Life Cycle Assessment of Dried Organic Apple Value Chains Considering Conventional and Heat-Pump-Assisted Drying Processes: The Case of Sweden

Abstract

:1. Introduction

1.1. General Introduction

1.2. Literature Review on LCA of Apple Fruits

| Scope | Functional Unit | Country | Yield (t/ha) | CED (GJ/FU | GWP (kg CO2 eq/FU) | Ref. |

|---|---|---|---|---|---|---|

| Cradle-to-farm gate; conventional apple production | Ton of fresh apples | Greece | 32.4 | 1.21 | 89 | [14] |

| Cradle-to-consumer gate | Kg of exported fresh apples | Chile (production); UK (consumption) | 47.2 | na | 0.54 | [15] |

| Cradle-to-consumer gate | Fresh apples | France | 37.8 | [21] | ||

| Cradle-to-consumer gate; conventional | Ton of fresh apples | Italy | 70 | 11.4 | 612 | [16] |

| Cradle-to-consumer gate; organic | Ton of fresh apples | Italy | 50 | 11.2 | 588 | [16] |

| Cradle-to-grave | Kg of fresh apples | Spain | 48.81 | na | 0.302 | [17] |

| Conventional production | Ha of apple orchard | Turkey | 40.9 | 29.2 | 1464.07 | [18] |

| Organic production | Ha of apple orchard | Turkey | 38.7 | 25.94 | 1344.27 | [18] |

| Cradle-to-farm gate | Kg of fresh apples | Italy | 58.6 | na | 0.514 | [25] |

| Cradle-to-farm gate | Ton of fresh apples | Portugal | na | na | 76 | [23] |

| Cradle-to-farm gate (conventional production system) | Ton of fresh apples at farm gate | Belgium | 43.1 | na | 67.7 | [11] |

| Cradle-to-farm gate (integrated production system) | 53.5 | na | 65.9 | |||

| Cradle-to-farm gate (organic production) | 48.6 | na | 154 | |||

| Cradle-to-grave | Kg of fresh apples | UK | 0.019 | 1.4 | [24] |

2. Materials and Methods

2.1. Goal and Scope Definition

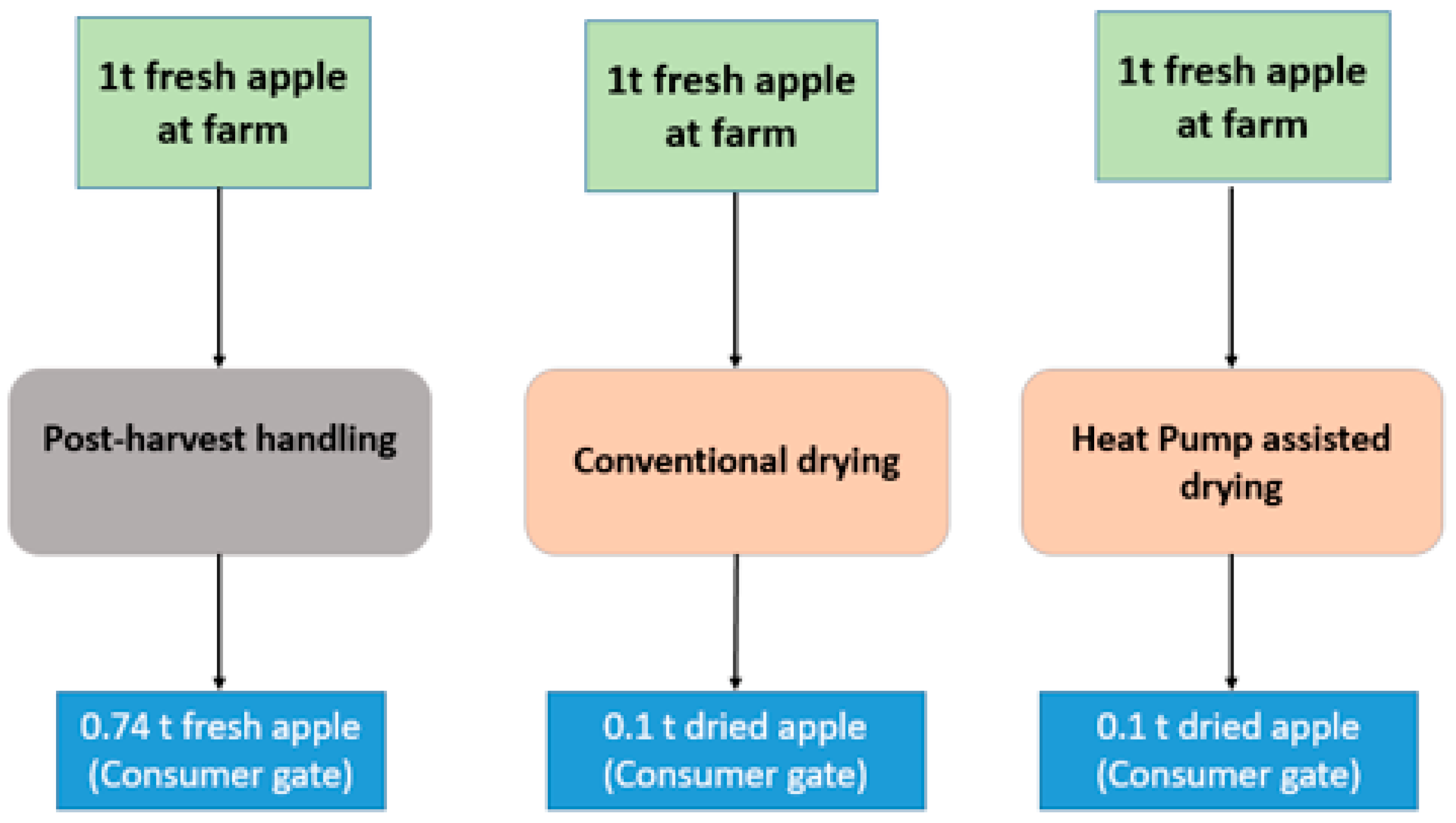

2.2. System Boundary and Product Value Chain Description

2.2.1. Agricultural Production of Organic Apples

2.2.2. Apple Drying and Post-Harvest Handling

2.2.3. Transport Segments

2.3. Life Cycle Inventory

2.4. Life Cycle Impact Assessment

2.4.1. Impact Categories

2.4.2. Allocation Principle

2.4.3. Sensitivity Analysis

3. Results

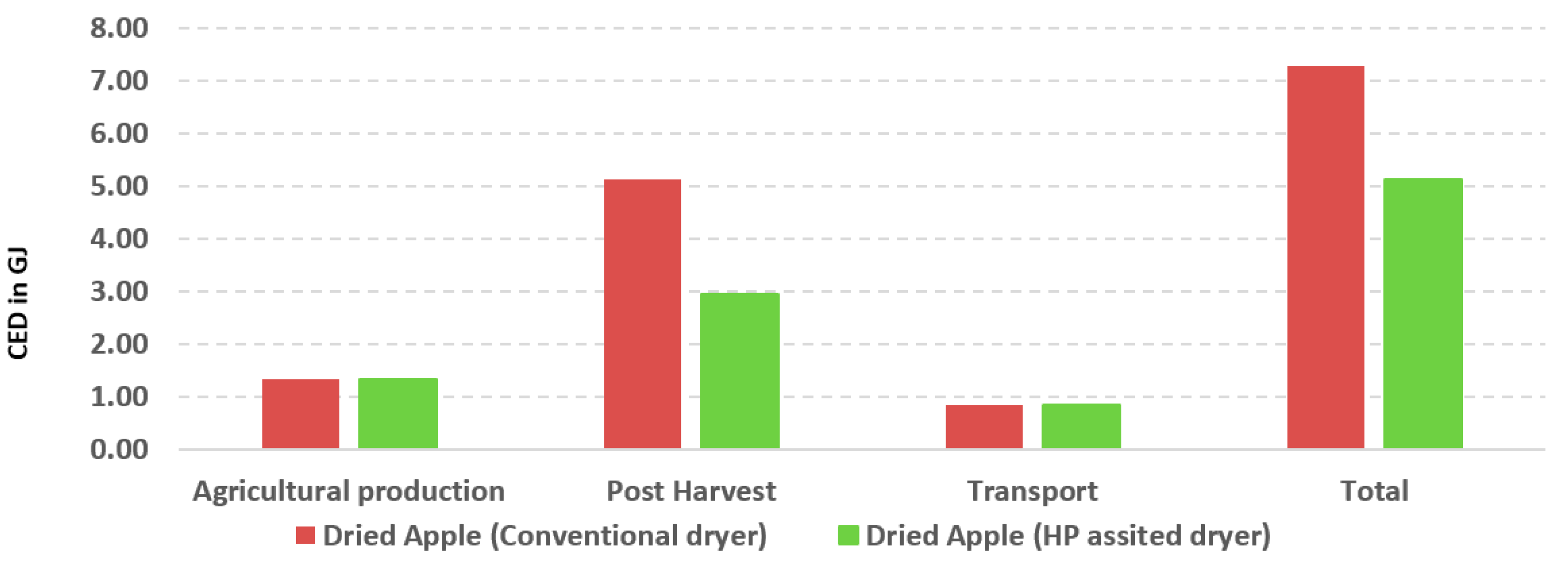

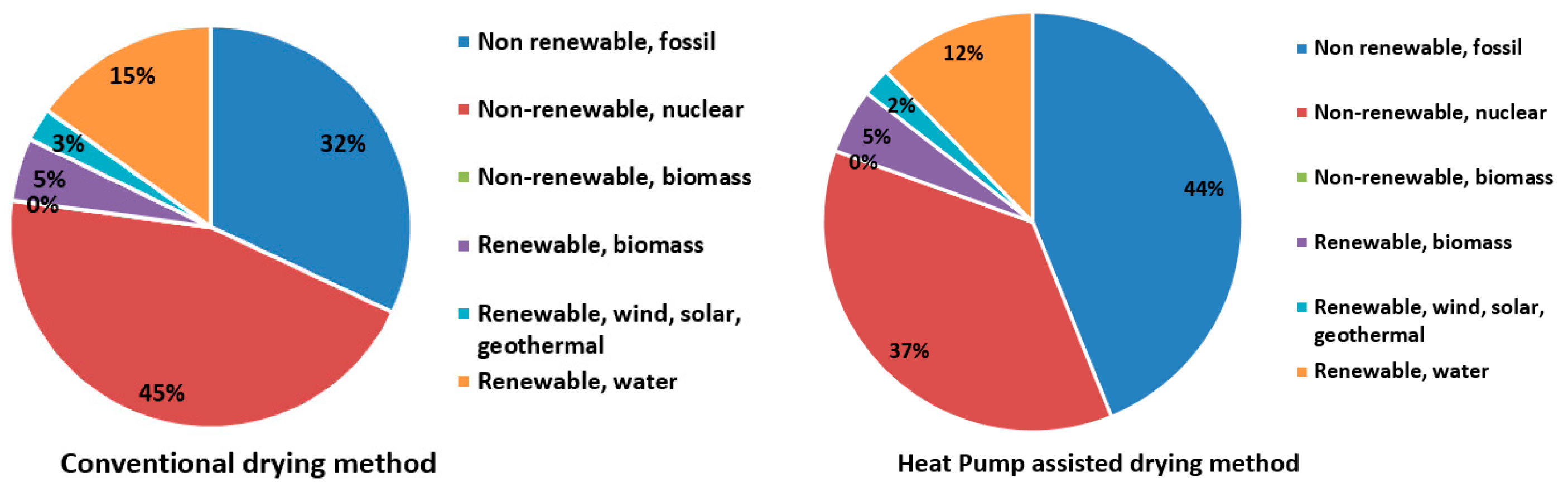

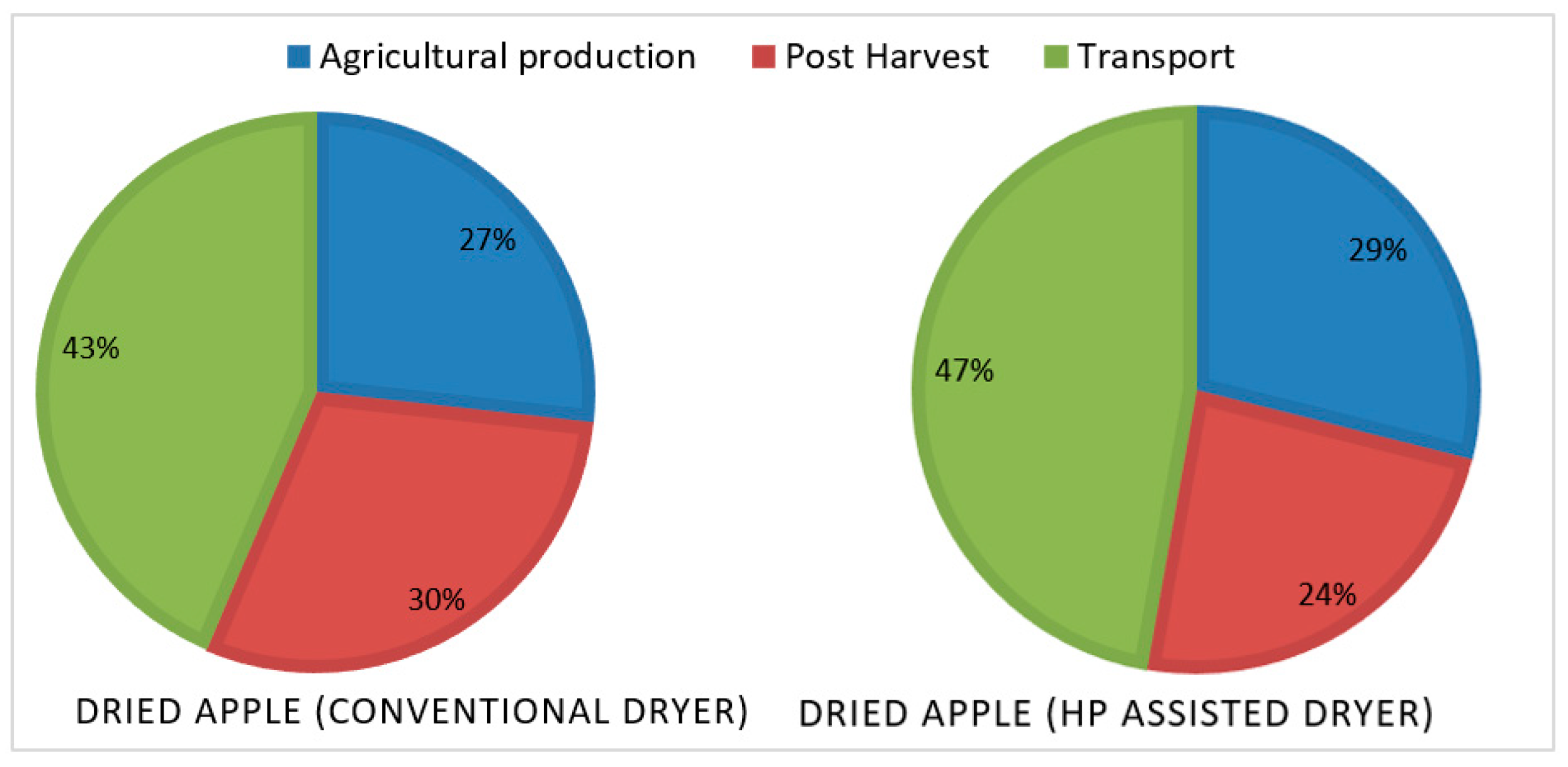

3.1. Cumulative Energy Demand of Apple Value Chain

3.2. Global Warming Potential of Organic Apple Value Chain

3.3. Acidification and Eutrophication Impact of Organic Apple Value Chain

3.4. Sensitivity Analysis

4. Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Foley, J. The Other Inconvenient Truth. TED Talks, Filmed October 2010. 2010. Available online: http://www.ted.com/talks/jonathan_foley_the_other_inconvenient_truth#t-540163 (accessed on 26 October 2015).

- Gomiero, T. Chapter 2—Organic agriculture: Impact on the environment and food quality. In Environmental Impact of Agro-Food Industry and Food Consumption; Academic Press: New York, NY, USA, 2021; pp. 31–58. [Google Scholar] [CrossRef]

- Cattaneo, A.; Federighi, G.; Vaz, S. The environmental impact of reducing food loss and waste: A critical assessment. Food Policy 2021, 98, 101890. [Google Scholar] [CrossRef]

- Read, Q.D.; Brown, S.; Cuéllar, A.D.; Finn, S.M.; Gephart, J.A.; Marston, L.T.; Meyer, E.; Weitz, K.A.; Muth, M.K. Assessing the environmental impacts of halving food loss and waste along the food supply chain. Sci. Total Environ. 2020, 712, 136255. [Google Scholar] [CrossRef]

- van der Werf, H.M.G.; Knudsen, M.T.; Cederberg, C. Towards better representation of organic agriculture in life cycle assessment. Nat. Sustain. 2020, 3, 419–425. [Google Scholar] [CrossRef]

- Clark, S. Organic Farming and Climate Change: The Need for Innovation. Sustainability 2020, 12, 7012. [Google Scholar] [CrossRef]

- Jönsson, Å.H. Organic Apple Production in Sweden: Cultivation and Cultivars. Ph.D. Thesis, Department of Crop Science, Faculty of Landscape Planning, Horticulture and Agricultural Science, Swedish University of Agricultural Sciences, Alnarp, Sweden, 2007. ISSN 1652-6880, ISBN 978-9-15767-313-8. Available online: https://pub.epsilon.slu.se/1338/1/%C3%85J_finalversion.pdf (accessed on 20 April 2020).

- Eurostat. Production of Fruit and Vegetables. 2016. Available online: https://ec.europa.eu/eurostat/documents/2995521/7517627/5-22062016-AP-EN.pdf/8247b23e-f7fd-4094-81ec-df1b87f2f0bb (accessed on 2 February 2024).

- Roy, P.; Nei, D.; Orikasa, T.; Xu, Q.; Okadome, H.; Nakamura, N.; Shiina, T. A review of life cycle assessment (LCA) on some food products. J. Food Eng. 2009, 90, 1–10. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, J.; Hou, L.; Xu, X.; Zhu, Y.; Zhai, B.; Liu, Z. Comparative assessment of environmental impacts, mitigation potentials, and economic benefits of rain-fed and irrigated apple production systems on China’s Loess Plateau. Sci. Total Environ. 2023, 869, 161791. [Google Scholar] [CrossRef]

- Goossens, Y.; Annaert, B.; De Tavernier, J.; Mathijs, E.; Keulemans, W.; Geeraerd, A. Life cycle assessment (LCA) for apple orchard production systems including low and high productive years in conventional, integrated and organic farms. Agric. Syst. 2017, 153, 81–93. [Google Scholar] [CrossRef]

- Kai, T.; Adhikari, D. Effect of Organic and Chemical Fertilizer Application on Apple Nutrient Content and Orchard Soil Condition. Agriculture 2021, 11, 340. [Google Scholar] [CrossRef]

- Keyes, S.; Tyedmers, P.; Beazley, K. Evaluating the environmental impacts of conventional and organic apple production in Nova Scotia, Canada, through life cycle assessment. J. Clean. Prod. 2015, 104, 40–51. [Google Scholar] [CrossRef]

- Bartzas, G.; Vamvuka, D.; Komnitsas, K. Comparative life cycle assessment of pistachio, almond and apple production. Inf. Process. Agric. 2017, 4, 188–198. [Google Scholar] [CrossRef]

- Iriarte, A.; Yáñez, P.; Villalobos, P.; Huenchuleo, C.; Rebolledo-Leiva, R. Carbon footprint of southern hemisphere fruit exported to Europe: The case of Chilean apple to the UK. J. Clean. Prod. 2021, 293, 126118. [Google Scholar] [CrossRef]

- Longo, S.; Mistretta, M.; Guarino, F.; Cellura, M. Life Cycle Assessment of organic and conventional apple supply chains in the North of Italy. J. Clean. Prod. 2017, 140, 654–663. [Google Scholar] [CrossRef]

- Vinyes, E.; Asin, L.; Alegre, S.; Muñoz, P.; Boschmonart, J.; Gasol, C.M. Life Cycle Assessment of apple and peach production, distribution and consumption in Mediterranean fruit sector. J. Clean. Prod. 2017, 149, 313–320. [Google Scholar] [CrossRef]

- Ekinci, K.; Demircan, V.; Atasay, A.; Karamursel, D.; Sarica, D. Energy, Economic and Environmental Analysis of Organic and Conventional Apple Production in Turkey. Erwerbs-Obstbau 2020, 62, 1–12. [Google Scholar] [CrossRef]

- Fabbri, S.; Olsen, S.I.; Owsianiak, M. Improving environmental performance of post-harvest supply chains of fruits and vegetables in Europe: Potential contribution from ultrasonic humidification. J. Clean. Prod. 2018, 182, 16–26. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Figueroa-Torres, G.; Azapagic, A. The extent of food waste generation in the UK and its environmental impacts. Sustain. Prod. Consum. 2021, 26, 532–547. [Google Scholar] [CrossRef]

- Loiseau, E.; Colin, M.; Alaphilippe, A.; Coste, G.; Roux, P. To what extent are short food supply chains (SFSCs) environmentally friendly? Application to French apple distribution using Life Cycle Assessment. J. Clean. Prod. 2020, 276, 124166. [Google Scholar] [CrossRef]

- Svanes, E.; Johnsen, F.M. Environmental life cycle assessment of production, processing, distribution and consumption of apples, sweet cherries and plums from conventional agriculture in Norway. J. Clean. Prod. 2019, 238, 117773. [Google Scholar] [CrossRef]

- Gonçalves, I.; Neto, B. A Life Cycle Assessment of Dehydrated Apple Snacks. Sustainability 2023, 15, 16304. [Google Scholar] [CrossRef]

- Frankowska, A.; Jeswani, H.K.; Azapagic, A. Life cycle environmental impacts of fruits consumption in the UK. J. Environ. Manag. 2019, 248, 109111. [Google Scholar] [CrossRef] [PubMed]

- Medici, M.; Canavari, M.; Toselli, M. Interpreting Environmental Impacts Resulting from Fruit Cultivation in a Business Innovation Perspective. Sustainability 2020, 12, 9793. [Google Scholar] [CrossRef]

- Le Féon, S.; Benezech, T.; Bris, G.Y.-L.; Aubin, J.; Sampers, I.; Herreman, D.; Pénicaud, C. Life cycle assessment of a small-scale and low-input organic apple value chain including fresh fruit, juice and applesauce. Clean. Environ. Syst. 2023, 11, 100141. [Google Scholar] [CrossRef]

- Reynolds, C.J.; Buckley, J.D.; Weinstein, P.; Boland, J. Are the Dietary Guidelines for Meat, Fat, Fruit and Vegetable Consumption Appropriate for Environmental Sustainability? A Review of the Literature. Nutrients 2014, 6, 225–2265. [Google Scholar] [CrossRef]

- PRẻ Consultants. SimaPro Database Manual, Version 2.9. 2015. Available online: https://www.pre-sustainability.com/download/DatabaseManualMethods.pdf (accessed on 17 January 2017).

- Frischknecht, R.; Wyss, F.; Knöpfel, S.B.; Lützkendorf, T.; Balouktsi, M. Cumulative energy demand in LCA: The energy harvested approach. Int. J. Life Cycle Assess 2015, 20, 957. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management, Life Cycle Assessment Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 28 February 2024).

- ISO 14044:2006; Environmental Management, Life Cycle Assessment Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 28 February 2024).

- Curran, M.A. Life cycle assessment in the agri-food sector: Case studies, methodological issues, and best practices. Int. J. Life Cycle Assess 2016, 21, 785–787. [Google Scholar] [CrossRef]

- Johansson, D. Life Cycle Assessment (LCA) of Apples—A Comparison between Apples Produced in Sweden, Italy and Argentina. Master’s Thesis, Swedish University of Agricultural Sciences, Uppsala, Sweden, 2015. Available online: https://stud.epsilon.slu.se/8390/17/johansson_d_150922.pdf (accessed on 12 January 2018).

- Stadig, M. Life Cycle Analysis of Apple Production. Case Study for Sweden, New Zeeland, and France. SIK Report No 683. 2001. Available online: https://www.diva-portal.org/smash/get/diva2:959114/FULLTEXT01.pdf (accessed on 6 January 2020).

- SINTEF Energy Research, Norway. 2020. Available online: https://sintef.brage.unit.no/sintef-xmlui/handle/11250/3077573 (accessed on 2 December 2023).

- Omoleye, O. Assessment of Food Losses and Waste and Related Greenhouse Gas Emissions Along a Fresh Apples Value Chain. Master’s Thesis, Swedish University of Agricultural Sciences, Uppsala, Sweden, 2020. Available online: https://stud.epsilon.slu.se/16253 (accessed on 2 April 2021).

- Csaki, D.; Rudolfsson, A. Internal Logistics Solutions for Äppelriket. Högskolan Kirstianstad. 2005. Available online: https://researchportal.hkr.se/ws/portalfiles/portal/35123933/FULLTEXT01.pdf (accessed on 15 January 2023).

- Curran, M.A. Life Cycle Assessment Student Handbook; Wiley, Scrivener Publishing: New York, NY, USA, 2015; ISBN 978-1-11908-354-2. [Google Scholar]

- Karlsson, H. Seasonal Vegetables: An Environmental Assessment of Seasonal Food. Master’s Thesis, Norwegian University of Life Sciences, Ås, Norway, 2011. Available online: https://core.ac.uk/download/pdf/30889678.pdf (accessed on 2 November 2020).

- Milà i Canals, L.; Burnip, G.M.; Cowell, S.J. Evaluation of the environmental impacts of apple production using Life Cycle Assessment (LCA): Case study in New Zealand. Agric. Ecosyst. Environ. 2006, 114, 226–238. [Google Scholar] [CrossRef]

- Alaphilippe, A.; Boissy, J.; Simon, S.; Godard, C. Environmental impact of intensive versus semi-extensive apple orchards: Use of a specific methodological framework for Life Cycle Assessments (LCA) in perennial crops. J. Clean. Prod. 2016, 127, 555–561. [Google Scholar] [CrossRef]

- Cheng, J.; Wang, Q.; Li, D.; Yu, J. Comparative Analysis of Environmental and Economic Performance of Agricultural Cooperatives and Smallholder Farmers for Apple Production in China. Agriculture 2022, 12, 1281. [Google Scholar] [CrossRef]

- Zhu, Z.; Jia, Z.; Peng, L.; Chen, Q.; He, L.; Jiang, Y.; Ge, S. Life cycle assessment of conventional and organic apple production systems in China. J. Clean. Prod. 2018, 201, 156–168. [Google Scholar] [CrossRef]

- Raghu, K.C. Comparative Lifecycle Assessment on Organic and Conventional Carrots-Case: Carrots from South-Savo and Imported Carrots from Italy. Master’s Thesis, Faculty of Technology, Lappeenranta University of Technology, Lappeenranta, Finland, 2014. [Google Scholar] [CrossRef]

- Stoessel, F.; Juraske, R.; Pfister, S.; Hellweg, S. Life cycle inventory and carbon and water footprint of fruits and vegetables: Application to Swiss retail. Environ. Sci. Technol. 2012, 46, 3253–3262. [Google Scholar] [CrossRef] [PubMed]

- Le Féon, S.; Benezech, T.; Bris, G.Y.-L.; Aubin, J.; Sampers, I.; Herreman, D.; Pénicaud, C. Datasets for the environmental assessment of an apple value chain including fresh fruits, juice and applesauce from an organic low-input production farm. Data Brief 2023, 51, 109824. [Google Scholar] [CrossRef] [PubMed]

- Swedish Environmental Protection Agency. Swedish Environmental Objectives. Available online: https://www.naturvardsverket.se/en/om-miljoarbetet/swedish-environmental-objectives/ (accessed on 15 January 2023).

| Country | Yearly Apple Production | |

|---|---|---|

| Harvested Production (in 1000 Tons) | Share of EU Production (%) | |

| EU | 12,685.4 | 100% |

| Poland | 3168.8 | 25 |

| Germany | 973.5 | 7.7 |

| Italy | 2441.6 | 19.2 |

| Spain | 593.6 | 4.7 |

| Romania | 459.6 | 3.6 |

| Sweden | 25.4 | 0.2 |

| Description | Unit | Quantity | Data Source * |

|---|---|---|---|

| Agricultural production | |||

| Diesel for ploughing, harrowing, and planting | kg | 0.21 | [34] |

| Organic fertilizer | kg | 12 | [16] |

| Fertilizer transport distance | km | 50 | |

| Water for irrigation | kg | 54,000 | Estimated based on the literature [34] |

| Electricity for irrigation | MJ | 64.42 | |

| Energy for pruning (including crushing/mulching) | kg | 3.34 | |

| Energy (diesel) for harvesting activities | kg | 9.83 | |

| Post-harvest process | |||

| Energy for storing (cooling) | MJ | 34.4 | Estimated considering 20 days before drying process |

| Water (washing etc.) | kg | 2900 | [16] |

| Energy for sorting | MJ | 5.33 | [34] |

| Electricity for apple slicing | kwh | 1.3 | Estimated considering a commercial machine of 1.5 t/2 kwh capacity |

| Apple drying | |||

| Fresh apple at farm (FU) | t | 1 | |

| Fresh apple at drying processing facility | t | 0.74 | Reducing 26% cumulative loss [36] |

| Dried apple | t | 0.1 | It is 12% of the fresh apple weight just before drying process [35] |

| Conventional dryer | |||

| Dryer weight (stainless steel) | kg/FU | 0.37 | Estimated based on dryer mass of 600 kg and life span of 20 years [35] |

| Electricity for drying 0.74 t (i.e., per FU) | kwh | 543 | Estimated based on data from [35] |

| Heat pump (HP) drying | |||

| Dryer weight (stainless steel) | kg/FU | 0.37 | Estimated based on dryer mass of 600 kg and life span of 20 years [35] |

| Weight of HP dryer (steel) | kg/FU | 0.31 | Based on HP weight of 500 kg and life span of 20 years; it is a customized HP (i.e., heat pump + same conventional drier) [35] |

| Electric energy for drying 0.74 t fresh apple (i.e., per FU) | kwh | 296 | Estimated based on 2.2 kg water/kwh (and 12 kg dried apple per 100 kg fresh apple) |

| Energy for dried apple packaging process | MJ | 0.72 | Estimated based on the literature [34] |

| Dried apple weight (per FU) | ton | 0.1 | Estimated based on data from [35] |

| Packaging plastic for dried apple (polyethylene) | kg | 0.3 | |

| Packaging carton for dried apple | kg | 12 | Estimated based on the literature [16] |

| Retailer | |||

| Electricity for cooling at retailer for fresh apple | MJ | 17.2 | Estimated based on the literature [34] |

| Transport | |||

| Transport from farm to processing facility | km | 80 | Assumed based on information from primary data survey |

| Transport from processing facility to retailer | km | 50 | [37] |

| Transport from retailer to consumer | km | 5 | Assumption |

| Impact Category | Unit | Agricultural Production | Post-Harvest | Transport | Total |

|---|---|---|---|---|---|

| Dried apple (conventional drying) | |||||

| Terrestrial acidification | kg SO2 eq | 0.1511 | 0.1169 | 0.1101 | 0.3781 |

| Freshwater eutrophication | kg P eq | 0.0126 | 0.0181 | 0.0061 | 0.0368 |

| Marine eutrophication | kg N eq | 0.0010 | 0.0064 | 0.0005 | 0.0079 |

| Dried apple (HP-assisted drying) | |||||

| Terrestrial acidification | kg SO2 eq | 0.1511 | 0.0870 | 0.1101 | 0.3482 |

| Freshwater eutrophication | kg P eq | 0.0126 | 0.0130 | 0.0061 | 0.0318 |

| Marine eutrophication | kg N eq | 0.0010 | 0.0048 | 0.0005 | 0.0063 |

| Change in Drying Energy | Dried Apple (Conventional Dryer) | Dried Apple (HP-Assisted Dryer) | ||||||

|---|---|---|---|---|---|---|---|---|

| CED | % | GWP | % | CED | GWP | % | ||

| (−30%) reduction | 5.89 | 19.20 | 123.00 | 5.30 | 4.37 | 14.65 | 116.00 | 3.30 |

| (−15%) reduction | 6.59 | 9.60 | 127.00 | 2.20 | 4.75 | 7.20 | 118.00 | 1.67 |

| Basic scenario | 7.29 | 0.00 | 129.89 | 0.00 | 5.12 | 0.00 | 120.00 | 0.00 |

| (+15%) increase | 7.98 | 9.47 | 133.00 | 2,39 | 5.50 | 7.40 | 122.00 | 1.67 |

| (+30) increase | 8.68 | 19.10 | 137.00 | 5.47 | 5.87 | 14.65 | 124.00 | 3.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bosona, T. Life Cycle Assessment of Dried Organic Apple Value Chains Considering Conventional and Heat-Pump-Assisted Drying Processes: The Case of Sweden. Agriculture 2024, 14, 461. https://doi.org/10.3390/agriculture14030461

Bosona T. Life Cycle Assessment of Dried Organic Apple Value Chains Considering Conventional and Heat-Pump-Assisted Drying Processes: The Case of Sweden. Agriculture. 2024; 14(3):461. https://doi.org/10.3390/agriculture14030461

Chicago/Turabian StyleBosona, Techane. 2024. "Life Cycle Assessment of Dried Organic Apple Value Chains Considering Conventional and Heat-Pump-Assisted Drying Processes: The Case of Sweden" Agriculture 14, no. 3: 461. https://doi.org/10.3390/agriculture14030461