Modeling the Mechanical Properties of Root–Substrate Interaction with a Transplanter Using Artificial Neural Networks

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials and Instruments

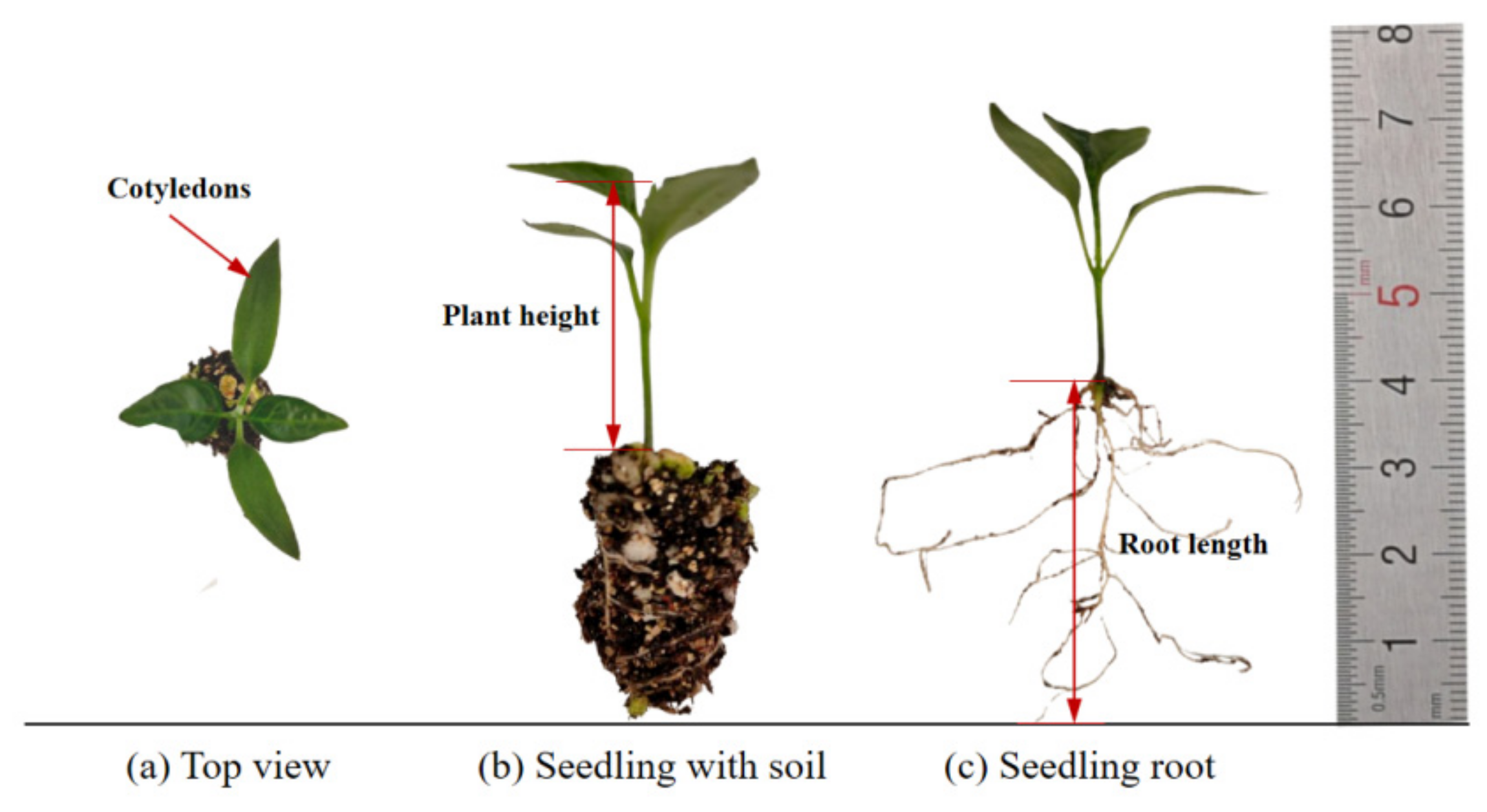

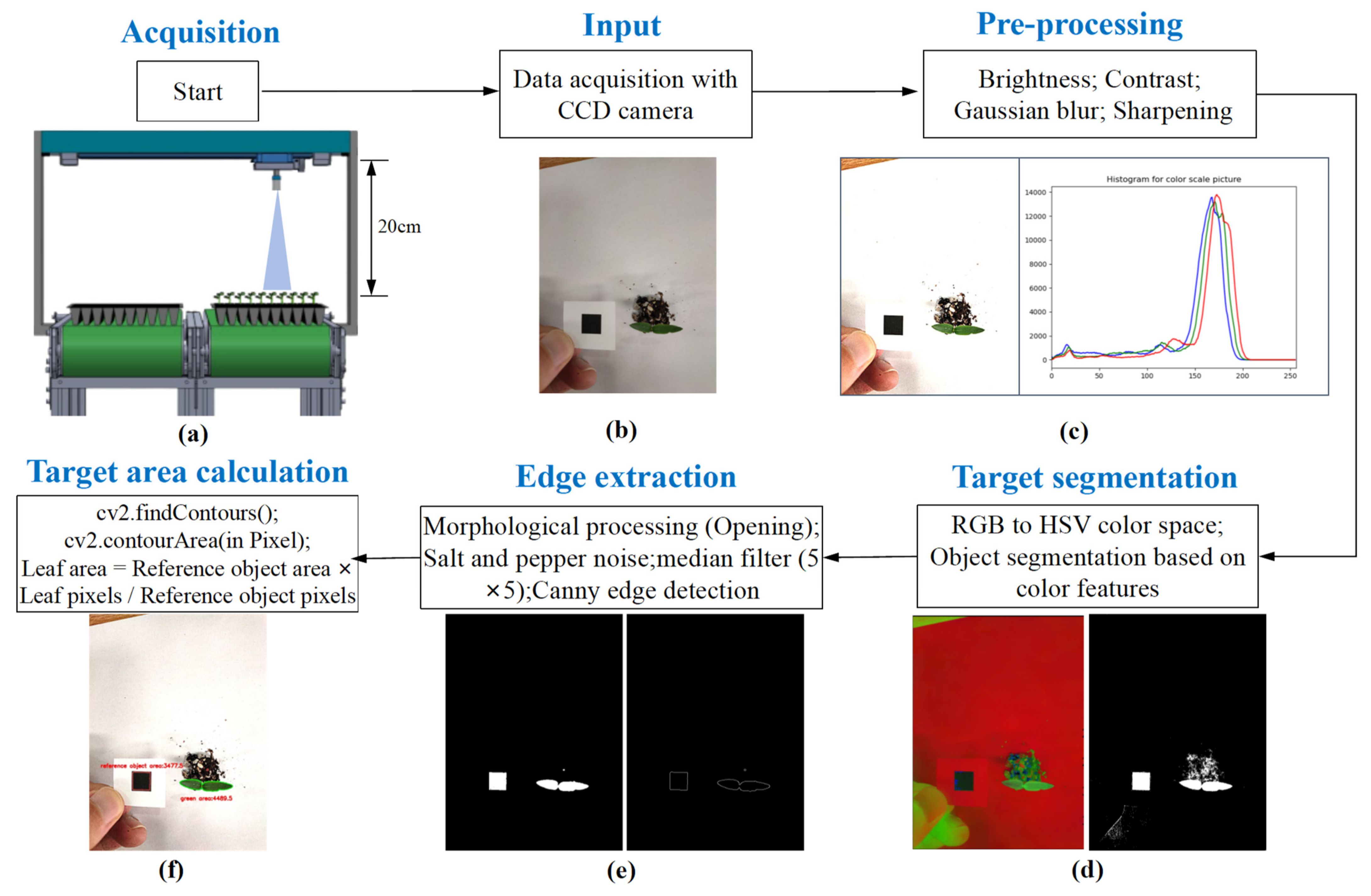

2.2. Test Methods for Plant Morphological Parameters

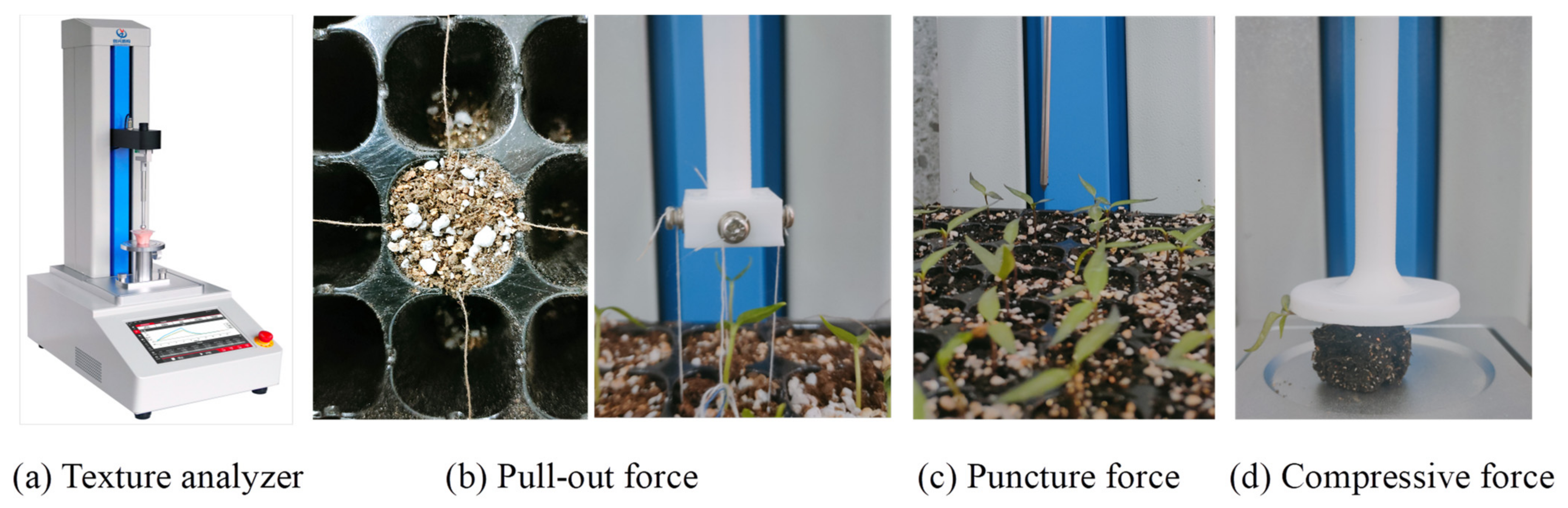

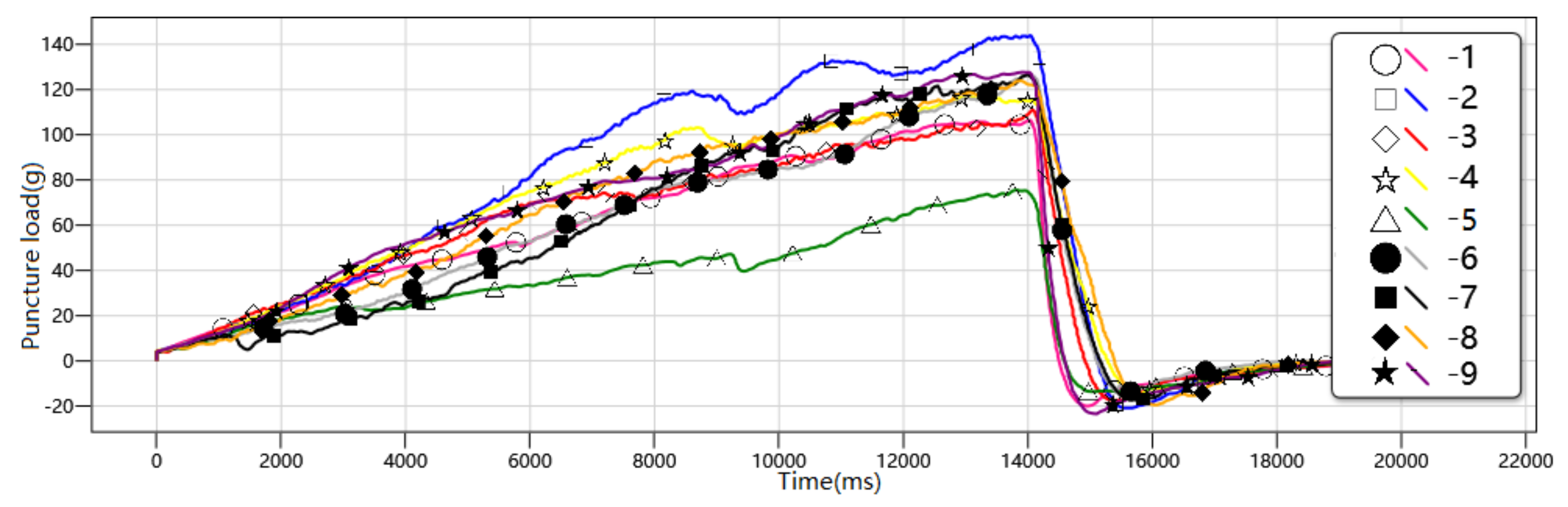

2.3. Test Methods for Mechanical Properties

2.4. BPNN Construction

- Mean square error (MSE):

- Mean absolute error (MAE):

- Mean absolute percentage error (MAPE):

- Coefficient of determination (R2):

3. Results and Discussion

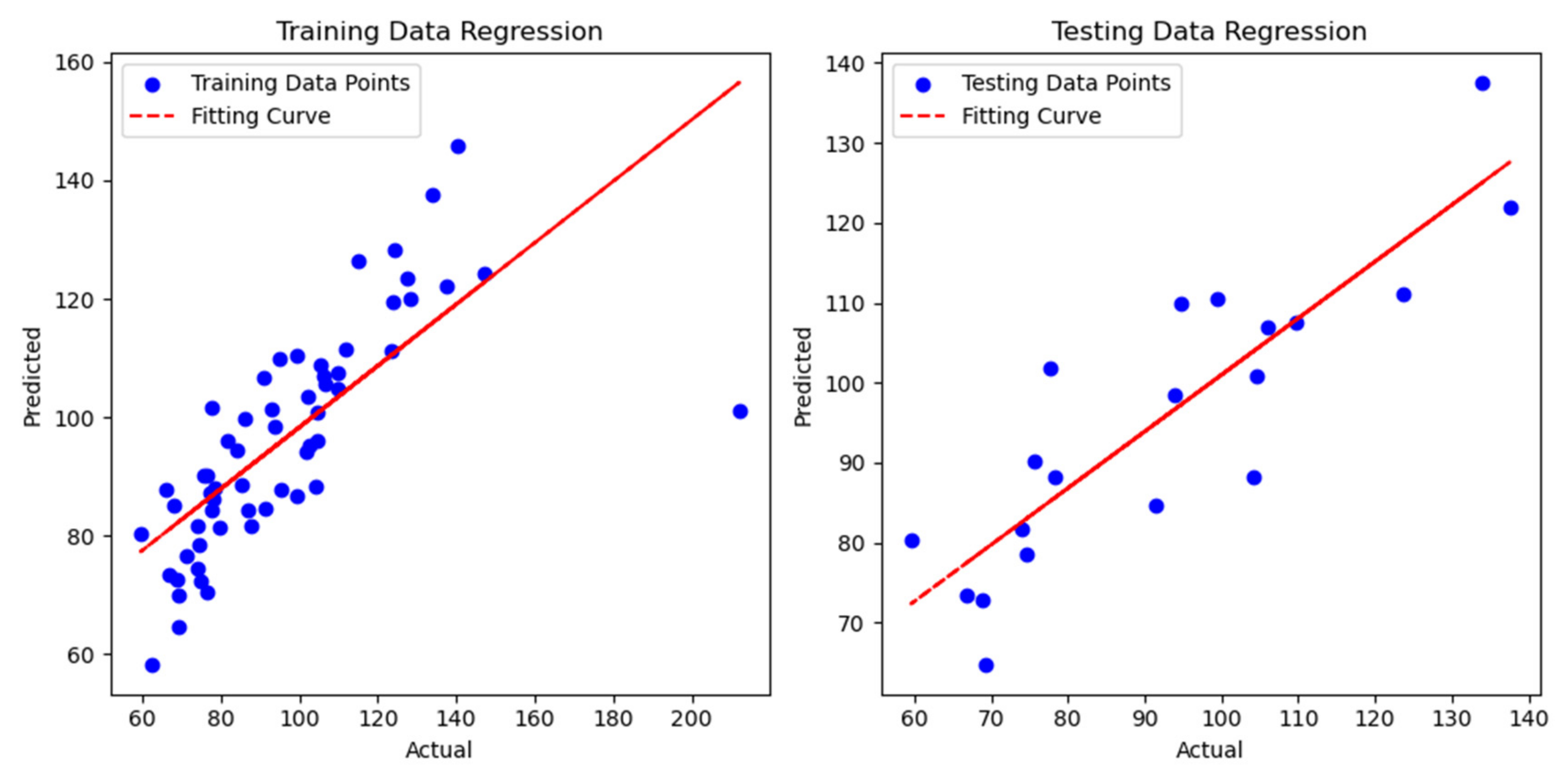

3.1. Neural Network Framework Results

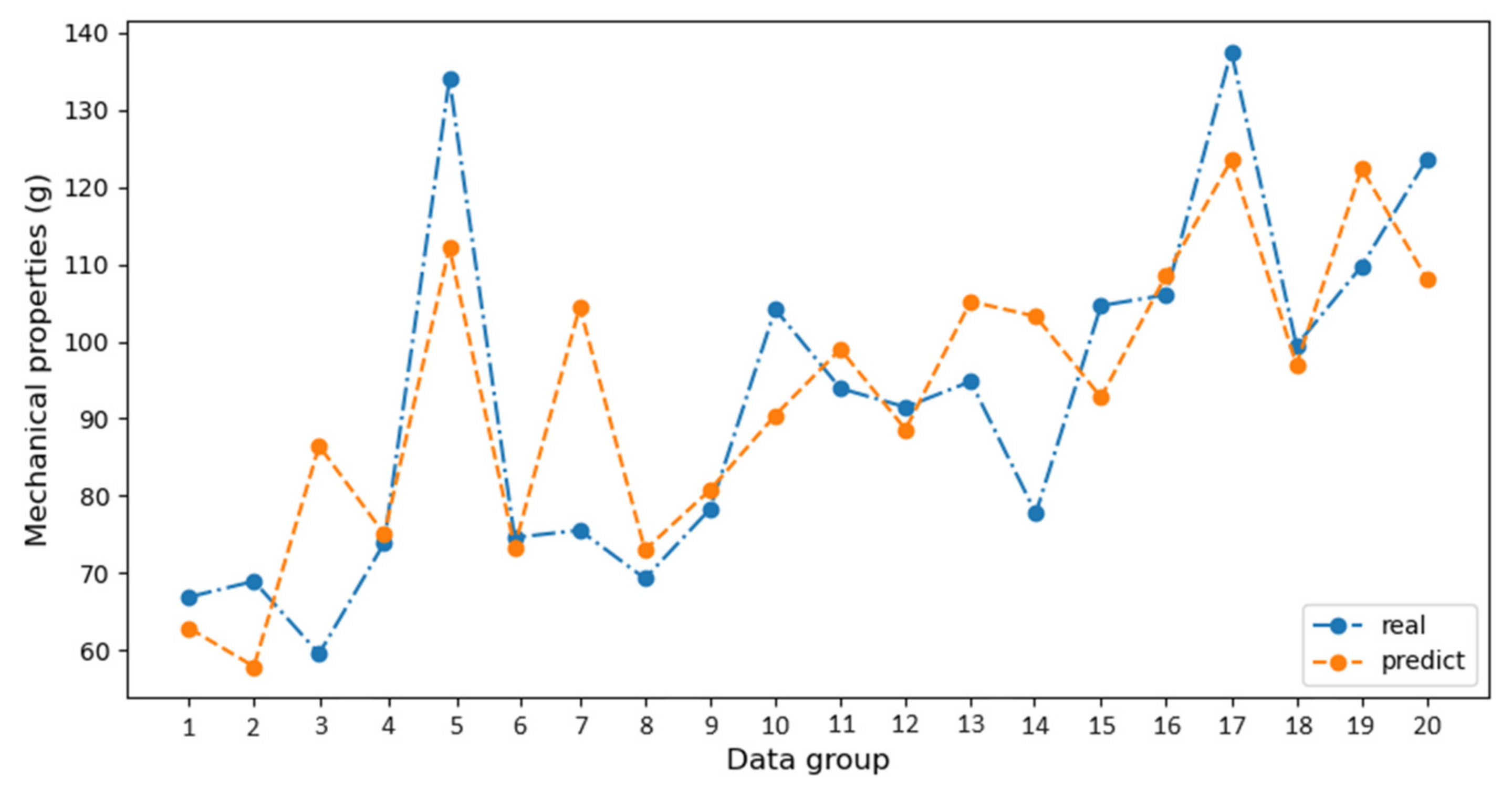

3.2. Prediction Verification Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rahul, K.; Raheman, H.; Paradkar, V. Design and development of a 5R 2DOF parallel robot arm for handling paper pot seedlings in a vegetable transplanter. Comput. Electron. Agric. 2013, 166, 105014. [Google Scholar] [CrossRef]

- Tian, Z.; Ma, W.; Yang, Q.; Yao, S.; Zhang, M.; Duan, F.; Xu, H. Research status and problem analysis of plug seedling transplanter in greenhouse. J. China Agric. Univ. 2022, 27, 22–38. [Google Scholar]

- Hu, J.; Han, L.; Wen, Y.; Yu, S.; Yang, Y. Mechanical properties of different vegetable seedlings associated with automatic transplanting. J. Agric. Mech. Res. 2018, 40, 132–136. [Google Scholar]

- Mohamed, S.; Liu, J. Effect of soil moisture content and end-effector speed on pick-up force and lump damage for seedling transplanting. AgriEngineering 2019, 1, 26. [Google Scholar] [CrossRef]

- Jiang, Z.; Hu, Y.; Jiang, H.; Tong, J. Design and force analysis of end-effector for plug seedling transplanter. PLoS ONE 2017, 12, e0180229. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Cao, W.; Tian, D.; Ouyang, Y.; Zhao, H. Optimization experiment of transplanting actuator parameters based on mechanical property of seedling pot. Trans. CSAE 2016, 32, 32–39. [Google Scholar]

- Ren, Z.; Wang, W.; Feng, J.; Yu, J. Experimental study on mechanical properties of plug seedlings. J. Chin. Agric. Mech. 2020, 41, 169–174. [Google Scholar]

- Zhang, N.; Kang, J.; Wang, X.; Peng, Q.; Zhang, C.; Wang, Y. Simulation and experiment on seeding performance of peanutroller type hill-drop planter based on EDEM. J. Chin. Agric. Mech. 2021, 42, 1–6. [Google Scholar]

- Wang, M.; Liu, Q.; Ou, Y.; Zou, X. Numerical simulation and verification of seed-filling performance of single-bud billet sugarcane seed-metering device based on EDEM. Agriculture 2022, 12, 983. [Google Scholar] [CrossRef]

- Bai, H.; Li, X.; Zeng, F.; Su, Q.; Cui, J.; Wang, J.; Zhang, Y. Calibration and experiments of the simulation bonding parameters for plug seedling substrate block. INMATEH Agric. Eng. 2023, 69, 617–625. [Google Scholar] [CrossRef]

- Gao, G.; Wang, K.; Sun, X. Verification for EDEM simulation of process of jacking tray-seedling by steel needle in grafting machine and parameter optimization. Trans. CSAE 2017, 33, 29–35. [Google Scholar]

- Bai, H. Based on the collision damage test and prediction model of the cavity tray seedling of the hanging cup transplanter. Inn. Mong. Agric. Univ. 2023, 3, 16–65. [Google Scholar]

- Emmert-Streib, F.; Yang, Z.; Feng, H.; Tripathi, S.; Dehmer, M. An introductory review of deep learning for prediction models with big data. Front. Artif. Intell. 2020, 28, 4. [Google Scholar] [CrossRef] [PubMed]

- Jiang, M. Research on decision support system for prediction and control of apple tree diseases and insect pests. Shandong Agric. Univ. 2015, 14, 35–56. [Google Scholar]

- Arthit, A.; Supachai, P.; Kullapapruk, P. The role of pig size prediction in supply chain planning. Biosyst. Eng. 2012, 113, 298–307. [Google Scholar]

- Pareek, C.M.; Tewari, V.K.; Machavaram, R.; Brajesh, N. Optimizing the seed-cell filling performance of an inclined plate seed metering device using integrated ANN-PSO approach. Artif. Intell. Agric. 2021, 5, 1–12. [Google Scholar] [CrossRef]

- Kumar, S.P.; Tewari, V.K.; Chandel, A.K.; Mehta, C.R.; Pareek, C.M.; Chethan, C.R.; Nare, B. Modelling specific energy requirement for a power-operated vertical axis rotor type intra-row weeding tool using Artificial Neural Network. Appl. Sci 2023, 13, 10084. [Google Scholar] [CrossRef]

- Wang, M.; Wan, P.; Guo, J.; Xu, J.; Chai, Y.; Yue, M. Relationships among Leaf, Stem and Root Traits of the Dominant Shrubs from Four Vegetation Zones in Shaanxi Province, China. Isr. J. Ecol. Evol. 2017, 4, 25–32. [Google Scholar] [CrossRef]

- Tong, J.; Li, J.; Jiang, H. Machine vision techniques for the evaluation of seedling quality based on leaf area. Biosyst. Eng. 2013, 115, 369–379. [Google Scholar] [CrossRef]

- Tian, Z.; Ma, W.; Yang, Q.; Yao, S.; Guo, X.; Duan, F. Design and experiment of gripper for greenhouse plug seedling transplanting based on EDM. Agronomy 2022, 12, 1487. [Google Scholar] [CrossRef]

- Uzair, M.; Jamil, N. Effects of hidden layers on the efficiency of neural networks. In Proceedings of the IEEE 23rd International Multitopic Conference (INMIC), Bahawalpur, Pakistan, 5–7 November 2020; pp. 1–6. [Google Scholar]

- Karsoliya, S.; Abul Kalam Azad, M. Approximating number of hidden layer neurons in multiple hidden layer BPNN architecture. Int. J. Eng. Trends Technol. 2012, 3, 714–717. [Google Scholar]

- Guan, C.; Xu, T.; Cui, Z.; Yang, Y.; Chen, Y.; Gao, Q. Optimized parameters for compression molding of vegetable seedling substrate block for mechanical transplanting. Agric. Eng. J. 2020, 29, 1–12. [Google Scholar]

- Liu, W.; Tian, S.; Wang, Q. Key technologies of plug tray seedling transplanters in protected agriculture: A review. Agriculture 2023, 13, 1488. [Google Scholar] [CrossRef]

- Pohan, S.; Warsito, B.; Suryono, S. Back propagation artificial neural network for prediction plant seedling growth. J. Phys. Conf. Ser 2020, 1524, 012147. [Google Scholar] [CrossRef]

- Zhou, M.M.M.; Kimbeng, C.A.; Tew, T.L.; Gravois, K.A.; Pontif, M.J. Artificial neural network models as a decision support tool for selection in sugarcane: A case study using seedling populations. Crop Sci. 2011, 51, 21–31. [Google Scholar] [CrossRef]

- Hara, P.; Piekutowska, M.; Niedbała, G. Prediction of Pea (Pisum sativum L.) seeds yield using artificial neural networks. Agriculture 2023, 13, 661. [Google Scholar] [CrossRef]

- Han, L.; Mao, H.; Hu, J.; Miao, X.; Tian, K.; Yang, X. Experiment on mechanical property of seedling pot for automatic transplanter. Trans. Chin. Soc. Agric. Eng. 2013, 29, 24–29. [Google Scholar]

| No. | Number of Hidden Layers | Hidden Layer 1 | Hidden Layer 2 | Hidden Layer 3 | MAE | MSE | MAPE (%) | R2 |

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 5 | 5 | 0 | 11.289 | 191.325 | 12.350% | 0.607 |

| 2 | 2 | 6 | 6 | 0 | 12.023 | 231.834 | 13.924% | 0.524 |

| 3 | 2 | 7 | 7 | 0 | 11.761 | 231.280 | 13.727% | 0.525 |

| 4 | 2 | 8 | 8 | 0 | 13.637 | 268.522 | 15.624% | 0.448 |

| 5 | 2 | 9 | 9 | 0 | 13.550 | 257.552 | 15.164% | 0.471 |

| 6 | 2 | 10 | 10 | 0 | 12.867 | 228.178 | 14.509% | 0.531 |

| 7 | 2 | 11 | 11 | 0 | 12.189 | 224.697 | 13.687% | 0.539 |

| 8 | 2 | 12 | 12 | 0 | 9.327 | 143.817 | 11.132% | 0.705 |

| 9 | 2 | 13 | 13 | 0 | 11.710 | 218.793 | 13.588% | 0.551 |

| 10 | 2 | 14 | 14 | 0 | 9.527 | 157.982 | 10.935% | 0.676 |

| 11 | 2 | 15 | 15 | 0 | 7.669 | 88.842 | 9.076% | 0.867 |

| 12 | 3 | 5 | 5 | 2 | 12.155 | 239.242 | 13.654% | 0.509 |

| 13 | 3 | 6 | 6 | 3 | 11.876 | 206.582 | 13.571% | 0.576 |

| 14 | 3 | 7 | 7 | 3 | 13.495 | 283.368 | 15.416% | 0.418 |

| 15 | 3 | 8 | 8 | 4 | 13.942 | 289.851 | 15.917% | 0.405 |

| 16 | 3 | 9 | 9 | 4 | 13.497 | 258.325 | 15.250% | 0.471 |

| 17 | 3 | 10 | 10 | 5 | 9.117 | 138.587 | 10.582% | 0.715 |

| 18 | 3 | 11 | 11 | 5 | 11.715 | 191.551 | 13.375% | 0.607 |

| 19 | 3 | 12 | 12 | 6 | 12.847 | 233.136 | 14.804% | 0.521 |

| 20 | 3 | 13 | 13 | 6 | 12.998 | 252.724 | 14.989% | 0.481 |

| 21 | 3 | 14 | 14 | 7 | 12.572 | 229.730 | 14.844% | 0.528 |

| 22 | 3 | 15 | 15 | 7 | 9.191 | 141.258 | 10.884% | 0.710 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Z.; Gao, A.; Ma, W.; Jiang, H.; Cao, D.; Wang, W.; Qian, J.; Xu, L. Modeling the Mechanical Properties of Root–Substrate Interaction with a Transplanter Using Artificial Neural Networks. Agriculture 2024, 14, 651. https://doi.org/10.3390/agriculture14050651

Tian Z, Gao A, Ma W, Jiang H, Cao D, Wang W, Qian J, Xu L. Modeling the Mechanical Properties of Root–Substrate Interaction with a Transplanter Using Artificial Neural Networks. Agriculture. 2024; 14(5):651. https://doi.org/10.3390/agriculture14050651

Chicago/Turabian StyleTian, Zhiwei, Ang Gao, Wei Ma, Huanyu Jiang, Dongping Cao, Weizi Wang, Jianping Qian, and Lijia Xu. 2024. "Modeling the Mechanical Properties of Root–Substrate Interaction with a Transplanter Using Artificial Neural Networks" Agriculture 14, no. 5: 651. https://doi.org/10.3390/agriculture14050651

APA StyleTian, Z., Gao, A., Ma, W., Jiang, H., Cao, D., Wang, W., Qian, J., & Xu, L. (2024). Modeling the Mechanical Properties of Root–Substrate Interaction with a Transplanter Using Artificial Neural Networks. Agriculture, 14(5), 651. https://doi.org/10.3390/agriculture14050651