Abstract

The adoption of a no-till system presents difficulties in maintaining the potential crop yield under long-term conditions when compacted soil layers are observed in the field. The research objective was to assess the benefits of soil intervention in a traditional area of no-till system while considering the production parameters of corn (Zea mays L.) under tropical conditions. The area was installed considering 24 experimental units, including 6 treatments, a 3 × 2 scheme, and 4 repetitions (3 soil management systems and 2 crop hybrids). The soil scarification was carried out at two depths, 0.15 m and 0.30 m, to compare its influence on corn yield. The number of days of plants’ emergence, seed depth, longitudinal distribution of seedlings, phytotechnical parameters, and crop yield in the field were evaluated. The dataset was subjected to the F Test and Tukey test (p < 0.05) to compare the means by each attribute and treatment. The adopted hybrids, as well as soil-management systems in the experimental area, did not interfere with the quality of the sowing and quantitative parameters of the crop (CV = 15% for normal distribution on plants’ spacing within rows). So, there is no need to scarify soil with the aim of increasing corn yield under the evaluated field conditions.

1. Introduction

The current adoption of non-tillering systems in Brazil is around 36 Mha, which represents 54% of the agricultural area available for the production of grains in the country. The system has been implemented by national farmers since 1979, considering the main benefits associated with soil conservation, reduction in water consumption, improvement in organic matter contents, and the mitigation of the gas emissions of the greenhouse effect [1]. Different studies have reported the non-tillering system to be a sustainable practice to increase crop yield [2], reduce soil losses [3], and the costs of production [4], mainly when integrated with the initiatives of crop rotation. Medeiros et al. [5] reported that the average soil loss for the state of São Paulo, the location of this study, is around 118 Mg ha−1 year−1 when considering the areas cultivated with annual agricultural crops. Globally, 33% of the soil surface is already degraded, and about 12 Mha of land is lost annually [6,7]. So, it is evident that developing sustainable alternatives in farm management are required to maintain soil texture and fertility.

To preserve soil conditions for food production, it is common to diversify annual crops, such as soybean, corn, and sorghum, in the same area over consecutive growing seasons. Corn (Zea mays L.) is the most common and economically relevant for promoting crop rotation under tropical conditions. About 19 Mha in Brazil is cultivated with corn, and its average yield is 6.7 t ha−1 nationally. Michelon et al. [8] observed an increment in corn yield under the integration of cover crops and Fabaceae species. They also reported an increase in the organic matter content and availability of macronutrients in the soil.

Small farmers in developing countries are faced with a lack of capacity in managing crop residues, mainly in cereal-based agroecosystems. Their condition limits the potential benefits of adopting agricultural practices to enhance soil fertility at large scale. Some technological challenges in adopting no-till systems were identified by Setia et al. [9], which were associated with challenges on agronomical management, packaging, standardization, and the adoption of machinery for seeding. They also suggested some strategies to overcome this, such as intensive on-farm trials and adaptative research, policies to support capacity building, and local solutions from the manufacture of agricultural machinery.

Crop residue management is also an important strategy in agricultural systems for maintaining soil fertility and its properties over the seasons [10]. But, in some cases, it is beneficial to execute the scarification of layers according to the variability in root development in the field. Nascimento et al. [11] observed an increase in grain yield integrating mechanical soil scarification and cover crops for rice (Oryza sativa L.) due to its capacity to minimize the surface layer of soil compaction. Other studies have also highlighted the effects of mechanical scarification on the physical attributes of soil while considering suitable conditions for root growth and water infiltration [12,13].

Other technical alternatives are commonly implemented in agriculture to maintain soil health. For example, Cherubin et al. [14] measured it according to the straw removal in sugarcane, and the authors pointed out that intensive straw removal induced soil health degradation. The physical degradation of soil, mainly under clayey conditions, was the main factor for yield losses. Idowu et al. [15] studied the influence of soil management on soil quality in an irrigated area with corn silage. Their results demonstrated that the implementation of a no-till system improved the diversity index and total fungi biomass of soil, but no increment in plant population and silage yield was observed.

Lopes et al. [16] and Correia et al. [17] described methods to assess the operational performance of mechanized soil tillage and sowing systems under different field conditions, focusing on their influence on crop yield. The research objective was to assess the benefits of soil interventions in a traditional area of no-till system considering the production parameters of corn under tropical conditions, as well as to characterize its relationship with the operational performance of the agricultural machinery. The hypothesis was established by describing the scientific contribution, in relation to the corn yield and machinery performance, of the mechanical soil intervention in a conventional area of grain cultivation with the NT system. The context of agricultural engineering and technology applied to soil management systems is also discussed in this paper.

2. Materials and Methods

2.1. Experimental Area

This study was conducted in an agricultural area of 1.0 ha, traditionally managed under a no-till system, over 20 years, at the facilities of School of Agricultural and Veterinary Sciences, Jaboticabal, State of São Paulo, Brazil. The geographical coordinates of the area are 21°14′ S, 48°16′ W, 560 m above sea level, and a terrain slope of 4%. The soil type of the region is categorized as typical Eutrophic Red Latosol composed of sand (200 g kg−1), silt (290 g kg−1), and clay (510 g kg−1).

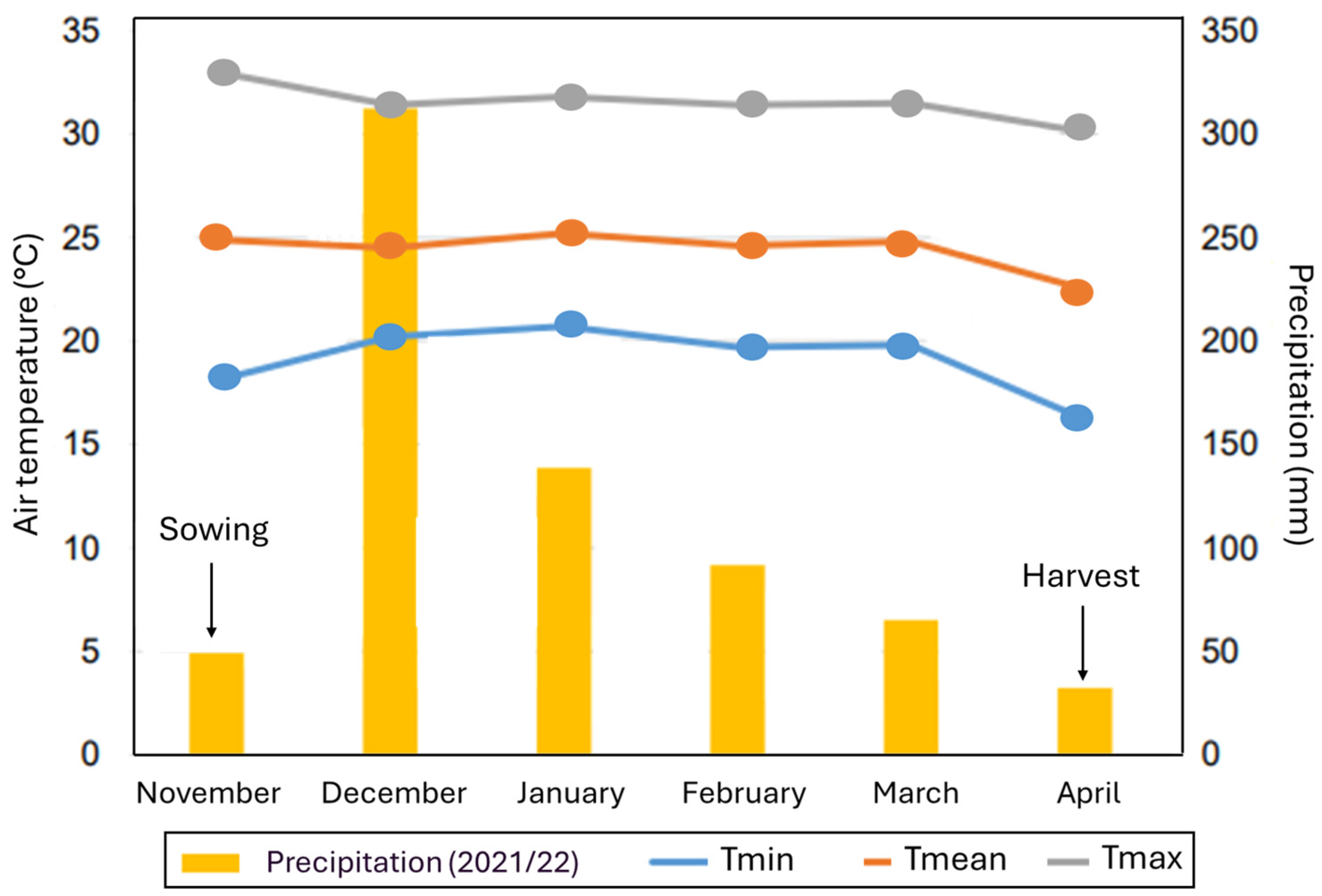

The climate of the region is classified by Köppen as Cwa [18]—dry season in winter and high relative humidity in summer. The mechanized sowing of corn occurred in November 2021 and its harvesting in April 2022 due to the meteorological conditions. The data on air temperature and precipitation were obtained, weekly, from a local weather station (Figure 1). The plots were installed at the field considering 24 experimental units of 10 m × 20 m size, spaced 15 m apart from each other. Each experimental unit was composed of nine rows in a row spacing of 0.45 m, which is traditionally adopted by national farmers in the grain cultivation.

Figure 1.

Air temperature and precipitation during the period of study.

2.2. Data Acquisition

The mechanical resistance of soil to the penetration was obtained by means of a penetrometer of impact to assess what soil depths would be prepared with scarifier equipment according to the methodology described by Stolf et al. [19]. It was measured randomly by considering 10 sampling points with 0.50 m in-depth and the number of hits made by the penetrometer in intervals of 0–0.25 and 0.25–0.50 m. The mean values for each measured depth were 3.5 and 6.6 MPa, respectively. So, it was determined that soil scarification would be carried out at depths of 0.15 m and 0.30 m, below of soil layers with assessed mechanical resistance to the penetration.

The crop parameters evaluated in the field over the growing season were longitudinal distribution of the plants after emergence, initial and final population of the plants, seed depth, plant height, stem diameter, number of ears per row, number of grains per row, dry matter mass, corn yield, and mass of 1,000 grains. The spacing between plants (Xi) was measured according to the method proposed by Kurachi et al. [20]. Normal spacing was considered on interval of 0.17–0.51 m, double for Xi lower than 0.17 m, and in-row gap for Xi higher than 0.51 m.

The initial population of the plants was counted after emergence stabilization, and that of final population was counted during period of harvesting. A centimeter ruler was used to measure the height of the plants while considering three plants per plot on reproductive crop stage. The mean diameter of the stem, located above the first node of the adventitious roots, was measured using a pachymeter in the same plants from height measurement.

The number of rows and the number of grains were counted per row of five ears in each plot, chosen randomly within the experimental area. Two plants without ears were weighed per plot to obtain the weight of the matter mass in the straw. A sample was taken and subjected to drying in an oven with forced air circulation, at 65 °C until constant mass, determining the water content, and, subsequently, the value of grain production was determined using the dry matter mass per hectare. The yield values per plot were obtained using a mechanical threshing machine of grains. The grains were separated and weighed, and the values (Y) were adjusted to 13% of water content [21,22] according to Equation (1).

where Y is the mass of grains on humidity of 13% (kg); m is the initial mass of the sample (kg); U is the real water content of the grains (%). The crop yield was obtained by converting Y to kg ha−1.

Y = m × [(100 − U)/(100 − 13)]

The operational parameters of agricultural machinery were also measured in the field while considering the variables associated with sliding of the seeder and wheels of the tractor, travel speed, and the operational field capacity (FC). The slippage of the seeder’s wheels (PS) was calculated as function of the wheel’s perimeter and its route in the plot, that is, the number of theoretical turns, obtained by the perimeter of the wheel, in relation to the number of real turns (Equation (2)).

where PS is slippage of seeder’s wheels (%); VR is the real number of turns of the seeder drive wheel; VT is the theoretical cycle of the seeder drive wheel. The tractor’s slippage (PRT) was determined by means of the number of turns of the wheels with load and without load (Equation (3)).

where PRT is wheelset slipping (%); VCC is the number of turns of the wheels with load; VCS is the number of turns of the wheels without load.

PS = [(VR − VT)/VR] × 100

PRT = [(VCC − VSC)/VCC] × 100

The travel speed was obtained in relation to the spacing covered in each plot over 20 m about the time set on the route. The operational field capacity (FC) was obtained considering the useful width of the seeder–fertilizer and its travel speed [23] (Equation (4)). The efficiency of equipment was set as 75% based on the field conditions.

where FC is the operational field capacity (ha h−1); W is the useful width of equipment (m); S is the travel speed (m s−1).

FC = W × S × 0.36 × 0.75

2.3. Field Management

The crop hybrids were selected according to the local conditions of environment and the current practices of agronomical management in the field. Hybrid A was P4285VYHR (Pioneer®), and Hybrid B was MG593PWU (Morgan®). Both hybrids were seeded with population of 65,000 plants ha−1 and density of 2.92 seeds m−1, assuming their capacity for crop germination and purity. Three soil-management systems were considered in the experimental area: one no-till (NT) system and two in-depth soil-scarification systems (0.15 m and 0.30 m).

The weed’s desiccation was performed in the entire area before sowing with 2.2 kg ha−1 of Glyphosate. The mechanized soil tillage and sowing were performed by a tractor (4 × 2 TDA) with maximum power of 110.28 kW (150 cv), rotation of 2000 rpm on engine, and constant speed of 1.80 m s−1. The mass of the tractor was distributed 40% on forward and 60% on rear (mass/power of 56 kg cv−1). The tire pressure was checked before each operation to follow the specifications of the manufacturer.

A drag seeder–fertilizer was used for corn sowing. The equipment (Figure 2A) is composed of a pneumatic seed dosing disc; one helical seed distributor–fertilizer configured for direct seeding with 17″ front cutting disc; rod-type furrower at 0.10 m in-depth adjusted to deposition of the fertilizer at 0.08 m; double 15″ mismatched discs for seeds deposition at 0.05 m of depth; and “V” compacting wheels configured for nine rows spaced 0.45 m apart. The AST/MATIC 450 equipment with seven rods was used to scarify soil using useful width of 2.80 m and weight of 2,115 kg equipped with straw cutting discs and crushing roller (Figure 2B).

Figure 2.

Equipment seeder–fertilizer (A), soil scarifier (B).

2.4. Data Analysis

The experimental area was designed using randomized blocks with 6 treatments in a 3 × 2 scheme, with four replications, 3 soil-management systems, and 2 corn hybrids, totaling 24 experimental units. Table 1 describes the treatments established in study.

Table 1.

Description of the treatments in the experimental area.

The original dataset was subjected to the F Test and, when applicable, to Tukey test (p < 0.05) to compare the mean values between each treatment. All statistical analyses were performed in R software version 4.2.2. The data dispersion was calculated by means of coefficient of variation (CV) by dividing the standard deviation by the mean value of each variable per treatment.

3. Results and Discussion

The descriptive statistic of the dataset is shown in Table 2. No statistical difference was observed in values of the seedling emergence, seed depth, and plants’ spacing under induced variations in the environment (hybrids and soil management). A higher CV was observed for a double distribution (Xi < 0.17 m; CV = 174%) of the seeds for both conditions in the experimental area. The data dispersion for a double distribution of grains is commonly reported in the literature while considering high-variability CV values above 25% [24,25]. The normal distribution of the seeds demonstrated a low data dispersion (CV = 15%) that is required for sowing operations in the field. This demonstrated the importance of the local calibration of agricultural machinery before operation and monitoring its performance in the field.

Table 2.

Mean values of the seed’s emergence, seed depth, and distribution within rows, subject to different treatments.

The number of days for plant emergence was the same for all conditions of soil management and crop hybrids. The seed depth was uniform (about 0.04 m) for all induced conditions in the field, demonstrating the operational control of agricultural machinery during the sowing even using different strategies of soil tillage. Amorim et al. [26] also observed a uniform seed depth under different treatments and operational parameters of the assembly (seeder–fertilizer) because its variation was more significant when there was no control of the assembly’s speed.

No statistical difference was observed in crop parameters measured in the field (Table 3), such as plant height, stem diameter, the number of grains per row, and the number of ears per row, under induced variations in the environment (hybrids and soil management systems). This could be explained by other factors affecting crop development (i.e., water content and nutrient availability), which were considered uniform across the field. The NT system promoted higher values of phytotechnical attributes of the crop compared to other soil-management systems. These results consolidated the potential benefits of the NT system to corn yield, as highlighted by Rinaldi et al. [27].

Table 3.

Mean values of the crop parameters subject to different treatments.

The initial plant population was statistically different between hybrids installed in the field (Table 4). Hybrid B had a greater plant population in the initial stage of the crop compared to Hybrid A. As a consequence, the crop yield was greater for Hybrid B (about 11 t ha−1) in comparison to Hybrid A (about 10 t ha−1). The crop yield demonstrated higher variation (CV = 24%) among the crop variables due to the non-uniformity of the plant development and soil factors over the field. No difference was evidenced between soil-management systems in relation to the crop yield, demonstrating that the selection of the hybrids by the environment is more significant than the proposal of increasing it. Despite the difference in the initial plant populations between the evaluated hybrids, it did not interfere with the final plant’s population because the parameter is more associated with seed depth and the spacing of the in-row plants. Rolim et al. [28] observed the same effect by comparing the initial and final plant populations for corn under hydric stress. It is not possible to confirm those results for the long-term adoption of soil-management systems because some studies related to an increase in corn yield values, such as that by Somavilla et al. [29], found an increment in crop yield under mechanical intervention (soil scarification) compared to the continuous adoption of the NT system when considering two consecutive seasons.

Table 4.

Mean values of the plant population, dry mass, and corn yield subject to different treatments.

There was a statistical difference between the NT system and soil-scarification methods related to the operational performance of the agricultural machinery for all variables considered in data acquisition (PS, PRT, speed, and FC). But there was no difference when comparing its values under the induced variation of the hybrids (Table 5). The mean values of PS under the NT system were two times lower than the values observed in both soil scarification depths, and PRT was three times higher under the NT system due to the low area of contact of the tires with the soil surface. Consequently, PRT had greater variation (CV = 69%) among the evaluated variables of machinery performance. Fleck et al. [30] observed a similar effect when comparing the operational performance of both soil-management systems for rice cultivation. The variable FC was smaller for the NT system (1.59 ha h−1) compared to the values obtained for soil scarification (about 1.70 ha−1). So, increasing the operational speed of the assembly promoted higher FC for the evaluated field conditions. Zimmermann et al. [31] described that this increase did not affect the quality of soil tillage and reduced the energy demand of the tractor.

Table 5.

Mean values of the agricultural machinery performance. PS: slippage of the seeder’s wheels; PRT: tractor’s slippage; FC: operational field capacity.

Future studies should focus on including more crop hybrids as well as variations in the adjustment of the agricultural machinery to obtain higher levels of corn yield using multiple environmental and field conditions. Agricultural engineering and technology sectors could assist the development of national policies to consolidate the adoption of NT system for food production and, in some cases, to advise soil scarification according to the compacted soil layer as an alternative to increase crop yield. Also, automated adjustments on agricultural machinery could be performed by the industry to improve the FC by means of speed control as function of soil condition. For example, considering agricultural practices under tropical conditions, it is common to observe variation in soil texture, terrain slope, and residual straw, but currently, the mechanized systems are configured and designed while assuming uniform field conditions.

4. Conclusions

The adopted soil-management systems did not interfere with variables of sowing quality, phytotechnical parameters of the crop, and crop yield. A difference was observed in yield among the implemented hybrids for the same environment. It was not feasible to carry out soil scarification as a method for increasing crop yield in the conditions of the experimental area. The slip rate of the tractor’s rear wheels achieved better performance in the no-till system. The travel speed and the operational field capacity achieved better rates under the soil-scarification method. Considering that the corn yield did not demonstrate any statistical difference between treatments in the short term, it is recommended to maintain an NT system for agricultural areas traditionally cultivated without soil intervention. Long-term studies and multi-temporal analysis are suggested to characterize and compare the performance of soil-management systems regarding grain yield and quality.

Author Contributions

Conceptualization, E.d.C.M. and C.E.A.F.; methodology, E.d.C.M., A.L. and C.E.A.F.; validation, E.d.C.M. and C.E.A.F.; formal analysis, E.d.C.M. and R.F.d.Q.; data curation, E.d.C.M. and R.F.d.Q.; writing—original draft preparation, E.d.C.M. and T.F.C.; writing—review and editing T.F.C.; supervision, C.E.A.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The dataset is available upon request from the authors.

Acknowledgments

The authors express gratitude to the members of the Laboratory of Machinery and Agricultural Mechanization (LAMMA) from the School of Agricultural and Veterinary Sciences, São Paulo State University (UNESP), as well as the collaborators from Farm of Teaching, Research and Extension (FEPE) of the same institution.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Nunes, V.J.; Leite, E.S.; de Lima, J.M.; Barbosa, R.S.; Santos, D.N.; Dias, F.P.M.; Nóbrega, J.C.A. Soil preparation systems and type of fertilization as affecting physical attributes of cohesive soil under eucalyptus in Northeastern Brazil. Acta Sci. 2023, 45, e58010. [Google Scholar] [CrossRef]

- Calonego, C.; Raphael, J.P.; Rigon, J.P.; Oliveira Neto, L.; Rosolem, C.A. Soil compaction management and soybean yields with cover crops under no-till and occasional chiseling. Eur. J. Agron. 2017, 85, 31–37. [Google Scholar] [CrossRef]

- Salomão, P.E.A.; Kriebel, W.; dos Santos, A.A.; Martins, A.C.E. A importância do sistema de plantio direto na palha para reestruturação do solo e restauração da matéria orgânica. Res. Soc. Dev. 2020, 9, 549–870. [Google Scholar] [CrossRef]

- Aguiar, E.B.; Schleder, E.J.D.; Santos, B.V.H.; Aguena, F.A.F. Plantio Direto na Cultura da Mandioca. Uniciências 2021, 25, 2–9. [Google Scholar] [CrossRef]

- Medeiros, G.D.O.R.; Giarolla, A.; Sampaio, G.; Marinho, M.D.A. Estimates of Annual Soil Loss Rates in the State of São Paulo, Brazil. Rev. Bras. De Ciência Do Solo 2016, 40, e0150497. [Google Scholar] [CrossRef]

- FAO. Status of the World’s Soil Resources: Main Report; Food and Agricultural Organization of the United Nations (FAO): Rome, Italy, 2015; Available online: https://openknowledge.fao.org/server/api/core/bitstreams/6ec24d75-19bd-4f1f-b1c5-5becf50d0871/content (accessed on 23 July 2024).

- FAO; IAEA. Use of 137Cs for Soil Erosion Assessment; Fulajtar, E., Mabit, L., Renschler, C.S., Yi, A.L.Z., Eds.; Food and Agricultural Organization of the United Nations (FAO): Rome, Italy; International Atomic Energy Agency (IAEA): Vienna, Austria, 2017; Available online: https://openknowledge.fao.org/server/api/core/bitstreams/e331eae7-d943-4633-af47-8280eef6b87e/content#:~:text=The%20use%20of%20137Cs%20for,by%20the%20international%20research%20community (accessed on 23 July 2024).

- Michelon, C.J.; Junges, E.; Casali, C.A.; Pellegrini, J.B.R.; Neto, L.R.; de Oliveira, Z.B.; Oliveira, M.B. Atributos do solo e produtividade do milho cultivado em sucessão a plantas de cobertura de inverno. Rev. De Ciências Agroveterinárias 2019, 18, 230–239. [Google Scholar] [CrossRef][Green Version]

- Setia, R.; Singh, B.P.; Gupta, N. Challenges and Opportunities in Managing Crop Residue for Multiple Benefits. In No-Till Farming Systems for Sustainable Agriculture; Dang, Y., Dalal, R., Menzies, N., Eds.; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Turmel, M.S.; Speratti, A.; Baudron, F.; Verhulst, N.; Govaerts, B. Crop residue management and soil health: A systems analysis. Agric. Syst. 2015, 134, 6–16. [Google Scholar] [CrossRef]

- Nascimento, V.D.; Arf, O.; Alves, M.C.; Souza, E.J.D.; Silva, P.R.T.d.; Kaneko, F.H.; Filho, M.C.M.T.; Jalal, A.; da Silva Oliveira, C.E.; Sabundjian, M.T.; et al. Cover Crops and Mechanical Scarification in the Yield and Industrial Quality of Upland Rice. Front. Environ. Sci. 2022, 10, 895993. [Google Scholar] [CrossRef]

- Fan, Y.-F.; Gao, J.-L.; Sun, J.-Y.; Liu, J.; Su, Z.-J.; Hu, S.-P.; Wang, Z.-G. Potentials of straw return and potassium supply on maize (Zea mays L.) photosynthesis, dry matter accumulation and yield. Sci. Rep. 2022, 12, 799. [Google Scholar] [CrossRef]

- Nunes, L.A.P.L.; Soares, B.K.F.; de Sousa, R.S.; Ibiapina, T.V.B.; Barbosa, L.R. Physical indicators after mechanical scarification in a Yellow Oxisol under no-tillage. Científica 2020, 48, 396–402. [Google Scholar] [CrossRef]

- Cherubin, M.R.; Bordonal, R.O.; Castioni, G.A.; Guimarães, E.M.; Lisboa, I.P.; Moraes, L.A.A.; Menandro, L.M.S.; Tenelli, S.; Cerri, C.E.P.; Karlen, D.L.; et al. Soil health response to sugarcane straw removal in Brazil. Ind. Crops Prod. 2021, 163, 113315. [Google Scholar] [CrossRef]

- Idowu, O.J.; Sultana, S.; Darapuneni, M.; Beck, L.; Steiner, R. Short-term Conservation Tillage Effects on Corn Silage Yield and Soil Quality in an Irrigated, Arid Agroecosystem. Agronomy 2019, 9, 455. [Google Scholar] [CrossRef]

- Lopes, J.E.; Chioderoli, C.A.; Monteiro, L.D.A.; Santos, M.A.D.; Cleef, E.H.V.; Nascimento, E.M. Operational and energy performance of the tractor-scarifier assembly: Tires, ballasting and soil cover. Rev. Bras. De Eng. Agrícola E Ambient. 2019, 23, 800–804. [Google Scholar] [CrossRef]

- Correia, T.P.S.; Fontana, J.L.C.; Lopes, A.G.C.; Pereira, R.S.; Silva, P.R.A. Operational costs of giant bamboo cultivation in different soil preparation systems. Energ. Na Agric. 2020, 35, 170–179. [Google Scholar] [CrossRef]

- Alvares, C.A.; Stape, J.L.; Sentelhas, P.C.; Gonçalves, J.D.M.; Sparovek, G. Köppen’s climate classification map for Brazil. Meteorol. Z. 2013, 22, 711–728. [Google Scholar] [CrossRef]

- Stolf, R.; Murakami, J.H.; Brugnaro, C.; Silva, L.G.; Silva, L.C.F.D.; Margarido, L.A.C. Penetrômetro de impacto stolf-programa computacional de dados em Excel-vba. Rev. Bras. De Ciência Do Solo 2014, 38, 774–782. [Google Scholar] [CrossRef]

- Kurachi, S.A.H.; Costa, J.A.S.; Bernardi, J.A.; Coelho, J.L.D.; Silveira, G.M. Avaliação tecnológica de semeadoras e/ou adubadoras: Tratamento de dados de ensaios e regularidade de distribuição longitudinal de sementes. Bragantia 1989, 48, 249–262. [Google Scholar] [CrossRef]

- Brasil—Ministério da Agricultura, Pecuária e Abastecimento. Regras para Análise de Sementes. Brasília: SNDA/DNPV/CLAV. 2019; 398p. Available online: https://www.gov.br/agricultura/pt-br/assuntos/insumos-agropecuarios/arquivos-publicacoes-insumos/2946_regras_analise__sementes.pdf (accessed on 4 March 2024).

- ISO 6540:2021; Maize—Determination of Moisture Content (on Milled Grains and on Whole Grains). ISO: Geneva, Switzerland, 2021.

- Mialhe, L.G. Máquinas Agrícolas: Ensaio & Certificação; Fundação de Estudos Agrários Luiz de Queiroz: Piracicaba, Brazil, 1996. (In Portuguese) [Google Scholar]

- Arcoverde, S.N.S.; de Souza, C.M.A.; Cortez, J.W.; Guazina, R.A.; Maciak, P.A.G. Qualidade do processo de semeadura da cultura do milho de segunda safra. Rev. Eng. Na Agric. 2017, 24, 383–392. [Google Scholar] [CrossRef][Green Version]

- Ferreira, F.M.; Oss, L.L.; de Almeida Carneiro, M.; Litter, F.A. Distribuição longitudinal na semeadura do milho com semeadoras de precisão mecânica e pneumática. Nativa 2019, 7, 296–300. [Google Scholar] [CrossRef]

- Amorim, M.Q.; de Araujo Nicolau, F.E.; de Araujo Mendonça, C.; dos Santos, P.R.A.; Chioderoli, C.A. Desempenho operacional do conjunto trator semeadora adubadora de fluxo contínuo em função da pressão de inflação dos rodados e velocidade de deslocamento. Energ. Na Agric. 2019, 34, 152–161. [Google Scholar] [CrossRef]

- Rinaldi, P.C.N.; Zampiroli, R.; de Alvarenga, C.B.; de Araújo Gallis, R.B.; Fernandes, H.C. Métodos de avaliação da distribuição longitudinal de plântulas no estabelecimento inicial da cultura do milho. Nativa 2021, 9, 157–162. [Google Scholar] [CrossRef]

- Rolim, J.I.M.; de Araújo Nicolau, F.E.; Mota, A.M.D.; Pinto, A.A.; da Camara, F.T. Desenvolvimento e produtividade do milho em sistema plantio direto no cariri cearense. Rev. Eng. Na Agric. 2019, 27, 122–131. [Google Scholar] [CrossRef]

- Somavilla, L.; Pinto, M.A.B.; Basso, C.J.; Da Ros, C.O.; da Silva, V.R.; Brun, T.; Santi, A.L. Resposta da soja e milho a intervenção mecânica do solo e aplicação de gesso agrícola em superfície. Semin. Ciências Agrárias 2016, 37, 95–102. [Google Scholar] [CrossRef]

- Fleck, A.G.; Marchesan, E.; Schlosser, J.F.; de Oliveira, D.S.; Prochnow, M.H.; Soares, C.F.; Herzog, D. Soil deep tillage performed before soybean cultivation on the rice cultivation in the following harvest. Ciência Rural. 2023, 53, e20210621. [Google Scholar] [CrossRef]

- Zimmermann, G.G.; Jasper, S.P.; Savi, D.; Francetto, T.R.; Cortez, J.W. Full-powershift energy behavior tractor in soil tillage operation. Eng. Agrícola 2023, 43, e20230054. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).