Optimization of Rotary Blade Wear and Tillage Resistance Based on DEM-MBD Coupling Model

Abstract

:1. Introduction

2. Materials and Methods

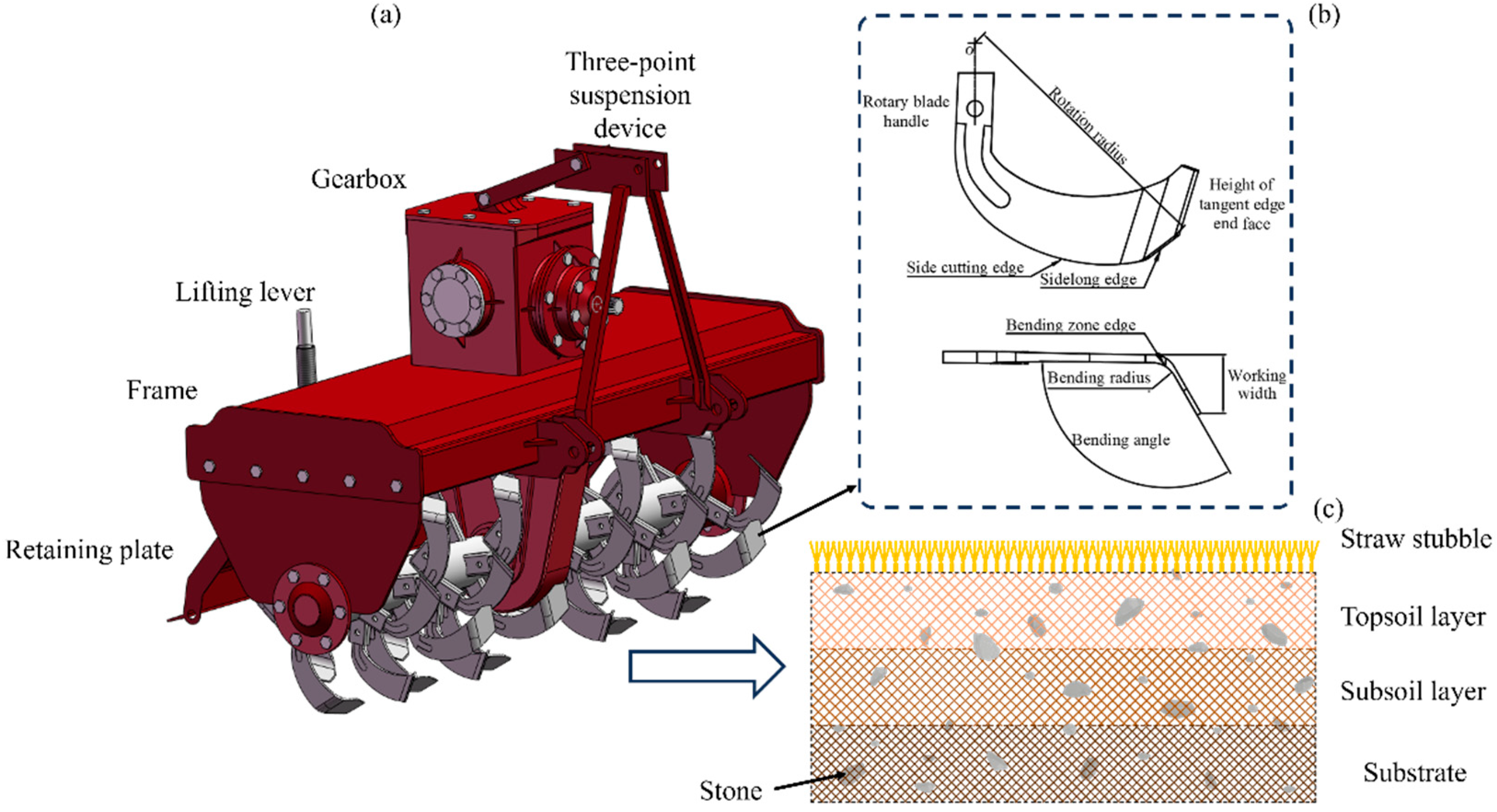

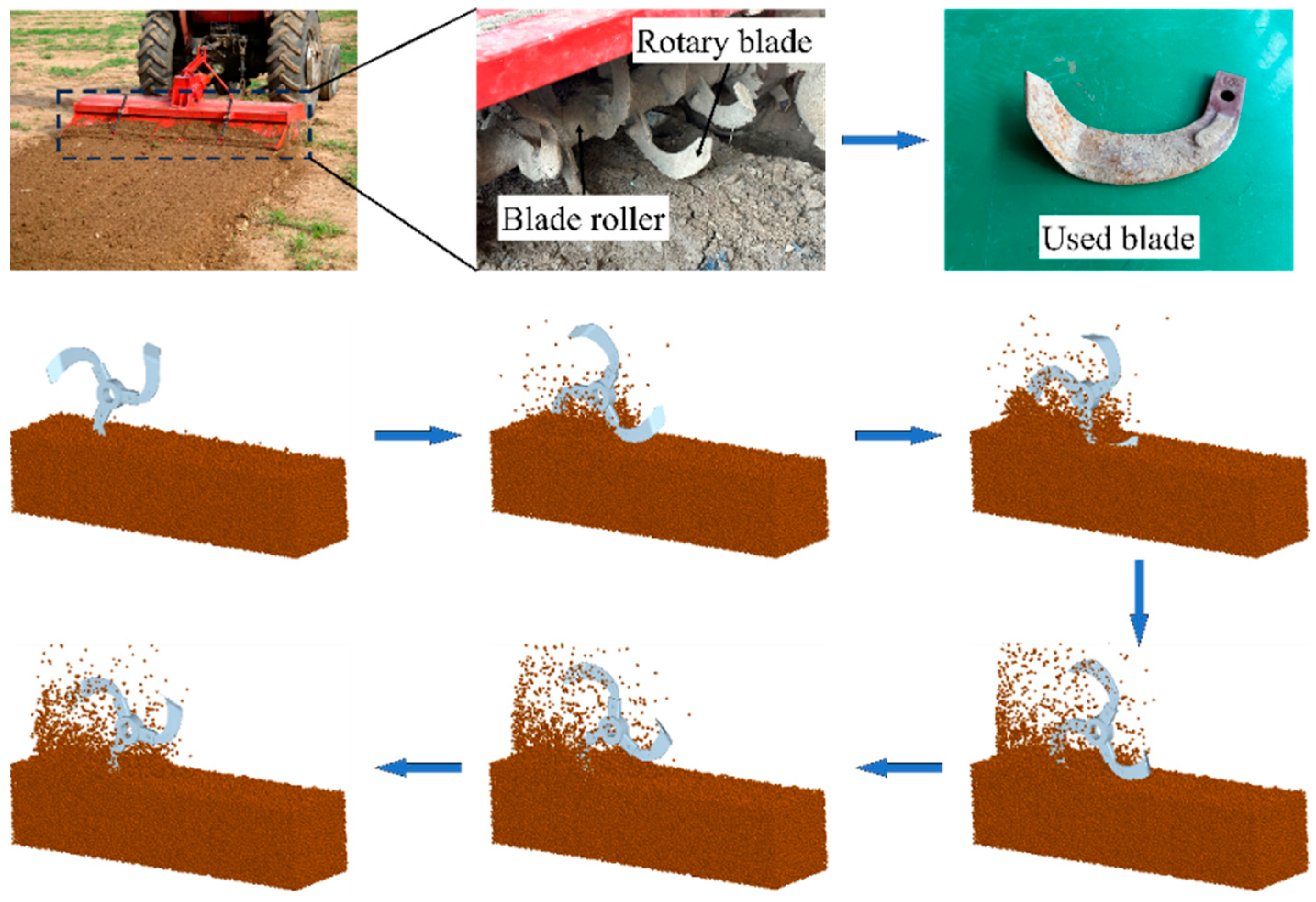

2.1. The Structure and Working Principle of the Blade Roller

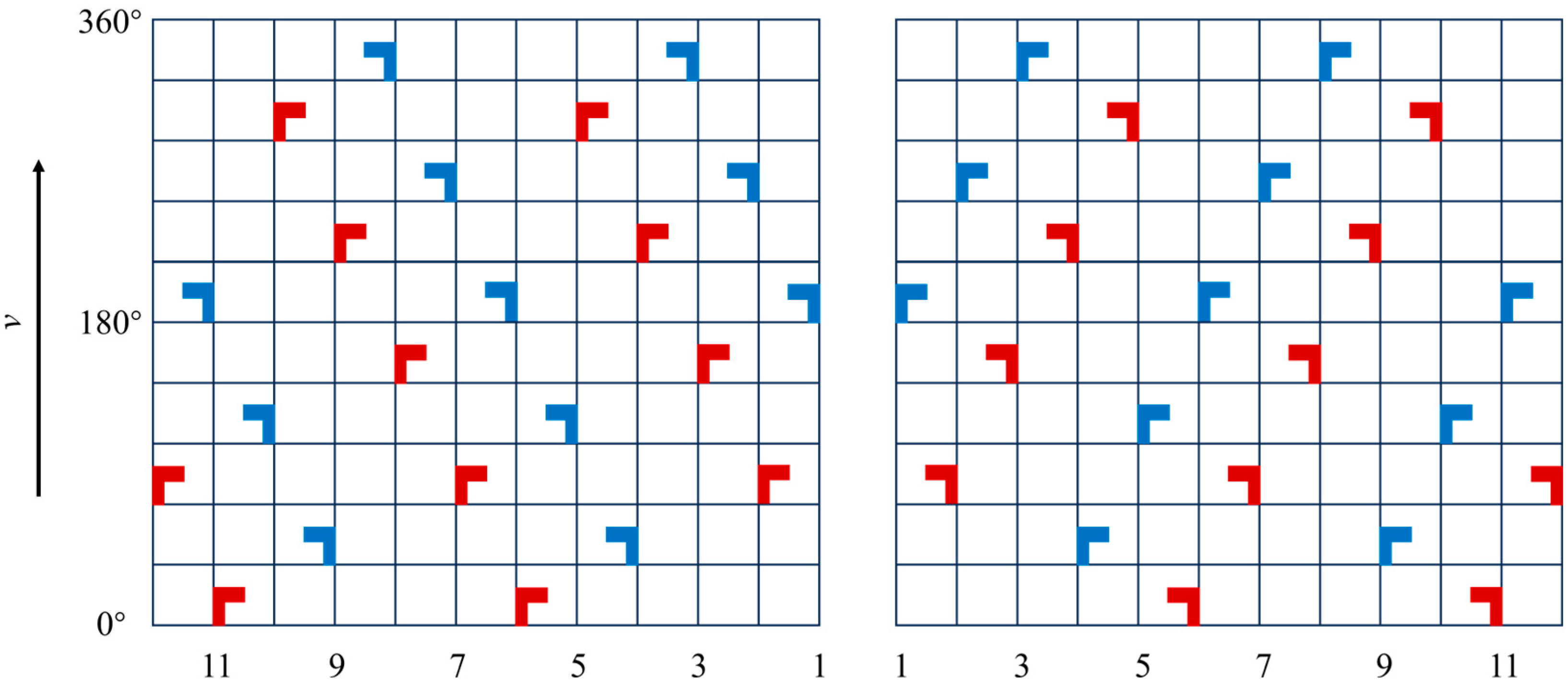

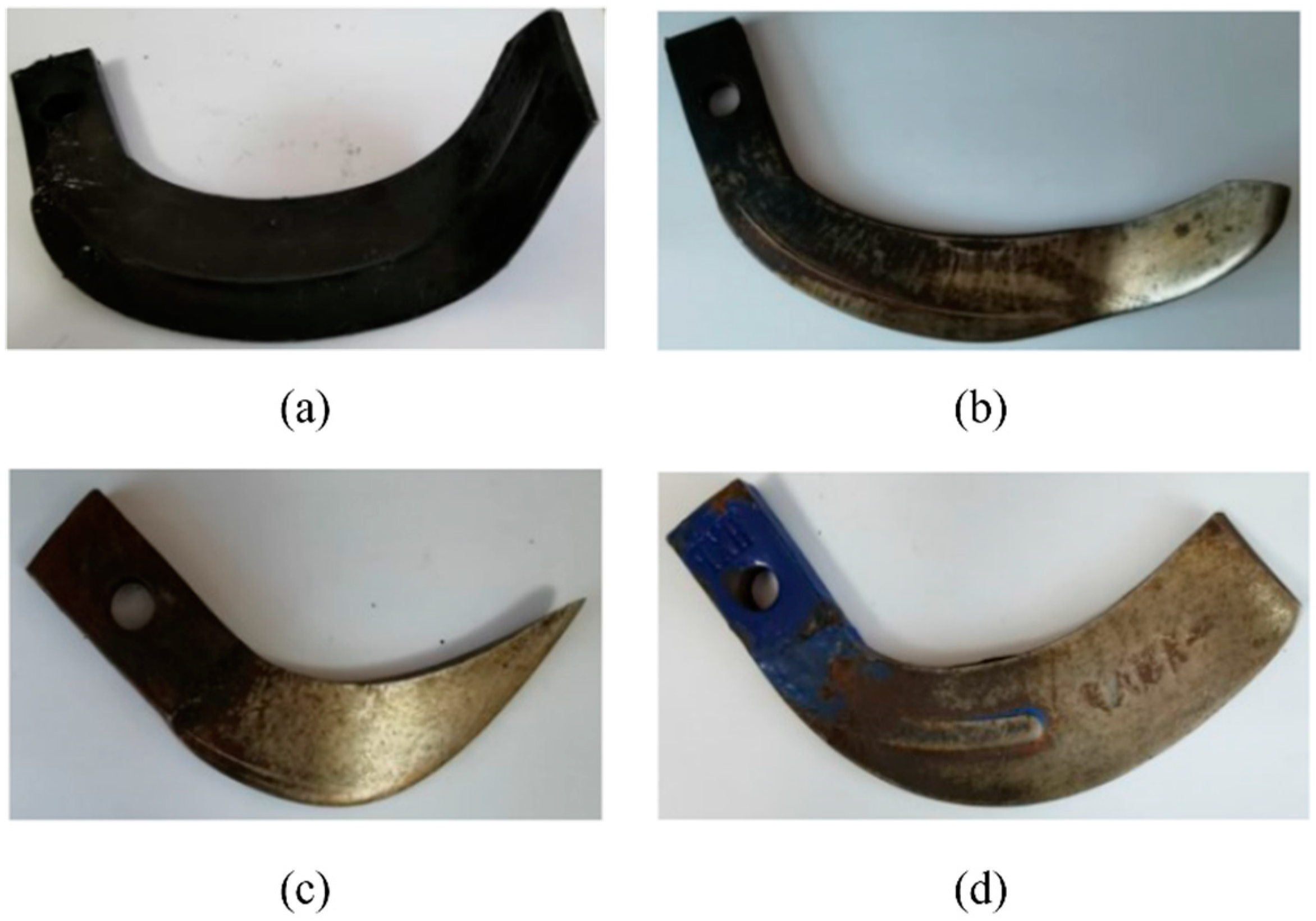

2.2. Model and Arrangement of the Rotary Blade

2.3. Analysis of Dynamics and Wear Mechanism of the Rotary Blade

2.3.1. Motion Trajectory of the Rotary Blade

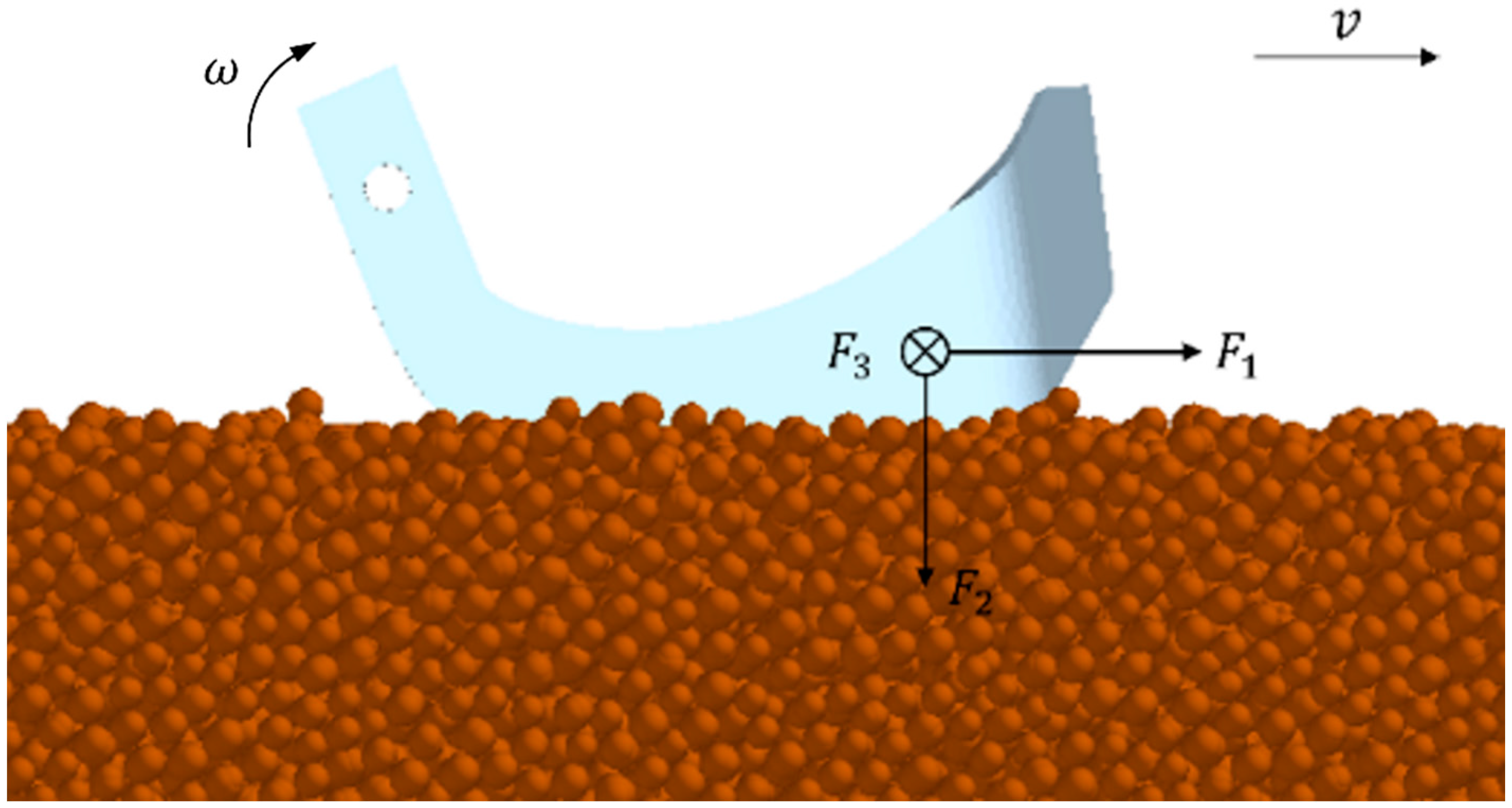

2.3.2. Force Analysis of the Rotary Blade

2.3.3. Mechanism of Rotary Blade Wear Loss

2.4. Rotary Blade–Soil Coupling Simulation Model

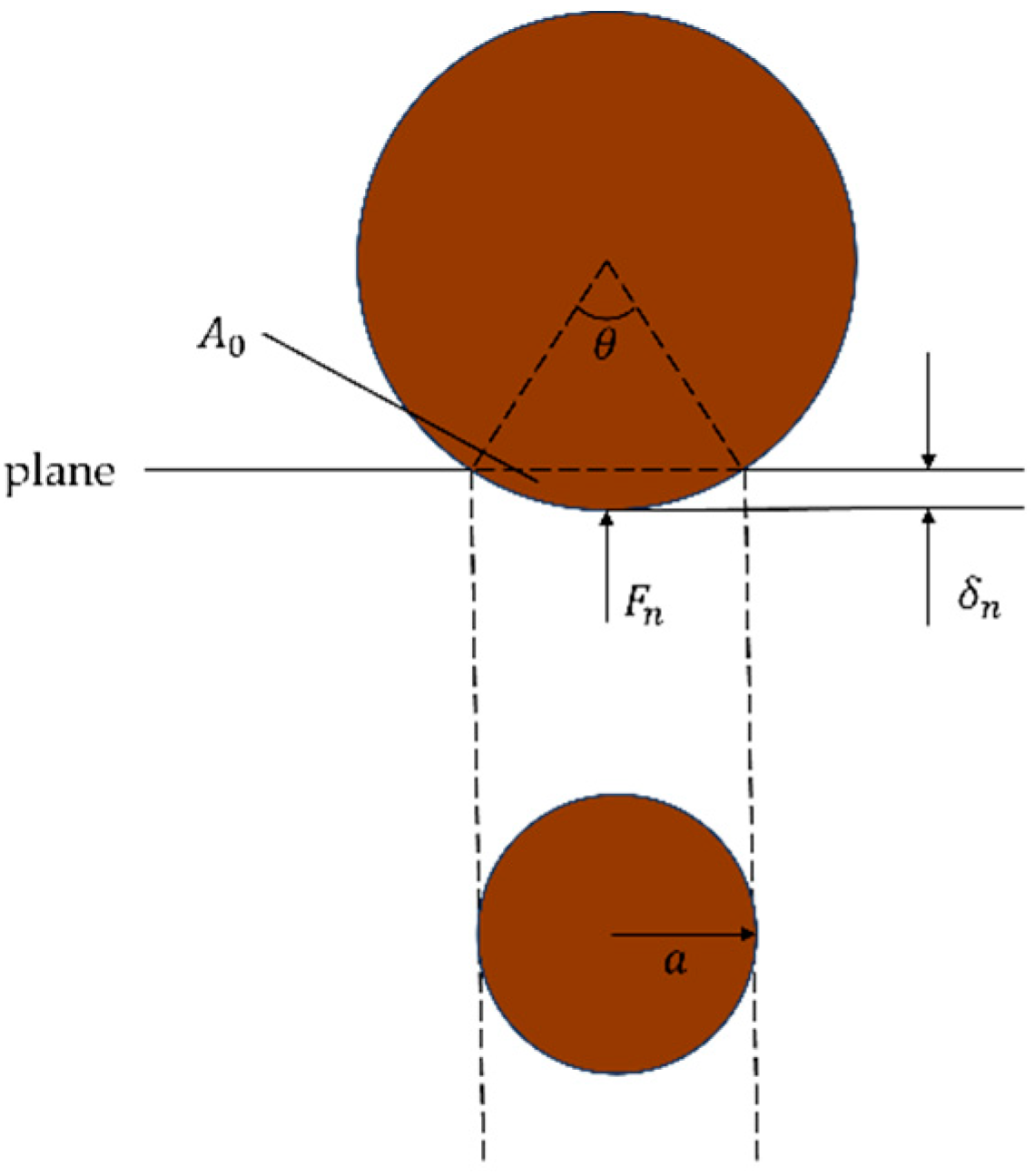

2.4.1. Soil Contact Modeling

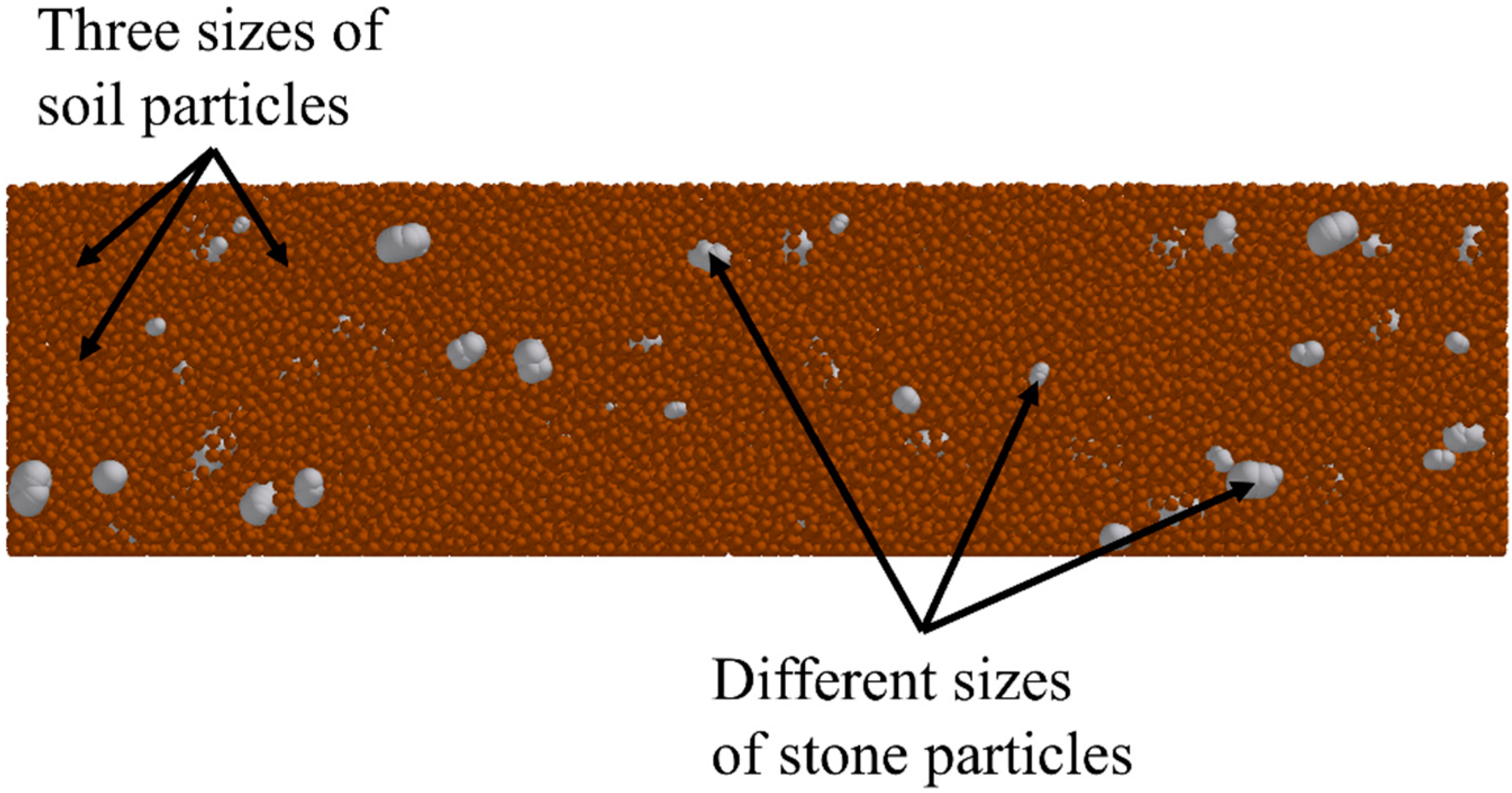

2.4.2. Soil Trough Model

2.4.3. EDEM-RecurDyn Coupling Model

2.5. Simulation Analysis of the Original Rotary Blade

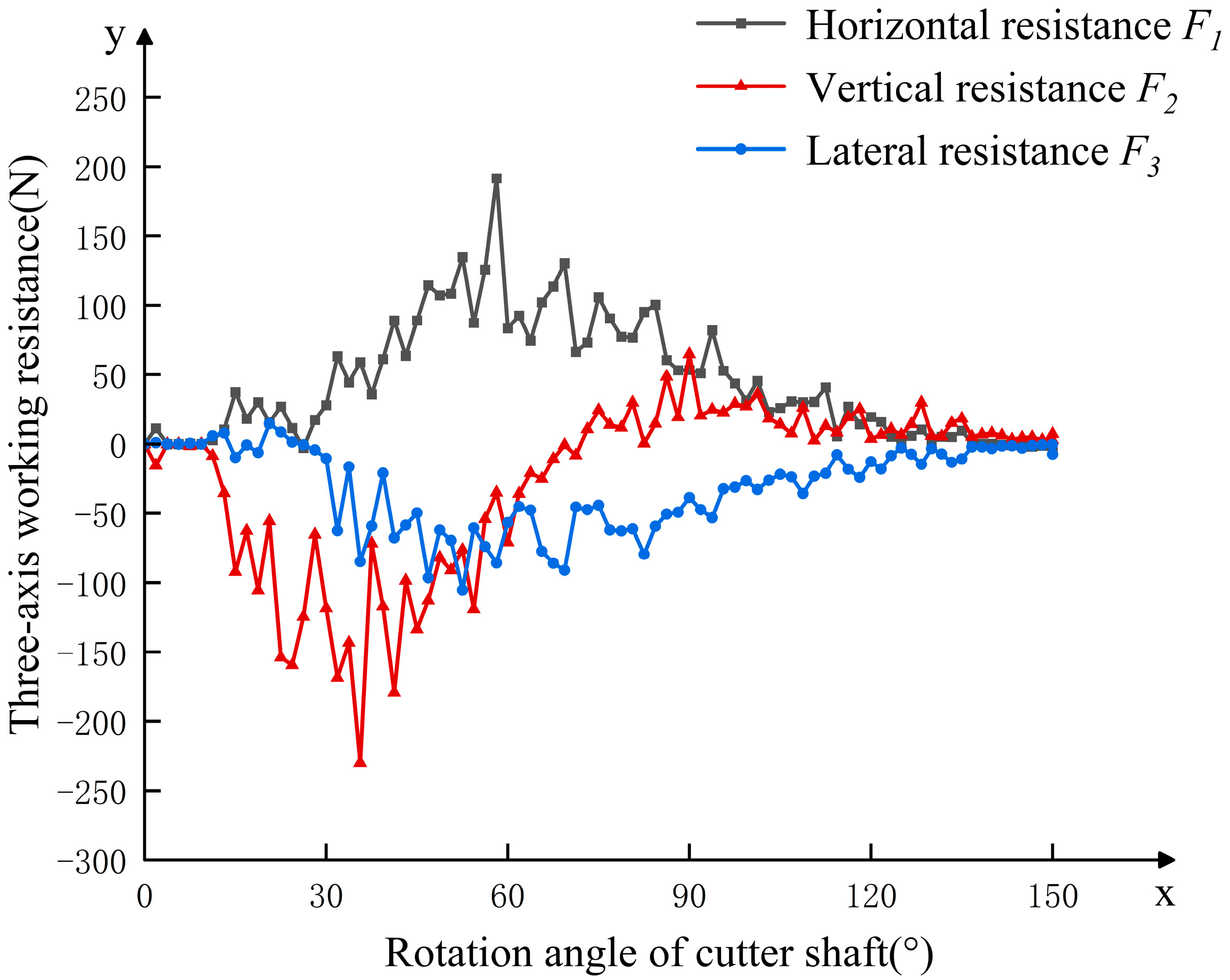

2.5.1. Resistance Analysis of the Rotary Blade

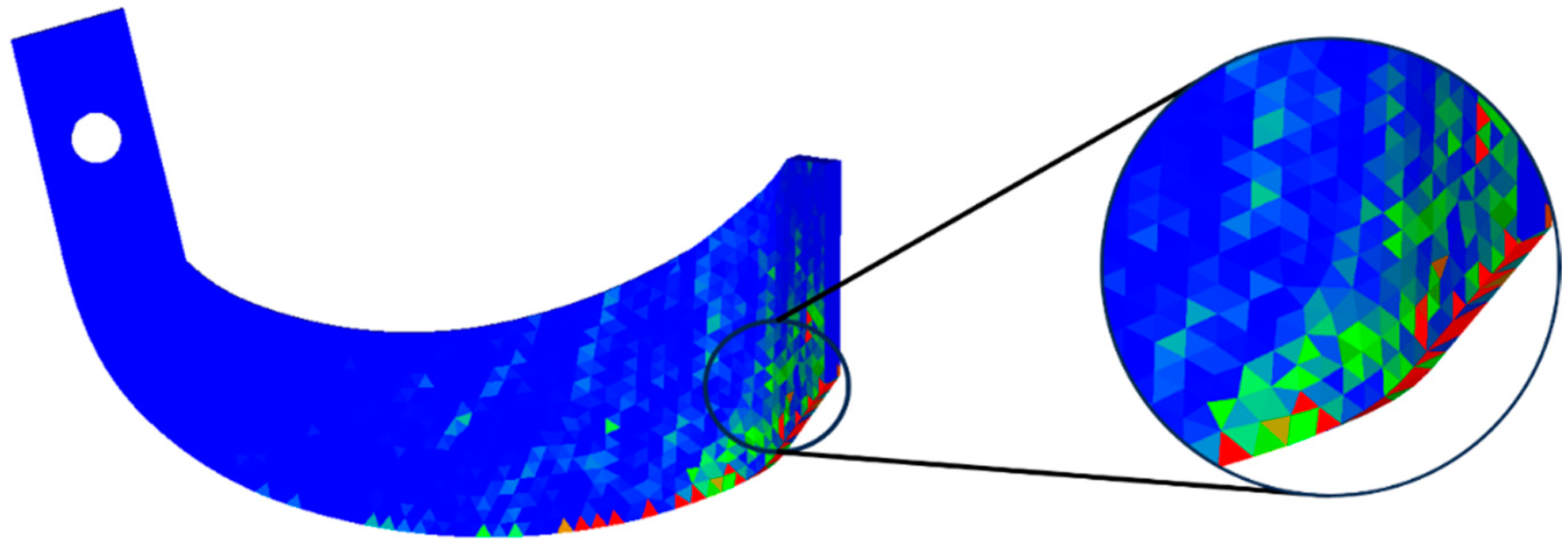

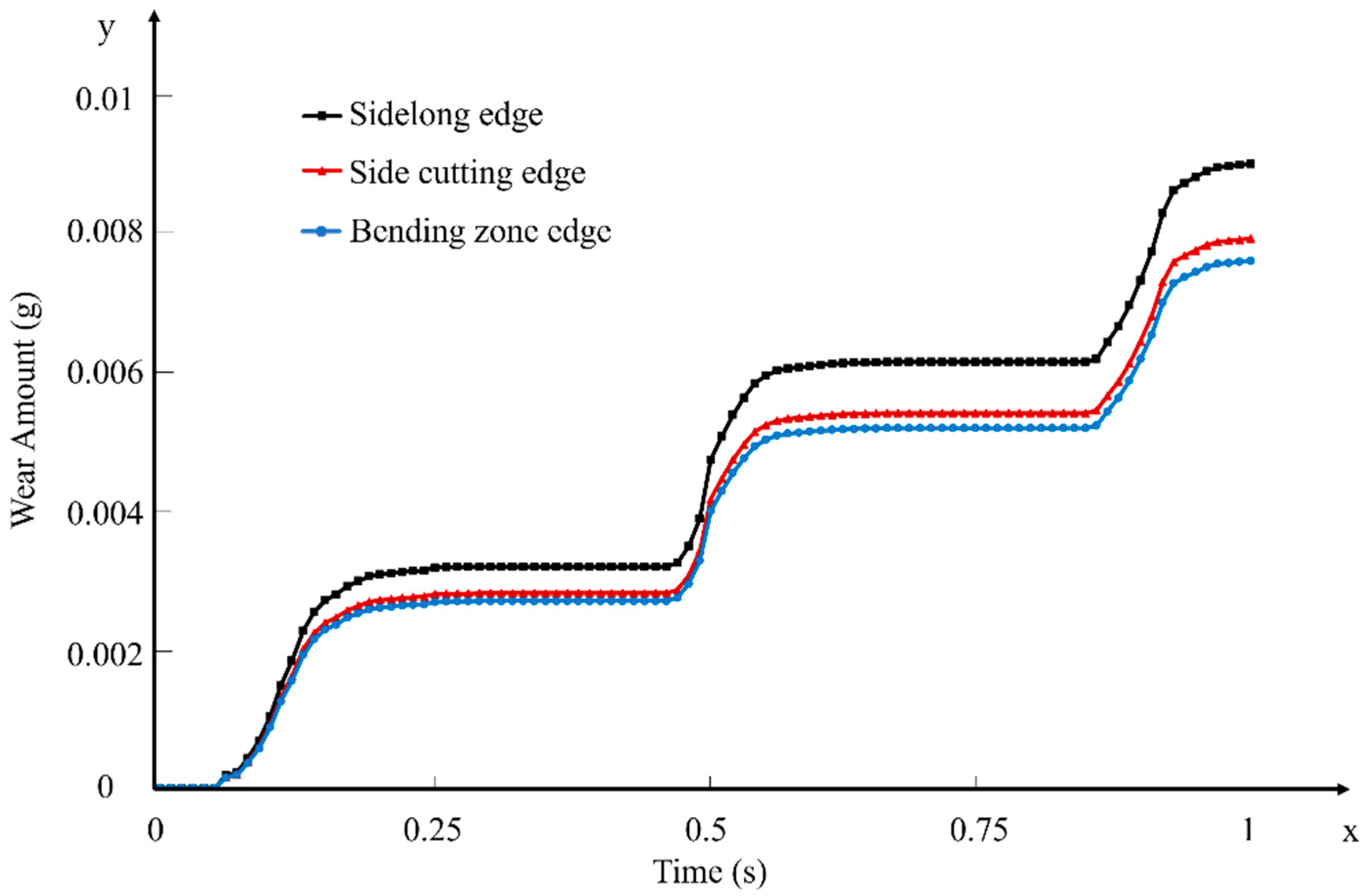

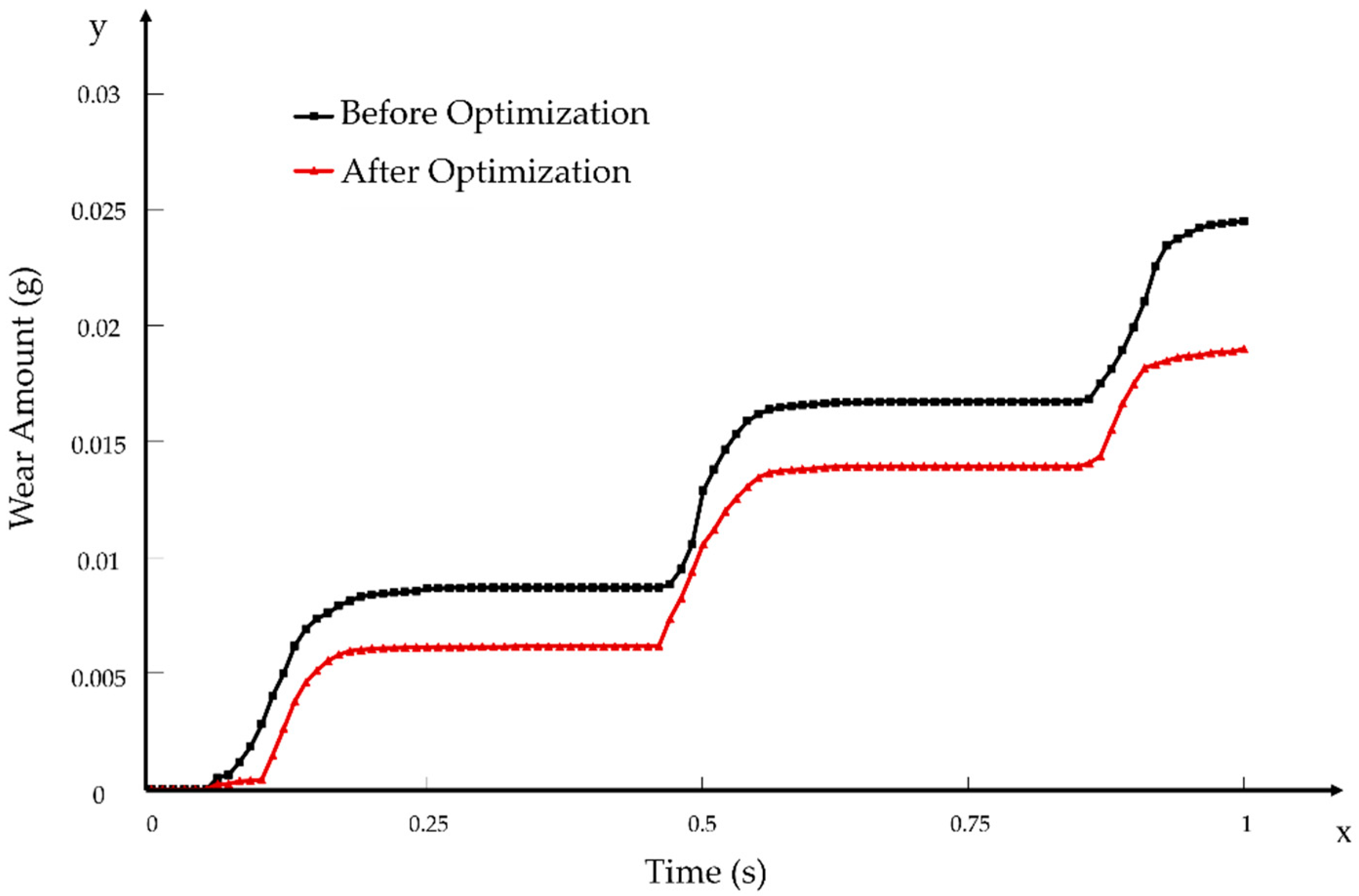

2.5.2. Wear Analysis of Rotary Blade

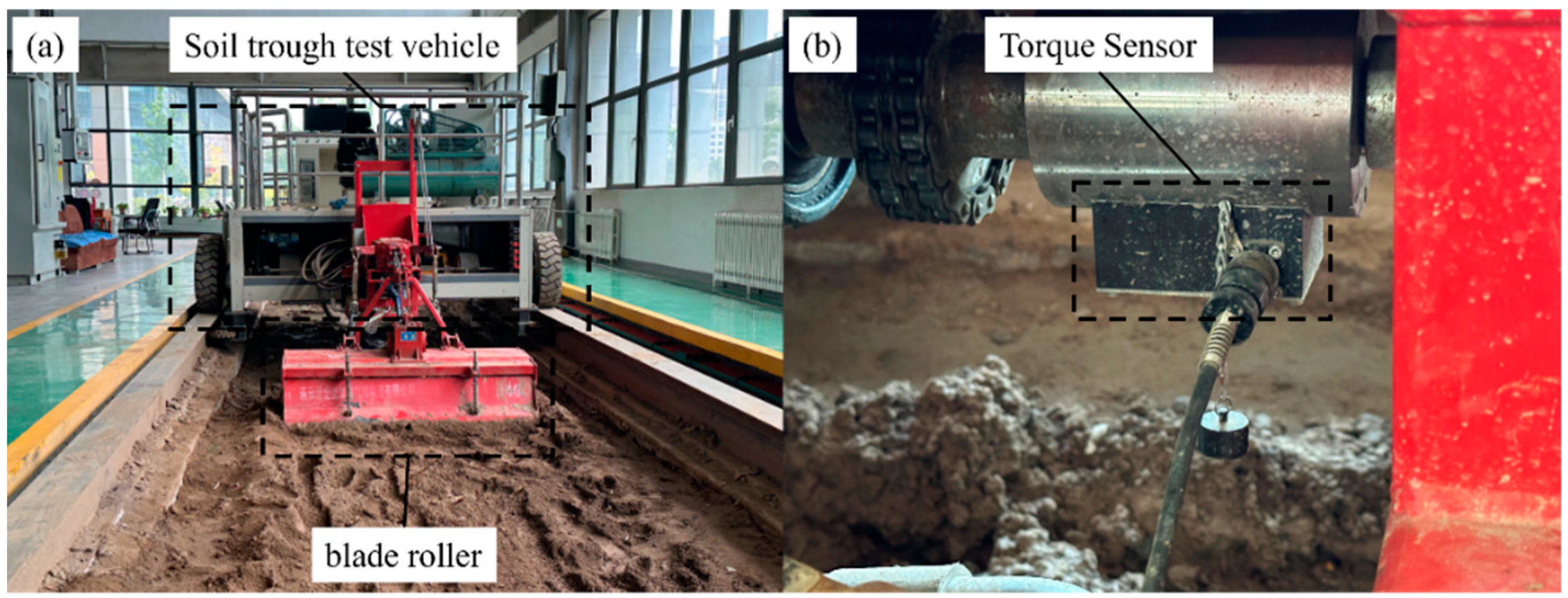

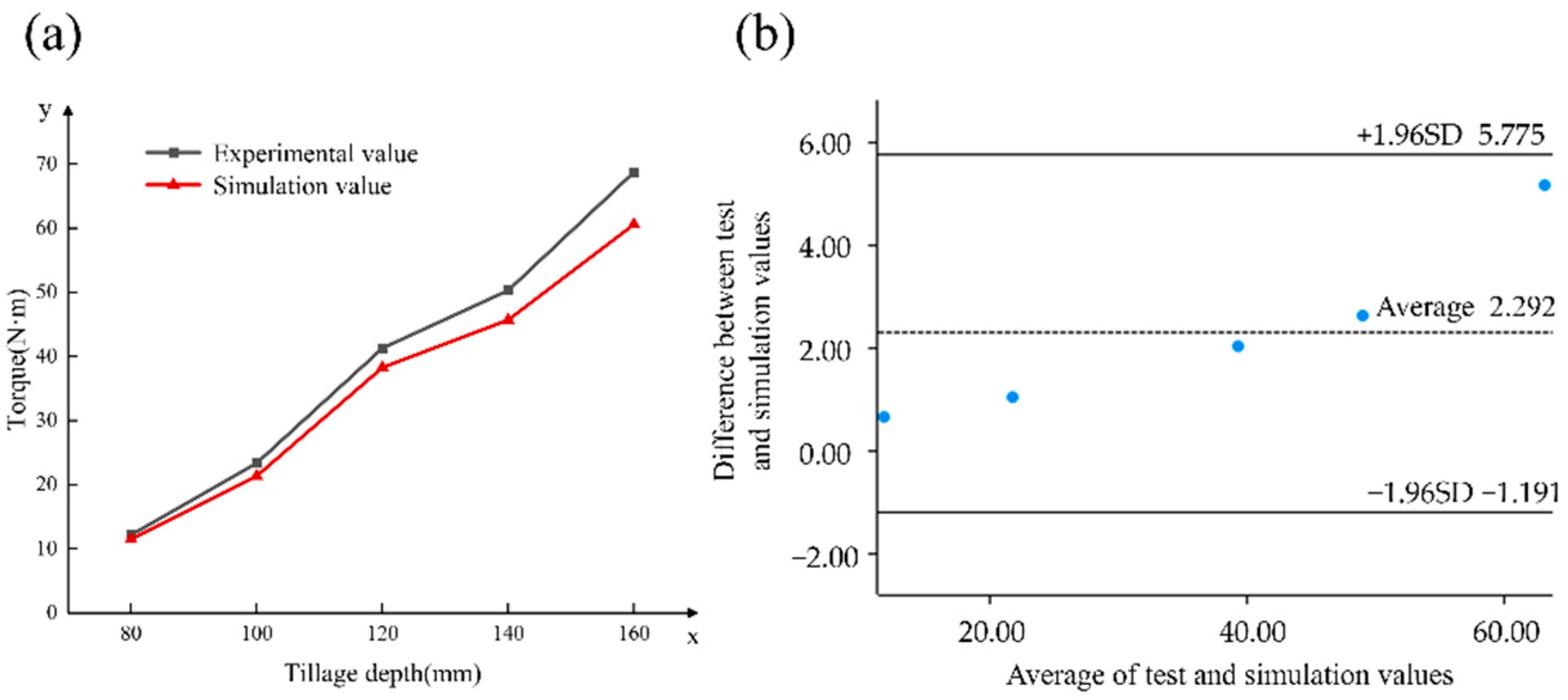

2.6. Simulation Model Validation

2.7. Optimized Design of Rotary Blades

3. Results and Discussion

3.1. Analytical Results of the Central Composite Design

3.1.1. Analysis of Variance for Parameter Optimization

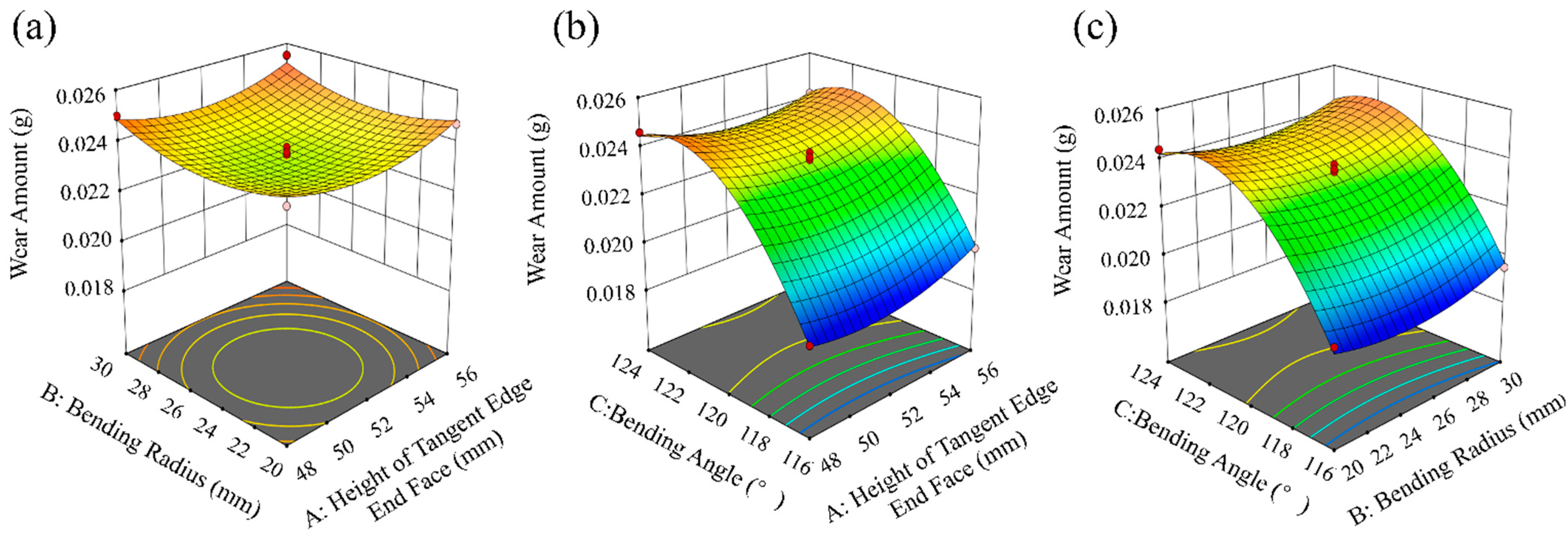

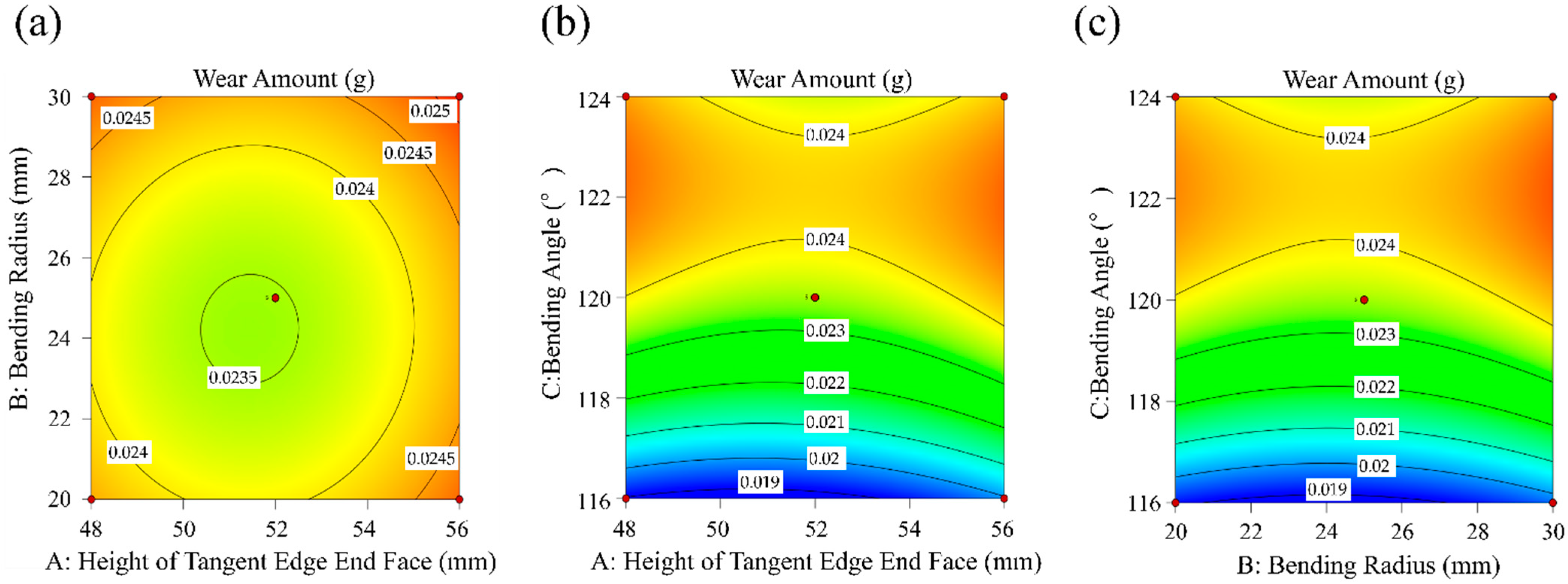

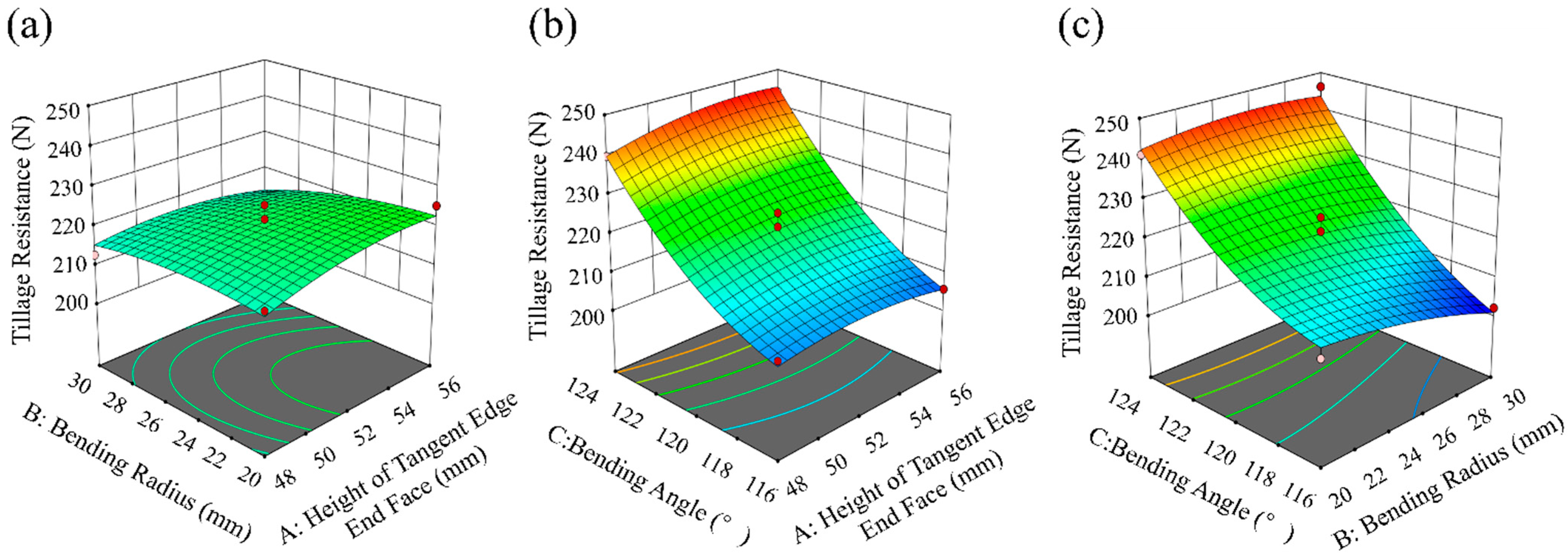

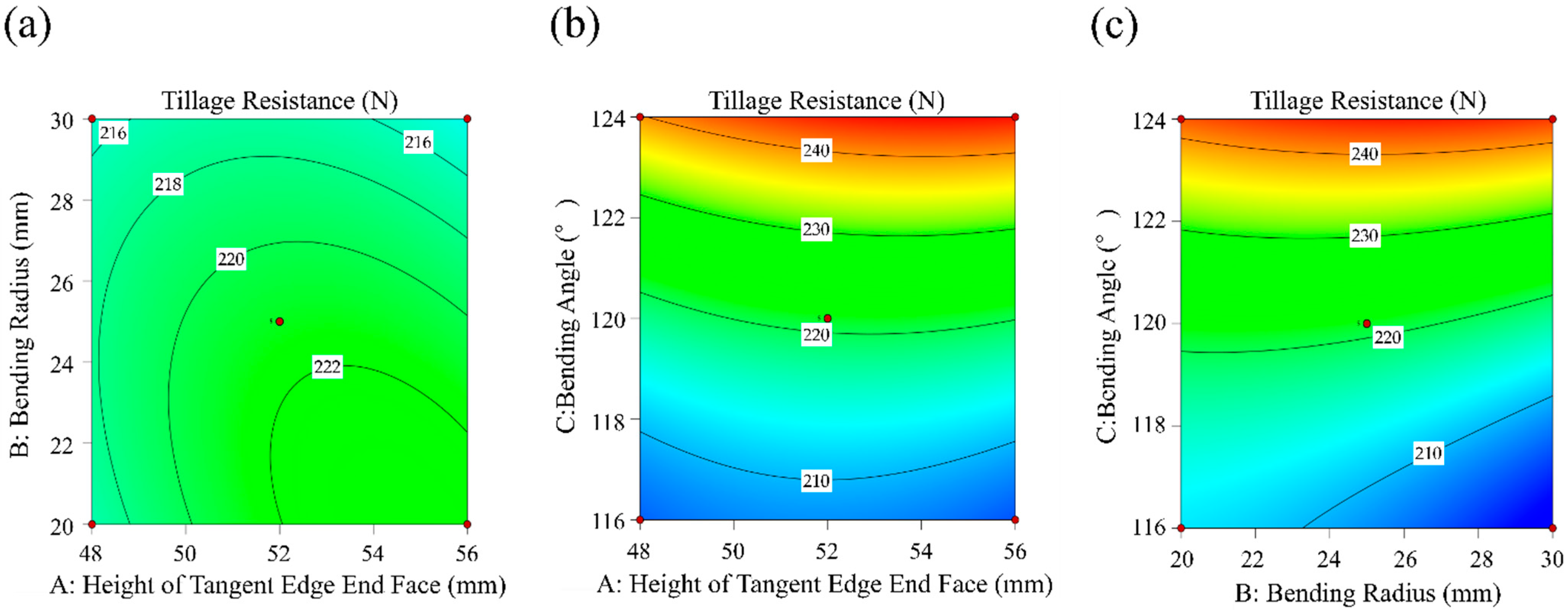

3.1.2. Analysis of Response Surfaces and Contour Caps for Different Evaluation Indexes

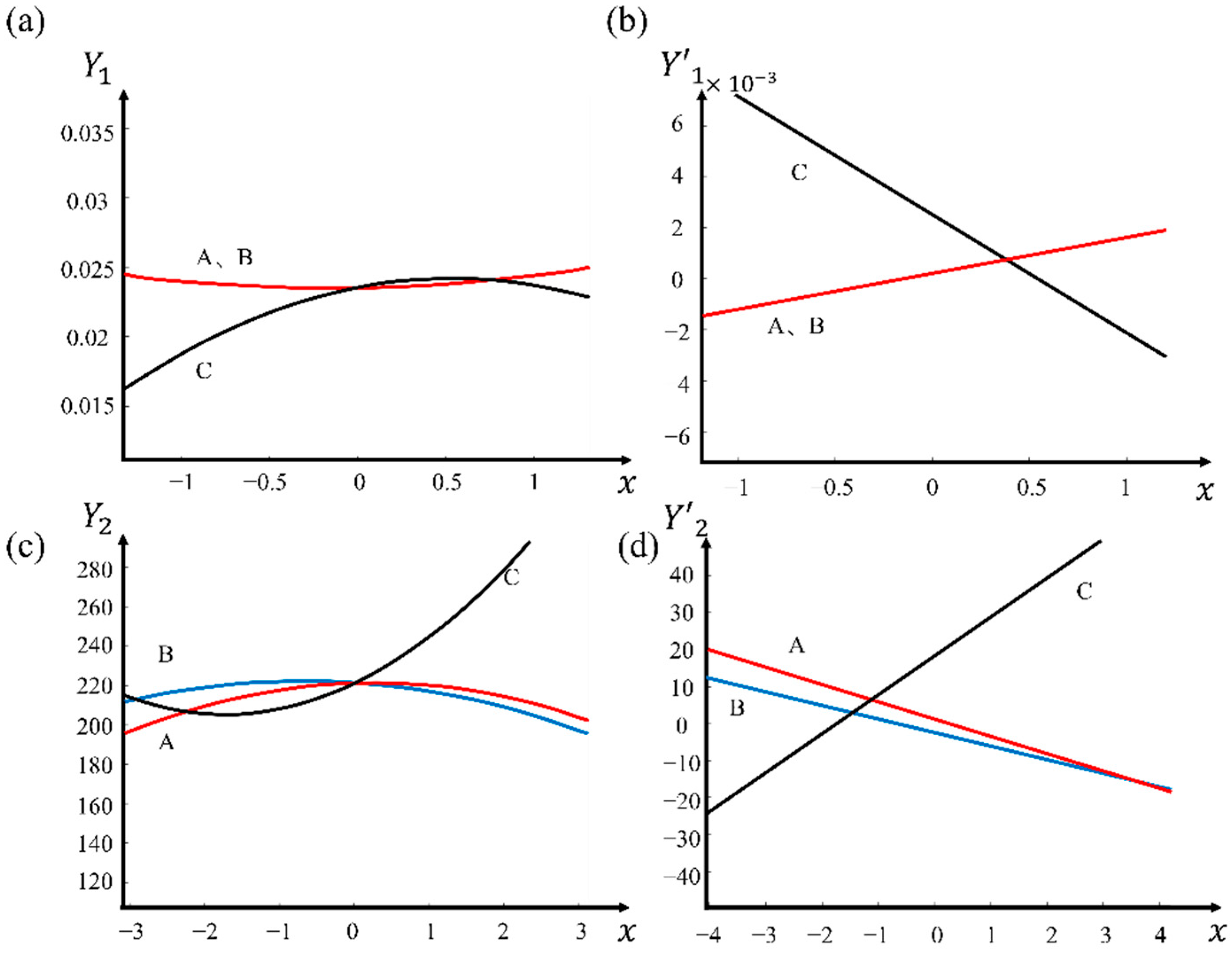

3.2. Regression Curves and Marginal Effect of Factors

3.3. Optimal Parameter Combination

3.4. Comparative Tests of the Rotary Blade

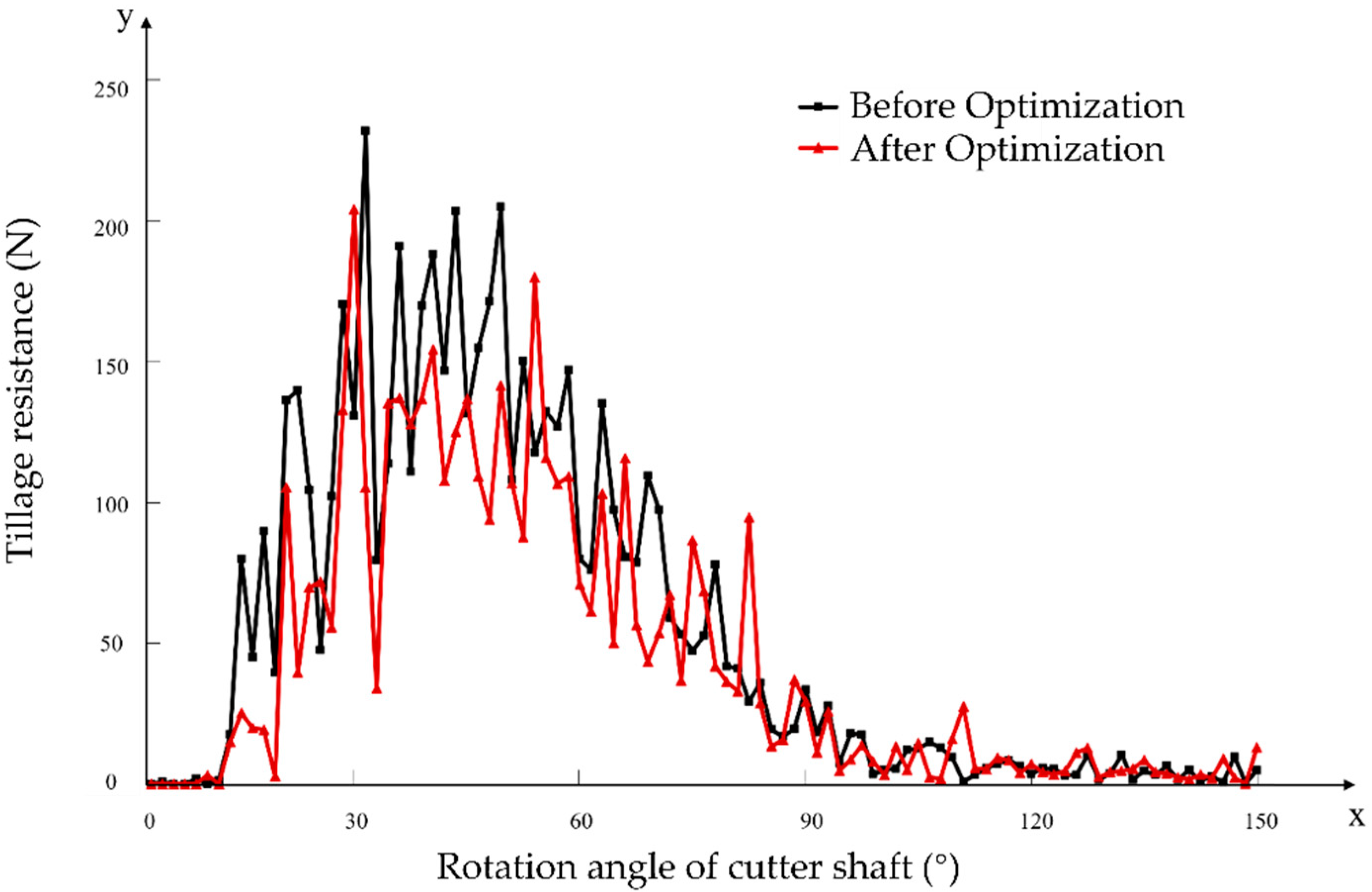

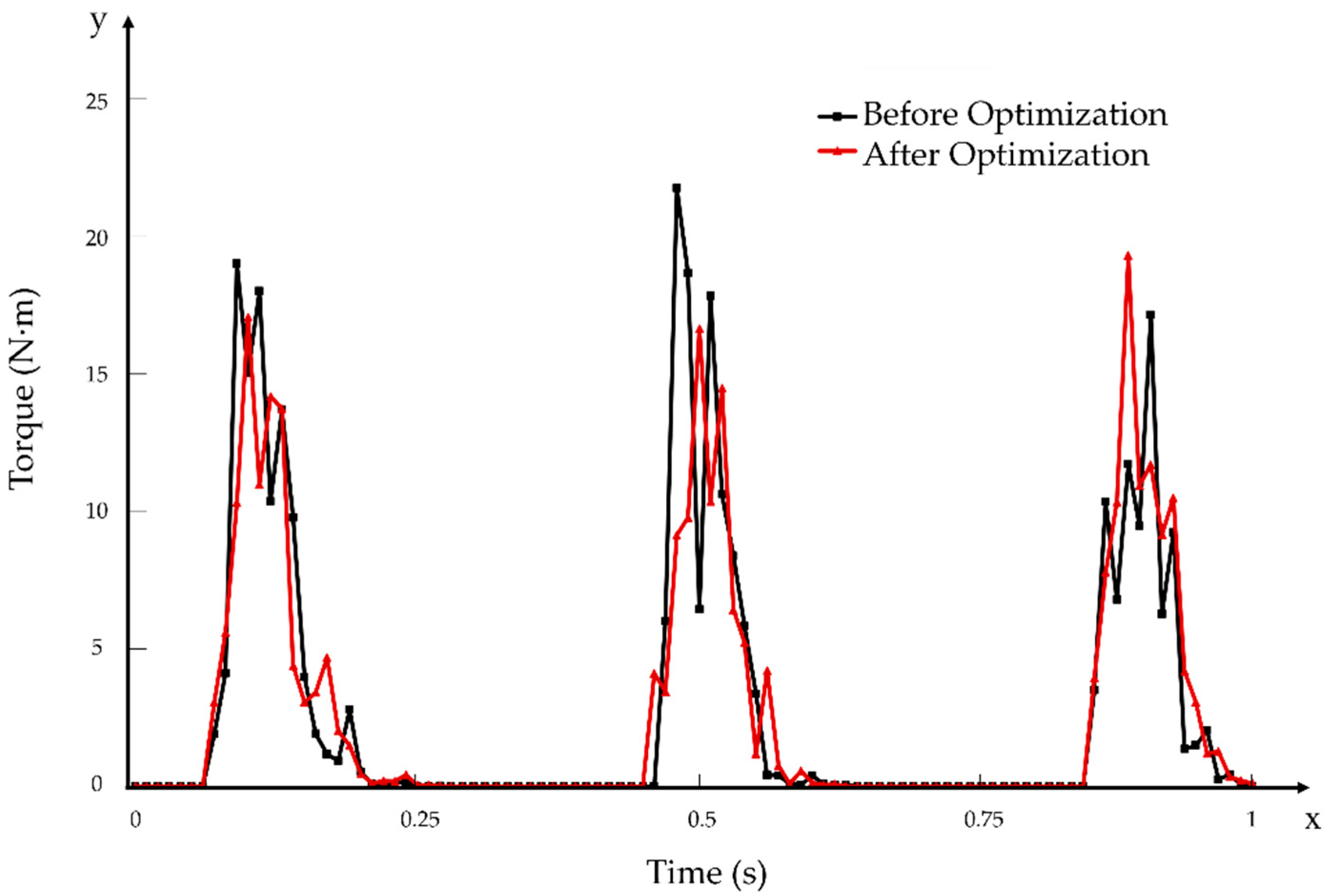

3.4.1. Comparison of the Tillage Resistance

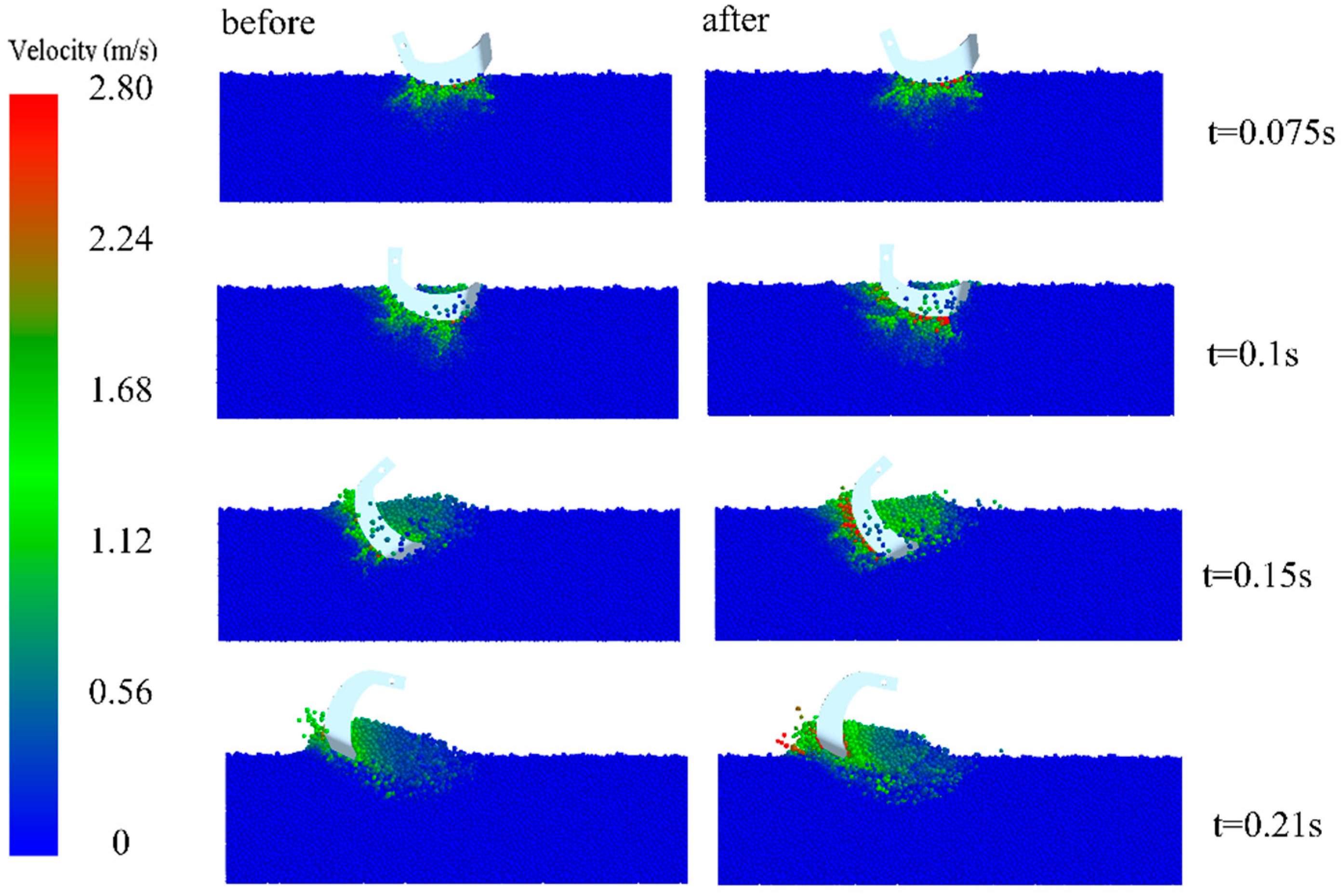

3.4.2. Comparison of Soil Disturbance Situation

3.4.3. Comparison of Cross-Sections for Soil Disturbance

3.4.4. Field Test of the Optimized and Unoptimized Rotary Blade

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Nomenclature | |

|---|---|

| Symbols | |

| Cross-sectional area of the indentation () | |

| Height of tangent edge end face (mm) | |

| Radius of the contact area between particles (mm) | |

| Bending radius (mm) | |

| Bending angle (°) | |

| Freedom | |

| Equivalent modulus of elasticity | |

| F-value | |

| Three-axis working resistance of rotary blade (N) | |

| Sliding friction (N) | |

| Contact force on soil particles (N) | |

| Penetration resistance of rotary blade (N) | |

| Sum of resistance (N) | |

| Tilling depth of rotary blade (mm) | |

| Particle hardness (Pa) | |

| Relative sliding distance between particles (mm) | |

| Mean square | |

| Positive pressure (N) | |

| Rotational speed of blade shaft () | |

| p-value | |

| Maximum compressive stress (Pa) | |

| Radius of particles (mm) | |

| Rotational radius of rotary blade (mm) | |

| Cutting spacing of soil (mm) | |

| Sum of squares | |

| Time (s) | |

| Forward speed of rotary blade () | |

| Soil particles in mutual contact with the blade surface | |

| Wear amount (g) | |

| Tillage resistance (N) | |

| Number of blades | |

| Greek Letters | |

| Center angle of the arc (°) | |

| Yield stress (Pa) | |

| Angular velocity of rotary blade () | |

| Rotary tillage speed ratio | |

| Angle of the cutting edge (°) | |

| Coefficient of sliding friction | |

| Wear constant | |

| Ratio of the actual to the theoretical material removal | |

| Directional overlap (mm) | |

| Abbreviations | |

| DEM | Discrete element method |

| MBD | Multibody dynamics |

| CCD | Central composite design |

| CCF | Central composite face-centered design |

| RSM | Surface response method |

| SPH | Smoothed particle hydrodynamics |

| Terms | |

| Tillage resistance | The force that acts on the surface of the rotary blade and impedes its movement |

| Wear mount | Changes in quality of rotary blade before and after plowing |

| Soil disturbance | The process of displacement, deformation, or destruction between soil particles |

| Torque | Torque on the rotary blade shaft |

References

- Adajar, J.B.; Alfaro, M.; Chen, Y.; Zeng, Z.W. Calibration of discrete element parameters of crop residues and their interfaces with soil. Comput. Electron. Agric. 2021, 188, 11. [Google Scholar] [CrossRef]

- Matin, M.A.; Fielke, J.M.; Desbiolles, J.M.A. Torque and energy characteristics for strip-tillage cultivation when cutting furrows using three designs of rotary blade. Biosyst. Eng. 2015, 129, 329–340. [Google Scholar] [CrossRef]

- Zhang, G.S.; Zhang, Z.Q.; Xiao, M.H.; Bartos, P.; Bohata, A. Soil-cutting simulation and parameter optimization of rotary blade’s three-axis resistances by response surface method. Comput. Electron. Agric. 2019, 164, 10. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, D.W.; He, X.N.; Shang, S.Q.; Zhao, Z.; Tan, Y.; Wang, H.Q. Simulation analysis and test validation of reverse rotary tiller operation power consumption. J. Agric. Mech. Res. 2024, 46, 15–21+82. [Google Scholar]

- Li, S.T.; Chen, X.B.; Chen, W.; Zhu, S.P.; Li, Y.W.; Yang, L.; Xie, S.Y.; Yang, M.J. Soil-cutting simulation and parameter optimization of handheld tiller’s rotary blade by Smoothed Particle Hydrodynamics modelling and Taguchi method. J. Clean. Prod. 2018, 179, 55–62. [Google Scholar] [CrossRef]

- Sun, J.; Jiang, H.; Zheng, X.; Nong, H.L.; Zeng, B.S.; Yang, W. Simulation of ultra deep rotary tillage tool based on soil disturbance. J. Agric. Mech. Res. 2024, 46, 66–71. [Google Scholar]

- Wang, X.Z.; Fang, W.Q.; Han, D.L.; Chen, X.G. Review of the research on soil disturbance by tools. Appl. Sci. 2022, 13, 338. [Google Scholar] [CrossRef]

- Zhang, X.N.; You, Y.; Wang, D.C.; Wang, Z.Y.; Liao, Y.Y.; Li, S.B. Soil failure characteristics and loosening effectivity of compacted grassland by subsoilers with different plough points. Biosyst. Eng. 2024, 237, 170–181. [Google Scholar] [CrossRef]

- Yang, Y.W.; Tong, J.; Ma, Y.H.; Jiang, X.H.; Li, J.L. Design and experiment of biomimetic rotary tillage blade based on multiple claws characteristics of mole rats. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2019, 35, 37–45. [Google Scholar]

- Zhang, Z.H.; Chen, Z.Y.; Lai, Q.H.; Sun, W.Q.; Xie, G.F.; Tong, J. Design and experiments of the Bouligand structure inspired bionic wear resistant soil-engaging component for the agricultural machinery. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2023, 39, 28–37. [Google Scholar]

- Kim, Y.S.; Siddique, M.A.; Kim, W.S.; Kim, Y.J.; Lee, S.D.; Lee, D.K.; Hwang, S.J.; Nam, J.S.; Park, S.U.; Lim, R.G. DEM simulation for draft force prediction of moldboard plow according to the tillage depth in cohesive soil. Comput. Electron. Agric. 2021, 189, 18. [Google Scholar] [CrossRef]

- Ucgul, M.; Saunders, C. Simulation of tillage forces and furrow profile during soil-mouldboard plough interaction using discrete element modelling. Biosyst. Eng. 2020, 190, 58–70. [Google Scholar] [CrossRef]

- Ucgul, M.; Saunders, C.; Fielke, J.M. Comparison of the discrete element and finite element methods to model the interaction of soil and tool cutting edge. Biosyst. Eng. 2018, 169, 199–208. [Google Scholar] [CrossRef]

- Zhang, L.B.; Cai, Z.X.; Wang, L.W.; Zhang, R.X.; Liu, H.F. Coupled Eulerian-Lagrangian finite element method for simulating soil-tool interaction. Biosyst. Eng. 2018, 175, 96–105. [Google Scholar] [CrossRef]

- Wu, Z.Y.; Wang, X.S.; Liu, D.W.; Xie, F.P.; Ashwehmbom, L.G.; Zhang, Z.Z.; Tang, Q.J. Calibration of discrete element parameters and experimental verification for modelling subsurface soils. Biosyst. Eng. 2021, 212, 215–227. [Google Scholar] [CrossRef]

- Chen, X.Y.; Chen, M.D.; Liu, M.M.; Li, Y.; Yang, D.Q.; Wu, H.H. Design and Experiment of Sweet Potato Ridging and Forming Machine. Agriculture 2023, 13, 1641. [Google Scholar] [CrossRef]

- Song, P.; Lyu, J.Q. Effects of coupling simulation of self-excited vibratory subsoiler based on EDEM-RecurDyn. J. Northeast. Univ. 2023, 54, 87–94. [Google Scholar]

- Yuan, J.; Yu, J.Q. Analysis on operational process of self-excited vibrating subsoiler based on DEM-MBD coupling algorithm. Trans. Chin. Soc. Agric. Mach. 2020, 51, 17–24. [Google Scholar]

- Liu, Y.; Liu, Y.P.; Zhang, T. Load analysis of rotary cutter shaft for power tiller based on DEM and MBD theory. J. Agric. Sci. Technol. 2020, 22, 79–86. [Google Scholar]

- Zhang, Z.H.; Zhao, L.L.; Lai, Q.H.; Tong, J. Operation mechanism analysis and experiments of shovel-type rolling soil-engaging components based on DEM-MBD coupling. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2022, 38, 10–20. [Google Scholar]

- Dong, X.Q.; Su, C.; Zheng, H.N.; Han, R.Q.; Li, Y.L.; Wan, L.P.C.; Song, J.N.; Wang, J.C. Analysis of soil disturbance process by vibrating subsoiling based on DEM-MBD coupling algorithm. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2022, 38, 34–43. [Google Scholar]

- Tekeste, M.Z.; Balvanz, L.R.; Hatfield, J.L.; Ghorbani, S. Discrete element modeling of cultivator sweep-to-soil interaction: Worn and hardened edges effects on soil-tool forces and soil flow. J. Terramechanics 2019, 82, 1–11. [Google Scholar] [CrossRef]

- Cucinotta, F.; Scappaticci, L.; Sfravara, F.; Morelli, F.; Mariani, F.; Varani, M.; Mattetti, M. On the morphology of the abrasive wear on ploughshares by means of 3D scanning. Biosyst. Eng. 2019, 179, 117–125. [Google Scholar] [CrossRef]

- Tekeste, M.Z.; Way, T.R.; Syed, Z.; Schafer, R.L. Modeling soil-bulldozer blade interaction using the discrete element method (DEM). J. Terramechanics 2020, 88, 41–52. [Google Scholar] [CrossRef]

- Xiong, P.Y.; Yang, Z.; Sun, Z.Q.; Zhang, Q.Q.; Huang, Y.Q.; Zhang, Z.W. Simulation analysis and experiment for three-axis working resistances of rotary blade based on discrete element method. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2018, 34, 113–121. [Google Scholar]

- Yang, Z.K.; Zhang, K.P.; Zhang, Y.; An, J. Discrete Element Method-Multibody Dynamics Coupling Simulation and Experiment of Rotary Tillage and Ridging Process for Chili Pepper Cultivation. Agronomy 2024, 14, 446. [Google Scholar] [CrossRef]

- Makarov, S.A.; Danilin, A.V.; Levchenko, G.V.; Kalinichenko, E.B.; Ivaniva, L.M. Investigation of kinematic parameters of the rotary working body of a universal rotary cultivator. IOP Conf. Ser. Earth Environ. Sci. 2022, 979, 012058. [Google Scholar] [CrossRef]

- Hao, J.J.; Yu, H.J.; Zhao, J.G.; Li, J.C.; Ma, Z.K.; Cai, J.J. Design and test of wedge drag reduction rotary blade. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2019, 35, 55–64. [Google Scholar]

- Zhu, C.S. Study on Characteristics and Wear Resistance Modification of Wire Arc Additive Remanufacturing of Damaged Rotary Tillage Cutter. Doctoral Thesis, Jiangsu University, Zhenjiang, China, 2021. [Google Scholar]

- Hoormazdi, G.; Küpferle, J.; Röttger, A.; Theisen, W.; Hackl, K.A. Concept for the Estimation of Soil-Tool Abrasive Wear Using ASTM-G65 Test Data. Int. J. Civ. Eng. 2019, 17, 103–111. [Google Scholar] [CrossRef]

- Yao, Q.; Han, X.R.; Hu, Y.H.; Guo, Z.H.; Fan, P.W.; Zhang, Y.Q. Field wear tests of ploughshares in the southern Xinjiang region. Eng. Fail. Anal. 2024, 163, 12. [Google Scholar] [CrossRef]

- Chen, G.M.; Schott, D.L.; Lodewijks, G. Sensitivity analysis of DEM prediction for sliding wear by single iron ore particle. Eng. Comput. 2017, 34, 2031–2053. [Google Scholar] [CrossRef]

- Wang, G.M.; Guo, X.Y.; Zhao, C.J.; Wang, J.H. Soil visual simulation study based on particle system. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2008, 24, 152–158. [Google Scholar]

- Shi, L.R.; Zhao, W.Y.; Sun, W. Parameter calibration of soil particles contact model of farmland soil in northwest arid region based on discrete element method. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2017, 33, 181–187. [Google Scholar]

- Patidar, P.; Soni, P.; Jain, A.; Mahore, V. Modelling soil-rotor blade interaction of vertical axis rotary tiller using discrete element method (DEM). J. Terramechanics 2024, 112, 59–68. [Google Scholar] [CrossRef]

- Fang, Y.Y.; Zhang, K.P.; Yang, Z.K. Simulation analysis and experiment of ploughing process in northwest arid region based on discrete element method. Acta Agric. Univ. Jiangxiensis 2024, 46, 1323–1340. [Google Scholar] [CrossRef]

- Arbizu, I.P.; Pérez, C.J.L. Surface roughness prediction by factorial design of experiments in turning processes. J. Mater. Process. Technol. 2003, 143, 390–396. [Google Scholar] [CrossRef]

- Yu, H.J. Optimal Design and Experiment of Wedge Drag Reduction Rotary Blade. Master’s Thesis, Hebei Agricultural University, Baoding, China, 2019. [Google Scholar]

| Material Property/Contact Parameters | Soil | 65Mn Rotary Blade | Particle—Particle | Particle—Rotary Blade |

|---|---|---|---|---|

| Poisson’s ratio | 0.35 | 0.28 | ||

| Material density (kg·m−3) | 1600 | 7850 | ||

| Shear modulus (Mpa) | 56 | 78,600 | ||

| Surface energy (J/m2) | 5.75 | / | ||

| Coefficient of static friction | 0.30 | 0.50 | ||

| Coefficient of kinetic friction | 0.14 | 0.05 | ||

| Coefficient of restitution | 0.25 | 0.50 |

| Matrix | Constrained Body | Type of Constraint |

|---|---|---|

| Ground | Soil trough | Fixed joint |

| Ground | Lid | Translate joint |

| Blade roller | Rotary blade | Fixed joint |

| Ground | Blade roller | G-motion: Revolute + translate joint |

| Experimental Factors | Level | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| A—Height of Tangent Edge End Face /mm | 48 | 52 | 56 |

| B—Bending Radius /mm | 20 | 25 | 30 |

| C—Bending Angle /° | 116 | 120 | 124 |

| No. | A/(mm) | B/(mm) | C/(°) | Wear Amount /(×10−2 g) | Tillage Resistance /N |

|---|---|---|---|---|---|

| 1 | 52 | 30 | 124 | 2.42 | 246.2 |

| 2 | 52 | 20 | 116 | 1.94 | 209.5 |

| 3 | 52 | 25 | 120 | 2.36 | 219.1 |

| 4 | 48 | 30 | 120 | 2.50 | 212.7 |

| 5 | 52 | 25 | 120 | 2.31 | 219.5 |

| 6 | 52 | 20 | 124 | 2.44 | 241.1 |

| 7 | 48 | 20 | 120 | 2.41 | 217.8 |

| 8 | 52 | 25 | 120 | 2.35 | 225.5 |

| 9 | 56 | 20 | 120 | 2.47 | 225.3 |

| 10 | 52 | 25 | 120 | 2.34 | 220.3 |

| 11 | 52 | 25 | 120 | 2.38 | 221.9 |

| 12 | 48 | 25 | 124 | 2.46 | 239.7 |

| 13 | 48 | 25 | 116 | 1.90 | 207.6 |

| 14 | 56 | 25 | 116 | 1.98 | 205.6 |

| 15 | 56 | 30 | 120 | 2.55 | 212.6 |

| 16 | 52 | 30 | 116 | 1.95 | 202.0 |

| 17 | 56 | 25 | 124 | 2.42 | 243.9 |

| Evaluation Index | Variation Source | Significance | |||||

|---|---|---|---|---|---|---|---|

| Wear Amount | Model | 0.0001 | 9 | 8.204 × 10−6 | 77.03 | <0.0001 | |

| A | 2.812 × 10−7 | 1 | 2.812 × 10−7 | 2.64 | 0.1482 | ||

| B | 3.200 × 10−7 | 1 | 3.200 × 10−7 | 3.00 | 0.1266 | ||

| C | 0.0000 | 1 | 0.0000 | 455.50 | <0.0001 | ||

| AB | 2.500 × 10−9 | 1 | 2.500 × 10−9 | 0.0235 | 0.8826 | ||

| AC | 3.600 × 10−7 | 1 | 3.600 × 10−7 | 3.38 | 0.1086 | ||

| BC | 2.250 × 10−8 | 1 | 2.250 × 10−8 | 0.2113 | 0.6597 | ||

| A2 | 1.976 × 10−6 | 1 | 1.976 × 10−6 | 18.55 | 0.0035 | ||

| B2 | 1.834 × 10−6 | 1 | 1.834 × 10−6 | 17.22 | 0.0043 | ||

| C2 | 0.0000 | 1 | 0.0000 | 202.83 | <0.0001 | ||

| Residual error | 7.455 × 10−7 | 7 | 1.065 × 10−7 | ||||

| Lack-of-fit | 4.775 × 10−7 | 3 | 1.592 × 10−7 | 2.38 | 0.2110 | ||

| Pure error | 2.680 × 10−7 | 4 | 6.700 × 10−8 | ||||

| Cor Total | 0.0001 | 16 | |||||

| Tillage Resistance | Model | 2944.56 | 9 | 327.17 | 35.93 | <0.0001 | |

| A | 11.52 | 1 | 11.52 | 1.27 | 0.2978 | ||

| B | 51.01 | 1 | 51.01 | 5.60 | 0.0498 | ||

| C | 2671.80 | 1 | 2671.80 | 293.41 | <0.0001 | ||

| AB | 14.44 | 1 | 14.44 | 1.59 | 0.2483 | ||

| AC | 9.61 | 1 | 9.61 | 1.06 | 0.3385 | ||

| BC | 39.69 | 1 | 39.69 | 4.36 | 0.0752 | ||

| A2 | 22.86 | 1 | 22.86 | 2.51 | 0.1571 | ||

| B2 | 14.10 | 1 | 14.10 | 1.55 | 0.2534 | ||

| C2 | 116.94 | 1 | 116.94 | 12.84 | 0.0089 | ||

| Residual error | 63.74 | 7 | 9.11 | ||||

| Lack-of-fit | 36.67 | 3 | 12.22 | 1.81 | 0.2857 | ||

| Pure error | 27.07 | 4 | 6.77 | ||||

| Cor Total | 3008.30 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, Z.; Zhang, Y.; Zhang, K.; Wang, J.; Yang, J.; Zheng, X.; Chen, S.; Yang, Z.; Luo, B. Optimization of Rotary Blade Wear and Tillage Resistance Based on DEM-MBD Coupling Model. Agriculture 2025, 15, 328. https://doi.org/10.3390/agriculture15030328

Mao Z, Zhang Y, Zhang K, Wang J, Yang J, Zheng X, Chen S, Yang Z, Luo B. Optimization of Rotary Blade Wear and Tillage Resistance Based on DEM-MBD Coupling Model. Agriculture. 2025; 15(3):328. https://doi.org/10.3390/agriculture15030328

Chicago/Turabian StyleMao, Zhiqiang, Yang Zhang, Keping Zhang, Jiuxin Wang, Junqian Yang, Xiaobao Zheng, Shuaikang Chen, Zhongqing Yang, and Biao Luo. 2025. "Optimization of Rotary Blade Wear and Tillage Resistance Based on DEM-MBD Coupling Model" Agriculture 15, no. 3: 328. https://doi.org/10.3390/agriculture15030328

APA StyleMao, Z., Zhang, Y., Zhang, K., Wang, J., Yang, J., Zheng, X., Chen, S., Yang, Z., & Luo, B. (2025). Optimization of Rotary Blade Wear and Tillage Resistance Based on DEM-MBD Coupling Model. Agriculture, 15(3), 328. https://doi.org/10.3390/agriculture15030328