Strip Tillage Improves Productivity of Direct-Seeded Oilseed Rape (Brassica napus) in Rice–Oilseed Rape Rotation Systems

Abstract

:1. Introduction

2. Materials and Methods

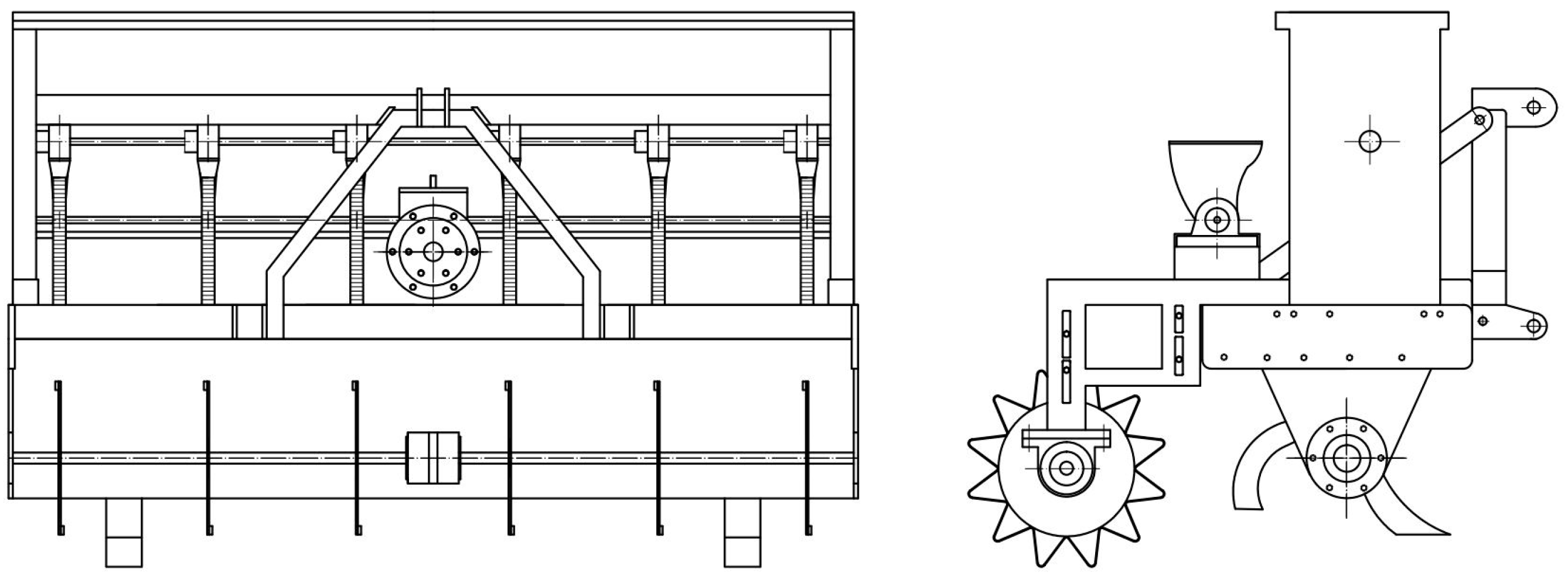

2.1. The Machine Structure and Working Principle of the Strip-Tillage Oilseed Rape Seeder

2.2. Comparison of Different Oilseed Rape Seeding Regimes

2.2.1. Field Trial Design

2.2.2. Sowing Efficiency and Energy Consumption

2.2.3. Topsoil Disturbance

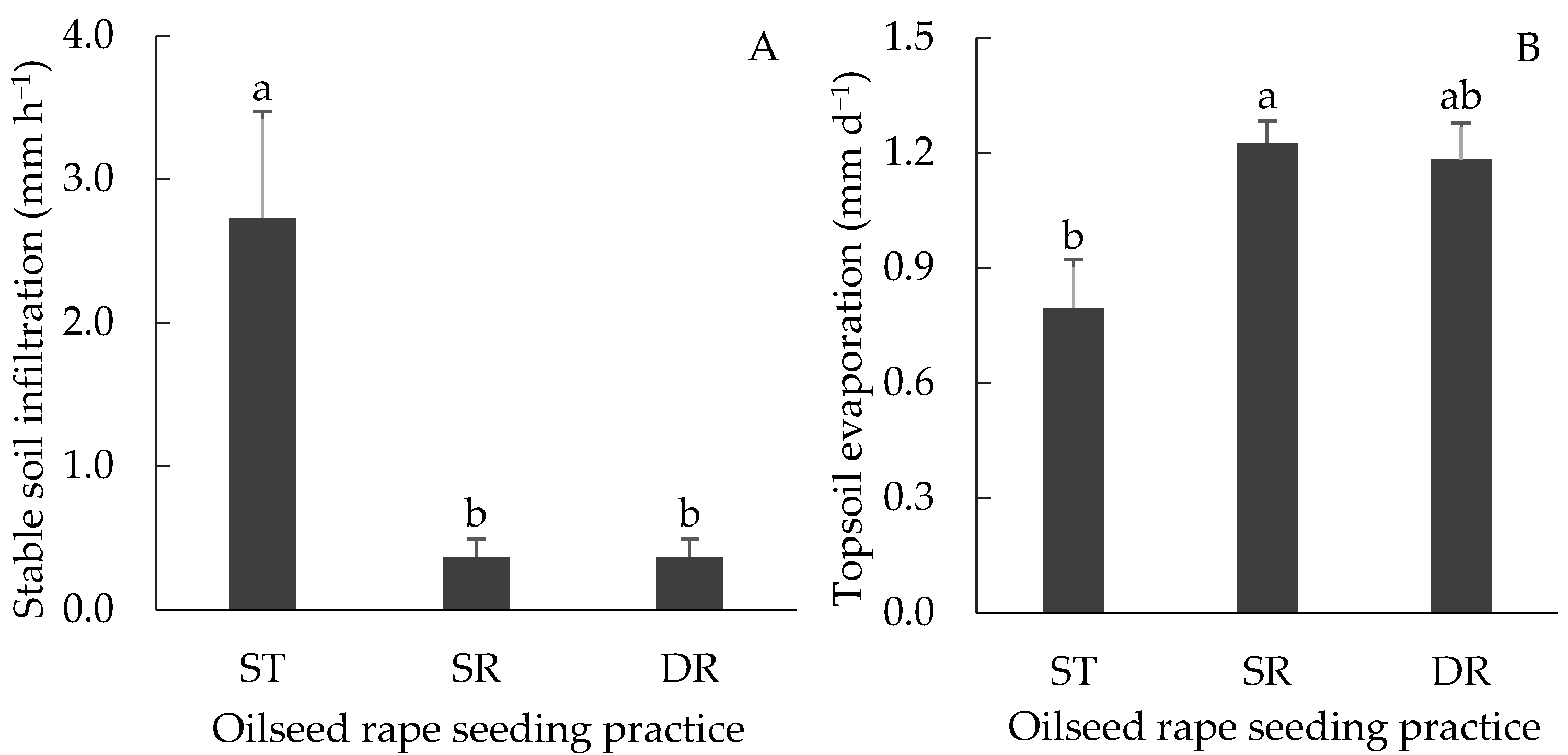

2.2.4. Soil Infiltration and Topsoil Evaporation after Seeding

2.2.5. Seedling Emergence

2.2.6. Agronomic Characters Measurement at Seedling Stage

2.2.7. Yield and Yield Components Investigation

2.2.8. Weed Occurrence Survey

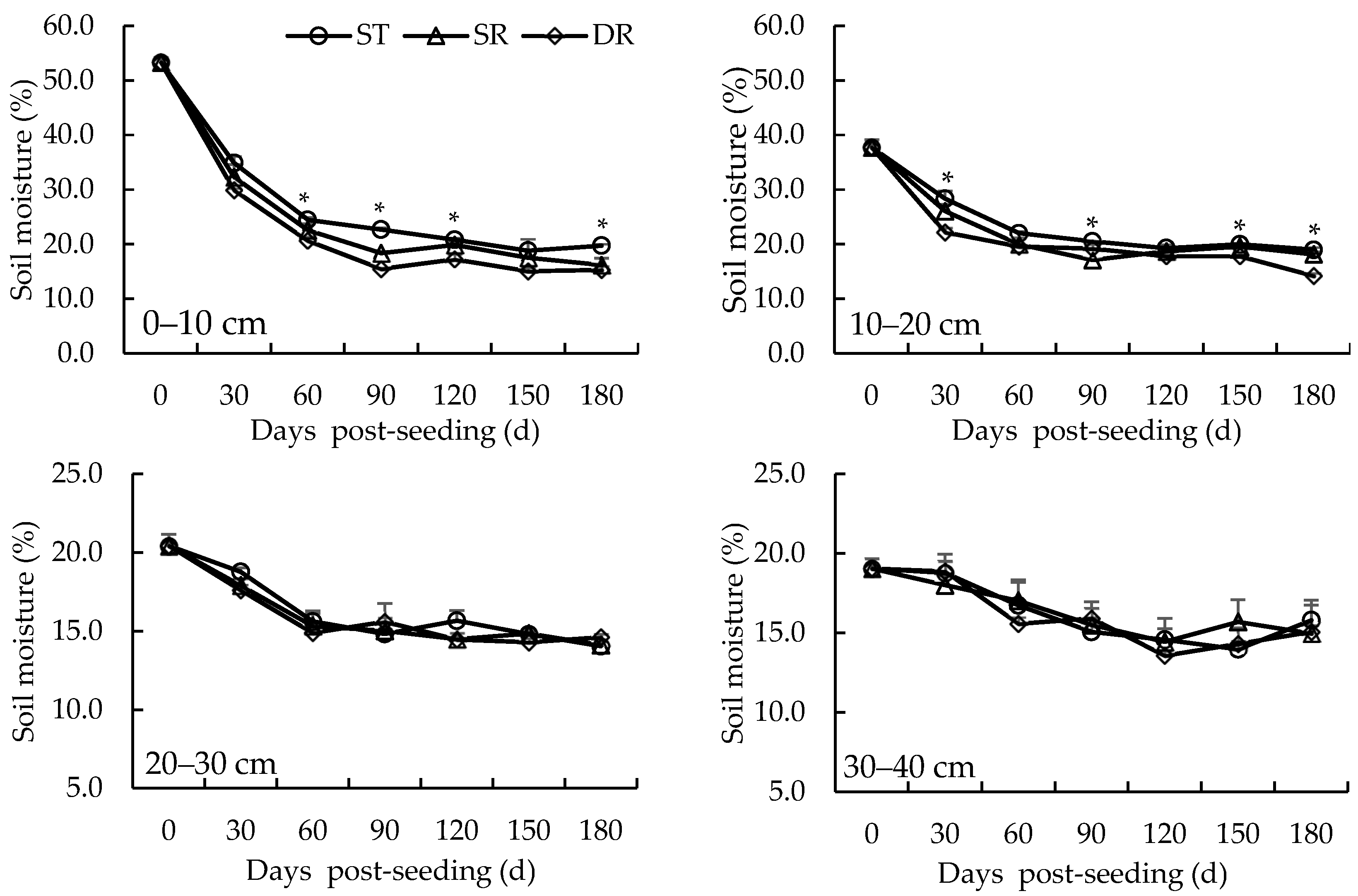

2.2.9. Soil Moisture Change

2.3. Data Analysis

3. Results

3.1. Variance Analysis of Seed Yield and Yield Components

3.2. Yield and Yield Components

3.3. Seeding Efficiency, Energy Consumption, and Soil Disturbance

3.4. Seedling Establishments

3.5. Agronomic Characters at Seedling Stage

3.6. Weed Occurrence

3.7. Soil Infiltration and Evaporation Post-Seeding

3.8. Soil Moisture Change during Oilseed Rape Growth

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bonjean, A.P.; Dequidt, C.; Sang, T.; Limagrain, G. Rapeseed in China. OCL 2016, 236, D605. [Google Scholar] [CrossRef]

- Hu, Q.; Hua, W.; Yin, Y.; Zhang, X.; Liu, L.; Shi, J.; Zhao, Y.; Lu, Q.; Chen, C.; Wang, H. Rapeseed research and production in China. Crop J. 2017, 5, 127–135. [Google Scholar] [CrossRef]

- Li, F.; Guo, K.; Liao, X. Risk assessment of china rapeseed supply chain and policy suggestions. Int. J. Environ. Res. Public Health 2023, 20, 465. [Google Scholar] [CrossRef] [PubMed]

- He, A.; Yuan, B.; Jin, Z.; Man, J.; Peng, S.; Zhang, L.; Liu, H.; Nie, L. Comparative study on annual yield, water consumption, irrigation water use efficiency and economic benefits of different rice-oilseed rape rotation systems in Central China. Agric. Water Manag. 2021, 247, 106741. [Google Scholar] [CrossRef]

- Li, L.; Li, J.; Wei, C.; Yang, C.; Zhong, S. Effect of mechanized ridge tillage with rice-rape rotation on paddy soil structure. Agriculture 2022, 12, 2147. [Google Scholar] [CrossRef]

- Liao, Y.; Gao, L.; Liao, Q.; Zhang, Q.; Liu, L.; Fu, Y. Design and test of side deep fertilizing device of combined precision rapeseed seeder. Trans. Chin. Soc. Agric. Mach. 2020, 51, 65–75. [Google Scholar] [CrossRef]

- Wu, M.; Guan, C.; Tang, C.; Chen, S.; Luo, H.; Wang, G.; Xie, F.; Li, X.; Yang, W. Experimental research on 2BYF-6 type no-tillage rape combine seeder in paddy stubble field. Trans. Chin. Soc. Agric. Eng. 2007, 23, 172–175. [Google Scholar] [CrossRef]

- Wei, G.; Zhang, Q.; Liu, L.; Xiao, W.; Sun, W.; Liao, Q. Design and experiment of plowing and rotary tillage buckle device for rapeseed direct seeder. Trans. Chin. Soc. Agric. Mach. 2020, 51, 38–46. [Google Scholar] [CrossRef]

- Keller, T.; Arvidsson, J.; Dexter, A.R. Soil structures produced by tillage as affected by soil water content and the physical quality of soil. Soil Tillage Res. 2007, 92, 45–52. [Google Scholar] [CrossRef]

- Ding, J.; Li, F.; Le, T.; Xu, D.; Zhu, M.; Li, C.; Zhu, X.; Guo, W. Tillage and seeding strategies for wheat optimizing production in harvested rice fields with high soil moisture. Sci. Rep. 2021, 11, 119. [Google Scholar] [CrossRef]

- Li, C.; Tang, Y.; McHugh, A.D.; Wu, X.; Liu, M.; Li, M.; Xiong, T.; Ling, D.; Tang, Q.; Liao, M.; et al. Development and performance evaluation of a wet-resistant strip-till seeder for sowing wheat following rice. Biosyst. Eng. 2022, 220, 146–158. [Google Scholar] [CrossRef]

- Jaskulska, I.; Jaskulski, D. Strip-till one-pass technology in central and eastern Europe: A MZURI pro-til hybrid machine case study. Agronomy 2020, 10, 925. [Google Scholar] [CrossRef]

- Dou, S.; Wang, Z.; Tong, J.; Shang, Z.; Deng, A.; Song, Z.; Zhang, W. Strip tillage promotes crop yield in comparison with no tillage based on a meta-analysis. Soil Tillage Res. 2024, 240, 106085. [Google Scholar] [CrossRef]

- Licht, M.A.; Al-Kaisi, M. Strip-tillage effect on seedbed soil temperature and other soil physical properties. Soil Tillage Res. 2005, 80, 233–249. [Google Scholar] [CrossRef]

- Tabatabaeekoloor, R. Soil characteristics at the in-row and inter-row zones after strip-tillage. Afr. J. Agric. Res. 2011, 6, 6598–6603. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, X.; Sun, L.; Ren, J.; Yuan, Y.; Zang, S. Influence of tillage on the Mollisols physicochemical properties, seed emergence and yield of maize in northeast China. Agriculture 2021, 11, 939. [Google Scholar] [CrossRef]

- Mikha, M.M.; Hergert, G.W.; Qiao, X.; Maharjan, B. Soil chemical properties after 12 years of tillage and crop rotation. Agron. J. 2020, 112, 4395–4406. [Google Scholar] [CrossRef]

- David, B.; Lucie, B.; Perla, K.; Pavel, C.; Katerina, P.; Vlastimil, M.; Jan, V. Growth and yield of winter oilseed rape under strip-tillage compared to conventional tillage. Plant Soil Environ. 2021, 67, 85–91. [Google Scholar] [CrossRef]

- Saldukaitė, L.; Šarauskis, E.; Zabrodskyi, A.; Adamavičienė, A.; Buragienė, S.; Kriaučiūnienė, Z.; Savickas, D. Assessment of energy saving and GHG reduction of winter oilseed rape production using sustainable strip tillage and direct sowing in three tillage technologies. Sustain. Energy Technol. Assess. 2022, 51, 101911. [Google Scholar] [CrossRef]

- Jankowski, K.J.; Sokólski, M.; Szatkowski, A.; Załuski, D. The effects of tillage systems on the management of agronomic factors in winter oilseed rape cultivation: A case study in North-Eastern Poland. Agronomy 2024, 14, 437. [Google Scholar] [CrossRef]

- Hobbs, P.R.; Sayre, K.; Gupta, R. The role of conservation agriculture in sustainable agriculture. Philos. Trans. R. Soc. B Biol. Sci. 2008, 363, 543–555. [Google Scholar] [CrossRef] [PubMed]

- Hendrix, B.J.; Young, B.G.; Chong, S. Weed management in strip tillage corn. Agron. J. 2004, 96, 229–235. [Google Scholar] [CrossRef]

- Ren, Z.; Zhang, G.; Wang, B.; Shi, Y. Effects of double-ring diameter on soil infiltration rate. J. Soil Water Conserv. 2012, 26, 94–99. [Google Scholar]

- Liu, M.; Wang, S.; Fan, J.; Fu, W.; Du, M. Rapid in-situ determination of soil evaporation with cutting ring method. Chin. J. Soil Sci. 2021, 52, 55–61. [Google Scholar]

- Cai, G.; Yang, Q.; Chen, H.; Yang, Q.; Zhang, C.; Fan, C.; Zhou, Y. Genetic dissection of plant architecture and yield-related traits in Brassica napus. Sci. Rep. 2016, 6, 21625. [Google Scholar] [CrossRef] [PubMed]

- Su, Y.; Gabrielle, B.; Makowski, D. A global dataset for crop production under conventional tillage and no tillage systems. Sci. Data 2021, 8, 33. [Google Scholar] [CrossRef] [PubMed]

- Gawęda, D.; Haliniarz, M. Grain yield and quality of winter wheat depending on previous crop and tillage system. Agriculture 2021, 11, 133. [Google Scholar] [CrossRef]

- Li, H.; He, J.; Gao, H.; Chen, Y.; Zhang, Z. The effect of conservation tillage on crop yield in China. Front. Agric. Sci. Eng. 2015, 2, 179–185. [Google Scholar] [CrossRef]

- Wardak, D.L.R.; Padia, F.N.; de Heer, M.I.; Sturrock, C.J.; Mooney, S.J. Zero tillage has important consequences for soil pore architecture and hydraulic transport: A review. Geoderma 2022, 422, 115927. [Google Scholar] [CrossRef]

- Kumar, V.; Mahaja, G.; Dahiya, S.; Chauhan, B.S. Challenges and opportunities for weed management in no-till farming systems. In No-Till Farming Systems for Sustainable Agriculture; Dang, Y., Dalal, R., Menzies, N., Eds.; Springer: Berlin/Heidelberg, Germany; Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Radicetti, E.; Mancinelli, R. Sustainable weed control in the agro-ecosystems. Sustainability 2021, 13, 8639. [Google Scholar] [CrossRef]

- Pramanick, B.; Mahapatra, B.S.; Datta, D.; Dey, P.; Singh, S.P.; Kumar, A.; Paramanik, B.; Awasthi, N. An innovative approach to improve oil production and quality of mustard (Brassica juncea L.) with multi-nutrient-rich polyhalite. Heliyon 2023, 9, e13997. [Google Scholar] [CrossRef] [PubMed]

| Year | Factor | October | November | December | January | February | March | April |

|---|---|---|---|---|---|---|---|---|

| 2021/2022 | Mean temperature (°C) | 17.3 | 11.3 | 8.3 | 7.7 | 7.4 | 17.0 | 18.3 |

| Rainfall (mm) | 114.8 | 3.2 | 1.7 | 3.1 | 24.2 | 18.2 | 70.7 | |

| 2022/2023 | Mean temperature (°C) | 18.3 | 15.2 | 7.2 | 6.6 | 10.0 | 14.0 | 18.9 |

| Rainfall (mm) | 27.6 | 1.8 | 0.5 | 0.1 | 6.3 | 21.4 | 32.3 |

| Factor | Oilseed Yield | Seedling Number per m2 | Surviving Plants per m2 | Number of Siliques per Plant | Number of Seeds per Silique | 1000-Seed Dry Weight |

|---|---|---|---|---|---|---|

| Year (Y) | 3.1 | 191.4 ** | 90.4 ** | 0.3 | 42.6 ** | 10.0 * |

| Seeding practice (S) | 14.9 ** | 5.5 * | 18.0 ** | 9.7 ** | 2.0 | 0.4 |

| Y × S | 4.3 | 7.4 * | 26.8 ** | 0.2 | 0.002 | 2.1 |

| Year | Seeding Practice | Oilseed Yield (kg ha−1) | Surviving Plants per m2 | Number of Siliques per Plant | Number of Seeds per Silique | 1000-Seed Dry Weight (g) |

|---|---|---|---|---|---|---|

| 2021/2022 | ST | 2838 ± 168 a | 28.9 ± 1.1 b | 284.5 ± 27.7 a | 13.6 ± 1.6 a | 4.22 ± 0.10 a |

| SR | 2655 ± 496 a | 41.1 ± 3.6 a | 196.9 ± 69.1 a | 12.3 ± 1.0 a | 4.13 ± 0.07 a | |

| 2022/2023 | ST | 2899 ± 385 a | 24.0 ± 1.1 b | 286.6 ± 8.9 a | 17.8 ± 0.8 a | 3.82 ± 0.09 a |

| SR | 1947 ± 218 b | 24.5 ± 1.0 b | 225.0 ± 36.2 ab | 16.5 ± 1.1 a | 3.99 ± 0.27 a | |

| DR | 1399 ± 211 b | 27.2 ± 1.5 a | 138.0 ± 67.1 b | 17.3 ± 0.7 a | 3.84 ± 0.12 a |

| Seeding Practice | Seeding Efficiency (h ha−1) | Fuel Consumption (L ha−1) | NCED | ACDED (cm) | NCLD | ACDLD (cm) | NCMD | ACDMD (cm) |

|---|---|---|---|---|---|---|---|---|

| ST | 3.0 | 18.7 | 0 b | - | 0 c | - | 71.5 ± 8.9 a | 5.6 ± 0.5 b |

| SR | 4.2 | 40.5 | 1.9 ± 3.3 b | 26.2 ± 0.5 a | 22.9 ± 5.7 a | 15.1 ± 1.8 a | 19.0 ± 8.7 b | 5.5 ± 1.1 b |

| DR | 8.0 | 94.5 | 9.5 ± 3.3 a | 27.1 ± 4.5 a | 15.2 ± 3.3 b | 16.2 ± 2.0 a | 3.8 ± 6.6 b | 7.5 ± 0.7 a |

| Year | Seeding Practice | Seedling Number per m2 | CVSD (%) |

|---|---|---|---|

| 2021/2022 | ST | 47.0 ± 3.0 a | 11.1 ± 1.7 b |

| SR | 56.6 ± 4.0 a | 27.0 ± 8.3 a | |

| 2022/2023 | ST | 27.0 ± 2.8 a | 11.0 ± 2.0 a |

| SR | 26.8 ± 2.8 a | 11.5 ± 5.8 a | |

| DR | 31.5 ± 2.7 a | 10.2 ± 4.9 a |

| Year | Seeding Practice | Diameter of Stem Base (cm) | Number of Green Leaves per Plant | Dry Mass per Plant (g) | Dry Mass per m2 (g) |

|---|---|---|---|---|---|

| 2021/2022 | ST | 4.55 ± 0.12 a | 5.93 ± 0.29 a | 1.27 ± 0.19 a | 60.3 ± 13.1 a |

| SR | 3.73 ± 0.26 b | 5.36 ± 0.23 b | 0.88 ± 0.10 b | 50.4 ± 8.4 a | |

| 2022/2023 | ST | 4.75 ± 0.36 a | 4.92 ± 0.20 a | 1.50 ± 0.22 a | 40.2 ± 2.4 a |

| SR | 3.63 ± 0.27 b | 4.19 ± 0.20 b | 0.92 ± 0.16 b | 24.3 ± 3.2 b | |

| DR | 3.45 ± 0.20 b | 4.00 ± 0.02 b | 0.65 ± 0.08 b | 20.6 ± 3.9 b |

| Seeding Practice | Total Weed Density (Seedlings m−2) | Polypogon Fugax Density (Seedlings m−2) |

|---|---|---|

| ST | 529 ± 18 b | 525 ± 18 b |

| SR | 3560 ± 966 a | 3553 ± 967 a |

| DR | 3235 ± 1342 a | 3224 ± 1334 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Li, M.; Xiong, T.; Yang, H.; Peng, X.; Wang, Y.; Qin, H.; Li, H.; Tang, Y.; Fan, G. Strip Tillage Improves Productivity of Direct-Seeded Oilseed Rape (Brassica napus) in Rice–Oilseed Rape Rotation Systems. Agriculture 2024, 14, 1356. https://doi.org/10.3390/agriculture14081356

Li C, Li M, Xiong T, Yang H, Peng X, Wang Y, Qin H, Li H, Tang Y, Fan G. Strip Tillage Improves Productivity of Direct-Seeded Oilseed Rape (Brassica napus) in Rice–Oilseed Rape Rotation Systems. Agriculture. 2024; 14(8):1356. https://doi.org/10.3390/agriculture14081356

Chicago/Turabian StyleLi, Chaosu, Ming Li, Tao Xiong, Hongkun Yang, Xiaoqin Peng, Yong Wang, Haiyan Qin, Haojie Li, Yonglu Tang, and Gaoqiong Fan. 2024. "Strip Tillage Improves Productivity of Direct-Seeded Oilseed Rape (Brassica napus) in Rice–Oilseed Rape Rotation Systems" Agriculture 14, no. 8: 1356. https://doi.org/10.3390/agriculture14081356