Research on a Novel Heat Treatment Process for Boron Steel Used for Soil-Engaging Components of Tillage Machinery

Abstract

:1. Introduction

2. Materials and Methods

2.1. Composition and Phase Transition Temperatures of Experimental Steels

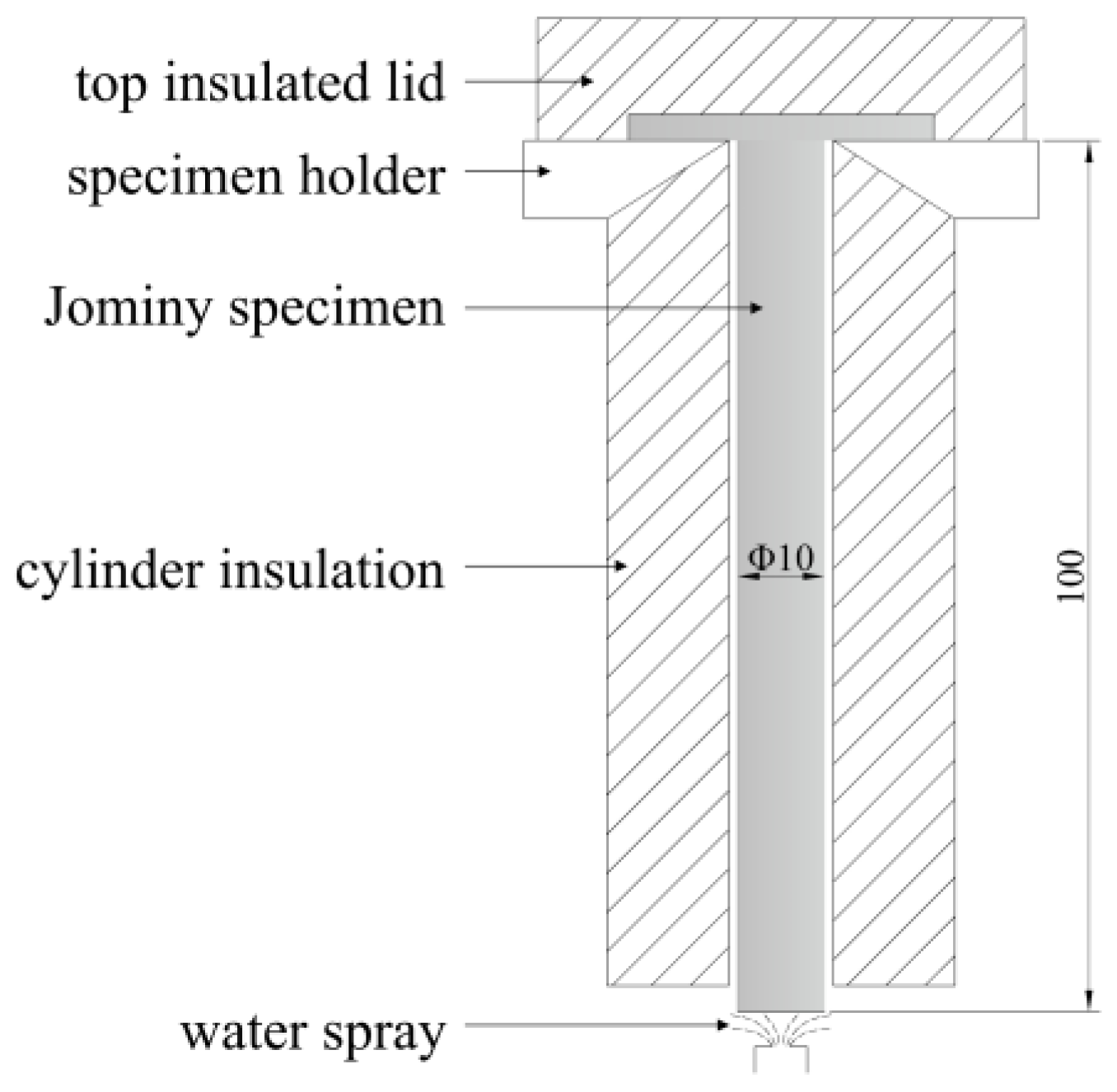

2.2. Jominy End Quench Test of Experimental Steels

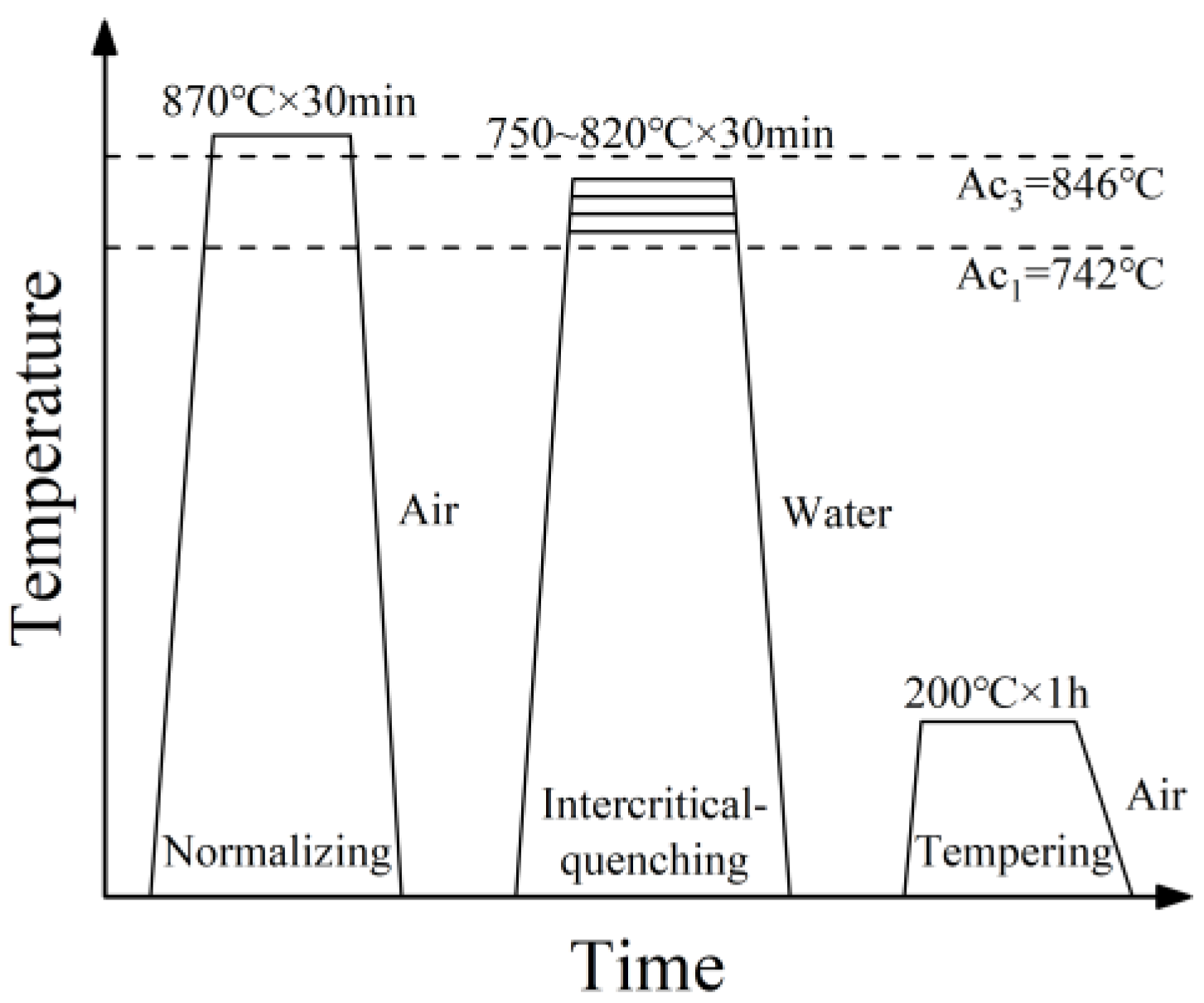

2.3. Heat Treatment Process Route Design

2.4. Mechanical Property Testing and Microstructure Observation

3. Results and Discussion

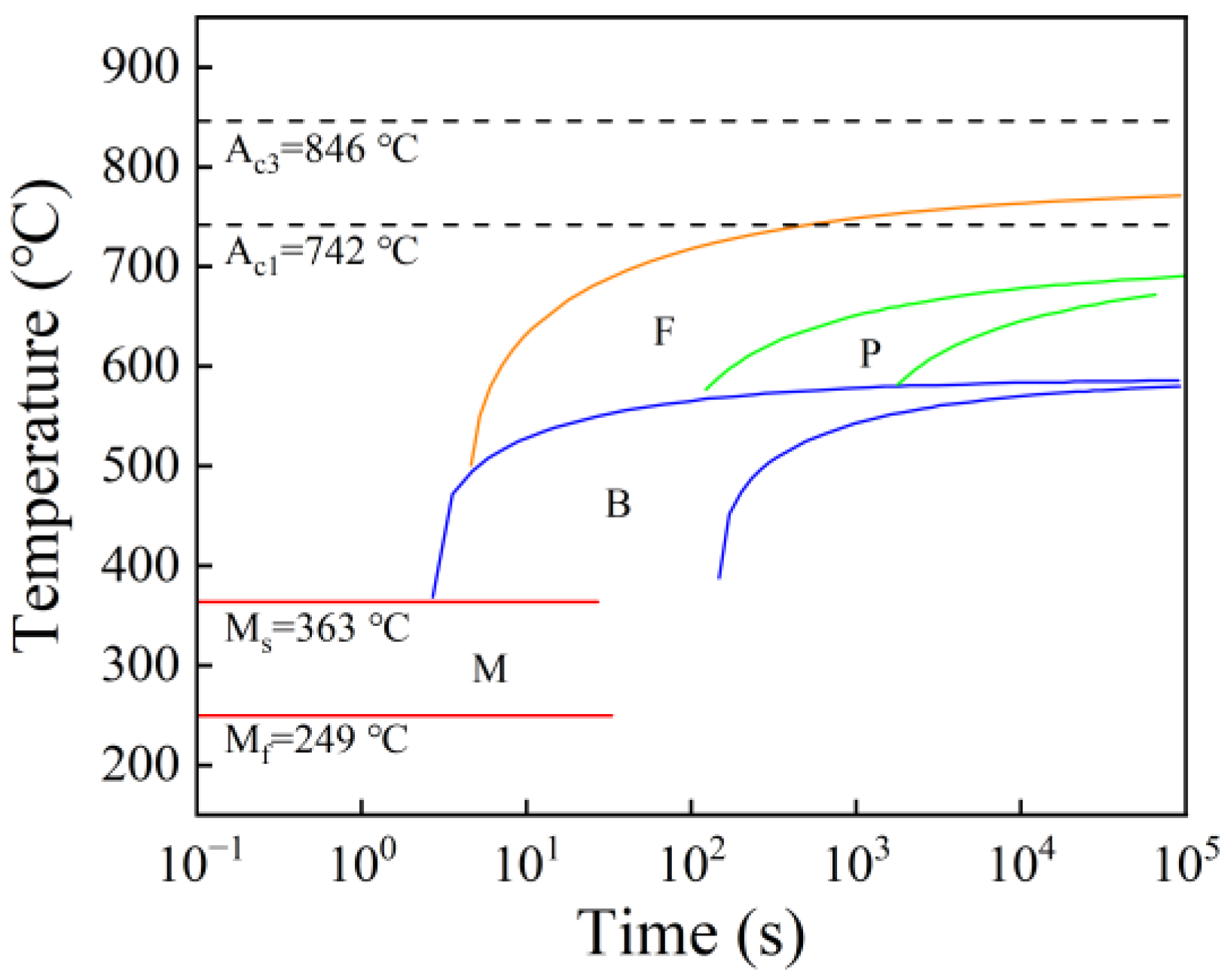

3.1. Hardenability of 27MnCrB5 Steel

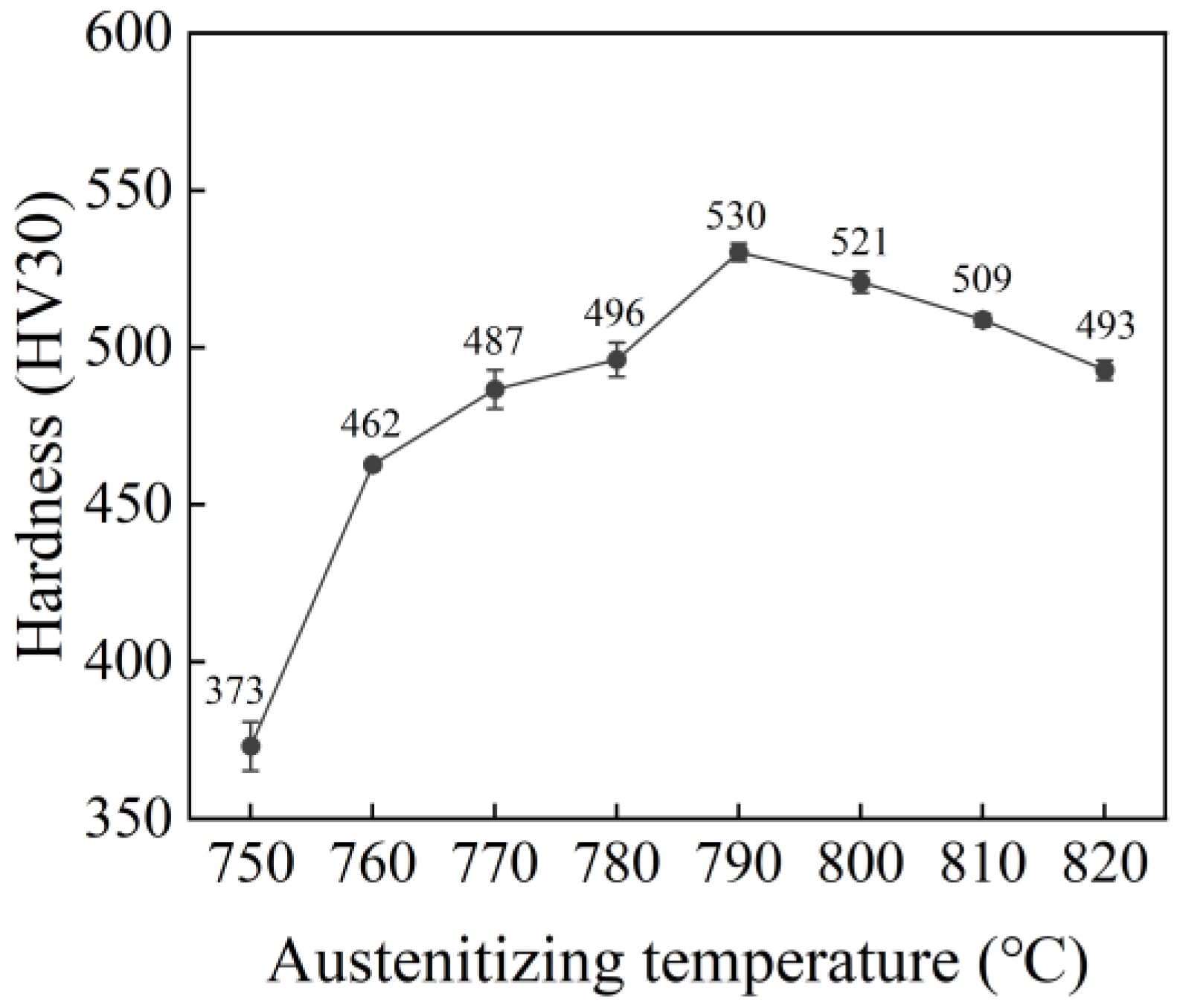

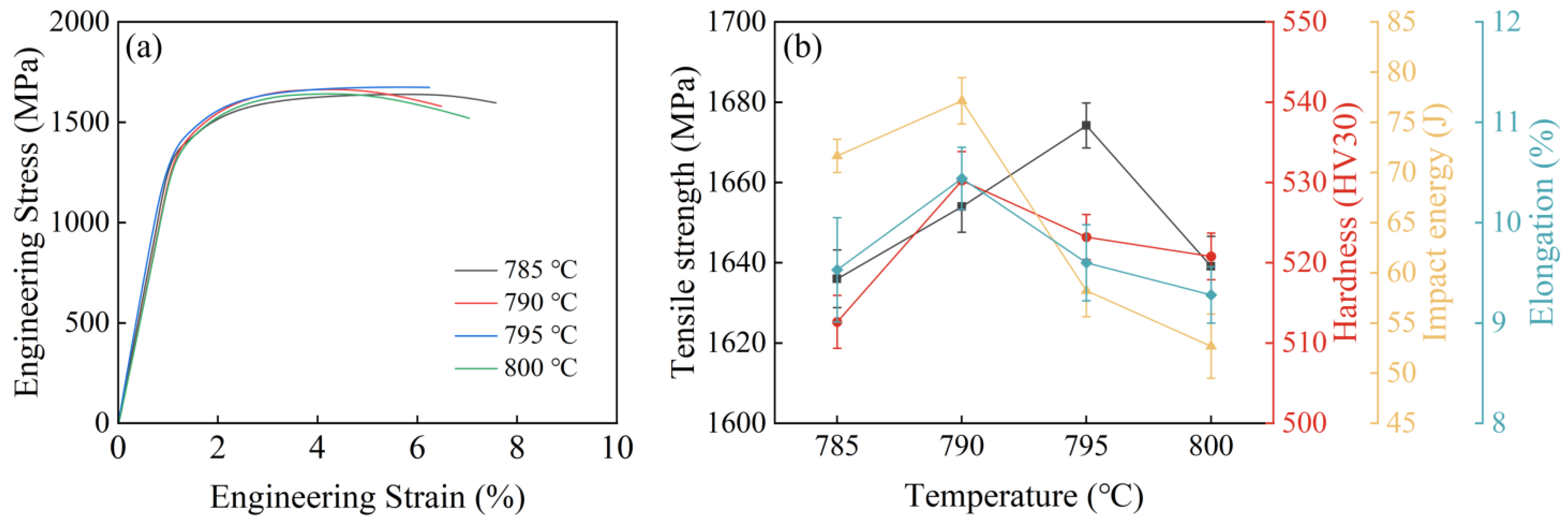

3.2. Mechanical Properties of Materials

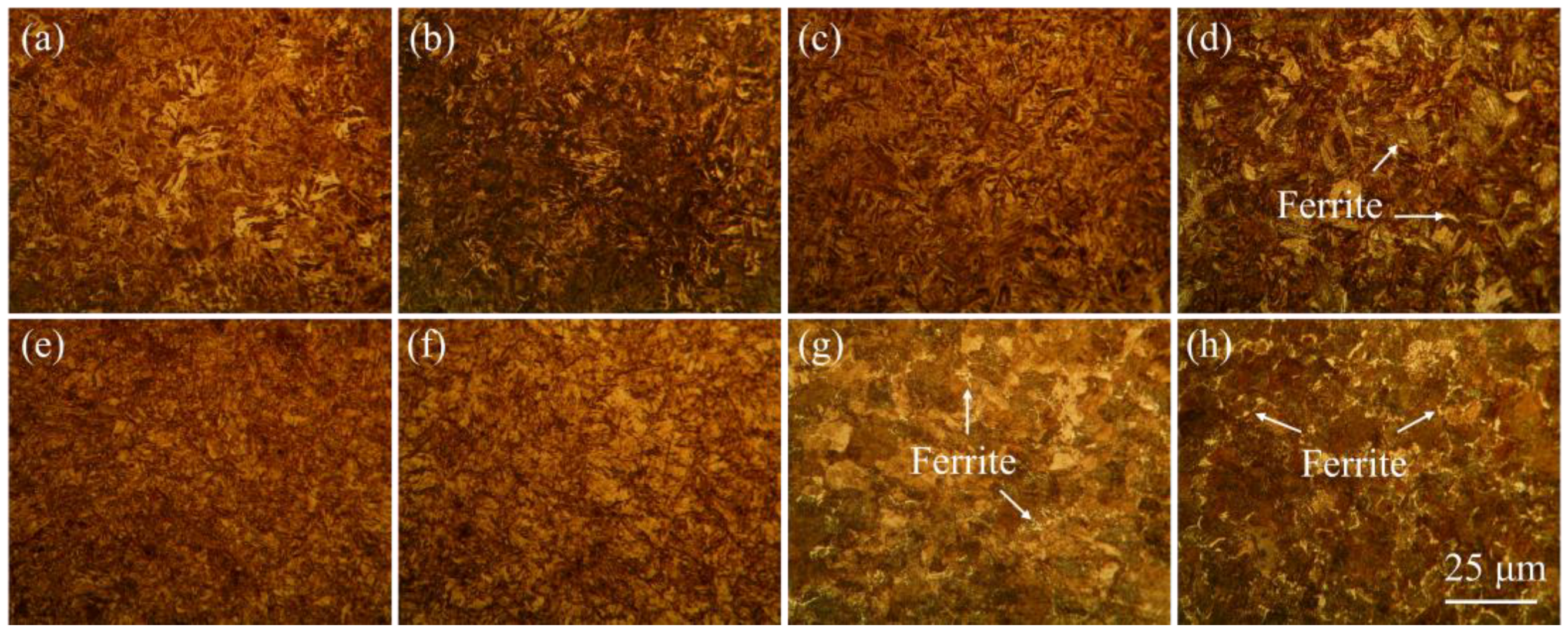

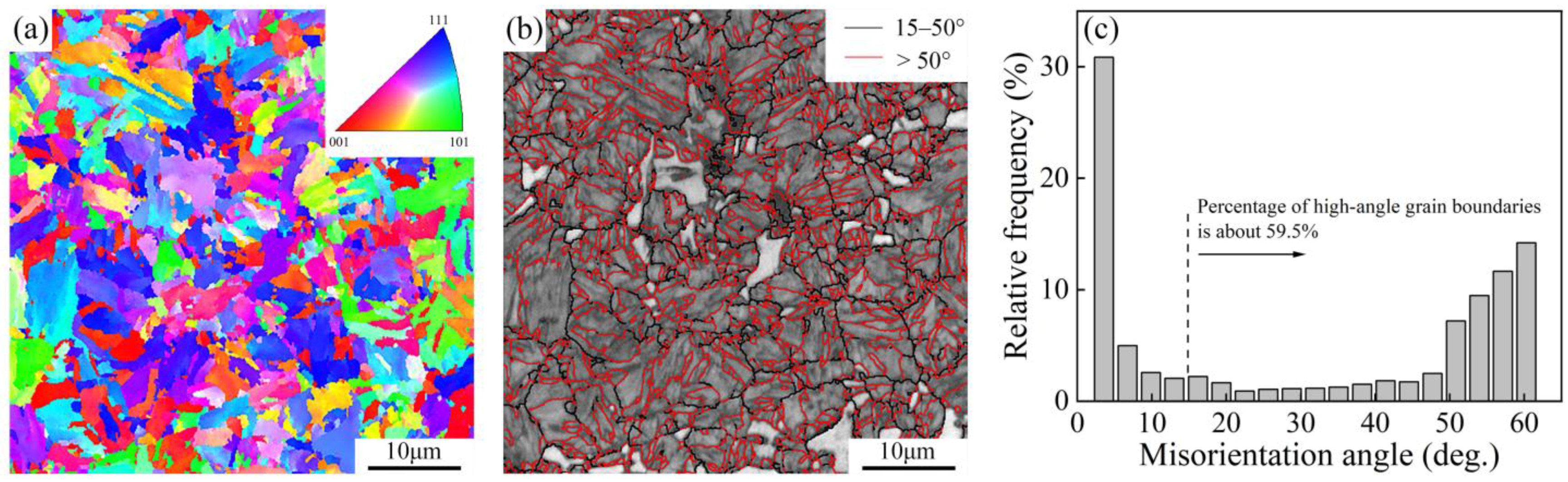

3.3. Microstructure of Materials

4. Conclusions

- (1)

- The Jominy test was conducted in this paper, and it was found that 27MnCrB5 steel exhibits superior hardenability in comparison to 65Mn steel, which is primarily attributed to the presence of a markedly low concentration of the element boron in the 27MnCrB5 steel. The presence of boron impedes the formation of ferrite at austenite grain boundaries during quenching and cooling. This was achieved through diffusion of boron into the original austenite grain boundaries, thereby reducing the energy of these boundaries. Consequently, the premature formation of equilibrium phases such as ferrite and pearlite was suppressed, thereby enabling the steel to be quenched to obtain a martensite-based microstructure with high strength and hardness.

- (2)

- The relationship between the macro-mechanical properties of 27MnCrB5 steel and the intercritical quenching temperature is not monotonic. The macro-mechanical properties exhibit a trend of initially increasing and subsequently decreasing with increasing quenching temperature. This phenomenon can be attributed to the fact that altering the intercritical quenching temperature changes the volume fraction of martensite in the steel, along with the carbon content in the martensite. Consequently, the impact on the macroscopic properties of the material is markedly complex.

- (3)

- The mechanical experimental results showed that, by selecting an intercritical quenching temperature of 790 °C, 27MnCrB5 steel with excellent comprehensive mechanical properties could be obtained. The SEM images showed that 27MnCrB5 steel retains a minor amount of ferrite within the martensitic matrix after intercritical quenching at 790 °C, which was observed to be uniformly distributed and of fine grain. Further analysis by EBSD indicated that the predominant type of grain boundaries at this temperature was characterized by a high proportion of high-angle boundaries (approximately 59.5%), which is conducive to impeding crack propagation, thereby enhancing the material’s toughness.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Jin, H.; Hongwen, L.I.; Haitao, C.H.; Caiyun, L.U.; Qingjie, W.A. Research progress of conservation tillage technology and machine. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2018, 49, 1–19. [Google Scholar]

- Solangi, K.A.; Siyal, A.A.; Wu, Y.; Abbasi, B.; Solangi, F.; Lakhiar, I.A.; Zhou, G. An assessment of the spatial and temporal distribution of soil salinity in combination with field and satellite data: A case study in Sujawal District. Agronomy 2019, 9, 869. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, H.; Liu, J.; Yang, S.X. Control method of seedbed compactness based on fragment soil compaction dynamic characteristics. Soil Tillage Res. 2020, 198, 104551. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Gao, J.; Syed, T.N.; Chandio, F.A.; Tunio, M.H.; Ahmad, F.; Solangi, K.A. Overview of the aeroponic agriculture–An emerging technology for global food security. Int. J. Agric. Biol. Eng. 2020, 13, 1–10. [Google Scholar] [CrossRef]

- Liang, Z. Selecting the proper material for a grain loss sensor based on DEM simulation and structure optimization to improve monitoring ability. Precis. Agric. 2021, 22, 1120–1133. [Google Scholar] [CrossRef]

- Iqbal, B.; Zhao, T.; Yin, W.; Zhao, X.; Xie, Q.; Khan, K.Y.; Zhao, X.; Nazar, M.; Li, G.; Du, D. Impacts of soil microplastics on crops: A review. Appl. Soil Ecol. 2023, 181, 104680. [Google Scholar] [CrossRef]

- Lianji, W.; Jinyang, L.; Hong, H.; Lu, L.; Xin, B.; Chunlin, C. Research status and prospect of adhesion reduction and desorption technology for agricultural machinery parts touching soil. J. Chin. Agric. Mech. 2021, 42, 214. [Google Scholar]

- Salem, A.E.; Wang, H.; Gao, Y.; Zha, X.; Abdeen, M.A.; Zhang, G. Effect of biomimetic surface geometry, soil texture, and soil moisture content on the drag force of soil-touching parts. Appl. Sci. 2021, 11, 8927. [Google Scholar] [CrossRef]

- Guan, C.; Fu, J.; Xu, L.; Jiang, X.; Wang, S.; Cui, Z. Study on the reduction of soil adhesion and tillage force of bionic cutter teeth in secondary soil crushing. Biosyst. Eng. 2022, 213, 133–147. [Google Scholar] [CrossRef]

- Guo, C.; Li, G.; Zhang, J.; Jin, X.; Xue, J.; He, C.; Lu, L. Influence of the sweep angle of the cross knife opener on soil disturbance. INMATEH-Agric. Eng. 2020, 62, 317–324. [Google Scholar] [CrossRef]

- Chen, K.; Yang, X.; Li, W.; Xia, G.; Wang, S.; Wang, K. Study on the wear and corrosion resistance of Fe–Mo coatings on 65Mn steel ploughshares by laser cladding. Appl. Phys. A 2022, 128, 795. [Google Scholar] [CrossRef]

- Xu, L.; Song, Z.; Li, M.; Li, F.; Guo, J.; Gao, M. Self-grinding silage knife strengthened with Ni–WC alloy prepared by laser cladding. Appl. Sci. 2021, 11, 10236. [Google Scholar] [CrossRef]

- Yazici, A. Wear behavior of carbonitride-treated ploughshares produced from 30MnB5 steel for soil tillage applications. Met. Sci. Heat Treat. 2011, 53, 248–253. [Google Scholar] [CrossRef]

- Su, Z.; Li, J.; Zhang, Z.; Ren, S.; Shi, Y.; Wang, X. Analysis of the mechanical properties and wear characteristics of nail teeth based on sowing layer residual film recovery machine. Eng. Fail. Anal. 2023, 143, 106869. [Google Scholar] [CrossRef]

- Białobrzeska, B. Effect of alloying additives and microadditives on hardenability increase caused by action of boron. Metals 2021, 11, 589. [Google Scholar] [CrossRef]

- Taylor, K.A.; Hansen, S.S. The boron hardenability effect in thermomechanically processed, direct-quenched 0.2 Pct C steels. Metall. Trans. A 1990, 21, 1697–1708. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, F.; Li, C.; He, Y. Dissolution and precipitation behaviors of boron bearing phase and their effects on hardenability and toughness of 25CrMoNbB steel. Mater. Sci. Eng. A 2017, 701, 45–55. [Google Scholar] [CrossRef]

- Gu, J.F.; Han, L.Z.; Chen, R.K. Effect of normalising on grain refinement of large low pressure rotors: Numerical and experimental studies. Int. Heat Treat. Surf. Eng. 2014, 8, 70–75. [Google Scholar] [CrossRef]

- Prasad, R.; Kumar, S. Study of the influence of deformation and thermal treatment on the ultrasonic behaviour of steel. J. Mater. Process. Technol. 1994, 42, 51–59. [Google Scholar] [CrossRef]

- Sun, C.; Fu, P.X.; Liu, H.W.; Liu, H.H.; Du, N.Y. Effect of tempering temperature on the low temperature impact toughness of 42CrMo4-V steel. Metals 2018, 8, 232. [Google Scholar] [CrossRef]

- Dudko, V.; Yuzbekova, D.; Gaidar, S.; Vetrova, S.; Kaibyshev, R. Tempering behavior of novel low-alloy high-strength steel. Metals 2022, 12, 2177. [Google Scholar] [CrossRef]

- Gojic, M.; Kosec, B.; Anzel, I.; Kosec, L.; Preloscan, A. Hardenability of steels for oil industry. J. Achiev. Mater. Manuf. Eng. 2007, 23, 23–26. [Google Scholar]

- Kandpal, B.C.; Chutani, A.; Gulia, A.; Sadanna, C. A review on Jominy test and determination of effect of alloying elements on hardenability of steel using Jominy end quench test. Int. J. Adv. Eng. Technol. 2011, 1, 65. [Google Scholar]

- Maitrepierre, P.; Thivellier, D.; Tricot, R. Influence of boron on the decomposition of austenite in low carbon alloyed steels. Metall. Trans. A 1975, 6, 287–301. [Google Scholar] [CrossRef]

- Ding, W.; Liu, Y.; Xie, J.; Sun, L.; Liu, T.; Yuan, F.; Pan, J. Effect of carbide precipitation on the evolution of residual stress during tempering. Metals 2019, 9, 709. [Google Scholar] [CrossRef]

- Tao, Q.; Wang, J.; Galindo-Nava, E.I. Effect of low-temperature tempering on confined precipitation and mechanical properties of carburised steels. Mater. Sci. Eng. A 2021, 822, 141688. [Google Scholar] [CrossRef]

- Kwak, K.; Mine, Y.; Morito, S.; Ohmura, T.; Takashima, K. Correlation between strength and hardness for substructures of lath martensite in low-and medium-carbon steels. Mater. Sci. Eng. A 2022, 856, 144007. [Google Scholar] [CrossRef]

- Hutchinson, B.; Hagström, J.; Karlsson, O.; Lindell, D.; Tornberg, M.; Lindberg, F.; Thuvander, M. Microstructures and hardness of as-quenched martensites (0.1–0.5% C). Acta Mater. 2011, 59, 5845–5858. [Google Scholar] [CrossRef]

- Hansson, P.; Melin, S. Grain boundary influence on short fatigue crack growth rate. Int. J. Fract. 2010, 165, 199–210. [Google Scholar] [CrossRef]

- Yang, W.; Duan, X.; Liu, C.; Qu, P.; Fu, H.; Zhang, J.; Liu, L. Damage tolerance of low angle grain boundary in a fourth generation Nickel-based single crystal superalloy at 1100 °C service conditions. Mater. Sci. Eng. A 2023, 881, 145338. [Google Scholar] [CrossRef]

- Li, Q.; Zhou, L.; Pan, Y.; Ma, J.; Zhou, X.; Jiang, H.; Xie, Z.; Fang, F. Formation of nano martensite grain with specific angle grain boundary during the drawing process of 316L stainless steel. Mater. Sci. Eng. A 2024, 897, 146309. [Google Scholar] [CrossRef]

- Furuhara, T.; Maki, T. Grain boundary engineering for superplasticity in steels. J. Mater. Sci. 2005, 40, 919–926. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cr | Nb | Al | Ti | B | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.28 | 0.29 | 1.08 | 0.0019 | 0.0008 | 0.50 | 0.03 | 0.02 | 0.06 | 0.004 | Bal. |

| Sample Number | Normalizing/°C | Austenitizing/°C | Tempering/°C |

|---|---|---|---|

| No. 1 | 870 | 820 | 200 |

| No. 2 | 810 | ||

| No. 3 | 800 | ||

| No. 4 | 795 | ||

| No. 5 | 790 | ||

| No. 6 | 785 | ||

| No. 7 | 780 | ||

| No. 8 | 770 | ||

| No. 9 | 760 | ||

| No. 10 | 750 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.; Sun, Z.; Guo, S.; Fu, J. Research on a Novel Heat Treatment Process for Boron Steel Used for Soil-Engaging Components of Tillage Machinery. Agriculture 2024, 14, 1555. https://doi.org/10.3390/agriculture14091555

Guo Y, Sun Z, Guo S, Fu J. Research on a Novel Heat Treatment Process for Boron Steel Used for Soil-Engaging Components of Tillage Machinery. Agriculture. 2024; 14(9):1555. https://doi.org/10.3390/agriculture14091555

Chicago/Turabian StyleGuo, Yifan, Zeyu Sun, Shun Guo, and Jiale Fu. 2024. "Research on a Novel Heat Treatment Process for Boron Steel Used for Soil-Engaging Components of Tillage Machinery" Agriculture 14, no. 9: 1555. https://doi.org/10.3390/agriculture14091555

APA StyleGuo, Y., Sun, Z., Guo, S., & Fu, J. (2024). Research on a Novel Heat Treatment Process for Boron Steel Used for Soil-Engaging Components of Tillage Machinery. Agriculture, 14(9), 1555. https://doi.org/10.3390/agriculture14091555