Staggered-Phase Spray Control: A Method for Eliminating the Inhomogeneity of Deposition in Low-Frequency Pulse-Width Modulation (PWM) Variable Spray

Abstract

:1. Introduction

2. Materials and Methods

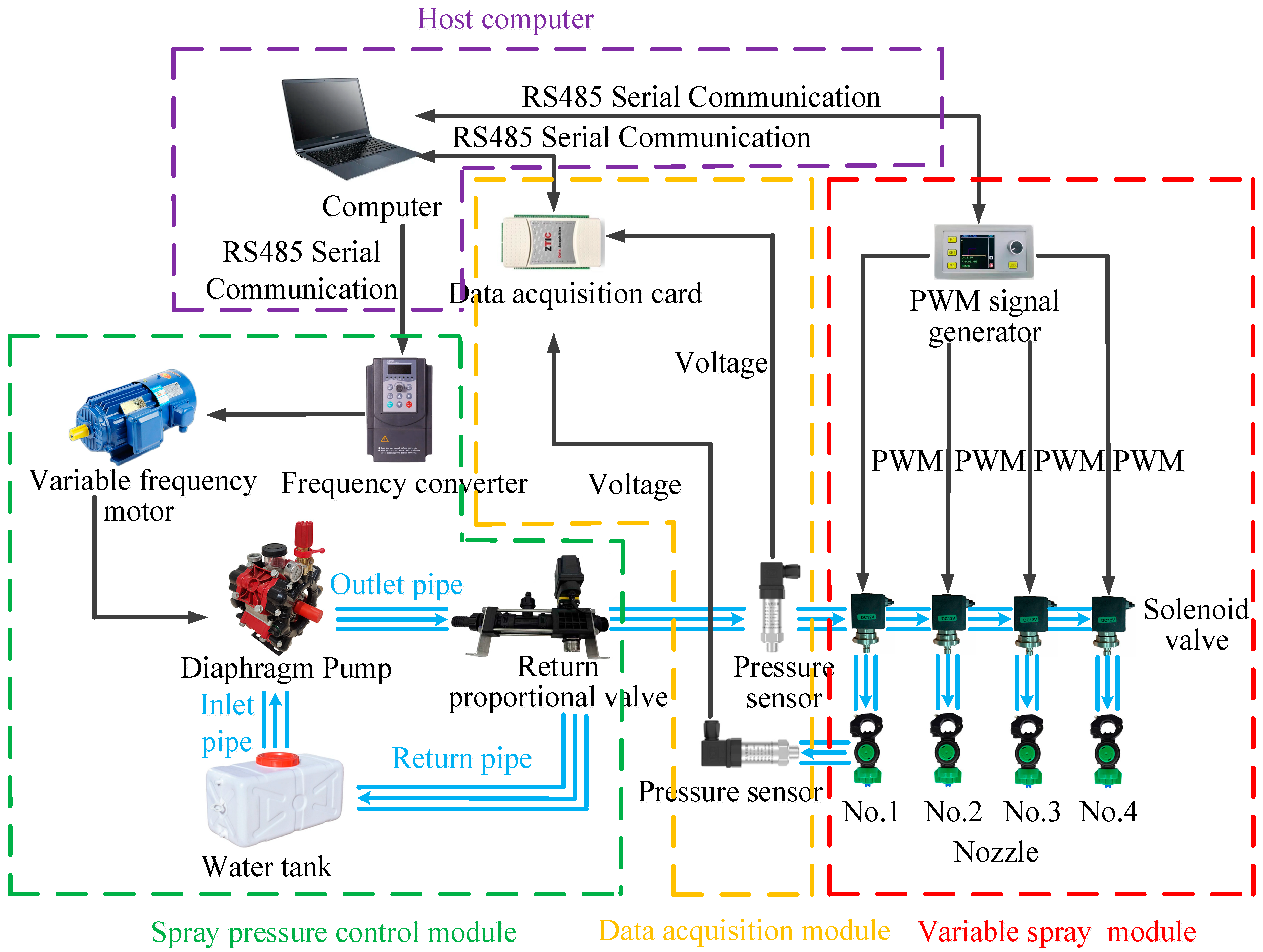

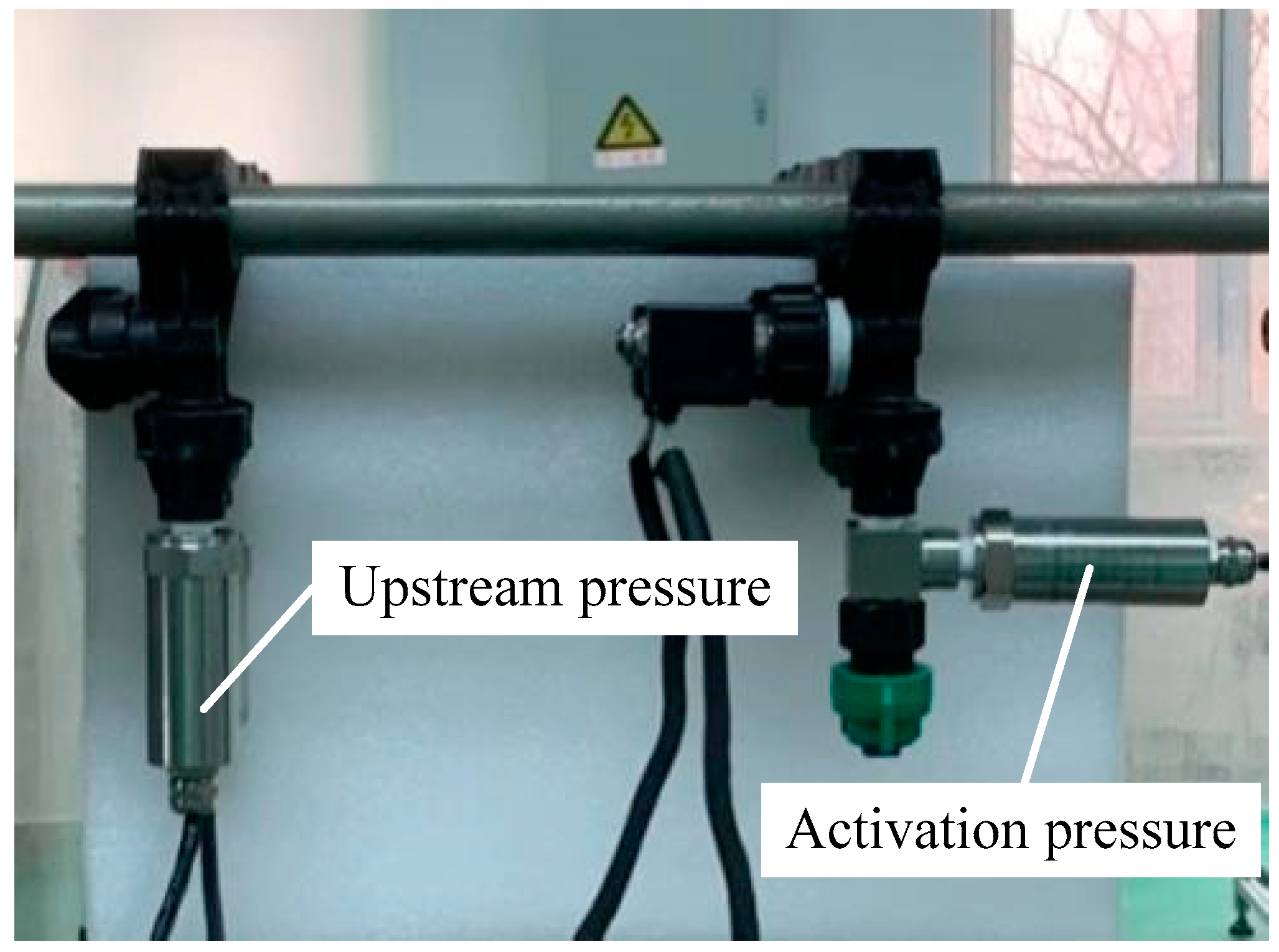

2.1. Staggered-Phase PWM Variable Spraying System Pressure Fluctuation Test

2.1.1. Test Bench Design

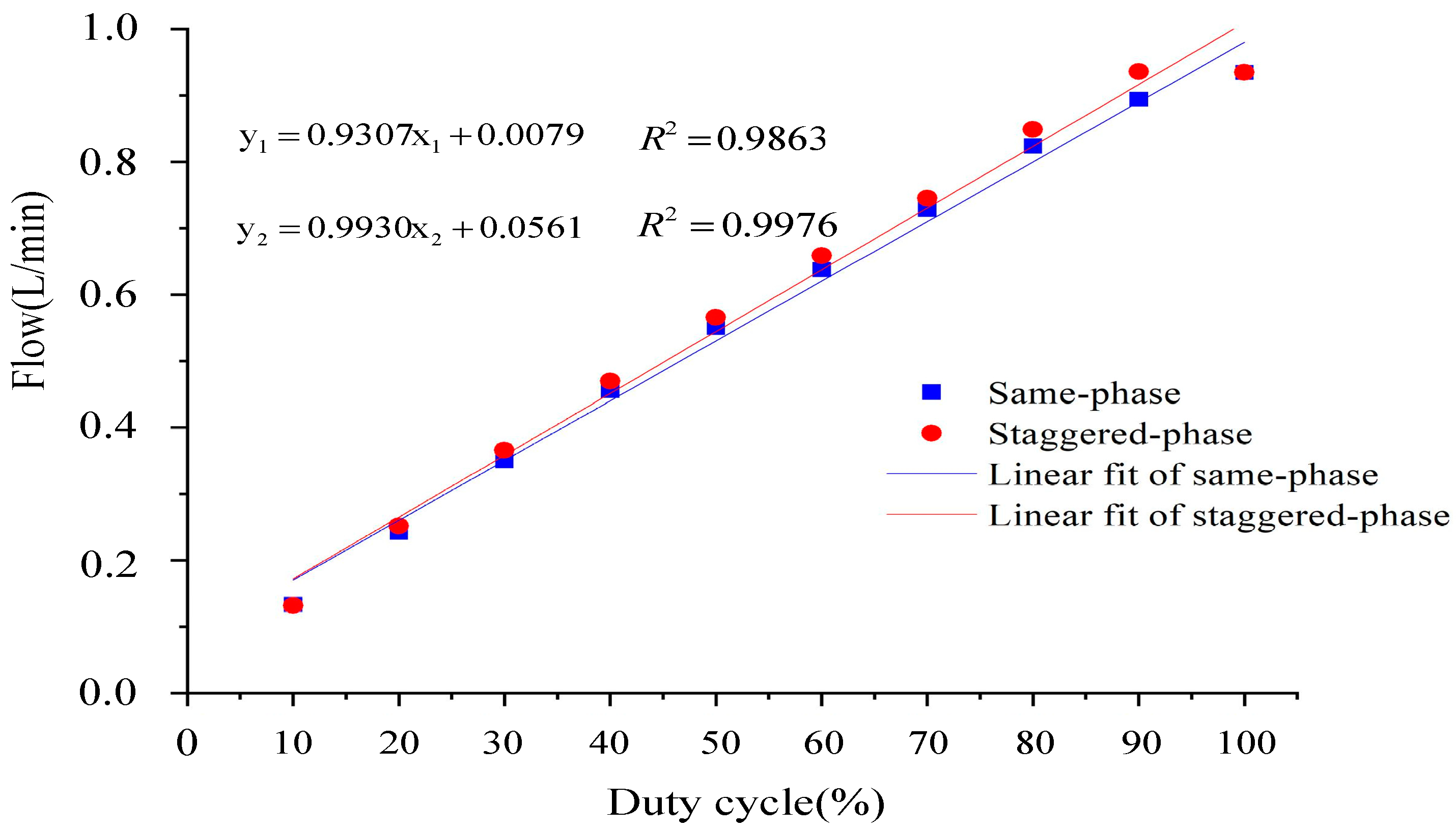

2.1.2. Nozzle Flow Test

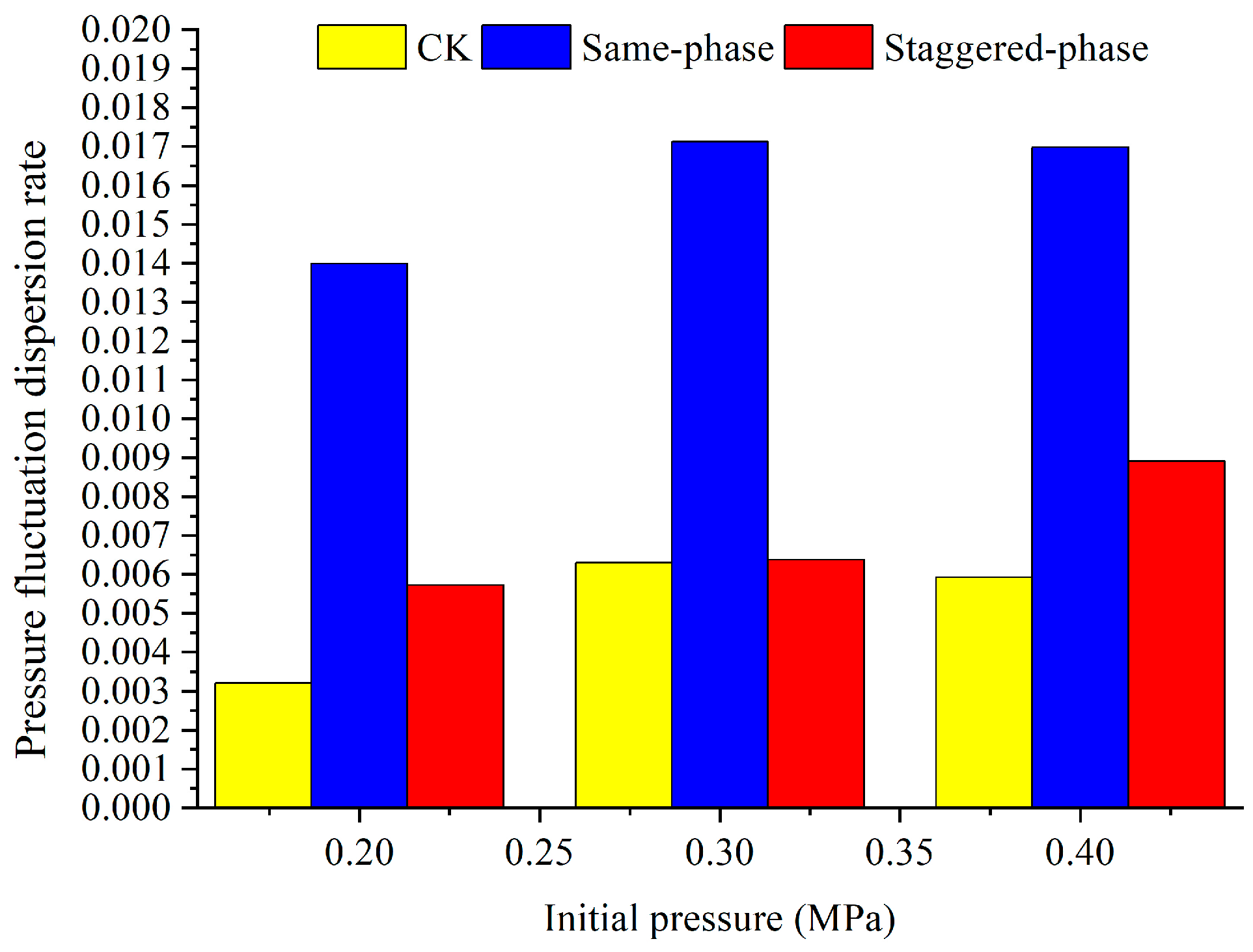

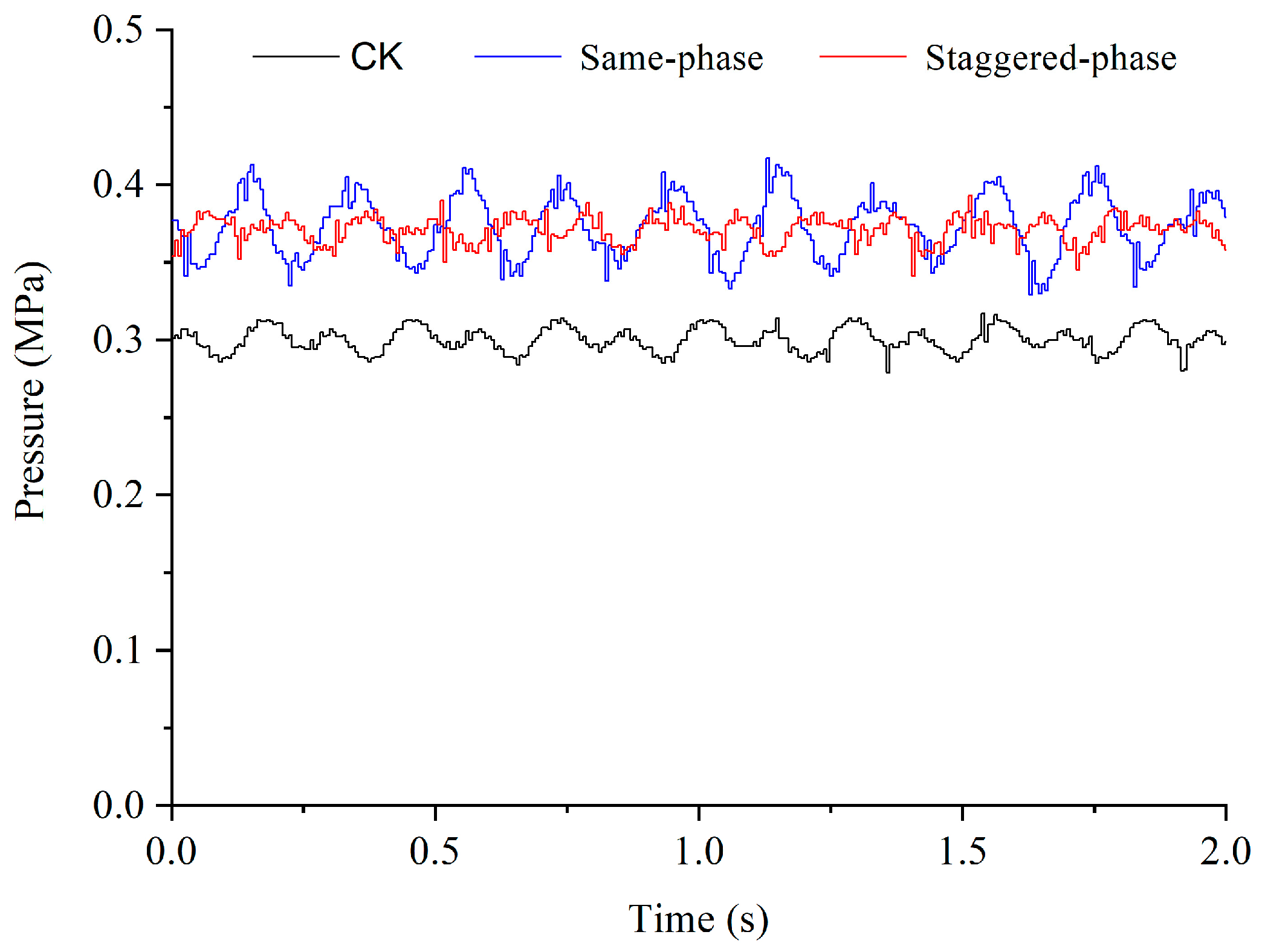

2.1.3. Pressure Fluctuation Test of the Same-Phase or Staggered-Phase PWM Variable Spray System under Different Initial Pressures

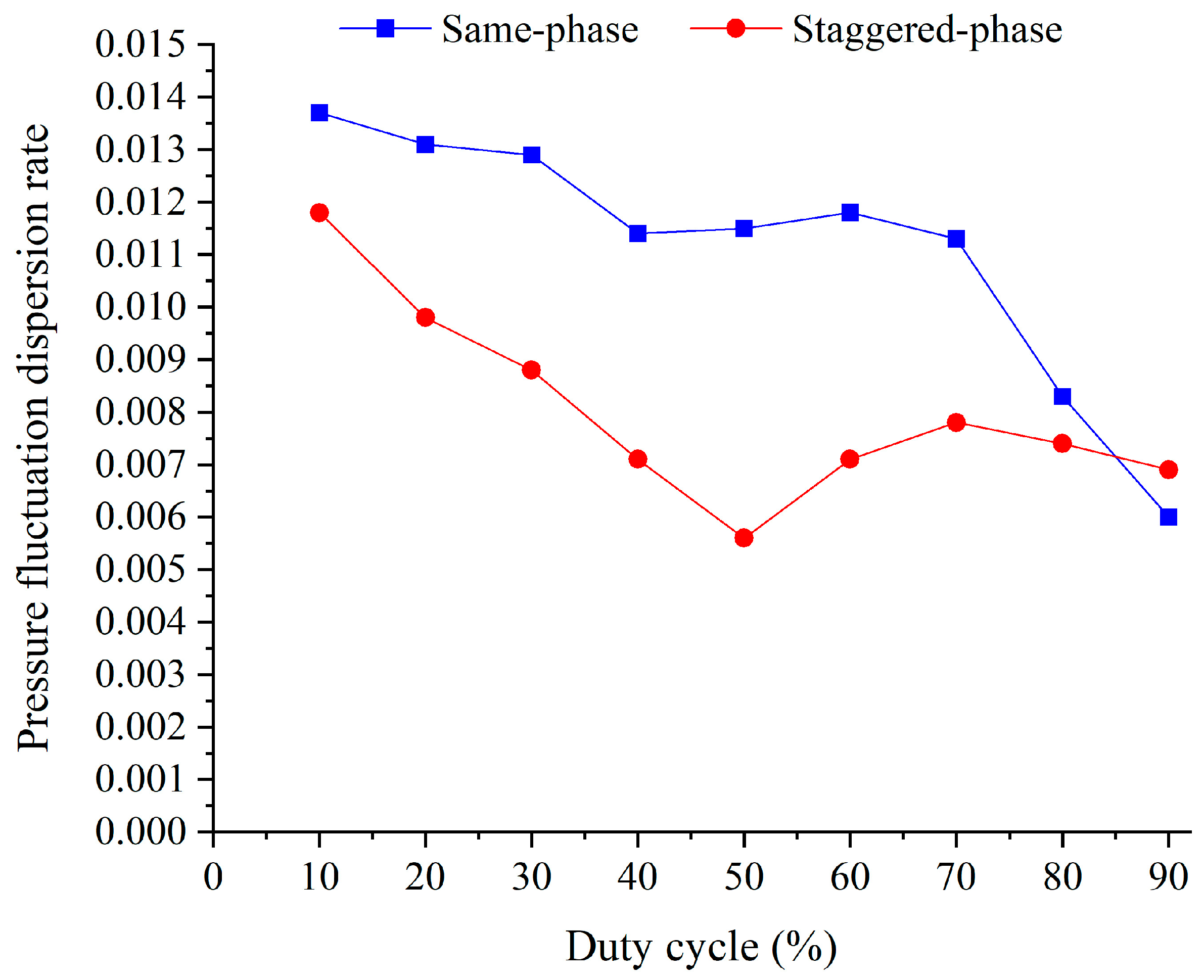

2.1.4. Pressure Fluctuation Test of the Same-Phase or Staggered-Phase PWM Variable Spray System under Different Duty Cycles

2.1.5. Pressure Fluctuation Test of the Same-Phase or Staggered-Phase PWM Variable Spray System at Different Frequencies

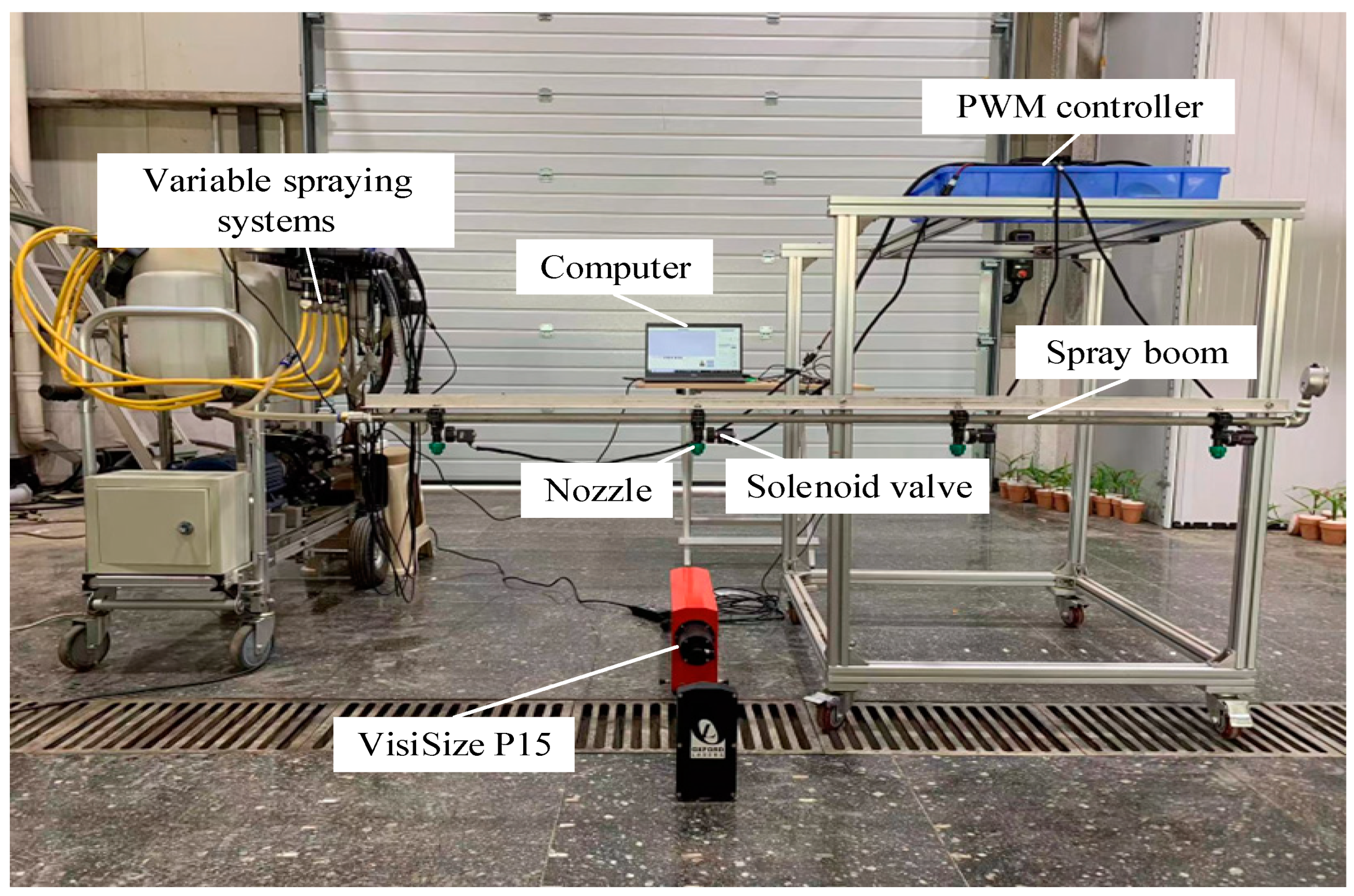

2.2. Atomization Test of Staggered-Phase PWM Variable Spraying System

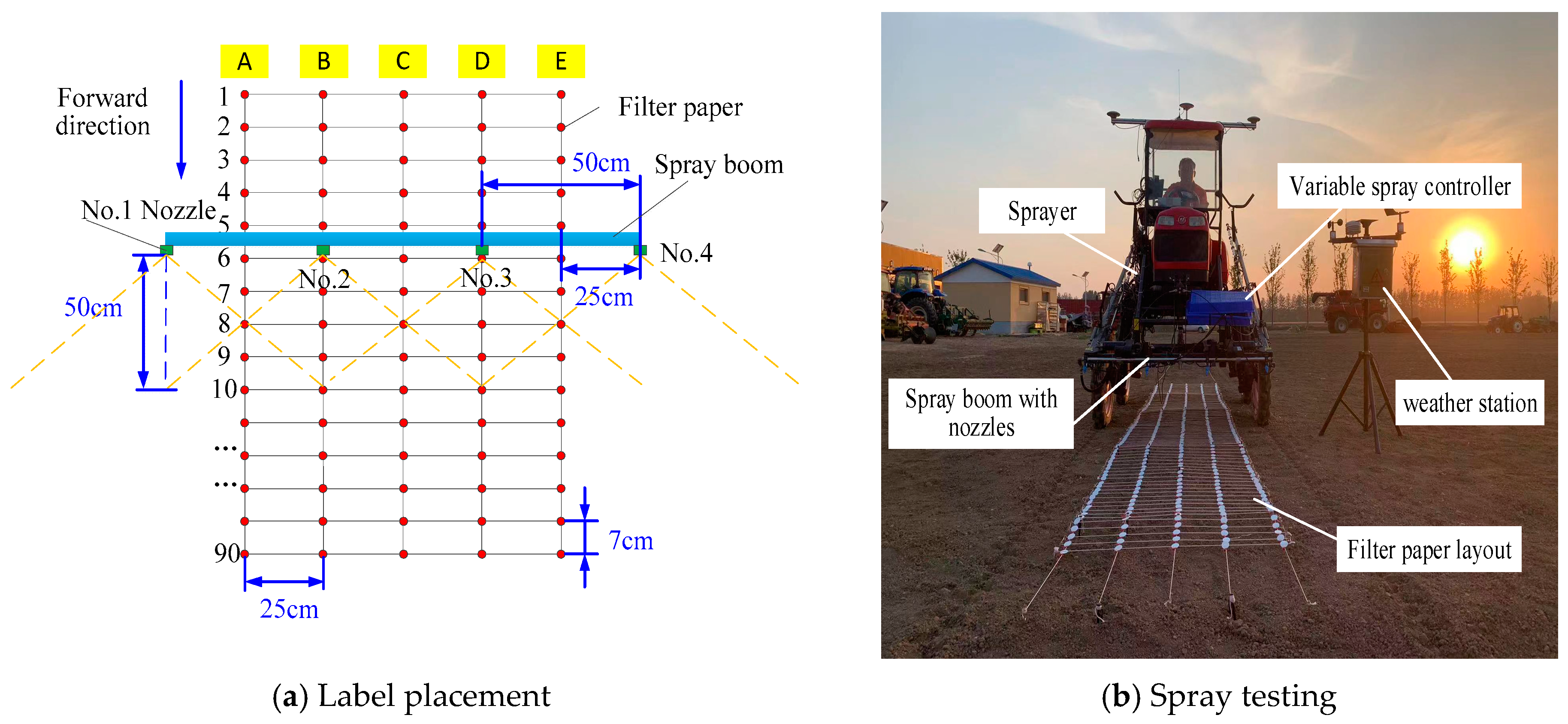

2.3. Staggered-Phase PWM Variable Spraying System Droplet Deposition Test

3. Test Results and Analysis

3.1. Pressure Fluctuation Test Results and Analysis

3.1.1. Different Initial Pressures

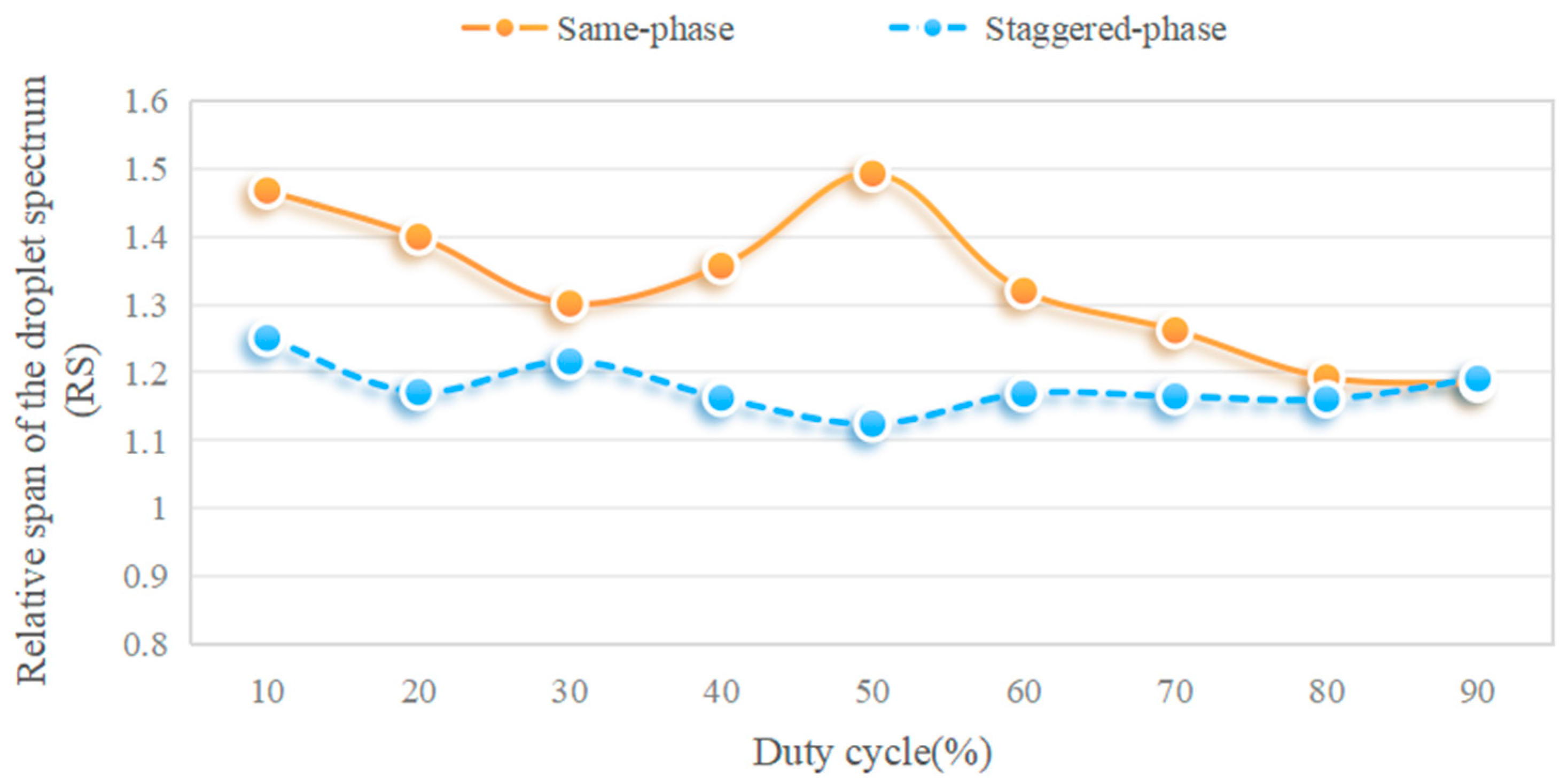

3.1.2. Different Duty Cycles

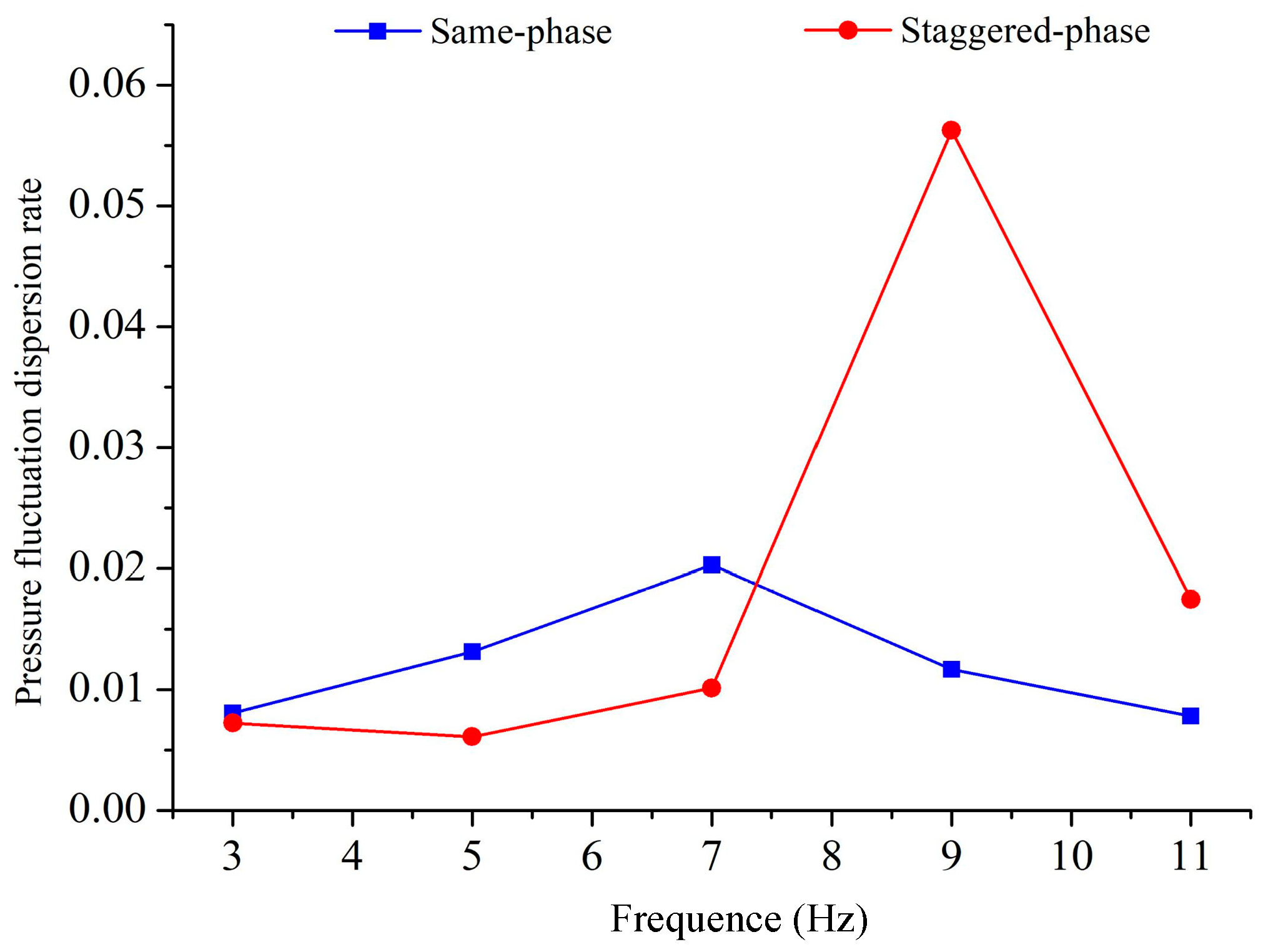

3.1.3. Different Frequencies

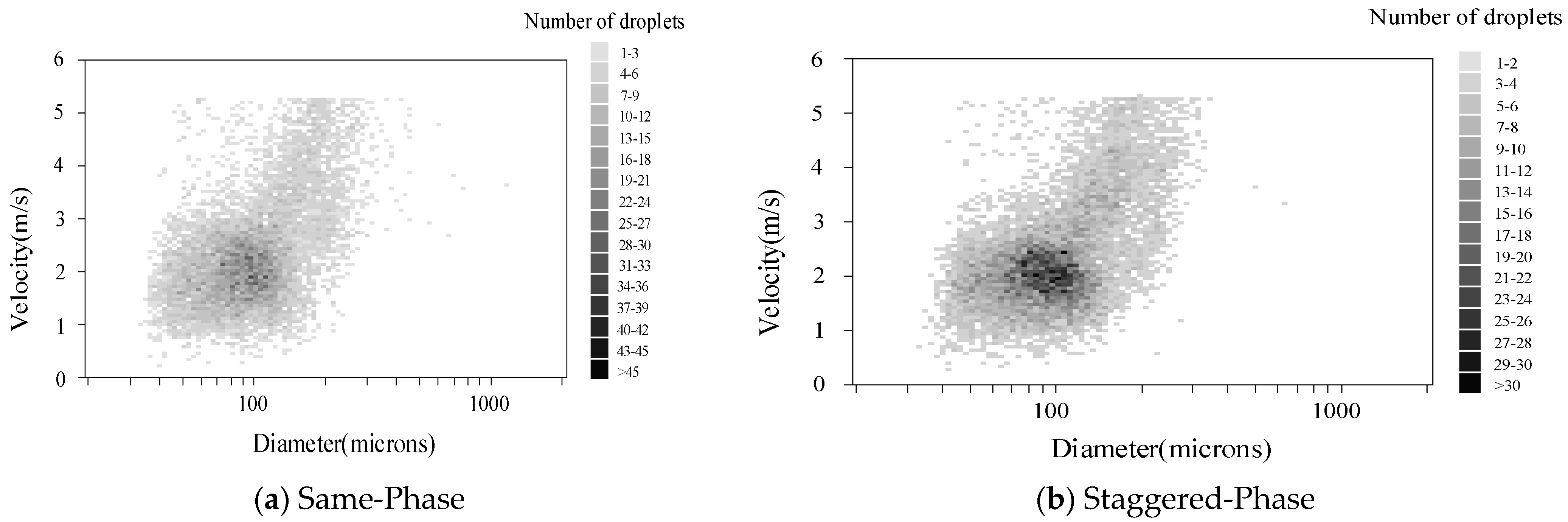

3.2. Atomization Test Results and Analysis

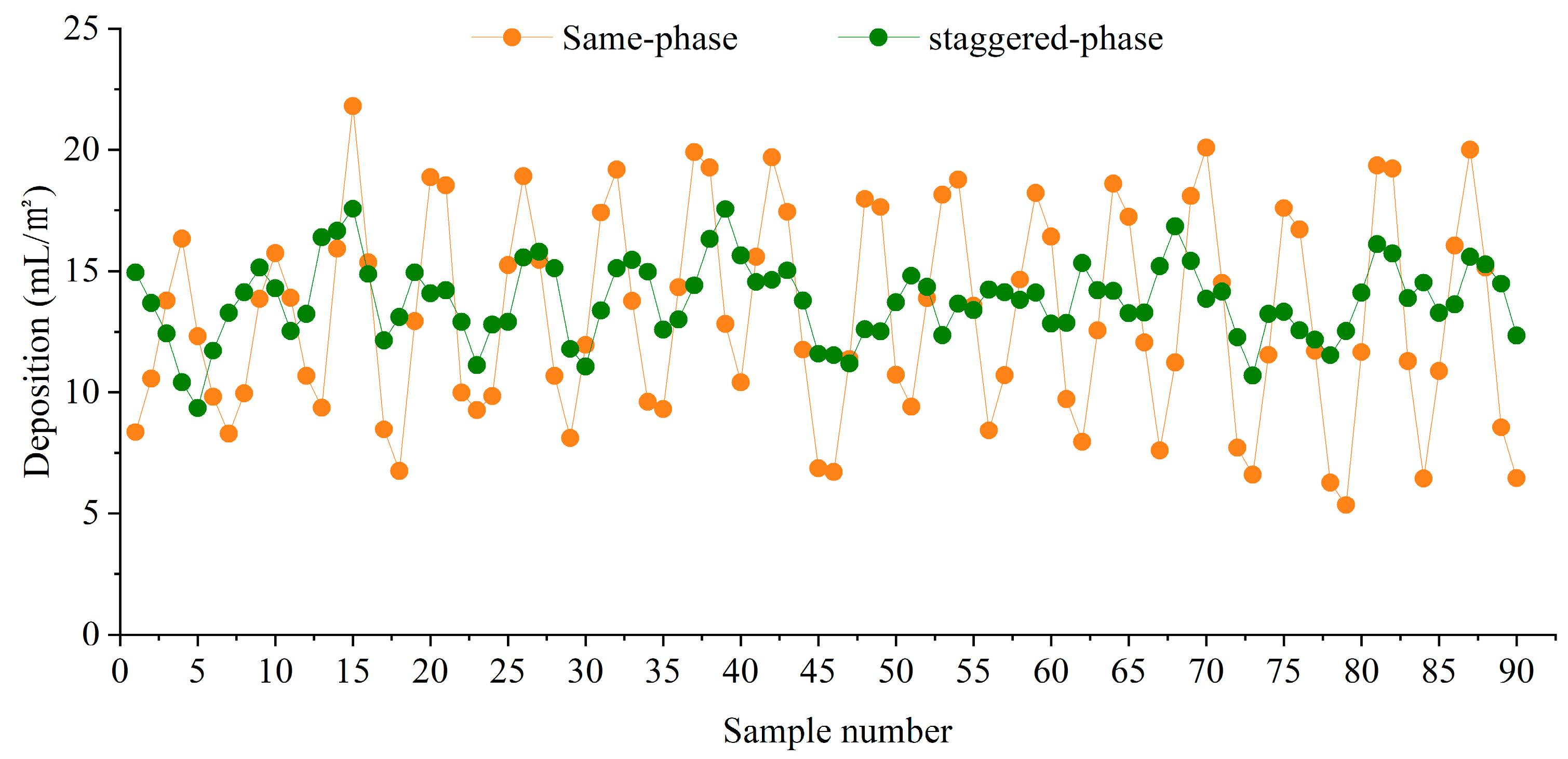

3.3. Spray Deposition Test Results

4. Discussion

- At present, most pieces of literature showed that the main way to improve application accuracy is through flow control, turn compensation, and high-resolution overlap control by pulsing an electronically actuated solenoid valve [38,39,40,41]. Literature [46] showed that by increasing the frequency of the solenoid valve from 15 Hz to 30 Hz, the coefficient of variation of the different nozzles could be reduced by 6.07–18.31%. This will reduce most of the nonuniform deposition. But at the same time, the high cost of high-frequency solenoid valves and narrow flow regulation have brought some concerns. This paper focuses on the research of variable spray systems with low-frequency control, which is one of the effective methods that provides consideration to the cost, ensures the flow adjustment width, and plays a positive role in promoting the popularization of variable spray systems in the world.

- The deposition test results in this study showed that the variable spray system (duty cycle 50%, initial pressure 0.3 MPa) with staggered driving mode had a deposition variation coefficient of 12.88% in the spray bar direction, which was far less than the standard 20%. The forward direction deposition uniformity variation coefficient was 11.61%, which was very close to the literature. Pierre Robert et al. conducted a study on the deposition characteristics of a PWM variable spray system under different duty cycles; their results showed that the longitudinal deposition variation coefficient was 10% at a 100% duty cycle [45], and the forward direction deposition variation coefficient of the spray boom of continuous spray was 10%. This method basically eliminated the inhomogeneity deposition caused by frequent switching of the nozzle based on the PWM variable spray.

- The phase-shifting driving method used in this study is a completely opposite signal-shifting method for odd- and even-numbered nozzles. The experimental results showed that the uniformity of droplet deposition was significantly improved, and many ways could be used to achieve phase shifting. In the future, further research can be conducted on other shifting methods to provide a theoretical basis for the development of variable spraying systems and precision spraying equipment.

5. Conclusions

- To address the problems of pipeline pressure fluctuations and poor forward direction deposition uniformity, which is caused by the simultaneous opening and closing of nozzles in the same-phase-driven PWM variable spray system, a staggered-phase driving method for odd- and even-numbered nozzles was proposed, and a variable spray system based on staggered-phase driving was developed. By building a series of test platforms for the study of pressure fluctuation characteristics, atomization characteristics, and deposition characteristics, the relevant characteristics of the PWM variable spray system driven by the same and staggered phases were analyzed, and the significance of the relevant influencing factors was analyzed.

- The experimental results from the pressure fluctuation characteristics of the staggered-phase-driven PWM variable spray system under different initial pressures showed that the dispersion rate of the pressure fluctuation of the staggered-phase-driven system decreased by 62.78%, and the fluctuation amplitude of the upstream pressure decreased by 40.91%. The nozzle’s activation pressure was quickly reached, and the fluctuations decreased and became more stable. Under different duty ratios, the dispersion rate of the pressure fluctuations in the same-phase-driven PWM variable spray system decreased with increasing duty cycle, and the dispersion rate of pressure fluctuations in the staggered-phase-driven PWM spray system initially decreased and then increased with an increasing duty cycle. When the duty cycle was 50%, the dispersion rate of the pressure fluctuation of the system was the lowest. Under different frequencies, the dispersion rate of the pressure fluctuation of the same-phase-driven and staggered-phase PWM spray systems initially increased and then decreased with increasing frequency. The maximum corresponding frequency values of the pressure fluctuation rates for the same-phase and staggered-phase systems were 7 Hz and 9 Hz, respectively. The PWM control parameters had a significant impact on the upstream pressure fluctuations with the following trend as follows: initial pressure > duty cycle > frequency. The test results can provide a basis for the subsequent choice of operating parameters for the sprayer.

- The experimental results of the atomization characteristics research showed that there was a minimal difference between the PWM variable spray droplets of , but the RS of the PWM variable spray system (driven by the staggered phase) decreased by 24.83% compared with the same phase, and the of the droplet size decreased by 4.40% compared with the same phase. These results indicated that the staggered-phase driving mode had better atomization characteristics in the tests with different duty cycles, and the droplet size was more uniform and consistent.

- The experimental results of the deposition characteristics research showed that the longitudinal average deposition amount in the forward direction of the staggered PWM variable spray system was 13.79, an increase of 4.87% compared with the deposition amount in the same phase of 13.15. Additionally, the was used to determine the droplet deposition uniformity and decreased from 32.48% to 11.61%; this represents an overall decrease of 20.87%. The inhomogeneity sedimentation was significantly reduced. The of the transverse deposition in the spray’s forward direction of the PWM variable spray system (driven by the staggered phase) was 12.88%; this value represented an increase of 2.79% compared with 10.09% in the same phase, and the deposition uniformity in the spray’s forward direction was slightly reduced but remained within the allowable range.

- In this study, the PWM variable spray system was driven by odd- and even-numbered spray heads with completely opposite signal staggering (a phase difference of 180°). The results showed that the uniformity of droplet deposition significantly improved. In the future, the effect of the stagger-phase difference on the pressure fluctuations in variable spray systems could be studied, which could provide a theoretical basis for the development of variable spray systems and precise spray equipment.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, L.; Wallhead, M.; Zhu, H.; Fulcher, A. Control of insects and diseases with intelligent variable-rate sprayers in ornamental nurseries. J. Environ. Hortic. 2019, 37, 90–100. [Google Scholar] [CrossRef]

- Salcedo, R.; Zhu, H.; Zhang, Z.; Wei, Z.; Chen, L.; Ozkan, E.; Falchieri, D. Foliar deposition and coverage on young apple trees with PWM-controlled spray systems. Comput. Electron. Agric. 2020, 178, 105794. [Google Scholar] [CrossRef]

- Dekeyser, D.; Foqué, D.; Duga, A.T.; Verboven, P.; Hendrickx, N.; Nuyttens, D. Pesticide deposition assessment using different application techniques in artificial orchard trees. Crop Prot. 2014, 64, 187–197. [Google Scholar] [CrossRef]

- Van de Zande, J.C.; Huijsmans, J.F.M.; Porskamp, H.A.J.; Michielsen, J.M.G.P.; Stallinga, H.; Holterman, H.J. Spray techniques: How to optimise pesticide deposition and minimise spray drift. Environmentalist 2008, 28, 9–17. [Google Scholar] [CrossRef]

- Zhu, H.; Zondag, R.H.; Derksen, R.C.; Reding, M.; Krause, C.R. Influence of spray volume on spray deposition and coverage within nursery trees. J. Environ. Hortic. 2008, 26, 51–57. [Google Scholar] [CrossRef]

- Schepers, J. Precision agriculture for sustainability. Precis. Agric. 2019, 20, 1–3. [Google Scholar] [CrossRef]

- Chin, R.; Catal, C.; Kassahun, A. Plant disease detection using drones in precision agriculture. Precis. Agric. 2023, 24, 1663–1682. [Google Scholar] [CrossRef]

- Khan, S.; Tufail, M.; Khan, M.T.; Khan, Z.A.; Anwar, S. Deep learning-based identification system of weeds and crops in strawberry and pea fields for a precision agriculture sprayer. Precis. Agric. 2021, 22, 1711–1727. [Google Scholar] [CrossRef]

- Bish, M.D.; Bradley, K.W. Survey of Missouri pesticide applicator practices, knowledge, and perceptions. Weed Technol. 2017, 31, 165–177. [Google Scholar] [CrossRef]

- EC. European Commission—Farm to Fork Strategy—For a Fair, Healthy and Environmentally-Friendly Food System. Available online: https://ec.europa.eu/food/farm2fork_en (accessed on 22 December 2020).

- Grella, M.; Gioelli, F.; Marucco, P.; Zwertvaegher, I.; Mozzanini, E.; Mylonas, N.; Nuyttens, D.; Balsari, P. Field assessment of a pulse width modulation (PWM) spray system applying different spray volumes: Duty cycle and forward speed effects on vines spray coverage. Precis. Agric. 2022, 23, 219–252. [Google Scholar] [CrossRef]

- Lan, Y.; Shengde, C.; Fritz, B.K. Current status and future trends of precision agricultural aviation technologies. Int. J. Agric. Biol. Eng. 2017, 10, 1–17. [Google Scholar]

- He, X. Research progress and developmental recommendations on precision spraying technology and equipment in China. Smart Agric. 2020, 2, 133–146. [Google Scholar]

- Dou, H.; Zhai, C.; Chen, L.; Wang, X.; Zou, W. Comparison of orchard target-oriented spraying systems using photoelectric or ultrasonic sensors. Agriculture 2021, 11, 753. [Google Scholar] [CrossRef]

- Zhai, C.; Zhao, C.; Ning, W.; Long, J.; Wang, X.; Weckler, P.; Zhang, H. Research progress on precision control methods of air-assisted spraying in orchards. Trans. Chin. Soc. Agric. Eng. 2018, 34, 1–15. [Google Scholar]

- Gil, E.; Escola, A.; Rosell, J.R.; Planas, S.; Val, L. Variable rate application of plant protection prod-ucts in vineyard using ultrasonic sensors. Crop Prot. 2017, 26, 1287–1297. [Google Scholar] [CrossRef]

- Jeon, H.Y.; Zhu, H. Development of a variable-rate sprayer for nursery liner applications. Trans. ASABE 2012, 55, 303–312. [Google Scholar] [CrossRef]

- Campos, J.; Gallart, M.; Llop, J.; Ortega, P.; Salcedo, R.; Gil, E. On-farm evaluation of prescription map-based variable rate application of pesticides in vineyards. Agronomy 2020, 10, 102. [Google Scholar] [CrossRef]

- Palleja, T.; Landers, A. Real time canopy density estimation using ultrasonic envelope signals in the orchard and vineyard. Comput. Electron. Agric. 2015, 115, 108–117. [Google Scholar] [CrossRef]

- Gu, C.C.; Zhai, C.Y.; Wang, X.; Wang, S.L. CMPC: An innovative lidar-based method to estimate tree canopy meshing-profile volumes for orchard target-oriented spray. Sensors 2021, 21, 42–52. [Google Scholar] [CrossRef] [PubMed]

- Llorens, J.; Gil, E.; Llop, J.; Escola, A. Variable rate dosing in precision viticulture: Use of electronic devices to improve application efficiency. Crop Prot. 2010, 29, 239–248. [Google Scholar] [CrossRef]

- Chen, Y.; Zhu, H.; Ozkan, H.E. Development of variable-rate sprayer with laser scanning sensor to synchronize spray outputs to tree structures. Trans. ASABE 2012, 55, 773–781. [Google Scholar] [CrossRef]

- Grella, M.; Miranda-Fuentes, A.; Marucco, P.; Balsari, P. Field assessment of a newly-designed pneumatic spout to contain spray drift in vineyards: Evaluation of canopy distribution and off-target losses. Pest Manag. Sci. 2020, 76, 4173–4191. [Google Scholar] [CrossRef]

- Cai, J.; Wang, X.; Gao, Y.; Yang, S.; Zhao, C. Design and performance evaluation of a variable-rate orchard sprayer based on a laser-scanning sensor. Int. J. Agric. Bio-Log. Eng. 2019, 12, 51–57. [Google Scholar] [CrossRef]

- Giles, D.K.; Comino, J.A. Variable flow control for pressure atomization nozzles. SAE Trans. J. Commerical Veh. 1989, 98, 237–249. [Google Scholar]

- Anglund, E.A.; Ayers, P.D. Field evaluation of response times for a variable rate (pressure-based and injection) liquid chemical applicator. Appl. Eng. Agric. 2003, 19, 273–282. [Google Scholar] [CrossRef]

- Giles, D.K.; Comino, J.A. Droplet size and spray pattern characteristics of an electronic flow con-troller for spray nozzles. J. Agric. Eng. Res. 1990, 47, 249–267. [Google Scholar] [CrossRef]

- Lebeau, F.; El Bahir, L.; Destain, M.F.; Kinnaert, M.; Hanus, R. Improvement of spray deposit homogeneity using a PWM spray controller to compensate horizontal boom speed variation. Comput. Electron. Agric. 2004, 43, 149–161. [Google Scholar] [CrossRef]

- Lang, J.P. Evaluation of pulse width modulation sprays for spray quality. In Proceedings of the ASABE International Meeting, Kansas City, MO, USA, 21–24 July 2013. [Google Scholar]

- Gil, E.; Llorens, J.; Llop, J.; Fàbregas, X.; Escolà, A.; Rosell-Polo, J.R. Variable rate sprayer Part 2-vineyard prototype: Design, implementation, and validation. Comput. Electron. Agric. 2013, 95, 136–150. [Google Scholar] [CrossRef]

- Butts, T.; Butts, L.; Luck, J.; Fritz, B.; Hoffmann, W.; Kruger, G. Droplet size and nozzle tip pressure from a pulse-width modulation sprayer. Biosyst. Eng. 2019, 178, 52–69. [Google Scholar] [CrossRef]

- Butts, T.; Samples, C.; Franca, L.; Hoffmann, W.; Luck, J.; Kruger, G. Optimum Droplet Size Using a Pulse-Width Modulation Sprayer for Applications of 2,4-D Choline Plus Glyphosate. Agron. J. 2019, 111, 1425–1432. [Google Scholar] [CrossRef]

- Butts, T.; Luck, J.; Fritz, B.; Hoffmann, W.; Kruger, G. Evaluation of spray pattern uniformity using three unique analyses as impacted by nozzle, pressure, and pulse-width modulation duty cycle. Pest Manag. Sci. 2019, 75, 1875–1886. [Google Scholar] [CrossRef] [PubMed]

- Giles, D.K. Pulse width modulation for nozzle flow control: Principles, development and status of the technology. Asp. Appl. Biol. 2020, 144, 59–66. [Google Scholar]

- Giles, D.K.; Ben-Salem, E. Spray droplet velocity and energy in intermittent flow from hydraulic nozzles. J. Agric. Eng. Res. 1992, 51, 101–112. [Google Scholar] [CrossRef]

- Giles, D.K.; Andersen, P.G.; Nilars, M. Flow control and spray cloud dynamics from hydraulic atomizers. Trans. ASAE 2002, 45, 539–546. [Google Scholar] [CrossRef]

- Gopala Pillai, S.; Tian, L.; Zheng, J. Evaluation of a flow control system for site-specific herbicide applications. Trans. ASABE 1999, 42, 863–870. [Google Scholar] [CrossRef]

- Sharda, A.; Fulton, J.P.; Mcdonald, T.P.; Zech, W.C.; Darr, M.J.; Brodbeck, C.J.; Fulton, J.P. Real-time pressure and flow dynamics due to boom section and individual nozzle control on agricultural sprayers. Trans. ASABE 2010, 53, 1363–1371. [Google Scholar] [CrossRef]

- Zhang, C.; Zhai, C.; Zhao, X.; Zou, W.; Zhang, M.; Zhao, C. Experimental study on the pressure fluctuation characteristics of target spray system. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2022, 38, 31–39. [Google Scholar]

- Salcedo, R.; Zhu, H.; Jeon, H.; Ozkan, E.; Wei, Z.; Gil, E. Characterisation of activation pressure, flowrate and spray angle for hollow-cone nozzles controlled by pulse width modulation. Biosyst. Eng. 2022, 218, 139–152. [Google Scholar] [CrossRef]

- Sharda, A.; Luck, J.D.; Fulton, J.P.; McDonald, T.P.; Shearer, S.A. Field application uniformity and accuracy of two rate control systems with automatic section capabilities on agricultural sprayers. Precis. Agric. 2013, 14, 307–322. [Google Scholar] [CrossRef]

- Al-Saqer, S.M.; Hassan, G.M. Optimization of Solenoid Valve for Variable Rate Application System. Am. J. Agric. Biol. Sci. 2011, 6, 348–355. [Google Scholar] [CrossRef]

- Han, S.; Hendrickson, L.L.; Ni, B.; Zhang, Q. Modification and testing of a commercial sprayer with PWM solenoids for precision spraying. Appl. Eng. Agric. 2001, 17, 591. [Google Scholar]

- Mangus, D.L.; Sharda, A.; Engelhardt, A.; Flippo, D.; Strasser, R.; Luck, J.D.; Griffin, T. Analyzing the nozzle spray fan pattern of an agricultural sprayer using pulse width modulation technology to generate an on-ground coverage map. Trans. ASABE 2017, 60, 315–325. [Google Scholar]

- Pierce Robert, A.; Ayers Paul, D. Evaluation of deposition and application accuracy of a pulse width modulation variable ratefield sprayer. SAE Pap. 2001. [Google Scholar] [CrossRef]

- Li, L.; He, X.; Song, J.; Zhong, C. Spray characteristics on pulse-width modulation variable application based on high frequency electromagnetic valve. Trans. Chin. Soc. Agric. Eng. Trans. CSAE 2016, 32, 97–103. [Google Scholar]

- Wei, Z.; Zhu, H.; Zhang, Z. Droplet size spectrum, activation pressure, and flow rate discharged from pwm flat-fan nozzles. Trans. ASABE 2021, 64, 313–325. [Google Scholar] [CrossRef]

- Yang, Q.; Yuan, F.; Ma, Y.; Shi, K.; Yang, G.; Zhu, J. Electrostatic powder coated osmotic pump tablets: Influence factors of coating powder adhesion and film formation. Powder Technol. 2020, 360, 444–451. [Google Scholar] [CrossRef]

- Pendar, M.R.; Cândido, S.; Páscoa, J.C. Optimization of Painting Efficiency Applying Unique Techniques of High-voltage Conductors and Nitrotherm Spray: Developing Deep Learning Models Using computational fluid dynamics dataset. Phys. Fluids 2023, 35, 075119. [Google Scholar] [CrossRef]

- ANSI/ASAE S572.1 MAR2009(R2017); Spray Nozzle Classification by Droplet Spectra. ASABE: St. Joseph, MI, USA, 2017.

- GB/T24677 1-2009; Boom Sprayer-Technical Requirements. China Standard Publisher: Beijing, China, 2010.

| Same-Phase Test | Staggered-Phase Test | CK | |

|---|---|---|---|

| Initial pressure (MPa) | 0.2, 0.3, 0.4 | 0.2, 0.3, 0.4 | 0.2, 0.3, 0.4 |

| Reflow ratio (%) | 40 | 40 | 40 |

| Frequency (Hz) | 5 | 5 | 5 |

| Duty cycle (%) | 50 | 50 | 100 |

| Variables | Obs | Mean | Std.Err. | Std.Dev. | [95% Conf. Interval] | |

|---|---|---|---|---|---|---|

| Same-phase | 15 | 0.0126379 | 0.000952 | 0.0036872 | 0.010596 | 0.0146798 |

| Staggered-phase | 15 | 0.0077807 | 0.0004588 | 0.0017771 | 0.0067966 | 0.0087648 |

| diff | 15 | 0.0048572 | 0.0008984 | 0.0034797 | 0.0029302 | 0.0067841 |

| Mean (diff) = mean (Same phase—Staggered phase) | t = 5.4062 | |||||

| Ho:mean (diff) = 0 | degrees of freedom = 14 | |||||

| Ha: mean(diff) < 0 | Ha:mean (dift) ! = 0 | Ha:mean (diff) > 0 | ||||

| Pr(T < t) = 1.0000 | Pr (|T| > |t|) = 0.0001 | Pr (T > t) = 0.0000 | ||||

| Variables | Same-Phase | Same-Phase | Same-Phase | Same-Phase | Staggered-Phase |

|---|---|---|---|---|---|

| Duty cycle | −0.00123 ** | −0.00123 ** | −0.00128 ** | ||

| (0.000) | (0.000) | (0.000) | |||

| Frequency | 0.000653 | 0.000653 | −0.00235 * | ||

| (0.747) | (0.626) | (0.086) | |||

| Initial pressure | 1.211 ** | 1.211 ** | 1.212 ** | ||

| (0.000) | (0.000) | (0.000) | (0.000) | (0.000) | |

| Constant | 0.344 ** | 0.279 ** | −0.0811 ** | −0.0228 ** | −0.0141 * |

| (0.000) | (0.000) | (0.000) | (0.003) | (0.070) | |

| Observations | 11,481 | 11,481 | 11,481 | 11,481 | 11,481 |

| Duty Cycle (%) | Same-Phase | Staggered-Phase | ||||

|---|---|---|---|---|---|---|

| (μm) | (μm) | (μm) | (μm) | (μm) | (μm) | |

| 10 | 70.50 | 141.50 | 271.90 | 73.10 | 143.80 | 250.50 |

| 20 | 72.53 | 136.50 | 263.60 | 75.23 | 155.33 | 257.17 |

| 30 | 73.40 | 141.57 | 257.63 | 76.93 | 142.10 | 249.77 |

| 40 | 75.00 | 142.70 | 268.60 | 84.13 | 150.07 | 258.60 |

| 50 | 81.63 | 146.77 | 300.77 | 82.87 | 145.13 | 246.10 |

| 60 | 82.73 | 154.60 | 286.83 | 88.40 | 160.47 | 275.90 |

| 70 | 85.30 | 156.53 | 282.83 | 91.93 | 163.20 | 282.03 |

| 80 | 88.63 | 159.17 | 278.47 | 93.70 | 168.40 | 289.13 |

| 90 | 91.10 | 161.37 | 282.10 | 94.67 | 170.23 | 297.37 |

| Same-Phase | Staggered-Phase | |

|---|---|---|

| ) | 13.15 | 13.79 |

| (%) | 32.48 | 11.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Zhai, C.; Zhang, M.; Zhang, C.; Zou, W.; Zhao, C. Staggered-Phase Spray Control: A Method for Eliminating the Inhomogeneity of Deposition in Low-Frequency Pulse-Width Modulation (PWM) Variable Spray. Agriculture 2024, 14, 465. https://doi.org/10.3390/agriculture14030465

Zhang C, Zhai C, Zhang M, Zhang C, Zou W, Zhao C. Staggered-Phase Spray Control: A Method for Eliminating the Inhomogeneity of Deposition in Low-Frequency Pulse-Width Modulation (PWM) Variable Spray. Agriculture. 2024; 14(3):465. https://doi.org/10.3390/agriculture14030465

Chicago/Turabian StyleZhang, Chunfeng, Changyuan Zhai, Meng Zhang, Chi Zhang, Wei Zou, and Chunjiang Zhao. 2024. "Staggered-Phase Spray Control: A Method for Eliminating the Inhomogeneity of Deposition in Low-Frequency Pulse-Width Modulation (PWM) Variable Spray" Agriculture 14, no. 3: 465. https://doi.org/10.3390/agriculture14030465

APA StyleZhang, C., Zhai, C., Zhang, M., Zhang, C., Zou, W., & Zhao, C. (2024). Staggered-Phase Spray Control: A Method for Eliminating the Inhomogeneity of Deposition in Low-Frequency Pulse-Width Modulation (PWM) Variable Spray. Agriculture, 14(3), 465. https://doi.org/10.3390/agriculture14030465