Research and Prediction of Wear Characteristics of Alfalfa Densification Die Based on the Discrete Element Method

Abstract

:1. Introduction

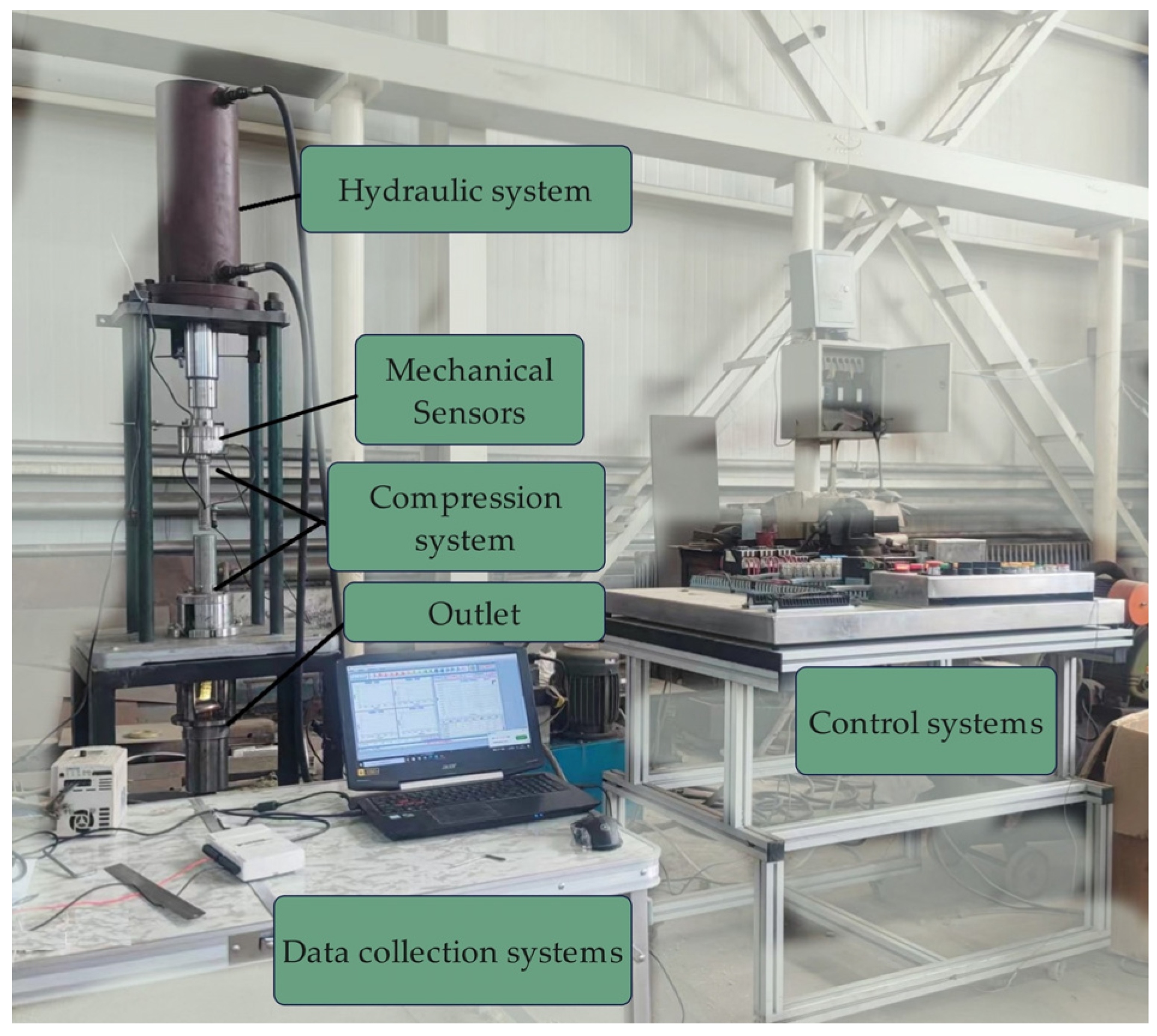

2. Materials and Methods

2.1. Materials

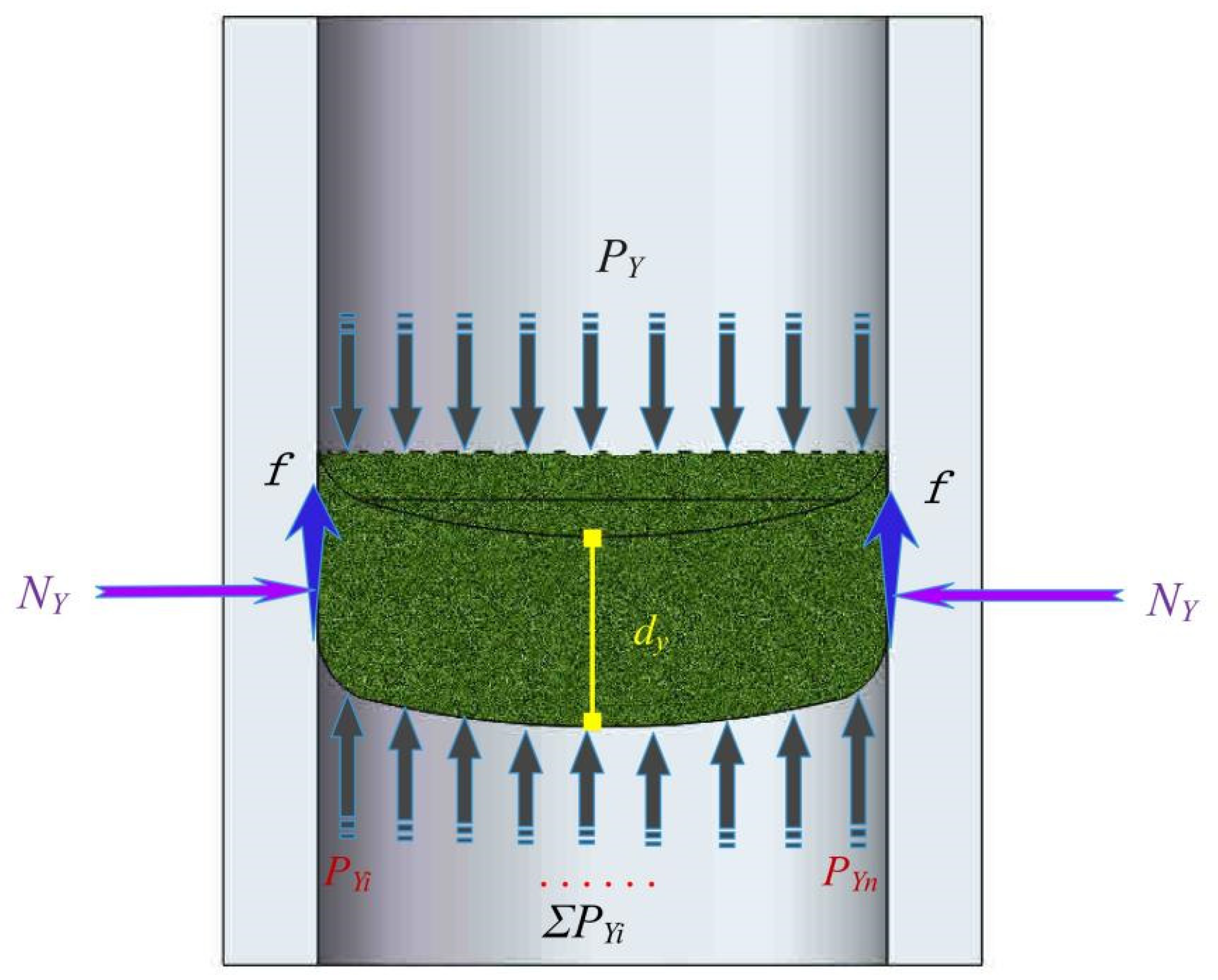

2.2. Experimental Principles

3. Discrete Element Simulation Experiment

3.1. Interaction Model

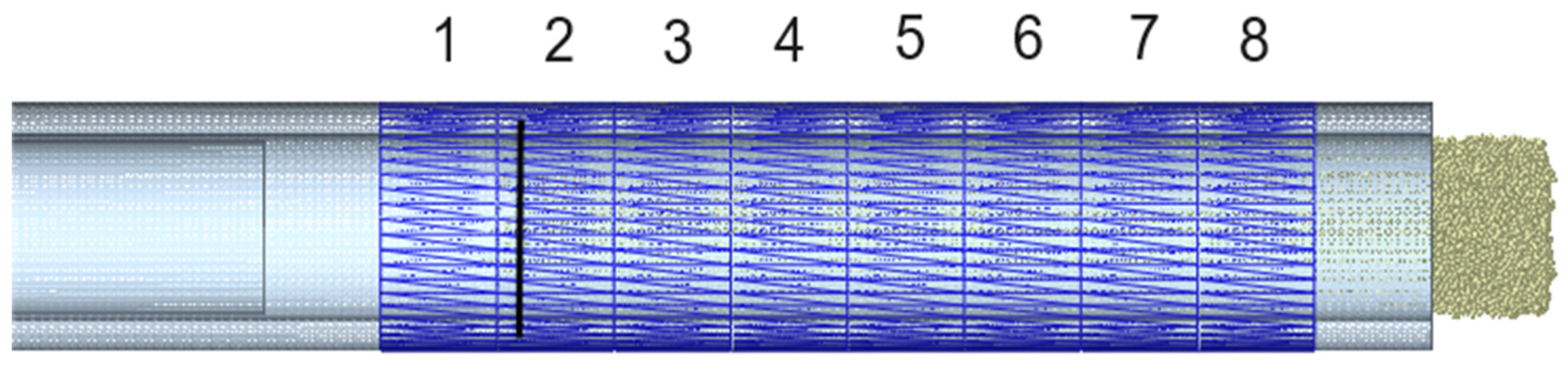

3.2. Particle Model and Die Model

3.3. Particle Model and Die Model

3.4. DEM Parameter Settings

4. Results and Discussion

4.1. Die Wear Analysis

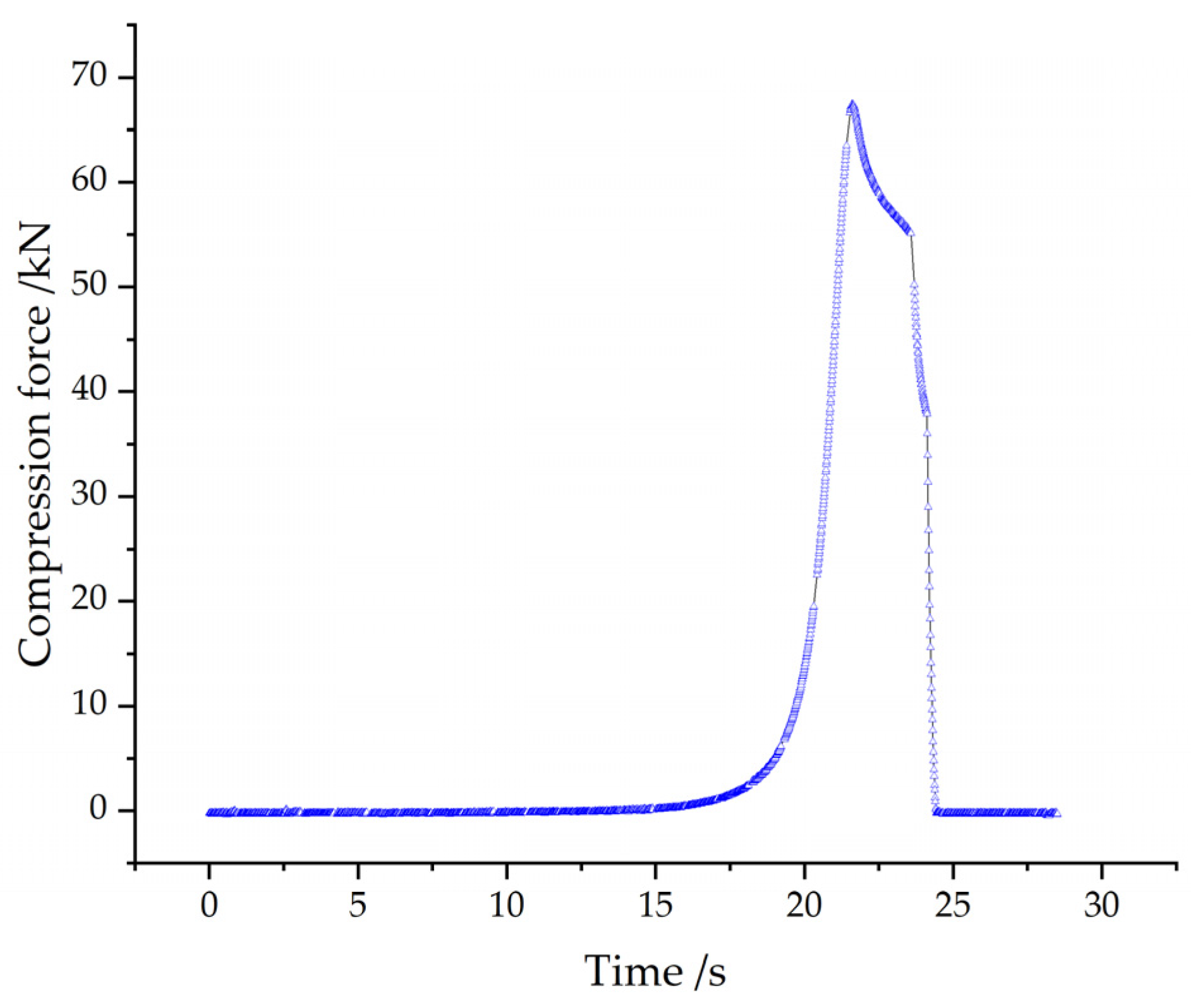

4.1.1. Results of the Experiment

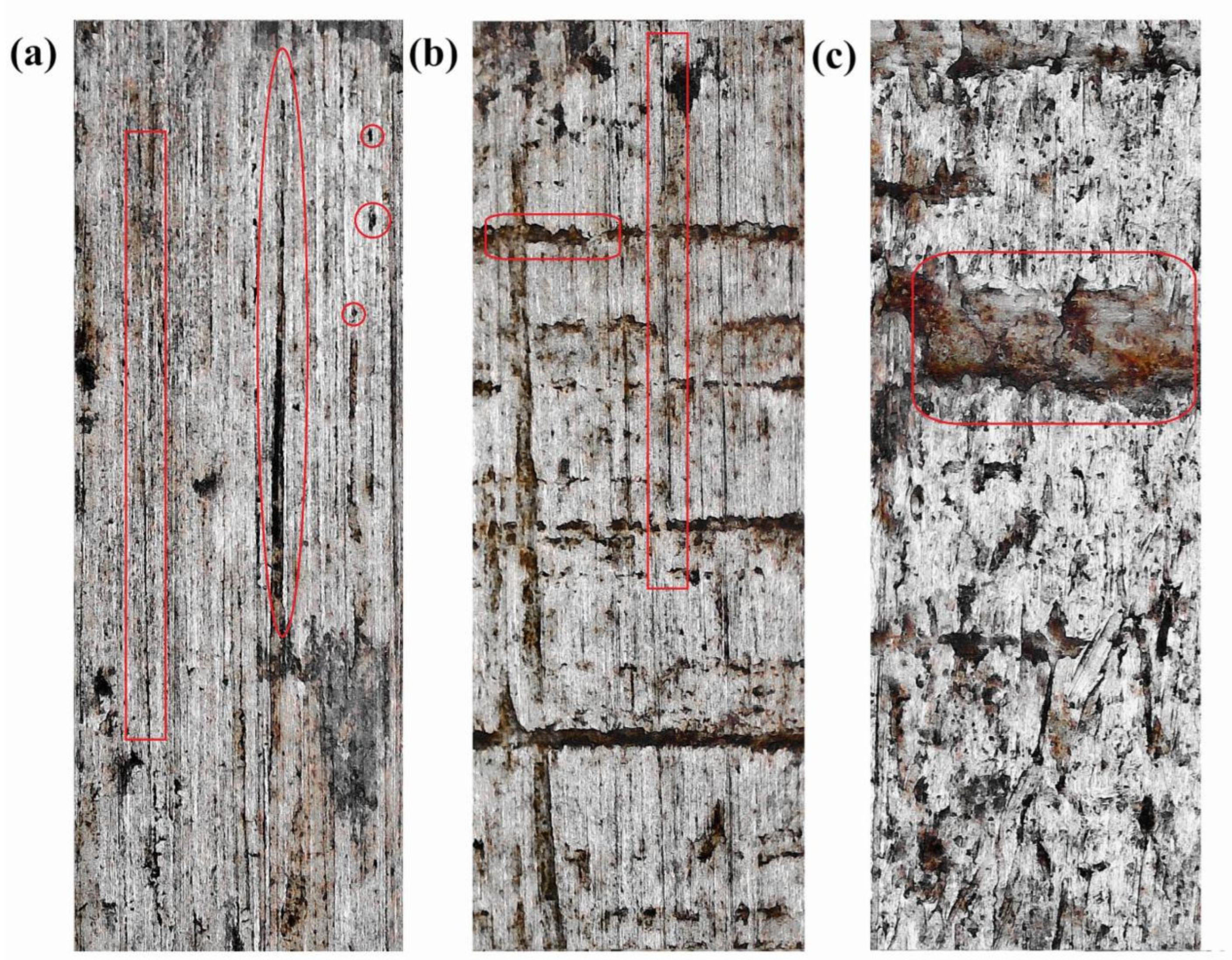

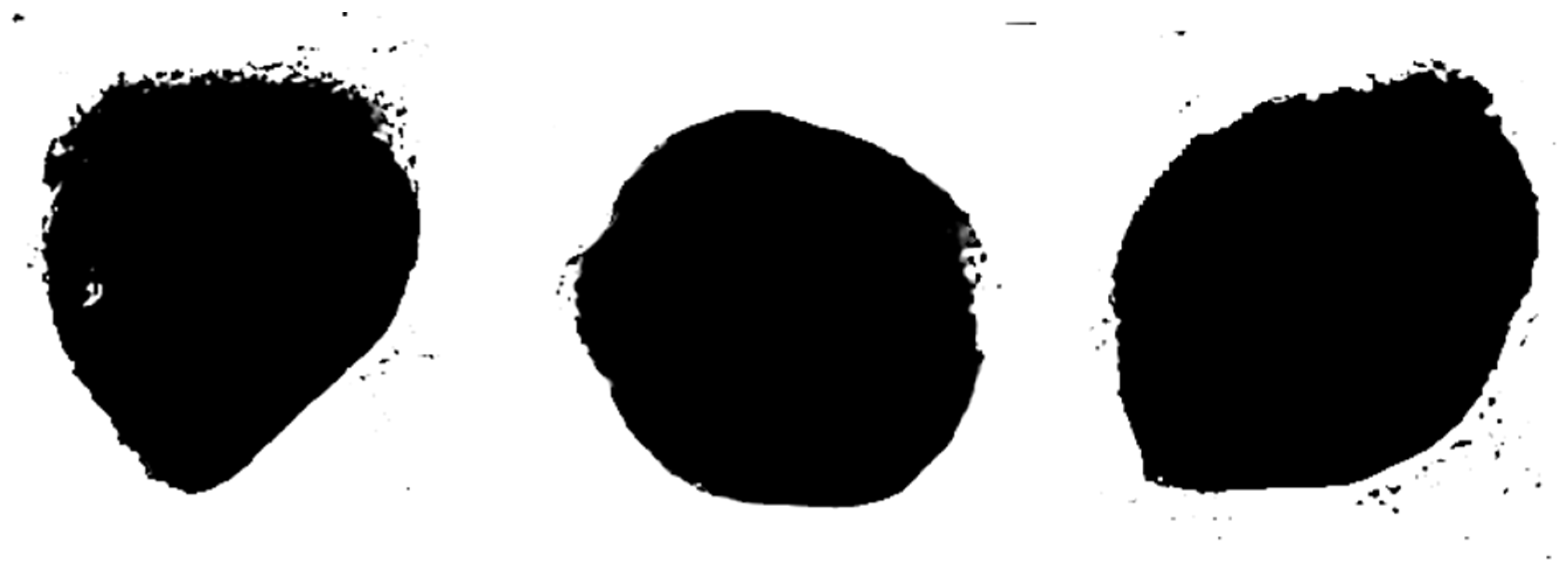

4.1.2. Microscopic Observation of the Mold Working Surface

4.1.3. The Relationship between Compression Force and Die Wear

4.2. Simulation Experimental Results and Discussion

4.2.1. Setting of DEM Parameters

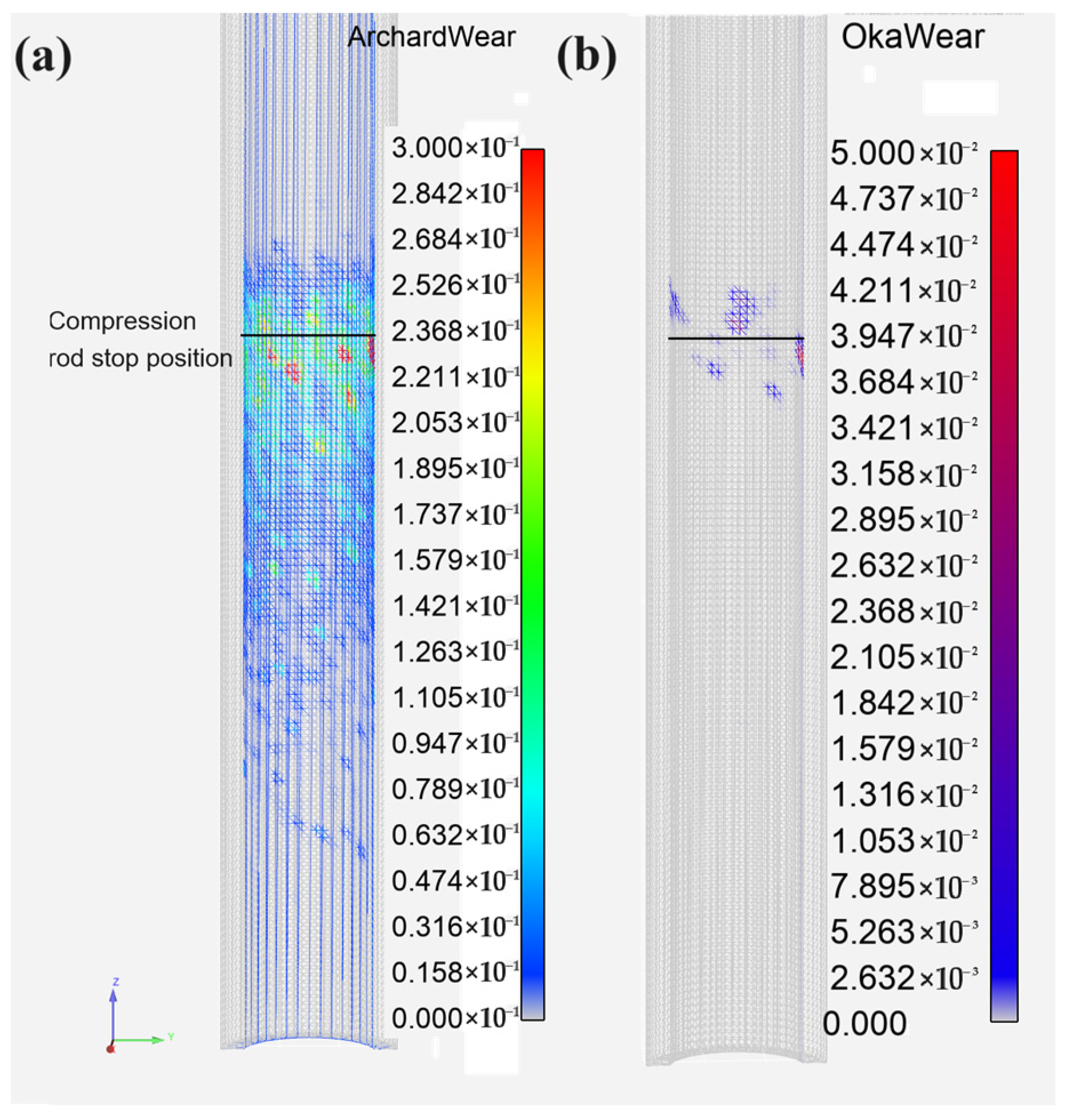

4.2.2. Simulated Test Wear Conditions

4.2.3. Stress Transmission and Wear Conditions

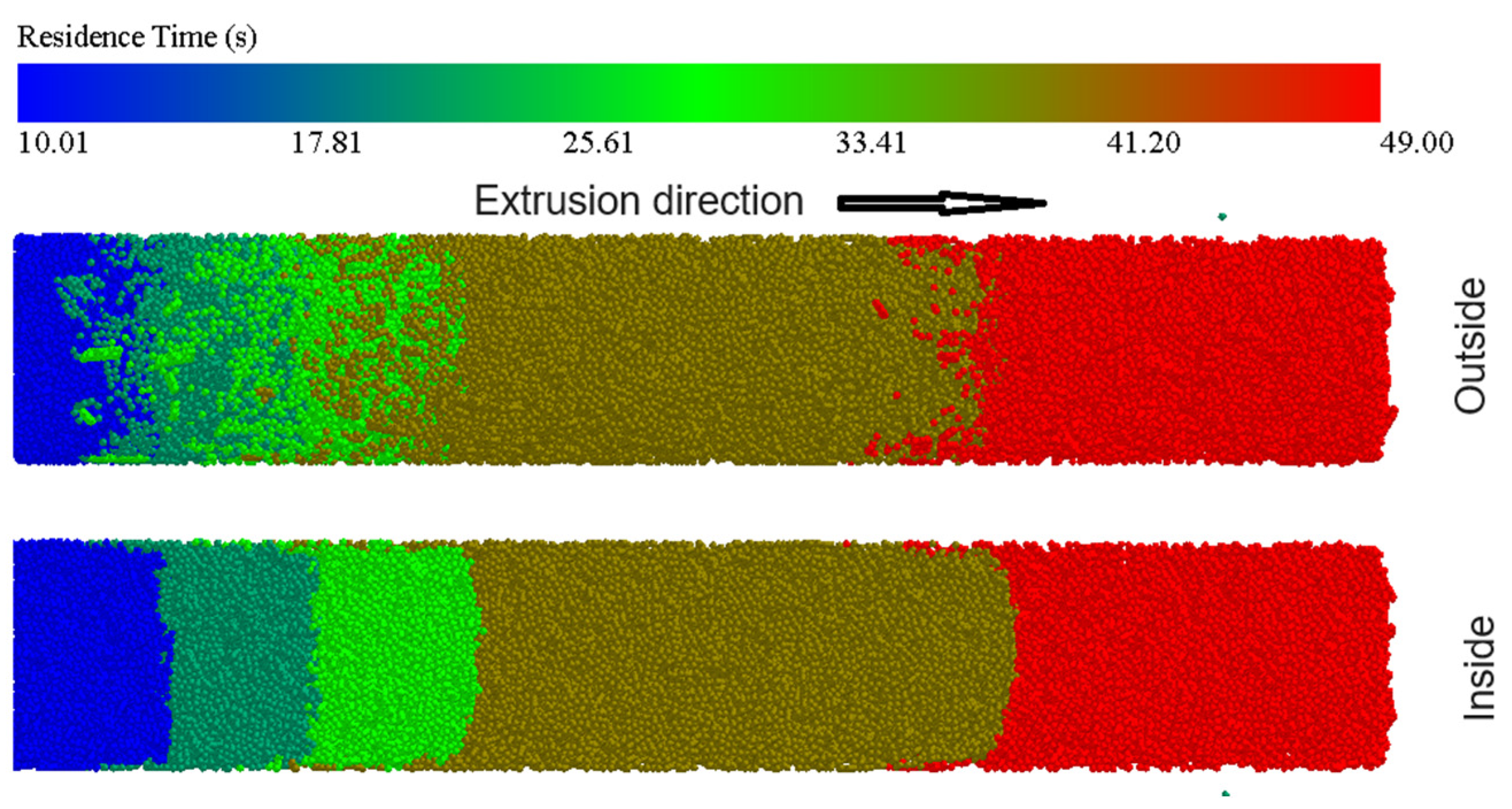

4.2.4. Particle Movement and Wear Conditions

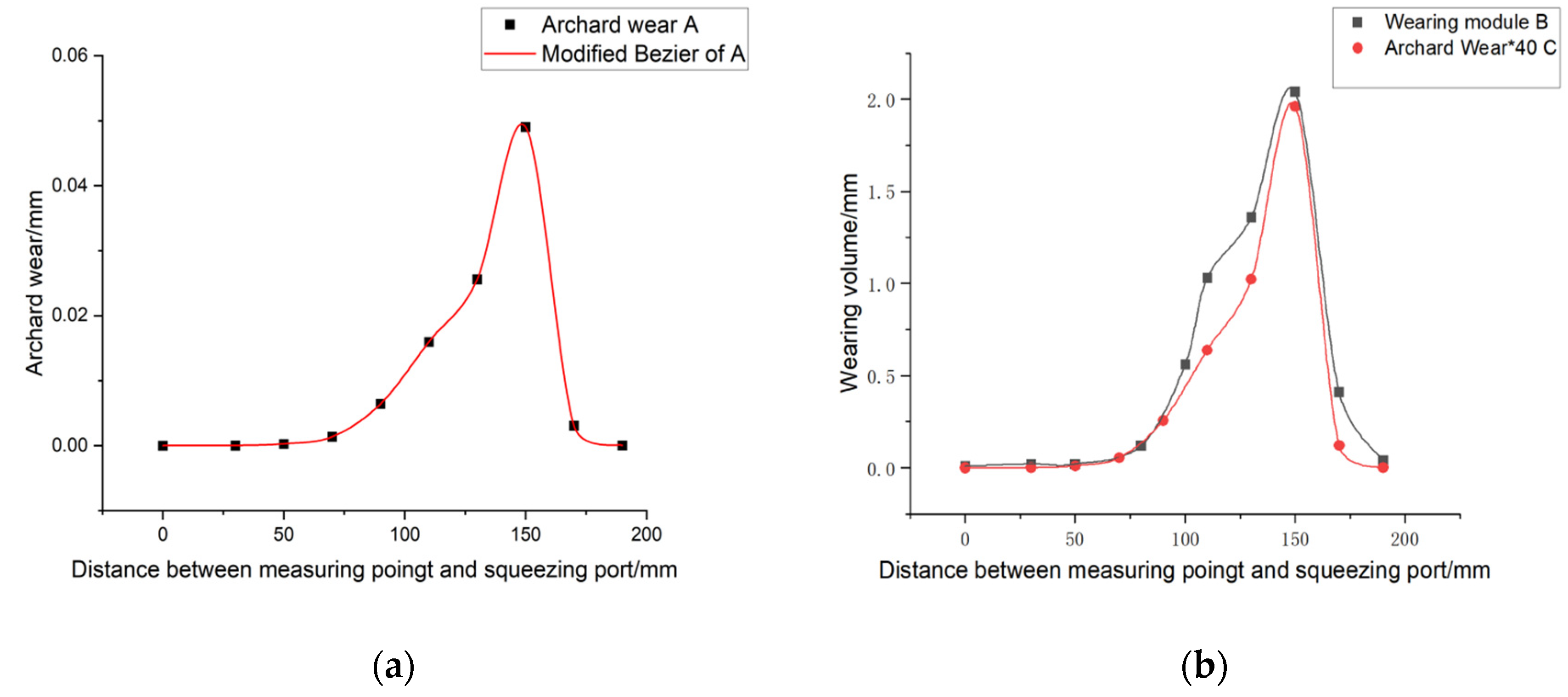

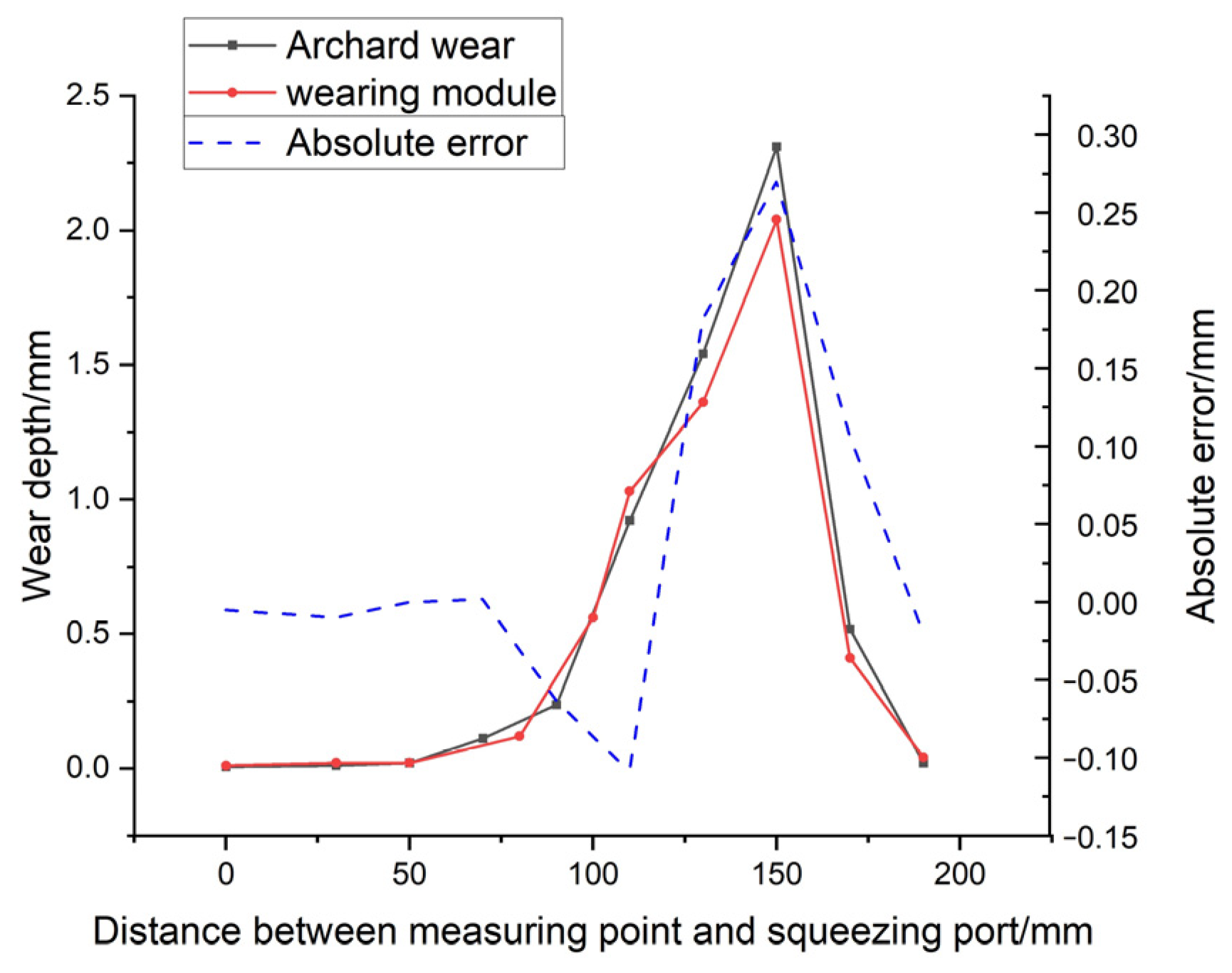

4.3. Simulation Model Validation Results

4.4. DEM Analysis

5. Conclusions

- The study observed and analyzed the micro-wear of 45 steel. The primary wear mechanisms of the mold were identified as micro-cutting by abrasive particles and high-pressure plastic fatigue wear. By juxtaposing the compression force distribution [9] with the wear depth distribution, it was deduced that significant wear is more likely to occur near the ram’s stopping position. The mold wear depth gradually decreases along the compression extrusion direction, but the wear depth distribution is uneven at the same radial level. These findings provide valuable insights for improving future numerical models.

- The distribution of force chains exhibits a significant correlation with the pattern of die wear. The interaction between particles and the die generates force chains, which, when sliding relative to the die’s inner wall, induce a micro-cutting effect on the particles. This process facilitates localized wear on the die, ultimately forming characteristic furrows on the inner surface of the die. This phenomenon not only reveals the direct influence of force chain distribution on die wear but also provides crucial insights into understanding wear mechanisms in complex particulate systems.

- According to the DEM results, the particle shape and size were modeled based on particle morphology. The predicted wear distribution and the force change law during the compaction stage of the densification process were consistent with the experimental results. In actual wear experiments, the adhesion of particles to the die wall plays a unique role in reducing wear, and the discrete element model also characterizes this phenomenon but cannot calculate the amount of wear reduction. During the compression stage, the particles exhibit local active motion, which differs from the actual situation.

- The current numerical models face a significant challenge in effectively addressing speed anomalies. While the corrected predictive model results can reliably and effectively forecast mold wear conditions by processing and calibrating the data, it is important to acknowledge that more robust numerical models are being developed through parameter optimization and testing to overcome these limitations.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Demirbas, M.F.; Balat, M.; Balat, H. Potential contribution of biomass to the sustainable energy development. Energy Conv. Manag. 2009, 50, 1746–1760. [Google Scholar] [CrossRef]

- Miloš; Matúš, P. K.Ľ.Š. Design of pressing tools for pelleting machines. World J. Adv. Eng. Technol. Sci. 2021, 4, 52–62. [Google Scholar] [CrossRef]

- Cutz, L.; Haro, P.; Santana, D.; Johnsson, F. Assessment of biomass energy sources and technologies: The case of Central America. Renew. Sustain. Energy Rev. 2016, 58, 1411–1431. [Google Scholar] [CrossRef]

- Song, X.; Zhang, S.; Wu, Y.; Cao, Z. Investigation on the properties of the bio-briquette fuel prepared from hydrothermal pretreated cotton stalk and wood sawdust. Renew. Energy 2020, 151, 184–191. [Google Scholar] [CrossRef]

- Vaish, S.; Sharma, N.K.; Kaur, G. A review on various types of densification/briquetting technologies of biomass residues. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1228, 12019. [Google Scholar] [CrossRef]

- Jiang, Q.H.; Wu, K.; Sun, Y.; Xia, X. Wear mechanism analysis of ring die of pellet mill. Trans. CSAE 2013, 29, 42–49, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Orisaleye, J.I.; Ojolo, S.J.; Ajiboye, J.S. Mathematical modelling of die pressure of a screw briquetting machine, Journal of King Saud University. Eng. Sci. 2020, 32, 555–560. [Google Scholar] [CrossRef]

- Wang, H.Y. Analysis of Heat and Stress Transfer of Compression with Assisted Vibrationfor Alfalfa Straw Based on Discrete Element Method; Inner Mongolia Agricultural University: Hohhot, China, 2021. [Google Scholar] [CrossRef]

- Du, H.J. Multi-Scale Mechanical Analysis and Parameter Optimization of Alfalfa Densification Molding; Inner Mongolia Agricultural University: Hohhot, China, 2023. [Google Scholar] [CrossRef]

- Du, H.; Lei, T.; Ma, Y.; Li, Y.; Yang, X.; Du, X. Effect of process parameters on quality of alfalfa block. BioResources 2024, 19, 3234–3248. [Google Scholar] [CrossRef]

- Zhang, W.; Zhou, J.; Zhang, X.L.; Zhang, Y.; Liu, K. Quantitative investigation on force chain lengths during high velocity compaction of ferrous powder. Mod. Phys. Lett. B 2019, 33, 1950113. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, X. The Application of Ceramic Wear Resistant Materials in Biomass Briquetting Equipment. Energy Environ. 2014, 25, 1003–1009. [Google Scholar] [CrossRef]

- Thompson, J. Wear and Impact Analysis of Granular Materials Using Discrete Element Method Simulations. Ph.D. Thesis, Swansea University Prifysgol Abertawe, Swansea, UK, 2023. [Google Scholar] [CrossRef]

- Ren, S.; Lil, J.; Shil, Y.; Wen, B.; Lil, L.; Su, Z. Wear characteristics of flat die in flat die pellet mills based on Glycyrrhiza uralensis. Mater. Res. Express 2022, 9, 076510. [Google Scholar] [CrossRef]

- Zhou, G.A. Study on the Forming Mechanism of Biomass Molding Machine and Wear Test of Key Components; College of Engineering Hefei: Hefei, China, 2023. [Google Scholar] [CrossRef]

- Chen, S.; Ding, H.; Tang, Z.; Hao, S.; Zhao, Y. Influence of rice straw forming factors on ring die wear and improved wear prediction model during briquetting. Biosyst. Eng. 2022, 214, 122–137. [Google Scholar] [CrossRef]

- Wen, B.H.; Liu, L.; Liu, S.Y.; Zheng, K.X.; Hua, L.; Wang, S. Analysis and Research of Force and Motion of Screw-Type Extrusion Molding Biomass. Adv. Mater. Res. 2012, 614–615, 452–459. [Google Scholar] [CrossRef]

- Argatov, I.I.; Bae, J.W.; Chai, Y.S. A Simple Model for the Wear Accumulation in Partial Slip Hertzian Contact. Int. J. Appl. Mech. 2020, 12, 2050074. [Google Scholar] [CrossRef]

- Capozza, R.; Hanley, K.J. A comprehensive model of plastic wear based on the discrete element method. Powder Technol. 2022, 410, 117864. [Google Scholar] [CrossRef]

- Sun, H.; Ma, H.; Zhao, Y. DEM investigation on conveying of non-spherical particles in a screw conveyor. Particuology 2022, 65, 17–31. [Google Scholar] [CrossRef]

- Yu, H.; Liu, H.; Zhang, S.; Zhang, J.; Han, Z. Research progress on coping strategies for the fluid-solid erosion wear of pipelines. Powder Technol. 2023, 422, 118457. [Google Scholar] [CrossRef]

- Du, H.J.; Lei, T.; Zhang, Y.A.; Wu, P.; Ma, Y.H.; Bu, K. Evolution of force chain in vibration compression of alfalfa. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2022, 38, 33–40, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Zhao, L.; Jin, X.; Liu, X. Numerical research on wear characteristics of drum based on discrete element method (DEM). Eng. Fail. Anal. 2020, 109, 104269. [Google Scholar] [CrossRef]

- Xia, X.; Sun, Y.; Wu, K.; Jiang, Q. Wear mechanism of ring die for straw briquetting machine. Trans. CSAE 2014, 30, 32–39, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Zhang, Z.; Mei, F.; Xiao, P.; Zhao, W.; Zhu, X. Discrete element modelling and simulation parameters calibration for the compacted straw cube. Biosyst. Eng. 2023, 230, 301–312. [Google Scholar] [CrossRef]

- Tang, H.; Xu, W.; Zhao, J.; Xu, C.; Wang, J. Comparison of rice straw compression characteristics in vibration mode based on discrete element method. Biosyst. Eng. 2023, 230, 191–204. [Google Scholar] [CrossRef]

- Ghatrehsamani, S.; Akbarzadeh, S.; Khonsari, M.M. Application of Continuum Damage Mechanics to Predict Wear in Systems Subjected to Variable Loading. Tribol. Lett. 2021, 69, 163. [Google Scholar] [CrossRef]

- Oka, Y.I.; Okamura, K.; Yoshida, T. Practical estimation of erosion damage caused by solid particle impact. Part 1: Effects of impact parameters on a predictive equation. Wear 2005, 259, 95–101. [Google Scholar] [CrossRef]

- Wang, H.; Wu, P.; He, H.; Ma, Y.; Bu, K.; Xue, J. Calibration of parameters for discrete element simulation model for alfalfa with different moisture contents based on angle of repose test. BioResources 2022, 17, 1467–1484. [Google Scholar] [CrossRef]

- Ma, Y.H.; Song, C.D.; Xuan, C.Z.; Wang, H.Y.; Yang, S.; Wu, P. Parameters calibration of discrete element model for alfalfa straw compression simulation. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2020, 36, 22–30, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Nielsen, S.K.; Mandø, M. Experimental and numerical investigation of die designs in biomass pelleting and the effect on layer formation in pellets. Biosyst. Eng. 2020, 198, 185–197. [Google Scholar] [CrossRef]

- Du, H.J.; Ma, Y.; Lie, T.; Wu, P. Effect of vibrational frequency on alfalfa opening compression process. Bioresources 2022, 17, 6706–6717. [Google Scholar] [CrossRef]

- Jiang, Q.H. Study on the Mechanism and Technology of Rotary Extrusion Forming of Feed Poeder. Nabjing University of Science and Technology, Nanjing, China, 2018. Available online: https://xueshu.baidu.com/usercenter/paper/show?paperid=114y0py0b53604e0p9460cw0m1540359 (accessed on 30 July 2024).

- Zuo, M.M. Dynamic Characteristics of Solid Granules by Superimposing High Frequency Vibrations. Yanshan University, Qinhuangdao, China, 2018. Available online: https://dzzyfx.imau.edu.cn/piskns.cnki.net/kcms2/article/abstract?v=WdAl4K16JyWTptEZ8UwJM9cefuRjmIvlHChMKjrY5TTKFcg6sXZWUBaUYqU9icy9nejjt1ESdsWT-dBR278SB2Rn3vP-FJfz_F5UuIogJ0o-fbl4pGAR5P_kSDR_zJ-xTzapUBaUrYnbRwAYbib75g==&uniplatform=NZKPT&language=CHS (accessed on 30 July 2024).

- Kraus, M.; Lenzen, M.; Merklein, M. Contact pressure-dependent friction characterization by using a single sheet metal compression test. Wear 2021, 476, 203679. [Google Scholar] [CrossRef]

- Chung, R.J.; Jiang, J.; Pang, C.; Yu, B.; Eadie, R.; Li, D.Y. Erosion-corrosion behaviour of steels used in slurry pipelines. Wear 2021, 477, 203771. [Google Scholar] [CrossRef]

- Zhou, L.; Li, T.; Liu, Z.; Ma, H.; Xu, C.; Dong, Y.; Zhao, Y. An impact energy erosion model with an energy allocation rule for the discrete element method. Wear 2024, 540–541, 205233. [Google Scholar] [CrossRef]

- Lindqvist, M.; Evertsson, C.M. Liner wear in jaw crushers. Miner. Eng. 2003, 16, 1–12. [Google Scholar] [CrossRef]

- De, X.; Zhang, B.; Guo, W.; Yang, J.; Zhang, J.; Zhai, X. Surface morphology of blended molding pellets made of desert caragana and maize stover. BioResources 2023, 18, 3019–3032. [Google Scholar] [CrossRef]

- Pang, H.S.; Yang, Y.X.; Yin, X.; Zhang, B. Experimental and simulation study of a grinding screw surface based on cross-viscosity cellulose. J. Beijing Univ. Chem. Technol. (Nat. Sci.) 2024, 51, 67–75. [Google Scholar] [CrossRef]

- Bastola, A.; Stewart, D.; Dini, D. Three-dimensional finite element simulation and experimental validation of sliding wear. Wear 2022, 504–505, 204402. [Google Scholar] [CrossRef]

| Parameters | Unit | Value | Source | |

|---|---|---|---|---|

| Alfalfa | ||||

| Poisson’s ratio | _ | 0.35 | [9,30] | |

| Solid density | kg/m3 | 1000 | [9,30] | |

| Young’s modulus | MPa | 22.6 | [9,30] | |

| Steel | ||||

| Poisson’s ratio | _ | 0.3 | [29] | |

| Solid density | kg/m3 | 7800 | [29] | |

| Young’s modulus | GPa | 70 | [29] | |

| Alfalfa–alfalfa | ||||

| Coefficient of restitution | _ | 0.11 | [29] | |

| Coefficient of static friction | _ | 0.47 | [29] | |

| Coefficient of rolling friction | _ | 0.23 | [29] | |

| Alfalfa–steel | ||||

| Coefficient of restitution | _ | 0.16 | [29] | |

| Coefficient of static friction | _ | 0.8 | [29] | |

| Coefficient of rolling friction | _ | 0.225 | [29] | |

| EEPA | ||||

| Surface energy | J/m2 | 9.5 | [9,29] | |

| Contact plasticity ratio | _ | 0.8 | [9,29,30] | |

| Tensile exp | _ | 1.5 | [9,29,30] | |

| Tangential stiff multiplier | _ | 0.667 | [9,29,30] | |

| Slope exo | _ | 1.5 | [9,29,30] | |

| Pull-off force | N | 0 | [29,30] | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, H.; Du, H.; Ma, Y.; Su, H.; Xuan, C.; Xue, J. Research and Prediction of Wear Characteristics of Alfalfa Densification Die Based on the Discrete Element Method. Agriculture 2024, 14, 1260. https://doi.org/10.3390/agriculture14081260

Du H, Du H, Ma Y, Su H, Xuan C, Xue J. Research and Prediction of Wear Characteristics of Alfalfa Densification Die Based on the Discrete Element Method. Agriculture. 2024; 14(8):1260. https://doi.org/10.3390/agriculture14081260

Chicago/Turabian StyleDu, Haijun, Hailong Du, Yanhua Ma, He Su, Chuanzong Xuan, and Jing Xue. 2024. "Research and Prediction of Wear Characteristics of Alfalfa Densification Die Based on the Discrete Element Method" Agriculture 14, no. 8: 1260. https://doi.org/10.3390/agriculture14081260