The Design and Experimentation of a Wheeled-Chassis Potato Combine Harvester with Integrated Bagging and Ton Bag-Lifting Systems

Abstract

:1. Introduction

2. Materials and Methods

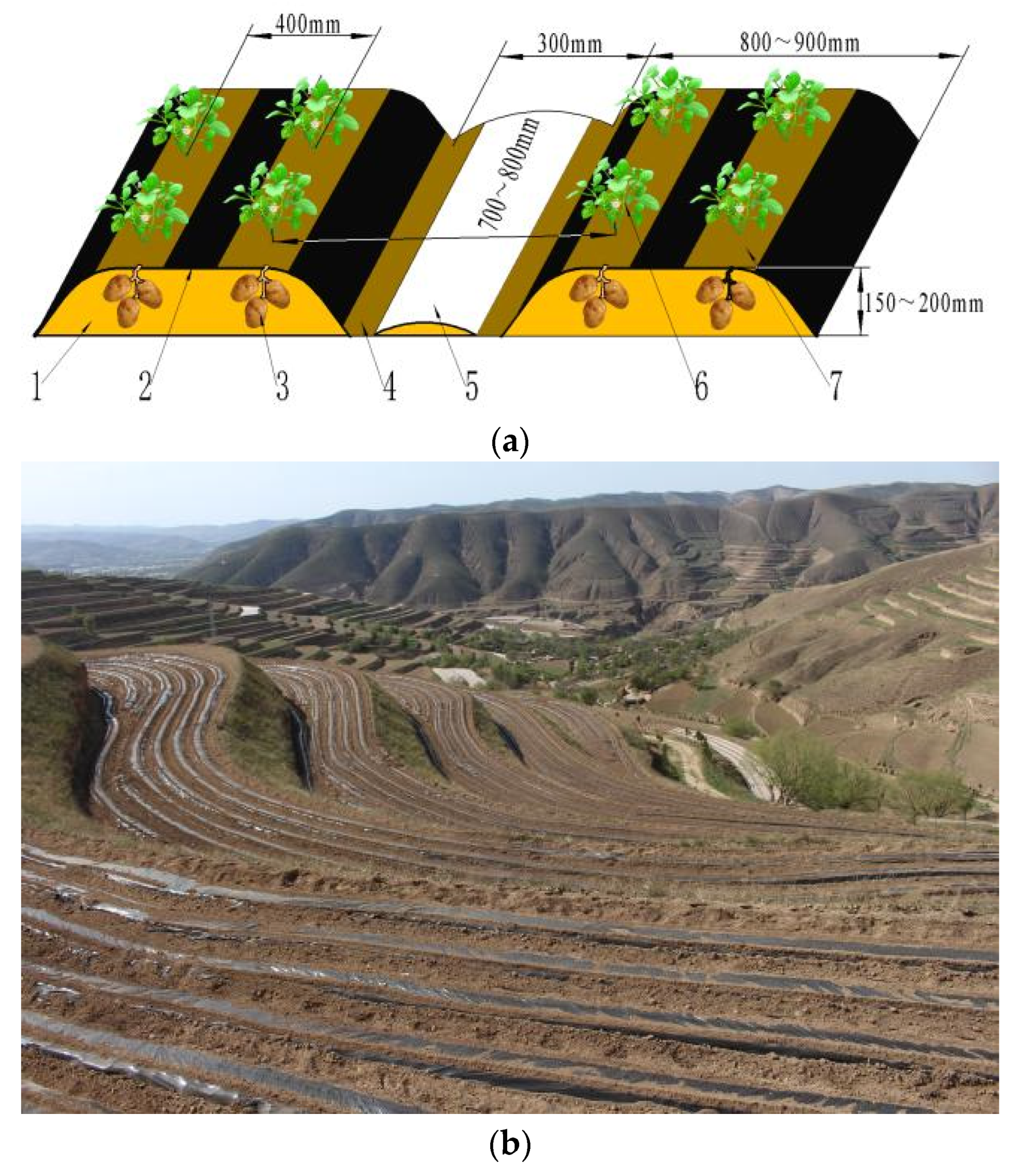

2.1. Planting Agronomy and Farmland Characteristics

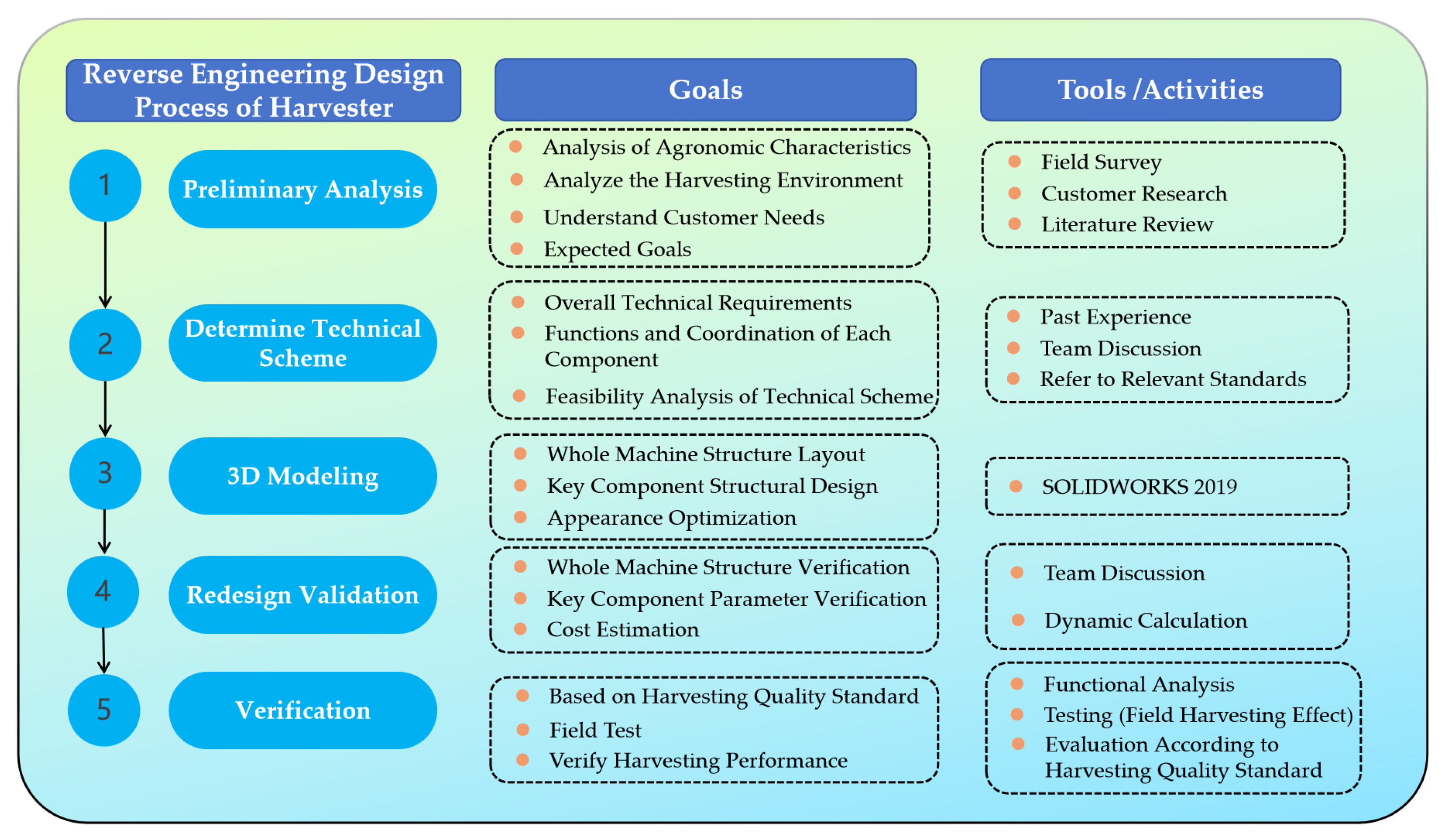

2.2. Research Method

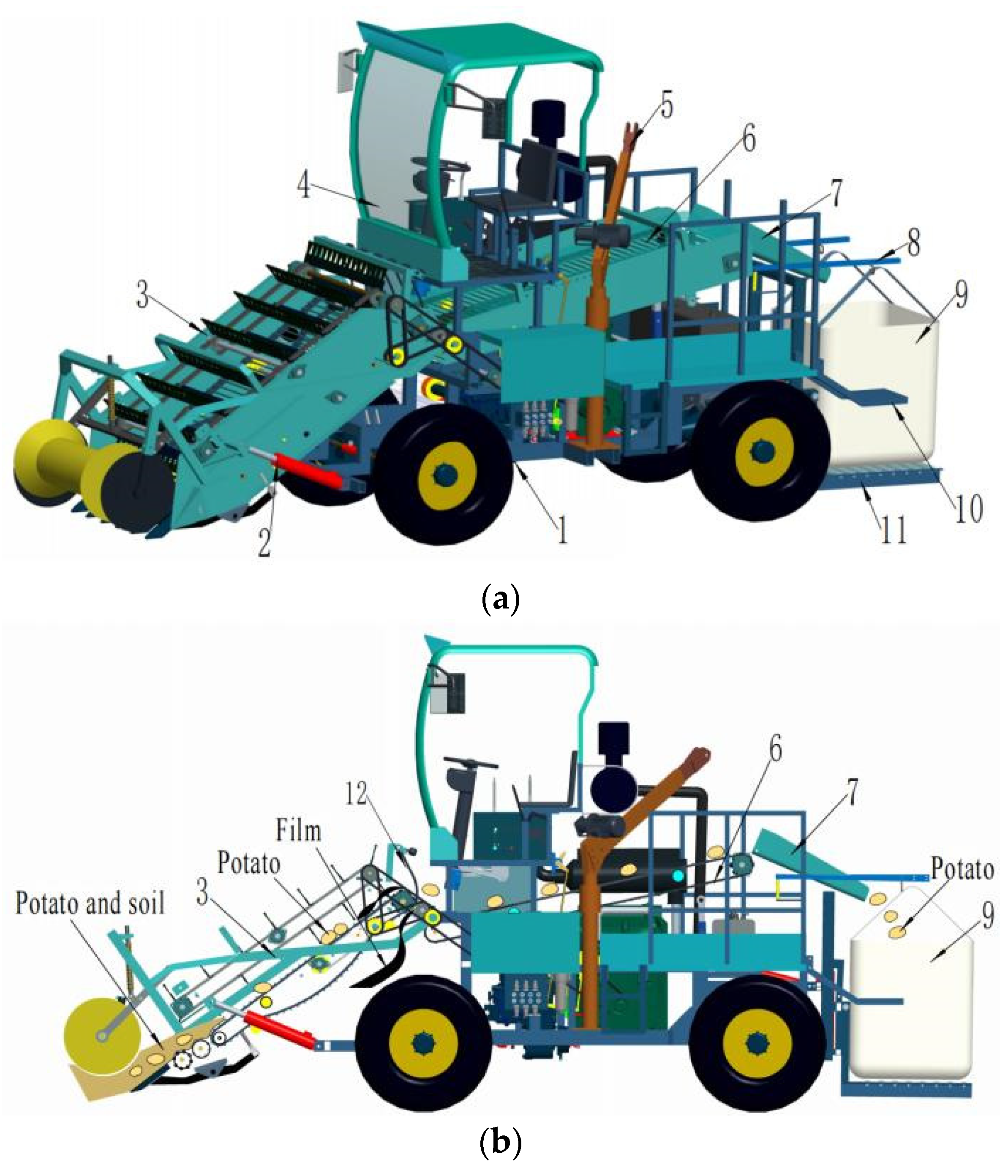

2.3. Overall Structure and Main Parameters

2.4. Working Principle

3. Key Working Units

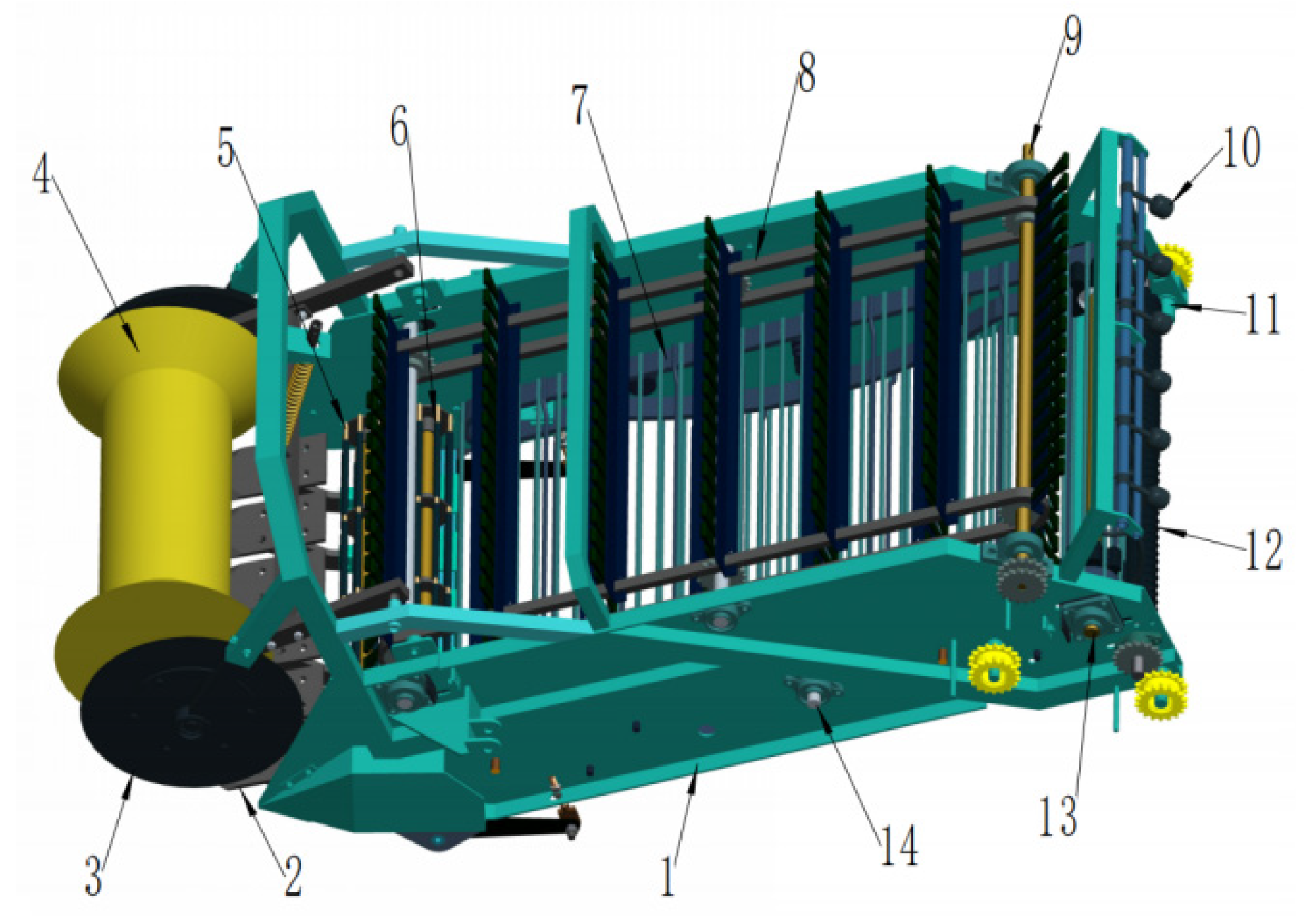

3.1. Front Harvesting Device

3.1.1. The Structure and Working Principle of the Front Harvesting Device

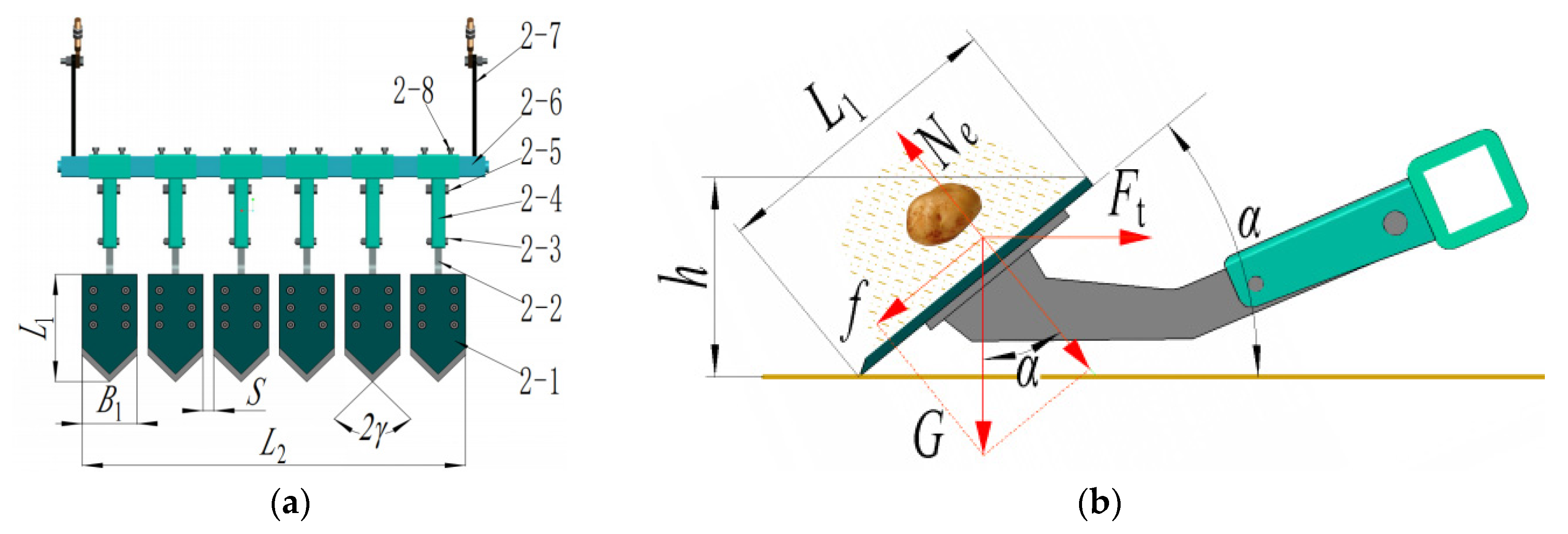

3.1.2. The Split-Type Digging Device

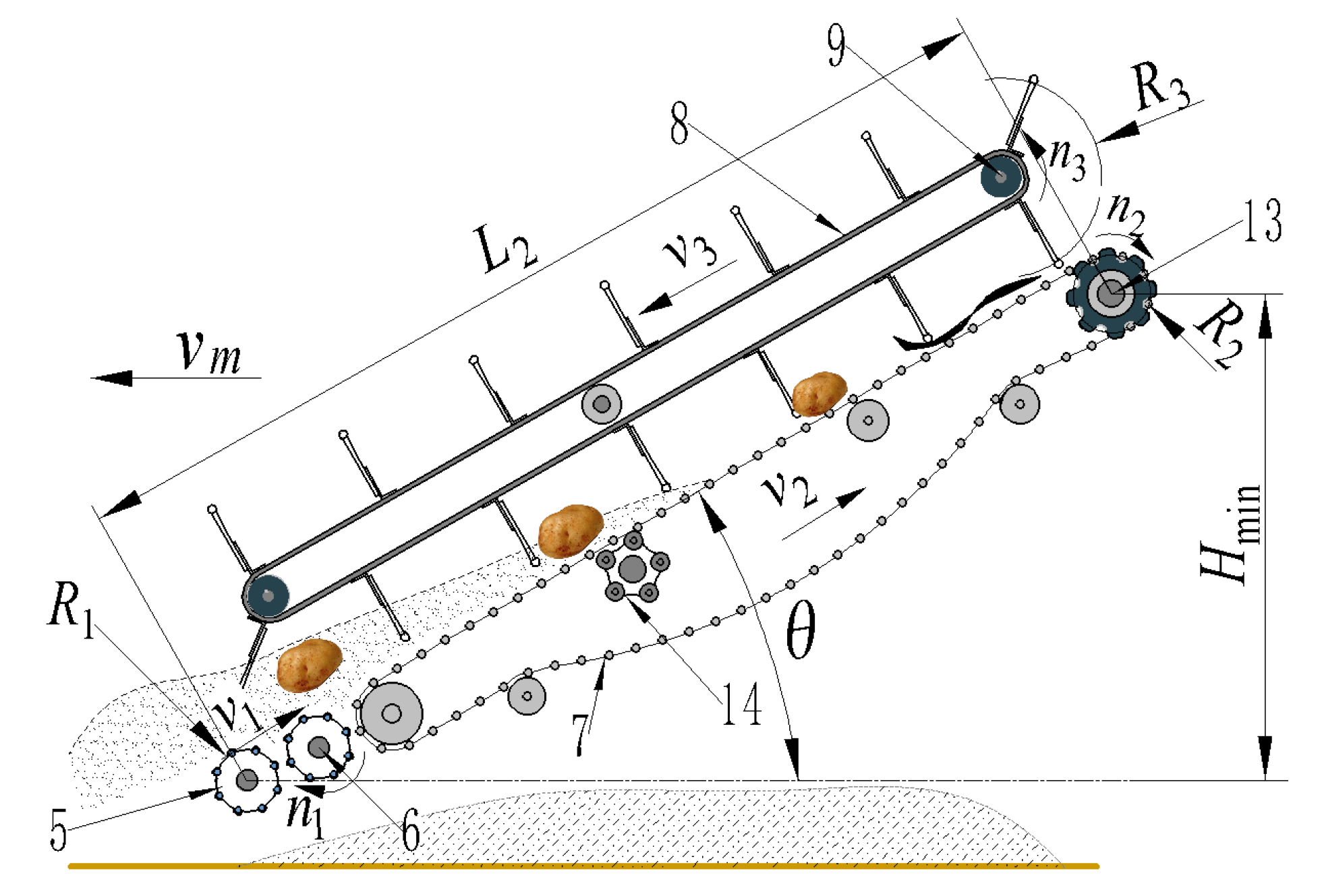

3.1.3. The Composite Separation and Lifting Device

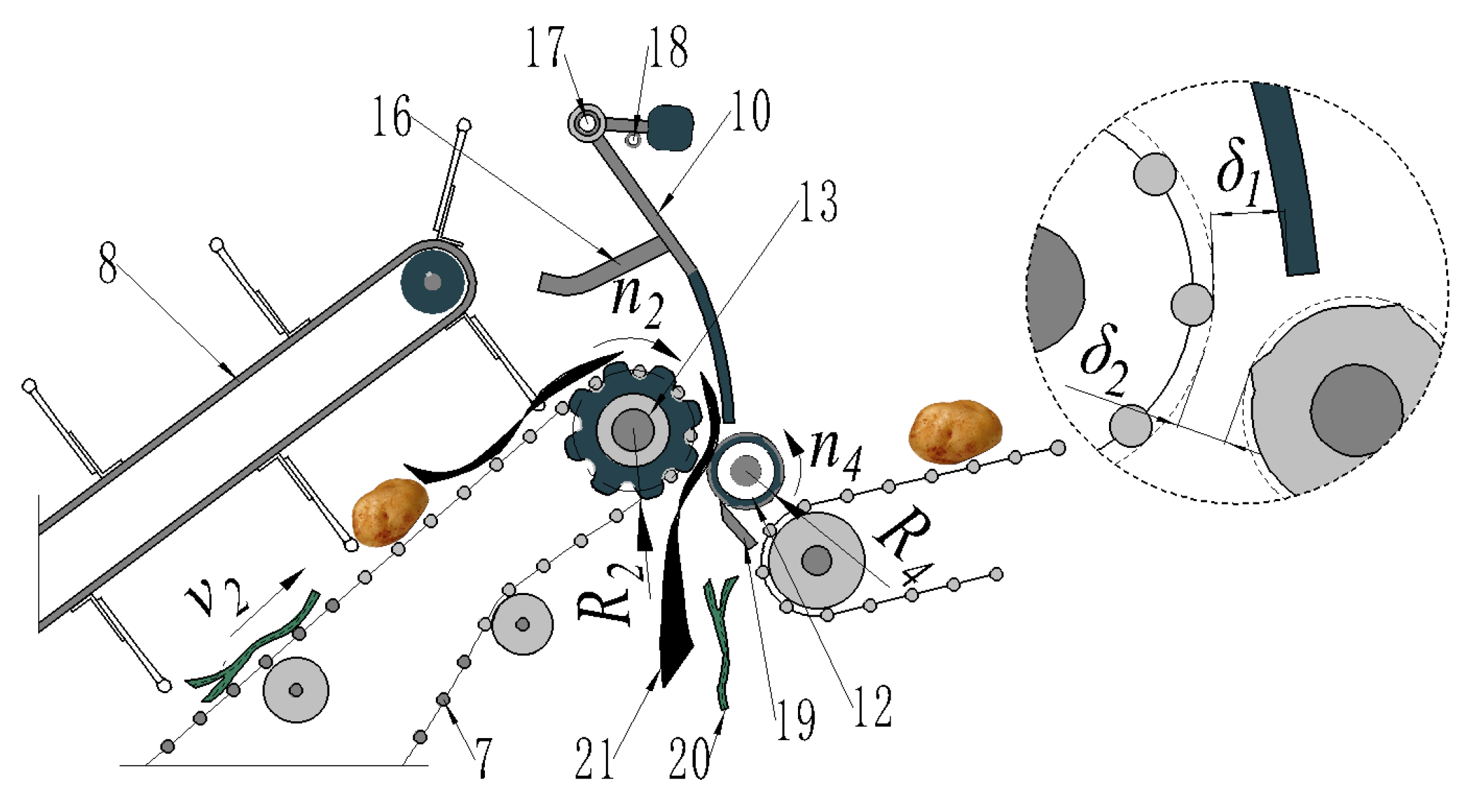

3.1.4. The Film and Vine Clearing Device

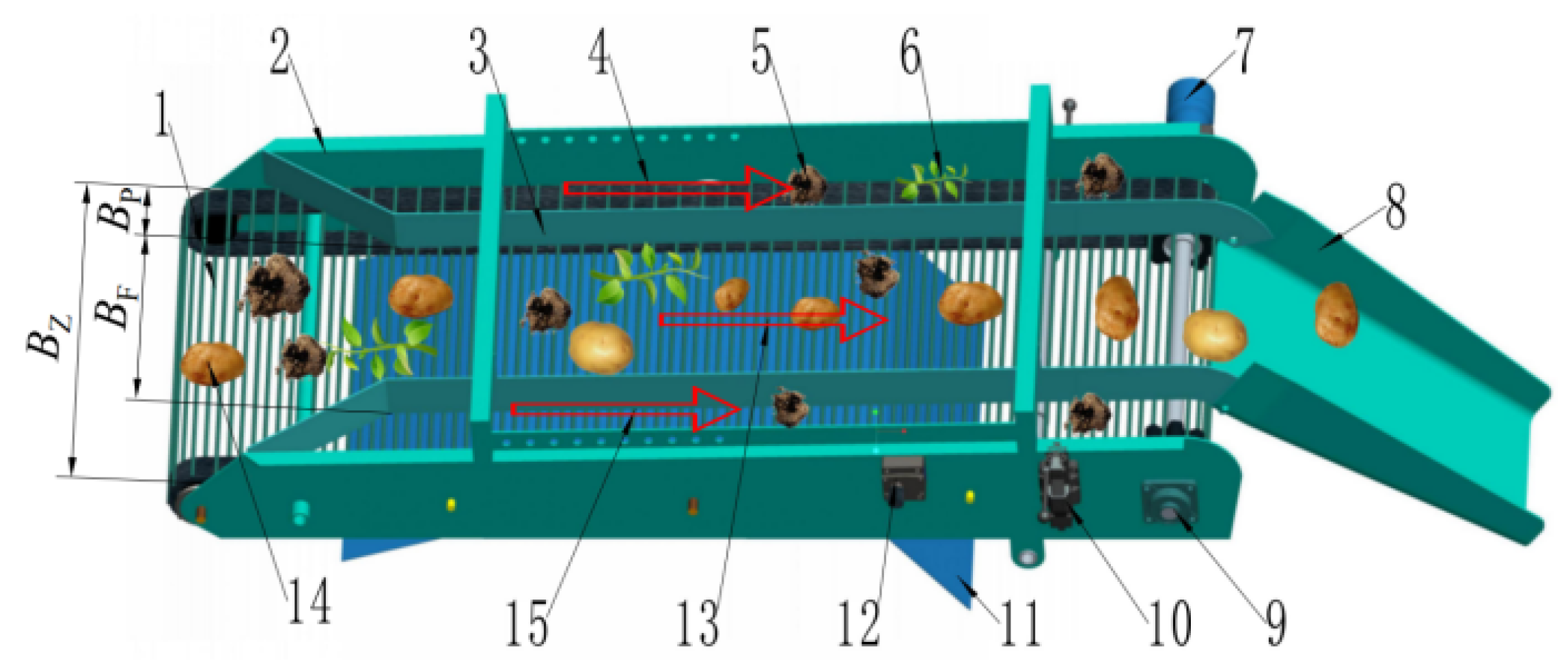

3.2. Picking Platforms with Different Paths

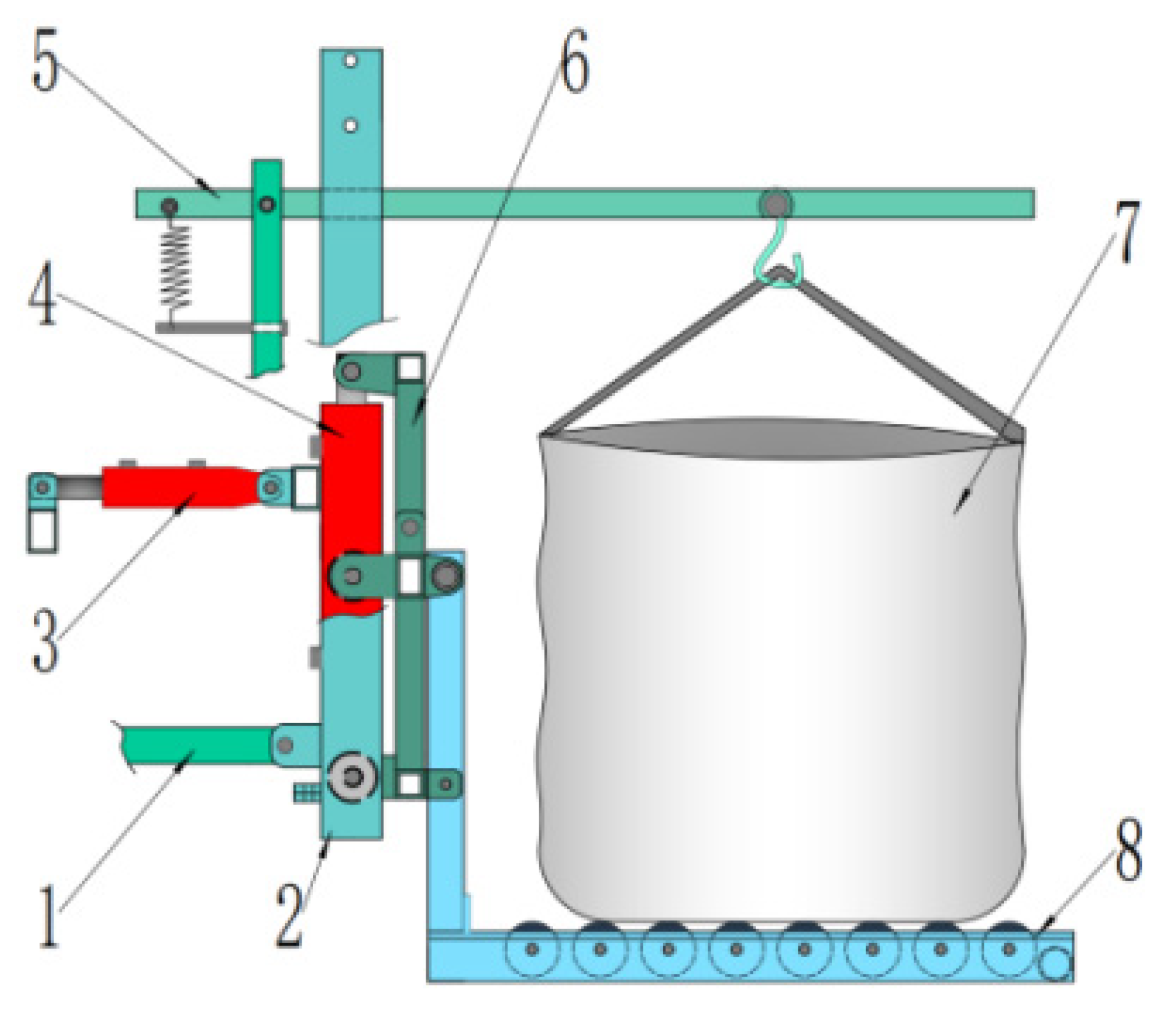

3.3. Ton Bag Self-Unloading Platform

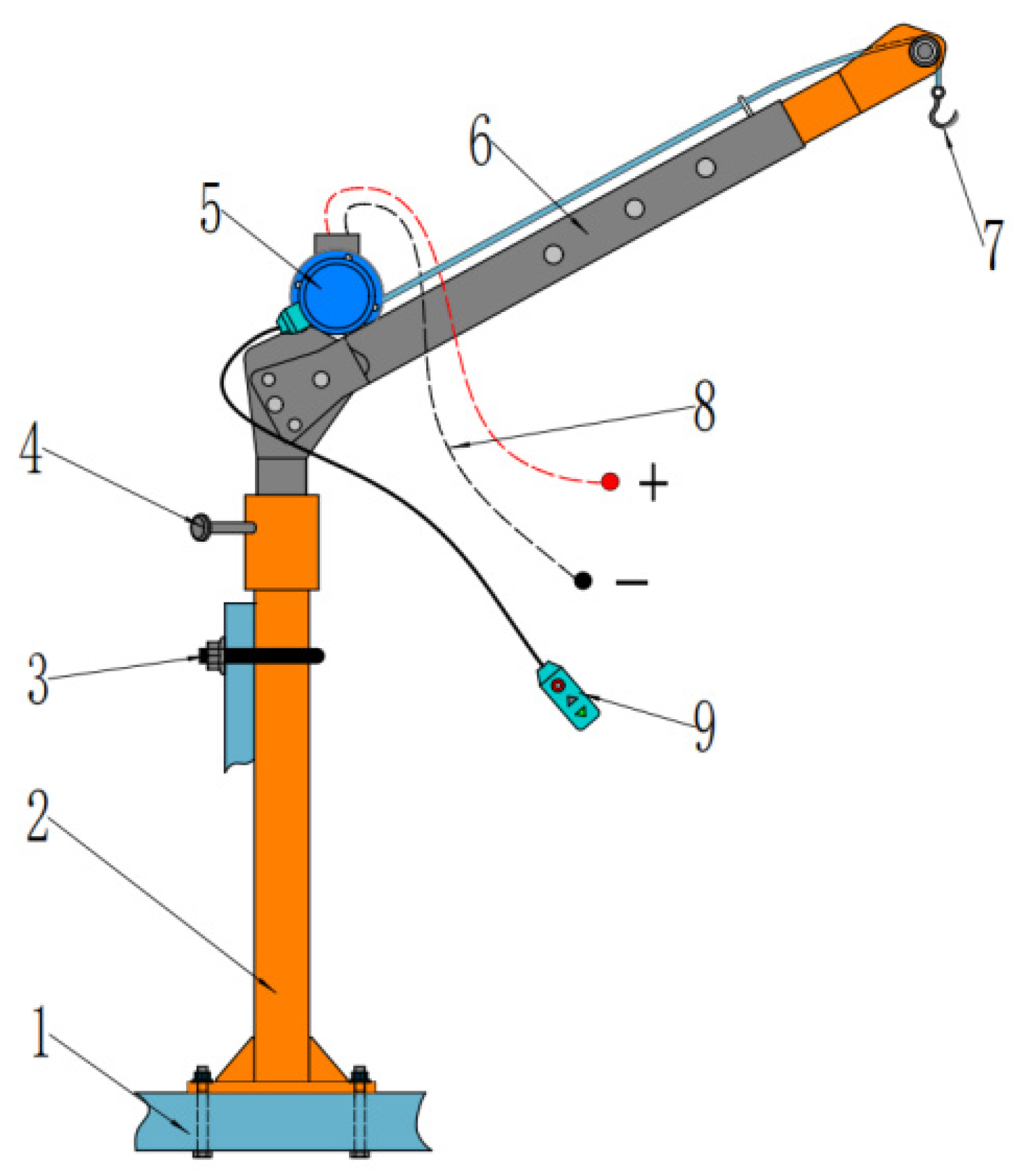

3.4. Electrical Lifting Device

4. Results

4.1. Experimental Conditions

4.2. Test Scheme and Method

4.3. Analysis of the Field Experiment Results

5. Discussion

6. Conclusions

- Based on the agronomic requirements and topographical characteristics of potato planting in the northwest arid region, the overall design scheme of the whole machine is determined. The key components are designed and analyzed by SOLID2019 3D software and a dynamic analysis model. The structure and working parameters of the split-type digging device, composite separation and lifting device, the film and vine clearing device, the picking platforms with different paths, the ton bag self-unloading platform, and the electrical lifting device were determined, which improved the potato harvesting quality and the reliability and adaptability of the key components.

- Field experiments have shown that the loss rate of the wheeled-chassis potato combine harvester with integrated bagging and ton bag-lifting systems is 2.1%, the potato damage rate is 1.7%, the skin breaking rate is 2.5%, the impurity content is 1.9%, and the productivity is about 0.15~0.23 hm2/h. The field performance test indicators all meet the national and industry standards requirements. The potato harvesting machine described in this article has a high degree of mechanization and good harvesting performance, which effectively improves work efficiency and saves a lot of labor costs, playing a good role in promoting the development of the potato industry in the arid areas of Northwest China.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Shi, M.; Zhang, R.; Zhang, W.; Liu, Y.; Sun, D.; Wang, X.; Qin, S.; Kang, Y. Legume-potato rotation affects soil physicochemical properties, enzyme activity, and rhizosphere metabolism in continuous potato cropping. Chem. Biol. Technol. Agric. 2023, 10, 132. [Google Scholar] [CrossRef]

- Jia, B.; Sun, W.; Zhao, Z.; Wang, H.; Zhang, H.; Liu, X.; Li, H. Design and field test of a remotely controlled self-propelled potato harvester with manual sorting platform. Am. J. Potato Res. 2023, 100, 193–209. [Google Scholar] [CrossRef]

- Ju, Y.; Sun, W.; Zhao, Z.; Wang, H.; Liu, H.; Zhang, H.; Li, H. Development and testing of a self-propelled machine for combined potato harvesting and residual plastic film retrieval. Machines 2023, 11, 432. [Google Scholar] [CrossRef]

- Wei, Z.; Li, H.; Mao, Y.; Sun, C.; Li, X.; Liu, W.; Su, G. Experiment and analysis of potato-soil separation based on impact recording technology. Int. J. Agric. Biol. Eng. 2019, 12, 71–80. [Google Scholar] [CrossRef]

- Li, X.; Wei, Z.; Su, G.; Wang, X.; Zhang, X.; Wang, X.; Cheng, X.; Jin, C. Parameter optimization and experiment of air-screen potato-stone cleaning device based on gas-solid coupling. Trans. Chin. Soc. Agric. Mach. 2024, 55, 96–108. [Google Scholar]

- Wang, X.; Wei, Z.; Su, G.; Meng, P.; Wang, F.; Zhang, X.; Wang, X.; Cheng, X.; Li, Z.; Jin, C. Design and experiment of simple harmonic disturbance separation device for potato harvester. Trans. Chin. Soc. Agric. Mach. 2024, 101–112. [Google Scholar]

- Wei, Z.; Wang, Y.; Li, X.; Wang, J.; Su, G.; Meng, P.; Han, M.; Jin, C.; Li, Z. Design and experiments of the potato combine harvester with elastic rubbing technology. Trans. Chin. Soc. Agric. Eng. 2023, 39, 60–69. [Google Scholar]

- Wei, Z.; Wang, X.; Li, X.; Wang, F.; Li, Z.; Jin, C. Design and experiment of crawler self-propelled sorting type potato harvester. Trans. Chin. Soc. Agric. Mach. 2023, 54, 95–106. [Google Scholar]

- Wang, H.; Zhao, W.; Sun, W.; Zhang, H.; Liu, X.; Li, H. Research progress on the technology and equipment for potato mechanized harvesting. Trans. Chin. Soc. Agric. Eng. 2023, 39, 1–22. [Google Scholar]

- Wei, Z.; Wang, Y.; Su, G.; Zhang, X.; Wang, X.; Cheng, X.; Li, X.; Jin, C. Research progress in the technology and equipment for potato mechanized harvesting and impurity removal. Trans. Chin. Soc. Agric. Eng. 2024, 40, 1–13. [Google Scholar]

- Li, T.; Yang, M.; Zhang, X.; Zhang, E.; Cheng, X.; Wang, X. Potato production technology and difference of mechanization level in northwest China. Trans. Chin. Soc. Agric. Mach. 2020, 51, 307–313. [Google Scholar]

- Wei, H.; Wang, D.; Lian, W.; Shao, S.; Yang, X.; Huang, X. Development of 4UFD-1400 type potato combine harvester. Trans. Chin. Soc. Agric. Eng. 2013, 29, 11–17. [Google Scholar]

- Wei, H.; Zhang, J.; Yang, X.; Huang, X.; Dai, L.; Sun, G.; Liu, X. Improved design and test of 4UFD-1400 type potato combine harvester. Trans. Chin. Soc. Agric. Eng. 2014, 30, 12–17. [Google Scholar]

- Zhang, Z.; Li, Y.; Wang, H.; Zhang, Z.; Liu, X. Research progress on key technology and equipment of potato mechanized harvest. J. Yunnan Agric. Univ. 2021, 36, 1092–1103. [Google Scholar]

- Yang, D.; Wang, X.; Liu, M.; Li, Y.; Chen, X.; Chen, Z. Design and experiment of self-propelled potato collecting and bagging machine. Trans. Chin. Soc. Agric. Mach. 2024, 55, 85–95. [Google Scholar]

- Wang, X.; Lyu, D.; Ren, J.; Zhang, M.; Meng, P.; Li, X. Design and parameter optimization of the cleaning device for a bagged potato combine harvester. Trans. Chin. Soc. Agric. Eng. 2022, 38, 8–17. [Google Scholar]

- Lyu, J.; Tian, Z.; Wu, J.; Yang, Y.; Shang, Q.; Wang, Y.; Liu, Z. Design and experiment on 4U1Z vibrating potato digger. Trans. Chin. Soc. Agric. Eng. 2015, 31, 39–47. [Google Scholar]

- Lyu, J.; Tian, Z.; Yang, Y.; Shang, Q.; Wu, J. Design and experimental analysis of 4U2A type double-row potato digger. Trans. Chin. Soc. Agric. Eng. 2015, 31, 17–24. [Google Scholar]

- Zhang, Z.; Wang, H.; Li, Y.; Yang, X.; Issa, I.; Zhang, Z. Design and experiment of multi-stage separation buffer potato harvester. Trans. Chin. Soc. Agric. Mach. 2021, 52, 96–109. [Google Scholar]

- Wei, Z.; Li, H.; Su, G.; Sun, C.; Liu, W.; Li, X. Development of potato harvester with buffer type potato-impurity separation sieve. Trans. Chin. Soc. Agric. Eng. 2019, 35, 1–11. [Google Scholar]

- Wei, Z.; Su, G.; Li, X.; Wang, F.; Sun, C.; Meng, P. Parameter optimization and test of potato harvester wavy sieve based on EDEM. Trans. Chin. Soc. Agric. Mach. 2020, 51, 109–122. [Google Scholar]

- Yang, R.; Yang, H.; Shang, S.; Ni, Z.; Liu, Z.; Guo, D. Design and experiment of vertical circular separating and conveying device for potato combine harvester. Trans. Chin. Soc. Agric. Eng. 2018, 34, 10–18. [Google Scholar]

- Yang, R.; Tian, G.; Shang, S.; Wang, B. Zhang, J.; Zhan, Y. Design and experiment of roller group type potato soil separator for potato harvester. Trans. Chin. Soc. Agric. Mach. 2023, 54, 107–118. [Google Scholar]

- Wang, F.; Cao, Q.; Li, Y.; Pang, Y.; Xie, K.; Zhang, Z. Design and trafficability experiment of self-propelled potato harvester in hilly and mountainous areas. Trans. Chin. Soc. Agric. Mach. 2023, 54, 10–19. [Google Scholar]

- Sun, W.; Wang, H.; Zhao, W.; Zhang, H.; Liu, X.; Wu, J. Design and experiment of potato digger with waste film recollection for complete film mulching, soil covering and ridge sowing pattern. Trans. Chin. Soc. Agric. Mach. 2018, 49, 105–114. [Google Scholar]

- Sun, W.; Liu, X.; Wang, H.; Zhang, H.; Wu, J.; Yang, X.; Wang, G. Design and test of double crank multi-rod hill-drop potato planter on plastic film. Trans. Chin. Soc. Agric. Eng. 2018, 34, 34–42. [Google Scholar]

- Fargnoli, M.; Vita, L.; Gattamelata, D.; Laurendi, V.; Tronci, M. A reverse engineering approach to enhance machinery design for safety. In Proceedings of the DESIGN 2012, the 12th International Design Conference, Dubrovnik, Croatia, 21–24 May 2012. [Google Scholar]

- Zhang, X. Agricultural Machinery Design Manual, 1st ed.; China Agricultural Science and Technology Press: Beijing, China, 2007; pp. 1053–1086. [Google Scholar]

- Chen, X.; Hu, Z.; Wang, B.; You, Z.; Peng, B.; Hu, L. Design and parameter optimization of sweet-potato-stalk separator for single row sweet potato combine harvester. Trans. Chin. Soc. Agric. Eng. 2019, 35, 12–21. [Google Scholar]

- Zhang, X.; Liu, J.; Shi, Z.; Jin, W.; Yan, J.; Yu, M. Design and parameter optimization of reverse membrane and soil separation device for residual film recovery machine. Trans. Chin. Soc. Agric. Eng. 2019, 35, 46–55. [Google Scholar]

- Cui, R.L.; Zhao, L.M. Design of Lifting Mechanism for MG650 Beam Lifting Machine. In Proceedings of the 9th National Local Mechanical Engineering Society Academic Annual Conference, Zhengzhou, China, 1–3 November 2019. [Google Scholar]

- NY/T 648-2015; Technical Specifications for Quality Evaluation of Potato Harvesters. Standards of China: Beijing, China, 2015.

- JB/T 14285-2022; Potato Harvesting Machinery. Standards of China: Beijing, China, 2022.

- Yang, X.; Wei, H.; Zhao, W.; Jiang, Y.; Dai, L.; Huang, X. Design and experiment of 4U-1600 set of pile type potato digger. Trans. Chin. Soc. Agric. Mach. 2020, 51, 83–92. [Google Scholar]

| Index | Data |

|---|---|

| Structural style | Wheeled self-propelled type |

| Engine power (kW) | 73.5 |

| Engine rated speed (R·min−1) | 2600 |

| Wheel track (m) | 1.38 |

| Wheelbase/m | 2.2 |

| Minimum turning radius (m) | 2.8 |

| Overall machine dimensions: (length × width × height) (m × m × m) | 5.6 × 1.78 × 2.8 |

| Working width (m) | 1.1 |

| Number of rows harvested | 2 |

| Digging depth (m) | 0~240 |

| Potato harvest method | Ton bag |

| Productivity (hm2·h−1) | 0.15~0.23 |

| Index | Parameter |

|---|---|

| Adapt to the size of ton bag (length × width × height)/(m × m × m) | 0.8 × 0.8 × 1 |

| Rope form | Double-ring |

| Roller platform minimum ground clearance (mm) | 200 |

| Roller platform maximum ground clearance (mm) | 520 |

| Lifting action hydraulic cylinder travel (mm) | 320 |

| Tilting action hydraulic cylinder travel (mm) | 100 |

| Roller platform maximum tilt angle (°) | 15 |

| Hydraulic cylinder control mode | Electrical control |

| Determination Standard | Technical Standard | Tests the Result |

|---|---|---|

| Potato loss rate (%) | ≤3 | 2.1 |

| Potato damage rate (%) | ≤2 | 1.7 |

| Skin breaking rate (%) | ≤3 | 2.5 |

| Impurity content (%) | ≤4 | 1.9 |

| Performance Index | Potato Harvesting Machine | |

|---|---|---|

| This Harvester | 4U-1600 Set of Pile-Type Potato Digger | |

| Productivity (hm2·h−1) | 0.15~0.23 | 0.35~0.55 |

| Potato damage rate (%) | 1.7 | 3.36 |

| Skin breaking rate (%) | 2.5 | / |

| Potato obvious rate (%) | Automatic bagging | 95.11 |

| Impurity content (%) | 1.9 | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Zhao, W.; Sun, W.; Liu, X.; Shi, R.; Zhang, H.; Chen, P.; Gao, K. The Design and Experimentation of a Wheeled-Chassis Potato Combine Harvester with Integrated Bagging and Ton Bag-Lifting Systems. Agriculture 2024, 14, 1461. https://doi.org/10.3390/agriculture14091461

Wang H, Zhao W, Sun W, Liu X, Shi R, Zhang H, Chen P, Gao K. The Design and Experimentation of a Wheeled-Chassis Potato Combine Harvester with Integrated Bagging and Ton Bag-Lifting Systems. Agriculture. 2024; 14(9):1461. https://doi.org/10.3390/agriculture14091461

Chicago/Turabian StyleWang, Hucun, Wuyun Zhao, Wei Sun, Xiaolong Liu, Ruijie Shi, Hua Zhang, Pengfei Chen, and Kuizeng Gao. 2024. "The Design and Experimentation of a Wheeled-Chassis Potato Combine Harvester with Integrated Bagging and Ton Bag-Lifting Systems" Agriculture 14, no. 9: 1461. https://doi.org/10.3390/agriculture14091461