Abstract

This study evaluates the efficacy of buried straw bioreactor (SBR) technology in enhancing soil properties, CO2 efflux, and crop yield, specifically focusing on Indian cowpea cultivation within a greenhouse environment. Conducted at the Yuxi Demonstration Park in Fujian, China, the experiment utilized a randomized block design incorporating seven treatments with varying straw application rates (4.5, 6, and 7.5 kg m−2) and burial depths (20 and 30 cm) alongside a control group. The investigation revealed that SBR technology significantly increased soil temperature, CO2 efflux, soil total nitrogen (TN), and total organic carbon (TOC), contributing to a marked improvement in the biomass of Indian cowpea roots, stems, and leaves. Notably, the optimal results were observed with 7.5 kg m−2 straw applied at a 20 cm depth, enhancing soil temperature by 1.5–2.0 °C and multiplying cowpea biomass by 2.1–6.4 times relative to the control. This treatment also led to the highest increases in soil TOC and CO2 efflux, demonstrating the potential of SBR technology for carbon sequestration and suggesting its application as a sustainable agricultural practice in cold regions to ameliorate the soil’s physical and nutritional characteristics, thus supporting enhanced crop production. The study underscores SBR technology’s role in addressing the challenge of agricultural waste through the effective reuse of crop straw, promoting the circular development of agriculture while safeguarding the ecological environment.

1. Introduction

Being one of the world’s largest agricultural countries, China produces over 600 million tons of crop straws annually, accounting for approximately one-third of global production [1]. This figure is on the rise as agriculture continues to expand [2]. Traditionally, developing countries have utilized crop straw for various purposes such as livestock feed, domestic heating, construction, and industrial raw materials [3]. However, with economic and social advancements, an increasing amount of crop straw is being abandoned in rural areas. In China, about 10% of all agricultural residues, which includes crop straw, are left to decay in fields [4], adversely affecting carbon dynamics in agroecosystems, increasing atmospheric greenhouse gas levels, and elevating particulate pollution. These practices lead to significant environmental and social challenges [5]. Furthermore, to swiftly dispose of agricultural waste post-harvest, many farmers in rural areas engage in controlled burning, a practice that contributes to greenhouse gas emissions and severe seasonal air pollution, exacerbating global warming [6]. Addressing the sustainable use of this biomaterial is therefore both urgent and critical.

Crop straw is a valuable renewable biomaterial that contains essential mineral nutrients such as carbon (C), phosphorus (P), and potassium (K), which are vital for crop growth and can significantly improve soil quality when used as an organic amendment [7]. However, due to variations in crop rotation patterns across regions and the associated labor costs, effectively managing crop straw in large-scale agricultural production poses a challenge [8]. In greenhouse production, long-term reliance on a single fertilizer application negatively impacts soil fertility, resulting in a significant accumulation of unused crop straw residues [9]. Moreover, the excessive return of straw to the field can lead to the formation of a hollow tillage layer, which hampers crop growth [10]. When crop straw is crushed, a substantial portion remains unturned or uncovered, resulting in water loss and hindering straw decomposition.

The straw biological reactor (SBR) emerges as a promising technology in organic cultivation, designed to reintegrate crop straws into fields effectively. This process mixes straw residues with selected microorganisms and activators before incorporation into field soils. It addresses two critical challenges: the inadequate CO2 supply for photosynthesis in greenhouses and the need to elevate soil temperature. SBR technology has shown success across diverse crop productions, including vegetables, cereals, and fruits [11]. In aerobic conditions, straw decomposition within the SBR releases CO2, H2O, organic matter, mineral nutrients, and heat [12], serving as valuable fertilizers that boost agricultural yield and crop quality [13]. Additionally, by increasing soil temperature and atmospheric CO2 levels, SBR technology fosters enhanced crop growth and yields. A study by Ji et al. [14] revealed that SBR technology elevated soil temperatures by 2.5–3.5 °C and boosted atmospheric CO2 concentrations by 89.5–137.6%, significantly improving the sugar content and yield of watermelon (Citrullus lanatus, cultivar Zaojia 8424). When applied with saline water irrigation, SBR also reduces soil salinity, Na+ concentration, and pH in the primary root zone, leading to greater plant biomass and fruit yield [13]. Moreover, returning straw to the soil enhances soil properties, stabilizes structure, and promotes cementation, playing a crucial role in soil water storage, moisture conservation, and water use efficiency, as well as reducing soil erosion [15,16]. Zuo et al. [17] discovered that burying straw and organic fertilizer into the 20–35 cm black soil layer decreased soil bulk density by 6.2–9.9%, raised soil water content by 7.8–22.9%, and increased corn yield by over 20%, outperforming traditional straw mulching and returning methods in enhancing the tillage layer.

Widely adopted in vegetable production in northern China, SBR has significantly improved CO2 concentration and temperature in greenhouses, promoting tomato growth and increasing yields by 12% compared to the control treatment [18]. It also lowers soil acidity and conductivity, enriches soil organic matter, and boosts microbial biomass, as shown in tomato greenhouse studies [12]. However, if excessive straw is returned to the field without timely burial, it can lead to nutrient loss and reduced efficiency due to water evaporation under sun exposure. Excessive straw coverage may also hinder decomposition, affecting no-tillage sowing and crop development.

Measuring the CO2 flux within the SBR greenhouse system is vital for understanding ecosystem responses to climate change. Nonetheless, research and application of SBR technology in southern China’s vegetable production remain limited, highlighting the need for further investigation into SBR’s effects and the optimal use of this technology. This study aims to enhance soil properties by determining the ideal depth for SBR and the appropriate thickness of covering soil, contributing to the development of a comprehensive evaluation framework and methodologies for in situ SBR application.

2. Materials and Methods

2.1. Study Site

The field experiment took place at Yuxi Demonstration Park in Fujian, China (25°36′ N, 119°3′ E). During the year of the experiment, the region received an average annual precipitation of 1525 mm, with an average temperature of 18.8 °C. The topsoil, characterized as loam, exhibited the following properties: a pH of 4.37, soil organic matter content of 1.6%, available nitrogen (N) content of 105.7 mg kg−1, available phosphorus content of 31.3 mg kg−1, and effective potassium content of 132.2 mg kg−1.

2.2. Experiment Design

In the greenhouse field trial, a randomized block design was applied with three replicates across seven treatments (Table 1). The greenhouse, measuring 10 m by 50 m, was covered with a polyethylene film and operated without supplementary lighting or heating. The seven treatments involved three levels of buried straw and two soil layers, labeled CK, T1, T2, T3, T4, T5, and T6. These treatments varied in straw amounts and soil depths, as detailed in Table 1. Corn stover served as the experimental biomass. Nitrogen fertilizer was applied as urea at a rate of 10 g of N per kg of stover. Additionally, microbial inoculants were inoculated at a rate of 3.33 g per kg of stover dosage.

Table 1.

Components of 7 straw bioreactor (SBR) treatments.

To establish the buried straw bioreactor (SBR), ditches measuring 10 × 100 × 30 cm (length × width × depth) were dug before transplanting and filled with different amounts of straw (0, 4.5, 6.0, and 7.5 kg m−2), which were premixed with microbial inoculants and urea. Soil, with a thickness of 20 and 30 cm, was then placed over the straw, and the SBR was regularly watered to maintain soil moisture. To promote straw decomposition, holes were drilled into the reactor at 30 cm spacing, allowing oxygen to flow through and release CO2. The pea cultivar used in this study was Indian cowpea (Vigna unguiculata L. Walp). The cowpea seeds were transplanted within 3–5 days after watering on both sides of the furrow, with a spacing of 30 × 15 cm.

2.3. Soil CO2 Efflux Measurement

Soil CO2 efflux was measured using an infrared gas analyzer (LICOR-8100A, LICOR Biosciences, Inc., Lincoln, NE, USA) from September to December. The accuracy of CO2 measurement ranged from 0 to 3000 ppm with an accuracy of ±1.5%. Cylindrical PVC chambers, with dimensions of 25 cm in diameter and 30 cm in height, were inserted approximately 2.4 cm into the soil to measure soil CO2 efflux. Each measurement lasted for 7 min, and there was a 1 min interval between two measurements to allow for the gases to exchange. The amount of soil CO2 efflux was determined based on the linear increase in chamber CO2 concentrations over time.

2.4. Soil Temperature

The soil temperature of each treatment was monitored using a digital thermometer from September to December. The thermometer was placed at a depth of 10 cm and 20 cm in the center of each plot, and readings were taken at 10:00 am and again at 15:00 on observation days 0, 15, 20, 30, 60, and 90. The daily temperature was calculated by averaging the two readings taken at each time point.

2.5. Soil Sampling and Soil Properties Analysis

Soil samples were collected at the end of the experience. Five samples were taken from each treatment, mixed, air-dried, and sieved through a 2 mm sieve for soil properties analysis.

The pH and electrical conductivity (EC) of the soil sample were measured by mixing the samples with deionized water in a ratio of 10:1 (w/v) and using a pH meter (Sartorius pp-15, Göttingen, NI, Germany) and a conductivity meter (S230-B, Mettler Toledo, Zurich, Switzerland), respectively. The soil total of Kjeldahl Nitrogen (TKN) was determined using the Kjeldahl method as described by Goyal et al. [19]. To digest the sample, 1.0 g of an air-dried soil sample was mixed with a Kjeldahl tablet, 5 mL of concentrated H2SO4, and 2.0g of accelerating agent and then boiled for 2 h at 300 W in an electric furnace. A mixture of 5 mL of 20 g L−1 boric acid and 20 mL of 10 mol L−1 NaOH was poured into the distillation chamber through a funnel, and the resulting solution was distilled. The distillate was titrated with a 0.01 mol L−1 H2SO4 solution using a mixture of methyl red and bromocresol green indicators until it reached a violet endpoint. For NO3−-N and NH4+-N determination, five grams of soil samples were mixed with 50 mL of 2 mol L−1 KCl in a conical flask and shaken at 120 r min−1 for 10 min. The mixture was decolorized with activated carbon and filtered to prevent color interference. The filtrate was then analyzed for NO3−-N and NH4+-N concentrations using a continuous-flow autoanalyzer (San++, Skalar, Delft, The Netherlands).

Soil available phosphorus (AP) was analyzed using the molybdenum antimony anti-oxidation method [20] after extraction with 0.5 mol L−1 NaHCO3 at pH 8.5.

Total organic carbon (TOC) was determined by extracting 5 g of soil with 50 mL water at a 1:10 (w/v) ratio using a TOC-VCPH analyzer (TOC, Shimadzu, Kyoto, Japan). Each sample was analyzed with three replications.

Moisture content (MC) was determined by drying the soil samples at 65 °C to a constant weight after 48 h in an oven.

Five Indian cowpeas were randomly collected at physiological maturity to measure aboveground and root biomass, as well as the number of beans harvested in each treatment.

2.6. Data Analysis

The concentration of atmospheric CO2 at the height of the CO2 detector (16 cm above the sediment surface) varied between 370 μmol m−2·s−1 to 410 μmol m−2·s−1. To account for this variation, CO2 fluxes were calculated with respect to an atmospheric CO2 concentration using software provided by Licor Corporation (LI-6400XT, Licor Corporation, Lincoln, NE, USA). Data were analyzed using Microsoft Excel 2019 and SPSS 19.0 statistical software. One-way ANOVA was conducted to determine significant differences between the treatments, and the Fisher LSD test was used for multiple comparisons.

A regression curve was fitted to the relationship between Soil CO2 efflux and soil temperature using the exponential equation:

where a and b are the regression coefficients, Rs is soil CO2 efflux(μmol m−2·s−1), and T is soil temperature (°C).

RS = aebT

3. Results

3.1. Biomass of Indian Cowpea

Table 2 illustrates the impact of various treatments on the biomass of Indian cowpea, revealing that treatments T1 through T6 resulted in a higher fresh weight of roots and stems/leaves compared to the control (CK). Specifically, the fresh root weight for treatments T1, T2, and T3 showed increases of 0.8, 2.7, and 7 times, respectively, over CK. For treatments T4, T5, and T6, the fresh root weight surged by more than five times in comparison to CK. Similarly, the fresh weight of stems/leaves for T1, T2, and T3 escalated by 2.1, 4.8, and 6.4 times, respectively, in opposition to CK, while for T4 to T6, it rose by over 5.8 times relative to CK. The use of SBR technology markedly boosted the biomass of roots, stems, and leaves in Indian cowpea.

Table 2.

Effects of different treatments on the biomass of Indian cowpea. Different letters within a column indicate significant differences at p < 0.05. Values shown are mean ± SD.

3.2. Soil Temperature

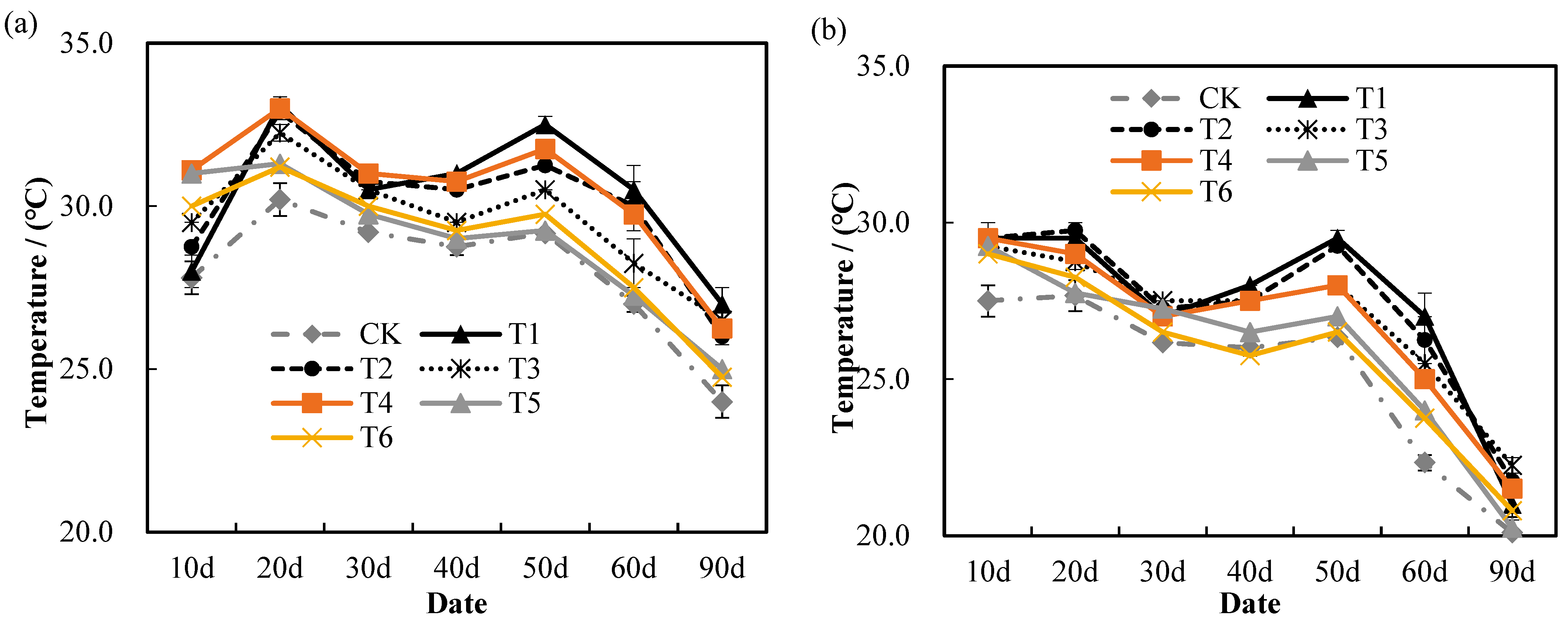

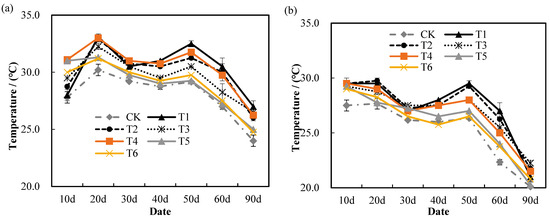

SBR treatments employing straw burial depths of 20 cm and 30 cm produced distinct soil temperature patterns at both 10 cm (Figure 1a) and 20 cm (Figure 1b) depths during the growth of Indian cowpea. Soil temperatures under SBR treatments were significantly higher compared to the control (CK) group. Notably, temperatures at a depth of 20 cm were lower than those at 10 cm for both SBR and CK treatments. At a 10 cm depth, temperatures for the 20 cm straw burial depth (T1–T3) were lower than for the 30 cm burial depth (T4–T6). However, at a 20 cm depth, there was no discernible difference between the two burial depths.

Figure 1.

Effects of different treatments (a) burial depth of 20 cm and (b) burial depth of 30 cm of buried straw bioreactor (SBR) technology on temperature. Values shown as mean ± SD.

To further explore SBR technology’s influence on soil temperature, we calculated the temperature difference between SBR and CK treatments. At the onset of Indian cowpea growth, burying straw at both 20 cm and 30 cm depths led to similar increases in soil temperature at the 20 cm depth: 1.7–2.0 °C for T1-T3 and 1.5–2.0 °C for T4–T6 compared to CK. Nonetheless, a 30 cm burial depth (T4–T6) yielded a more pronounced increase at a 10 cm depth, with temperature rises of 0.2–1.7 °C for T1–T3 and 2.2–3.7 °C for T4–T6. Toward the conclusion of the growth period (90 days), soil temperatures at a 10 cm depth for T1–T3 and T4–T6 had risen by 2.0–3.0 °C and 0.75–2.2 °C, respectively. The maximum and minimum temperatures at a 10 cm depth were recorded as 33.1 °C for T1 and 31.2 °C for T6, respectively, after 20 days.

Soil temperature measurements at a 20 cm depth revealed that applying 4.5 kg m−2 of straw at a 30 cm depth (T4) resulted in the most significant temperature increase throughout the growing season by 2.5 °C. Conversely, a burial depth of 20 cm (T1–T3) led to a uniform temperature increase of 2.0 °C, regardless of the straw amount used. However, for the same 30 cm depth, higher amounts of straw (T5 and T6) yielded less substantial temperature increases, with gains of 1.1 °C and 0.9 °C, respectively.

The room temperature in September was 28 °C and decreased to 15 °C in December. Soil temperatures under SBR treatments were higher at 1 °C in September and 5 °C in December at a 20 cm depth, and 7 °C in September and 12 °C in December at a 10 cm depth compared to the room temperature.

3.3. Soil Physicochemical Properties

The impact of SBR on soil physicochemical properties is demonstrated in Table 3. SBR treatment resulted in a soil pH range of 6.6 to 7.1, significantly higher than the control (CK) pH of 6.2. Notably, treatment of T2, which entailed burying straw at a depth of 20 cm with an application rate of 6 kg m−2, achieved the highest soil pH value. In contrast, T4, involving a 30 cm burial depth and a 4.5 kg m−2 straw amount, recorded the lowest pH value.

Table 3.

The effect of SBR on soil properties. Different letters within a column indicate significant differences at p < 0.05. Values shown are mean ± SD.

One-way ANOVA analysis revealed a significant impact of SBR treatments on soil moisture content. Straw buried at a depth of 20 cm (T1–T3) increased soil moisture by 32.6–42.2% relative to CK, whereas a 30 cm burial depth (T4–T6) enhanced moisture levels by 26.2–73.8%. Moreover, electrical conductivity (EC) was lower across all SBR treatments compared to CK, with mean EC values ranging from 31.0 to 35.7 μs cm−1.

SBR treatments also significantly elevated soil nitrate (NO3−-N) and ammonium (NH4+-N) concentrations within the 0–30 cm soil layer, surpassing both the 0–20 cm layer and CK levels. A 20 cm straw burial depth (T1–T3) increased NH4+-N levels by 15.2–30.3% compared to CK, while a 30 cm depth (T4–T6) boosted levels by 48.4–60.1%. Similarly, soil NO3–-N levels rose by 40.5–71.2% with a 20 cm depth and by 54.2–91.5% with a 30 cm depth.

Soil total phosphorus (TP) concentrations were significantly higher with SBR treatment across all treatments compared to CK, although TP levels did not significantly differ among the SBR treatments themselves.

The correlation analysis results of soil physical and chemical factors are shown in Table 4. There was a significant positive correlation between temperature and TOC, NO3−-N (p < 0.01). There was a significant positive correlation between TOC and pH, TN, and water content (p < 0.01). The concentration of NH4+-N was increased as the soil temperature increased.

Table 4.

Correlation analysis results of soil physical and chemical factors.

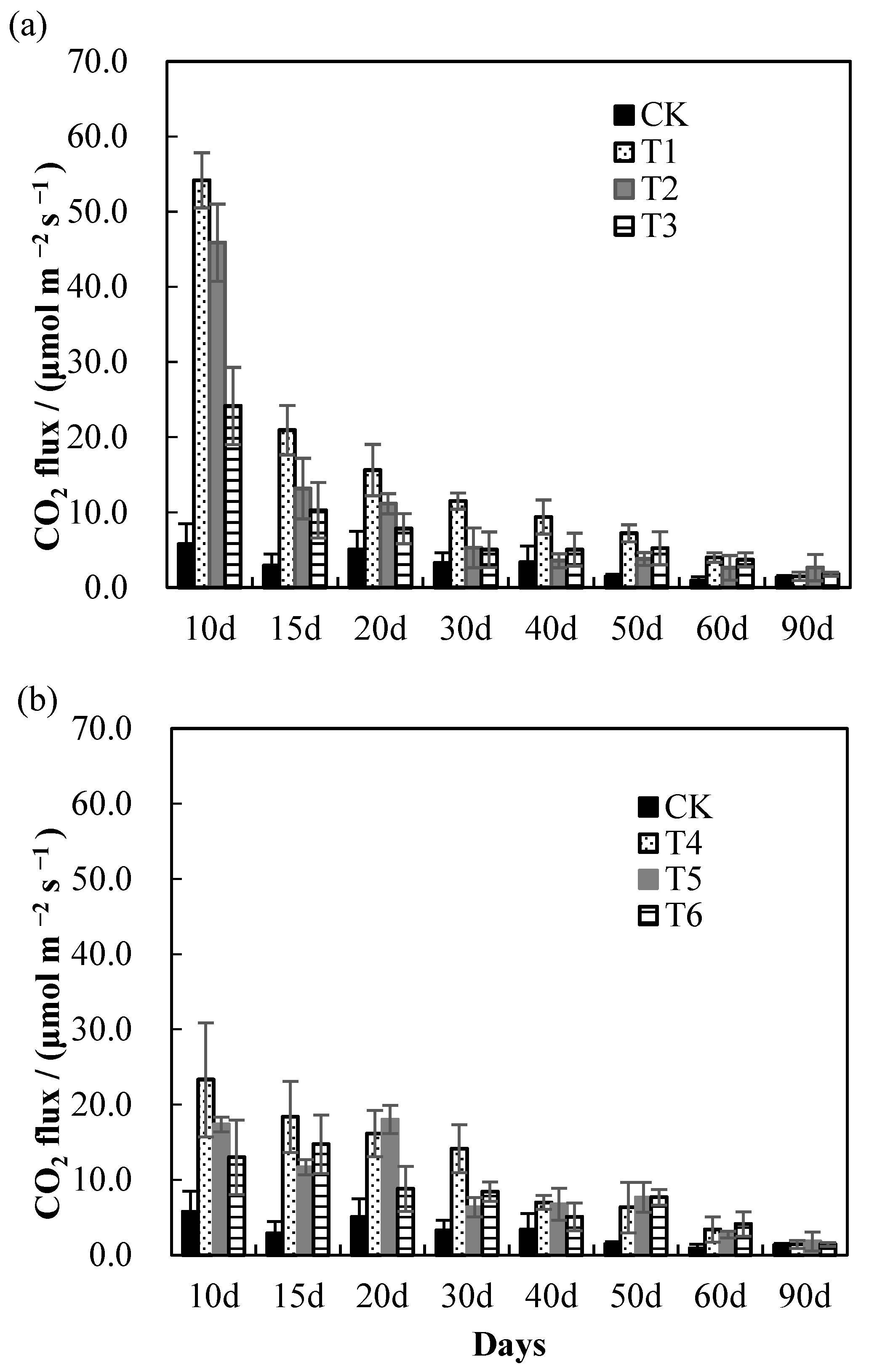

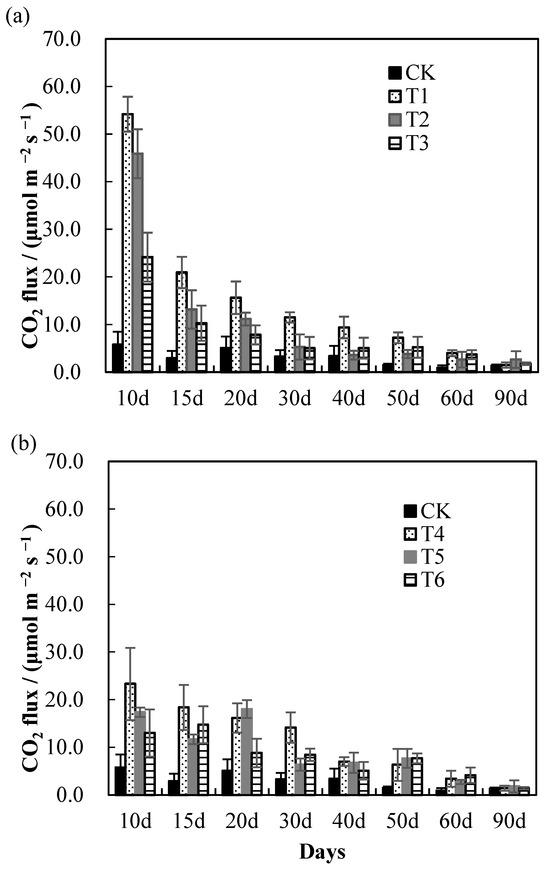

3.4. Soil CO2 Fluxes and Seasonal Variation

This study observed seasonal variations in soil CO2 efflux across all treatments, as shown in Figure 2. The results indicated a decreasing trend from September to December, with the highest soil CO2 efflux recorded in September over a period of 10 days. Among the treatments, burying 7.5 kg m−2 of straw at a depth of 20 cm (T3) resulted in the highest CO2 flux value (54.2 μmol m−2 s−1), while burying the same amount of straw at a depth of 30 cm (T4) yielded the lowest (13.0 μmol m−2 s−1). The soil CO2 flux decreased from late October to December, with the CO2 efflux of SBR treatments only increasing by 0.1–0.3 times compared to CK in December.

Figure 2.

Effects of different treatments (a) burial depth of 20 cm (b) burial depth of 30 cm of buried straw bioreactor (SBR) technology on CO2 flux.

Furthermore, the addition of buried straw was found to increase CO2 efflux. The highest CO2 efflux value was observed in treatments with the highest amounts of buried straw (7.5 kg m−2) under 20 or 30 cm soil layers. Initially, the CO2 efflux of T3 (burial depth: 20 cm, straw amount: 7.5 kg m−2) and T6 (burial depth: 30 cm, straw amount: 7.5 kg m−2) was 54.2 and 23.3 μmol m−2 s−1, respectively, which was 8.4 and 3.2 times higher compared to CK. In contrast, SBR treatments with a straw burial depth of 30 cm exhibited a lower CO2 efflux compared to those with a burial depth of 20 cm and the same amount of buried straw. Specifically, CO2 efflux values were 90% higher in T1 than in T4, 160% higher in T2 than in T5, and 140% higher in T3 than in T6 for straw application amounts of 4.5, 6, and 7.5 kg m−2, respectively.

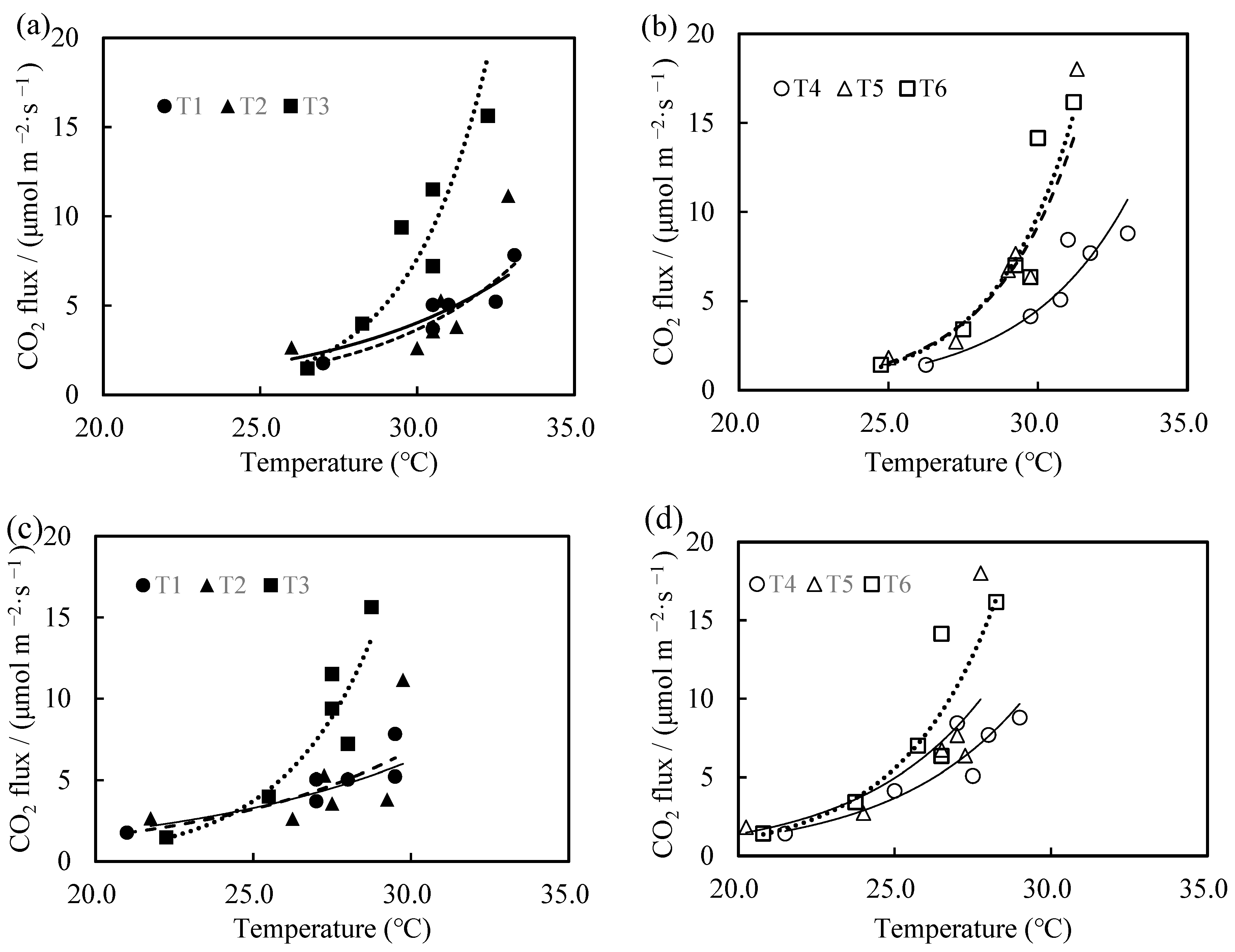

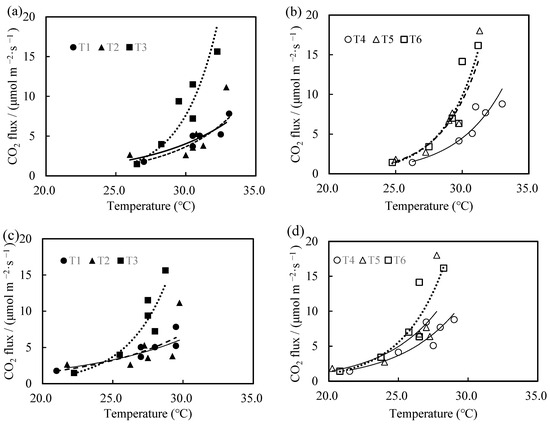

3.5. Effect of Soil Temperature on Soil CO2 Fluxes

An exponential correlation was observed between soil CO2 efflux and soil temperature across all SBR treatments, as shown in Figure 3. Soil CO2 efflux increased with rising soil temperature in all data sets. The determination coefficients (R2) for the relationship between soil CO2 efflux and soil temperature at a 10 cm depth were 0.85, 0.66, and 0.84 for T1, T2, and T3, respectively, and 0.80, 0.94, and 0.86 for T4, T5, and T6, respectively. Conversely, R2 values for the relationship at a 20 cm depth were 0.78, 0.44, and 0.84 for T1, T2, and T3, respectively, and 0.78, 0.63, and 0.81 for T4, T5, and T6, respectively. A stronger correlation between soil CO2 efflux and soil temperature was evident at a 10 cm depth compared to a 20 cm depth.

Figure 3.

Exponential relationships between soil temperature at 10 cm depth with CO2 efflux at a soil depth of 20 cm (a) and 30 cm (b) and soil temperature at 20 cm depth with CO2 efflux at a soil depth of 20 cm (c) and 30 cm (d).

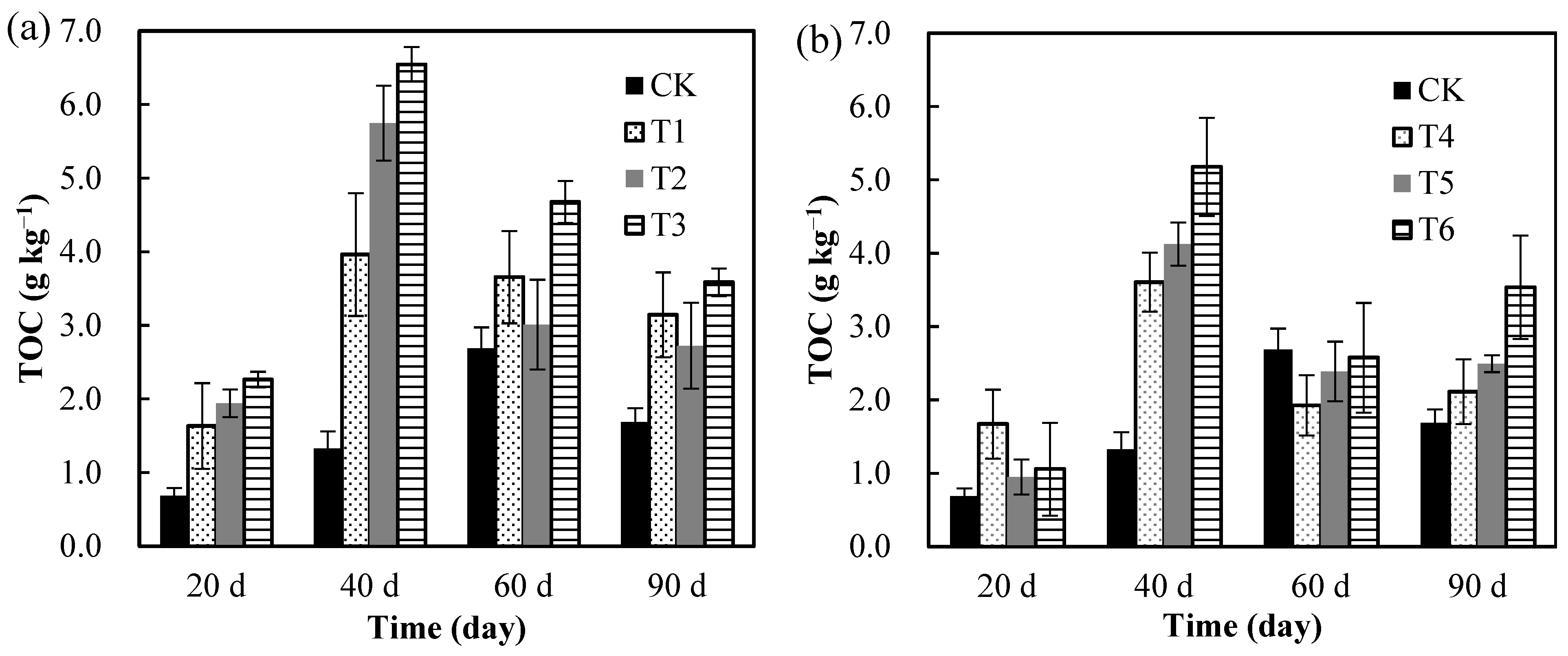

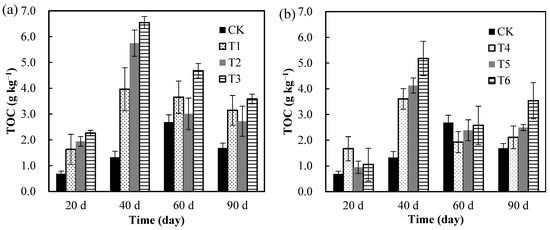

3.6. Soil Total Organic Carbon (TOC)

The total organic carbon (TOC) of the SBR treatments varied according to different straw amounts and burial depths, as depicted in Figure 4. TOC was significantly influenced by straw burial depths, showing a decrease as the burial depth increased during the Indian cowpea growing season. At a 20 cm depth, TOC values ranged from 3.1 to 4.2 g kg−1, whereas at a 30 cm depth, TOC values were between 2.3 and 3.1 g kg−1. Overall, soil TOC at a 20 cm depth was higher than at a 30 cm depth, averaging a 34% increase. Compared to the control (CK), soil TOC increased by 0.9–1.7 times at a 20 cm depth (T1–T3) and by 0.5–0.9 times at a 30 cm depth (T4–T6). Furthermore, TOC increased with a greater amount of buried straw. Specifically, at a 20 cm depth, the application of 7.5 kg m−2 of straw (T3) achieved the highest TOC value of 4.3 g kg−1 compared to other straw amounts (T1 and T2). Similarly, at a 30 cm depth, the average TOC content with 7.5 kg m−2 of straw (T6) was 3.1 g/kg, which was 33.0% and 24.0% higher than T4 and T5, respectively. The peak TOC content for T3 and T6 was observed on the 40th day of the experiment, whereas without SBR treatment, the peak was reached on the 60th day. After reaching the peak value, TOC content decreased as plant growth progressed. By the end of the experiment, the order of TOC content across all treatments was T3 > T6 > T1 > T2 > T5 > T4.

Figure 4.

Effects of different treatments (a) burial depth of 20 cm (b) burial depth of 30 cm of buried straw bioreactor (SBR) treatments on TOC content.

4. Discussion

This study reveals that utilizing straw biological reactor (SBR) technology not only helps maintain soil moisture but also improves soil temperature. Previous studies have demonstrated that returning buried straw to the field can influence soil water processes and increase crop yields, as noted by Yang et al. [21] and Zhang et al. [22]. Significantly, it enhances crop grain yield, aligning with findings from Qin et al. [23] and Xiong et al. [24]. Specifically, SBR technology increased soil temperature by 0.6–2.4 °C, promoted Indian cowpea growth, and improved aboveground biomass, leading to a yield increase of up to 20% compared to the control group. Moreover, returning crop straw to fields enhances soil fertility by boosting nutrient release, as Chen et al. [25] highlighted. In our study, SBR technology not only maintained soil total nitrogen (TN) concentration but also significantly improved nitrate (NO3−-N) levels, echoing the results of Li et al. [26]. Furthermore, incorporating higher amounts of straw resulted in increased soil nitrogen availability, in line with Stagnari et al. [27]. Notably, a higher straw amount in treatments T3 (20 cm burial depth) and T6 (30 cm burial depth) led to increased soil NO3−-N concentrations. T3 also exhibited the lowest ammonium (NH4+-N) concentration, which readily transformed into NO3−-N, corroborating with Latifmanesh et al. [28], who reported the lowest NH4+-N concentration with straw returned to the topsoil. Returning straw to the soil enhances nutrient release, whereas traditional straw return methods consume soil available nitrogen, as shown by Gao et al. [29].

The impact of different straw return techniques on soil properties could be related to the temperature and moisture content of the soil. Li et al. [30] found that using ridge-furrow plastic film mulch (RP) significantly increased soil moisture content and temperature compared to traditional buried straw return methods, resulting in an increase in soil organic matter content. Increased soil temperature has been shown to significantly enhance the decomposition rate of straw in the soil, thereby increasing the release of organic carbon and nitrogen across different soil layers, as reported by Latifmanesh et al. [28].

Soil fertility and structure, as well as the global carbon balance, are influenced by soil organic carbon (TOC), as noted by West and Marland [31] and Lal [32]. Previous research has indicated that TOC content in the topsoil layer (10 cm) increases with greater and deeper straw burial [30]. Our study observed that TOC content gradually increased over time as straw decomposed under different SBR treatments. The highest soil temperature and TOC content were noted in the SBR treatment by applying 7.5kg m−2 of straw at a 20 cm depth (T3). The larger amounts of straw applied in T3 led to a higher decomposition rate and TOC content, aligning with previous findings that higher amounts of straw result in increased nutrient release [27]. The straw burial reactor method could improve soil total nitrogen (TN), TOC, and crop yield, with the peak TOC value observed on the 40th day of SBR treatments, earlier than in the control group. Earlier studies have also demonstrated that increasing the amount of deeply buried straw enhances crop yield and soil fertility [33].

CO2 efflux is a critical indicator of soil respiration intensity [34]. The decomposition of organic carbon after applying easily decomposable straw to the soil led to an increase in CO2 efflux. CO2 efflux under different straw biological reactor technologies was significantly higher than in the control group, indicating that SBR could contribute to CO2 efflux and effectively address the CO2 deficit in greenhouses. The decomposition of straw plays a significant role in CO2 emission and the increase in soil organic carbon [35]. The results from all treatments showed that the SBR treatment with 7.5kg m−2 of straw buried at a 20 cm depth (T3) had the most significant positive effect on CO2 efflux and the yield of Indian cowpea.

In greenhouses, plant growth may be constrained by insufficient CO2 availability for photosynthesis. Straw, rich in complex organic compounds such as lignin and cellulose, can be buried in fields to alter soil organic matter composition, thereby increasing CO2 emissions from the soil [36]. Previous research has shown that soil CO2 production can rise following rainfall events, enhancing microbial activity and accelerating soil organic carbon decomposition [37]. This study explored the impact of straw biological reactor (SBR) technology on soil water content and CO2 efflux, finding that all SBR treatments enhanced soil water content and led to increased CO2 efflux, thus enriching the soil with CO2. The CO2 release varied significantly across seasons and exhibited a pronounced exponential relationship with soil temperature, a correlation well established in the literature [38].

Our findings indicate that the T3 (burial depth: 20 cm, straw amount: 7.5 kg m−2) treatment yielded the highest soil temperature and CO2 efflux, with CO2 efflux following a logarithmic model across treatments. While treatments T1 (burial depth: 20 cm, straw amount: 4.5 kg m−2) and T2 (burial depth: 20 cm, straw amount: 6.5 kg m−2) demonstrated a slower response, T3-T6 entered an initial rapid phase, utilizing readily available compounds. Notably, CO2 efflux exhibited significant seasonal fluctuations, with the highest CO2 production and efflux occurring in the summer [39]. Furthermore, the study corroborated previous observations that CO2 efflux from topsoil is constrained by temperature in mid-winter and moisture in late summer [40], aligning with our results on the temporal variability of CO2 efflux. At the experiment’s outset, a microbial agent was added to the reactor to quicken straw decomposition and boost the CO2 supply in the greenhouse. However, with the onset of colder weather in November, CO2 efflux began to decline.

5. Conclusions

The straw buried biological reactor (SBR) has proven to be instrumental in enhancing the yield of Indian cowpea, as well as soil parameters such as TOC, NO3--N, and temperature, all of which are critical for plant growth. Its application across various treatments significantly boosted the yield of Indian cowpea, particularly notable with the use of 7.5 kg m−2 of straw buried at a 30 cm depth. This underscores the potential of SBR technology for carbon sequestration. Furthermore, the technology was effective in improving CO2 efflux and soil temperature, offering protection against freezing injury during the winter cultivation of vegetables. The findings advocate for the use of 7.5 kg m−2 of straw buried at a 20 cm depth as the optimal strategy for employing SBR technology. This innovative method opens new pathways for the comprehensive utilization of crop straw, addressing agricultural waste challenges while preserving the ecological environment. This study was a temporary achievement; further, similar studies should be considered in various environments factors and years for generalization of the results. In sum, SBR technology fosters sustainable, efficient, and circular development in agriculture.

Author Contributions

Conceptualization, Methodology, Data curation, Investigation, Software, Formal analysis, Writing—original draft, Drafting final manuscript, C.L.; Sample testing, Software, J.Y.; Writing and revisions of final manuscript, B.Z.; Data curation, Investigation, Formal analysis, Y.L.; Funding acquisition, Resources, Supervision, Project administration, Y.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Central Government Guided Local Science and Technology Development projects (Grant No. 2021L3021), Fujian Province Public Welfare Scientific Research Program (Grant No. 2023R1062), Science and Technology Project of Fujian Academy of Agricultural Sciences (Grant No. XTCXGC2021010).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data presented in this study are available in this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Li, N.; Wen, S.; Wei, S.; Li, H.; Feng, Y.; Ren, G.; Yang, G.; Han, X.; Wang, X.; Ren, C. Straw incorporation plus biochar addition improved the soil quality index focused on enhancing crop yield and alleviating global warming potential. Environ. Technol. Innov. 2021, 21, 101316. [Google Scholar] [CrossRef]

- Fischer, R.; Connor, D. Issues for cropping and agricultural science in the next 20 years. Field Crop. Res. 2018, 222, 121–142. [Google Scholar] [CrossRef]

- Liu, P.; He, J.; Li, H.; Wang, Q.; Lu, C.; Zheng, K.; Liu, W.; Zhao, H.; Lou, S. Effect of straw retention on crop yield, soil properties, water use efficiency and greenhouse gas emission in China: A meta-analysis. Int. J. Plant Prod. 2019, 13, 347–367. [Google Scholar] [CrossRef]

- Cui, Z.; Dou, Z.; Chen, X.; Ju, X.; Zhang, F. Managing agricultural nutrients for food security in China: Past, present, and future. Agron. J. 2014, 106, 191–198. [Google Scholar] [CrossRef]

- He, K.; Zhang, J.; Zeng, Y. Rural households’ willingness to accept compensation for energy utilization of crop straw in China. Energy 2018, 165, 562–571. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, B.Y.; Liu, S.L.; Qi, J.; Wang, X.; Pu, C.; Li, S.; Zhang, X.; Yang, X.; Lal, R.; et al. Sustaining crop production in China’s cropland by crop residue retention: A meta-analysis. Land Degrad. Dev. 2020, 31, 694–709. [Google Scholar] [CrossRef]

- Zhu, L.; Hu, N.; Zhang, Z.; Xu, J.; Tao, B.; Meng, Y. Short-term responses of soil organic carbon and carbon pool management index to different annual straw return rates in a rice-heat cropping system. Catena 2015, 135, 283–289. [Google Scholar] [CrossRef]

- Tian, F.; Xia, K.; Wang, J.; Song, Z.; Yan, Y.; Li, F.; Wang, F. Design and experiment of self-propelled straw forage crop harvester. Adv. Mech. Eng. 2021, 13, 16878140211024455. [Google Scholar] [CrossRef]

- Zhang, S.; Li, M.; Cui, X.; Pan, Y. Effect of different straw retention techniques on soil microbial community structure in wheat-maize rotation system. Front. Microbiol. 2023, 13, 1069458. [Google Scholar] [CrossRef] [PubMed]

- Meng, X.; Guo, Z.; Yang, X.; Su, W.; Li, Z.; Wu, X.; Pu, C.; Li, S.; Zhang, X.; Yang, X.; et al. Straw incorporation helps inhibit nitrogen leaching in maize season to increase yield and efficiency in the Loess Plateau of China. Soil Tillage Res. 2021, 211, 105006. [Google Scholar] [CrossRef]

- Liang, X.; Lin, L.; Ye, Y.; Gu, J.; Wang, Z.; Xu, L.; Jin, Y.; Ru, Q.; Tian, G. Nutrient removal efficiency in a rice-straw denitrifying bioreactor. Bioresour. Technol. 2015, 198, 746–754. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Tian, Y.; Gao, L.; Peng, X.; Tong, E. Effects of straw biological reactor and microbial agents on physicochemical properties and microbial diversity of tomato soil in solar greenhouse. Trans. Chin. Soc. Agric. Eng. 2014, 6, 153–164, (In Chinese with English Abstract). [Google Scholar]

- Cao, Y.; Tian, Y.; Gao, L.; Chen, Q. Attenuating the negative effects of irrigation with saline water on cucumber (Cucumis sativus L.) by application of straw biological-reactor. Agric. Water Manag. 2016, 163, 169–179. [Google Scholar]

- Ji, M.; Xu, J.; Zhan, G.; Yang, F.; Liu, J. Effects of built-in biological reactor with different crop straws on sugar content and yield of watermelon. Mater. Res. Innov. 2015, 19, S8-470–S8-473. [Google Scholar] [CrossRef]

- Zhu, K.; Tan, X.; Gu, B.; Lin, J. Evaluation of Potential Amounts of Crop Straw Available for Bioenergy Production and Bio-Technology Spatial Distribution in China Under Ecological and Cost Constraints. J. Clean. Prod. 2021, 292, 125958. [Google Scholar] [CrossRef]

- Singh, R.J.; Deshwal, J.; Sharma, N.; Ghosh, B.; Bhattacharyya, R. Effects of conservation tillage based agro-geo-textiles on resource conservation in sloping croplands of Indian Himalayan Region. Soil Tillage Res. 2019, 191, 37–47. [Google Scholar] [CrossRef]

- Zuo, Q.; Kuai, J.; Zhao, L.; Hu, Z.; Wu, J.; Zhou, G. The effect of sowing depth and soil compaction on the growth and yield of rapeseed in rice straw returning field. Field Crop. Res. 2017, 203, 47–54. [Google Scholar] [CrossRef]

- Zhang, G.; Liu, F.; Gu, J.; Song, Y.; Mou, J. Effects of biological reactor technology on yield and quality of tomato. Jiangsu Agric. Sci. 2013, 41, 116–117, (In Chinese with English Abstract). [Google Scholar]

- Goyal, K.; Singh, N.; Jindal, S.; Kaur, R.; Goya, A.; Awasthi, R. Kjeldahl method. Adv. Tech. Anal. Chem. 2022, 1, 105–112. [Google Scholar]

- Saudner, D.H. Determination of available phosphorus in tropical soils by extraction with sodium hydroxide. Soil Sci. 1956, 82, 457–464. [Google Scholar] [CrossRef]

- Yang, H.; Zhai, S.; Li, Y.; Zhou, J.; He, R.; Liu, J.; Xue, Y.; Meng, Y. Waterlogging Reduction and Wheat Yield Increase through Long-Term Ditch-Buried Straw Return in a Rice-wheat Rotation System. Field Crop. Res. 2017, 209, 189–197. [Google Scholar] [CrossRef]

- Zhang, M.; Han, X.; Dang, P.; Wang, H.; Chen, Y.; Qin, X.; Siddique, K.H.M. Decreased Carbon Footprint and In-creased Grain Yield Under Ridge–furrow Plastic Film Mulch with Ditch-Buried Straw Returning: A Sustainable Option for Spring Maize Production in China. Sci. Total Environ. 2022, 838, 156412. [Google Scholar] [CrossRef] [PubMed]

- Qin, X.; Li, Y.; Han, Y.; Hu, Y.; Li, Y.; Wen, X.; Liao, Y.; Siddique, K.H. Ridge-furrow mulching with black plastic film improves maize yield more than white plastic film in dry areas with adequate accumulated temperature. Agric. For. Meteorol. 2018, 262, 206–214. [Google Scholar] [CrossRef]

- Xiong, L.; Liang, C.; Ma, B.; Shah, F.; Wu, W. Carbon footprint and yield performance assessment under plastic film mulching for winter wheat production. J. Clean. Prod. 2020, 270, 122468. [Google Scholar] [CrossRef]

- Chen, P.-Z.; Cui, J.-Y.; Hu, L.; Zheng, M.-Z.; Cheng, S.-P.; Huang, J.-W.; Mu, K.-G. Nitrogen Removal Improvement by Adding Peat in Deep Soil of Subsurface Wastewater Infiltration System. J. Integr. Agric. 2014, 13, 1113–1120. [Google Scholar] [CrossRef]

- Li, Y.; Hu, Y.; Song, D.; Liang, S.; Qin, X.; Siddique, K.H.M. The Effects of Straw Incorporation with Plastic Film Mulch on Soil Properties and Bacterial Community Structure on the Loess Plateau. Eur. J. Soil Sci. 2021, 72, 979–994. [Google Scholar] [CrossRef]

- Stagnari, F.; Galieni, A.; Speca, S.; Cafiero, G.; Pisante, M. Effects of straw mulch on growth and yield of durum wheat during transition to conservation agriculture in Mediterranean environment. Field Crop. Res. 2014, 167, 51–63. [Google Scholar] [CrossRef]

- Latifmanesh, H.; Deng, A.; Li, L.; Chen, Z.; Zheng, Y.; Bao, X.; Zheng, C.; Zhang, W. How incorporation depth of corn straw affects straw decomposition rate and C&N release in the wheat-corn cropping system. Agric. Ecosyst. Environ. 2020, 300, 107000. [Google Scholar] [CrossRef]

- Gao, X.; Liu, W.; Li, X.; Zhang, W.; Bu, S.; Wang, A. A Novel Fungal Agent for Straw Returning to Enhance Straw Decomposition and Nutrients Release. Environ. Technol. Innov. 2023, 30, 103064. [Google Scholar] [CrossRef]

- Li, Y.; Song, D.; Dang, P.; Wei, L.; Qin, X.; Siddique, K.H. Combined ditch buried straw return technology in a ridge–furrow plastic film mulch system: Implications for crop yield and soil organic matter dynamics. Soil Tillage Res. 2020, 199, 104596. [Google Scholar] [CrossRef]

- West, T.O.; Marland, G. A synthesis of carbon sequestration, carbon emissions, and net carbon flux in agriculture: Comparing tillage practices in the United States. Agric. Ecosyst. Environ. 2002, 91, 217–232. [Google Scholar] [CrossRef]

- Lal, R. Soil carbon sequestration impacts on global climate change and food security. Science 2004, 304, 1623–1627. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Chen, X.; Wei, T.; Yang, Z.; Jia, Z.; Yang, B.; Han, Q.; Ren, X. Effects of straw incorporation on the soil nutrient contents, enzyme activities, and crop yield in a semiarid region of China. Soil Tillage Res. 2016, 160, 65–72. [Google Scholar] [CrossRef]

- Song, W.; Tong, X.; Zhang, J.; Meng, P.; Li, J. Autotrophic and heterotrophic components of soil respiration caused by rhizosphere priming effects in a plantation. Plant Soil Environ. 2017, 63, 295–299. [Google Scholar] [CrossRef]

- Badia, D.; Marti, M.C.; Aguirre, A.J. Straw management effects on CO2 efflux and C storage in different Mediterranean agricultural soils. Sci. Total Environ. 2013, 465, 233–239. [Google Scholar] [CrossRef] [PubMed]

- Zavalloni, C.; Vicca, S.; Büscher, M.; de la Providencia, I.E.; de Boulois, H.D.; Declerck, S.; Nijs, I.; Ceulemans, R. Exposure to Warming and CO2 Enrichment Promotes Greater Above-Ground Biomass, Nitrogen, Phosphorus and Arbuscular Mycorrhizal Colonization in Newly Established Grasslands. Plant Soil 2012, 359, 121–136. [Google Scholar] [CrossRef]

- Casals, P.; Lopez-Sangil, L.; Carrara, A.; Gimeno, C.; Nogués, S. Autotrophic and heterotrophic contributions to short-term soil CO2 efflux following simulated summer precipitation pulses in a Mediterranean dehesa. Glob. Biogeochem. Cycles 2011, 25, 3012. [Google Scholar] [CrossRef]

- Wang, X.; Wang, J.; Wang, J. Seasonality of Soil Respiration Under Gypsum and Straw Amendments in an Arid Saline-Alkali Soil. J. Environ. Manag. 2021, 277, 111494. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Zhao, C.; Jia, H.; Niu, B.; Sheng, Y.; Shi, F. Effects of nitrogen fertilizer, soil temperature and moisture on the soil-surface CO2 efflux and production in an oasis cotton field in arid northwestern China. Geoderma 2017, 308, 93–103. [Google Scholar] [CrossRef]

- Casals, P.; Romanyà, J.; Cortina, J.; Bottner, P.; Coûteaux, M.-M.; Vallejo, V.R. CO2 efflux from a Mediterranean semi-arid forest soil. I. Seasonality and effects of stoniness. Biogeochemistry 2000, 48, 261–281. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).