Effect of A PLC-Based Drinkers for Fattening Pigs on Reducing Drinking Water Consumption, Wastage and Pollution

Abstract

:1. Introduction

2. Materials and Methods

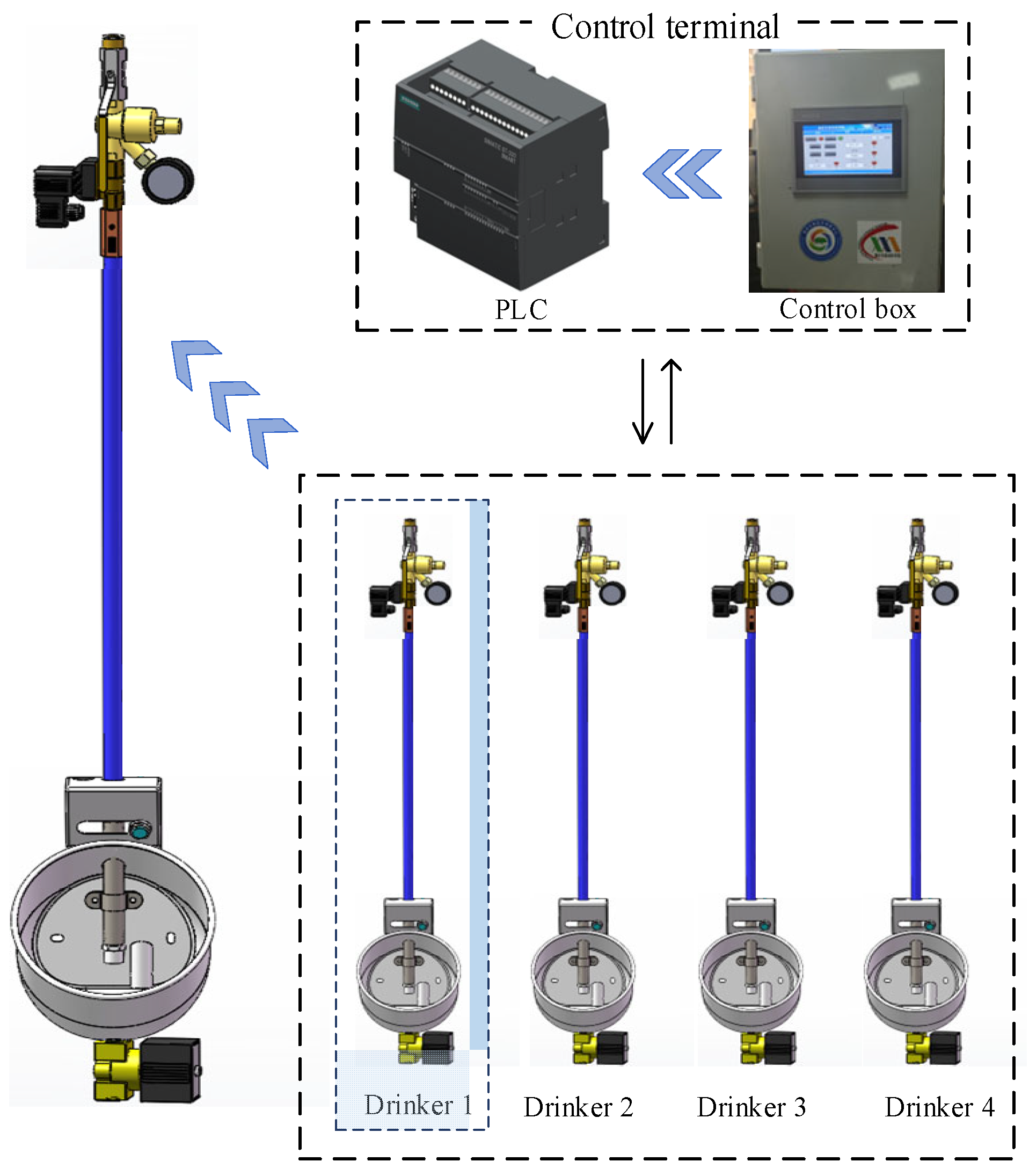

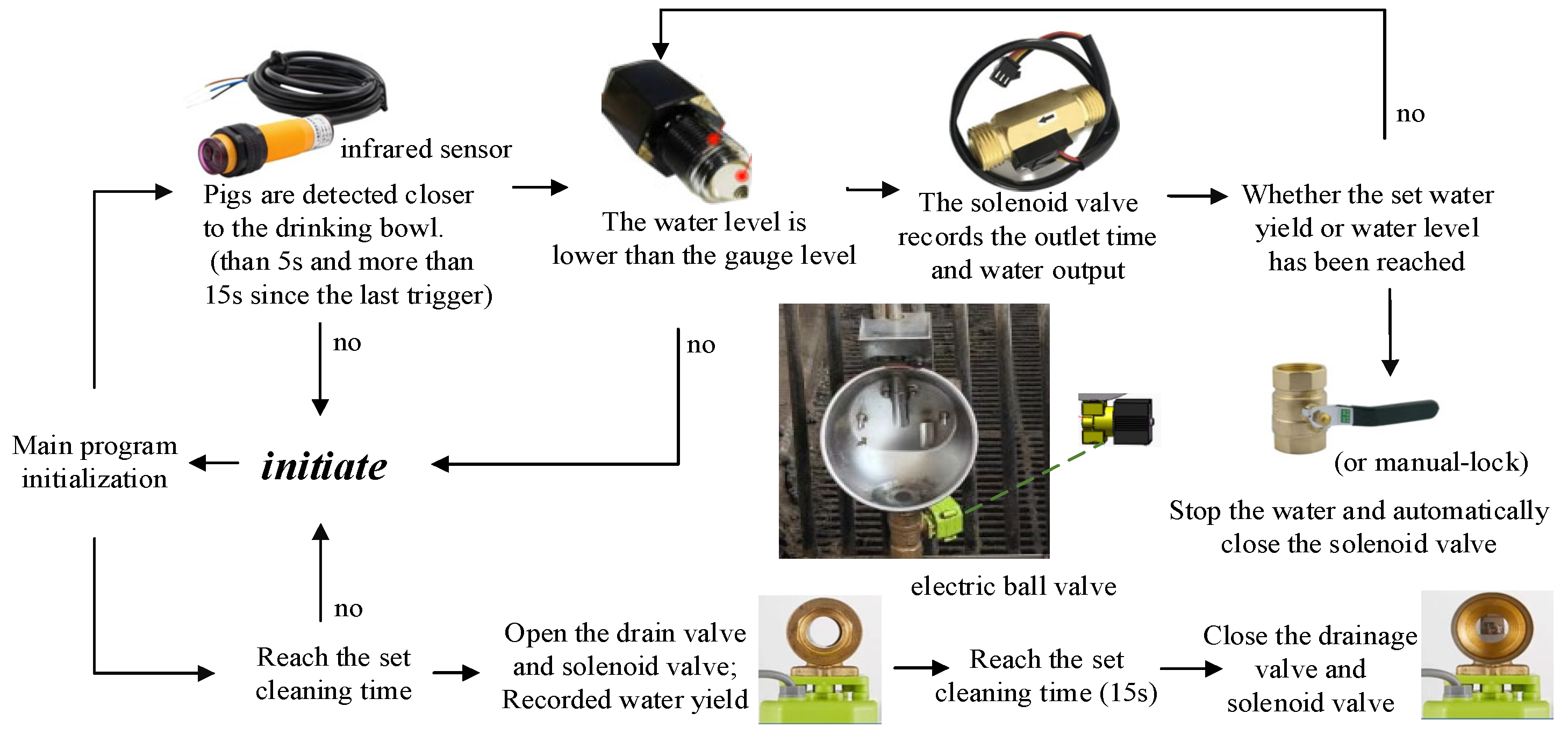

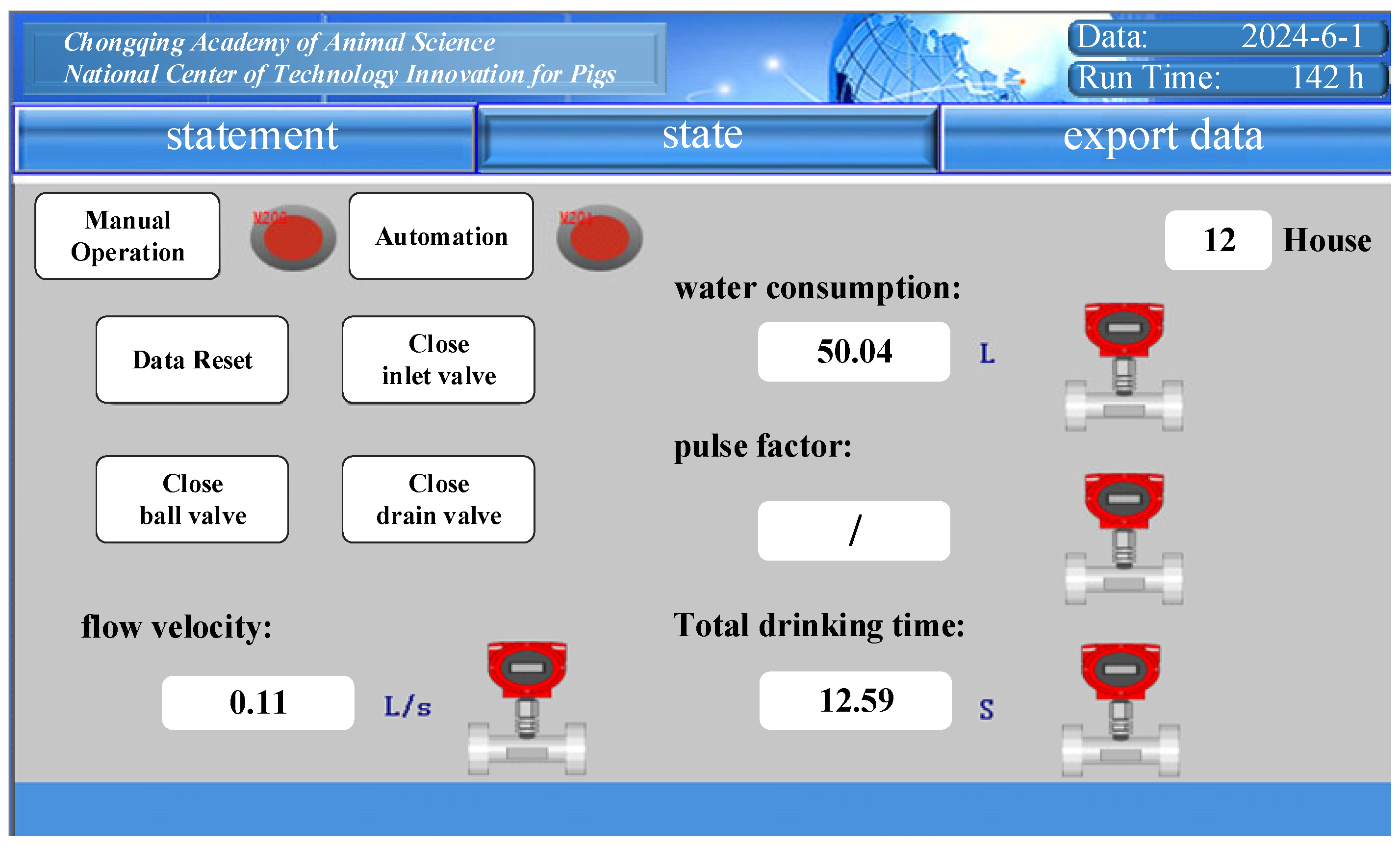

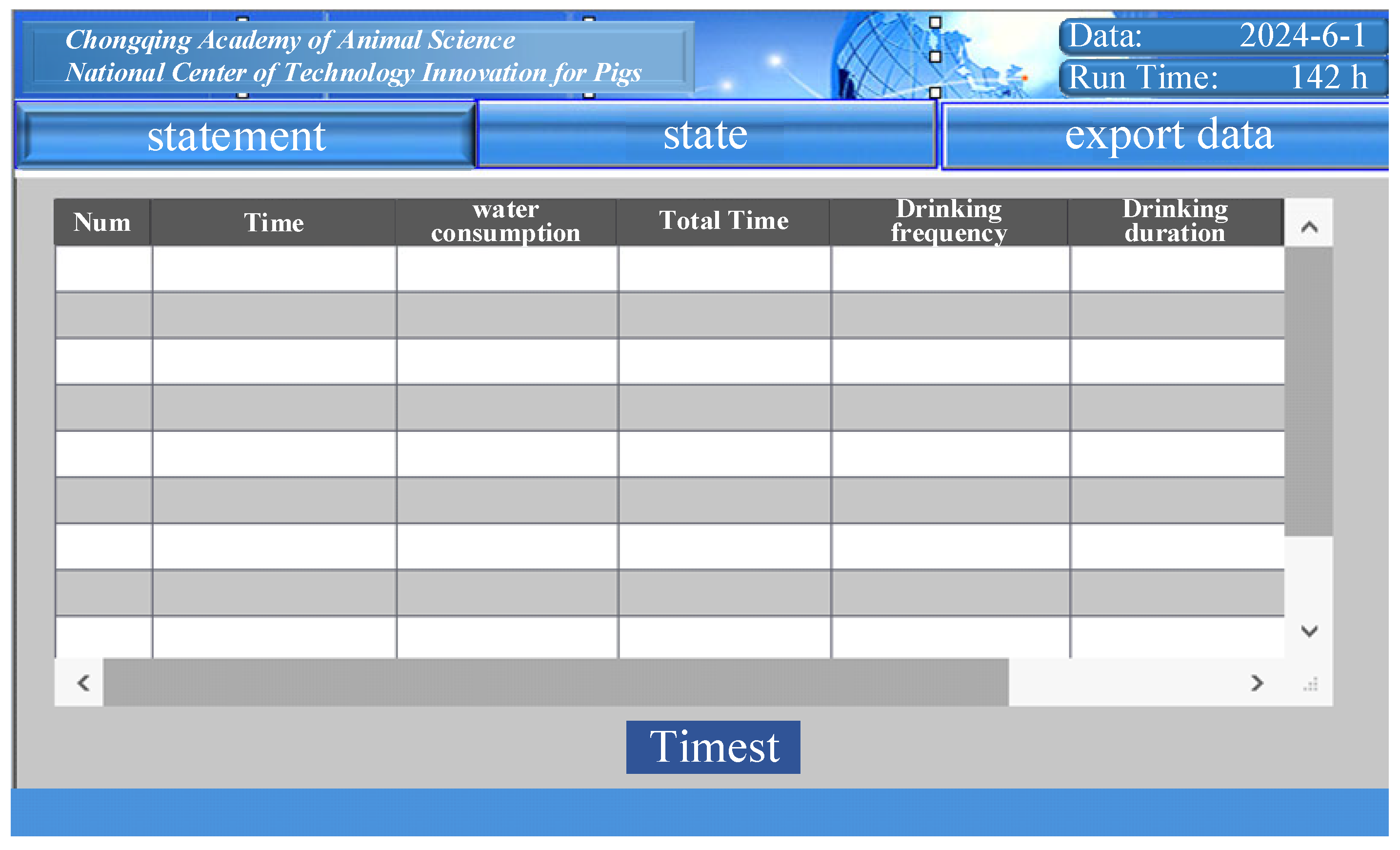

2.1. Intelligent Drinking Water Controller Based on PLC

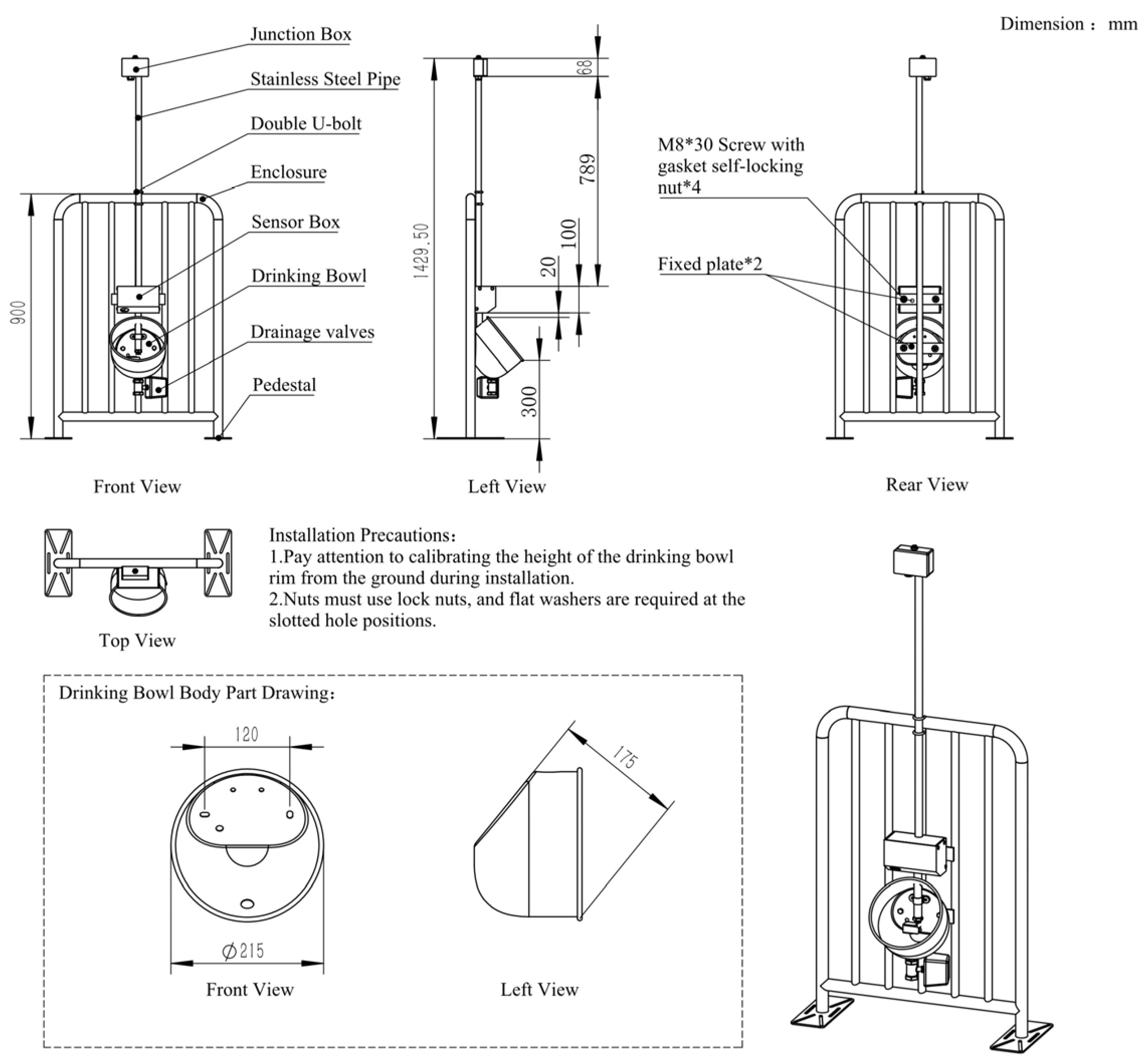

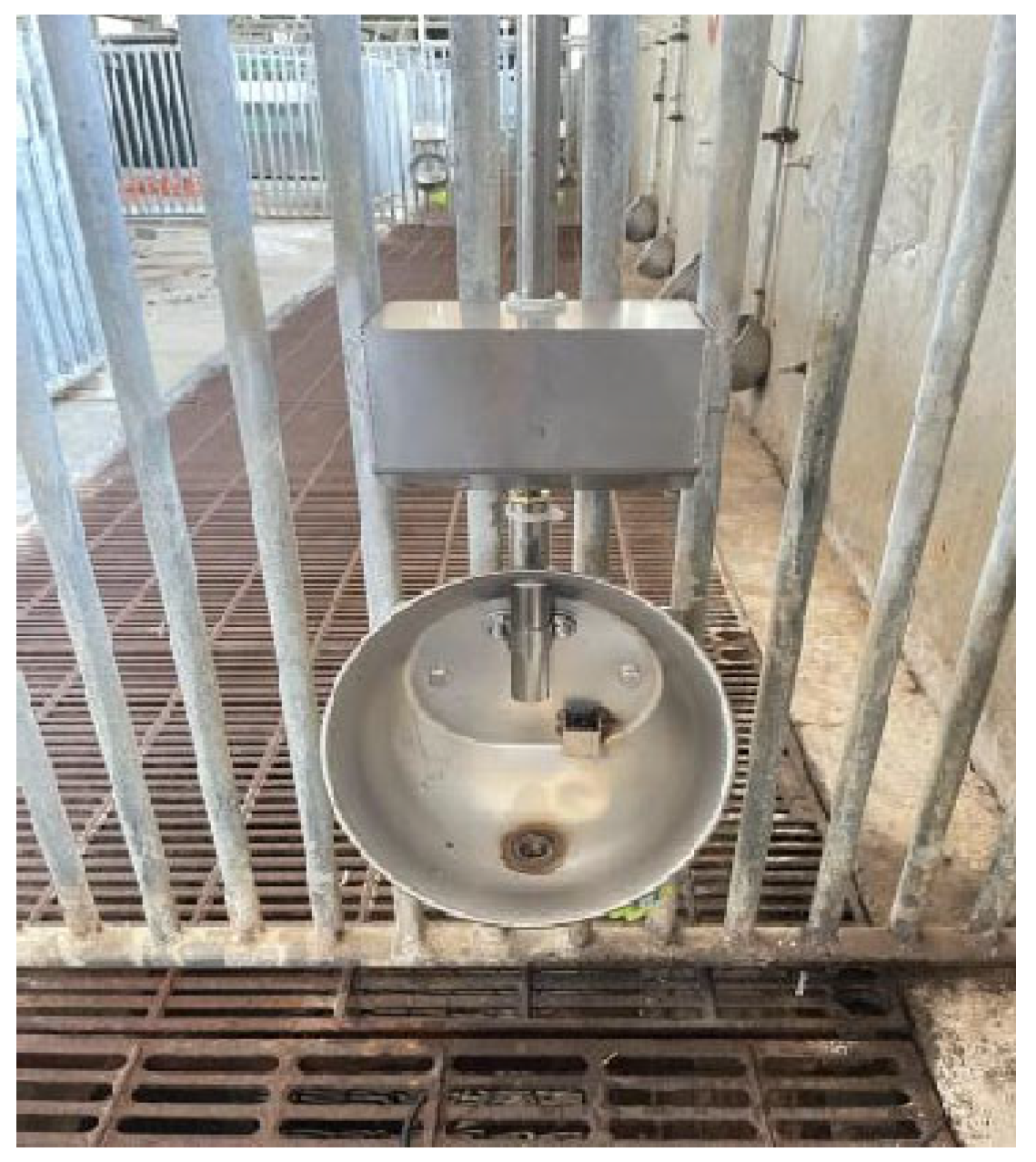

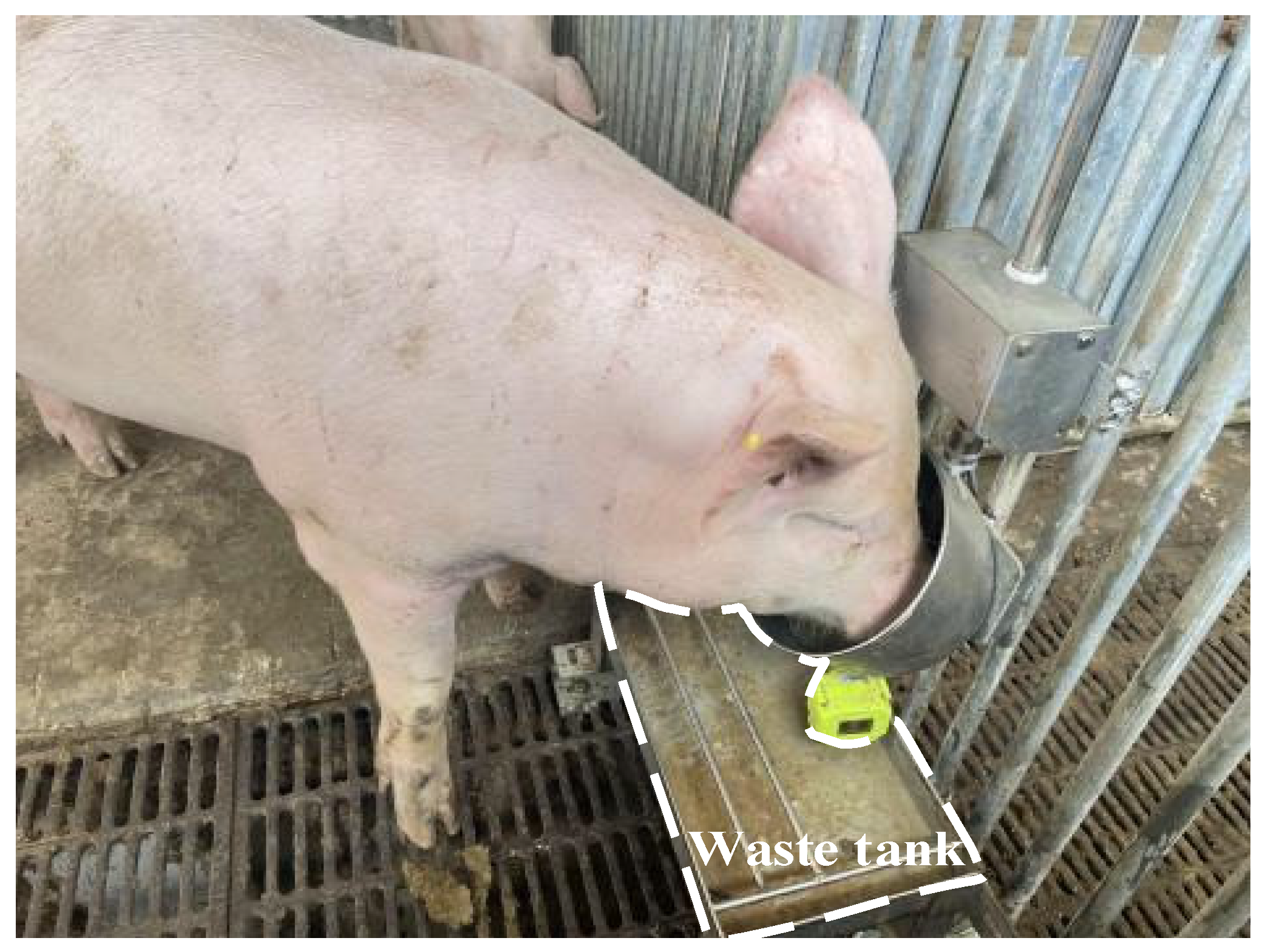

2.1.1. Drinking Bowl Module

- The drinker is composed of a water level detection module, pig water-drinking behavior identification module, water consumption detection module, water pressure regulation module and drainage module.

- Water level detection module:

- Pig water-drinking behavior identification module:

- Water consumption detection module:

- Water pressure regulation module and drainage module:

2.1.2. PLC System

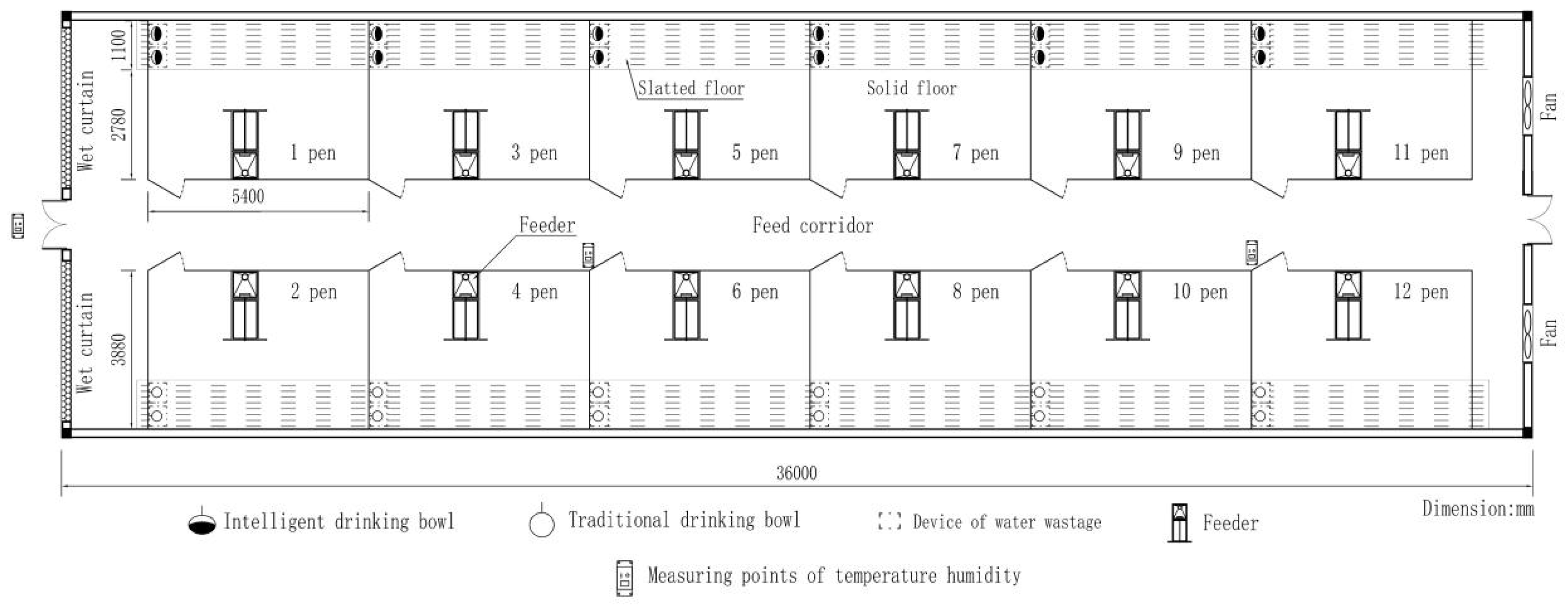

2.2. Experimental Arrangement

2.2.1. Experimental Condition

2.2.2. Experimental Object

2.3. Experimental Evaluation Index

2.3.1. Drinker Performance

- Water consumption:

- Water waste:

- Water utilization rate:

- Water quality:

2.3.2. Drinking Behavior and Weight Change

- Frequency and duration of water-drinking:

- Weight change:

- Frequency and duration of water-drinking:

3. Results

3.1. Performance Analysis of Drinker

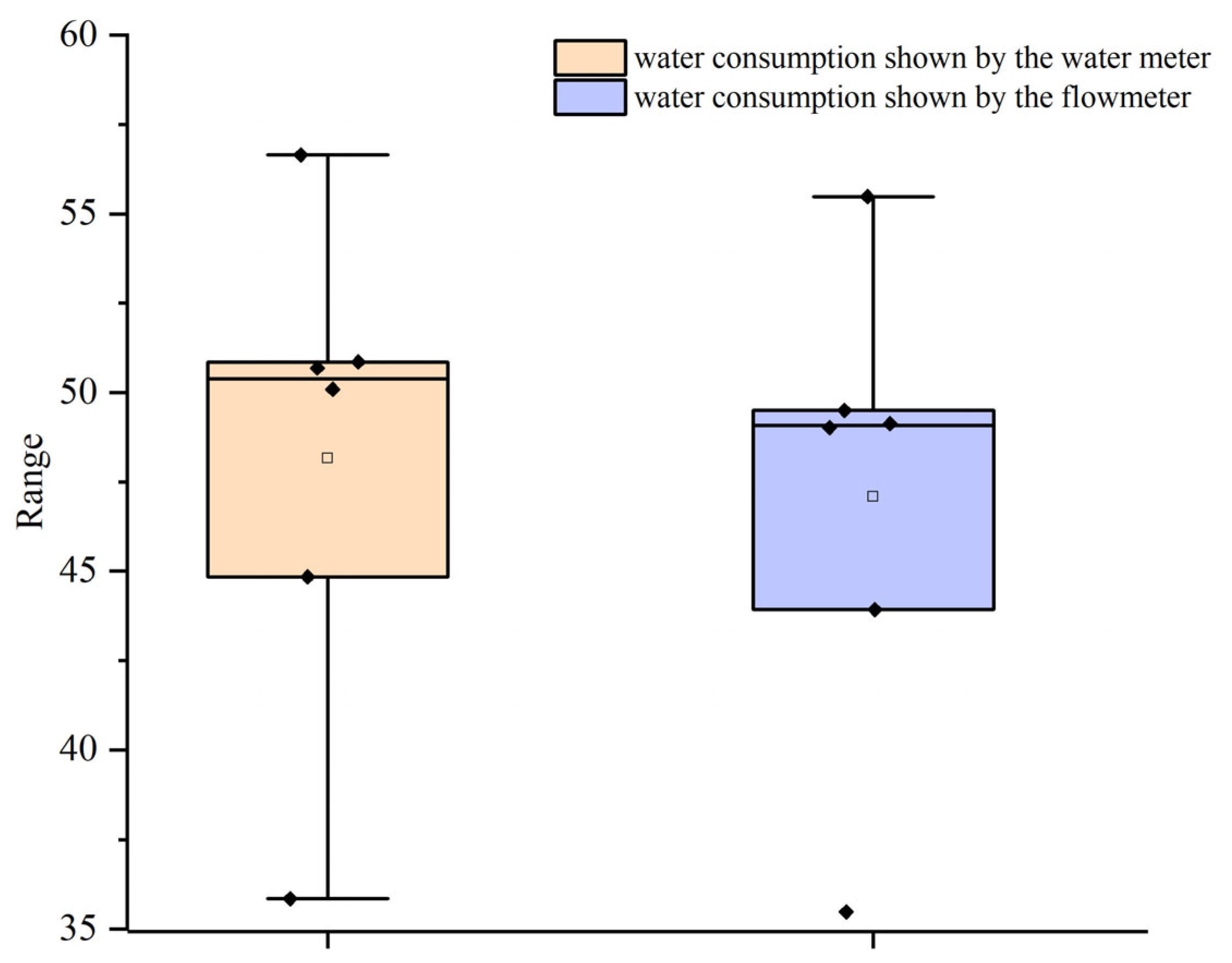

3.1.1. Water Consumption

3.1.2. Water Waste

3.1.3. Water Utilization Analysis

3.1.4. Water Quality Analysis

3.2. Analysis of Water-Drinking Behavior and Weight Change

3.2.1. Analysis of Weight Change

3.2.2. Analysis of Drinking Frequency and Drinking Duration

4. Discussion

- Water consumption and waste:

- Drinking water quality:

- Pig health status:

- Intelligent monitoring of the pigs’ drinking frequency and duration:

5. Conclusions

- Improvement and intellectualization of control accuracy: Although there are Intelligent drinking water controllers that can meet the drinking water needs of different pigs to a certain extent, there is still room for improvement. Future research could focus on improving camera functions to accurately capture and predict the drinking habits of individual pigs, and flexibly adjust the drinking regimen according to their health status, growth stage, and environmental factors (such as temperature and humidity) [40]. For example, machine learning techniques can be applied to analyze drinking data from pigs to optimize their drinking plans.

- Reduce the pollution of feces in drinking water: pig feed and feces will inevitably enter drinking water bowls and pollute the water quality. In the future, we will consider taking protective measures, such as adding baffles or shielding curtains in combination with the automatic cleaning module of the Intelligent drinking water controllers, to reduce water pollution.

- During the experiment, we found that drinking bowls became damaged. After careful investigation, one of the reasons is that pigs play with drinking bowls. Therefore, we decided to update the housing of the drinker to a metal material for increased durability. At the same time, this discovery also indicated that pigs have a certain need for toys. In the future, to improve breeding management practice and improve the welfare of pigs, we will consider introducing appropriate welfare toys into the breeding environment [41].

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Yang, L.; Wang, H.; Chen, R.; Xiao, D. Research progress and prospect of intelligent pig factory. J. South China Agric. Univ. 2023, 44, 13–23. [Google Scholar]

- Feng, C.; Zhao, Z.; Zhou, G.; Hong, S. Thinking on the prevention and control of swine disease under the normal condition of African Swine fever. Today’s Anim. Husb. Vet. Med. 2022, 38, 27–28. (In Chinese) [Google Scholar]

- Li, N.; He, X.; Zhou, Y. Comparison of ammonia emission reduction policies and technologies in Animal husbandry in China and foreign countries. China Anim. Husb. 2024, 2, 41–42. [Google Scholar]

- Jia, Z.; Zhai, H.; Su, H.; Cui, J.; Wang, W.; Li, A.; Zhou, H.; Li, W.; Teng, X. Comparison of pig breeding management and biosafety operation in China and the United States. China Anim. Quar. 2021, 38, 37–42. (In Chinese) [Google Scholar]

- Kamphues, J.; Flachowsky, G.; Rieger, H.; Meyer, U. Für und Wider eine Verabreichung von Futtermittelzusatzstoffen über das Tränkwasser. Übersichten zur Tierernährung 2019, 43, 205–248. [Google Scholar]

- Ingram, D.L. Evaporative Cooling in the Pig. Nature 1965, 207, 415–416. [Google Scholar] [CrossRef]

- Jessen, C. Wärmebilanz und Thermoregulation. In Physiologie der Haustiere; Engelhardt, W.V., Breves, G., Eds.; Enke in HippokratesVerlag GmbH: Stuttgart, Germany, 2000. [Google Scholar]

- TierSchNutztV. Verordnung zum Schutz Landwirtschaftlicher Nutztiere und Anderer zur Erzeugung Tierischer Produkte Gehaltener Tiere bei Ihrer Haltung (Tierschutz-Nutztierhaltungsverordnung—TierSchNutztV). 2021. Available online: https://www.gesetze-im-internet.de/tierschnutztv/TierSchNutztV.pdf (accessed on 27 June 2021).

- Schiavon, S.; Emmans, G.C. A model to predict water intake of a pig growing in a known environment on a known diet. Br. J. Nutr. 2000, 84, 873–883. [Google Scholar] [CrossRef]

- Gill, B.P. Water Use by Pigs Managed under Various Conditions of Housing, Feeding, and Nutrition. Ph.D. Thesis, University of Plymouth, Plymouth, UK, 1989. [Google Scholar]

- Zhou, Z.; Shao, W.; Zhang, R.; Zhang, X. Challenges and countermeasures on the water use in the process of urbanization and industrialization of China. China Water Resour. 2015, 1, 7–10. [Google Scholar]

- Wang, M.; Xue, X.; Liu, J.; Wang, W.; Han, M.; Yi, L.; Wu, Z. Effect of different allocations of wet-dry feeders and drinkers on production performance and water saving of finishing pigs. Trans. Chin. Soc. Agric. Eng. 2018, 34, 66–72. [Google Scholar] [CrossRef]

- Tavares, J.M.R.; Filho, P.B.; Coldebella, A.; Oliveira, P.D. The water disappearance and manure production at commercial growing-finishing pig farms. Livest. Sci. 2014, 169, 146–154. [Google Scholar] [CrossRef]

- Wang, M.; Zhao, W.; Wu, Z.; Liu, J.; Chen, Z.; Lü, N. Comparison experiment of total water consumption and water leakage of different types of drinker for nursery pig. Trans. Chin. Soc. Agric. Eng. 2017, 33, 242–247. [Google Scholar]

- Wang, M.; Yi, L.; Liu, J.; Zhao, W.; Wu, Z. Water consumption and wastage of nursery pig with different drinkers at different water pressures in summer. Trans. Chin. Soc. Agric. Eng. 2017, 33, 161–166. [Google Scholar]

- Smith, J.; Johnson, D. Development of a PLC-based Smart Watering System for Efficient Irrigation Management. J. Irrig. Drain. Eng. 2021, 147, 04021019. [Google Scholar]

- Martinez, D.; Garcia, P.; Benitez, A. A PLC-driven Precision Irrigation System Using Wireless Sensor Networks. Comput. Electron. Agric. 2023, 198, 106434. [Google Scholar]

- Misra, S.; van Middelaar, C.E.; O’Driscoll, K.; Quinn, A.J.; de Boer, I.J.; Upton, J. The water footprint of pig farms in Ireland based on commercial farm data. Clean. Water 2024, 2, 100023. [Google Scholar] [CrossRef]

- Alarcón, L.V.; Allepuz, A.; Mateu, E. Biosecurity in pig farms: A review. Porc. Health Manag. 2021, 7, 5. [Google Scholar] [CrossRef]

- Lin, H.; He, J.; Li, H.; Wang, C.; Li, H.; Tan, L. Design and Experiment of Automatic Variable speed Straw crushing and Returning Device Driven by Equal diameter CAM based on PLC Control. Trans. Chin. Soc. Agric. Mach. 2024, 55, 96–110. (In Chinese) [Google Scholar]

- Zhang, C.; Wang, Z.; Fu, J.; Zong, Z.; Yang, J.; Hou, Q.; Liu, G. Design of drinking water control system for sheep in northern winter based on PLC. Heilongjiang Anim. Husb. Vet. Sci. 2021, 7, 52–54+59+155. (In Chinese) [Google Scholar]

- Lenshi, T.; Rajaganapathy, V.; Mandal, P.K.; Ganesan, R.; Venugopal, S.; Raghy, R.; Sreekumar, D. Pig feeding practices of backyard pig farmers in Imphal, Manipur. Indian Vet. J. 2024, 101, 58–61. [Google Scholar]

- Baxter, S.H. Designing the Pig Pen. In Manipulating Pig Production II; Barnett, J.L., Hennessy, D.P., Eds.; Australasian Pig Science Association: Werribee, Australia, 1989; pp. 191–206. Available online: https://www.apsa.asn.au/wp-content/uploads/2021/11/1989-Manipulating-Pig-Production-II.pdf (accessed on 27 June 2021).

- Tan, L.; Gu, X.H. Study on water flow rate, installation height and quantity of pig teat drinking water dispenser. J. Anim. Sci. Vet. Med. 2009, 41, 47–49. [Google Scholar]

- Luo, Y.; Xia, J.; Lu, H.; Luo, H.; Lv, E.; Zeng, Z.; Li, B.; Meng, F.; Yang, A. Automatic Recognition and Quantification Feeding Behaviors of Nursery Pigs Using Improved YOLOV5 and Feeding Functional Area Proposals. Animals 2024, 14, 569. [Google Scholar] [CrossRef] [PubMed]

- Godyń, D.; Nowicki, J.; Herbut, P. Effects of environmental enrichment on pig welfare—A review. Animals 2019, 9, 383. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Xiong, X.; Wu, X.; Liu, G.; Zhou, K.; Yin, Y. Effects of stocking density on growth performance, blood parameters and immunity of growing pigs. Anim. Nutr. 2020, 6, 529–534. [Google Scholar] [CrossRef]

- Edwards, L. Drinking Water Quality and Its Impact on the Health and Performance of Pigs; Innovation Project 2A-118; Co-Operative Research Centre for High Integrity Australian Pork: Willaston, Australia, 2018; Available online: https://porkcrc.com.au/wp-content/uploads/2018/08/2A-118-Drinking-Water-Quality-Final-Report.pdf (accessed on 27 June 2021).

- Yazici-Karabulut, B.; Kocer, Y.; Yesilnacar, M.I. Bottled water quality assessment through entropy-weighted water quality index (EWQI) and pollution index of groundwater (PIG): A case study in a fast-growing metropolitan area in Türkiye. Int. J. Environ. Health Res. 2024, 34, 61–72. [Google Scholar] [CrossRef]

- Liu, C.; Ye, H.; Wang, L.; Lu, S.; Li, L. Novel tracking method for the drinking behavior trajectory of pigs. Int. J. Agric. Biol. Eng. 2024, 16, 67–76. [Google Scholar] [CrossRef]

- Faverjon, C.; Bernstein, A.; Grütter, R.; Nathues, C.; Nathues, H.; Sarasua, C.; Sterchi, M.; Vargas, M.E.; Berezowski, J. A transdisciplinary approach supporting the implementation of a big data project in livestock production: An example from the Swiss pig production industry. Front. Vet. Sci. 2019, 6, 215. [Google Scholar] [CrossRef] [PubMed]

- Dohmen, R.; Catal, C.; Liu, Q. Computer vision-based weight estimation of livestock: A systematic literature review. N. Z. J. Agric. Res. 2022, 65, 227–247. [Google Scholar] [CrossRef]

- Broom, D.M.; Fraser, A.F. Domestic Animal Behaviour and Welfare, 5th ed.; CABI Publishing: Cambridge, MA, USA, 2015. [Google Scholar]

- Ren, Q.; Chen, D.; Cao, S.; Li, X.; Wang, M.; Teng, J.; Du, X.; Huang, Y.; Gao, X.; Liu, C.; et al. The Microbiota Dynamics in Water Distribution System of Pig Farm. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4760755 (accessed on 27 June 2021).

- Sefeedpari, P.; Pishgar-Komleh, S.H.; Aarnink, A.J. Model Adaptation and Validation for Estimating Methane and Ammonia Emissions from Fattening Pig Houses: Effect of Manure Management System. Animals 2024, 14, 964. [Google Scholar] [CrossRef]

- Sanad, H.; Mouhir, L.; Zouahri, A.; Moussadek, R.; El Azhari, H.; Yachou, H.; Ghanimi, A.; Oueld Lhaj, M.; Dakak, H. Assessment of Groundwater Quality Using the Pollution Index of Groundwater (PIG), Nitrate Pollution Index (NPI), Water Quality Index (WQI), Multivariate Statistical Analysis (MSA), and GIS Approaches: A Case Study of the Mnasra Region, Gharb Plain, Morocco. Water 2024, 16, 1263. [Google Scholar] [CrossRef]

- Beilage, E.G. Literaturübersicht zur Unterbringung von Sauen währned Geburtsvorbereitung, Geburt und Säugezeit (Hessisches Ministerium für Umwelt, Klimaschutz, Landwirtschaft und Verbraucherschutz). 2020. Available online: https://tierschutz.hessen.de/sites/tierschutz.hessen.de/files/2022-11/literaturuebersicht_unterbringung_sauen_0.pdf#:~:text=Die%20Unterbringung%20von%20Sauen%20w%C3%A4hrend%20der%20Geburtsvorbereitung,#:~:text=Die%20Unterbringung%20von%20Sauen%20w%C3%A4hrend%20der%20Geburtsvorbereitung (accessed on 27 June 2021).

- Faucitano, L.; Conte, S.; Pomar, C.; Paiano, D.; Duan, Y.; Zhang, P.; Drouin, G.; Rina, S.; Guay, F.; Devillers, N. Application of extended feed withdrawal time preslaughter and its effects on animal welfare and carcass and meat quality of enriched-housed pigs. Meat Sci. 2020, 167, 108163. [Google Scholar] [CrossRef]

- Borell, E.V.; Bonneau, M.; Holinger, M.; Prunier, A.; Stefanski, V.; Zöls, S.; Weiler, U. Welfare aspects of raising entire male pigs and Immunocastrates. Animals 2020, 10, 2140. [Google Scholar] [CrossRef] [PubMed]

- Khullar, V.; Singh, H.P.; Miro, Y.; Anand, D.; Mohamed, H.G.; Gupta, D.; Kumar, N.; Goyal, N. IoT Fog-Enabled Multi-Node Centralized Ecosystem for Real Time Screening and Monitoring of Health Information. Appl. Sci. 2022, 12, 9845. [Google Scholar] [CrossRef]

- Li, Y.; Wang, C.; Huang, S.; Liu, Z.; Wang, H. Effects of stocking density and toy provision on production performance, behavior and physiological indexes of finishing pigs. Trans. Chin. Soc. Agric. Eng. 2021, 37, 191–198. [Google Scholar]

| Experimental Arrangement | Experimental Group | Control Group |

|---|---|---|

| 6 June 2024–26 June 2024 Fattening pigs (100–110 kg) | 6 pens, 2 intelligent drinking water controllers per pen (12 in total) | 6 pens, 2 ordinary drinking bowls per pens (12 in total) |

| Experimental Group | DWE | Control Group | DWC |

|---|---|---|---|

| Pen 1 | 8.09 | Pen 2 | 10.07 |

| Pen 3 | /1 | Pen 4 | 6.50 |

| Pen 5 | 7.24 | Pen 6 | 9.13 |

| Pen 7 | 6.41 | Pen 8 | 8.05 |

| Pen 9 | 7.26 | Pen 10 | 11.34 |

| Pen 11 | 5.12 | Pen 12 | 8.41 |

| Average | 6.82 ± 1.12 a | Average | 8.92 ± 1.86 b |

| Experimental Group | Wasted Water/L | Control Group | Waste Water/L |

|---|---|---|---|

| Pen 1 | 1.31 | Fence 2 | 4.08 |

| Pen 3 | 0.57 | Fence 4 | 3.50 |

| Pen 5 | 1.12 | Fence 6 | 3.65 |

| Pen 7 | 2.01 | Fence 8 | 9.22 |

| Pen 9 | 1.12 | Fence 10 | 10.88 |

| Pen 11 | 1.69 | Fence 12 | 6.56 |

| Sum total | 7.81 a | Sum total | 37.89 b |

| Average | 1.30 ± 0.50 | Average | 6.32 ± 3.14 |

| Experimental Group | Control Group | ||

|---|---|---|---|

| Pen 1 | 97.69% | Fence 2 | 94.21% |

| Pen 3 | /1 | Fence 4 | 92.30% |

| Pen 5 | 97.79% | Fence 6 | 94.29% |

| Pen 7 | 95.52% | Fence 8 | 83.64% |

| Pen 9 | 97.80% | Fence 10 | 86.30% |

| Pen 11 | 95.29% | Fence 12 | 88.86% |

| Average | 96.64% ± 1.4% a | Average | 90.08% ± 4.29% b |

| Experimental Group | Control Group | ||

|---|---|---|---|

| Pens | ME/kg | Pens | MC/kg |

| Pen 1 | 24.77 ± 4.44 | Pen 2 | 14.88 ± 2.39 |

| Pen 3 | 15.60 ± 3.81 | Pen 4 | 14.25 ± 1.71 |

| Pen 5 | 17.85 ± 1.72 | Pen 6 | 19.43 ± 2.11 |

| Pen 7 | 15.00 ± 3.75 | Pen 8 | 21.87 ± 4.90 |

| Pen 9 | 14.65 ± 2.33 | Pen 10 | 16.63 ± 4.35 |

| Pen 11 | 15.85 ± 0.21 | Pen 12 | 14.23 ± 5.42 |

| DME | 0.82 ± 0.17 a | DMC | 0.80 ± 0.14 b |

| FCRE | 3.10 a | FCRC | 3.18 b |

| Experimental Group | Drinking Frequency | Drinking Duration/s | Mean Drinking Time/s |

|---|---|---|---|

| Pen 1 | 248.78 | 3130.92 | 12.58 |

| Pen 3 | 244.30 | 3559.65 | 14.57 |

| Pen 5 | 307.65 | 3465.10 | 11.26 |

| Pen 7 | 222.23 | 2924.80 | 13.16 |

| Pen 9 | 353.04 | 4550.47 | 12.89 |

| Pen 11 | 244.25 | 3109.70 | 12.73 |

| Average | 270.04 | 3456.77 | 12.80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Wang, H.; Pan, X.; Yu, Z.; Tang, M.; Zeng, Y.; Qi, R.; Liu, Z. Effect of A PLC-Based Drinkers for Fattening Pigs on Reducing Drinking Water Consumption, Wastage and Pollution. Agriculture 2024, 14, 1525. https://doi.org/10.3390/agriculture14091525

Liu J, Wang H, Pan X, Yu Z, Tang M, Zeng Y, Qi R, Liu Z. Effect of A PLC-Based Drinkers for Fattening Pigs on Reducing Drinking Water Consumption, Wastage and Pollution. Agriculture. 2024; 14(9):1525. https://doi.org/10.3390/agriculture14091525

Chicago/Turabian StyleLiu, Jiayao, Hao Wang, Xuemin Pan, Zhou Yu, Mingfeng Tang, Yaqiong Zeng, Renli Qi, and Zuohua Liu. 2024. "Effect of A PLC-Based Drinkers for Fattening Pigs on Reducing Drinking Water Consumption, Wastage and Pollution" Agriculture 14, no. 9: 1525. https://doi.org/10.3390/agriculture14091525