Screening and Evaluation of Biomechanical Properties and Morphological Characteristics of Peduncles in Foxtail Millet

Abstract

:1. Introduction

2. Materials and Methods

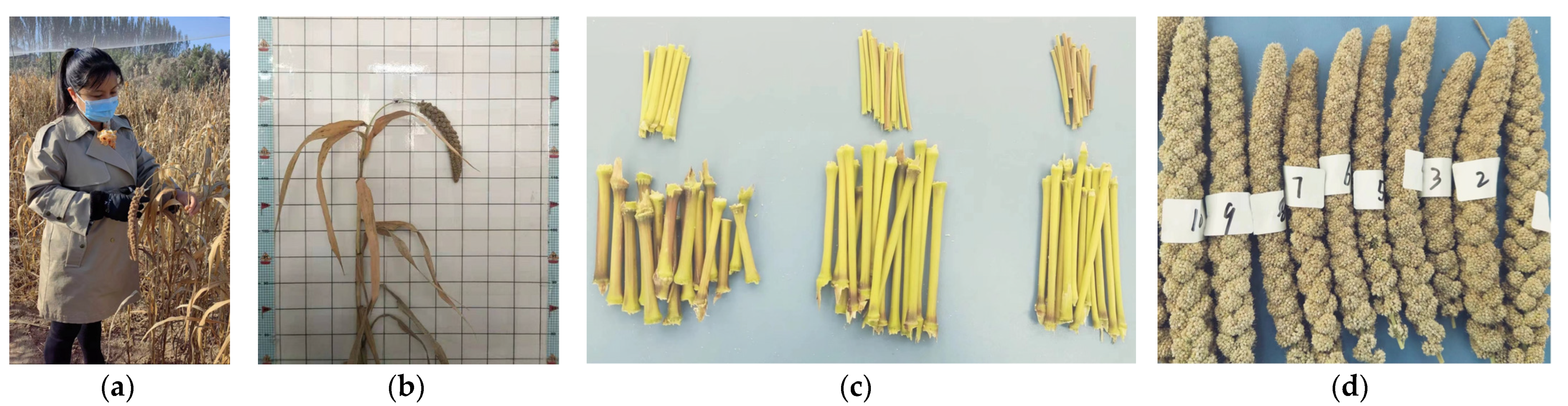

2.1. Experimental Materials

2.2. Index Determination

2.2.1. Morphological Characteristics

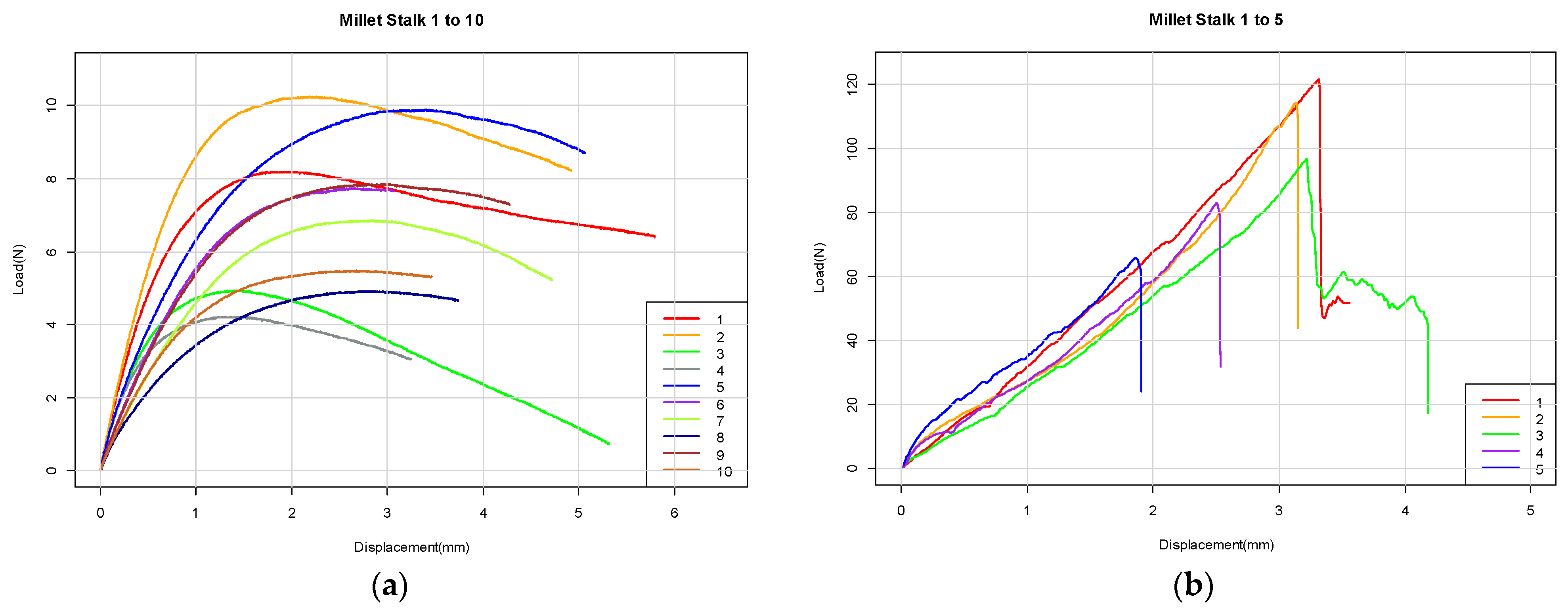

2.2.2. Biomechanical Properties

2.3. Data Processing and Analysis Methods

2.3.1. Data Preprocessing

2.3.2. Multi-Index Screening Method

2.3.3. The Entropy Weighting Method

2.3.4. The TOPSIS Comprehensive Evaluation Method

2.3.5. The RSR Comprehensive Evaluation Method

3. Results

3.1. Descriptive Statistical Analysis

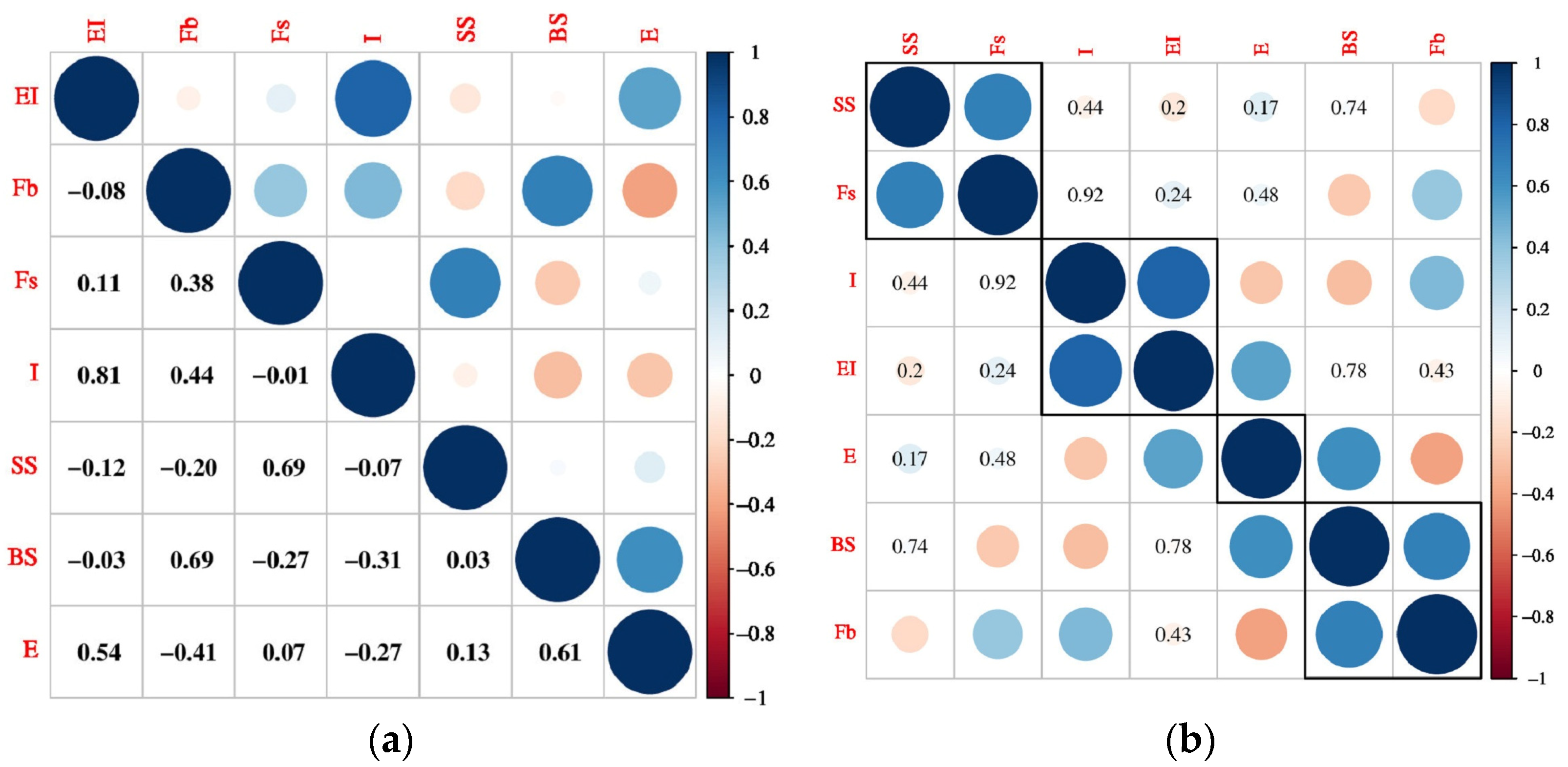

3.2. Screening Indicators

3.3. Index Weighting Based on the Entropy Value Method

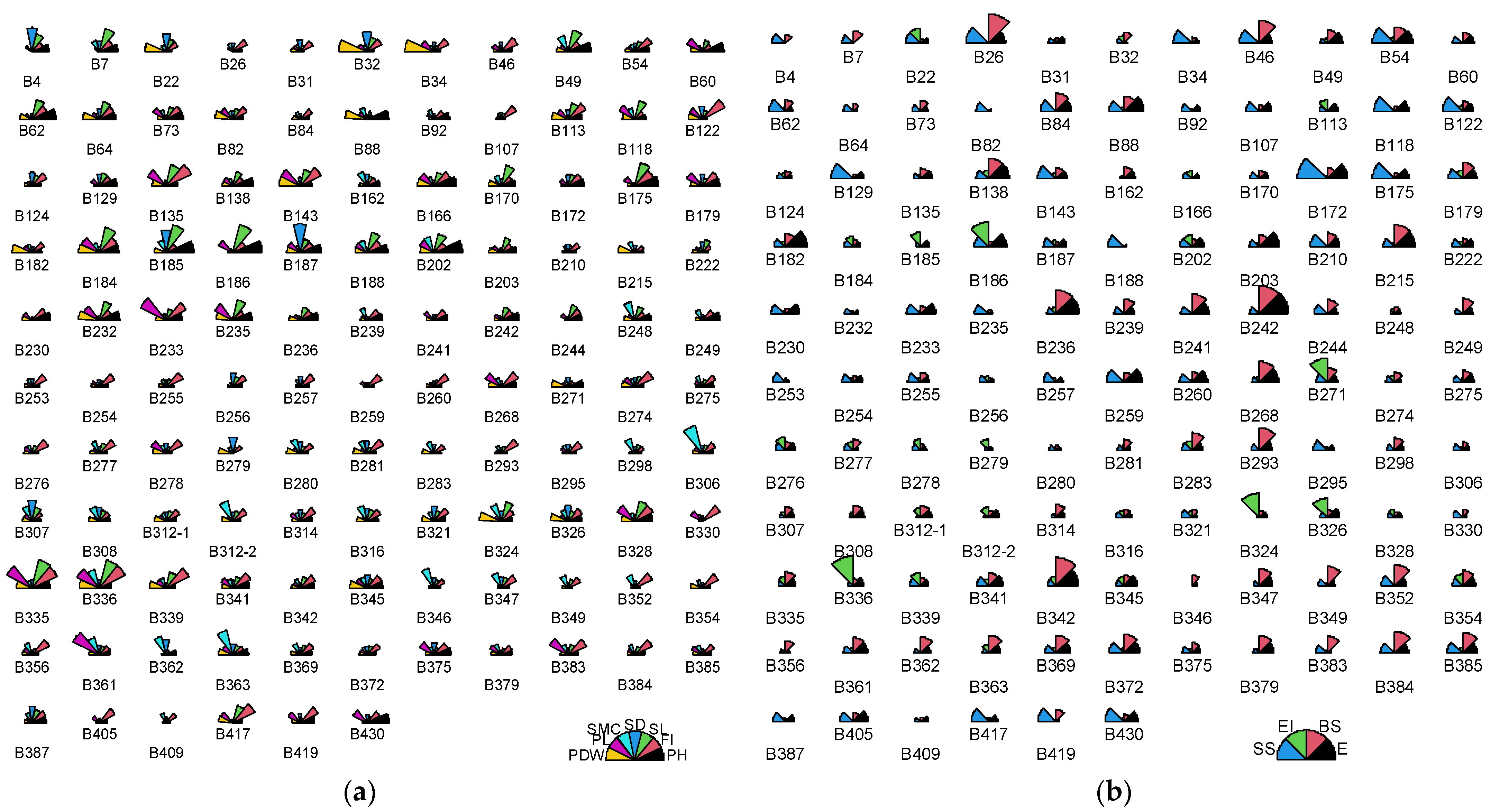

3.4. TOPSIS-RSR Comprehensive Evaluation

4. Discussion

4.1. Screening of the Measured Indicators

4.1.1. Partial Correlation Analysis of the Indicators

4.1.2. Cluster Analysis of the Indicators

4.2. Assigning Weights for the Selected Indicators

4.3. Comprehensive Evaluation of Participating Foxtail Millet Accessions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, S.G.; Liu, F.; Liu, M.; Cheng, R.H.; Xia, E.J.; Diao, X.M. Current status and future prospective of foxtail millet production and seed industry in China. Sci. Agric. Sin. 2021, 54, 459–470. [Google Scholar] [CrossRef]

- Sharma, N.; Niranjan, K. Foxtail millet: Properties, processing, health benefits, and uses. Food Rev. Int. 2018, 34, 329–363. [Google Scholar] [CrossRef]

- Jia, G.Q.; Diao, X.M. Current status and perspectives of innovation studies related to foxtail millet seed industry in China. Sci. Agric. Sin. 2022, 55, 653–665. [Google Scholar] [CrossRef]

- Yu, B.X.; Wang, H.; Yang, J.; Duan, H.; Wang, Y.Y.; Li, Z. Effects of Paclobutrazol and Ethephon on the Panicle Neck, Panicle Traits and Grain Filling of Foxtail Millet. J. Nuclear Agric. Sci. 2019, 33, 1199–1207. [Google Scholar] [CrossRef]

- Xu, H.F. Current status and development trends of mechanized production of foxtail millet. Agric. Technol. Eq. 2014, 17, 38–39. [Google Scholar]

- Yang, Z.J.; Liu, H.X.; Wu, H.Y.; Chen, J.Z. Developing direction of millet harvesting mechanization and the associated machines. J. Hebei Agric. Sci. 2013, 17, 6–8. [Google Scholar] [CrossRef]

- Yang, Y.; Lei, J.S.; Wang, J.; Wang, S. Development status and countermeasures of millet production mechanization in shanxi. Agric. Technol. Eq. 2017, 333, 61–63. [Google Scholar] [CrossRef]

- Yu, Z.J. Experimental and analytical study on the mechanization harvesting technology of foxtail millet. Farm. Mach. 2017, 60, 103–105. [Google Scholar] [CrossRef]

- Du, Y.W.; Zhao, J.F.; Wang, G.H.; Li, Y.F.; Zhao, G.Y.; Yan, X.G. Study of Lodging Resistance of Spring-Sowing Foxtail Millet in Maturity Stages. Crops 2019, 35, 141–145. [Google Scholar] [CrossRef]

- Xia, X.; Yang, Z.; Cheng, R.; Shi, Z.; Wu, H.; Liu, H.; Liu, M.; Zhao, Y.; Li, X.; Jiao, H.; et al. Technical Regulation of Foxtail Millet Production by Combining Machinery and Agronomy. Agric. Sci. Technol. 2016, 17, 1106–1109. [Google Scholar] [CrossRef]

- Zhang, N.; Li, H.B.; Zhang, Y.Q.; Cui, Q.L.; Sun, Q.F. Experimental Study on the Friction Characteristics of Millet Leaves at Harvest Time. J. Agric. Mech. Res. 2019, 41, 154–161. [Google Scholar] [CrossRef]

- Tian, B.H.; Luan, S.R.; Zhang, L.X.; Liu, Y.L.; Zhang, L.; Li, H.J. Penalties in yield and yield associated traits caused by stem lodging at different developmental stages in summer and spring foxtail millet cultivars. Field Crops Res. 2018, 217, 104–112. [Google Scholar] [CrossRef]

- Diao, X.M. Breeding innovation creates new development in millet seed industry. China Seed Ind. 2022, 325, 4–7. [Google Scholar] [CrossRef]

- Song, X.E.; Wang, H.; Dong, Q.; Qiu, T.; Shi, C.; Li, X.; Dong, S.; Zhao, J.; Guo, P.; Yuan, X.Y. Comprehensive Evaluation and Main Identification Indexes of Herbicide Resistance of High-Quality Foxtail Millet (Setaria italica L.). Agronomy 2023, 13, 3033. [Google Scholar] [CrossRef]

- Zhang, L.; Ma, K.; Zhao, X.; Li, Z.; Zhang, X.; Li, W.; Meng, R.; Lu, B.; Yuan, X.Y. Development of a comprehensive quality evaluation system for foxtail millet from different ecological regions. Foods 2023, 12, 2545. [Google Scholar] [CrossRef] [PubMed]

- Feng, G.J.; Hu, X.W.; Zhao, Y.; Yu, M.; Zhang, S.G.; Zhou, D.L. Research progress, problems and development prospect of foxtail millet industry in Xinjiang. Xinjiang Agric. Sci. 2023, 60, 1887–1893. [Google Scholar] [CrossRef]

- Zhang, N.; Wu, W.; Li, S.; Wang, Y.; Ma, Y.; Meng, X.; Zhang, Y. Comprehensive Evaluation of Paddy Quality by Different Drying Methods, Based on Gray Relational Analysis. Agriculture 2022, 12, 1857. [Google Scholar] [CrossRef]

- Zhou, H.; Dai, L.J.; Li, Y.P.; Huang, X.L.; Ma, Y.P. Grey Correlation Analysis and Evaluation of Main Agronomic Characters of 11 New Millet Cultivars. Gansu Agric. Sci. Technol. 2020, 12, 25–30. [Google Scholar] [CrossRef]

- Zhang, X.S.; Han, Y.L.; Fan, Y.Q.; Wang, Y.H.; Liu, J.Z.; Cao, H.; Zuo, H.J.; Miao, Z.F. Comprehensive Evaluation of Millet of Regional Test by Grey Relational Degree Analysis and DTOPSIS Method. Seed 2022, 41, 121–126+133. [Google Scholar] [CrossRef]

- Xing, G.F.; Hou, Y.; Wang, H.; Ren, C.; Ma, J.W.; Lu, C.D. Screening and Evaluation of Efficient Utilization of Selenium in Foxtail Millet at the Seedling Stage. J. Plant Genet. Resour. 2023, 24, 158–171. [Google Scholar] [CrossRef]

- Zhao, M.Q.; Wang, Z.J.; Bao, J.; Sun, L.; Zhang, Y.H.; Wen, R.; Jia, Y.S.; Ge, G.T. Analysis and evaluation of forage millet quality under different fertility and storage times using the membership function method. Pratacultural Sci. 2023, 40, 200–207. [Google Scholar] [CrossRef]

- Fan, Y.; Dong, S.Q.; Yuan, X.Y.; Yang, X.P.; Yao, X.; Guo, P.Y.; Yang, X.F. Comprehensive Evaluation of Foxtail Millet Germplasm Resources During germination Period and Drought Resistance Index Screening. J. China Agric. Univ. 2022, 27, 42–54. [Google Scholar] [CrossRef]

- Gao, Q.; Zhang, Y.; Lu, Z.F.; Yan, Q.; Li, K.K.; Chen, R.F.; Yang, Y.; Xu, L.; Zhou, W. Summer Millet Varieties for Planting in Kashgar of Xinjiang: Comprehensive Evaluation by DTOPSIS Method Based on Entropy Weight. Chin. Agric. Sci. Bull. 2024, 40, 42–47. [Google Scholar]

- Song, Z.Q.; Zhang, W.C.; Wang, S.; Zhang, Y.; Li, L.; Yang, Y.Y.; Liu, J.R. Comprehensive Evaluation of Foxtail Millet Test Varieties Based on the Integration of DTOPSIS Method and Fuzzy Evaluation Method with Entropy Weighting. Jiangsu Agric. Sci. 2023, 51, 49–54. [Google Scholar] [CrossRef]

- Song, H.; Guo, Y.; Xing, L.; Li, L.; Zang, H.Z.; Li, G.Q.; Wang, S.Y.; Zheng, G.Q. Comprehensive evaluation of foxtail millet varieties based on grey correlation degree, DTOPSIS and situational decision-making method. J. China Agric. Univ. 2023, 28, 42–56. [Google Scholar] [CrossRef]

- Tian, F.T. The Method of Ranks and Their Applications; China Statistics Press: Beijing, China, 1993. [Google Scholar]

- Fu, X.Q.; Chen, H.Y. Comprehensive power quality evaluation based on weighted rank sum ration method. Elect. Power Auto Equip. 2015, 35, 128–132. [Google Scholar] [CrossRef]

- Wang, Z.; Dang, S.; Xing, Y.; Li, Q.; Yan, H. Applying rank sum ratio (RSR) to the evaluation of feeding practices behaviors, and its associations with infant health risk in Rural Lhasa, Tibet. Int. J. Environ. Res. Public Health 2015, 12, 15173–15181. [Google Scholar] [CrossRef]

- Yuan, Z.H.; Feng, B.P.; Zhao, A.Q.; Liang, A.Q. Dynamic Analysis and Comprehensive Evaluation of Crop-Stem Lodging Resistance. Trans. CSAE 2002, 18, 30–31. [Google Scholar]

- Guo, Y.M.; Yuan, H.M.; Yin, Y.; Liang, L.; Li, H.B. Biomechanical evaluation and grey relational analysis of lodging resistance of stalk crops. Trans. CSAE 2007, 23, 14–18. [Google Scholar]

- Gao, M.; Xu, Y.; Qu, X.C.; Ma, Y.M.; Gao, Z.; Zhou, B.H.; Zhang, W.L. Identification and Evaluation on Lodging Resistance of Millet Varieties (Lines). J. Northeast Agric. Sci. 2024, 49, 50–53. [Google Scholar] [CrossRef]

- Jia, X.P.; Dong, P.H.; Zhang, H.X.; Kong, X.S. Analysis of growth and development characteristics and lodging resistance of different foxtail millet Cultivars (Strains). J. Henan Agric. Sci. 2015, 44, 27–31. [Google Scholar] [CrossRef]

- Liang, L.; Guo, Y.M. Correlation study of biomechanical properties and morphological characteristics of crop stalks. Trans. CSAE 2008, 24, 1–6. [Google Scholar]

- Zhang, Y.Q. Experimental Study on Cutting Mechanical Properties of Coarse Cereals Stem Related to Mechanical Harvest. Ph.D. Thesis, Shanxi Agricultural University, Taigu, China, 2019. [Google Scholar] [CrossRef]

- Zhu, X.; Wei, G. A Discussion on the Evaluation Criteria of Dimensionless Methods in Entropy Value Method. Stat. Decis. 2015, 422, 12–15. [Google Scholar] [CrossRef]

- Yan, L.K. Application of Correlation Coefficient and Biased Correlation Coefficient in Related Analysis. J. Yunnan Univ. Fin. Econ. 2003, 19, 78–80. [Google Scholar] [CrossRef]

- Xue, Y.; Chen, L.P. Statistical Modeling and R Software, 1st ed.; Tsinghua University Press: Beijing, China, 2007; pp. 397–420. [Google Scholar]

- Peng, W.; Li, Y.; Fang, Y.; Wu, Y.; Li, Q. Radar chart for estimation performance evaluation. IEEE Access 2019, 7, 113880–113888. [Google Scholar] [CrossRef]

- Kaczynski, D.; Wood, L.; Harding, A. Using radar charts with qualitative evaluation: Techniques to assess change in blended learning. Act. Learn. Higher Educ. 2008, 9, 23–41. [Google Scholar] [CrossRef]

- Nikitina, M.A.; Chernukha, I.M. Nonparametric statistics. Part 3. Correlation coefficients. Theory Pract. Meat Process. 2023, 8, 237–251. [Google Scholar] [CrossRef]

- He, M.L.; Wang, Z.L.; Du, X.F.; Han, K.N.; Lian, S.C.; Li, Y.X.; Cheng, K.; Li, Y.F.; Wang, J. Analysis of Plant Architecture and Yield Traits of Recombination Inbred Lines in Foxtail Millet. Acta Agric. Boreali-Sin. 2023, 38, 91–100. [Google Scholar] [CrossRef]

- Liu, S.C.; Cao, X.N.; Wen, Q.F.; Wang, H.G.; Tian, X.; Wang, J.J.; Chen, L.; Qin, H.B.; Wang, L.; Qiao, Z.J. Comprehensive Evaluation of Agronomic Traits and Quality Traits of Foxtail Millet Landrace in Shanxi. Sci. Agric. Sin. 2020, 53, 2137–2148. [Google Scholar] [CrossRef]

- Zhao, Q. A Review of Principal Component Analysis. Softw. Eng. 2016, 19, 1–3. [Google Scholar]

- Lin, H.M.; Du, Z.F. Some Problems in Comprehensive Evaluation in the Principal Component Analysis. Stat. Res. 2013, 30, 25–31. [Google Scholar] [CrossRef]

- Chen, H. Entropy method and application to determine weights of combination forecasting. J. Anhui Univ. Nat. Sci. 2003, 27, 1–4. [Google Scholar]

- Li, X.M. A Review of Multi-Index Comprehensive Evaluation Methods. Stat. Manag. 2022, 37, 45–48. [Google Scholar] [CrossRef]

- Çelikbilek, Y.; Tüysüz, F. An in-depth review of theory of the TOPSIS method: An experimental analysis. J. Manag. Anal. 2020, 7, 281–300. [Google Scholar] [CrossRef]

- Chakraborty, S. TOPSIS and Modified TOPSIS: A comparative analysis. Decis. Anal. J. 2022, 2, 100021. [Google Scholar] [CrossRef]

- Chen, F.; Wang, J.; Deng, Y. Road safety risk evaluation by means of improved entropy TOPSIS–RSR. Saf. Sci. 2015, 79, 39–54. [Google Scholar] [CrossRef]

| Dimension | Trait 1 | Min | Max | Mean | SD | CV (%) | |

|---|---|---|---|---|---|---|---|

| Biological Morphological Characteristics | Plant | Plant Height/PH (cm) | 84.94 | 202.50 | 136.44 | 23.35 | 17.11 |

| Natural Height/NH (cm) | 59.64 | 155.32 | 102.18 | 19.29 | 18.88 | ||

| Flexural Index/FI (%) | 9.28 | 38.96 | 25.20 | 4.42 | 17.54 | ||

| Spike | Length/SL (mm) | 141.36 | 327.24 | 213.44 | 41.85 | 19.61 | |

| Diameter/SD (mm) | 16.30 | 45.40 | 24.80 | 4.92 | 19.84 | ||

| Weight/SW (g) | 5.28 | 46.09 | 21.51 | 7.44 | 34.59 | ||

| Dry Weight/SDW (g) | 3.75 | 35.59 | 15.99 | 5.46 | 34.15 | ||

| Moisture Content/SMC (%) | 13.14 | 50.43 | 25.14 | 6.52 | 25.93 | ||

| Peduncle | Length/PL (cm) | 19.28 | 67.49 | 35.59 | 9.71 | 27.28 | |

| External Diameter/PED (mm) | 2.04 | 4.83 | 3.28 | 0.57 | 17.38 | ||

| Wall Thickness/PWT (mm) | 0.42 | 1.25 | 0.77 | 0.17 | 22.08 | ||

| Thickness-diameter Ratio/PTDR (%) | 0.17 | 0.36 | 0.23 | 0.03 | 13.04 | ||

| Weight/PW (g) | 0.57 | 13.70 | 5.69 | 2.71 | 47.63 | ||

| Dry Weight/PDW (g) | 0.24 | 5.00 | 1.97 | 0.88 | 44.67 | ||

| Moisture Content/PMC (%) | 45.78 | 72.66 | 64.61 | 3.96 | 6.13 | ||

| Biomechanical Properties | Bending | Cross-Sectional Moment of Inertia/I (mm4) | 0.90 | 31.22 | 7.35 | 5.81 | 79.05 |

| Elastic Modulus/E (MPa) | 668.78 | 5698.66 | 2523.35 | 890.37 | 35.29 | ||

| Bending Strength/BS (MPa) | 13.70 | 47.32 | 26.23 | 7.21 | 27.49 | ||

| Flexural Rigidity/EI (N·mm2) | 2817.79 | 72,497.11 | 16,165.49 | 12,437.23 | 76.94 | ||

| Maximum Bending Force/Fb (N) | 2.99 | 28.9 | 9.10 | 4.19 | 46.04 | ||

| Shearing | Shear Strength/SS (MPa) | 5.38 | 30.81 | 14.88 | 4.25 | 28.56 | |

| Maximum Shearing Force/Fs (N) | 15.38 | 204.28 | 88.67 | 35.8 | 40.37 | ||

| Indicator | Entropy Value | Information Utility Value | Weight (%) |

|---|---|---|---|

| Flexural Rigidity | 0.927 | 0.073 | 22.386 |

| Bending Strength | 0.964 | 0.036 | 11.037 |

| Spike Length | 0.964 | 0.036 | 10.870 |

| Peduncle Length | 0.965 | 0.035 | 10.834 |

| Spike Diameter | 0.967 | 0.033 | 9.952 |

| Elastic Modulus | 0.975 | 0.025 | 7.615 |

| Diameter of the Peduncle | 0.975 | 0.025 | 7.578 |

| Spike Weight | 0.978 | 0.022 | 6.761 |

| Shear Strength | 0.979 | 0.021 | 6.360 |

| Plant Height | 0.984 | 0.016 | 4.795 |

| Moisture Content of the Peduncle | 0.994 | 0.006 | 1.812 |

| Variety | Name | PISD (D+) | NISD (D−) | Composite Score | Sorting | RSR | Probit | Fitted RSR | Threshold * | Grading |

|---|---|---|---|---|---|---|---|---|---|---|

| B336 | Longgu6 | 0.492 | 0.733 | 0.598 | 1 | 1.000 | 7.855 | 1.160 | >6.5 | 4 |

| B324 | Jigu11 | 0.502 | 0.650 | 0.564 | 2 | 0.963 | 7.382 | 1.044 | ||

| B186 | Rangu | 0.556 | 0.658 | 0.542 | 3 | 0.937 | 7.114 | 0.979 | ||

| B271 | Fenggu12 | 0.515 | 0.576 | 0.528 | 4 | 0.918 | 6.945 | 0.937 | ||

| B326 | Jigu13 | 0.510 | 0.550 | 0.519 | 5 | 0.904 | 6.819 | 0.906 | ||

| B185 | Xiaohuanggu | 0.574 | 0.618 | 0.518 | 6 | 0.898 | 6.716 | 0.881 | ||

| B022 | Damaomaogu | 0.523 | 0.552 | 0.513 | 7 | 0.888 | 6.628 | 0.860 | ||

| B032 | Jiangu | 0.580 | 0.548 | 0.486 | 8 | 0.856 | 6.552 | 0.841 | ||

| B335 | Longgu5 | 0.580 | 0.533 | 0.479 | 9 | 0.845 | 6.484 | 0.824 | 5~6.5 | 3 |

| B342 | Gonggu68 | 0.588 | 0.516 | 0.467 | 10 | 0.828 | 6.421 | 0.809 | ||

| B307 | Yugu11 | 0.595 | 0.514 | 0.464 | 11 | 0.819 | 6.364 | 0.795 | ||

| B279 | Jigu24 | 0.639 | 0.518 | 0.448 | 12 | 0.799 | 6.312 | 0.782 | ||

| B187 | Zhouliwei | 0.622 | 0.503 | 0.447 | 13 | 0.793 | 6.262 | 0.770 | ||

| B339 | Longgu9 | 0.595 | 0.467 | 0.440 | 14 | 0.781 | 6.216 | 0.758 | ||

| B054 | Xiaozigen | 0.597 | 0.461 | 0.436 | 15 | 0.771 | 6.172 | 0.747 | ||

| B184 | Huangjiugenqi | 0.632 | 0.477 | 0.430 | 16 | 0.760 | 6.130 | 0.737 | ||

| B138 | Tie8396 | 0.611 | 0.453 | 0.426 | 17 | 0.751 | 6.090 | 0.727 | ||

| B242 | Zhongmou-baogu | 0.701 | 0.516 | 0.424 | 18 | 0.743 | 6.051 | 0.718 | ||

| B172 | Bachagu | 0.638 | 0.469 | 0.424 | 19 | 0.738 | 6.014 | 0.709 | ||

| B179 | Huangdanzigu | 0.599 | 0.430 | 0.418 | 20 | 0.727 | 5.979 | 0.700 | ||

| B345 | Chaogu13 | 0.606 | 0.431 | 0.416 | 21 | 0.719 | 5.945 | 0.692 | ||

| B236 | — | 0.653 | 0.464 | 0.416 | 22 | 0.713 | 5.911 | 0.684 | ||

| B308 | Yugu9 | 0.640 | 0.436 | 0.405 | 23 | 0.698 | 5.879 | 0.676 | ||

| B277 | Jigu21 | 0.632 | 0.430 | 0.405 | 24 | 0.693 | 5.848 | 0.668 | ||

| B363 | Chenggu 12 | 0.615 | 0.416 | 0.403 | 25 | 0.685 | 5.817 | 0.660 | ||

| B278 | Jigu22 | 0.639 | 0.431 | 0.403 | 26 | 0.679 | 5.787 | 0.653 | ||

| B283 | K325 | 0.645 | 0.431 | 0.401 | 27 | 0.672 | 5.758 | 0.646 | ||

| B007 | Hongniangu | 0.690 | 0.455 | 0.398 | 28 | 0.663 | 5.730 | 0.639 | ||

| B222 | Gouweisu | 0.634 | 0.418 | 0.397 | 29 | 0.658 | 5.702 | 0.632 | ||

| B143 | Hongniangu | 0.630 | 0.415 | 0.397 | 30 | 0.652 | 5.674 | 0.625 | ||

| B372 | Gonggu66 | 0.640 | 0.421 | 0.397 | 31 | 0.646 | 5.648 | 0.619 | ||

| B274 | Jigu18 | 0.639 | 0.418 | 0.396 | 32 | 0.639 | 5.621 | 0.612 | ||

| B113 | Xiaohonggu | 0.639 | 0.418 | 0.396 | 33 | 0.634 | 5.595 | 0.606 | ||

| B122 | Xiaohonggu | 0.648 | 0.424 | 0.395 | 34 | 0.628 | 5.570 | 0.600 | ||

| B026 | Jingu5 | 0.751 | 0.489 | 0.395 | 35 | 0.622 | 5.544 | 0.593 | ||

| B312-1 | Yugu7 | 0.628 | 0.406 | 0.392 | 36 | 0.614 | 5.519 | 0.587 | ||

| B202 | Jinshu | 0.648 | 0.417 | 0.392 | 37 | 0.608 | 5.495 | 0.581 | ||

| B256 | Maosu | 0.661 | 0.425 | 0.391 | 38 | 0.602 | 5.471 | 0.575 | ||

| B004 | Caopi-daobaqi | 0.705 | 0.449 | 0.389 | 39 | 0.594 | 5.447 | 0.569 | ||

| B312-2 | Yugu7 | 0.638 | 0.405 | 0.388 | 40 | 0.588 | 5.423 | 0.564 | ||

| B049 | Jiugu13 | 0.669 | 0.423 | 0.387 | 41 | 0.581 | 5.399 | 0.558 | ||

| B276 | Jigu20 | 0.652 | 0.409 | 0.386 | 42 | 0.574 | 5.376 | 0.552 | ||

| B385 | Baigu9 | 0.663 | 0.415 | 0.385 | 43 | 0.568 | 5.353 | 0.546 | ||

| B354 | Jigu28 | 0.645 | 0.400 | 0.383 | 44 | 0.561 | 5.330 | 0.541 | ||

| B316 | Ji07607 | 0.641 | 0.396 | 0.382 | 45 | 0.554 | 5.307 | 0.535 | ||

| B328 | Honggaigu | 0.664 | 0.406 | 0.380 | 46 | 0.546 | 5.285 | 0.530 | ||

| B369 | Gonggu61 | 0.649 | 0.397 | 0.379 | 47 | 0.541 | 5.262 | 0.524 | ||

| B321 | Lugu8 | 0.652 | 0.398 | 0.379 | 48 | 0.535 | 5.240 | 0.519 | ||

| B215 | Zheng448 | 0.705 | 0.426 | 0.377 | 49 | 0.527 | 5.218 | 0.513 | ||

| B124 | Daqingjie | 0.659 | 0.398 | 0.376 | 50 | 0.521 | 5.196 | 0.508 | ||

| B341 | Gonggu65 | 0.641 | 0.386 | 0.376 | 51 | 0.515 | 5.174 | 0.503 | ||

| B268 | Chigu8 | 0.692 | 0.413 | 0.374 | 52 | 0.508 | 5.152 | 0.497 | ||

| B135 | 78-0625 | 0.678 | 0.404 | 0.373 | 53 | 0.502 | 5.130 | 0.492 | ||

| B361 | Cang156 | 0.654 | 0.384 | 0.370 | 54 | 0.493 | 5.108 | 0.486 | ||

| B384 | Baigu7 | 0.696 | 0.407 | 0.369 | 55 | 0.486 | 5.087 | 0.481 | ||

| B175 | Guang37 | 0.726 | 0.422 | 0.368 | 56 | 0.480 | 5.065 | 0.476 | ||

| B046 | Maotigu | 0.724 | 0.414 | 0.364 | 57 | 0.470 | 5.043 | 0.470 | ||

| B182 | Heguzi | 0.687 | 0.390 | 0.362 | 58 | 0.463 | 5.022 | 0.465 | ||

| B170 | Maomaogu | 0.693 | 0.387 | 0.358 | 59 | 0.454 | 5.000 | 0.460 | 3.5~5 | 2 |

| B203 | Xiaolibaibuyuxi | 0.685 | 0.380 | 0.357 | 60 | 0.448 | 4.978 | 0.455 | ||

| B387 | Chaogu15 | 0.691 | 0.382 | 0.356 | 61 | 0.441 | 4.957 | 0.449 | ||

| B062 | Huangniangu | 0.696 | 0.384 | 0.356 | 62 | 0.435 | 4.935 | 0.444 | ||

| B255 | Huangsu | 0.683 | 0.377 | 0.356 | 63 | 0.430 | 4.913 | 0.439 | ||

| B293 | Nei701 | 0.727 | 0.396 | 0.353 | 64 | 0.421 | 4.892 | 0.433 | ||

| B383 | Baigu6 | 0.697 | 0.377 | 0.351 | 65 | 0.414 | 4.870 | 0.428 | ||

| B347 | Jigu25 | 0.723 | 0.391 | 0.351 | 66 | 0.408 | 4.848 | 0.423 | ||

| B379 | Gonggu74 | 0.696 | 0.375 | 0.350 | 67 | 0.402 | 4.826 | 0.417 | ||

| B064 | 60tianhuangtang | 0.706 | 0.379 | 0.349 | 68 | 0.396 | 4.804 | 0.412 | ||

| B088 | — | 0.701 | 0.373 | 0.347 | 69 | 0.388 | 4.782 | 0.406 | ||

| B031 | Baiyousha | 0.704 | 0.372 | 0.346 | 70 | 0.382 | 4.760 | 0.401 | ||

| B281 | Jigu29 | 0.698 | 0.362 | 0.342 | 71 | 0.372 | 4.738 | 0.396 | ||

| B241 | Damaosui | 0.730 | 0.376 | 0.340 | 72 | 0.365 | 4.715 | 0.390 | ||

| B349 | Fenggu1 | 0.732 | 0.374 | 0.338 | 73 | 0.358 | 4.693 | 0.384 | ||

| B314 | Yugu14 | 0.691 | 0.352 | 0.337 | 74 | 0.351 | 4.670 | 0.379 | ||

| B259 | Datounuo | 0.730 | 0.371 | 0.337 | 75 | 0.345 | 4.647 | 0.373 | ||

| B235 | Yangmaonuo | 0.739 | 0.373 | 0.336 | 76 | 0.339 | 4.624 | 0.368 | ||

| B162 | Leshanbainuo | 0.697 | 0.351 | 0.335 | 77 | 0.332 | 4.601 | 0.362 | ||

| B352 | Jingu1 | 0.761 | 0.383 | 0.335 | 78 | 0.327 | 4.577 | 0.356 | ||

| B210 | Nianxiaomi | 0.723 | 0.364 | 0.335 | 79 | 0.321 | 4.553 | 0.350 | ||

| B280 | Jigu26 | 0.720 | 0.362 | 0.335 | 80 | 0.316 | 4.529 | 0.344 | ||

| B118 | Xiaohonggu | 0.764 | 0.382 | 0.333 | 81 | 0.309 | 4.505 | 0.338 | ||

| B257 | Zhimasu | 0.722 | 0.357 | 0.331 | 82 | 0.301 | 4.481 | 0.332 | ||

| B260 | Huangnanuo | 0.720 | 0.355 | 0.330 | 83 | 0.295 | 4.456 | 0.326 | ||

| B129 | Guzi | 0.726 | 0.356 | 0.329 | 84 | 0.288 | 4.430 | 0.320 | ||

| B417 | Jingu39 | 0.737 | 0.361 | 0.329 | 85 | 0.282 | 4.405 | 0.314 | ||

| B166 | Chaqinggu | 0.712 | 0.345 | 0.326 | 86 | 0.275 | 4.379 | 0.307 | ||

| B362 | — | 0.748 | 0.360 | 0.325 | 87 | 0.268 | 4.352 | 0.301 | ||

| B375 | Gonggu70 | 0.693 | 0.334 | 0.325 | 88 | 0.262 | 4.326 | 0.294 | ||

| B248 | longzhaonuo | 0.711 | 0.341 | 0.324 | 89 | 0.256 | 4.298 | 0.288 | ||

| B275 | Jigu38 | 0.717 | 0.341 | 0.323 | 90 | 0.249 | 4.270 | 0.281 | ||

| B084 | Ise-455 | 0.766 | 0.361 | 0.320 | 91 | 0.241 | 4.242 | 0.274 | ||

| B034 | Esiniugu | 0.742 | 0.348 | 0.319 | 92 | 0.235 | 4.213 | 0.267 | ||

| B356 | 206058 | 0.749 | 0.343 | 0.314 | 93 | 0.224 | 4.183 | 0.259 | ||

| B254 | Nuosu | 0.723 | 0.327 | 0.311 | 94 | 0.216 | 4.152 | 0.252 | ||

| B306 | An06h-8023 | 0.719 | 0.324 | 0.311 | 95 | 0.210 | 4.121 | 0.244 | ||

| B107 | Jinxiangyu | 0.757 | 0.340 | 0.310 | 96 | 0.204 | 4.089 | 0.236 | ||

| B233 | Geqing1 | 0.734 | 0.324 | 0.306 | 97 | 0.194 | 4.055 | 0.228 | ||

| B244 | Jizhaohuanggu | 0.780 | 0.340 | 0.303 | 98 | 0.186 | 4.021 | 0.220 | ||

| B188 | Bailiaojiang | 0.801 | 0.348 | 0.303 | 99 | 0.180 | 3.986 | 0.211 | ||

| B295 | 09dong-chuang140 | 0.749 | 0.325 | 0.303 | 100 | 0.174 | 3.949 | 0.202 | ||

| B232 | Guang37 | 0.774 | 0.335 | 0.302 | 101 | 0.168 | 3.910 | 0.192 | ||

| B430 | Changnong35 | 0.736 | 0.318 | 0.302 | 102 | 0.163 | 3.870 | 0.183 | ||

| B298 | 03-992 | 0.756 | 0.326 | 0.301 | 103 | 0.157 | 3.828 | 0.172 | ||

| B082 | Zhaohenuo | 0.775 | 0.333 | 0.301 | 104 | 0.150 | 3.784 | 0.162 | ||

| B419 | Changnong35 | 0.765 | 0.313 | 0.290 | 105 | 0.135 | 3.738 | 0.150 | ||

| B249 | Wuzhaonuoxiaogu | 0.765 | 0.311 | 0.289 | 106 | 0.129 | 3.688 | 0.138 | ||

| B253 | Xiannuo | 0.782 | 0.314 | 0.287 | 107 | 0.121 | 3.636 | 0.125 | ||

| B073 | Qianchuanzi | 0.754 | 0.297 | 0.282 | 108 | 0.111 | 3.579 | 0.111 | ||

| B346 | Jixiang1 | 0.799 | 0.307 | 0.278 | 109 | 0.101 | 3.516 | 0.096 | ||

| B330 | Jinsuigu1 | 0.831 | 0.313 | 0.274 | 110 | 0.092 | 3.448 | 0.079 | <3.5 | 1 |

| B405 | 200108-2 | 0.800 | 0.289 | 0.265 | 111 | 0.079 | 3.372 | 0.060 | ||

| B239 | Jingu35 | 0.811 | 0.284 | 0.259 | 112 | 0.067 | 3.284 | 0.039 | ||

| B060 | Qinggu | 0.804 | 0.280 | 0.258 | 113 | 0.061 | 3.181 | 0.014 | ||

| B230 | Honggu | 0.810 | 0.261 | 0.243 | 114 | 0.042 | 3.055 | −0.018 | ||

| B409 | Jiugu13 | 0.857 | 0.248 | 0.225 | 115 | 0.019 | 2.886 | −0.059 | ||

| B092 | Zhushanuo | 0.833 | 0.235 | 0.220 | 116 | 0.009 | 2.618 | −0.125 |

| Independent Variable | Non-Standardized Coefficient | Standardized Coefficient | t-Value | p-Value | VIF | R2 | Adjusted R2 | F | |

|---|---|---|---|---|---|---|---|---|---|

| Coefficient | Standard Error | ||||||||

| Intercept | −0.767 | 0.016 | - | −48.844 | 0.000 *** | - | 0.983 | 0.982 | F = 6405.277 p = 0.000 *** |

| Probit | 0.245 | 0.003 | 0.991 | 80.033 | 0.000 *** | 1 | |||

| Source | Sum of Squares | Degrees of Freedom | Mean Square | F-Statistic | p-Value (Significance) |

|---|---|---|---|---|---|

| Between-group | 5.801 | 3 | 1.934 | 191.354 | 0.000 *** |

| Within-group | 1.132 | 112 | 0.01 | ||

| Total | 6.933 | 115 |

| Variable | Grading | Number | Mean | SD | Min | Max |

|---|---|---|---|---|---|---|

| Fitted RSR | 4 | 8 | 0.951 | 0.108 | 0.841 | 1.160 |

| 3 | 50 | 0.615 | 0.101 | 0.465 | 0.824 | |

| 2 | 51 | 0.308 | 0.102 | 0.096 | 0.460 | |

| 1 | 7 | −0.001 | 0.072 | −0.125 | 0.079 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Xing, G.; Liu, Z.; Zhang, Y.; Li, H.; Wang, Y.; Lu, J.; An, N.; Zhao, Z.; Wang, Z.; et al. Screening and Evaluation of Biomechanical Properties and Morphological Characteristics of Peduncles in Foxtail Millet. Agriculture 2024, 14, 1437. https://doi.org/10.3390/agriculture14091437

Zhang L, Xing G, Liu Z, Zhang Y, Li H, Wang Y, Lu J, An N, Zhao Z, Wang Z, et al. Screening and Evaluation of Biomechanical Properties and Morphological Characteristics of Peduncles in Foxtail Millet. Agriculture. 2024; 14(9):1437. https://doi.org/10.3390/agriculture14091437

Chicago/Turabian StyleZhang, Lili, Guofang Xing, Zhenyu Liu, Yanqing Zhang, Hongbo Li, Yuanmeng Wang, Jiaxin Lu, Nan An, Zhihong Zhao, Zeyu Wang, and et al. 2024. "Screening and Evaluation of Biomechanical Properties and Morphological Characteristics of Peduncles in Foxtail Millet" Agriculture 14, no. 9: 1437. https://doi.org/10.3390/agriculture14091437