Research on a Novel Citrus Reticulata ‘Chachi’ Orientation Adjustment Mechanism (COAM) and Machine Vision Guidance Control

Abstract

:1. Introduction

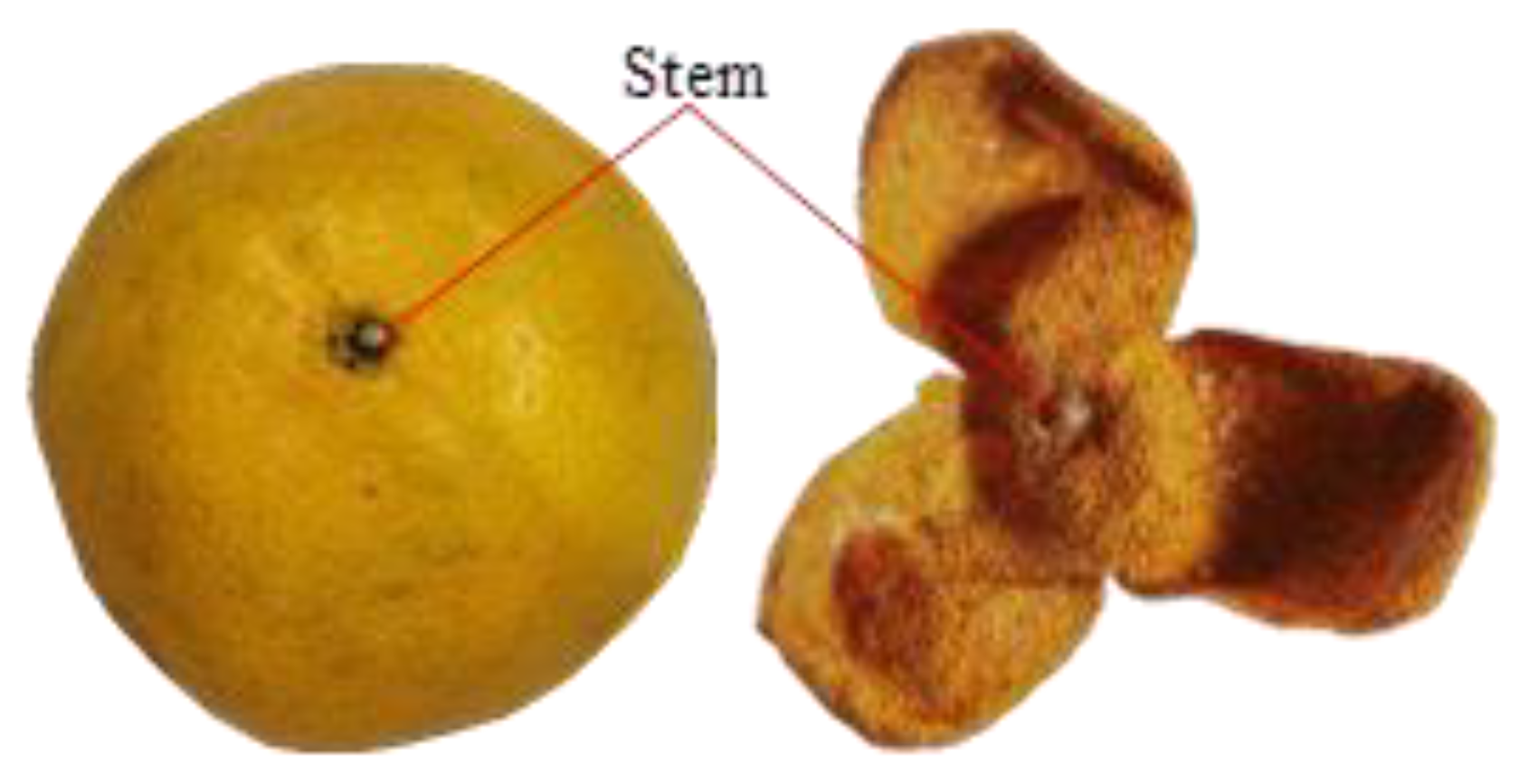

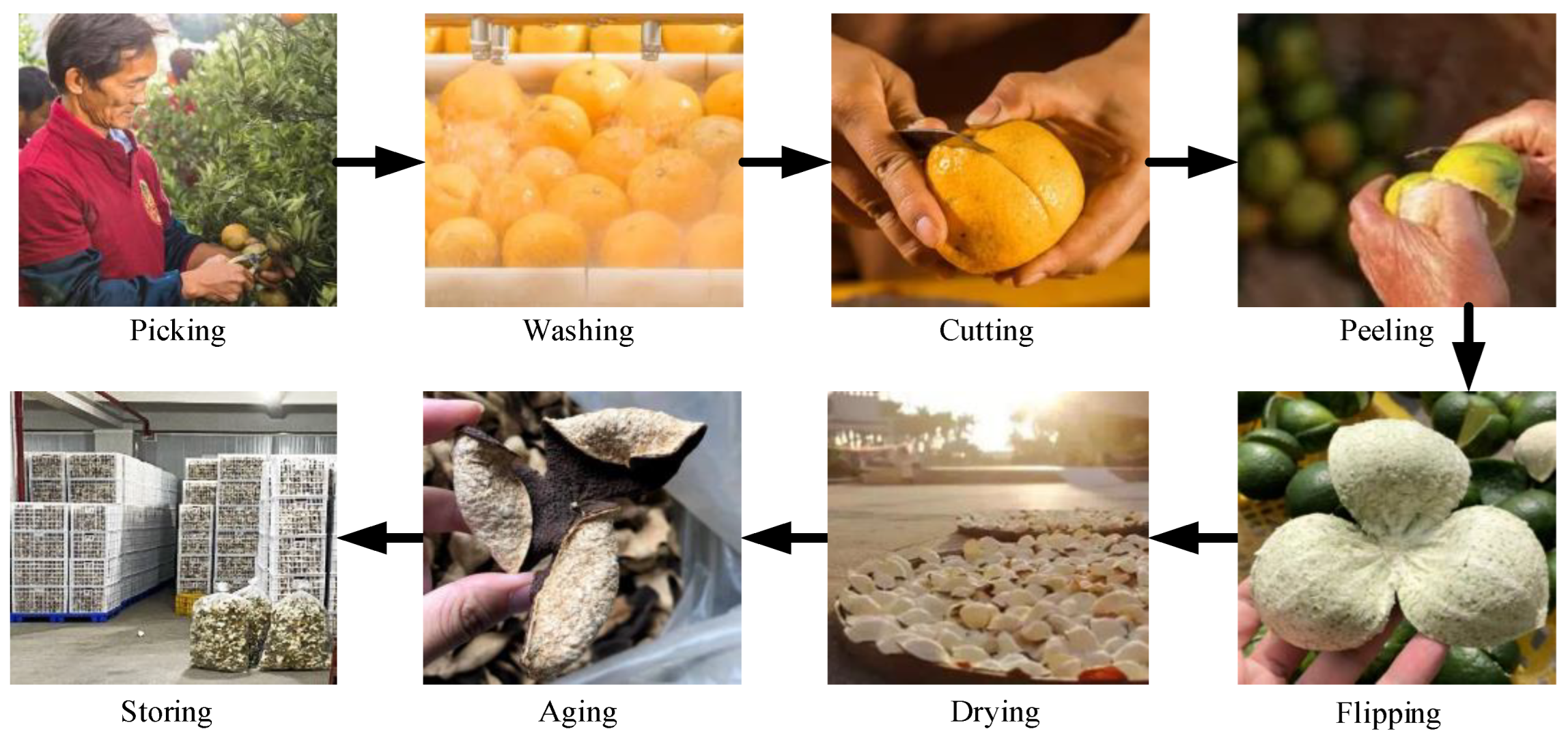

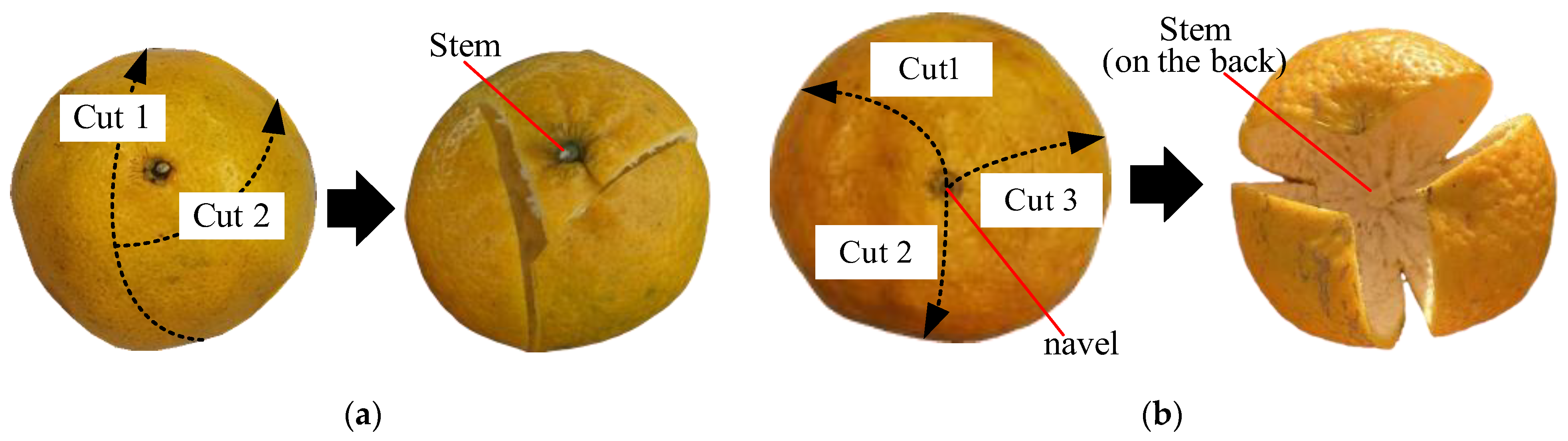

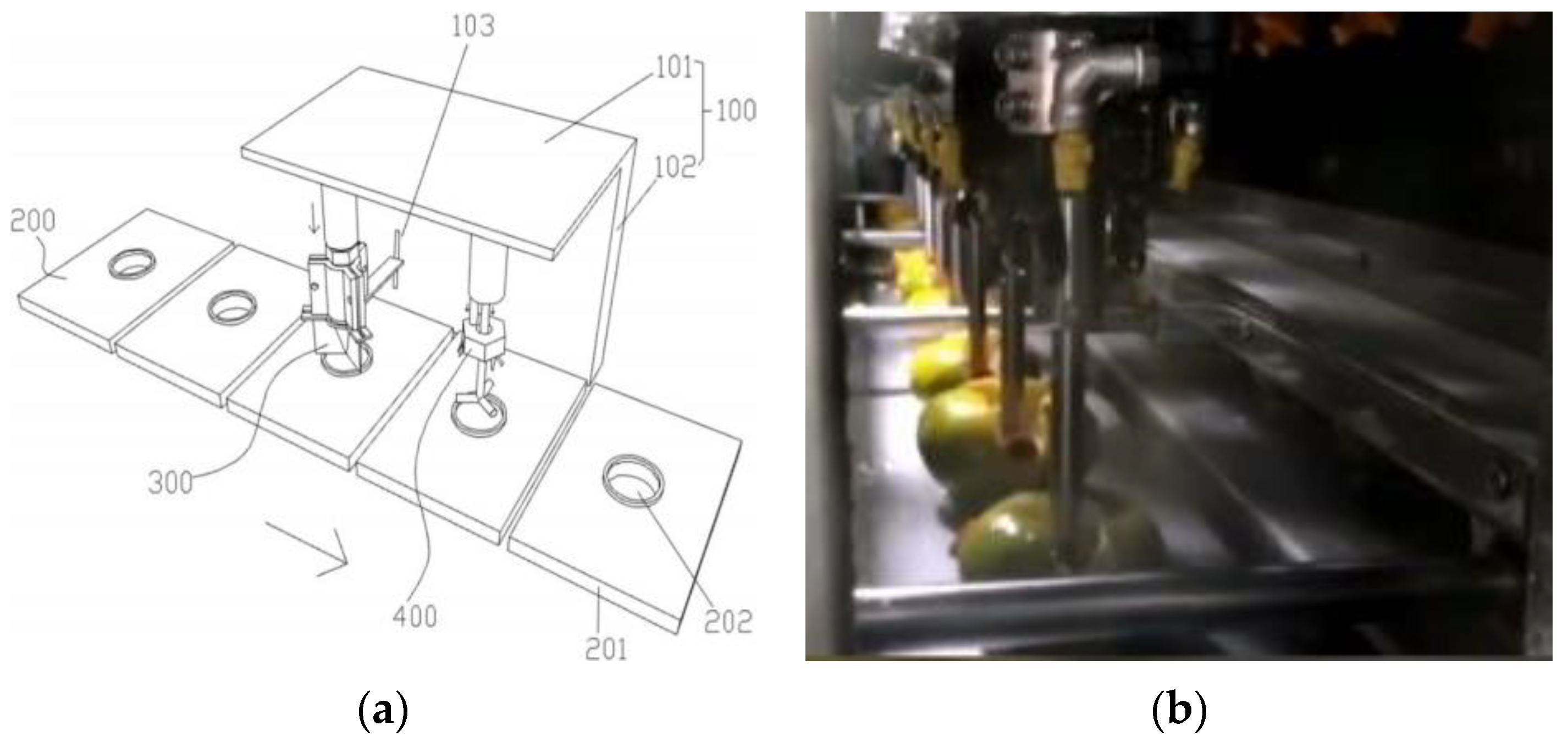

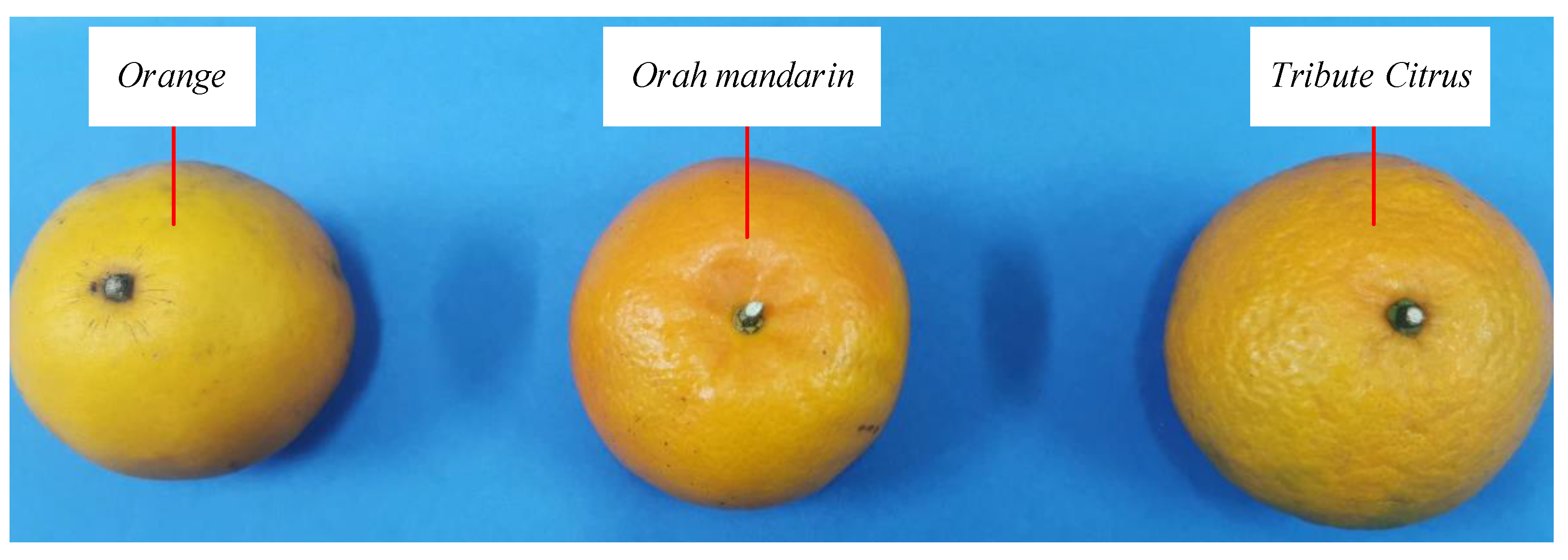

2. The Working Principle and Structure Design of the COAM

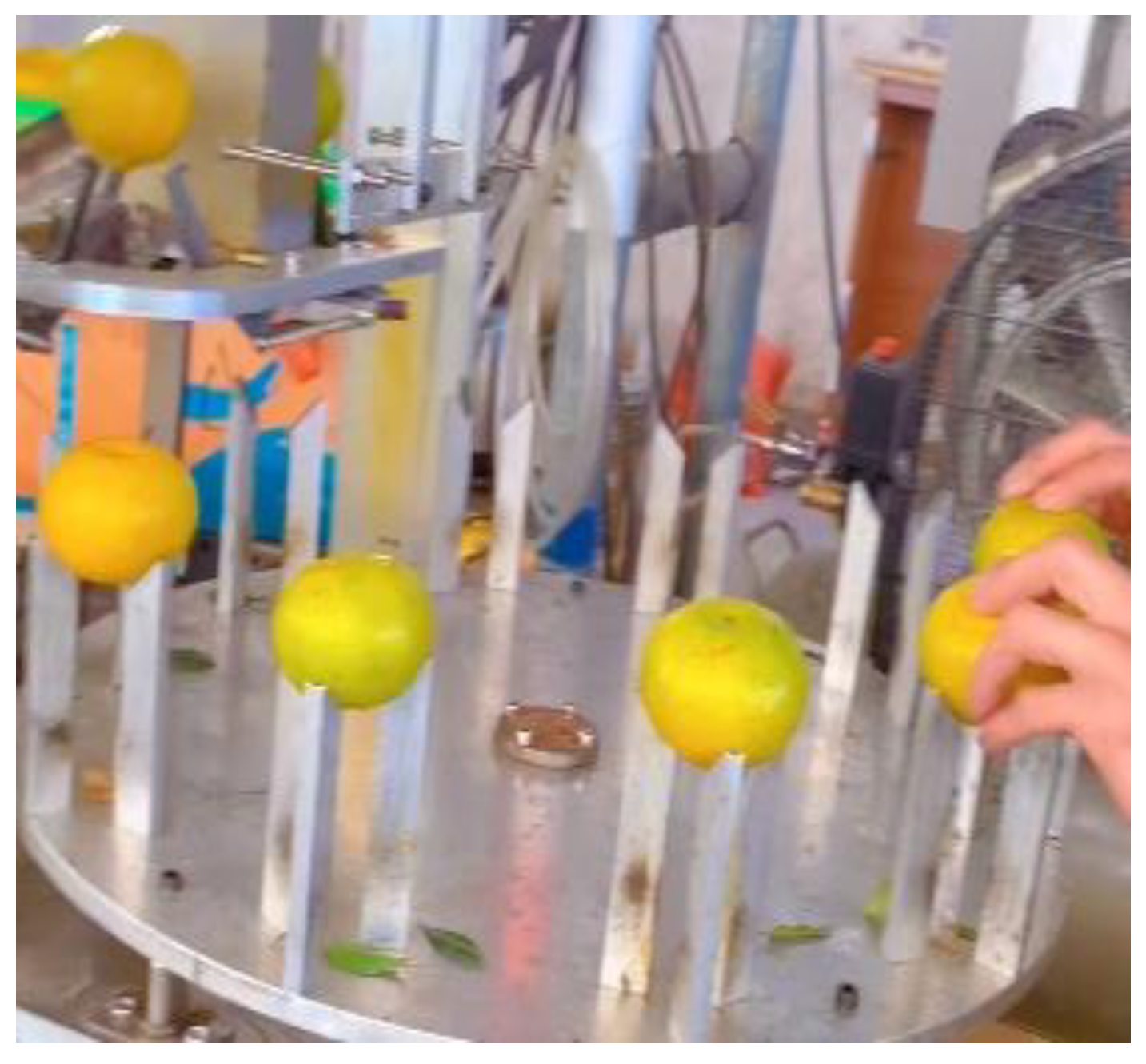

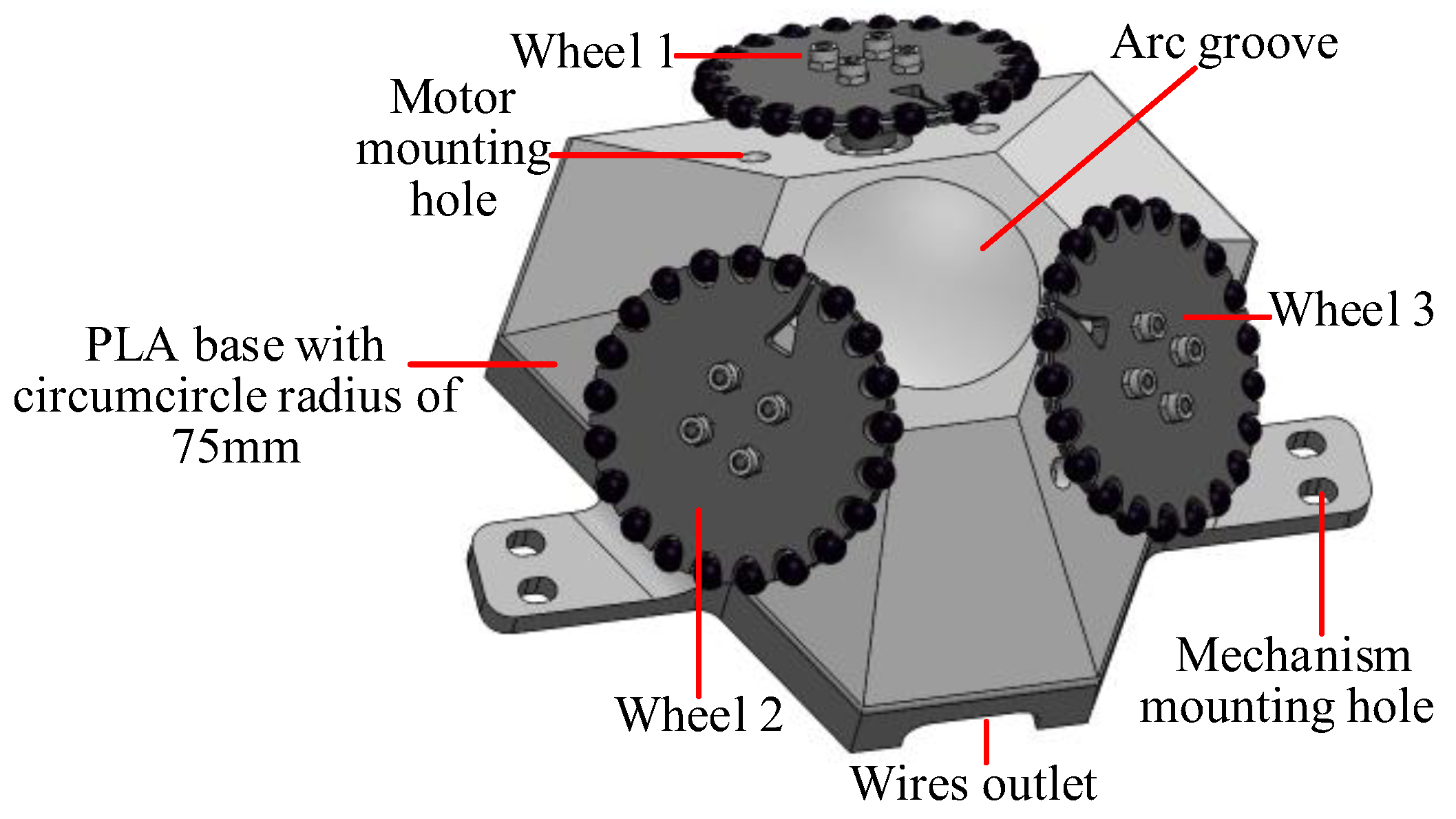

2.1. Mechanical Structure Design

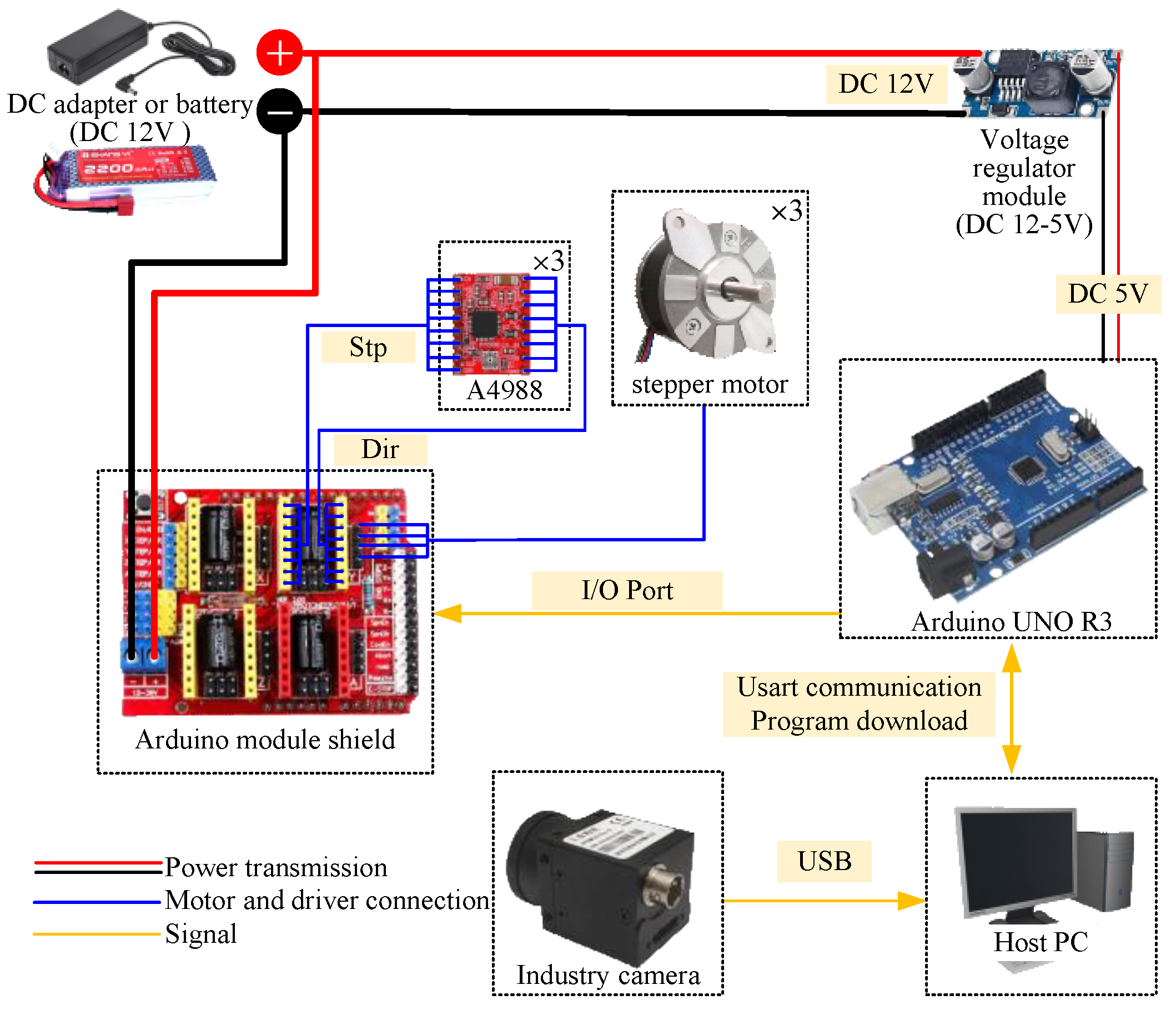

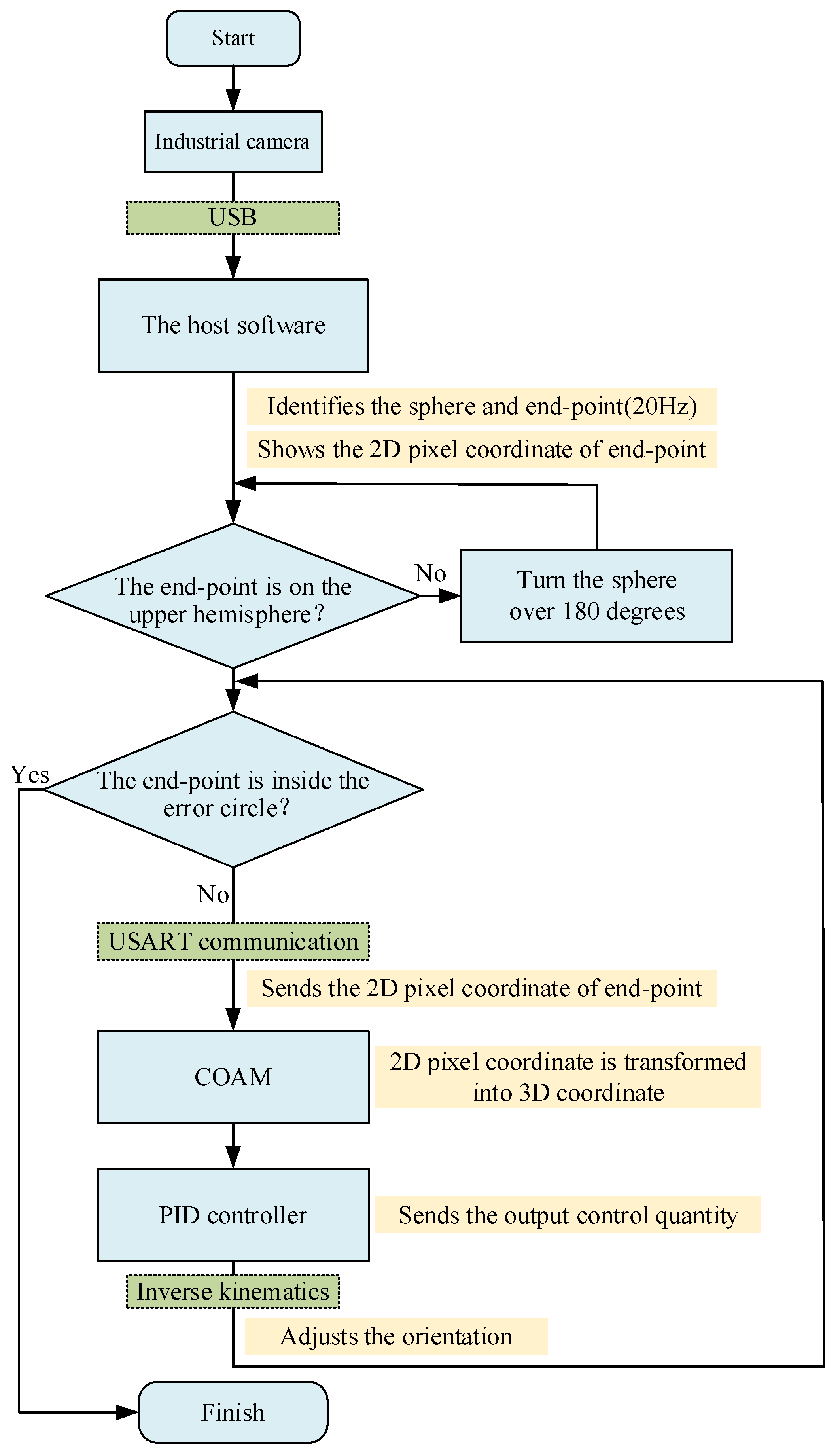

2.2. Electronic Control System Design

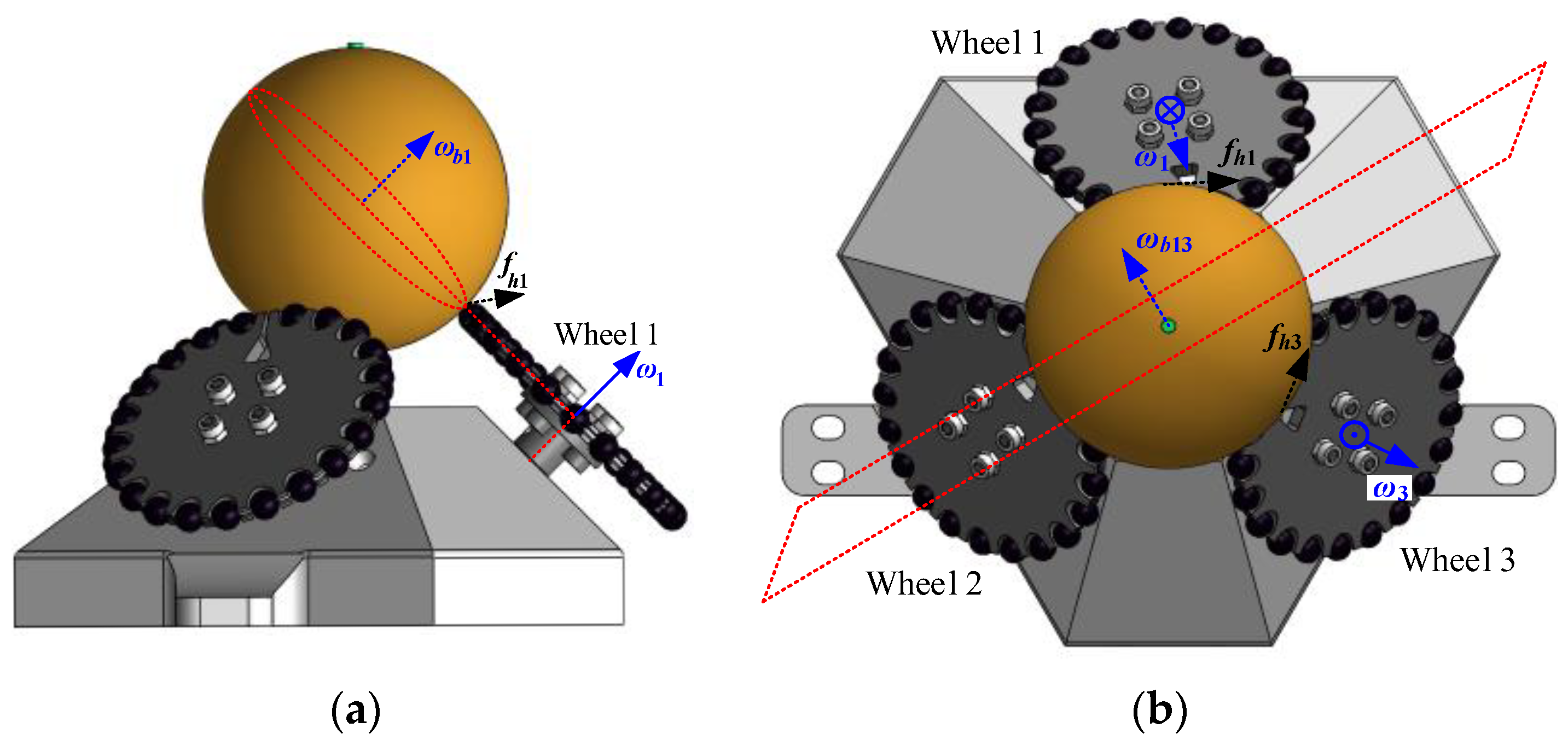

2.3. Principle of Mechanical Transmission

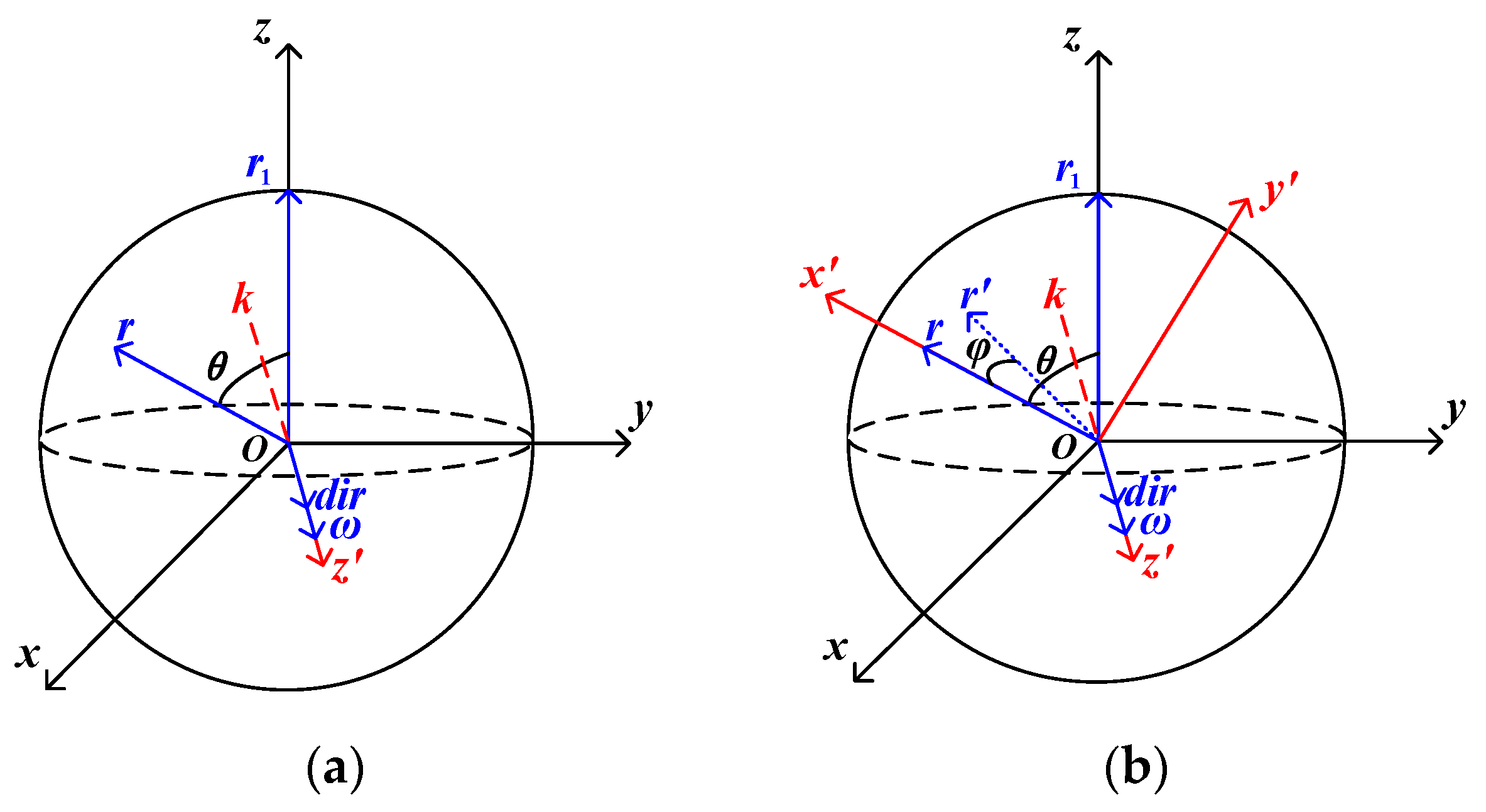

2.4. Kinematic Modelling

3. Open-Loop Orientation Adjustment Experiment

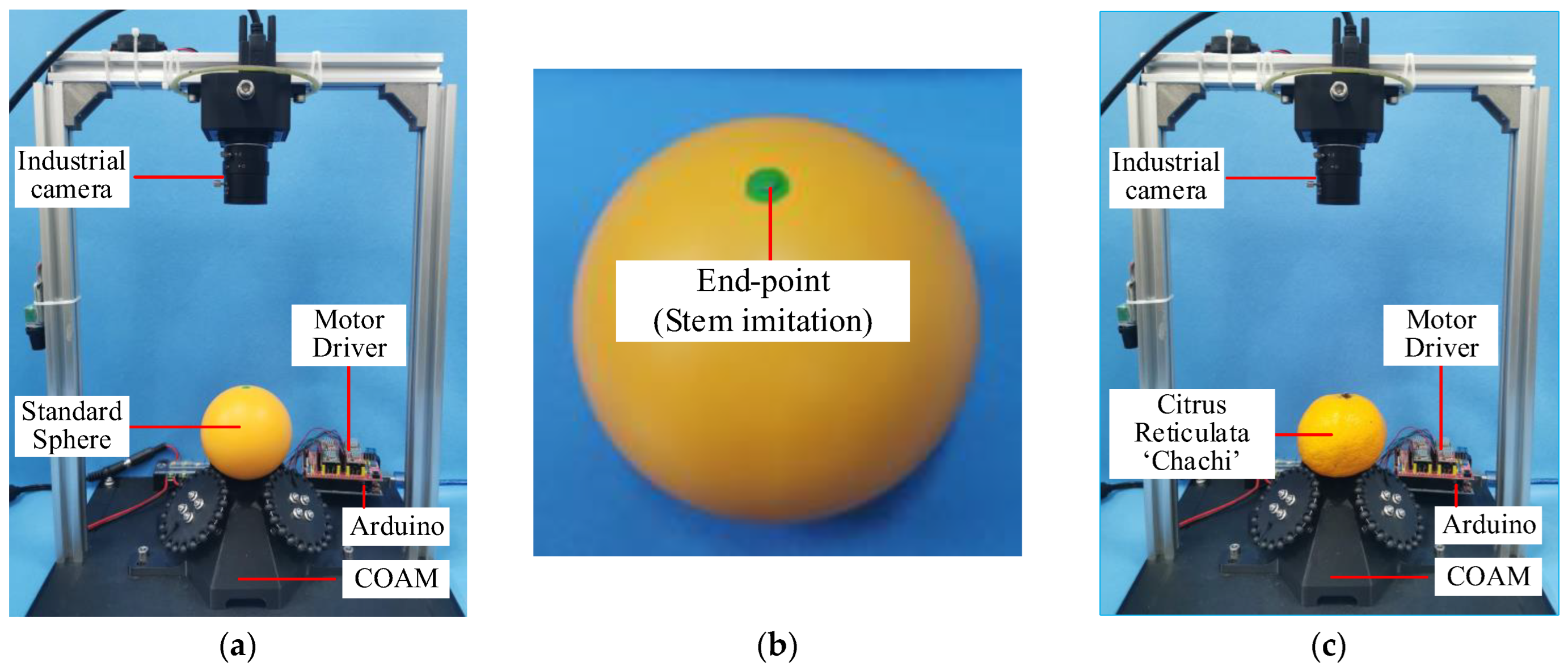

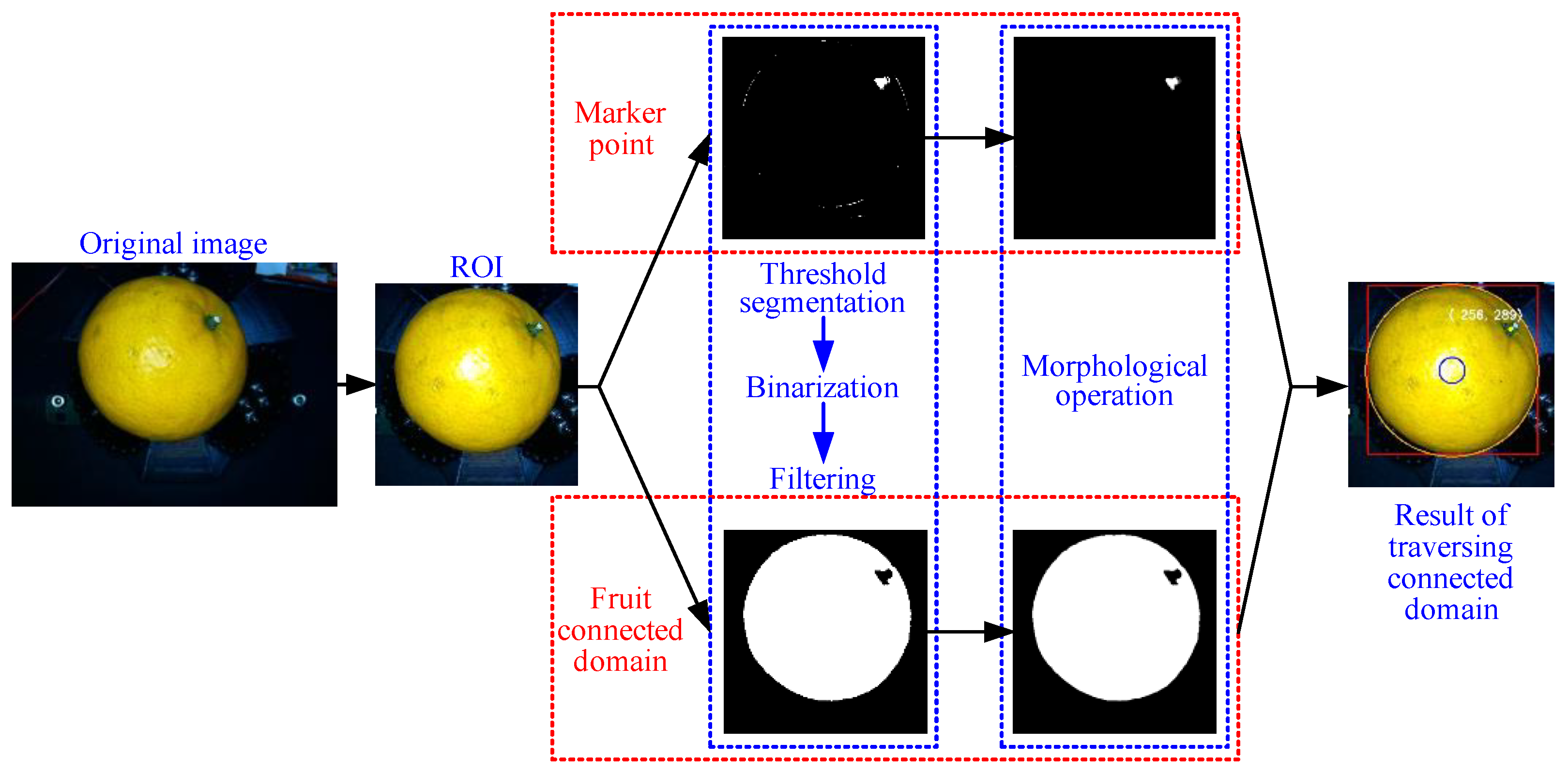

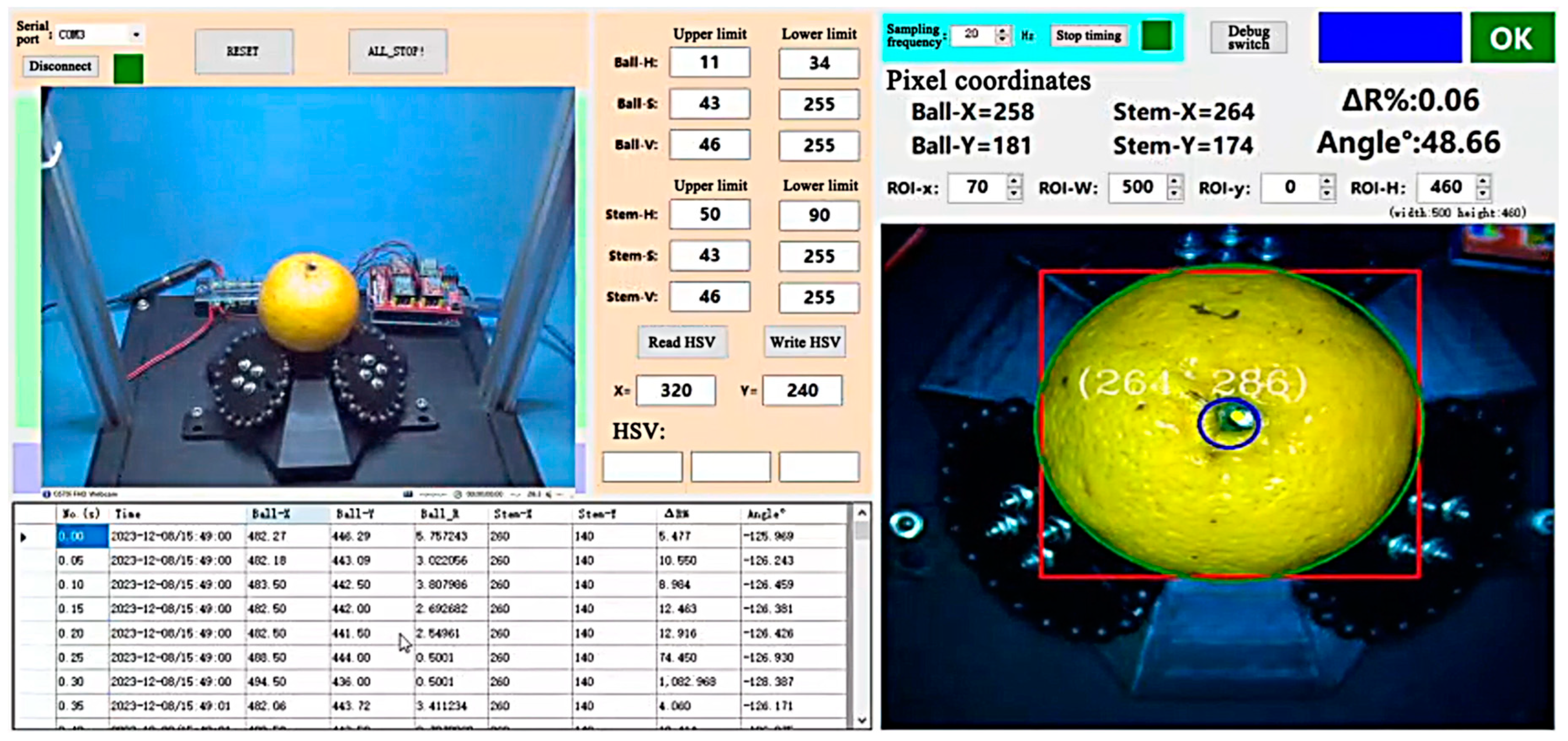

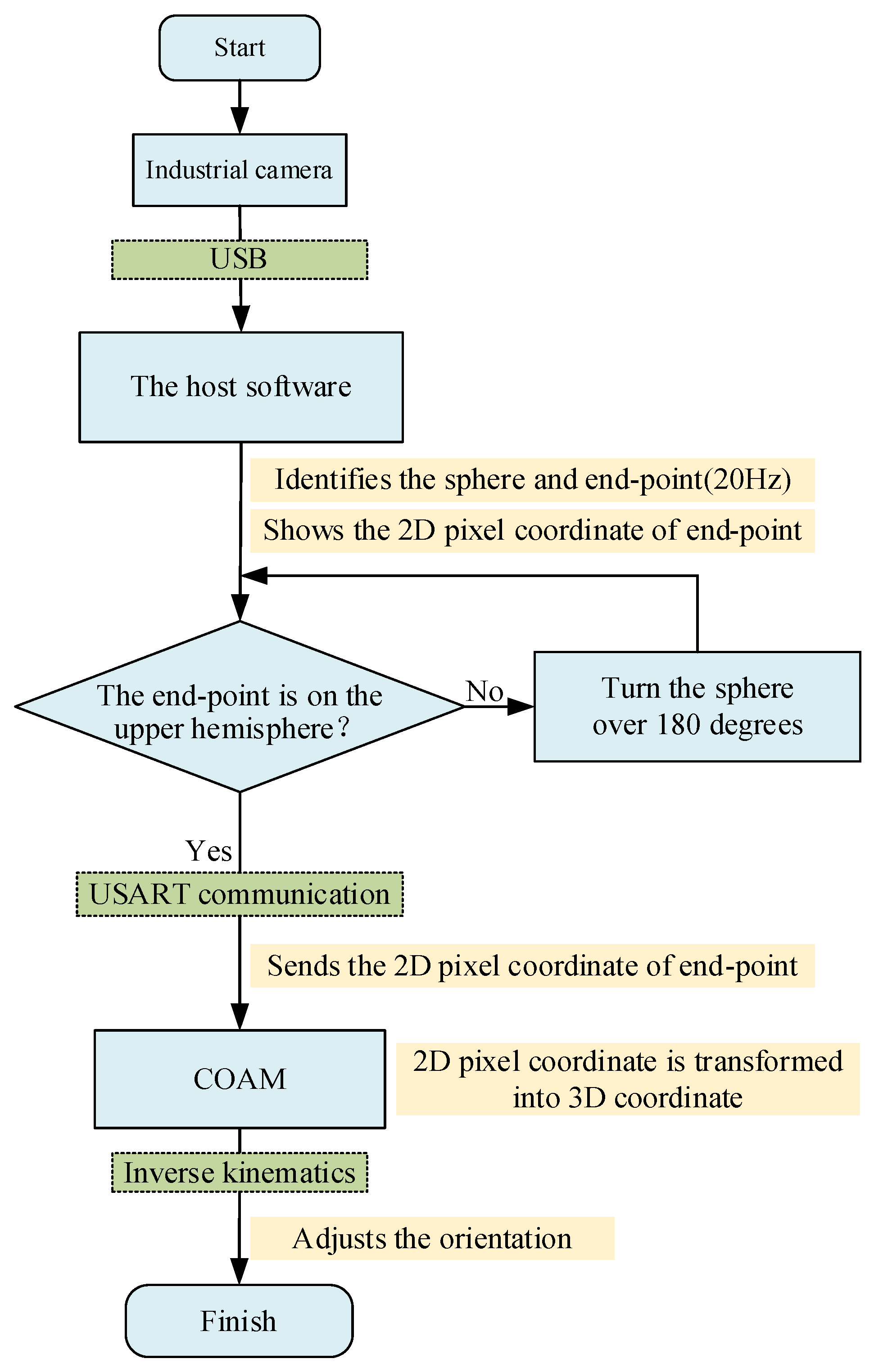

3.1. The Experimental Platform Setup and Machine Vision Recognition

3.2. Open-Loop Orientation Adjustment Experiment with Standard Sphere

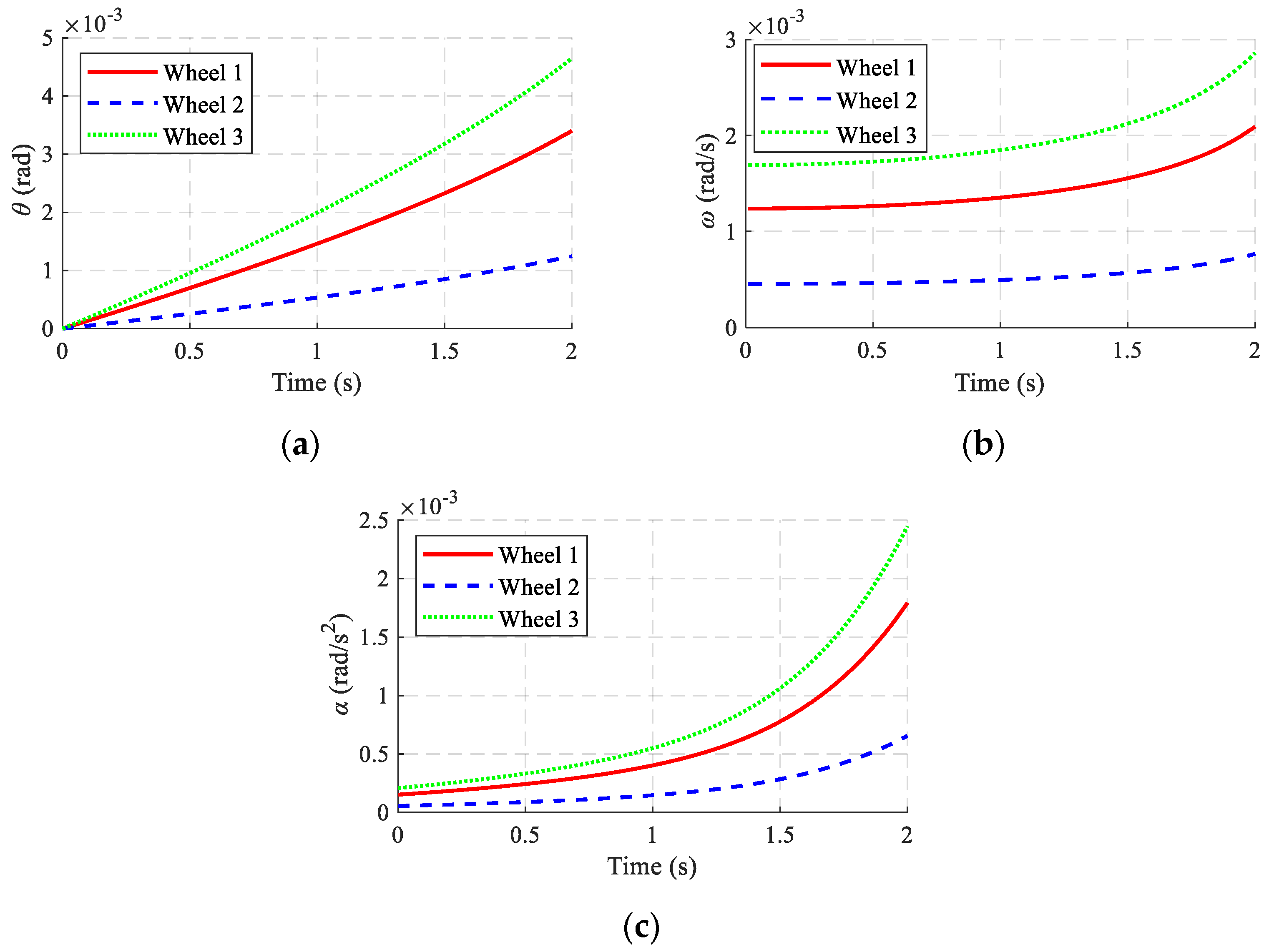

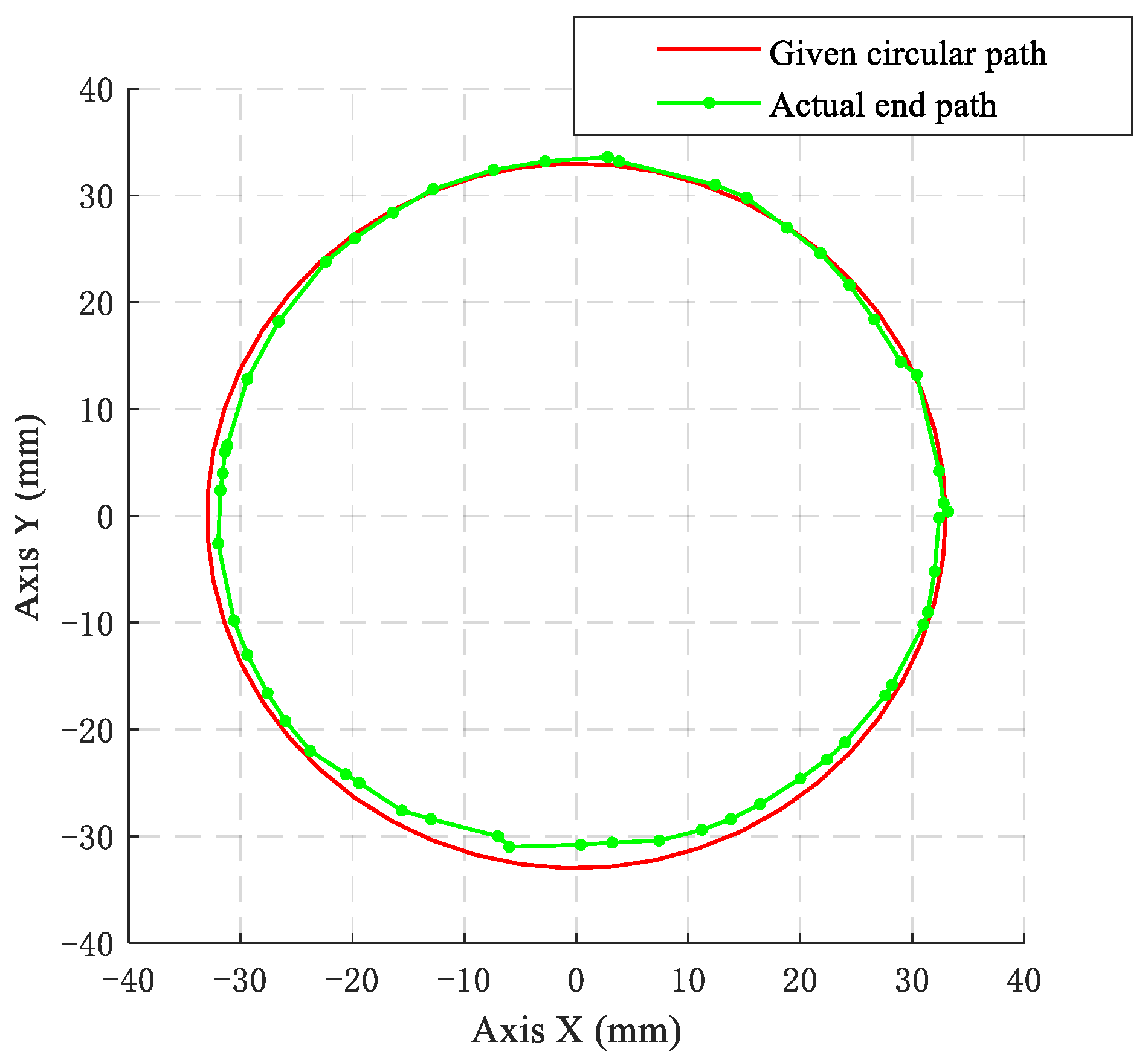

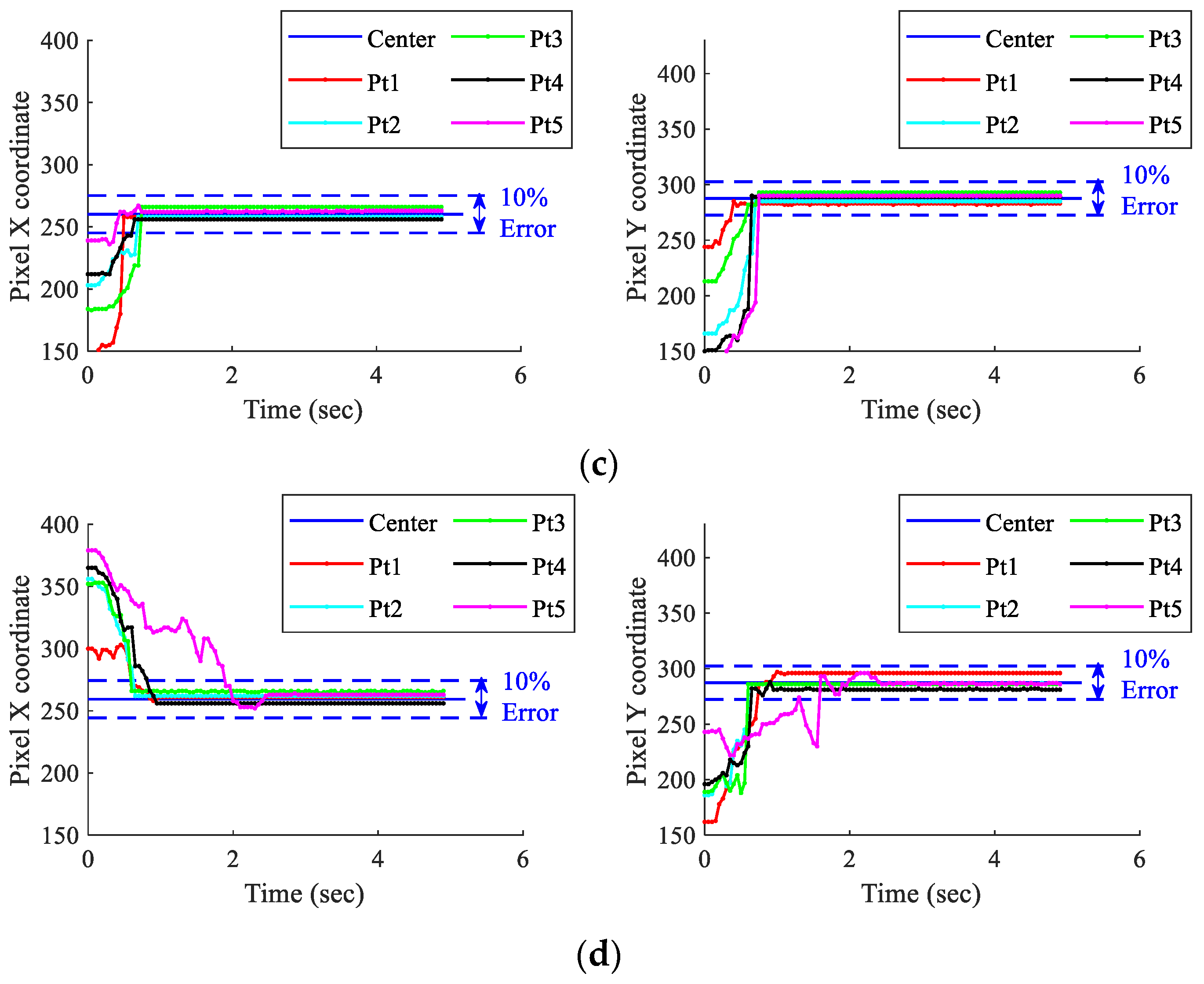

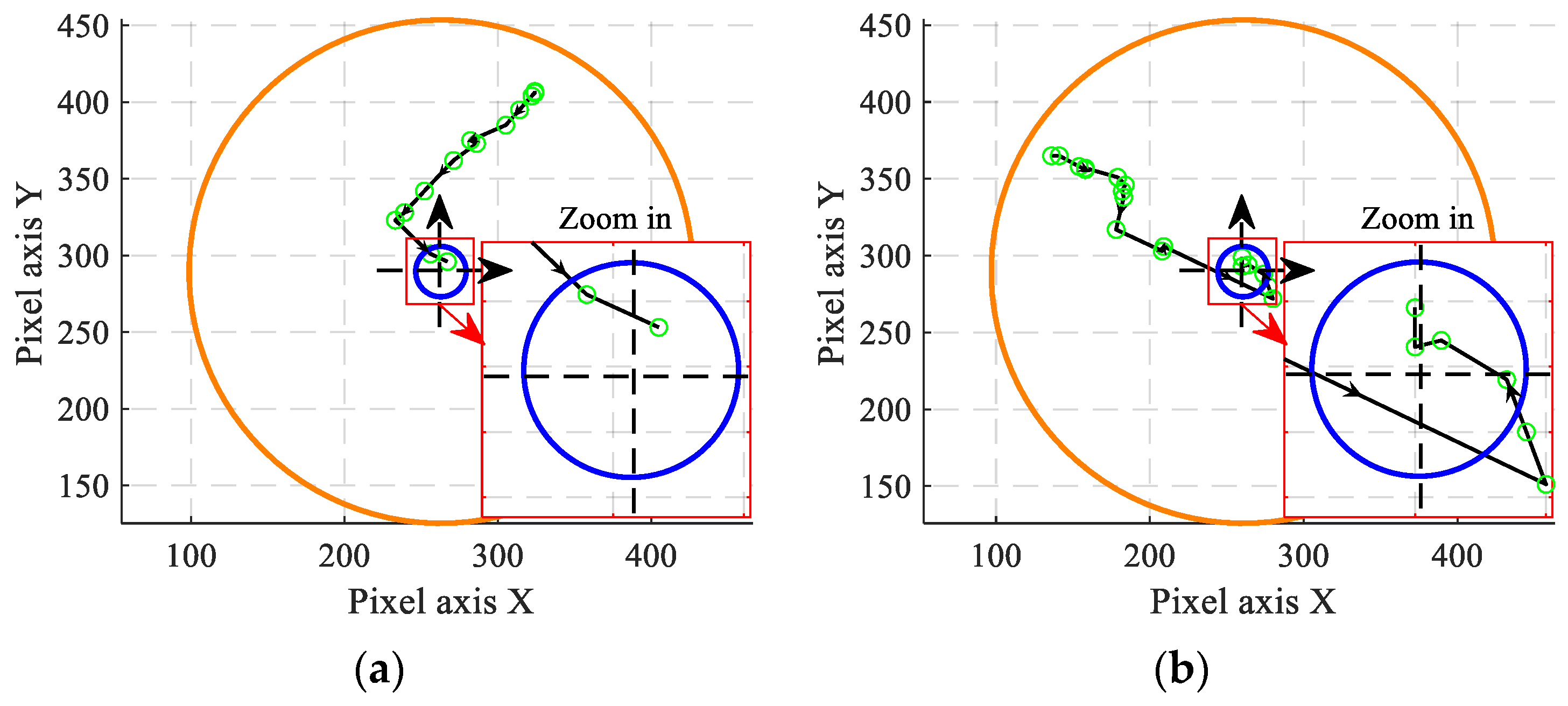

3.2.1. End-Point Trajectory Validation

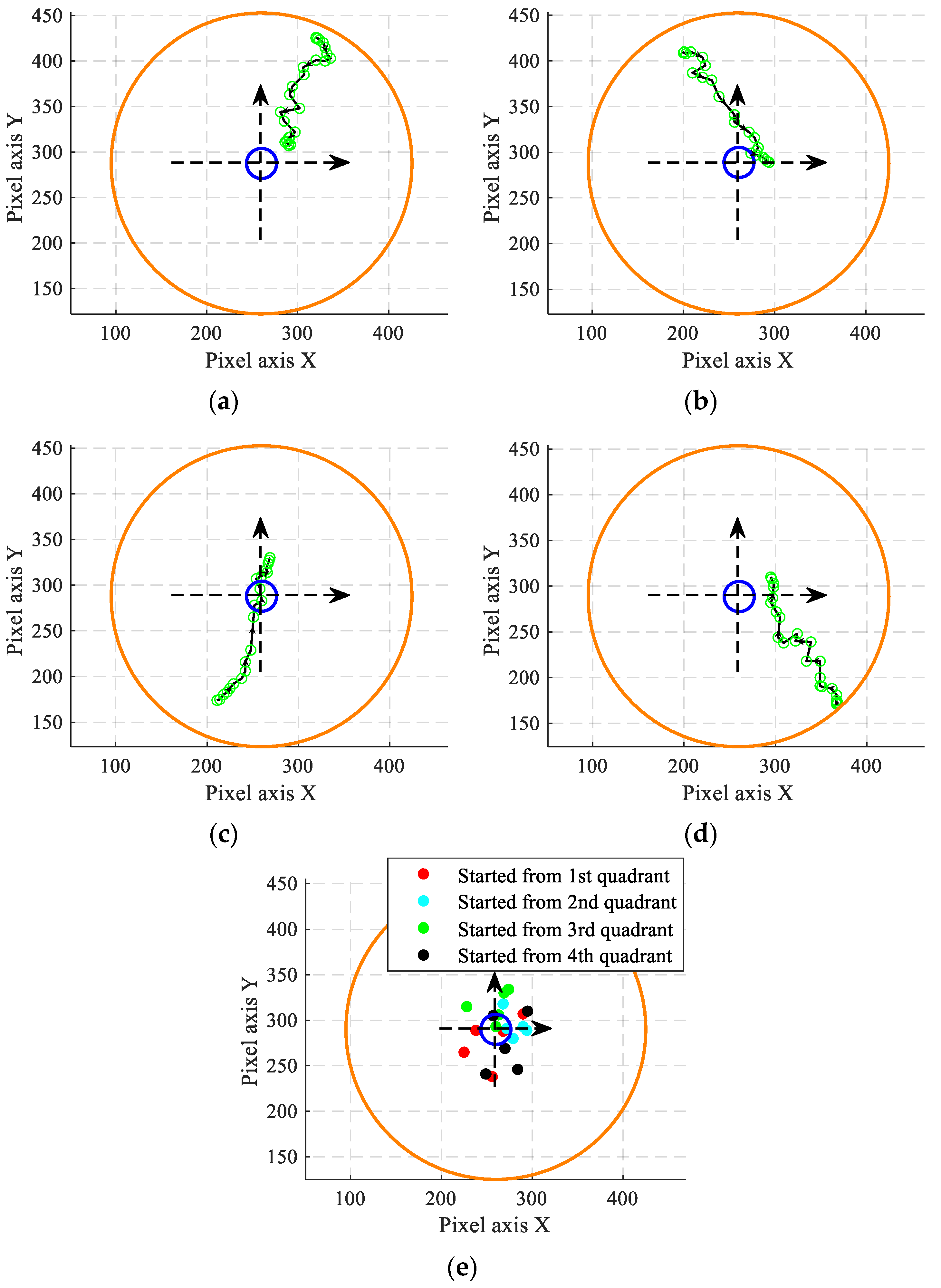

3.2.2. Open-Loop Orientation Adjustment Experiment

4. Closed-Loop Experiments with Different Algorithms

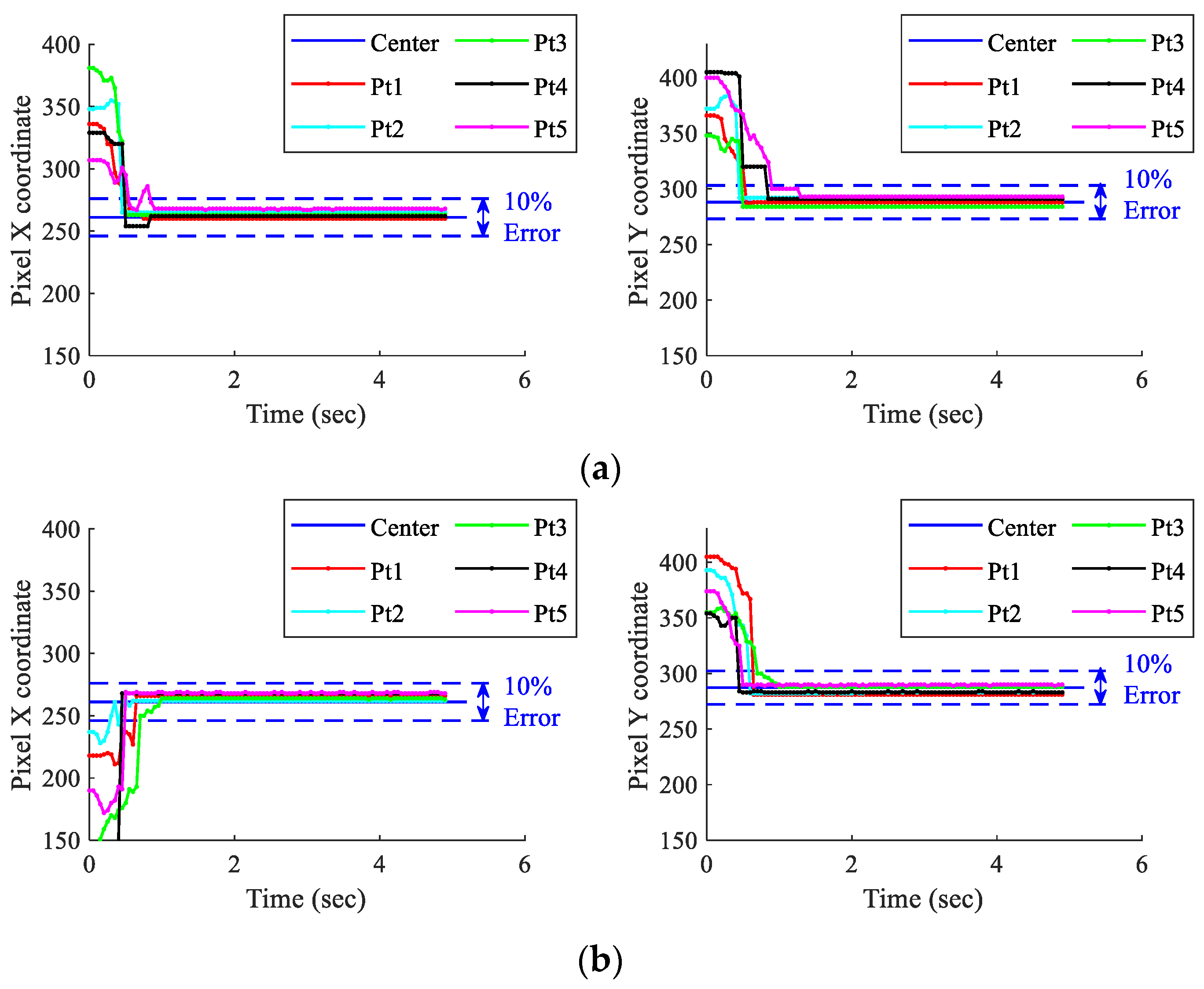

4.1. Closed-Loop Experiments Using PID Control

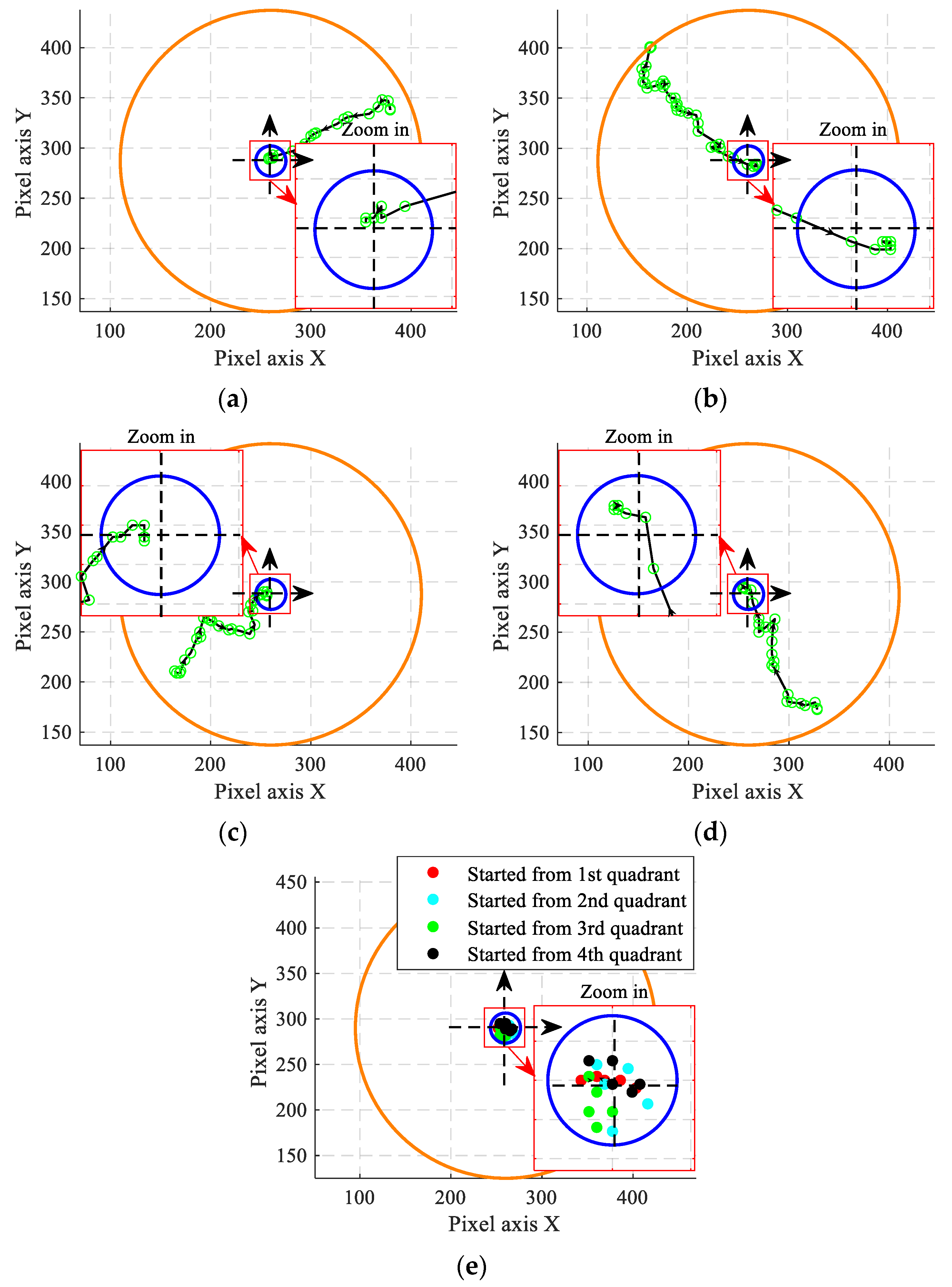

4.1.1. Standard Sphere Experiments (PID)

4.1.2. Citrus Reticulata ‘Chachi’ Experiments (PID)

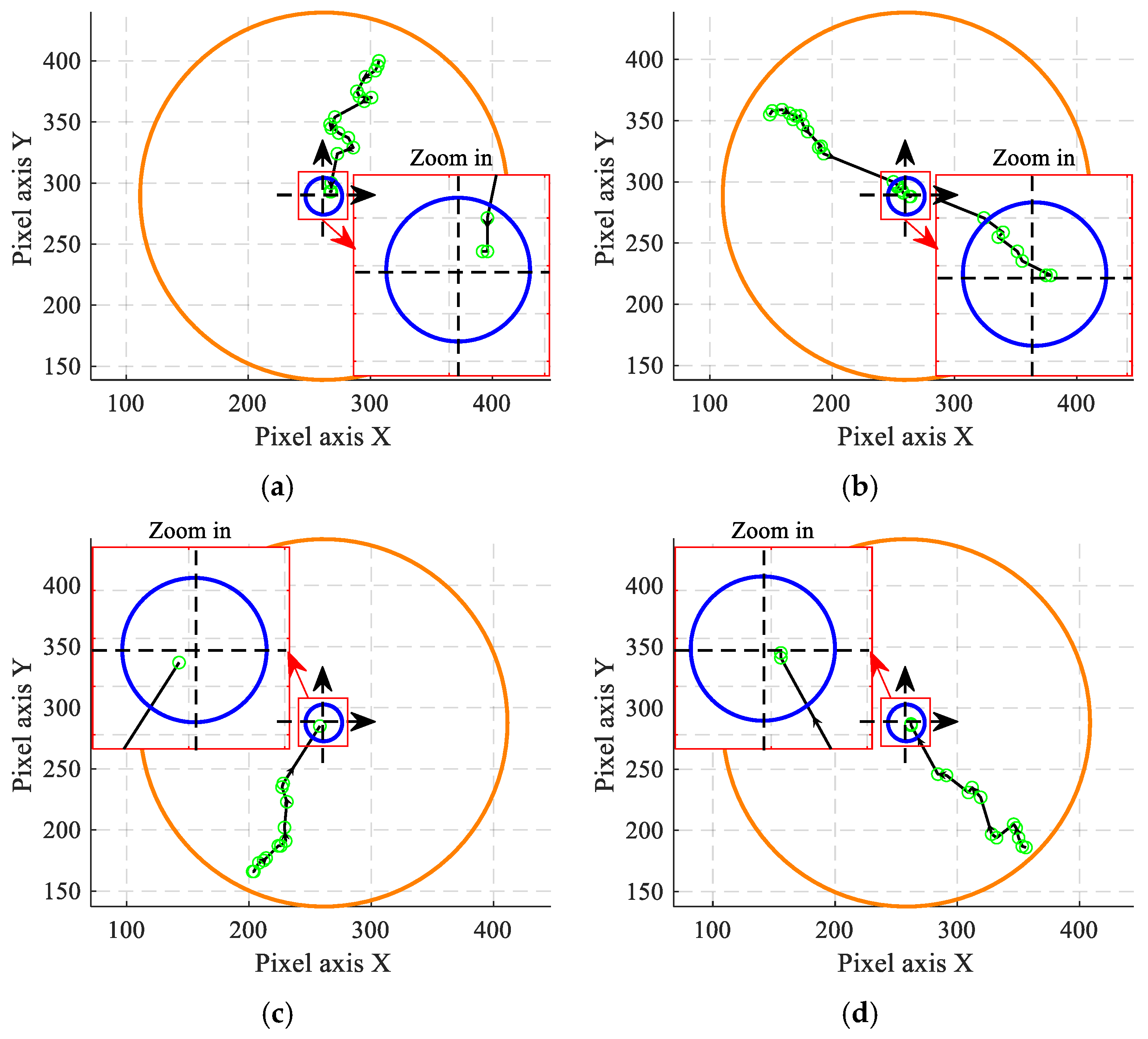

4.2. Closed-Loop Experiments Using LQR Control

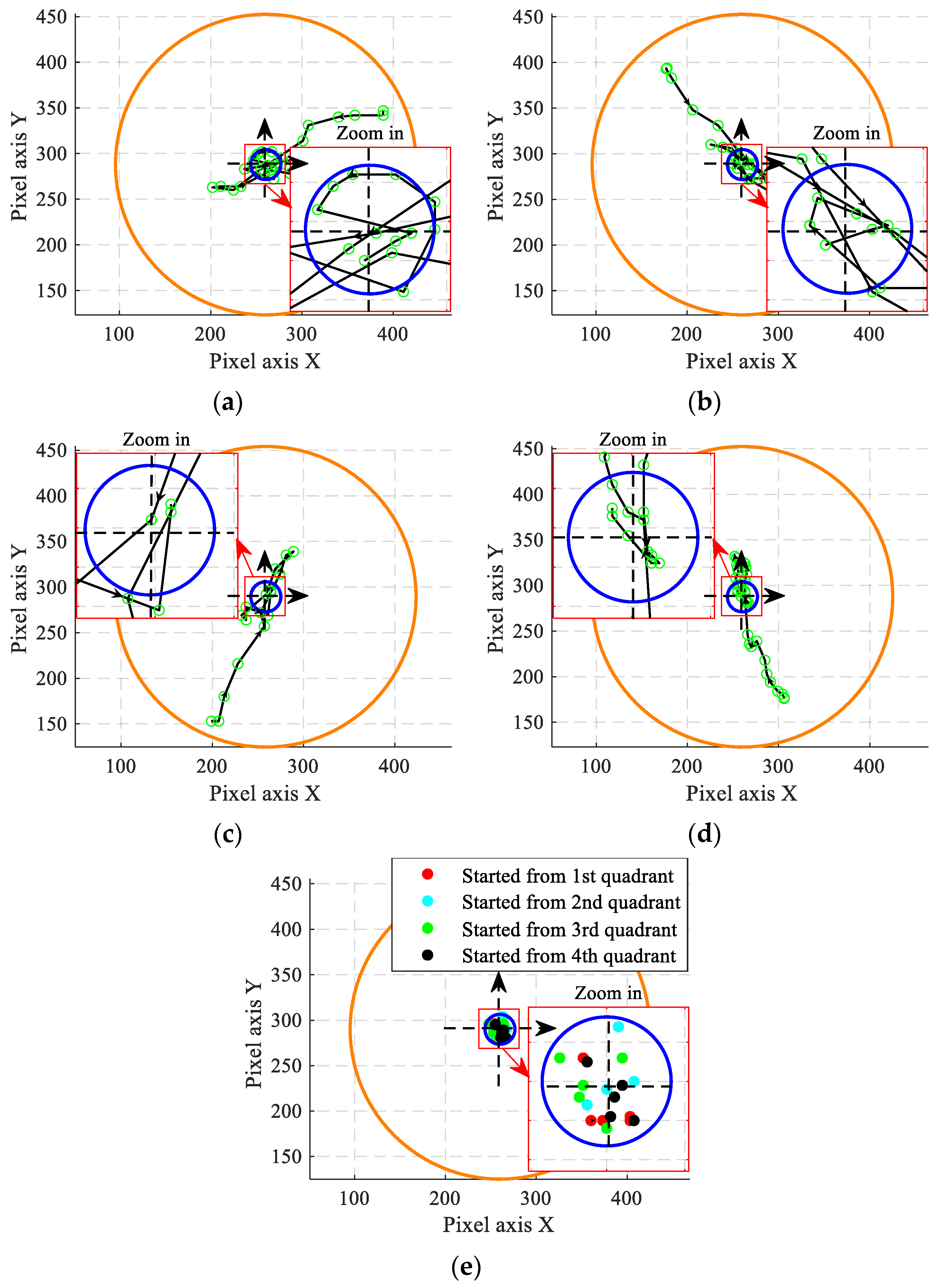

4.2.1. Standard Sphere Experiments (LQR)

4.2.2. Citrus Reticulata ‘Chachi’ Experiments (LQR)

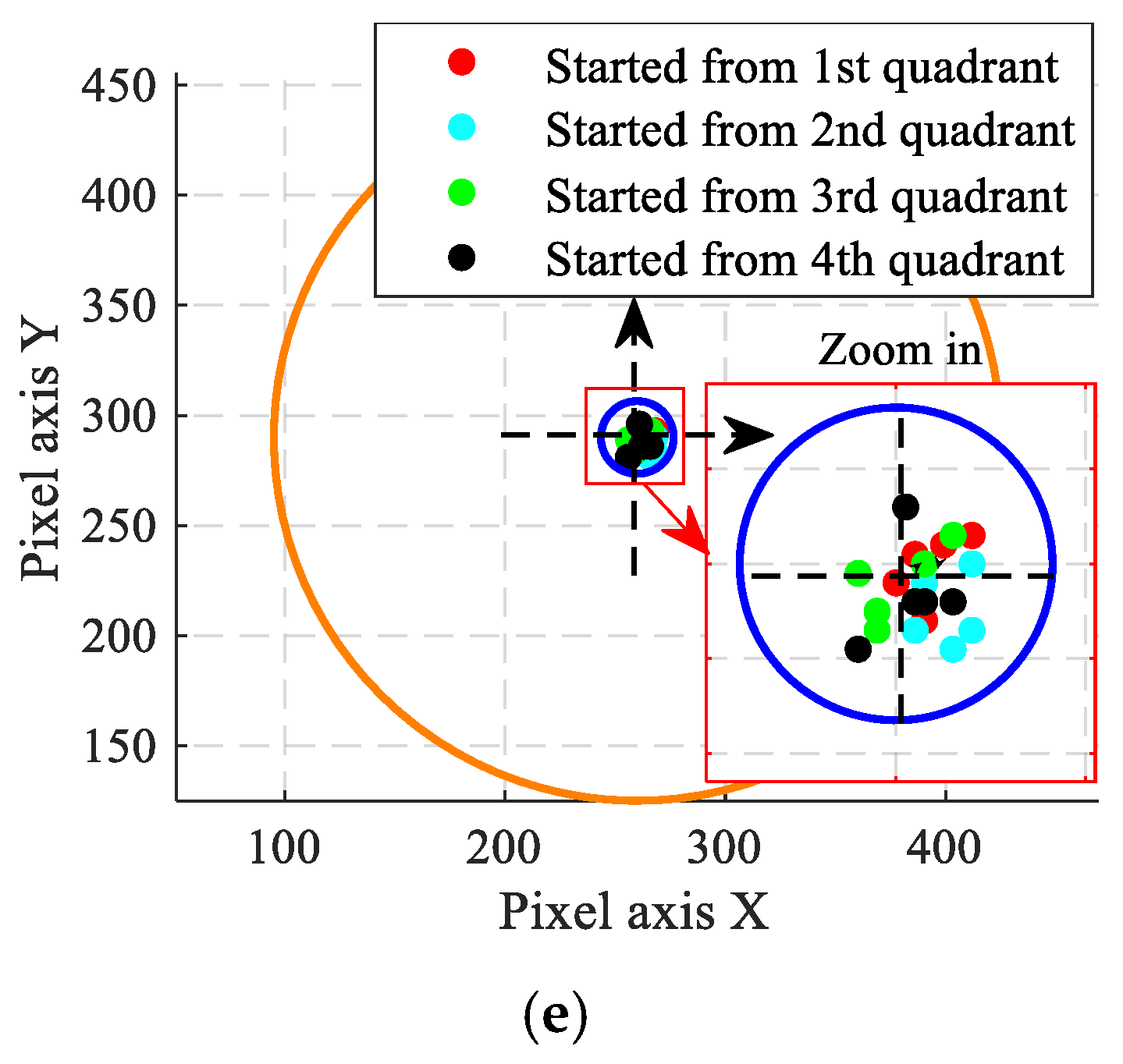

4.3. Results Comparison of Different Algorithms

5. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhan, R.; Liu, J.; Chen, L.; Han, Z.; Lu, Y.; Chen, W.; Chen, W. Investigation on the Production Status of Lingnan Herbal Medicine in Guangdong Province. J. Guangzhou Univ. Treditional Chin. Med. 2020, 37, 1836–1843. [Google Scholar]

- Liu, W.; Wei, W.; Chen, Y.; Zhao, J.; Fu, M.; Wang, X. Research Progress on Geographical Origin Traceability and Authentication of Citri Reticulatae Pericarpium. Food Sci. 2023, 45, 19–28. [Google Scholar]

- Huang, J.; Li, M.; Wu, J.; Mo, Z. Current Situation and Development Countermeasures of Xinhui Citrus lndustry Planting. Guangdong Seric. 2023, 57, 112–114. [Google Scholar]

- China NPCO. Pharmacopoeia of the People’s Republic of China Part One; 2020 ed.; China Medical Science and Technology Press: Beijing, China, 2020. [Google Scholar]

- Wang, Y.; Fan, Q.; Wu, H.; Wang, J.; Liao, W. Textual Research on the Basic Source of Chenpi and a Brief Introduction to the Planting History of Medicinal Material. Subtrop. Plant Sci. 2023, 52, 453–464. [Google Scholar]

- Yu, X.; Sun, S.; Guo, Y.; Liu, Y.; Yang, D.; Li, G.; Lü, S. Citri Reticulatae Pericarpium (Chenpi): Botany, ethnopharmacology, phytochemistry, and pharmacology of a frequently used traditional Chinese medicine. J. Ethnopharmacol. 2018, 220, 265–282. [Google Scholar] [CrossRef] [PubMed]

- Shorbagi, M.; Fayek, N.M.; Shao, P.; Farag, M.A. Citrus reticulata Blanco (the common mandarin) fruit: An updated review of its bioactive, extraction types, food quality, therapeutic merits, and bio-waste valorization practices to maximize its economic value. Food Biosci. 2022, 47, 101699. [Google Scholar] [CrossRef]

- Singh, I.P.; Gore, D.D.; Karkhele, S.; Vairappan, C.S. The Chemistry and Pharmacology of Mandarin Orange (Citrus reticulata). In Recent Advances in Pharmaceutical Innovation and Research; Springer: Singapore, 2023; pp. 305–320. [Google Scholar]

- Liu, M.; Wang, J.; Deng, H.; Geng, L. Comparative study on main components and detection methods of Pericarpium Citri Reticulatae from different habitats. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; p. 12018. [Google Scholar]

- Guan, X.; Yang, H.; Zhang, J.; Xu, J. Research Progress on Chemical Constituents and Pharmacological Effects of Tangerine Peel. Chin. Arch. Tradit. Chin. Med. 2023, 6, I0008. [Google Scholar]

- Liang, S.; Zhang, J.; Liu, Y.; Wen, Z.; Liu, X.; Dang, F.; Xie, T.; Wang, J.; Wang, Z.; Wu, H. Study on flavonoids and bioactivity features of pericarp of Citrus reticulata “Chachi” at different harvest periods. Plants 2022, 11, 3390. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Xu, Y.; Wen, J.; Yu, Y.; Wu, J.; Cheng, L.; Cheang, W.-S.; Liu, W.; Fu, M. Analysis of Flavonoid Metabolites in Citrus reticulata ‘Chachi’at Different Collection Stages Using UPLC-ESI-MS/MS. Foods 2023, 12, 3945. [Google Scholar] [CrossRef] [PubMed]

- Liang, P.; Chen, X.; Gong, M.; Xu, Y.; Tu, H.-S.; Zhang, L.; Liao, B.-S.; Qiu, X.-H.; Zhang, J.; Huang, Z.-H.; et al. Guang Chen Pi (the pericarp of Citrus reticulata Blanco’s cultivars ‘Chachi’) inhibits macrophage-derived foam cell formation. J. Ethnopharmacol. 2022, 293, 115328. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Jiang, Z.; Wen, M.; Wu, Z.; Zha, M.; Xu, W.; Zhang, L. Chemical variation of Chenpi (Citrus peels) and corresponding correlated bioactive compounds by LC-MS metabolomics and multibioassay analysis. Front. Nutr. 2022, 9, 825381. [Google Scholar] [CrossRef] [PubMed]

- Lai, Y. The Utilization of Xinhui Chenpi Geographical lndication from the Perspective of Brand Premium. China Trademark 2023, S1, 70–73. [Google Scholar]

- Wang, M.; Li, X.; Ding, H.; Chen, H.; Liu, Y.; Wang, F.; Chen, L. Comparison of the volatile organic compounds in Citrus reticulata ‘Chachi’peel with different drying methods using E-nose, GC-IMS and HS-SPME-GC-MS. Front. Plant Sci. 2023, 14, 1169321. [Google Scholar]

- Yan, X.; Liu, J.; Zhang, F. Traditional Production Techniques and Quality ldentification of Xinhui Citri Reticulatae Pericarpium. Chin. Pharm. Aff. 2022, 36, 41–44. [Google Scholar]

- Zeng, H.; Zeng, L.; Chen, J.; Chen, X.; Peng, R.; Huang, Z.; Zeng, X.; Zeng, Z. Research Progress on Chemical Constituents Difference of Citri Reticulatae Pericarpium with Different Storage Years. Asia-Pac. Tradit. Med. 2023, 19, 221–225. [Google Scholar]

- Yan, G.; Chen, D.; Mo, J.; Qu, J.; Sun, Z. Experimental Study on Dynamic Characteristics of Moisture Content of Citrus reticulata ‘Chachi’. Mod. Agric. Equip. 2022, 43, 31–38. [Google Scholar]

- Li, Z. Drawing up a new blueprint for the development of the hundred-billion-dollar industry of chenpi. China Brand 2024, 1, 44–45. [Google Scholar]

- Zhang, K.; Si, X.; Zhao, J.; Li, Z.; Liu, H.; Guo, Q. Development of Phellinus Igniarius and Tangerine Peel Compound Beverage. Beverage Ind. 2023, 26, 67–72. [Google Scholar]

- Liu, Q.; Yan, G.; Qu, J.; Chen, D.; Zhang, D.; Shen, R. Current status and countermeasures of primary processing machinery technology for Citrus reticulata Blanco (Citrus reticulata ‘Chachi’). J. Chin. Agric. Mech. 2021, 42, 91–98. [Google Scholar]

- Yan, G.; Qu, J.; Ou, G.; Mo, J.; Zhong, C.; Chen, D.; Liu, Q.; Zhang, D. Current situation and countermeasures of drying and storage technology and equipment of Citrus reticulata ’Chachi’. J. South. Agric. 2021, 52, 2543–2553. [Google Scholar]

- Deng, M. A Rapid Peeling Machine for Citrus Fruits. ZL201721250809.5, 16 October 2018. [Google Scholar]

- Wu, G. One Type of Automatic Device for Separating the Peel and Pulp of Citrus Fruits. ZL201720212220.X, 1 May 2018. [Google Scholar]

| Sphere Radius/mm | Wheel Radius/mm | Line Trajectory/mm | Circular Trajectory/mm |

|---|---|---|---|

| 35 | 25 |

| Numbers of Citrus Reticulata ‘Chachi’ and Points | 1st Quadrant | 2nd Quadrant | 3rd Quadrant | 4th Quadrant | |||||

|---|---|---|---|---|---|---|---|---|---|

| Error (%) | Speed (mm/s) | Error (%) | Speed (mm/s) | Error (%) | Speed (mm/s) | Error (%) | Speed (mm/s) | ||

| No.1 (70.90 mm in long-axis size, 166.78 g) | Point 1 | 3.83 | 11.75 | 4.12 | 18.31 | 7.55 | 13.62 | 4.62 | 18.17 |

| Point 2 | 2.61 | 19.82 | 1.81 | 17.16 | 4.43 | 14.70 | 4.58 | 18.01 | |

| Point 3 | 8.91 | 17.04 | 1.49 | 16.67 | 6.37 | 19.98 | 4.83 | 15.97 | |

| Point 4 | 8.74 | 17.04 | 6.81 | 11.65 | 2.52 | 11.73 | 3.45 | 12.95 | |

| Point 5 | 5.07 | 10.45 | 2.37 | 15.10 | 5.74 | 16.20 | 6.32 | 17.64 | |

| No.2 (70.55 mm in long-axis size, 164.52 g) | Point 1 | 1.81 | 19.23 | 7.86 | 13.14 | 0.85 | 9.84 | 1.70 | 11.07 |

| Point 2 | 8.73 | 14.63 | 2.30 | 15.83 | 6.37 | 14.30 | 0.68 | 16.65 | |

| Point 3 | 2.24 | 12.65 | 2.65 | 15.73 | 2.41 | 18.63 | 1.54 | 15.89 | |

| Point 4 | 4.69 | 16.69 | 1.17 | 16.03 | 1.28 | 13.98 | 0.21 | 15.26 | |

| Point 5 | 0.94 | 21.58 | 3.55 | 17.23 | 5.80 | 10.26 | 8.52 | 14.67 | |

| No.3 (69.56 mm in long-axis size, 165.22 g) | Point 1 | 5.11 | 12.77 | 8.43 | 17.63 | 2.40 | 14.52 | 1.98 | 15.69 |

| Point 2 | 3.24 | 16.07 | 1.35 | 20.42 | 4.25 | 11.99 | 1.25 | 18.54 | |

| Point 3 | 2.89 | 18.16 | 2.59 | 17.60 | 4.83 | 17.10 | 4.63 | 12.51 | |

| Point 4 | 3.86 | 16.65 | 7.74 | 14.37 | 1.86 | 12.78 | 5.84 | 14.99 | |

| Point 5 | 4.95 | 13.88 | 0.51 | 15.37 | 5.12 | 17.52 | 1.66 | 15.47 | |

| No.4 (68.08 mm in long-axis size, 164.21 g) | Point 1 | 2.64 | 16.25 | 4.11 | 16.52 | 2.16 | 11.55 | 8.92 | 12.68 |

| Point 2 | 5.85 | 17.42 | 5.68 | 18.55 | 4.21 | 16.91 | 2.65 | 16.85 | |

| Point 3 | 4.41 | 14.63 | 1.54 | 18.96 | 1.80 | 12.96 | 0.45 | 20.65 | |

| Point 4 | 2.63 | 14.27 | 6.32 | 16.41 | 7.66 | 15.24 | 6.33 | 17.42 | |

| Point 5 | 1.73 | 16.16 | 0.83 | 10.42 | 3.30 | 21.63 | 5.42 | 14.07 | |

| Average | 4.24 | 15.86 | 3.66 | 16.16 | 4.05 | 14.77 | 3.78 | 15.76 | |

| Variance | 5.25 | 7.37 | 6.32 | 5.54 | 4.18 | 9.52 | 6.51 | 5.29 | |

| Numbers of Citrus Reticulata ‘Chachi’ and Points | 1st Quadrant | 2nd Quadrant | 3rd Quadrant | 4th Quadrant | |||||

|---|---|---|---|---|---|---|---|---|---|

| Error (%) | Speed (mm/s) | Error (%) | Speed (mm/s) | Error (%) | Speed (mm/s) | Error (%) | Speed (mm/s) | ||

| No.1 (70.90 mm in long-axis size, 166.78 g) | Point 1 | 1.93 | 16.62 | 4.19 | 18.35 | 3.53 | 18.93 | 6.55 | 26.25 |

| Point 2 | 2.38 | 21.76 | 3.36 | 19.66 | 0.67 | 21.50 | 2.92 | 25.63 | |

| Point 3 | 2.80 | 26.42 | 2.34 | 27.50 | 2.95 | 20.76 | 4.70 | 16.93 | |

| Point 4 | 2.66 | 34.07 | 4.42 | 22.56 | 7.46 | 14.60 | 4.82 | 24.61 | |

| Point 5 | 6.13 | 28.98 | 5.06 | 17.83 | 2.87 | 20.35 | 1.99 | 22.83 | |

| No.2 (70.55 mm in long-axis size, 164.52 g) | Point 1 | 1.93 | 23.71 | 3.85 | 29.52 | 4.30 | 27.15 | 0.85 | 19.26 |

| Point 2 | 6.69 | 34.51 | 5.65 | 23.99 | 4.36 | 30.23 | 0.74 | 23.69 | |

| Point 3 | 4.51 | 30.77 | 5.10 | 20.98 | 7.85 | 14.11 | 4.38 | 23.98 | |

| Point 4 | 3.78 | 27.24 | 1.85 | 26.56 | 2.95 | 18.76 | 1.45 | 30.44 | |

| Point 5 | 2.58 | 16.37 | 3.50 | 20.55 | 6.42 | 26.36 | 2.65 | 22.55 | |

| No.3 (69.56 mm in long-axis size, 165.22 g) | Point 1 | 4.58 | 20.70 | 4.45 | 18.03 | 5.12 | 23.80 | 4.51 | 27.15 |

| Point 2 | 0.95 | 32.63 | 1.70 | 24.83 | 1.11 | 14.69 | 2.44 | 24.64 | |

| Point 3 | 2.67 | 27.02 | 3.85 | 29.12 | 0.85 | 30.83 | 6.85 | 26.61 | |

| Point 4 | 4.11 | 21.38 | 3.37 | 16.79 | 2.79 | 19.41 | 1.42 | 19.89 | |

| Point 5 | 4.55 | 20.75 | 1.25 | 35.28 | 2.63 | 15.63 | 2.10 | 32.37 | |

| No.4 (68.08 mm in long-axis size, 164.21 g) | Point 1 | 1.25 | 24.37 | 2.75 | 17.83 | 5.41 | 24.06 | 5.25 | 18.83 |

| Point 2 | 2.78 | 17.58 | 7.04 | 15.05 | 2.78 | 16.89 | 2.66 | 30.26 | |

| Point 3 | 3.45 | 16.31 | 3.42 | 18.26 | 4.50 | 17.37 | 3.30 | 17.60 | |

| Point 4 | 2.12 | 13.13 | 4.50 | 24.91 | 3.12 | 25.74 | 3.62 | 22.86 | |

| Point 5 | 2.76 | 23.08 | 5.85 | 16.56 | 6.30 | 29.89 | 6.17 | 15.57 | |

| Average | 3.23 | 23.87 | 3.88 | 22.21 | 3.90 | 21.55 | 3.47 | 23.60 | |

| Variance | 2.14 | 37.39 | 2.07 | 27.30 | 4.01 | 28.03 | 3.30 | 20.28 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, G.-Q.; Liang, J.-Y.; Chen, Q.-S.; Liang, D.-Y.; Zhou, X.-E.; Mo, J.-S. Research on a Novel Citrus Reticulata ‘Chachi’ Orientation Adjustment Mechanism (COAM) and Machine Vision Guidance Control. Agriculture 2024, 14, 1516. https://doi.org/10.3390/agriculture14091516

Yan G-Q, Liang J-Y, Chen Q-S, Liang D-Y, Zhou X-E, Mo J-S. Research on a Novel Citrus Reticulata ‘Chachi’ Orientation Adjustment Mechanism (COAM) and Machine Vision Guidance Control. Agriculture. 2024; 14(9):1516. https://doi.org/10.3390/agriculture14091516

Chicago/Turabian StyleYan, Guo-Qi, Jia-Yu Liang, Qiu-Shuo Chen, De-Yu Liang, Xi-En Zhou, and Jia-Si Mo. 2024. "Research on a Novel Citrus Reticulata ‘Chachi’ Orientation Adjustment Mechanism (COAM) and Machine Vision Guidance Control" Agriculture 14, no. 9: 1516. https://doi.org/10.3390/agriculture14091516