Optimization of Seed-Receiving Mechanism in Belt-Driven Seed Guide Tube Based on High-Speed Videography Experiment

Abstract

:1. Introduction

2. Materials and Methods

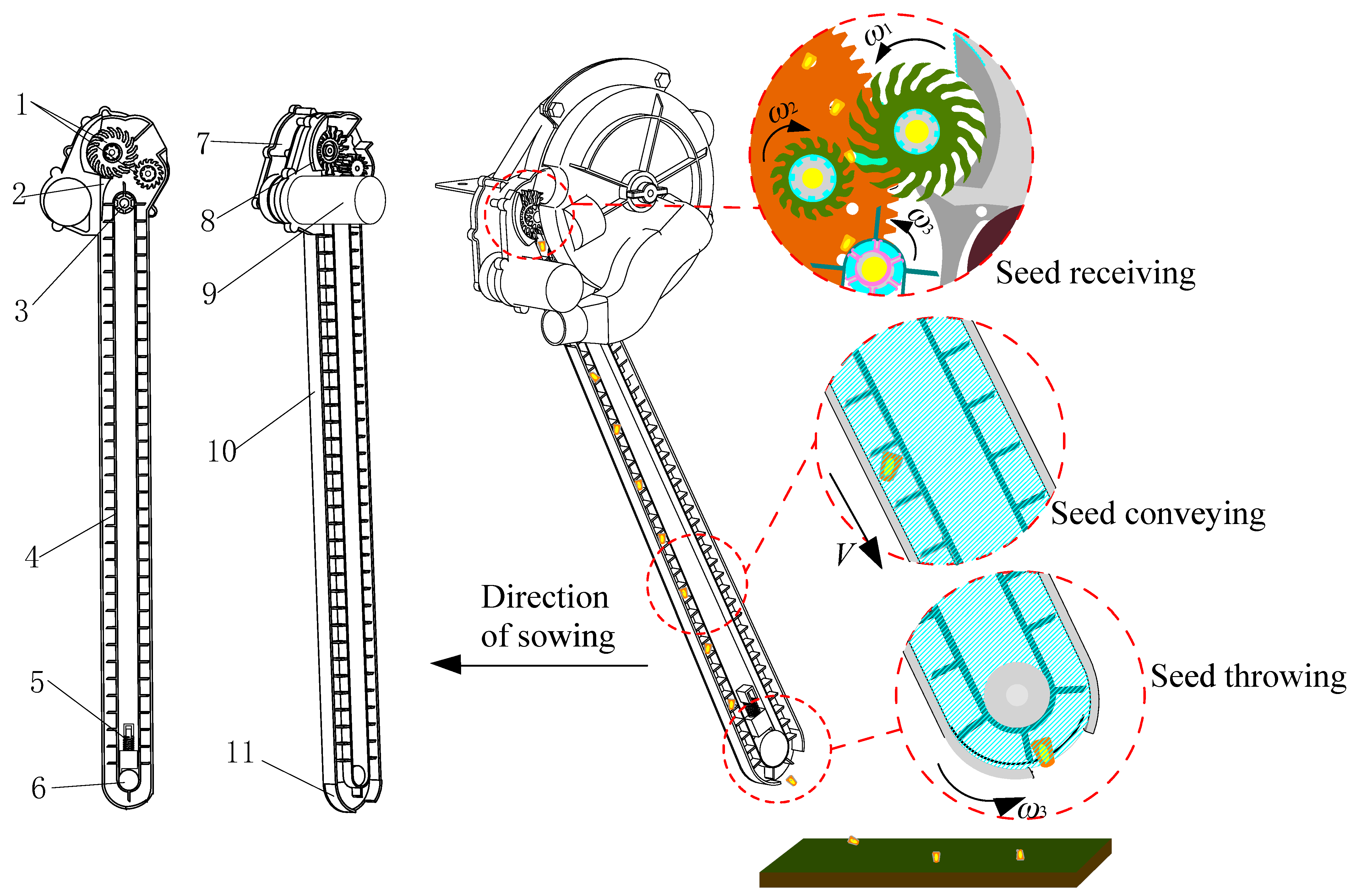

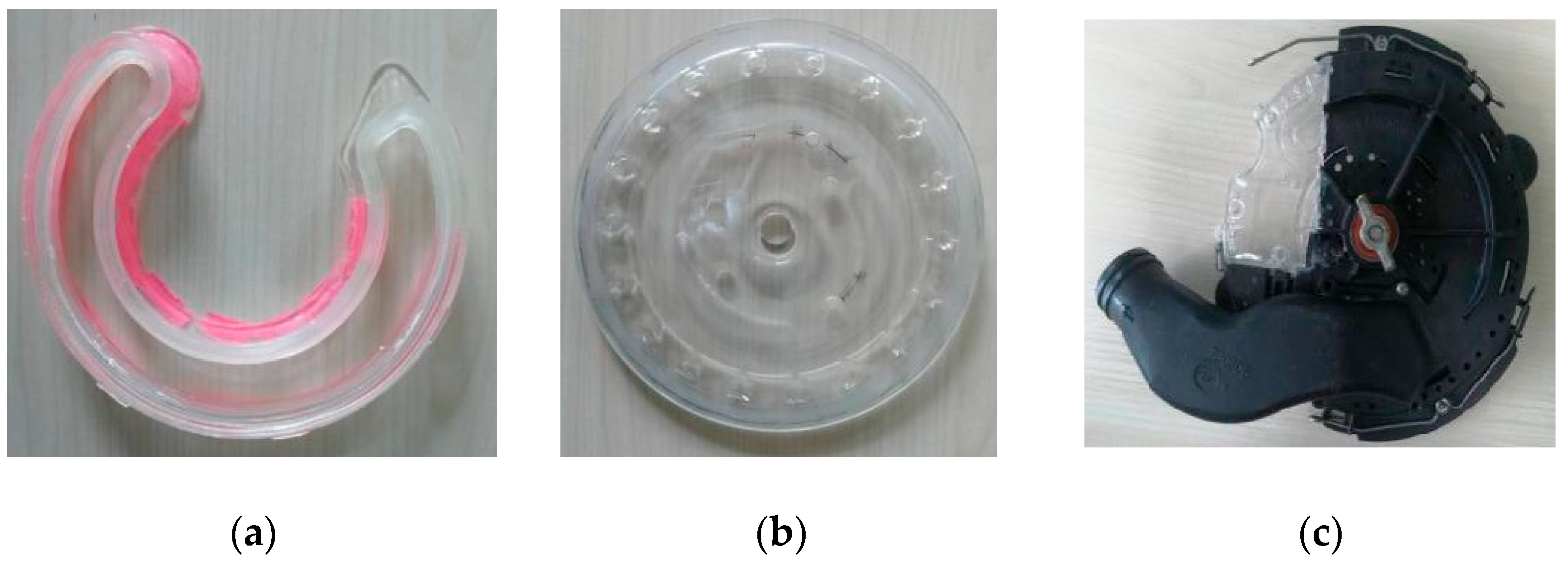

2.1. Structure and Operational Principles of the Belt-Driven Seed Guide Tube

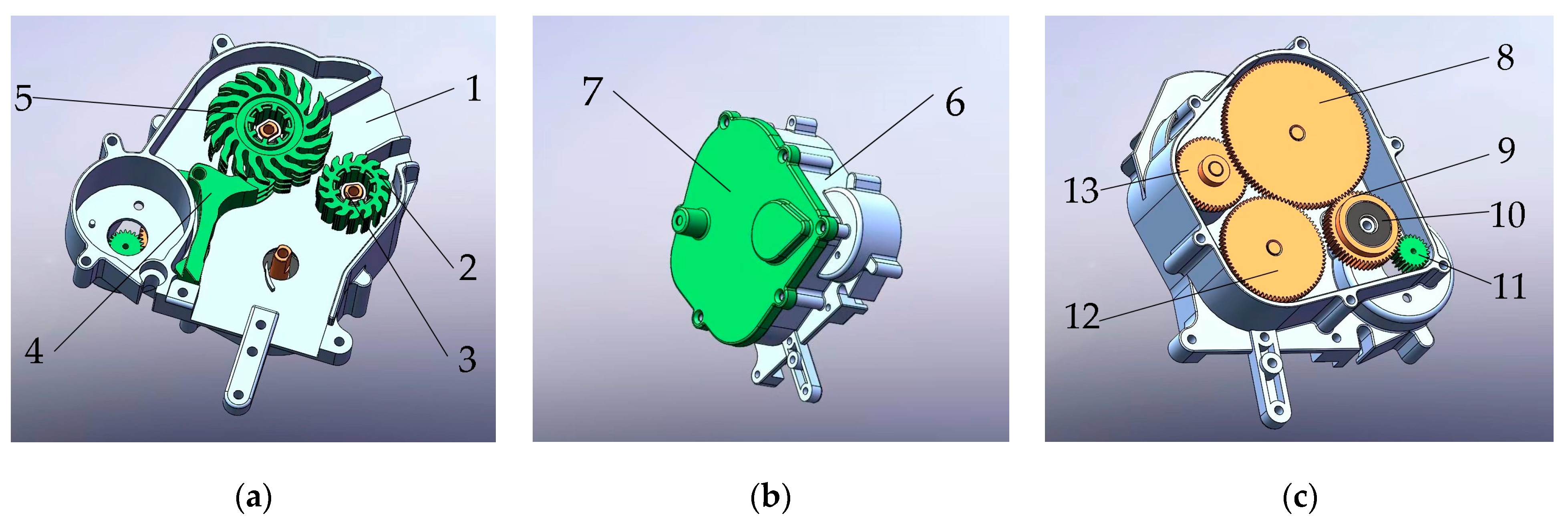

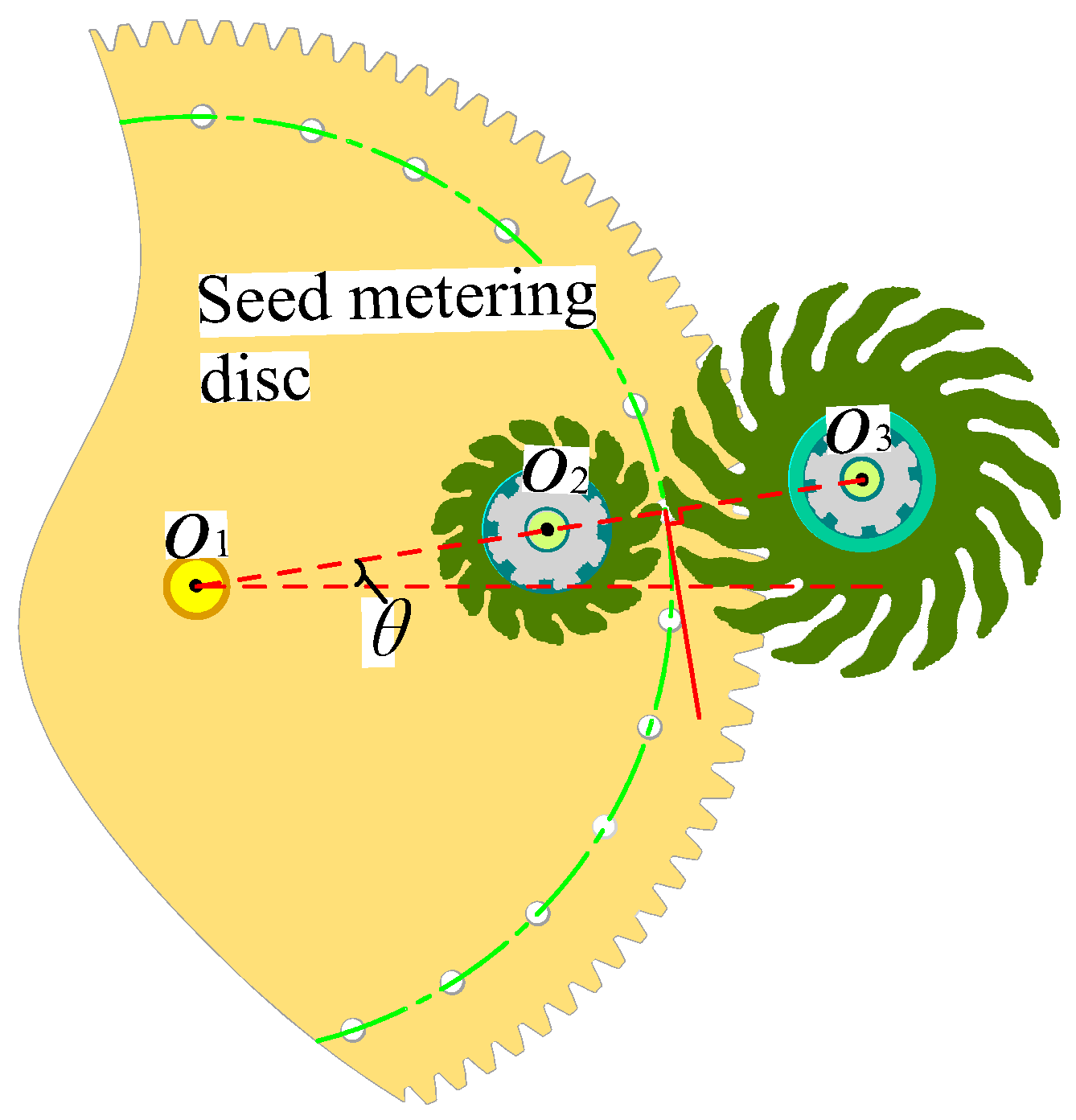

2.2. Configuration and Operational Concept Regarding Seed-Receiving Mechanism

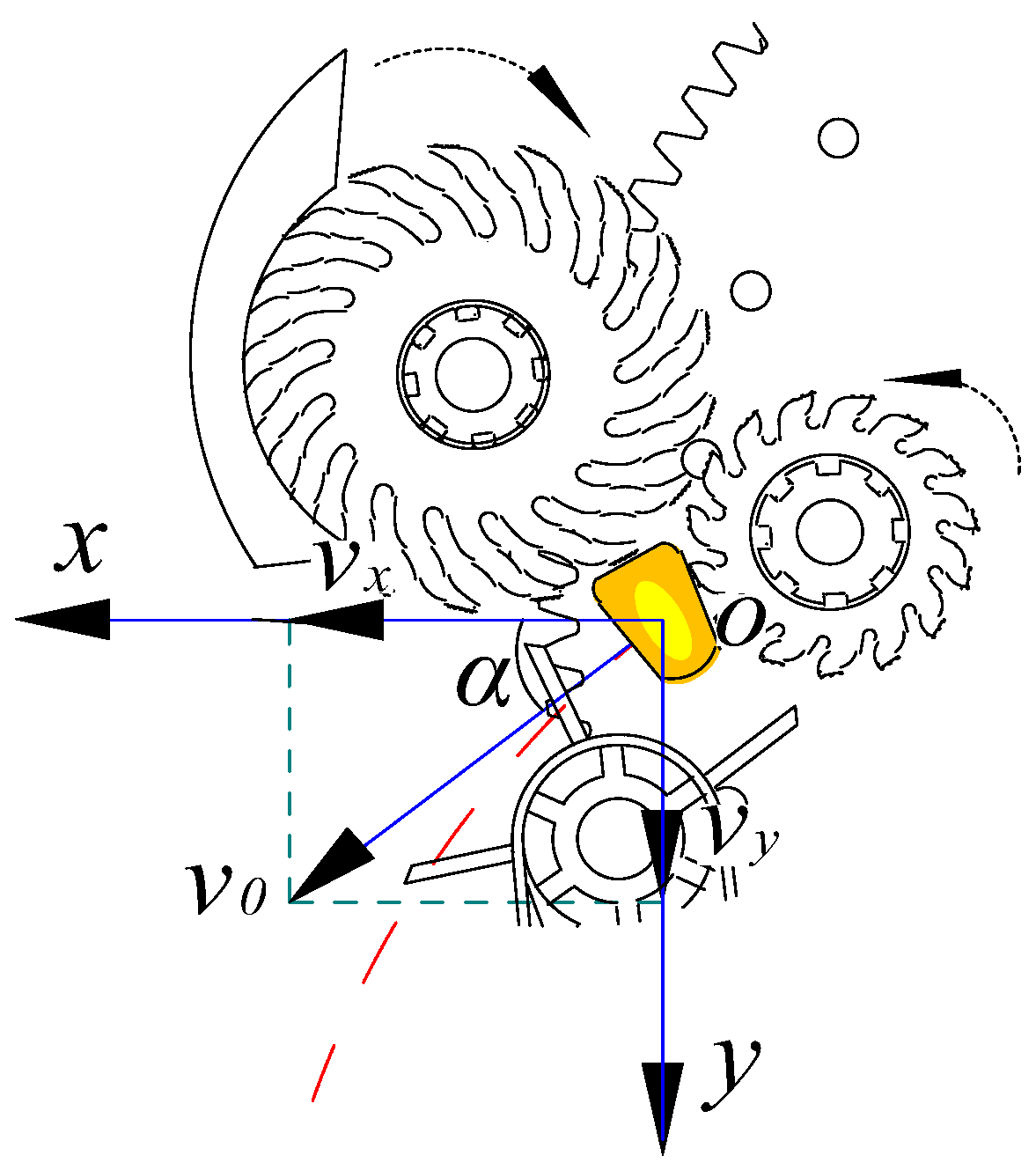

2.3. Design and Analysis for Seed-Receiving Mechanism

2.3.1. Geometric Parameters of Corn Seed

2.3.2. Seed-Receiving Gap of Main and Secondary Clamping Wheels

2.3.3. Deformation Parameters of Finger

2.3.4. Clamping Wheel Speed

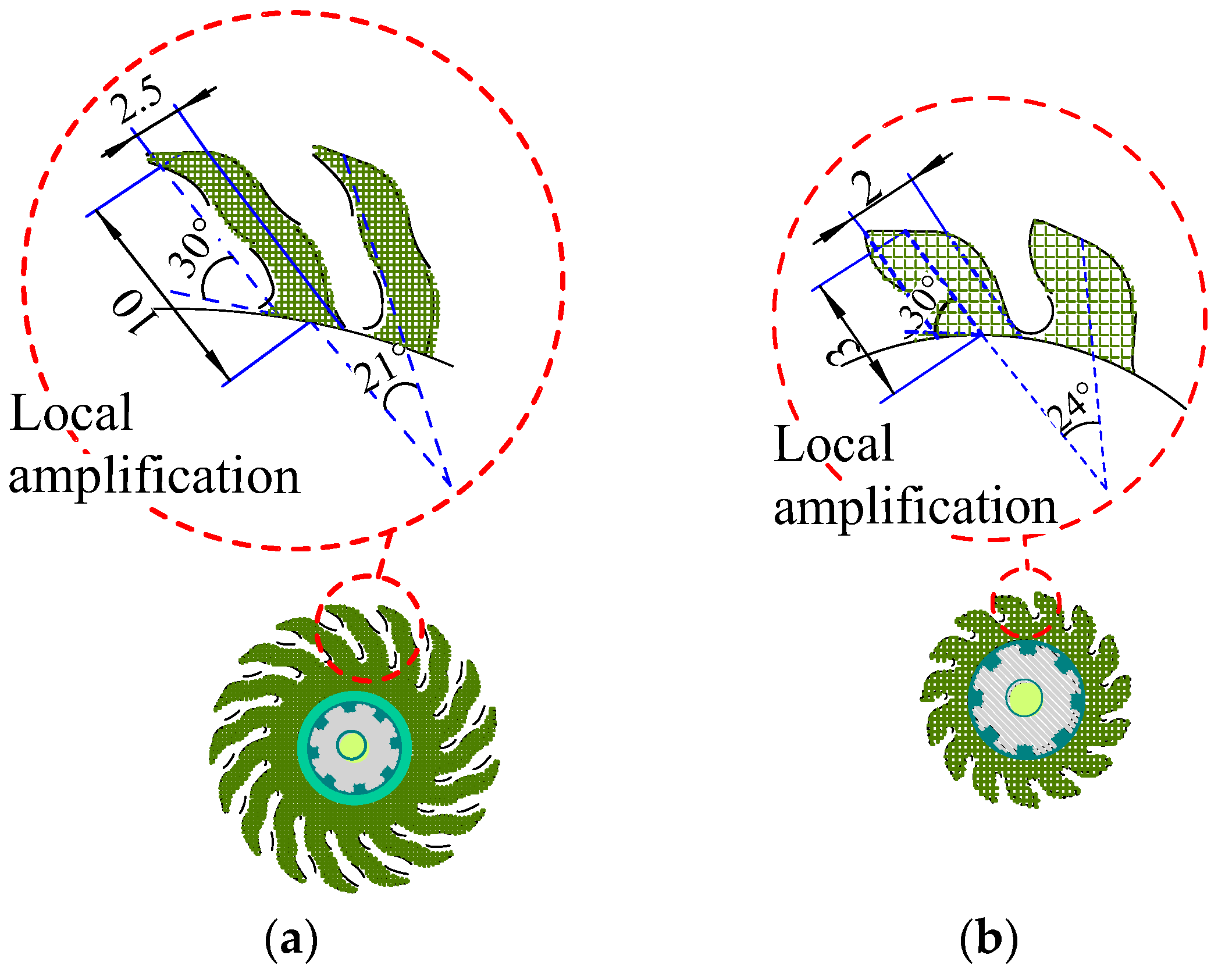

2.3.5. Finger Structure

2.3.6. Seed Picking Angle

2.4. Acquisition and Analysis of Seed Displacement Trajectory Based on High-Speed Videography

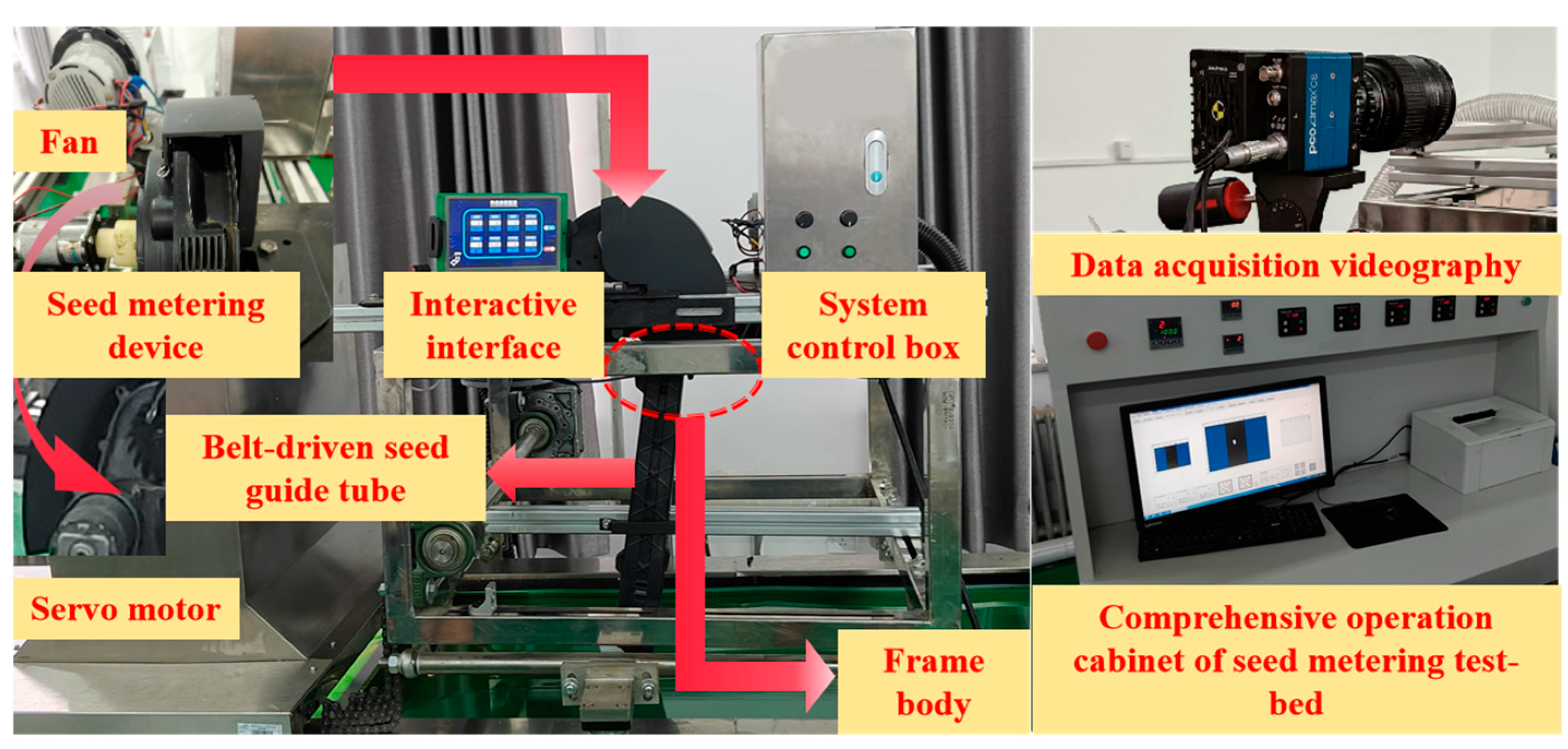

2.4.1. Experimental Conditions and Materials

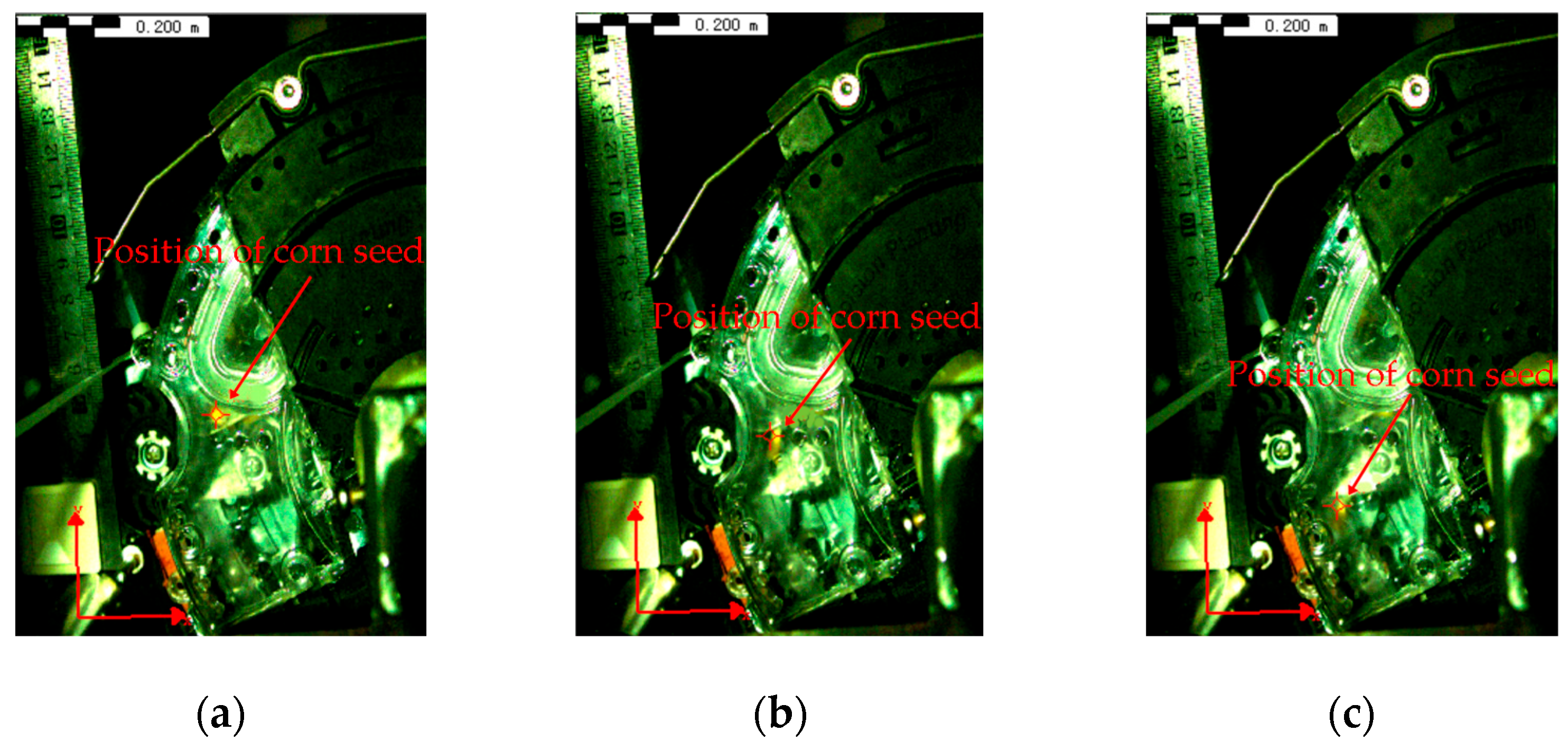

2.4.2. Experimental Method

3. Results and Discussion

3.1. Effect of Clamping Wheel Speed on Corn Seed Speed and Displacement Trajectory

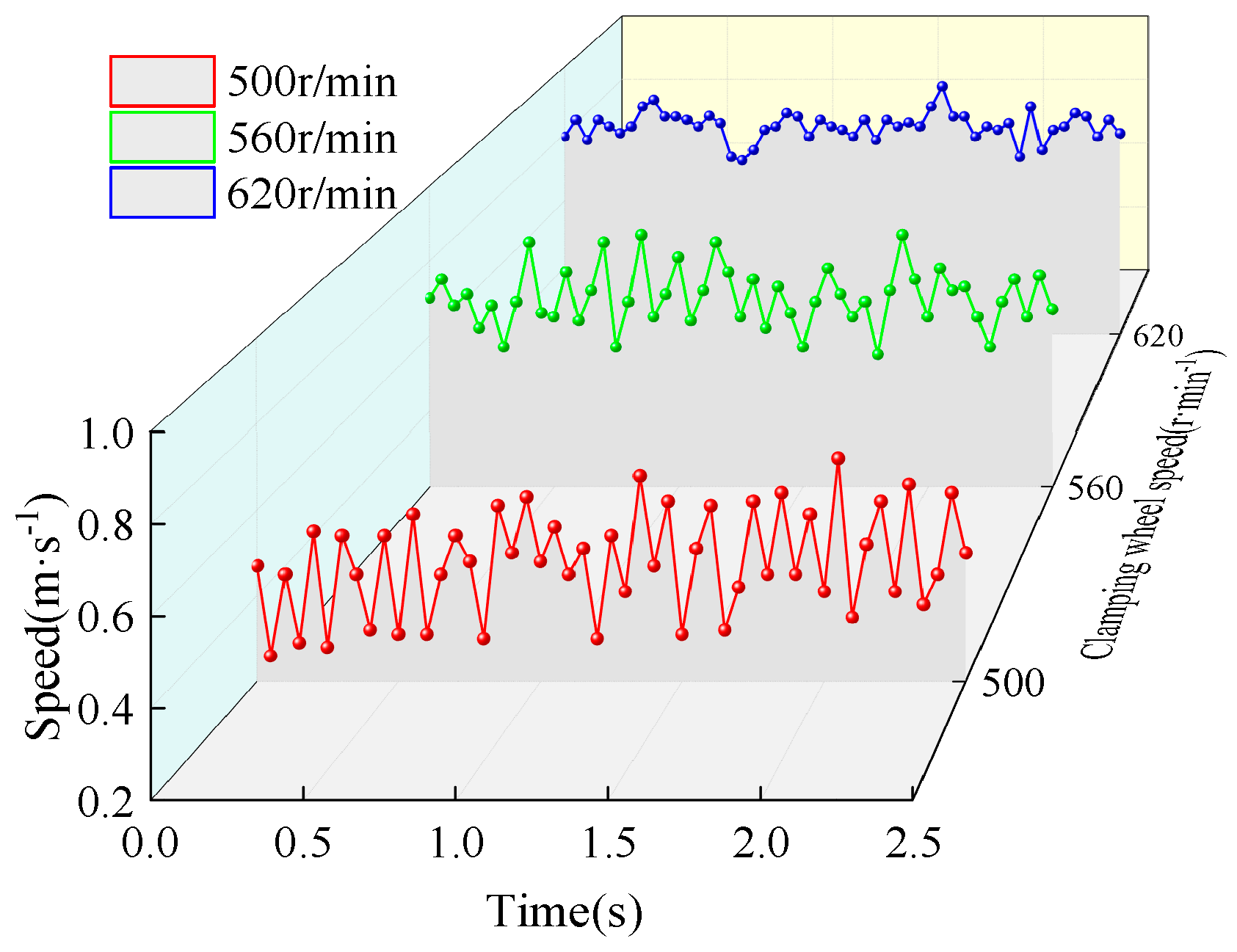

3.1.1. Effect of Clamping Wheel Speed on Corn Seed Speed

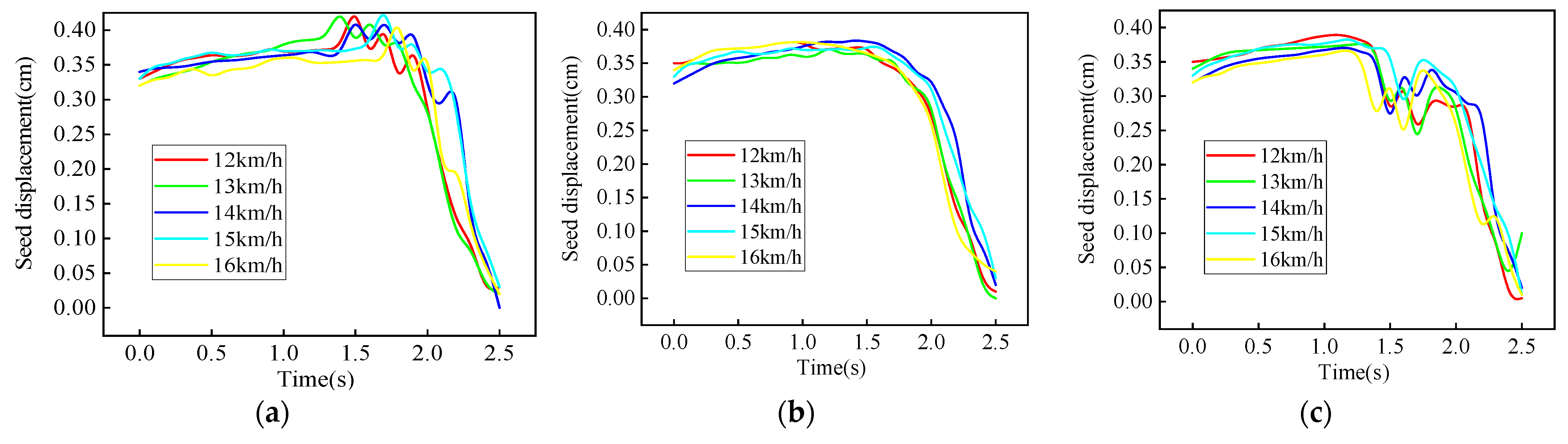

3.1.2. Effect of Clamping Wheel Speed on Corn Seed Displacement Trajectory

3.2. Effect of Seed-Receiving Angle on Corn Seed Speed and Displacement Trajectory

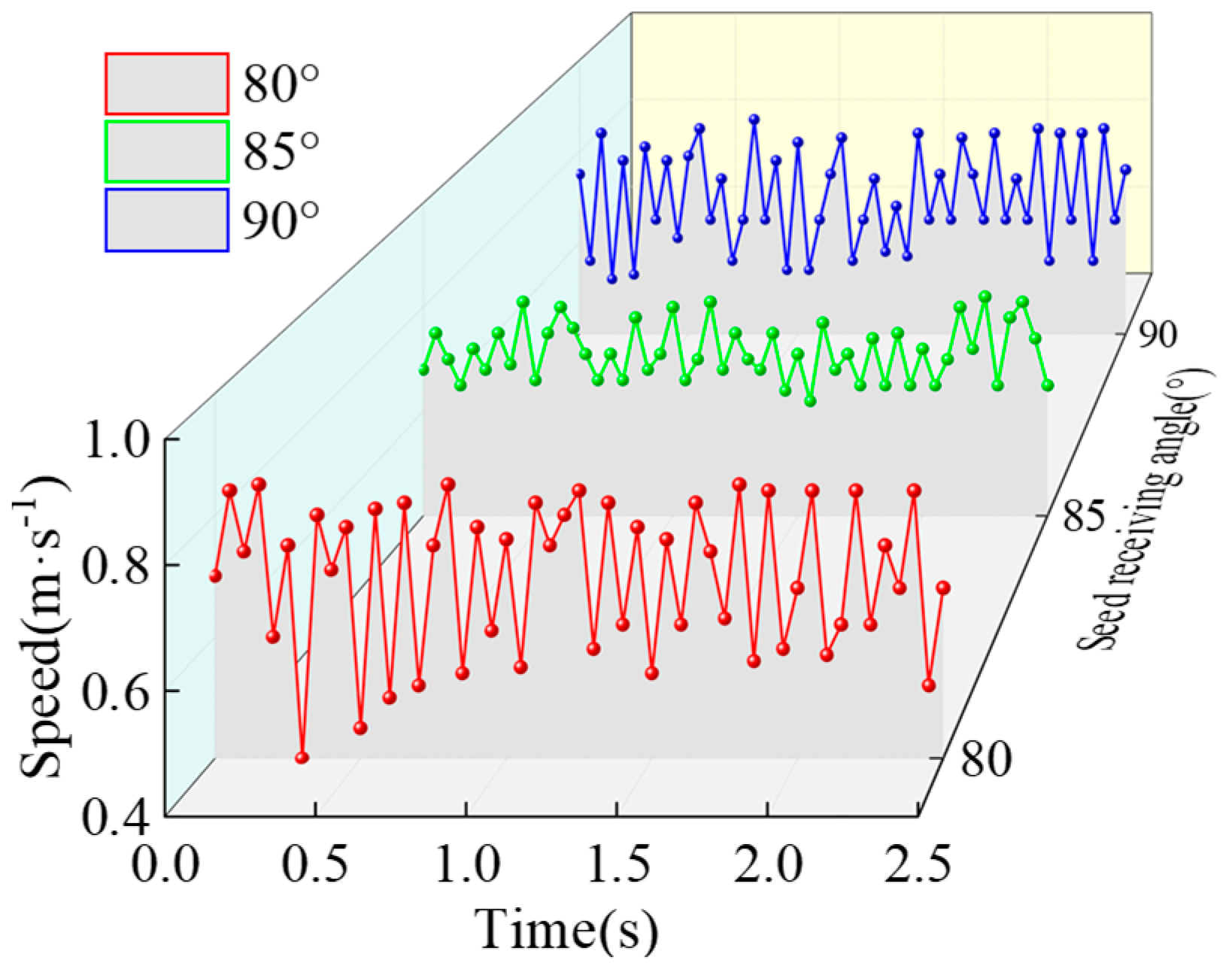

3.2.1. Effect of Seed-Receiving Angle on Corn Seed Speed

3.2.2. Effect of Seed-Receiving Angle on Corn Seed Displacement Trajectory

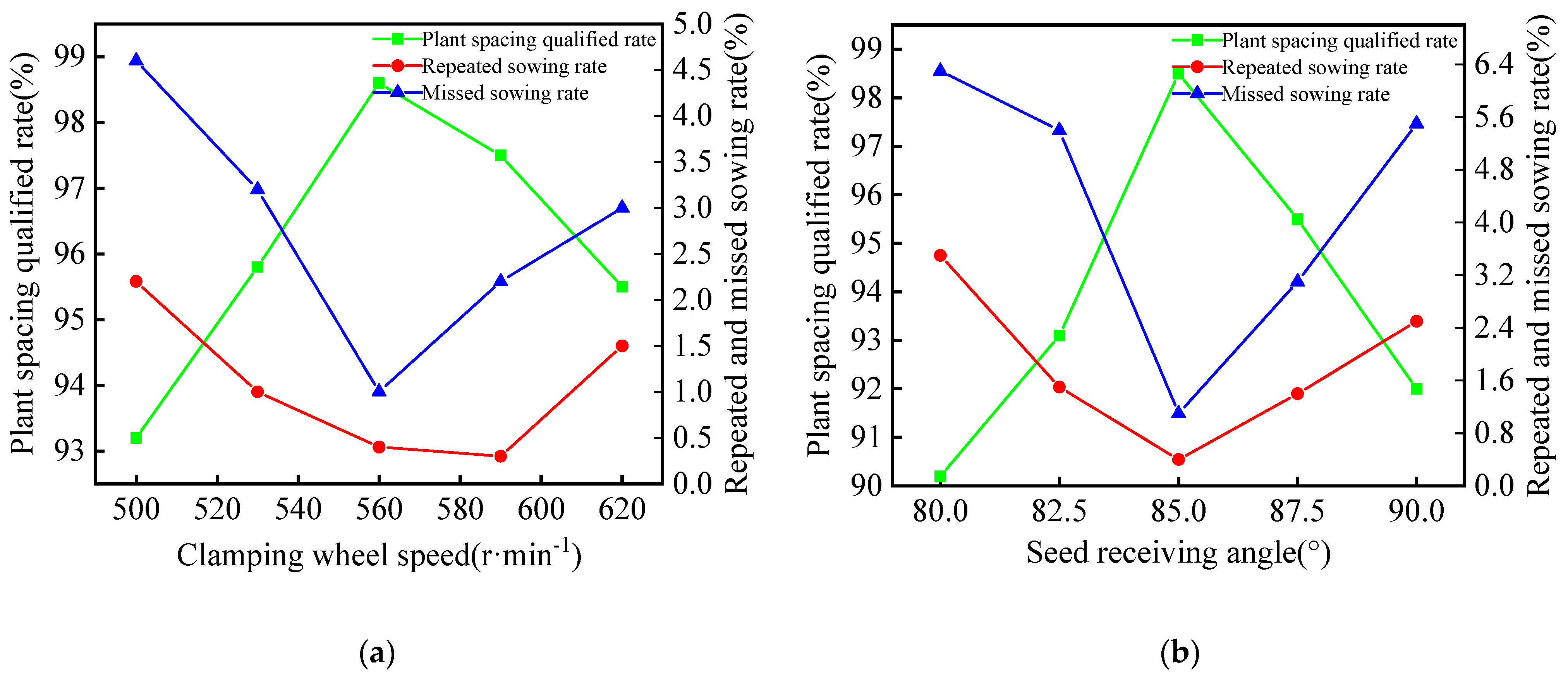

3.3. Verification Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, J.; Tian, Q.; Huang, Y.; Du, L.; Wang, L. Extraction of the corn planting area based on multi-temporal HJ-1 satellite data. In Proceedings of the 2011 19th International Conference on Geoinformatics, Shanghai, China, 24–26 June 2011; p. 4. [Google Scholar] [CrossRef]

- Virk, S.S.; Fulton, J.P.; Porter, W.M.; Pate, G.L. Row-crop planter performance to support variable-rate seeding of maize. Precis. Agric. 2020, 21, 603–619. [Google Scholar] [CrossRef]

- Lobell, D.B.; Schlenker, W.; Costa-Roberts, J. Climate trends and global crop production since 1980. Science 2011, 333, 616–620. [Google Scholar] [CrossRef] [PubMed]

- Tigchelaar, M.; Battisti, D.S.; Naylor, R.L.; Ray, D.K. Future warming increases probability of globally synchronized maize production shocks. Proc. Nat. Acad. Sci. USA 2018, 115, 6644–6649. [Google Scholar] [CrossRef] [PubMed]

- Erenstein, O.; Jaleta, M.; Sonder, K.; Mottaleb, K.; Prasanna, B.M. Global maize production, consumption and trade: Trends and R&D implications. Food Secur. 2022, 14, 1295–1319. [Google Scholar] [CrossRef]

- Grote, U.; Fasse, A.; Nguyen, T.T.; Erenstein, O. Food security and the dynamics of wheat and maize value chains in Africa and Asia. Front. Sustain. Food Syst. 2021, 4, 617009. [Google Scholar] [CrossRef]

- Wang, S.; Yi, S.; Zhao, B.; Li, Y.; Wang, G.; Li, S.; Sun, W. Photoelectric sensor-based belt-type high-speed seed guiding device performance monitoring method and system. Comput. Electron. Agric. 2024, 227, 109489. [Google Scholar] [CrossRef]

- Liu, Z.; Xia, J.; Hu, M.; Du, J.; Luo, C.; Zheng, K. Design and analysis of a performance monitoring system for a seed metering device based on pulse width recognition. PLoS ONE 2021, 16, e0261593. [Google Scholar] [CrossRef]

- Tang, H.; Xu, F.; Guan, T.; Xu, C.; Wang, J. Design and test of a pneumatic type of high-speed maize precision seed metering device. Comput. Electron. Agric. 2023, 211, 107997. [Google Scholar] [CrossRef]

- Zhang, J.; Hou, Y.; Ji, W.; Zheng, P.; Yan, S.; Hou, S.; Cai, C. Evaluation of a Real-Time Monitoring and Management System of Soybean Precision Seed Metering Devices. Agronomy 2023, 13, 541. [Google Scholar] [CrossRef]

- Badua, S.A.; Sharda, A.; Strasser, R.; Ciampitti, I. Ground speed and planter downforce influence on corn seed spacing and depth. Trans. ASABE 2021, 22, 1154–1170. [Google Scholar] [CrossRef]

- Chen, X.; Zhong, L. Design and test on belt-type seed delivery of air-suction metering device. Trans. CSAE 2012, 28, 8–15. [Google Scholar] [CrossRef]

- Ma, C.; Yi, S.; Tao, G.; Li, Y.; Wang, S.; Wang, G.; Gao, F. Research on receiving seeds performance of belt-type high-speed corn seed guiding device based on discrete element method. Agriculture 2023, 13, 1085. [Google Scholar] [CrossRef]

- Tang, H.; Xu, C.; Wang, Z.; Wang, Q.; Wang, J. Optimized design, monitoring system development and experiment for a long-belt finger-clip precision corn seed metering device. Front. Plant Sci. 2022, 13, 814747. [Google Scholar] [CrossRef]

- Lü, J.; Yang, Y.; Li, Z.; Tian, Z.; Shang, Q.; Wu, J.E. Design and experiment of cup-belt type potato seed-metering device. Trans. CSAE 2016, 32, 17–25. [Google Scholar] [CrossRef]

- Kocher, M.F.; Coleman, J.M.; Smith, J.A.; Kachman, S.D. Corn seed spacing uniformity as affected by seed tube condition. Appl. Eng. Agric. 2011, 27, 177–183. [Google Scholar] [CrossRef]

- Karayel, D.; Šarauskis, E.; Aktaş, A. Design and Experiment of a Helicoidal Seed Tube to Improve Seed Distribution Uniformity of Seed Drills. Processes 2022, 10, 1271. [Google Scholar] [CrossRef]

- Savi, D.; Kmiecik, L.L.; Neto, L.S.; da Silva, T.X.; Jasper, S.P. Influence of seed tube curvature on seed longitudinal distribution. Eng. Agríc. 2020, 40, 732–739. [Google Scholar] [CrossRef]

- Wang, B.; Liao, Q.; Wang, L.; Shu, C.; Cao, M.; Du, W. Design and test of air-assisted seed-guiding device of precision hill-seeding centralized seed-metering device for sesame. Agriculture 2021, 13, 393. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, W.; Ma, C.; Feng, Z.; Wang, J.; Yi, S.; Wang, S. Design and optimization of the seed conveying system for belt-type high-speed corn seed guiding device. Int. J. Agric. Biol. Eng. 2024, 17, 123–131. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, S.; Wang, W.; Lv, H.; Chen, Y.; Zhou, L.; Li, M.; Zhao, J. Design and Testing of Soybean Double-Row Seed-Metering Device with Double-Beveled Seed Guide Groove. Agriculture 2024, 14, 1595. [Google Scholar] [CrossRef]

- Li, H.; Liu, H.; Zhou, J.; Wei, G.; Shi, S.; Zhang, X.; Zhang, R.; Zhu, H.; He, T. Development and first results of a no-till pneumatic seeder for maize precise sowing in Huang-Huai-Hai plain of China. Agriculture 2021, 11, 1023. [Google Scholar] [CrossRef]

- Wen, W.; Wang, Y.; Wu, S.; Liu, K.; Gu, S.; Guo, X. 3D phytomer-based geometric modelling method for plants—The case of maize. AoB Plants 2021, 13, plab055. [Google Scholar] [CrossRef]

- Tang, H.; Xu, C.; Jiang, Y.; Wang, J.; Wang, Z.; Tian, L. Evaluation of physical characteristics of typical maize seeds in a cold area of north China based on principal component analysis. Processes 2021, 9, 1167. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, Y.; Hao, B.; Xu, X.; Zhao, Z.; Wang, Z.; Xue, Q. Grain Yield and Water Use Efficiency in Extremely-Late Sown Winter Wheat Cultivars under Two Irrigation Regimes in the North China Plain. PLoS ONE 2016, 11, e0153695. [Google Scholar] [CrossRef]

- Guo, H.; Cao, Y.; Song, W.; Zhang, J.; Wang, C.; Wang, C.; Yang, F.; Zhu, L. Design and simulation of a garlic seed metering mechanism. Agriculture 2021, 11, 1239. [Google Scholar] [CrossRef]

- Ding, Y.; Li, H.; Gao, J.; Yu, H.; Wang, Y.; Feng, D. Parameter Optimization of Finger Clip Plate Garlic Seed-Metering Device. Agriculture 2023, 13, 2071. [Google Scholar] [CrossRef]

- Cui, X.; Wang, Z.; Zhuang, T.; Sun, J.; Song, Y. Improving wheat seedling quality through deep ploughing and soil compaction at sowing in lime concretion black soil. PLoS ONE 2023, 18, e0288459. [Google Scholar] [CrossRef]

- Bai, S.; Yuan, Y.; Niu, K.; Shi, Z.; Zhou, L.; Zhao, B.; Wei, L.; Liu, L.; Zheng, Y.; An, S.; et al. Design and experiment of a sowing quality monitoring system of cotton precision hill-drop planters. Agriculture 2022, 12, 1117. [Google Scholar] [CrossRef]

| Seed Variety | Thousand-Grain Weight/g | Parameters | Maximum Value/mm | Minimum Value/mm | Average Value/mm |

|---|---|---|---|---|---|

| Demiya No. 1 | 286.33 | Length | 12.43 | 9.84 | 11.14 |

| Width | 8.85 | 6.41 | 7.63 | ||

| Thickness | 6.11 | 4.42 | 5.27 | ||

| Heyu 187 | 264.78 | Length | 12.21 | 9.68 | 10.95 |

| Width | 8.67 | 6.21 | 7.44 | ||

| Thickness | 5.98 | 4.30 | 5.14 | ||

| Fenghe No. 7 | 254.32 | Length | 12.01 | 9.57 | 10.79 |

| Width | 8.52 | 6.03 | 7.28 | ||

| Thickness | 5.88 | 4.12 | 5.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, C.; Zhao, Z.; Chen, X.; Tang, Y.; Song, N.; Xiao, Y.; Yang, X. Optimization of Seed-Receiving Mechanism in Belt-Driven Seed Guide Tube Based on High-Speed Videography Experiment. Agriculture 2025, 15, 174. https://doi.org/10.3390/agriculture15020174

Ma C, Zhao Z, Chen X, Tang Y, Song N, Xiao Y, Yang X. Optimization of Seed-Receiving Mechanism in Belt-Driven Seed Guide Tube Based on High-Speed Videography Experiment. Agriculture. 2025; 15(2):174. https://doi.org/10.3390/agriculture15020174

Chicago/Turabian StyleMa, Chengcheng, Zhihuan Zhao, Xiaomei Chen, Youyuan Tang, Ning Song, Yanfeng Xiao, and Xu Yang. 2025. "Optimization of Seed-Receiving Mechanism in Belt-Driven Seed Guide Tube Based on High-Speed Videography Experiment" Agriculture 15, no. 2: 174. https://doi.org/10.3390/agriculture15020174

APA StyleMa, C., Zhao, Z., Chen, X., Tang, Y., Song, N., Xiao, Y., & Yang, X. (2025). Optimization of Seed-Receiving Mechanism in Belt-Driven Seed Guide Tube Based on High-Speed Videography Experiment. Agriculture, 15(2), 174. https://doi.org/10.3390/agriculture15020174