Discrete Element-Based Design of a High-Speed Rotary Tiller for Saline-Alkali Land and Verification of Optimal Tillage Parameters

Abstract

:1. Introduction

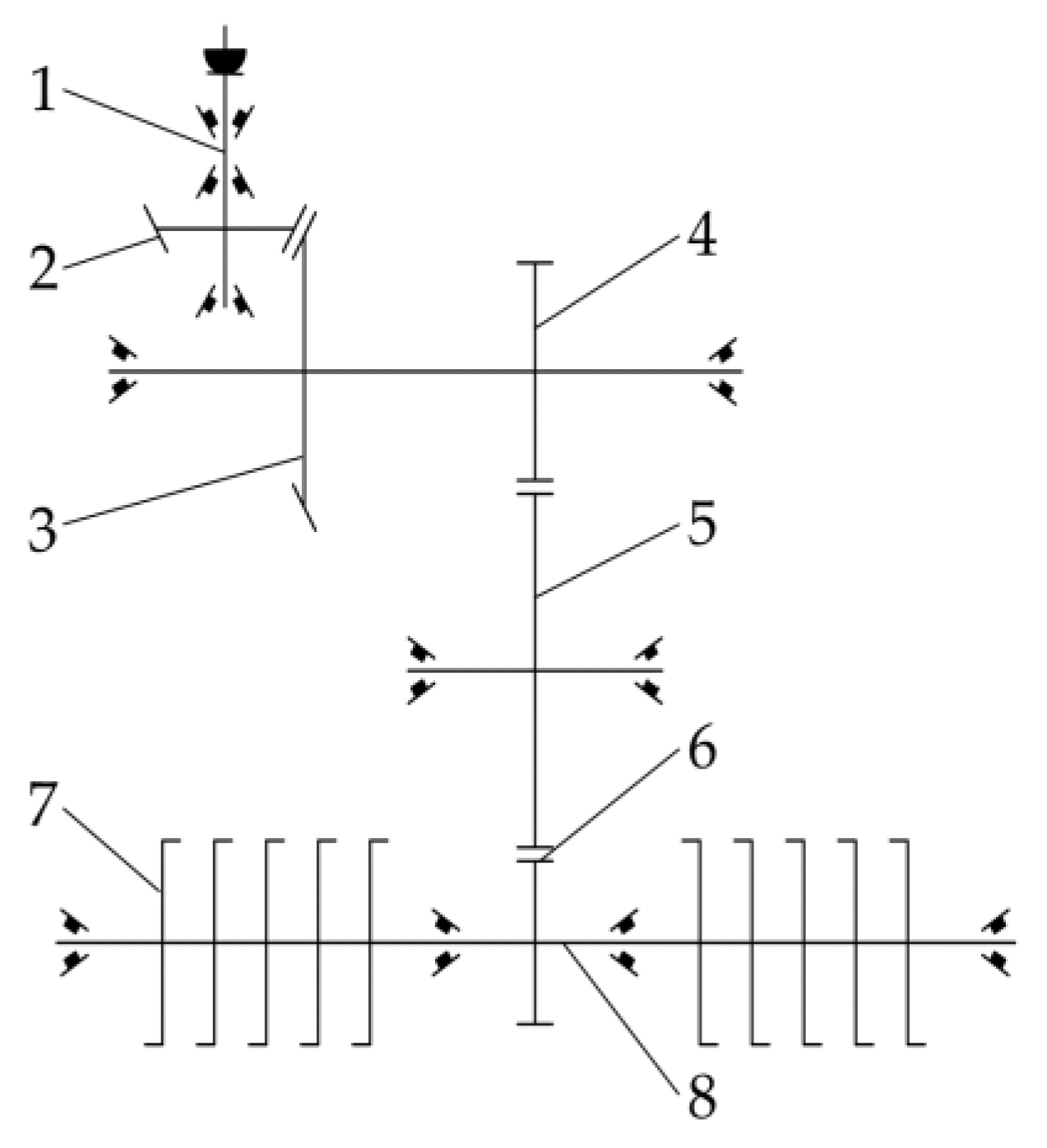

2. Machine Structure and Working Process

2.1. Complete Machine Structure

2.2. Working Process

3. Design of Key Mechanism Parameters

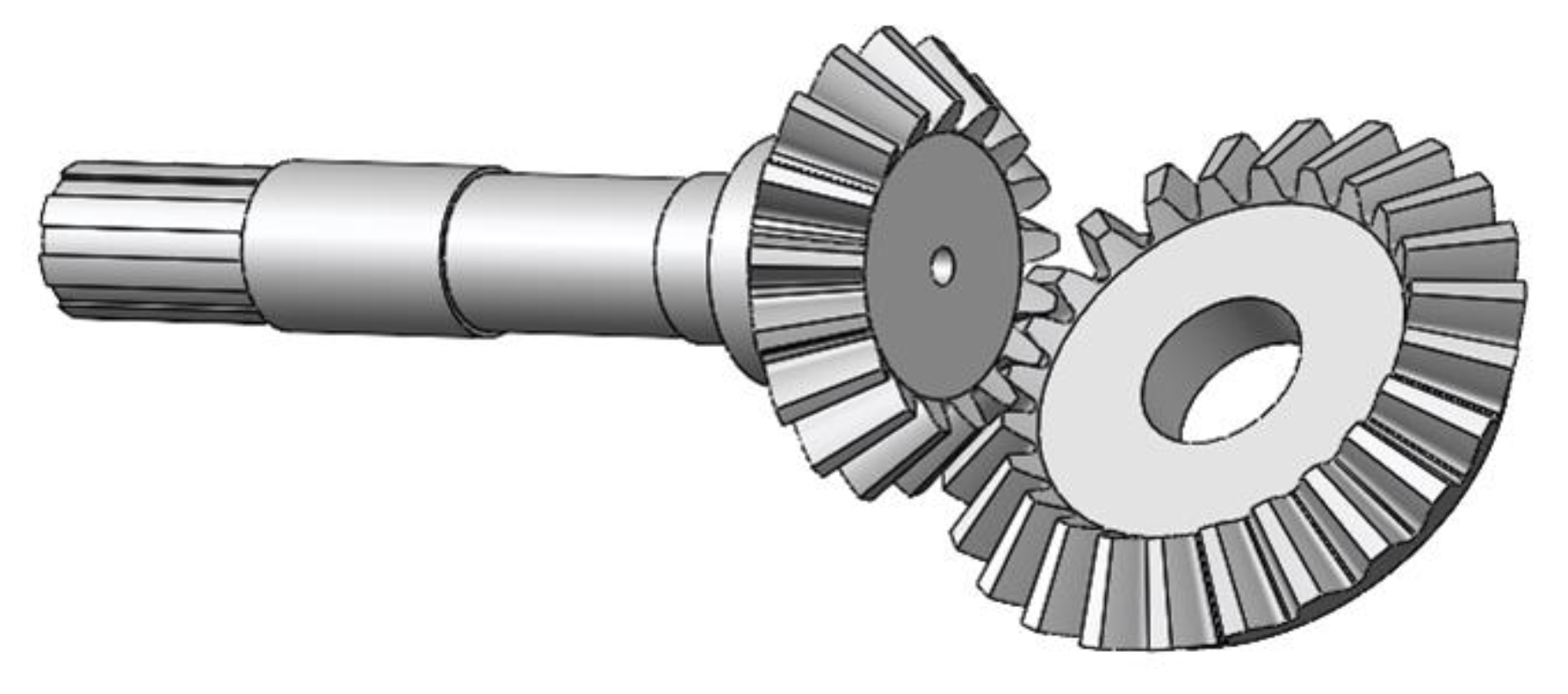

3.1. Drive Train Design

3.2. Mechanical Analysis and Parameter Design of the Rotary Tiller

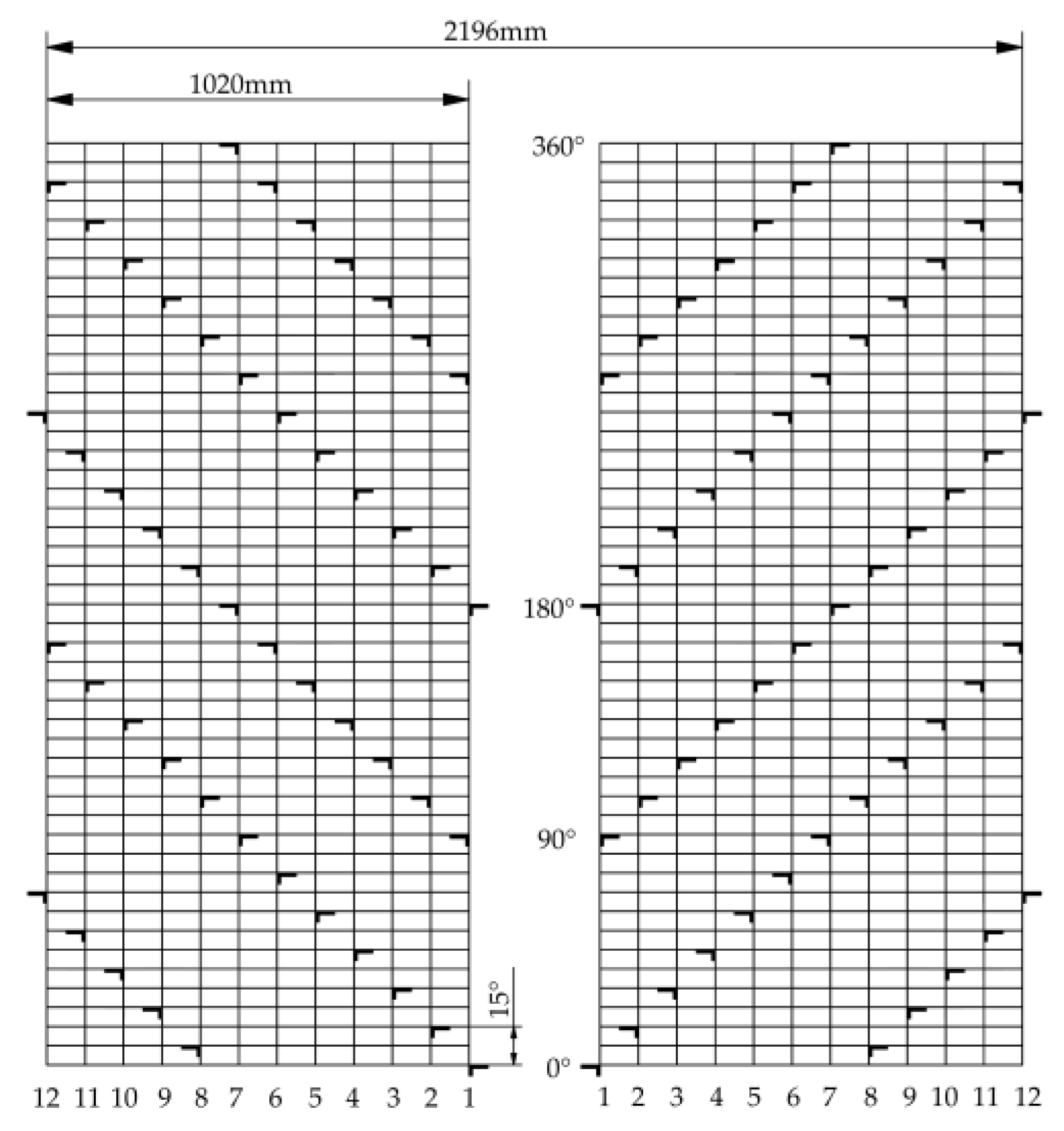

3.3. Analysis of Rotary Cutter Arrangement and Helical Rise Angle

4. Discrete Element Simulation

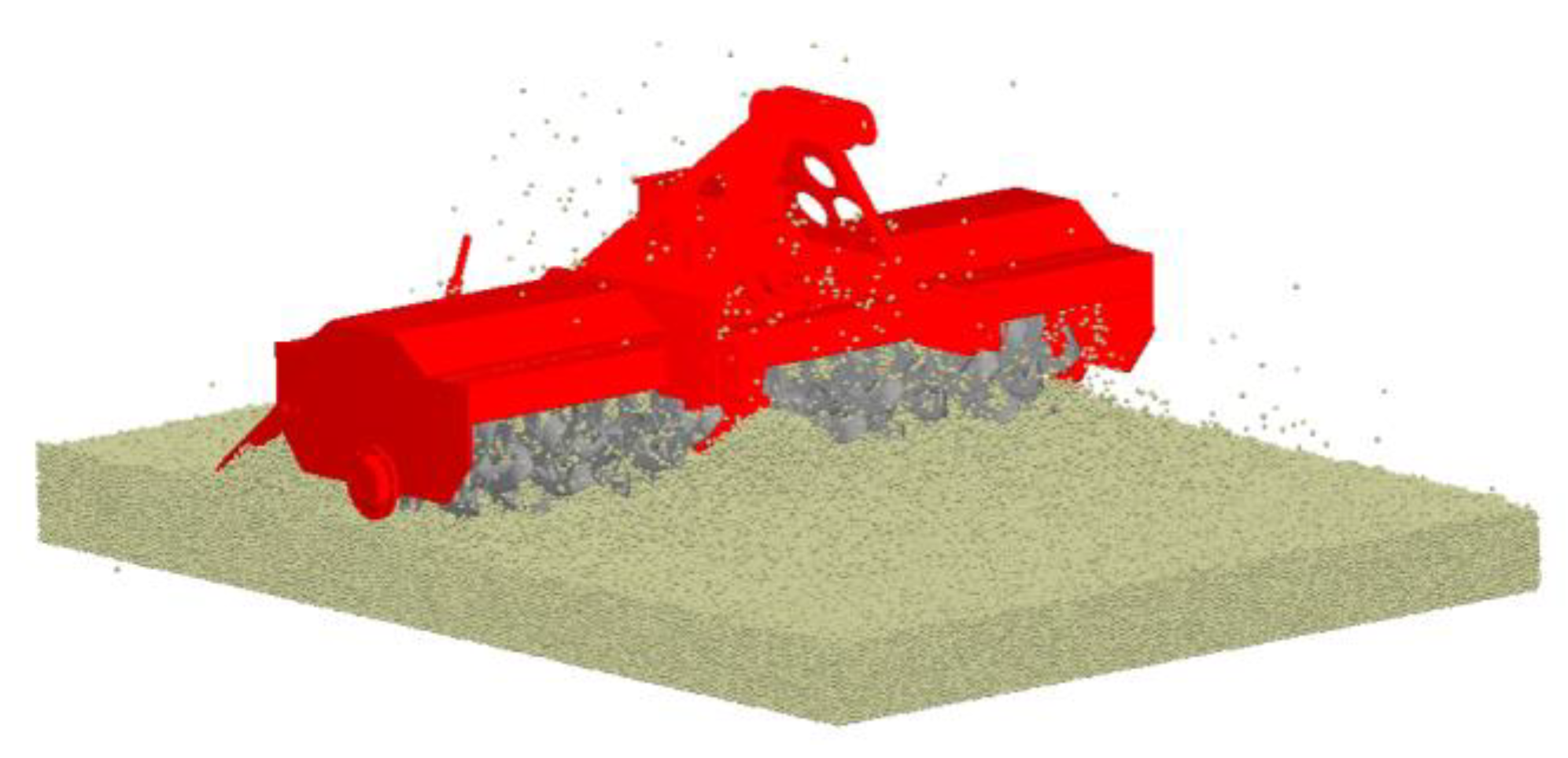

4.1. Simulation Modeling and Experimental Design

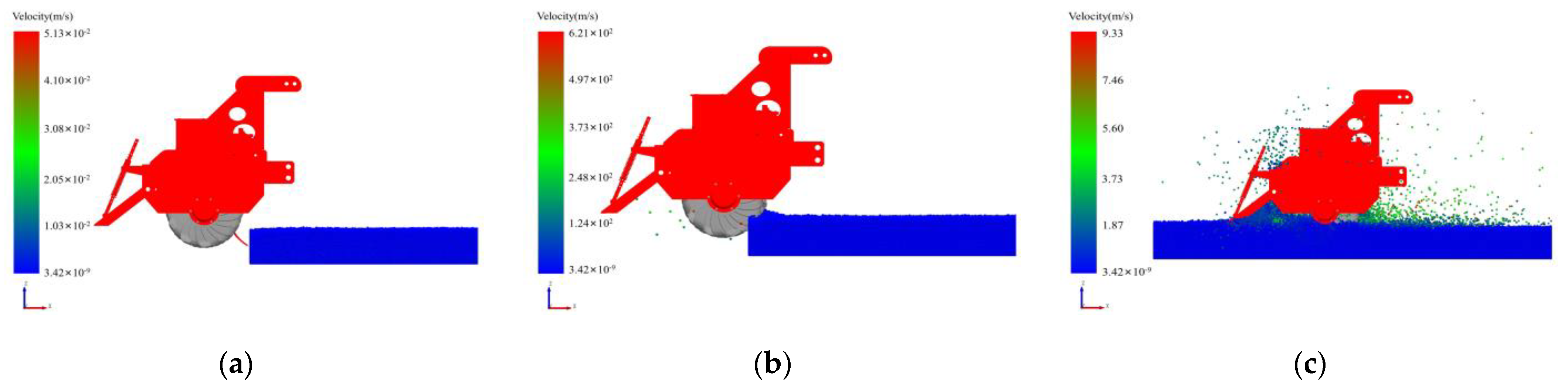

4.2. Simulation Results Analysis

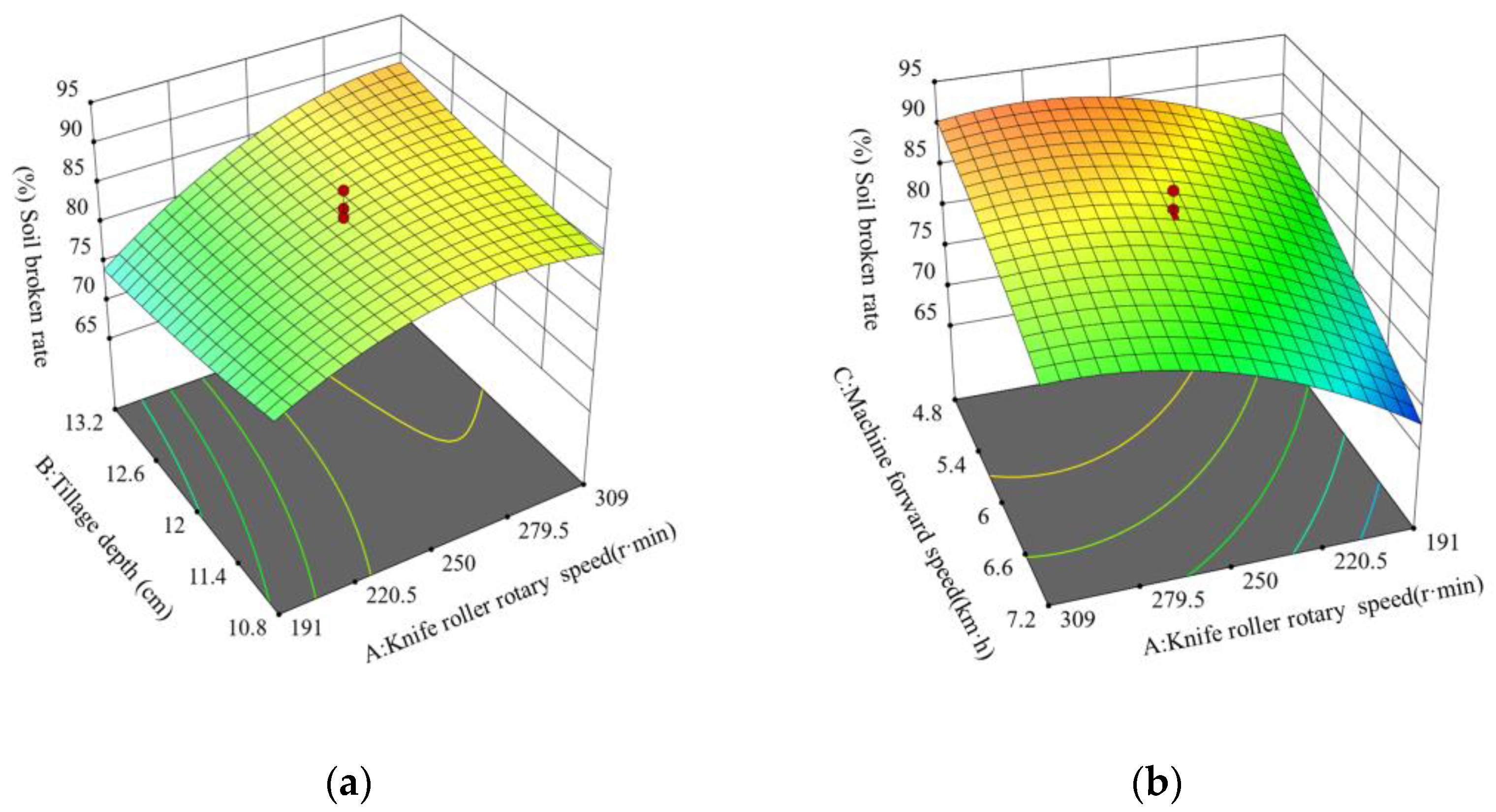

Response Surface Analysis

4.3. Optimal Parameter Combinations for High-Speed Rotary Tillers

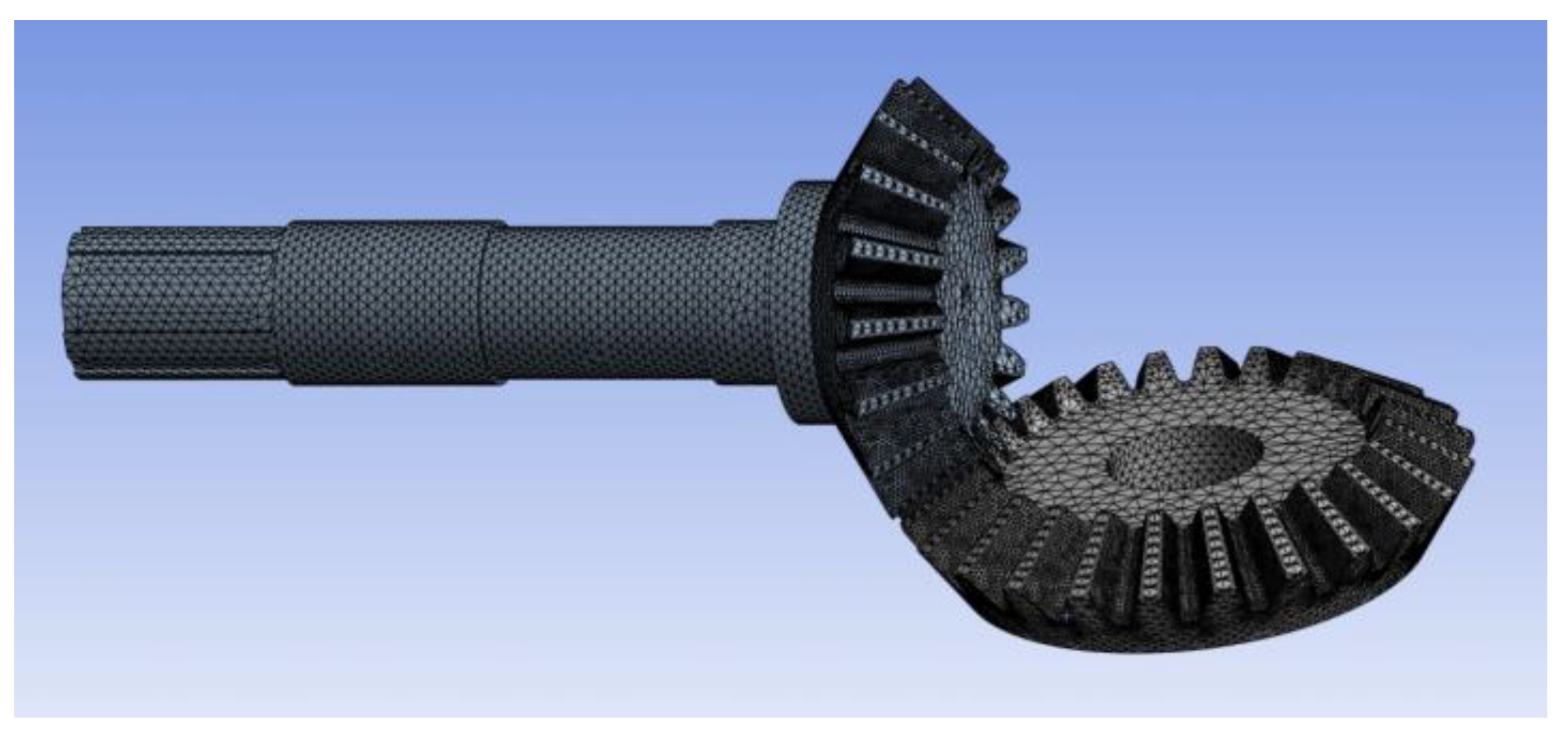

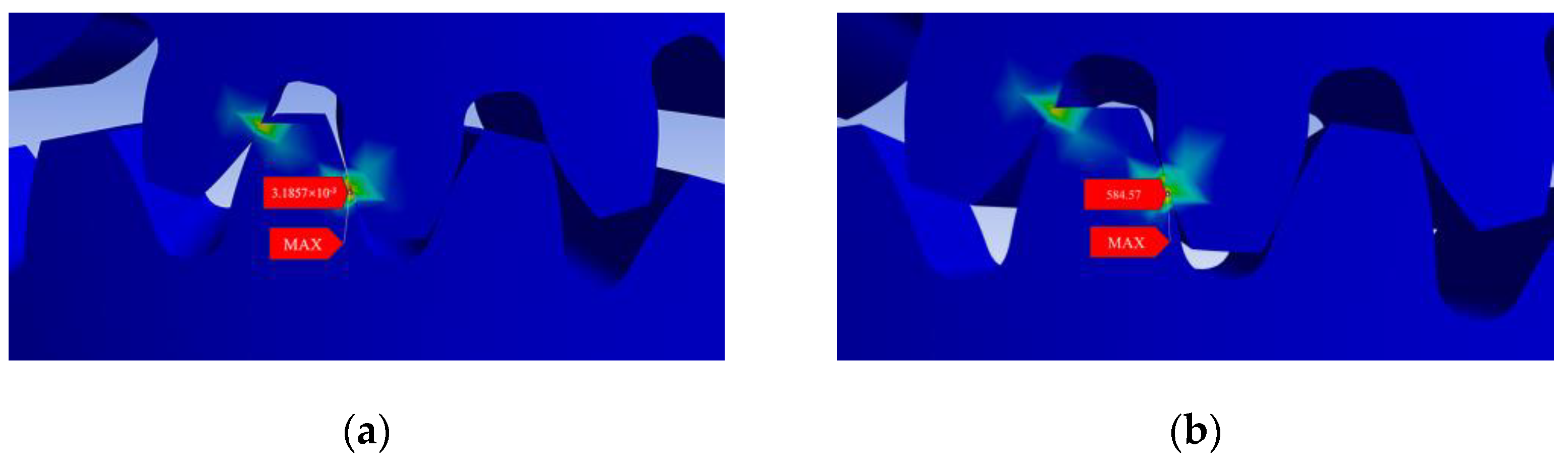

4.4. Transient Analysis of Gearbox Meshing Bevel Gears

5. Field Trials

5.1. Experimental Condition

5.2. Test Methods

5.2.1. Tillage Depth and Tillage Depth Stability

5.2.2. Soil-Breaking Rate

5.2.3. Vegetation Coverage Rate

5.2.4. Test Method for Land Surface Flatness

5.3. Test Results and Analysis

6. Conclusions

- (1)

- Aiming at the problem of efficiency of land preparation in saline land in Binhai New Area, a high-speed rotary tiller is designed to increase the number of successive cuts of rotary tiller knives per unit of time by determining the number of rotary tiller knives in the same plane and rotational speed of the knife axle, to reduce the time of soil cutting, improve the quality of rotary tillage and operational efficiency, and meet the requirements of local agronomic techniques in a single operation.

- (2)

- The theoretical analysis focused on the rotary tillage knife trajectory, the number of blades, and the arrangement of the helix rising angle, to determine the main factors affecting the quality of operation for the knife roller speed, plowing depth, and unit forward speed. Combined with the central orthogonal test and discrete element simulation, the optimal parameter combination for the high-speed rotary tiller is determined as follows: a knife roller speed at 310 r/min, tillage depth of 13.2 cm, and forward speed of the unit at 4.8 km/h. At this time, the simulation values of the soil-breaking rate and the land surface flatness were 90.6% and 18.2 mm, respectively.

- (3)

- Under the optimal combination established through field comparison tests, the results for the high-speed rotary tiller compared to the ordinary rotary tiller operation for the soil-breaking rate, tillage depth, tillage depth stability coefficient, and vegetation cover were 89.3%, 14.2 cm, 92.8%, 90.3%. The land surface flatness was 16.4 mm, which is superior to the ordinary rotary tiller operation effect, meeting the peanut pre-sowing preparation agronomic requirements for saline land in Binhai New Area.

- (4)

- The high-speed rotary tiller designed in this study performed remarkably in field trial operations in coastal saline soils, meeting the local agronomic requirements. However, its performance in other soil types (e.g., clay, sand, etc.) and under different humidity conditions needs to be verified. Differences in the physicochemical properties of soils may affect operating results, and soils that are too wet or too dry may require modifications to the machine construction to accommodate varying moisture working conditions. High-speed rotary tiller blades are prone to faster wear at high rotational speeds, requiring the use of wear-resistant materials or coatings to extend blade life. In the future, field tests will be conducted under different soil types and humidity conditions to optimize blade materials, and fatigue life tests will be conducted on key components to improve their reliability under long-term high loads. In addition, the matching of high-efficiency power systems with tractors will be studied to optimize energy consumption, reduce tractor power requirements, and improve overall operating efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Qin, K.; Ding, W.M.; Fang, Z.C.; Du, T.T.; Zhao, S.Q.; Wang, Z. Design and experiment of plowing and rotary tillage combined machine. Trans. Chin. Soc. Agric. Eng. 2016, 32, 7–16. [Google Scholar]

- Zhu, Q.Z.; Wu, G.W.; Chen, L.P.; Meng, Z.J.; Shi, J.T.; Zhao, C.J. Design of Stratified and Depth-Fixed Application Device of Base-fertilizer for Winter Wheat Based on Soil-covering Rotary Tillage. Trans. Chin. Soc. Agric. Eng. 2018, 34, 18–26. [Google Scholar]

- Gao, J.M.; Zhou, P.; Zhang, B.; Li, F.Y. Development and Test of High Speed Soil-cutting Simulation System Based on Smooth Particle Hydrodynamics. Trans. Chin. Soc. Agric. Eng. 2007, 8, 20–26. [Google Scholar]

- Liu, G.Y.; Xia, J.F.; Zheng, K.; Cheng, J.; Wei, Y.S.; Guo, L.W.; Li, X.F.; Zhang, J.M. Design and Experiments of the Barrier Type Rotary Anti-adhesion Blade Roller with Vibration Crosspiece. Trans. Chin. Soc. Agric. Eng. 2022, 38, 29–40. [Google Scholar]

- Fang, H.M.; Ji, C.Y.; Zhang, Q.Y.; Guo, J. Force Analysis of Rotary Blade Based on Distinct Element Method. Soc. Agric. Eng. 2016, 32, 54–59. [Google Scholar]

- Zhao, Z.; Wang, D.W.; Shang, S.Q.; Guo, P.; Gao, Z.H.; Xia, C.; Yan, H.P.; Hou, J.L. Design and Test of a Dual-axis Layered Rotary Tillage Stubble Exterminator in Saline-alkali Land based on Discrete Elements. Int. J. Agric. Biol. Eng. 2024, 17, 163–175. [Google Scholar] [CrossRef]

- Li, W.; Yang, J.; Tang, C.; Liu, X.; Xie, W.; Yao, R.; Wang, X. The Temporal–Spatial Dynamic Distributions of Soil Water and Salt under Deep Vertical Rotary Tillage on Coastal Saline Soil. Water 2022, 14, 3370. [Google Scholar] [CrossRef]

- Upadhyay, G.; Raheman, H. Effect of Velocity Ratio on Performance Characteristics of an Active-passive Combination Tillage Implement. Biosyst. Eng. 2020, 191, 1–12. [Google Scholar] [CrossRef]

- Salokhe, V.M.; Ramalingam, N. Effects of Direction of Rotation of a Rotary Tiller on Properties of Bangkok Clay Soil. Soil Tillage Res. 2001, 63, 65–74. [Google Scholar] [CrossRef]

- Asl, J.H.; Singh, S. Optimization and Evaluation of Rotary Tiller Blades: Computer Solution of Mathematical Relations. Soil Tillage Res. 2009, 106, 1–7. [Google Scholar] [CrossRef]

- Tian, Y.; Jin, L.; Zhao, Y.X. Experimental Research on the Paraments Impacted Homework PerFormance of Rotary Cultivator. J. Chin. Agric. Mech. 2016, 37, 1–4. [Google Scholar]

- Zheng, K.; McHugh, A.D.; Li, H.W.; Wang, Q.J.; Liu, C.Y.; Hu, H.N.; Liu, W.Z.; Zhang, Z.Q.; Liu, P.; He, J. Design and Experiment of Anti-vibrating and Anti-wrapping Rotary Components for Subsoiler Cum Rotary Tiller. Int. J. Agric. Biol. Eng. 2019, 12, 47–55. [Google Scholar] [CrossRef]

- Yang, Q.L.; Chen, G.B.; Xie, L.J.; Wang, Q.J.; He, J.; Li, H.W. Design and Experiment of Telescopic Finger Stalk of Maize Straw Burying Machine. Trans. Chin. Soc. Agric. Mach. 2020, 51, 35–45. [Google Scholar]

- Zhang, C.L.; Xia, J.F.; Zheng, J.M.; Zhou, H.; Zhu, Y.H.; Wang, J.W. Design and Experiment of Knife Roller for Six-head Spiral Straw Returning Cultivator. Trans. Chin. Soc. Agric. Mach. 2019, 50, 25–34. [Google Scholar]

- Zheng, K.; Li, Y.F.; Xia, J.F.; Liu, G.Y.; Cheng, J.; Kang, Q.X. Design and Experiment of Land Leveling Blade Roller of Ditching and Rotary Tiller with Gradual Spiral Angle. Trans. Chin. Soc. Agric. Mach. 2021, 52, 63–73. [Google Scholar]

- Matin, M.A.; Desbiolles, J.M.A.; Fielke, J.M. Strip-tillage using Rotating Straight Blades: Effect of Cutting Edge Geometry on Furrow Parameters. Soil Tillage Res. 2016, 155, 271–279. [Google Scholar] [CrossRef]

- Shi, J.Y.; He, R.Y.; Tao, S.K.; Xu, G.M.; Fan, C.; Ding, Q.S. Design and Operation Parameter Optimization of Plowing-Rotary-Leveling Compound Tiller; Nanjing Agricultural University: Nanjing, China, 2024. [Google Scholar]

- Qin, K.; Ding, W.M.; Fang, Z.C.; Du, T.T.; Zhao, S.Q.; Wang, Z. Analysis and Experiment of Tillage Depth and Width Stability for Plowing and Rotary Tillage Combined Machine. Trans. Chin. Soc. Agric. Eng. 2016, 32, 1–8. [Google Scholar]

- Li, B.F. Agricultural Mechanics; China Agricultural Press: Beijing, China, 2017. [Google Scholar]

- Yang, Y.W.; Tong, J.; Ma, Y.H.; Jiang, X.H.; Li, J.G. Design and Experiment of Biomimetic Rotary Tillage Blade Based on Multiple Claws Characteristics of Mole Rats. Trans. Chin. Soc. Agric. Eng. 2019, 35, 37–45. [Google Scholar]

- Yang, Y.; Hu, Z.; Gu, F.; Ding, Q. Simulation and Experimental Study of the Tillage Mechanism for the Optimal Design of Wheat Rotary Strip–Tiller Blades. Agriculture 2023, 13, 632. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, L.; Hu, X.; Wang, H.; Shi, X.; Ma, X. Simulation of Soil Cutting and Power Consumption Optimization of a Typical Rotary Tillage Soil Blade. Appl. Sci. 2022, 12, 8177. [Google Scholar] [CrossRef]

- GB T5669-2017; Rotary Tiller—Rotary Blades and Blade Holders. National Technical Committee for Standardization of Agricultural Machinery: Beijing, China, 2017.

- GB T5668-2017; Rotary Tiller. Standardization Administration of China: Beijing, China, 2017.

- Zhai, S.; Shi, Y.; Zhou, J.; Liu, J.; Huang, D.; Zou, A.; Jiang, P. Simulation Optimization and Experimental Study of the Working Performance of a Vertical Rotary Tiller Based on the Discrete Element Method. Actuators 2022, 11, 342. [Google Scholar] [CrossRef]

- Zhao, J.G.; Wang, A.; Ma, Y.J.; Li, J.C.; Hao, J.J.; Nie, Q.L.; Long, S.F.; Yang, Q.F. Design and Test of Soil Preparation Machine Combined Subsoiling, Rotary Tillage and Soil Breaking. Trans. Chin. Soc. Agric. Eng. 2019, 35, 46–54. [Google Scholar]

- Xiao, M.H.; Niu, Y.; Wang, K.X.; Zhou, J.B.; Ma, R.Q. Design of Self-excited Vibrating Rotary Tiller and Analysis of Its Performance in Reducing Torsion and Consumption. Trans. Chin. Soc. Agric. Mach. 2022, 53, 52–63. [Google Scholar]

- Guo, L.; Fang, Q.M.; Li, M.F.; Wang, Z.; Wang, C.; Zhang, L.Y. Parameter Calibration for Discrete Element Simulation of Red Clay Soils in Sloping Cropland in Central Yunnan. Trans. Chin. Soc. Agric. Mach. 2024, 55, 185–193+285. [Google Scholar]

- Adajar, J.B.; Alfaro, M.; Chen, Y.; Zeng, Z.W. Calibration of discrete element parameters of crop residues and their interfaces with soil. Comput. Electron. Agric. 2021, 188, 106349. [Google Scholar] [CrossRef]

- Mak, J.; Chen, Y.; Sadek, M.A. Determining Parameters of a Discrete Element Model for Soil–tool Interaction. Soil Tillage Res. 2012, 118, 117–122. [Google Scholar] [CrossRef]

- Wu, Z.Y.; Wang, X.S.; Liu, D.W.; Xie, F.P.; Ashwehmbom, L.G.; Zhang, Z.Z.; Tang, Q.J. Calibration of Discrete Element Parameters and Experimental Verification for Modelling Subsurface Soils. Biosyst. Eng. 2021, 212, 215–227. [Google Scholar] [CrossRef]

- Sun, J.B.; Liu, Q.; Yang, F.Z.; Liu, Z.J.; Wang, Z. Calibration of Discrete Element Simulation Parameters of Sloping Soil on Loess Plateau and Its Interaction with Rotary Tillage Components. Trans. Chin. Soc. Agric. Mach. 2022, 53, 63–73. [Google Scholar]

- Wang, D.W.; Lu, T.; Zhao, Z.; Shang, S.Q.; Zheng, S.; Liu, J. Calibration of Discrete Element Simulation Parameters for Cultivated Soil Layer in Coastal Saline alkali Soil. Trans. Chin. Soc. Agric. Mach. 2024, 55, 240–249. [Google Scholar]

- Liu, M.; Wang, J.; Feng, W.; Jing, H.; Wang, Y.; Guo, Y.; Xu, T. Calibration of Model Parameters for Soda Saline Soil-Subsoiling Component Interaction Based on DEM. Appl. Sci. 2023, 13, 11596. [Google Scholar] [CrossRef]

- Li, M.L.; Wang, L.Z.; Liao, Q.X.; Liao, Y.T.; Xiao, W.L.; Zhang, Q.S. Calibration of Rototilled Soil Discrete Element Parameters after Rotary Tillage in the Preparation Process of Rapeseed Mechanized Direct Seeding Micro-ridge Seed Bed. Trans. Chin. Soc. Agric. Eng. 2023, 39, 10–19. [Google Scholar]

- Xiang, W.; Wu, M.L.; Lü, J.N.; Quan, W.; Ma, L.; Liu, J.J. Calibration of Simulation Physical Parameters of Clay Loam Based on Soil Accumulation Test. Trans. Chin. Soc. Agric. Eng. 2019, 35, 116–123. [Google Scholar]

- Li, J.W.; Tong, J.; Hu, B.; Wang, H.B.; Mao, C.Y.; Ma, Y.H. Calibration of Parameters of Interaction between Clayey Black Soil with Different Moisture Content and Soil-engaging Component in Northeast China. Trans. Chin. Soc. Agric. Eng. 2019, 35, 130–140. [Google Scholar]

- Siddique, M.A.A.; Baek, S.-Y.; Baek, S.-M.; Jeon, H.-H.; Lee, J.-H.; Son, M.-A.; Yoon, S.-Y.; Kim, Y.-J.; Lim, R.-G. The Selection of an Energy-Saving Engine Mode Based on the Power Delivery and Fuel Consumption of a 95 kW Tractor during Rotary Tillage. Agriculture 2023, 13, 1376. [Google Scholar] [CrossRef]

- Tian, Y.; Jin, L.; Liu, X.W.; Zhao, Y.X. Model Analysis of the Assembly of Spindle and Straight Tooth Bevel Gear Based on Ansys Workbench. J. Chin. Agric. Mech. 2015, 36, 6–8. [Google Scholar]

- Sun, Y.T.; Tian, G.F.; Fu, Y.B. Research on Contact Performance of Spiral Bevel Gear Based on Finite Element Method. J. Mach. Des. 2023, 40, 62–67. [Google Scholar]

- Wang, J.Z. Transient Dynamics Analysis of Straight Bevel Gear Mechanisms. J. South. Agric. Mach. 2023, 54, 133–135+156. [Google Scholar]

- NY/T499-2013; Operating Quality for Rotary Tillers. Ministry of Agriculture of the People’s Republic of China: Beijing, China, 2013.

- Guan, C.S.; Cui, Z.C.; Gao, Q.S.; Wang, S.L.; Chen, Y.S.; Yang, Y.T. Design of Biaxial Rotary Tillage Soil Test Bench and Layered Tillage Test. Trans. Chin. Soc. Agric. Eng. 2021, 3, 28–37. [Google Scholar]

- Wang, J.F.; Yang, D.Z.; Fu, Z.D.; Wang, J.W.; Weng, W.X. Design and Experiment of Rice Straw Biaxial Deep-buried Returning Machine. Trans. Chin. Soc. Agric. Mach. 2023, 54, 21–30. [Google Scholar]

- Chinese Academy of Agricultural Mechanization Sciences. Agricultural Machinery Design Manual (Part 1); China Agricul-tural Machinery Press: Beijing, China, 2007. [Google Scholar]

- Zheng, H.H.; Du, N.; Wei, C.B.; Zhang, C.; Xu, Y. Mechanical Tillage Efficiency of Land Consolidation Based on Plot Area and Shape Trans. Chin. Soc. Agric. Mach. 2024, 55, 232–240+259. [Google Scholar]

- Hao, J.J.; Zhan, Z.G.; Hou, J.Y.; Zhao, J.G.; Liu, J.C.; Yin, C.F. Preparation and Microstructure Properties of Fe/WC/CeO2 Plasma Surfacing Layer for Rotary Blades. Chin. Soc. Agric. Eng. 2021, 37, 1–8. [Google Scholar]

| Material | Soil | 65 Mn |

|---|---|---|

| Density/(kg·m−3) | 2.27 × 103 | 7.865 × 103 |

| Poisson’s ratio | 0.32 | 0.30 |

| Shear modulus/Pa | 1.25 × 106 | 7.90 × 109 |

| Parametric | Numerical Value |

|---|---|

| Soil–soil recovery factor | 0.35 |

| Soil–soil static friction factor | 0.5 |

| Soil–soil rolling-friction factor | 0.15 |

| Soil–steel recovery factor | 0.3 |

| Soil–steel static friction factor | 0.5 |

| Soil–steel rolling friction factor | 0.15 |

| Normal rigidity/N·m−3 | 5 × 108 |

| Tangential rigidity/N·m−3 | 5 × 108 |

| Critical normal stress/Pa | 3 × 106 |

| Critical tangential stress/Pa | 3 × 106 |

| Encoding | Knife Roller Speed/r·min | Tillage Depth/cm | Machine Forward Speed/km·h |

|---|---|---|---|

| −1.68 | 150 | 10 | 4 |

| −1 | 191 | 10.8 | 4.8 |

| 0 | 250 | 12 | 6 |

| 1 | 309 | 13.2 | 7.2 |

| 1.68 | 350 | 14 | 8 |

| Serial Number | Factor | Soil-Breaking Rate Y1/% | Land Surface Flatness Y2/mm | ||

|---|---|---|---|---|---|

| A/r·min | B/cm | C/km·h | |||

| 1 | −1 | −1 | −1 | 87.3 | 22.4 |

| 2 | 1 | −1 | −1 | 90.1 | 21.8 |

| 3 | −1 | 1 | −1 | 78.7 | 32.4 |

| 4 | 1 | 1 | −1 | 91.2 | 19.1 |

| 5 | −1 | −1 | 1 | 69.4 | 44.6 |

| 6 | 1 | −1 | 1 | 78.1 | 39.2 |

| 7 | −1 | 1 | 1 | 67.4 | 48.6 |

| 8 | 1 | 1 | 1 | 84.9 | 26.8 |

| 9 | −1.68 | 0 | 0 | 66.7 | 47.9 |

| 10 | 1.68 | 0 | 0 | 83.4 | 25.6 |

| 11 | 0 | −1.68 | 0 | 87.5 | 29.4 |

| 12 | 0 | 1.68 | 0 | 86.3 | 26.6 |

| 13 | 0 | 0 | −1.68 | 93.4 | 15.2 |

| 14 | 0 | 0 | 1.68 | 72.6 | 44.6 |

| 15 | 0 | 0 | 0 | 83.4 | 24.8 |

| 16 | 0 | 0 | 0 | 86.2 | 26.5 |

| 17 | 0 | 0 | 0 | 84.6 | 25.1 |

| 18 | 0 | 0 | 0 | 82.6 | 22.3 |

| 19 | 0 | 0 | 0 | 88.4 | 21.5 |

| 20 | 0 | 0 | 0 | 85.1 | 24.8 |

| Source | Sum of Squares | Freedom | Mean Square | F | p-Value |

|---|---|---|---|---|---|

| Model | 1139.57 | 9 | 126.62 | 55.22 | <0.0001 ** |

| A | 354.56 | 1 | 354.56 | 154.62 | <0.0001 ** |

| B | 1.63 | 1 | 1.63 | 0.7108 | 0.4189 |

| C | 498.15 | 1 | 498.15 | 217.24 | <0.0001 ** |

| AB | 42.78 | 1 | 42.78 | 18.66 | 0.0015 ** |

| AC | 14.85 | 1 | 14.85 | 6.48 | 0.0291 * |

| BC | 18.91 | 1 | 18.91 | 8.25 | 0.0166 * |

| A2 | 192.30 | 1 | 192.30 | 83.86 | <0.0001 ** |

| B2 | 4.15 | 1 | 4.15 | 1.81 | 0.2082 |

| C2 | 10.22 | 1 | 10.22 | 4.46 | 0.0609 |

| Residual | 22.93 | 10 | 2.29 | ||

| Lack of Fit | 1.46 | 5 | 0.2912 | 0.0678 | 0.9949 |

| Pure Error | 21.48 | 5 | 4.30 | ||

| Cor Total | 1162.51 | 19 |

| Source | Sum of Squares | Freedom | Mean Square | F | p-Value |

|---|---|---|---|---|---|

| Model | 1872.91 | 9 | 208.10 | 68.00 | <0.0001 ** |

| A | 452.42 | 1 | 452.42 | 147.84 | <0.0001 ** |

| B | 2.47 | 1 | 2.47 | 0.8075 | 0.3900 |

| C | 934.07 | 1 | 934.07 | 305.24 | <0.0001 ** |

| AB | 105.85 | 1 | 105.85 | 34.59 | 0.0002 ** |

| AC | 22.11 | 1 | 22.11 | 7.23 | 0.0228 * |

| BC | 30.81 | 1 | 30.81 | 10.07 | 0.0099 ** |

| A2 | 281.58 | 1 | 281.58 | 92.02 | <0.0001 ** |

| B2 | 25.37 | 1 | 25.37 | 8.29 | 0.0164 * |

| C2 | 57.56 | 1 | 57.56 | 18.81 | 0.0015 ** |

| Residual | 30.60 | 10 | 3.06 | ||

| Lack of Fit | 12.89 | 5 | 2.58 | 0.7276 | 0.6322 |

| Pure Error | 17.71 | 5 | 3.54 | ||

| Cor Total | 1903.51 | 19 |

| Measurement Item | Argument |

|---|---|

| Test plot area/hm2 | 2.34 |

| Soil moisture content/% | 23.6 |

| Volume weight of soil/(g·cm−3) | 1.92 |

| Soil compactness/N Soil pH value | 249.6 7.8 |

| Average weed height/cm | 10–15 |

| Test Indicator | High-Speed Rotary Tiller | Ordinary Rotary Tiller |

|---|---|---|

| Forward speed/km·h Tillage depth/cm | 4.8 14.2 | 3.5 10.5 |

| Tillage depth stability factor/% | 92.8 | 82.8 |

| Soil-breaking rate/% | 89.3 | 79.4 |

| Vegetation cover rate/% | 90.3 | 81.2 |

| Land surface flatness/mm | 16.4 | 34.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, S.; Lu, T.; Liu, J.; Tian, Y.; Han, M.; Tai, M.; Gao, S.; Liu, T.; Wang, D.; Zhao, Z. Discrete Element-Based Design of a High-Speed Rotary Tiller for Saline-Alkali Land and Verification of Optimal Tillage Parameters. Agriculture 2025, 15, 269. https://doi.org/10.3390/agriculture15030269

Zheng S, Lu T, Liu J, Tian Y, Han M, Tai M, Gao S, Liu T, Wang D, Zhao Z. Discrete Element-Based Design of a High-Speed Rotary Tiller for Saline-Alkali Land and Verification of Optimal Tillage Parameters. Agriculture. 2025; 15(3):269. https://doi.org/10.3390/agriculture15030269

Chicago/Turabian StyleZheng, Shuai, Tong Lu, Jie Liu, Yu Tian, Miaomiao Han, Muhao Tai, Shuqi Gao, Tao Liu, Dongwei Wang, and Zhuang Zhao. 2025. "Discrete Element-Based Design of a High-Speed Rotary Tiller for Saline-Alkali Land and Verification of Optimal Tillage Parameters" Agriculture 15, no. 3: 269. https://doi.org/10.3390/agriculture15030269

APA StyleZheng, S., Lu, T., Liu, J., Tian, Y., Han, M., Tai, M., Gao, S., Liu, T., Wang, D., & Zhao, Z. (2025). Discrete Element-Based Design of a High-Speed Rotary Tiller for Saline-Alkali Land and Verification of Optimal Tillage Parameters. Agriculture, 15(3), 269. https://doi.org/10.3390/agriculture15030269