of seedling mortality is lower in this study (6.4% for perforated bags versus 11.7% for root trainers). Hence, the volume of the root trainers used in this study (180 mL) demonstrated a positive effect on performance. However, replanting represents an increase in labor costs, with an approximate cost of USD 200,000 per hectare for the farm where this research was conducted. Consequently, both containers were interesting alternatives to conventional polyethylene bags, with root trainers proving advantageous for the nursery phase and perforated bags for seedling survival.

This study aimed to evaluate the coffee plant’s response after transplanting seedlings grown in different containers, based on multispectral images acquired by UAVs. The results confirmed that this methodology can be used to assess the impacts of transplanting seedlings produced in different containers. As a recommendation for future research, it is important to highlight the relevance of incorporating analyses on how extreme weather events and climate change can affect these processes. Climatic variability and an increase in the frequency of extreme events, such as prolonged droughts and heavy rainfall, can significantly impact plant development and transplant efficacy, necessitating adaptive strategies for coffee management. Therefore, it is recommended to conduct in-depth research on the coffee root system’s resilience to these adverse conditions. Regarding UAVs, research with other multispectral cameras and hyperspectral cameras could be conducted to assess other coffee responses, primarily related to chlorophyll or flowering, and how these processes are influenced by climate change. Additionally, the use of artificial intelligence (such as machine learning and deep learning, among other AI tools) would represent new research alternatives for UAV image segmentation and the identification of features allowing volume estimation, fruit ripening, harvest prediction, identification of damage caused by extreme weather events, and development of adaptive management strategies.