Effect of Osmotic Dehydration in Tomato Juice on Microstructure of Garlic and on Drying Using Different Methods

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Materials

2.2. OS Preparation

2.3. Osmotic Dehydration

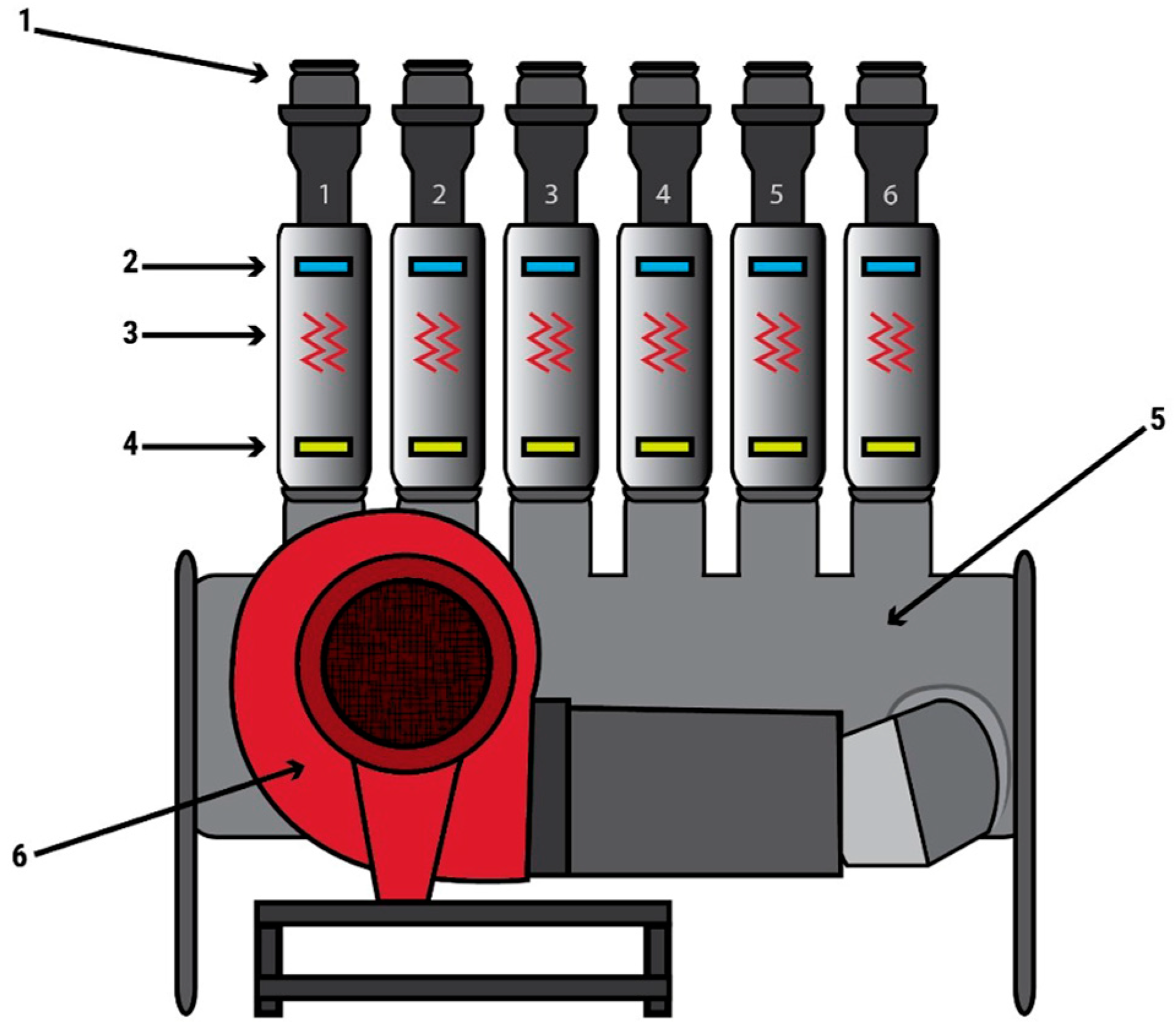

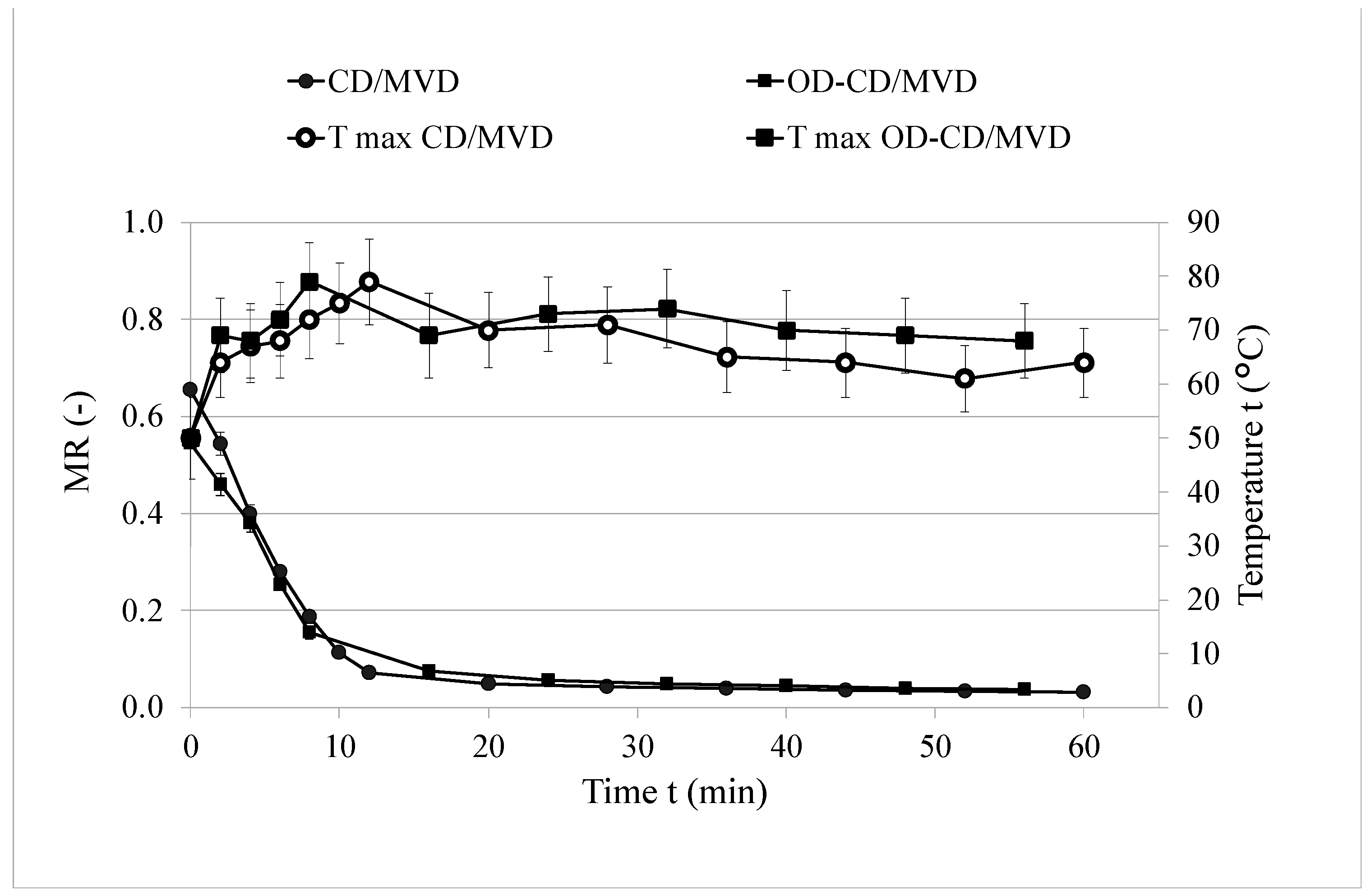

2.4. Drying and Drying Kinetics

2.5. Drying Model

2.6. Density

2.7. Porosity

2.8. Water Activity

2.9. Moisture Content

2.10. Color Parameters

2.11. Texture Profile Analysis (TPA)

2.12. Energy Consumption

2.13. Specific Energy Consumption

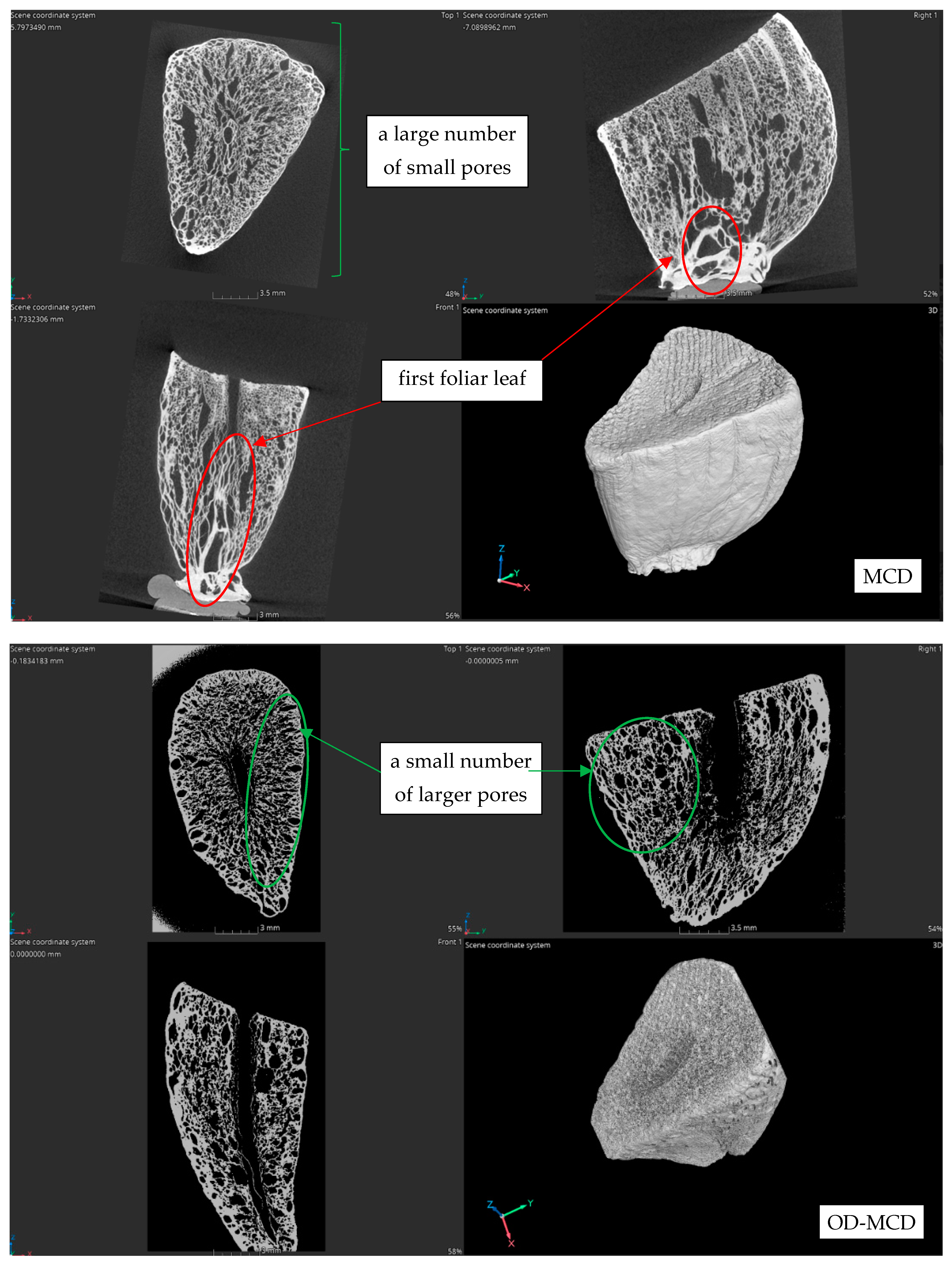

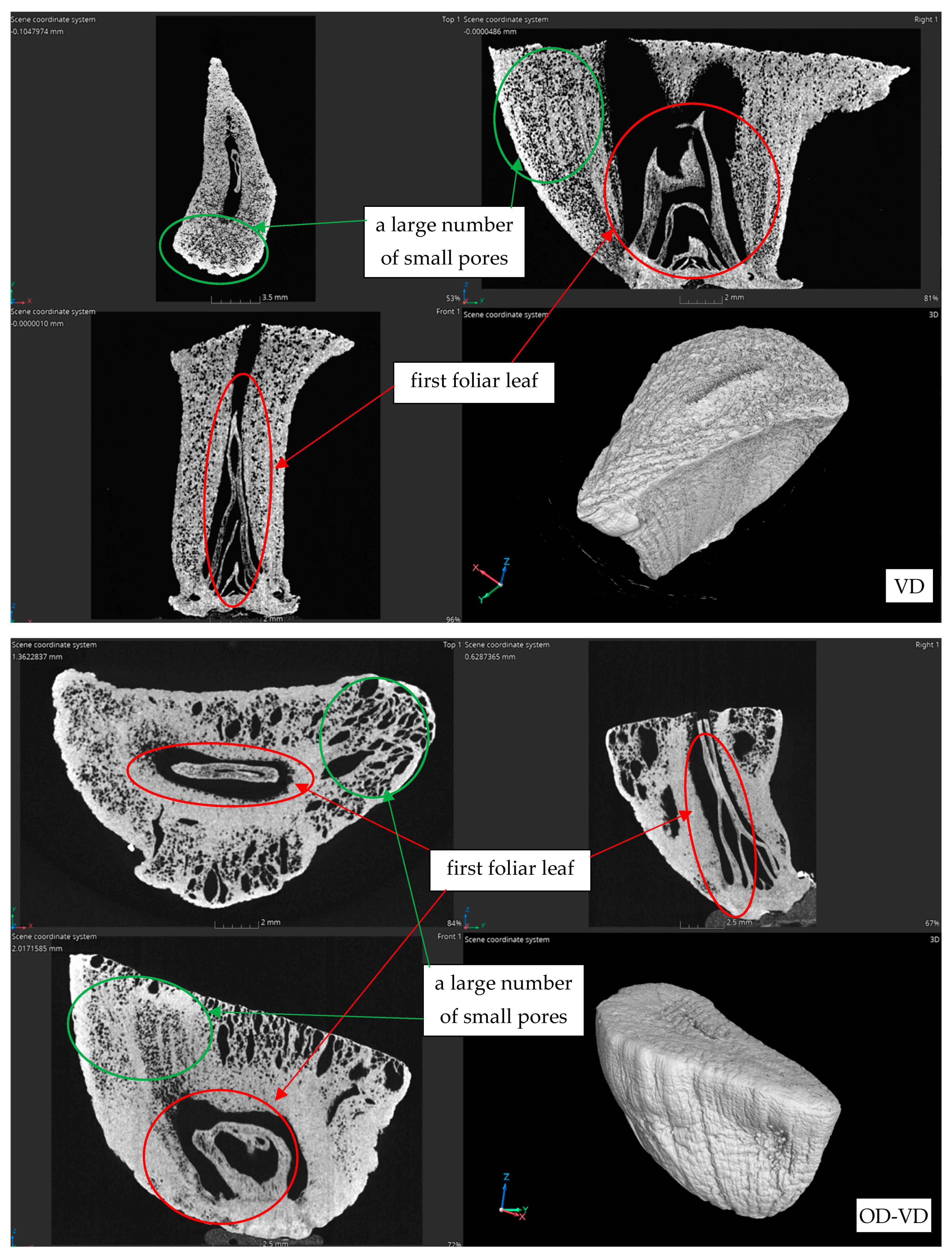

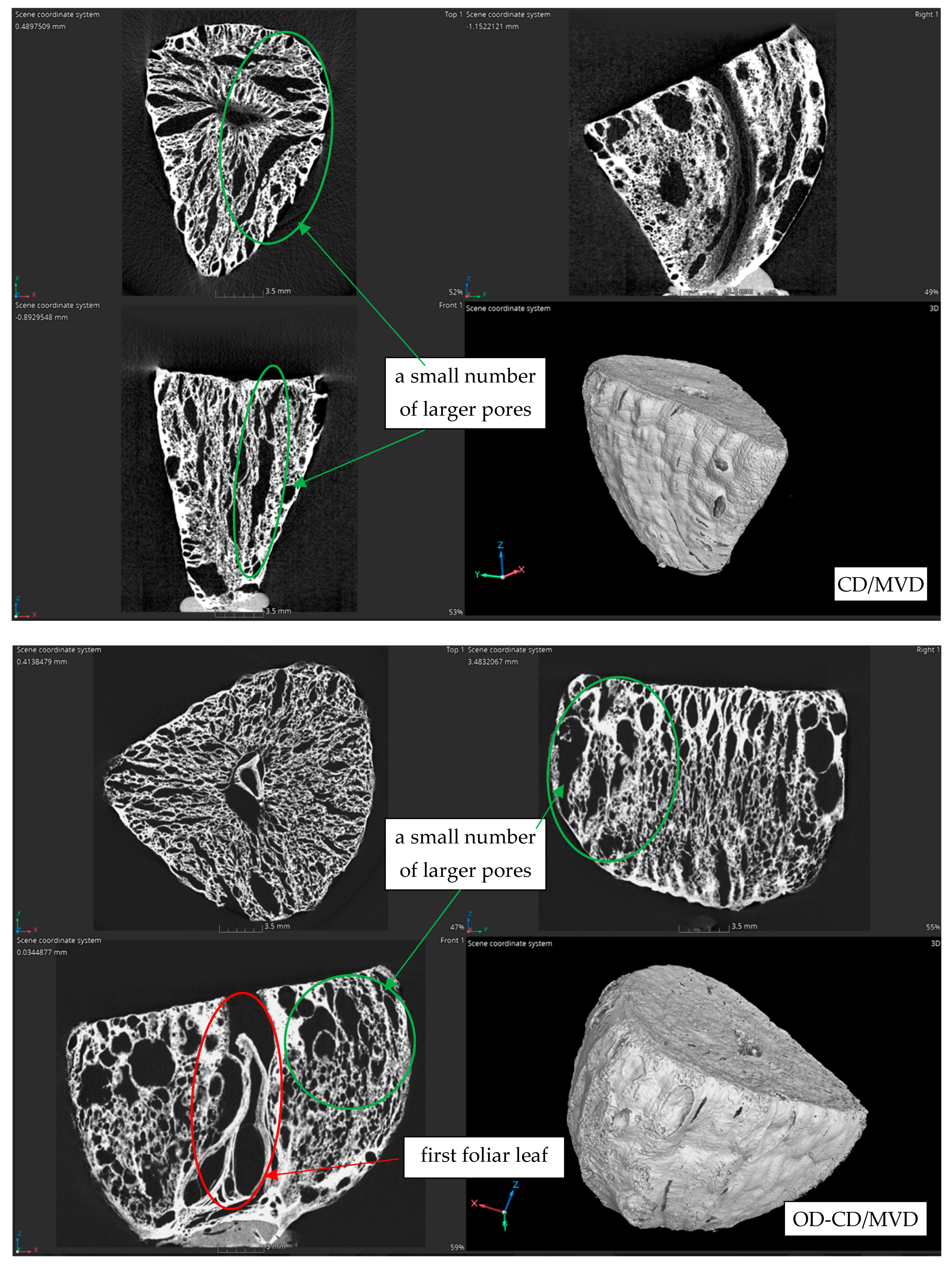

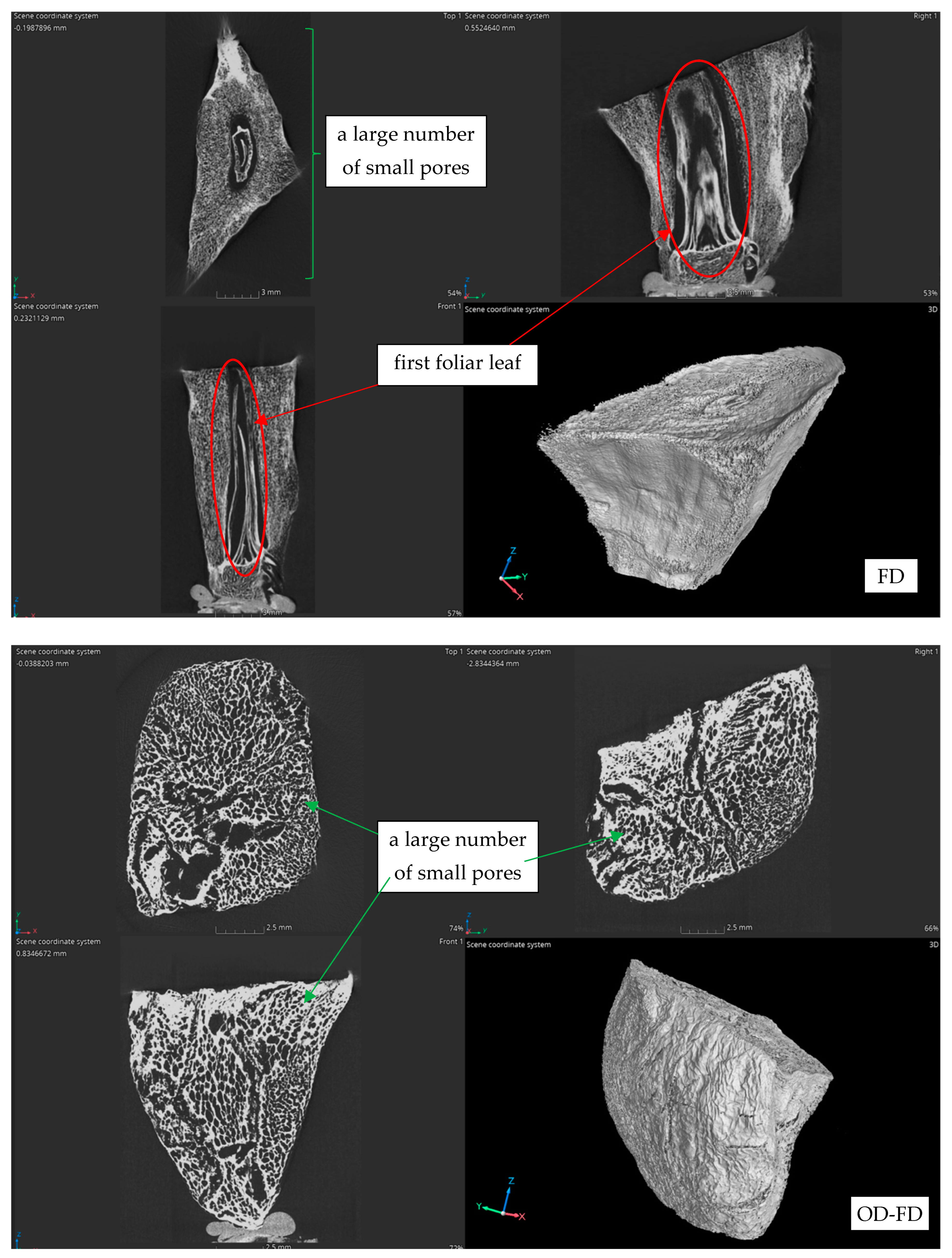

2.14. CT Scan Analysis

2.15. Statistical Analysis

3. Results and Discussion

3.1. Osmotic Dehydration

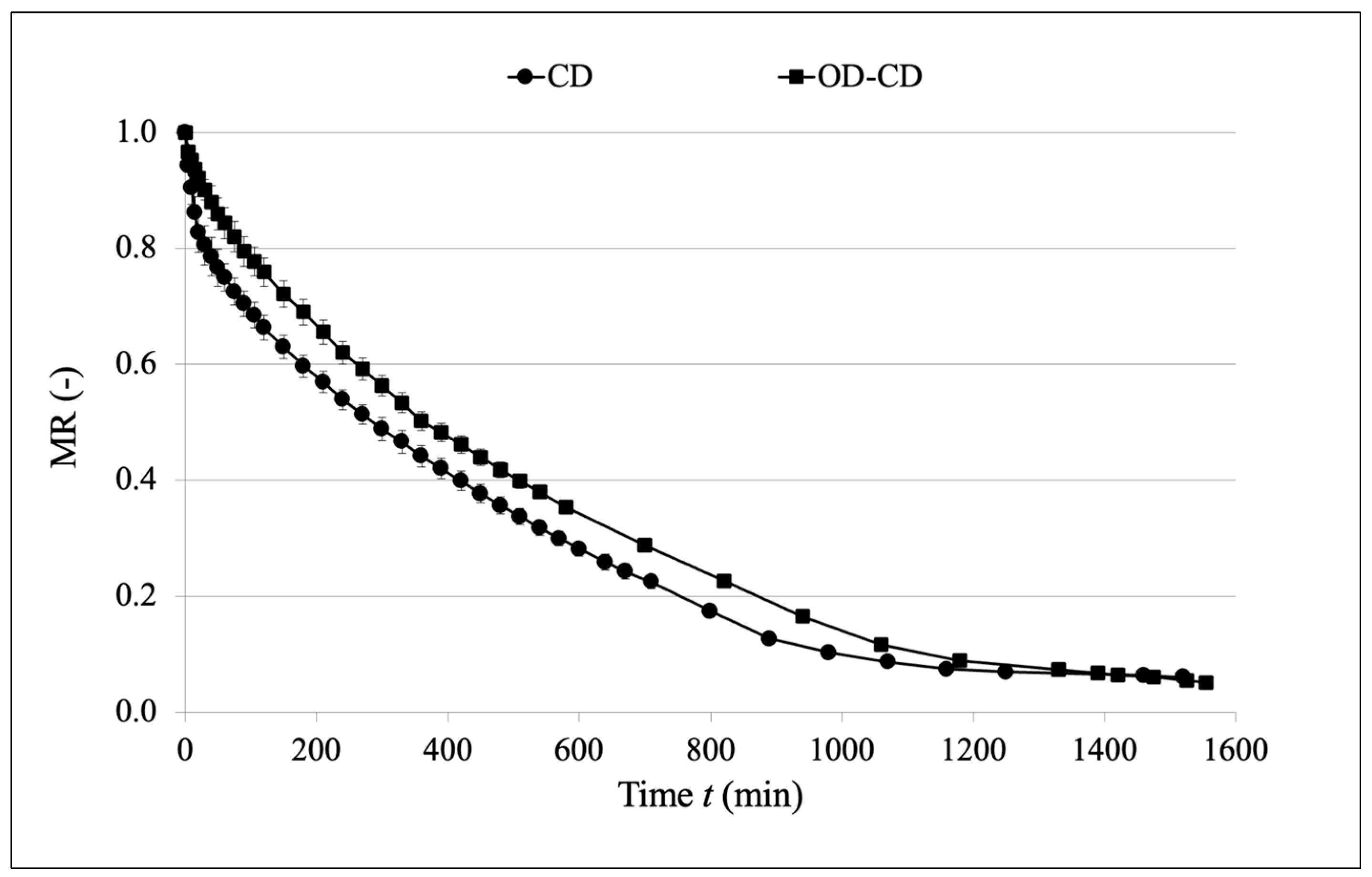

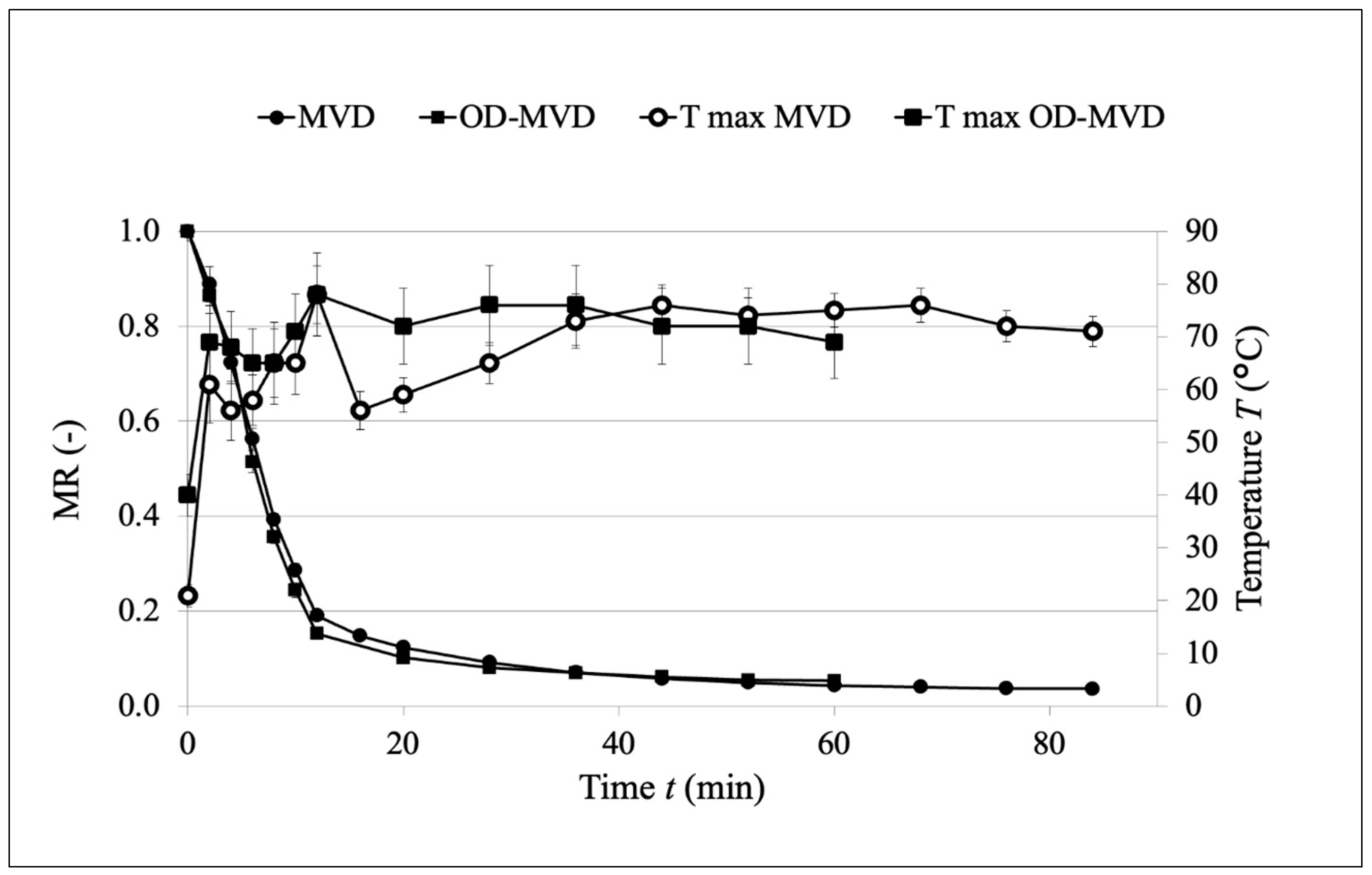

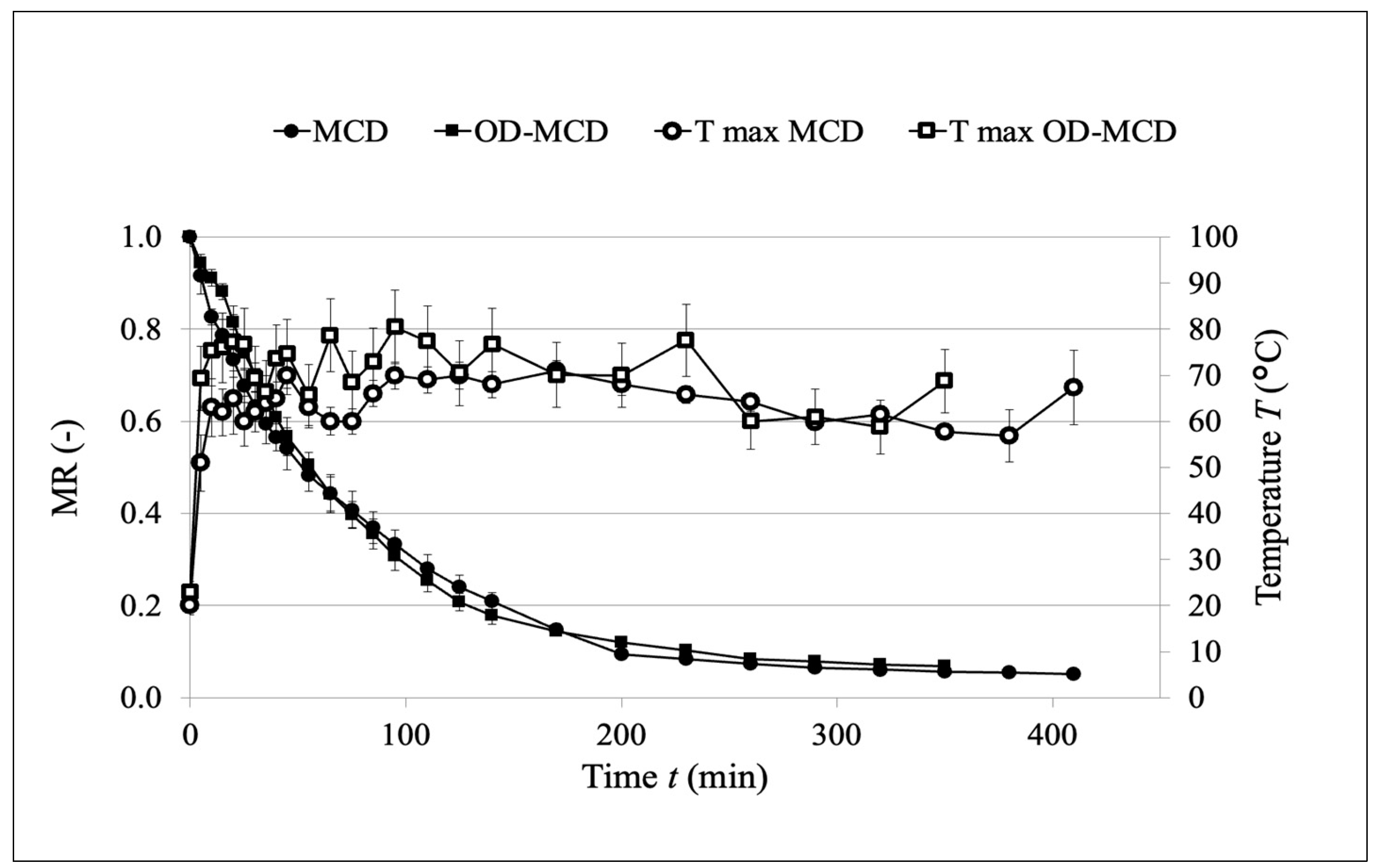

3.2. Drying Kinetics

3.3. Drying Model

3.4. Physical Properties of Dried Garlic

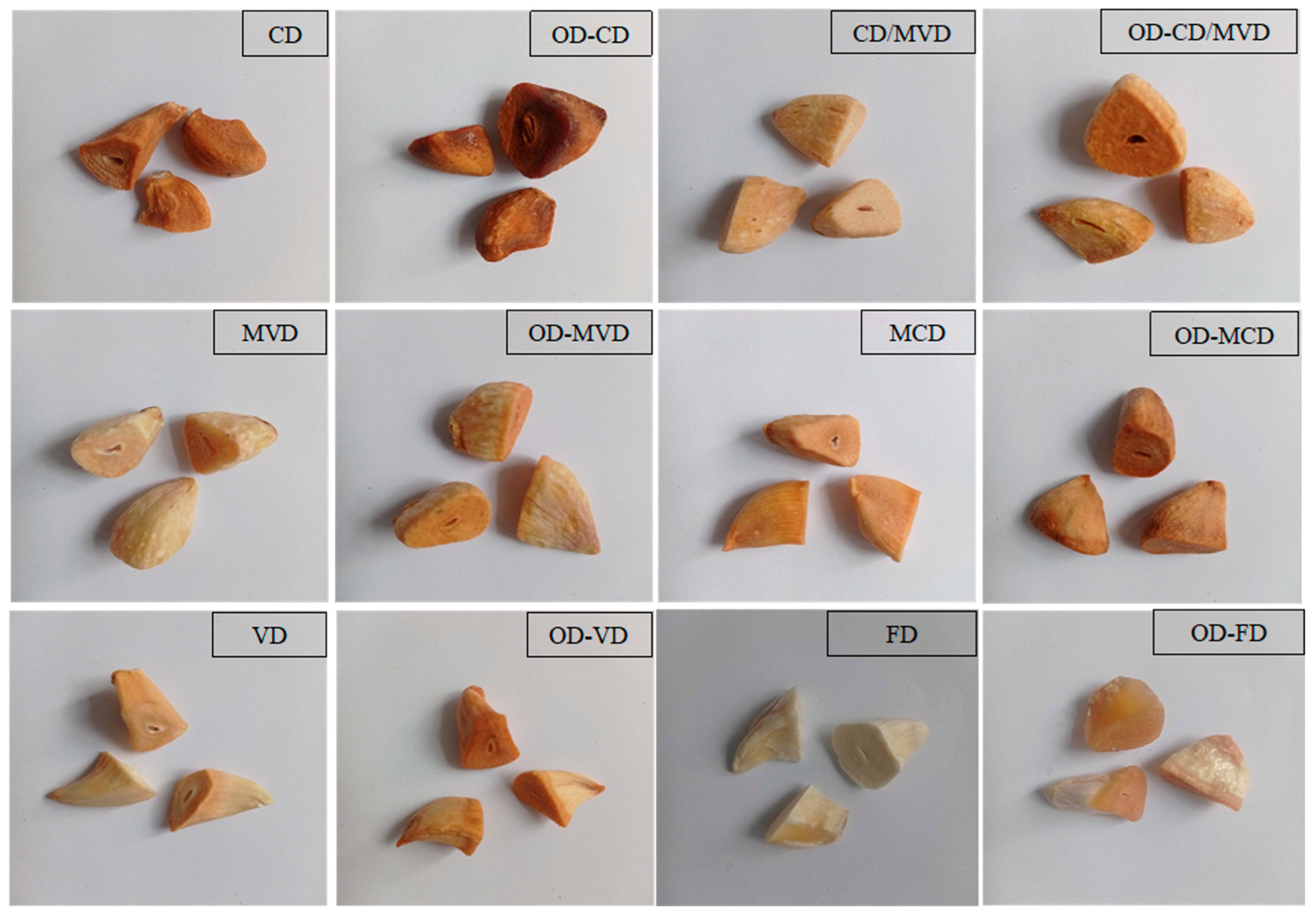

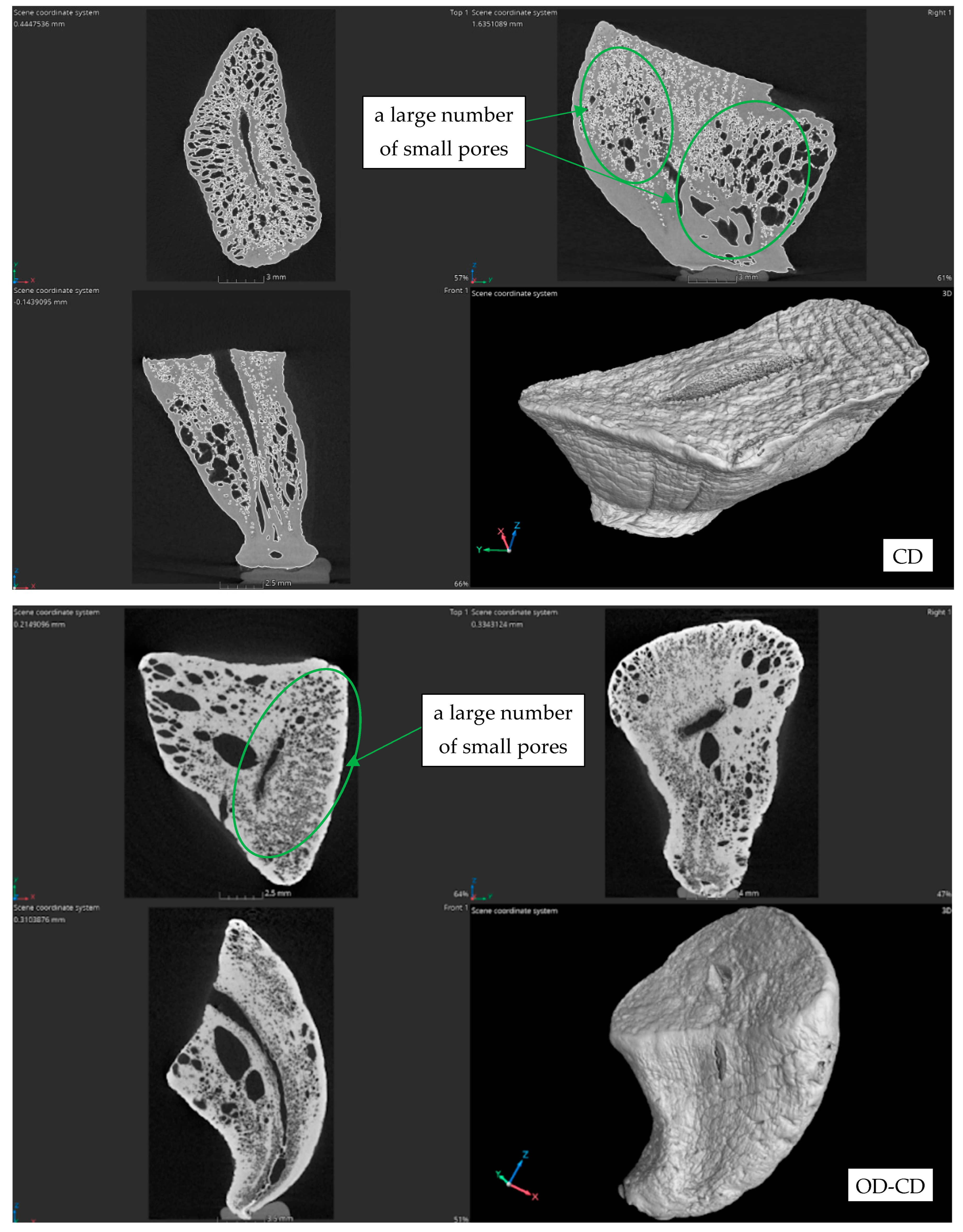

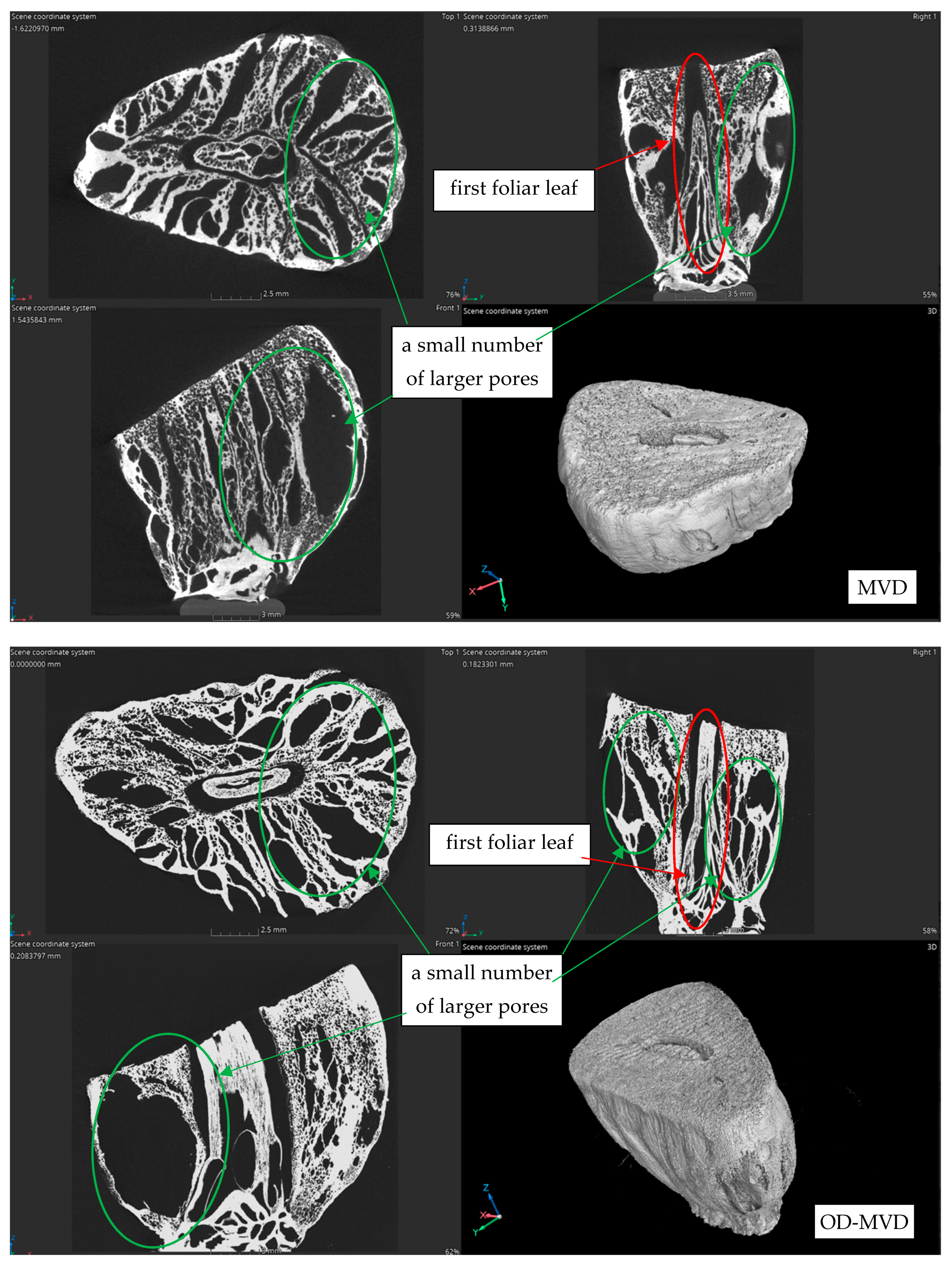

3.5. Structure and Texture

3.6. Energy Consumption and Specific Energy Consumption

4. Conclusions

- The process of osmotic dehydration in filtered concentrated tomato juice had a slight influence on the creation of the structure of the dried product. On the other hand, penetration of the substance from the juice into the garlic could significantly affect the chemical and sensory properties of the product, however, it requires more studies on the topic.

- Osmotic dehydration significantly increased the total color difference of the dried product compared to samples without osmotic dehydration for both the surface of the particles and the powder obtained from the dried product.

- Energy consumption during drying was significantly affected by the chosen drying method, while osmotic dehydration did not significantly affect energy consumption within the same drying method. Only a slight increase in the total processing time could be reported compared to the drying process without pretreatment.

- Based on drying kinetics, the Weibull model was fitted as the best-suited model for drying osmotically dehydrated and non-dehydrated garlic clove halves.

Future Perspectives and Practical Application

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Petrovska, B.; Cekovska, S. Extracts from the History and Medical Properties of Garlic. Pharmacogn. Rev. 2010, 4, 106. [Google Scholar] [CrossRef] [PubMed]

- Bhatwalkar, S.B.; Mondal, R.; Krishna, S.B.N.; Adam, J.K.; Govender, P.; Anupam, R. Antibacterial Properties of Organosulfur Compounds of Garlic (Allium sativum). Front. Microbiol. 2021, 12, 613077. [Google Scholar] [CrossRef]

- El-Saber Batiha, G.; Magdy Beshbishy, A.; G. Wasef, L.; Elewa, Y.H.A.; A. Al-Sagan, A.; Abd El-Hack, M.E.; Taha, A.E.; M. Abd-Elhakim, Y.; Prasad Devkota, H. Chemical Constituents and Pharmacological Activities of Garlic (Allium sativum L.): A Review. Nutrients 2020, 12, 872. [Google Scholar] [CrossRef]

- Shao, X.; Sun, C.; Tang, X.; Zhang, X.; Han, D.; Liang, S.; Qu, R.; Hui, X.; Shan, Y.; Hu, L.; et al. Anti-Inflammatory and Intestinal Microbiota Modulation Properties of Jinxiang Garlic (Allium sativum L.) Polysaccharides toward Dextran Sodium Sulfate-Induced Colitis. J. Agric. Food Chem. 2020, 68, 12295–12309. [Google Scholar] [CrossRef]

- Guan, M.-J.; Zhao, N.; Xie, K.-Q.; Zeng, T. Hepatoprotective Effects of Garlic against Ethanol-Induced Liver Injury: A Mini-Review. Food Chem. Toxicol. 2018, 111, 467–473. [Google Scholar] [CrossRef]

- Kuna, L.; Zjalic, M.; Kizivat, T.; Roguljic, H.; Nincevic, V.; Omanovic Kolaric, T.; Wu, C.H.; Vcev, A.; Smolic, M.; Smolic, R. Pretreatment of Garlic Oil Extracts Hampers Epithelial Damage in Cell Culture Model of Peptic Ulcer Disease. Medicina 2022, 58, 91. [Google Scholar] [CrossRef] [PubMed]

- Shang, A.; Cao, S.-Y.; Xu, X.-Y.; Gan, R.-Y.; Tang, G.-Y.; Corke, H.; Mavumengwana, V.; Li, H.-B. Bioactive Compounds and Biological Functions of Garlic (Allium sativum L.). Foods 2019, 8, 246. [Google Scholar] [CrossRef] [PubMed]

- Mathew, B.C.; Biju, R.S. Neuroprotective Effects of Garlic A Review. Libyan J. Med. 2008, 3, 23–33. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Dorrigiv, M.; Zareiyan, A.; Hosseinzadeh, H. Garlic (Allium sativum) as an Antidote or a Protective Agent against Natural or Chemical Toxicities: A Comprehensive Update Review. Phytother. Res. 2020, 34, 1770–1797. [Google Scholar] [CrossRef]

- Sah, R.; Singh, M.P.; Gohil, K.J. A Comprehensive Study of Allium sativum Linn. Curr. Funct. Foods 2024, 2, e291123224020. [Google Scholar] [CrossRef]

- Barreca, D.; Trombetta, D.; Smeriglio, A.; Mandalari, G.; Romeo, O.; Felice, M.R.; Gattuso, G.; Nabavi, S.M. Food Flavonols: Nutraceuticals with Complex Health Benefits and Functionalities. Trends Food Sci. Technol. 2021, 117, 194–204. [Google Scholar] [CrossRef]

- Yadav, A.K.; Singh, S.V. Osmotic Dehydration of Fruits and Vegetables: A Review. J. Food Sci. Technol. 2014, 51, 1654–1673. [Google Scholar] [CrossRef]

- Ashtiani, S.-H.M.; Aghkhani, M.H.; Feizy, J.; Martynenko, A. Effect of Cold Plasma Pretreatment Coupled with Osmotic Dehydration on Drying Kinetics and Quality of Mushroom (Agaricus bisporus). Food Bioprocess Technol. 2023, 16, 2854–2876. [Google Scholar] [CrossRef]

- Salehi, F. Recent Advances in the Ultrasound-Assisted Osmotic Dehydration of Agricultural Products: A Review. Food Biosci. 2023, 51, 102307. [Google Scholar] [CrossRef]

- Kowalska, H.; Marzec, A.; Kowalska, J.; Ciurzyńska, A.; Samborska, K.; Bialik, M.; Lenart, A. Rehydration Properties of Hybrid Method Dried Fruit Enriched by Natural Components. Int. Agrophysics 2018, 32, 175–182. [Google Scholar] [CrossRef]

- Tao, Y.; Zhang, J.; Jiang, S.; Xu, Y.; Show, P.-L.; Han, Y.; Ye, X.; Ye, M. Contacting Ultrasound Enhanced Hot-Air Convective Drying of Garlic Slices: Mass Transfer Modeling and Quality Evaluation. J. Food Eng. 2018, 235, 79–88. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Li, X.; Zhu, J.; Wang, X.; Ma, L. Drying Characteristics, Quality Changes, Parameters Optimization and Flavor Analysis for Microwave Vacuum Drying of Garlic (Allium sativum L.) Slices. LWT 2023, 173, 114372. [Google Scholar] [CrossRef]

- Calín-Sánchez, Á.; Figiel, A.; Wojdyło, A.; Szarycz, M.; Carbonell-Barrachina, Á.A. Drying of Garlic Slices Using Convective Pre-Drying and Vacuum-Microwave Finishing Drying: Kinetics, Energy Consumption, and Quality Studies. Food Bioprocess Technol. 2014, 7, 398–408. [Google Scholar] [CrossRef]

- Zhou, C.; Feng, Y.; Zhang, L.; Yagoub, A.E.A.; Wahia, H.; Ma, H.; Sun, Y.; Yu, X. Rehydration Characteristics of Vacuum Freeze- and Hot Air-Dried Garlic Slices. LWT 2021, 143, 111158. [Google Scholar] [CrossRef]

- Sharma, G.P.; Prasad, S. Effective Moisture Diffusivity of Garlic Cloves Undergoing Microwave-Convective Drying. J. Food Eng. 2004, 65, 609–617. [Google Scholar] [CrossRef]

- Sablani, S.S.; Rahman, M.S.; Al-Kuseibi, M.K.; Al-Habsi, N.A.; Al-Belushi, R.H.; Al-Marhubi, I.; Al-Amri, I.S. Influence of Shelf Temperature on Pore Formation in Garlic during Freeze-Drying. J. Food Eng. 2007, 80, 68–79. [Google Scholar] [CrossRef]

- Feng, Y.; Yu, X.; Yagoub, A.E.A.; Xu, B.; Wu, B.; Zhang, L.; Zhou, C. Vacuum Pretreatment Coupled to Ultrasound Assisted Osmotic Dehydration as a Novel Method for Garlic Slices Dehydration. Ultrason. Sonochemistry 2019, 50, 363–372. [Google Scholar] [CrossRef] [PubMed]

- Zimmer, A.; Masztalerz, K.; Lech, K. The Influence of the Pretreatment of Garlic (Allium sativum L.) and Tomato (Solanum lycopersicum L.) Osmotic Solution on Physical Properties of the Material. J. Food Process Eng. 2023, 46, e14314. [Google Scholar] [CrossRef]

- McCullough, M.L.; Giovannucci, E.L. Diet and Cancer Prevention. Oncogene 2004, 23, 6349–6364. [Google Scholar] [CrossRef] [PubMed]

- Shahrajabian, M.H.; Sun, W.; Cheng, Q. Chemical Components and Pharmacological Benefits of Basil (Ocimum basilicum): A Review. Int. J. Food Prop. 2020, 23, 1961–1970. [Google Scholar] [CrossRef]

- Sharma, G.P.; Prasad, S. Drying of Garlic (Allium sativum) Cloves by Microwave–Hot Air Combination. J. Food Eng. 2001, 50, 99–105. [Google Scholar] [CrossRef]

- Younis, M.; Abdelkarim, D.; Zein El-Abdein, A. Kinetics and Mathematical Modeling of Infrared Thin-Layer Drying of Garlic Slices. Saudi J. Biol. Sci. 2018, 25, 332–338. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Guo, X.; Bi, J.; Yi, J.; Chen, Q.; Wu, X.; Zhou, M. Drying of Garlic Slices (Allium sativum L.) and Its Effect on Thiosulfinates, Total Phenolic Compounds and Antioxidant Activity during Infrared Drying. J. Food Process. Preserv. 2017, 41, e12734. [Google Scholar] [CrossRef]

- von Horstig, M.-W.; Schoo, A.; Loellhoeffel, T.; Mayer, J.K.; Kwade, A. A Perspective on Innovative Drying Methods for Energy-Efficient Solvent-Based Production of Lithium-Ion Battery Electrodes. Energy Technol. 2022, 10, 2200689. [Google Scholar] [CrossRef]

- Masztalerz, K.; Łyczko, J.; Lech, K. Effect of Filtrated Osmotic Solution Based on Concentrated Chokeberry Juice and Mint Extract on the Drying Kinetics, Energy Consumption and Physicochemical Properties of Dried Apples. Molecules 2021, 26, 3274. [Google Scholar] [CrossRef]

- Noshad, M.; Savari, M.; Roueita, G. A Hybrid AHP-TOPSIS Method for Prospectively Modeling of Ultrasound-assisted Osmotic Dehydration of Strawberry. J. Food Process Eng. 2018, 41, e12928. [Google Scholar] [CrossRef]

- Calín-Sánchez, Á.; Lipan, L.; Cano-Lamadrid, M.; Kharaghani, A.; Masztalerz, K.; Carbonell-Barrachina, Á.A.; Figiel, A. Comparison of Traditional and Novel Drying Techniques and Its Effect on Quality of Fruits, Vegetables and Aromatic Herbs. Foods 2020, 9, 1261. [Google Scholar] [CrossRef] [PubMed]

- Turkiewicz, I.P.; Wojdyło, A.; Tkacz, K.; Lech, K.; Nowicka, P. Osmotic Dehydration as a Pretreatment Modulating the Physicochemical and Biological Properties of the Japanese Quince Fruit Dried by the Convective and Vacuum-Microwave Method. Food Bioprocess Technol. 2020, 13, 1801–1816. [Google Scholar] [CrossRef]

- Masztalerz, K.; Dróżdż, T.; Nowicka, P.; Wojdyło, A.; Kiełbasa, P.; Lech, K. The Effect of Nonthermal Pretreatment on the Drying Kinetics and Quality of Black Garlic. Molecules 2023, 28, 962. [Google Scholar] [CrossRef] [PubMed]

- Alibas, I. Characteristics of Chard Leaves during Microwave, Convective, and Combined Microwave-Convective Drying. Dry. Technol. 2006, 24, 1425–1435. [Google Scholar] [CrossRef]

- Kaya, A.; Aydın, O.; Demirtaş, C. Drying Kinetics of Red Delicious Apple. Biosyst. Eng. 2007, 96, 517–524. [Google Scholar] [CrossRef]

- Macedo, L.L.; Vimercati, W.C.; da Silva Araújo, C.; Saraiva, S.H.; Teixeira, L.J.Q. Effect of Drying Air Temperature on Drying Kinetics and Physicochemical Characteristics of Dried Banana. J. Food Process Eng. 2020, 43, e13451. [Google Scholar] [CrossRef]

- Toğrul, İ.T.; Pehlivan, D. Modelling of Drying Kinetics of Single Apricot. J. Food Eng. 2003, 58, 23–32. [Google Scholar] [CrossRef]

- Babalis, S.J.; Papanicolaou, E.; Kyriakis, N.; Belessiotis, V.G. Evaluation of Thin-Layer Drying Models for Describing Drying Kinetics of Figs (Ficus carica). J. Food Eng. 2006, 75, 205–214. [Google Scholar] [CrossRef]

- Lech, K.; Figiel, A.; Michalska, A.; Wojdyło, A.; Nowicka, P. The Effect of Selected Fruit Juice Concentrates Used as Osmotic Agents on the Drying Kinetics and Chemical Properties of Vacuum-Microwave Drying of Pumpkin. J. Food Qual. 2018, 2018, 7293932. [Google Scholar] [CrossRef]

- Lech, K.; Jursova, S.; Kobel, P.; Pustejovska, P.; Bilik, J.; Figiel, A.; Romański, L. The Relation between CRI, CSR Indexes, Chemical Composition and Physical Parameters of Commercial Metallurgical Cokes. Ironmak. Steelmak. 2019, 46, 124–132. [Google Scholar] [CrossRef]

- Figiel, A.; Tajner-Czopek, A. The Effect of Candy Moisture Content on Texture. J. Foodserv. 2006, 17, 189–195. [Google Scholar] [CrossRef]

- Chua, L.Y.W.; Chua, B.L.; Figiel, A.; Chong, C.H.; Wojdyło, A.; Szumny, A.; Lech, K. Characterisation of the Convective Hot-Air Drying and Vacuum Microwave Drying of Cassia alata: Antioxidant Activity, Essential Oil Volatile Composition and Quality Studies. Molecules 2019, 24, 1625. [Google Scholar] [CrossRef] [PubMed]

- da Silva, W.P.; da Silva e Silva, C.M.D.P.; de Farias Aires, J.E.; da Silva Junior, A.F. Osmotic Dehydration and Convective Drying of Coconut Slices: Experimental Determination and Description Using One-Dimensional Diffusion Model. J. Saudi Soc. Agric. Sci. 2014, 13, 162–168. [Google Scholar] [CrossRef]

- Kroehnke, J.; Szadzińska, J.; Radziejewska-Kubzdela, E.; Biegańska-Marecik, R.; Musielak, G.; Mierzwa, D. Osmotic Dehydration and Convective Drying of Kiwifruit (Actinidia deliciosa)—The Influence of Ultrasound on Process Kinetics and Product Quality. Ultrason. Sonochemistry 2021, 71, 105377. [Google Scholar] [CrossRef] [PubMed]

- Pavkov, I.; Radojčin, M.; Stamenković, Z.; Kešelj, K.; Tylewicz, U.; Sipos, P.; Ponjičan, O.; Sedlar, A. Effects of Osmotic Dehydration on the Hot Air Drying of Apricot Halves: Drying Kinetics, Mass Transfer, and Shrinkage. Processes 2021, 9, 202. [Google Scholar] [CrossRef]

- Igual, M.; García-Martínez, E.; Martín-Esparza, M.E.; Martínez-Navarrete, N. Effect of Processing on the Drying Kinetics and Functional Value of Dried Apricot. Food Res. Int. 2012, 47, 284–290. [Google Scholar] [CrossRef]

- Deliana, Y.; Wulandari, E.; Salam, I.M. Study the Rate of Drying and Level of Osmosis Dehydration on Physical Properties of Dried Mango Cengkir. IOP Conf. Ser. Earth Environ. Sci. 2020, 443, 012098. [Google Scholar] [CrossRef]

- Zhang, J.; Li, M.; Cheng, J.; Wang, J.; Ding, Z.; Yuan, X.; Zhou, S.; Liu, X. Effects of Moisture, Temperature, and Salt Content on the Dielectric Properties of Pecan Kernels During Microwave and Radio Frequency Drying Processes. Foods 2019, 8, 385. [Google Scholar] [CrossRef]

- Bai, B.; Li, L.; Hu, X.; Wang, Z.; Zhao, G. Increase in the Permeability of Tonoplast of Garlic (Allium sativum) by Monocarboxylic Acids. J. Agric. Food Chem. 2006, 54, 8103–8107. [Google Scholar] [CrossRef]

- Rahman, M.S.; Al-Shamsi, Q.H.; Bengtsson, G.B.; Sablani, S.S.; Al-Alawi, A. Drying Kinetics and Allicin Potential in Garlic Slices during Different Methods of Drying. Dry. Technol. 2009, 27, 467–477. [Google Scholar] [CrossRef]

- Ju, H.-Y.; Zhao, S.-H.; Mujumdar, A.S.; Fang, X.-M.; Gao, Z.-J.; Zheng, Z.-A.; Xiao, H.-W. Energy Efficient Improvements in Hot Air Drying by Controlling Relative Humidity Based on Weibull and Bi-Di Models. Food Bioprod. Process. 2018, 111, 20–29. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, Y.; Han, F.; Zhang, Y.; Wang, G.; Wu, Z.; Wu, W. Control Method for Continuous Grain Drying Based on Equivalent Accumulated Temperature Mechanism and Artificial Intelligence. Foods 2022, 11, 834. [Google Scholar] [CrossRef] [PubMed]

- Boateng, I.D.; Yang, X.-M.; Tahany, A.A.A.; Li, Y.-Y.; Yolandani. Drying Methods Affect Organoleptic and Physicochemical Properties of Rehydrated Ginkgo Seed Slices. Ind. Crops Prod. 2021, 160, 113166. [Google Scholar] [CrossRef]

- Yang, X.-H.; Deng, L.-Z.; Mujumdar, A.S.; Xiao, H.-W.; Zhang, Q.; Kan, Z. Evolution and Modeling of Colour Changes of Red Pepper (Capsicum annuum L.) during Hot Air Drying. J. Food Eng. 2018, 231, 101–108. [Google Scholar] [CrossRef]

- Issis, Q.-F.; Antonio, V.-G.; Elsa, U.; Valeria, V.; Nicole, C.; Jacqueline, P. Vacuum Drying Application to Maqui (Aristotelia chilensis [Mol] Stuntz) Berry: Weibull Distribution for Process Modelling and Quality Parameters. J. Food Sci. Technol. 2019, 56, 1899–1908. [Google Scholar] [CrossRef] [PubMed]

- Pashazadeh, H.; Zannou, O.; Koca, I. Modeling and Optimization of Drying Conditions of Dog Rose for Preparation of a Functional Tea. J. Food Process Eng. 2021, 44, e13632. [Google Scholar] [CrossRef]

- Zheng, Z.-A.; Wang, S.-Y.; Wang, H.; Xiao, H.; Liu, Z.-L.; Pan, Y.-H.; Gao, L. Comparative Study on the Influence of Various Drying Techniques on Drying Characteristics and Physicochemical Quality of Garlic Slices. Foods 2023, 12, 1314. [Google Scholar] [CrossRef] [PubMed]

- Yue, Y.; Zhang, Q.; Wan, F.; Ma, G.; Zang, Z.; Xu, Y.; Jiang, C.; Huang, X. Effects of Different Drying Methods on the Drying Characteristics and Quality of Codonopsis pilosulae Slices. Foods 2023, 12, 1323. [Google Scholar] [CrossRef]

- Auleda, J.M.; Raventós, M.; Sánchez, J.; Hernández, E. Estimation of the Freezing Point of Concentrated Fruit Juices for Application in Freeze Concentration. J. Food Eng. 2011, 105, 289–294. [Google Scholar] [CrossRef]

- Ratti, C. Hot Air and Freeze-Drying of High-Value Foods: A Review. J. Food Eng. 2001, 49, 311–319. [Google Scholar] [CrossRef]

- Chawla, A.S.; Kasler, D.R.; Sastry, S.K.; Yousef, A.E. Microbial Decontamination of Food Using Ozone. In Microbial Decontamination in the Food Industry; Elsevier: Amsterdam, The Netherlands, 2012; pp. 495–532. ISBN 978-0-85709-085-0. [Google Scholar]

- Melgosa, M.; Hita, E.; Poza, A.J.; Alman, D.H.; Berns, R.S. Suprathreshold Color-Difference Ellipsoids for Surface Colors. Color Res. Appl. 1997, 22, 148–155. [Google Scholar] [CrossRef]

- Dong, W.; Cheng, K.; Hu, R.; Chu, Z.; Zhao, J.; Long, Y. Effect of Microwave Vacuum Drying on the Drying Characteristics, Color, Microstructure, and Antioxidant Activity of Green Coffee Beans. Molecules 2018, 23, 1146. [Google Scholar] [CrossRef] [PubMed]

- Curcio, S.; Aversa, M. Influence of Shrinkage on Convective Drying of Fresh Vegetables: A Theoretical Model. J. Food Eng. 2014, 123, 36–49. [Google Scholar] [CrossRef]

- Rodríguez-Ramírez, J.; Méndez-Lagunas, L.; López-Ortiz, A.; Torres, S.S. True Density and Apparent Density During the Drying Process for Vegetables and Fruits: A Review. J. Food Sci. 2012, 77, R146–R154. [Google Scholar] [CrossRef] [PubMed]

- Yan, W.-Q.; Zhang, M.; Huang, L.-L.; Mujumdar, A.S.; Tang, J. Influence of Microwave Drying Method on the Characteristics of the Sweet Potato Dices: Microwave Drying on Sweet Potato Dices. J. Food Process. Preserv. 2013, 37, 662–669. [Google Scholar] [CrossRef]

- Nieto, A.B.; Salvatori, D.M.; Castro, M.A.; Alzamora, S.M. Structural Changes in Apple Tissue during Glucose and Sucrose Osmotic Dehydration: Shrinkage, Porosity, Density and Microscopic Features. J. Food Eng. 2004, 61, 269–278. [Google Scholar] [CrossRef]

- Thuwapanichayanan, R.; Prachayawarakorn, S.; Soponronnarit, S. Heat and Moisture Transport Behaviour and Quality of Chopped Garlic Undergoing Different Drying Methods. J. Food Eng. 2014, 136, 34–41. [Google Scholar] [CrossRef]

- Keselj, K.; Pavkov, I.; Radojcin, M.; Stamenkovic, Z. Comparison of Energy Consumption in the Convective and Freeze Drying of Raspberries. J. Process Energy Agric. 2017, 21, 192–196. [Google Scholar] [CrossRef]

- Motevali, A.; Minaei, S.; Khoshtagaza, M.H. Evaluation of Energy Consumption in Different Drying Methods. Energy Convers. Manag. 2011, 52, 1192–1199. [Google Scholar] [CrossRef]

- Khaing Hnin, K.; Zhang, M.; Mujumdar, A.S.; Zhu, Y. Emerging Food Drying Technologies with Energy-Saving Characteristics: A Review. Dry. Technol. 2019, 37, 1465–1480. [Google Scholar] [CrossRef]

| Pretreatment | Drying Method | Mc | Aw | ΔE | ||

|---|---|---|---|---|---|---|

| Surface | Center | Powder | ||||

| - | CD | 10.01 ± 1.27 c,d,* | 0.305 ± 0.007 d,e | 29.78 ± 1.22 c–e | 30.05 ± 3.90 a | 16.65 ± 0.26 g |

| OD † | CD | 10.78 ± 0.74 d | 0.333 ± 0.007 e | 37.09 ± 4.28 e | 44.91 ± 1.51 e | 20.43 ± 1.33 h |

| - | MVD | 6.39 ± 0.32 a,b | 0.243 ± 0.008 b,c | 9.40 ± 3.71 fg | 16.17 ± 4.13 c | 8.39 ± 0.27 a–c |

| OD | MVD | 6.3 ± 0.03 a,b | 0.277 ± 0.006 b–d | 16.29 ± 0.72 a,b | 30.12 ± 0.75 a | 12.67 ± 0.07 d, e |

| - | MCD | 8.67 ± 0.24 b–d | 0.297 ± 0.006 d,e | 23.74 ± 0.40 a–d | 22.84 ± 1.08 d | 5.12 ± 0.11 b |

| OD | MCD | 8.03 ± 0.94 a–d | 0.277 ± 0.013 b–d | 29.41 ± 1.61 c–e | 33.82 ± 0.33 a | 10.17 ± 0.45 a–d |

| - | VD | 8.04 ± 1.05 a–d | 0.281 ± 0.005 c,d | 18.06 ± 1.48 a,b | 12.81 ± 0.71 b, c | 9.87 ± 0.54 a |

| OD | VD | 7.73 ± 0.41a–c | 0.276 ± 0.018 b–d | 30.50 ± 3.17 d,e | 33.81 ± 0.71 a | 15.77 ± 0.43 f,g |

| - | CD/MVD | 5.23 ± 0.36 a | 0.194 ± 0.008 a | 17.98 ± 5.02 a,b | 10.54 ± 2.32 b, c | 6.85 ± 0.03 b,c |

| OD | CD/MVD | 5.67 ± 0.556 a | 0.241 ± 0.009 b | 22.18 ± 2.27 a–c | 33.96 ± 0.47 a | 10.65 ± 0.30 a–d |

| - | FD | 7.93 ± 1.05 a–d | 0.273 ± 0.011 b–d | 5.73 ± 2.00 f | 7.74 ± 0.42 b | 6.75 ± 0.74 b,c |

| OD | FD | 16.00 ± 0.71 e | 0.394 ± 0.012f | 10.44 ± 0.53 b–g | 31.94 ± 0.52 a | 13.46 ± 2.17 e,f |

| Pre- Treatment | Drying Method | Apparent Density | True Density | Pycnometer Density | Total Porosity | Open Porosity | Closed Porosity | Hardness | Cohesiveness |

|---|---|---|---|---|---|---|---|---|---|

| - | Fresh | 1.233 ± 0.021 | 1.444 ± 0.013 | 1.334 ± 0.059 | 14.7 ± 0.7 | 7.5 ± 2.5 | 7.1 ± 3.8 | - | - |

| - | CD | 0.885 ± 0.002 h,* | 1.465 ± 0.001 b | 1.245 ± 0.0.75 b | 39.6 ± 0.2 h | 28.8 ± 4.1 a | 10.8 ± 4.32 a | 707 ± 32 e | 0.144 ± 0.010 b |

| OD † | CD | 0.684 ± 0.002 e | 1.456 ± 0.004 b | 1.245 ± 0.107 b | 53.0 ± 0.6 d,e | 44.9 ± 4.9 b–d | 8.2 ± 4.9 a | 691 ± 15 e | 0.219 ± 0.010 c |

| - | MVD | 0.538 ± 0.001 b | 1.408 ± 0.001 a,b | 1.113 ± 0.110 a,b | 61.8 ± 0.6 g–i | 51.4 ± 4.8 c,d | 10.4 ± 4.8 a | 79 ± 7 a,b | 0.001 ± 0.001 a |

| OD | MVD | 0.497 ± 0.003 a | 1.465 ± 0.040 b | 1.214 ± 0.0250 b | 66.0 ± 1.2 i | 59.0 ± 0.6 d | 7.0 ± 1.7 a | 89 ± 6 a,b | 0.003 ± 0.001 a |

| - | MCD | 0.629 ± 0.009 d | 1.404 ± 0.061 a,b | 0.987 ± 0.070 a,b | 55.2 ± 1.3 e,f | 36.1 ± 5.5 b,c | 19.1 ± 6.8 a,b | 148 ± 12 c,d | 0.006 ± 0.001 a |

| OD | MCD | 0.714 ± 0.001 e, f | 1.304 ± 0.054 a | 0.818 ± 0.083 a | 45.2 ± 2.3 c | 12.3 ± 8.8 a | 32.9 ± 11.2 b | 149 ± 22 c,d | 0.005 ± 0.001 a |

| - | VD | 0.581 ± 0.003 c | 1.436 ± 0.009 a,b | 1.107 ± 0.102 a,b | 59.5 ± 0.1 f–h | 59.0 ± 0.5 c,d | 0.5 ± 0.6 a | 151 ± 14 c,d | 0.002 ± 0.001 a |

| OD | VD | 0.644 ± 0.002 d | 1.458 ± 0.018 b | 1.231 ± 0.067 b | 55.8 ± 0.4 e,f | 50.9 ± 3.3 c,d | 4.9 ± 2.9 a | 173 ± 15 d | 0.010 ± 0.001 a |

| - | CD/MVD | 0.503 ± 0.001 a | 1.388 ± 0.017 a,b | 1.033 ± 0.045 a,b | 63.8 ± 0.4 h,i | 51.3 ± 2.0 b–d | 12.5 ± 1.6 a,b | 49 ± 10 a | 0.002 ± 0.001 a |

| OD | CD/MVD | 0.583 ± 0.001 c | 1.381 ± 0.088 a,b | 1.197 ± 0.122 a,b | 57.7 ± 2.6 f,g | 51.0 ± 5.0 c,d | 6.7 ± 2.3 a,b | 86 ± 5 a–c | 0.006 ± 0.004 a |

| - | FD | 0.724 ± 0.015 f,g | 1.377 ± 0.014 a,b | 1.190 ± 0.132 a,b | 47.4 ± 0.6 c | 39.1 ± 1.27 b,c | 4.4 ± 1.5 a | 132 ± 31 b–d | 0.010 ± 0.010 a |

| OD | FD | 0.750 ± 0.002 g | 1.456 ± 0.024 b | 1.195 ± 0.082 a,b | 48.5 ± 0.7 c,d | 37.2 ± 0.18 b,c | 6.6 ± 0.8 a | 133 ± 10 b–d | 0.200 ± 0.059 b,c |

| Pre-Treatment | Drying | Energy Consumption, kJ | Specific Energy Consumption, kJ⋅g−1 | Total Time, min |

|---|---|---|---|---|

| - | CD | 31.920 ± 594 c,* | 911 ± 17 c | 1520 ± 28 f |

| OD † | CD | 32.997 ± 594 c | 942 ± 17 c | 1645 ± 28 g |

| - | MVD | 4337 ± 195 a | 118 ± 5 a | 84 ± 4 a |

| OD | MVD | 3574 ± 195 a | 95 ± 5 a | 150 ± 4 a,b |

| - | MCD | 10.268 ± 354 b | 283 ± 10 b | 410 ± 14 d |

| OD | MCD | 9107 ± 177 b | 245 ± 5 b | 440 ± 7 d |

| - | VD | 50.040 ± 1018 d | 1375 ± 28 d | 1390 ± 28 e |

| OD | VD | 50.382 ± 1018 d | 1387 ± 28 d | 1480 ± 28 e,f |

| - | CD/MVD | 7012 ± 195 a, b | 192 ± 5 a,b | 240 ± 4 b,c |

| OD | CD/MVD | 7013 ± 195 a, b | 182 ± 5 a,b | 326 ± 4 c,d |

| - | FD | 105.926 ± 2081 e | 2922 ± 57 e | 2880 ± 57 h |

| OD | FD | 106.268 ± 2081 e | 3362 ± 66 f | 2970 ± 57 h |

| Pretreatment | Drying | Constants | Statistics | ||||

|---|---|---|---|---|---|---|---|

| a | b | k | n | RMSE | R2 | ||

| CD | −0.3065 | −1.2749 | 0.0132 | 0.6349 | 0.021 | 0.9942 | |

| OD † | CD | −0.1091 | −1.0867 | 0.0036 | 0.8595 | 0.0105 | 0.9989 |

| MVD | 0.0581 | −0.9486 | 0.0502 | 1.4383 | 0.0225 | 0.9946 | |

| OD | MVD | 0.0692 | −0.9179 | 0.0306 | 1.7428 | 0.0218 | 0.9954 |

| MCD | 0.0225 | −0.9736 | 0.0249 | 0.8497 | 0.0126 | 0.9981 | |

| OD | MCD | 0.0729 | −0.9329 | 0.0088 | 1.1128 | 0.0103 | 0.9989 |

| VD | 0.044 | −0.9563 | 0.0039 | 0.9829 | 0.0063 | 0.9994 | |

| OD | VD | 0.0534 | −0.9471 | 0.0032 | 0.9995 | 0.0045 | 0.9997 |

| CD/MVD | 0.0389 | −0.5496 | 0.0401 | 1.6687 | 0.0053 | 0.9992 | |

| OD | CD/MVD | 0.0619 | −0.6194 | 0.0445 | 1.6638 | 0.0185 | 0.9958 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zimmer, A.; Masztalerz, K.; Lech, K. Effect of Osmotic Dehydration in Tomato Juice on Microstructure of Garlic and on Drying Using Different Methods. Agriculture 2024, 14, 1164. https://doi.org/10.3390/agriculture14071164

Zimmer A, Masztalerz K, Lech K. Effect of Osmotic Dehydration in Tomato Juice on Microstructure of Garlic and on Drying Using Different Methods. Agriculture. 2024; 14(7):1164. https://doi.org/10.3390/agriculture14071164

Chicago/Turabian StyleZimmer, Aleksandra, Klaudia Masztalerz, and Krzysztof Lech. 2024. "Effect of Osmotic Dehydration in Tomato Juice on Microstructure of Garlic and on Drying Using Different Methods" Agriculture 14, no. 7: 1164. https://doi.org/10.3390/agriculture14071164

APA StyleZimmer, A., Masztalerz, K., & Lech, K. (2024). Effect of Osmotic Dehydration in Tomato Juice on Microstructure of Garlic and on Drying Using Different Methods. Agriculture, 14(7), 1164. https://doi.org/10.3390/agriculture14071164