Smart Strip-Till One-Pass Machine: Winter Wheat Sowing Accuracy Assessment

Abstract

:1. Introduction

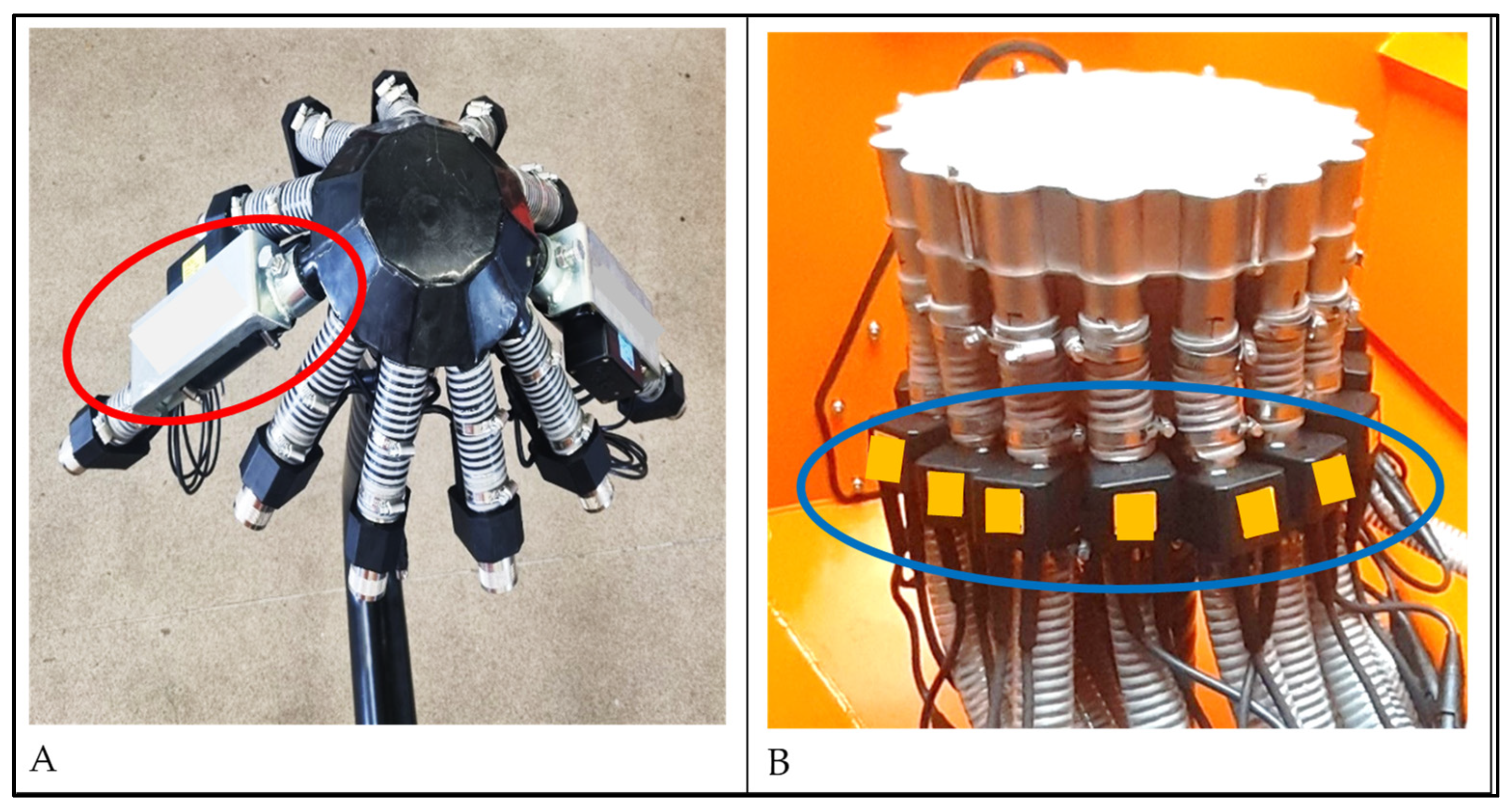

2. Materials and Methods

2.1. Subject, Scope and Location of Research

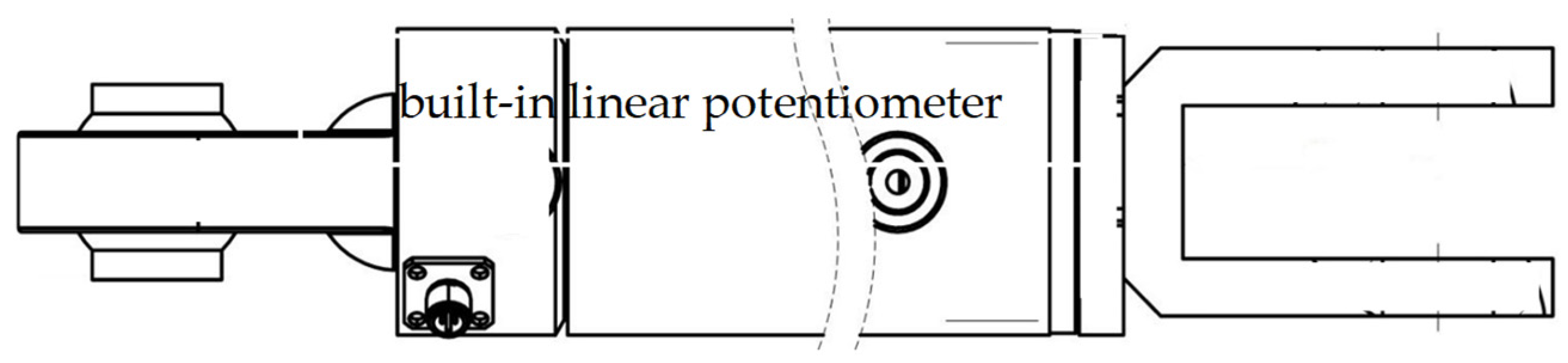

2.2. Laboratory Tests and Field Studies

2.3. Analysis of Results

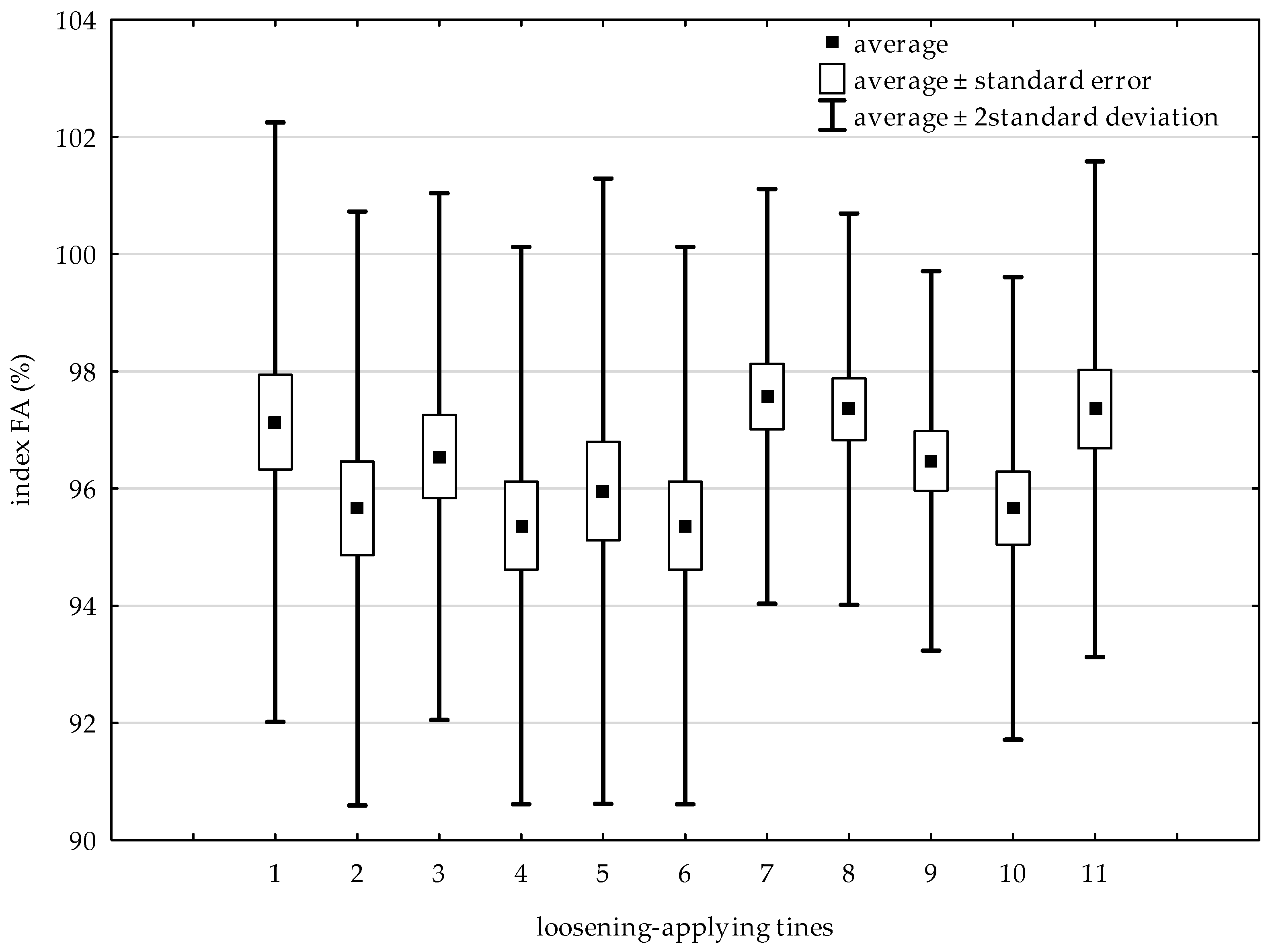

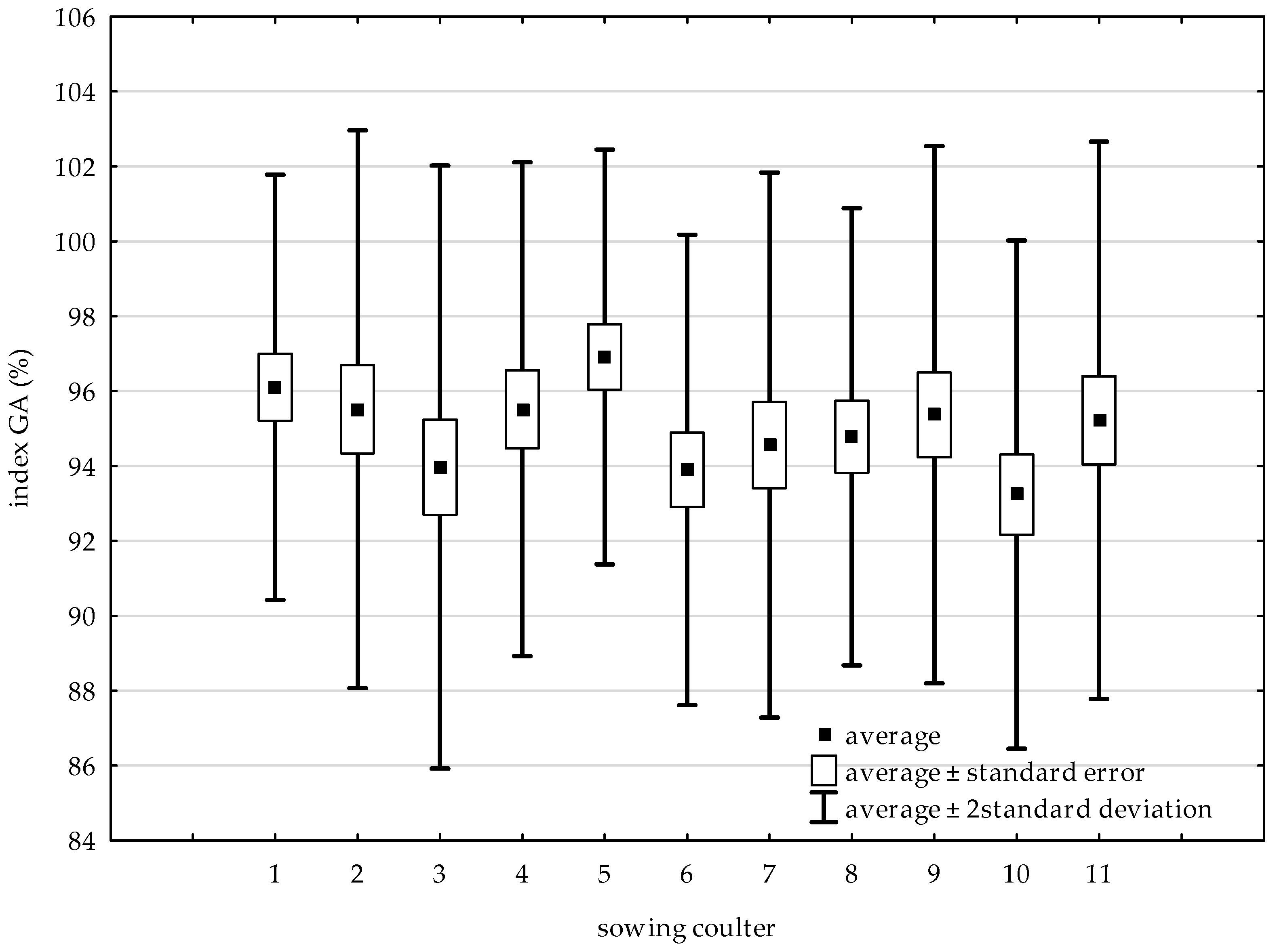

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhai, Z.; Martínez, J.F.; Beltran, V.; Martínez, N.L. Decision support systems for agriculture 4.0: Survey and challenges. Comput. Electron. Agric. 2020, 170, 105256. [Google Scholar] [CrossRef]

- Vlăduț, N.-V.; Ungureanu, N. Beyond Agriculture 4.0: Design and Development of Modern Agricultural Machines and Production Systems. Agriculture 2024, 14, 991. [Google Scholar] [CrossRef]

- Asonja, A.; Desnica, E. Reliability of agriculture universal joint shafts based on temperature measuring in universal joint bearing assemblies. Span. J. Agric. Res. 2015, 13, e0201. [Google Scholar] [CrossRef]

- Baillie, C.P.; Thomasson, J.A.; Lobsey, C.R.; McCarthy, C.L.; Antille, D.L. A Review of the State of the Art in Agricultural Automation. Part I: Sensing Technologies for Optimization of Machine Operation and Farm Inputs. In Proceedings of the 2018 ASABE Annual International Meeting, Detroit, MI, USA, 29 July–1 August 2018; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2018. [Google Scholar]

- Jha, K.; Doshi, A.; Patel, P.; Shah, M. A comprehensive review on automation in agriculture using artificial intelligence. Artif. Intell. Agric. 2019, 2, 1–12. [Google Scholar] [CrossRef]

- Romaneckas, K. Sustainable Tillage and Sowing Technologies. Agronomy 2022, 12, 2467. [Google Scholar] [CrossRef]

- Nandi, N.S.; Mallikarjuna, K.B.; Ashok, K.R.; Arunkumar, K.H.; Bale, A.S.; Vinay, N. Design and Fabrication of a Solar-Powered Bluetooth-Controlled Multipurpose Agromachine. In Precision Agriculture for Sustainability; Apple Academic Press: New York, NY, USA, 2024; pp. 221–240. [Google Scholar]

- Fawzia, H.; Ahmeda, D.; Mostafac, S.A.; Fudzeec, M.F.M.; Mahmoodd, M.A.; Zeebareee, S.R.; Ibrahimf, D.A. A review of automated decision support techniques for improving tillage operations. REVISTA AUS 2019, 26, 219–240. [Google Scholar]

- Zhang, Z.; Peng, X. Bio-tillage: A new perspective for sustainable agriculture. Soil Tillage Res. 2021, 206, 104844. [Google Scholar] [CrossRef]

- Peixoto, D.S.; da Silva, L.D.C.M.; de Melo, L.B.B.; Azevedo, R.P.; Araújo, B.C.L.; Carvalho, T.S.; de Moreira, S.G.; Curi, N.; Silva, B.M. Occasional tillage in notillage systems: A global meta-analysis. Sci. Total Environ. 2020, 745, 140887. [Google Scholar] [CrossRef] [PubMed]

- Różewicz, M. Review of current knowledge on strip-till cultivation and possibilities of its popularization in Poland. Pol. J. Agron. 2022, 49, 20–30. [Google Scholar]

- Jaskulska, I.; Jaskulski, D. Strip-Till One-Pass Technology in Central and Eastern Europe: A MZURI Pro-Til Hybrid Machine Case Study. Agronomy 2020, 10, 925. [Google Scholar] [CrossRef]

- Sims, B.; Kienzle, J. Sustainable Agricultural Mechanization for Smallholders: What Is It and How Can We Implement It? Agriculture 2017, 7, 50. [Google Scholar] [CrossRef]

- Agrawal, A. Automated seed sowing machine: A review. Asian J. Res. Soc. Sci. Humanit. 2021, 11, 251–258. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, D.; Xi, X.; Zhang, Y.; Chen, C.; Qu, J.; Dong, H.; Zhang, R. The Analysis of the Applications of Crop Seed Tape Sowing Technology and Equipment: A Review. Appl. Sci. 2021, 11, 11228. [Google Scholar] [CrossRef]

- Gierz, Ł.; Markowski, P. The Effect of the Distribution Head Tilt and Diffuser Variants on the Evenness of Sowing Rye and Oat Seeds with a Pneumatic Seed Drill. Materials 2020, 13, 3000. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhou, W.; Ma, C.; Feng, Z.; Wang, J.; Yi, S.; Wang, S. Design and optimization of the seed conveying system for belt-type high-speed corn seed guiding device. Int. J. Agric. Biol. Eng. 2024, 17, 123–131. [Google Scholar]

- Reis, Â.V.; Medeiros, F.A.; Ferreira, M.F.; Machado, R.L.T.; Romano, L.N.; Marini, V.K.; Francetto, T.R.; Machado, A.L.T. Technological Trends in Digital Agriculture and Their Impact on Agricultural Machinery Development Practices. Rev. Cienc. Agron. 2020, 51, 2–12. [Google Scholar] [CrossRef]

- Kim, W.S.; Lee, W.S.; Kim, Y.J. A review of the applications of the Internet of Things (IoT) for agricultural automation. J. Biosyst. Eng. 2020, 45, 385–400. [Google Scholar] [CrossRef]

- Aby, G.R.; Issa, S.F. Safety of Automated Agricultural Machineries: A Systematic Literature Review. Safety 2023, 9, 13. [Google Scholar] [CrossRef]

- Kim, Y.S.; Kim, T.J.; Kim, Y.J.; Lee, S.D.; Park, S.U.; Kim, W.S. Development of a real-time tillage depth measurement system for agricultural tractors: Application to the effect analysis of tillage depth on draft force during plow tillage. Sensors 2020, 20, 912. [Google Scholar] [CrossRef] [PubMed]

- Riegler-Nurscher, P.; Moitzi, G.; Prankl, J.; Huber, J.; Karner, J.; Wagentristl, H.; Vincze, M. Machine vision for soil roughness measurement and control of tillage machines during seedbed preparation. Soil Tillage Res. 2019, 196, 104351. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, S.; Kumar, N.; Kumari, S.; Danish, M. Sensor-based sowing machinery for precision farming. Int. J. Chem. Stud. 2020, 8, 13–15. [Google Scholar] [CrossRef]

- Wang, S.; Yi, S.; Zhao, B.; Li, Y.; Li, S.; Tao, G.; Mao, X.; Sun, W. Sowing Depth Monitoring System for High-Speed Precision Planters Based on Multi-Sensor Data Fusion. Sensors 2024, 24, 6331. [Google Scholar] [CrossRef] [PubMed]

- Rajesh, P.V.; Ashvin, J.; Harish, M.; Kishore, G.; Nidheesh, S. Fabrication of Equipment and IoT-Assisted Monitoring for Enhanced Zero-Till Farming. In Emerging Technologies and Marketing Strategies for Sustainable Agriculture; IGI Global Scientific Publishing: Hershey, PA, USA, 2024; pp. 209–233. [Google Scholar]

- Kumar, R.; Kumar, A. Worldwide approach of sensorbased sowing machinery: A Review. Curr. Adv. Agric. Sci. 2023, 15, 1–7. [Google Scholar] [CrossRef]

- Khan, N.; Ray, R.L.; Sargani, G.R.; Ihtisham, M.; Khayyam, M.; Ismail, S. Current Progress and Future Prospects of Agriculture Technology: Gateway to Sustainable Agriculture. Sustainability 2021, 13, 4883. [Google Scholar] [CrossRef]

- Bai, Y.; Zhang, B.; Xu, N.; Zhou, J.; Shi, J.; Diao, Z. Vision-based navigation and guidance for agricultural autonomous vehicles and robots: A review. Comput. Electron. Agric. 2023, 205, 107584. [Google Scholar] [CrossRef]

- Matin, M.A.; Desbiolles, J.M.A.; Fielke, J.M. Strip-tillage using rotating straight blades: Effect of cutting edge geometry on furrow parameters. Soil Tillage Res. 2016, 155, 271–279. [Google Scholar] [CrossRef]

- Nadykto, V.; Domeika, R.; Golub, G.; Kukharets, S.; Chorna, T.; Čėsna, J.; Hutsol, T. Research on a Machine–Tractor Unit for Strip-Till Technology. AgriEngineering 2023, 5, 2184–2195. [Google Scholar] [CrossRef]

- Barut, Z.B.; Ozdemir, S. Design Approaches of One-Pass Strip-Till Machines. In Proceedings of the 15th International Congress on Agricultural Mechanization and Energy in Agriculture, ANKAgEng 2023, Antalya, Turkey, 29 October–1 November 2023; Cavallo, E., Auat Cheein, F., Marinello, F., Saçılık, K., Muthukumarappan, K., Abhilash, P.C., Eds.; Lecture Notes in Civil Engineering 458. Springer: Cham, Switzerland, 2023. [Google Scholar]

- Li, C.S.; Tang, Y.L.; McHugh, A.D.; Wu, X.L.; Liu, M.; Li, M.; Xiong, T.; Ling, D.; Tang, Q.; Liao, M.; et al. Development and performance evaluation of a wet-resistant strip-till seeder for sowing wheat following rice. Biosyst. Eng. 2022, 220, 146–158. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, B.; Sun, M.; Sun, X.; Zhou, W.; Tang, H.; Wang, J. Design and Testing of an Automatic Strip-Till Machine for Conservation Tillage of Corn. Agronomy 2023, 13, 2357. [Google Scholar] [CrossRef]

- Benincasa, P.; Zorzi, A.; Panella, F.; Tosti, G.; Trevini, M. Strip tillage and sowing: Is precision planting indispensable in silage maize? Int. J. Plant Prod. 2017, 11, 577–588. [Google Scholar]

- Zhao, S.; Chen, Y. Seed distribution in soil and its effects on early plant growth. Appl. Eng. Agric. 2015, 31, 415–423. [Google Scholar]

- Ahmad, F.; Adeel, M.; Qiu, B.; Ma, J.; Shoaib, M.; Shakoor, A.; Chandio, F.A. Sowing uniformity of bed-type pneumatic maize planter at various seedbed preparation levels and machine travel speeds. Int. J. Agric. Biol. Eng. 2021, 14, 165–171. [Google Scholar] [CrossRef]

- Ahmed, K.; Saleh, A.; Musa, A.D.; Kalu, G. Determination of selected parameters that influence planting space uniformity on maize seed. Fudma J. Sci. 2023, 7, 30–33. [Google Scholar] [CrossRef]

- Jiang, X.; Zhang, J.; Liu, S.; Fu, L.; Huang, D. Development and Evaluation of a Universal Seed Discharger for Precision Planting in Corn-Soybean Cropping System. Processes 2024, 12, 1595. [Google Scholar] [CrossRef]

- Turan, J.; Višacki, V.; Mehandžić, S.; Findura, P.; Burg, P.; Sedlar, A. Sowing quality indicators for a seed drill with overpressure. Acta Univ. Agric. Silvic. Mendelianae Brun. 2014, 62, 1487–1492. [Google Scholar] [CrossRef]

- Liu, S.; Baret, F.; Andrieu, B.; Burger, P.; Hemmerlé, M. Estimation of Wheat Plant Density at Early Stages Using High Resolution Imagery. Front. Plant Sci. 2017, 8, 739. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Li, R.; Jin, X.; Ding, J.; Zhu, X.; Sun, C.; Guo, W. Evaluation of Seed Emergence Uniformity of Mechanically Sown Wheat with UAV RGB Imagery. Remote Sens. 2017, 9, 1241. [Google Scholar] [CrossRef]

- Tomantschger, K.; Tadić, V. Partial differential equations for cereal seeds distribution. Teh. Vjesn. 2021, 28, 624–628. [Google Scholar]

- Wang, B.; Gu, F.; Hu, Z.; Wu, F.; Chen, X.; Luo, W. Analysis and Evaluation of Influencing Factors on Uniform Sowing of Wheat with Wide Seed Belt after Sowing and Soil Throwing Device. Agriculture 2022, 12, 1455. [Google Scholar] [CrossRef]

- Liu, W.; Hu, J.; Zhao, X.; Yao, M.; Lakhiar, I.A.; Zhao, J.; Liu, J.; Wang, W. An Adaptive Roller Speed Control Method Based on Monitoring Value of Real-Time Seed Flow Rate for Flute-Roller Type Seed-Metering Device. Sensors 2021, 21, 80. [Google Scholar] [CrossRef]

- Statistica. Data Analysis Software System, Version 12; TIBCO Software Inc.: Palo Alto, CA, USA, 2017. Available online: http://sta-517tistica.io (accessed on 15 January 2019).

- Petrović, V.D.; Radojević, L.R.; Tomantschger, K.; Golubović, Z. The Uniformity of Wheat Seeding Over an Area and Depth. In Proceedings of the DAS-29, 29th Danubia-Adria Symposium, University of Belgrade, Belgrade, Serbia, 26–29 September 2012; pp. 166–169. [Google Scholar]

- Noor, H.; Khan, S.; Min, S.; Yu, S. Effect of different sowing methods and nitrogen rates on yield and quality of winter wheat in Loess Plateau of China. Appl. Ecol. Environ. Res. 2020, 18, 5701–5726. [Google Scholar] [CrossRef]

- Šarauskis, E.; Kazlauskas, M.; Naujokienė, V.; Bručienė, I.; Steponavičius, D.; Romaneckas, K.; Jasinskas, A. Variable Rate Seeding in Precision Agriculture: Recent Advances and Future Perspectives. Agriculture 2022, 12, 305. [Google Scholar] [CrossRef]

- He, S.; Li, X.; Chen, M.; Xu, X.; Zhang, W.; Chi, H.; Shao, P.; Tang, F.; Gong, T.; Guo, M.; et al. Excellent Canopy Structure in Soybeans Can Improve Their Photosynthetic Performance and Increase Yield. Agriculture 2024, 14, 1783. [Google Scholar] [CrossRef]

- Lu, Y.; Zhang, X.; Chen, S.; Shao, L.; Sun, H.; Niu, J. Increasing the planting uniformity improves the yield of summer maize. Agron. J. 2017, 109, 1463–1475. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, D.; Li, L.; Zhang, Z.; Liang, X.; Wen, Q.; Chen, G.; Wu, Q.; Zhai, Y. Effect of Planting Density on Canopy Structure, Microenvironment, and Yields of Uniformly Sown Winter Wheat. Agronomy 2023, 13, 870. [Google Scholar] [CrossRef]

- Zhai, Y.; Wu, Q.; Chen, G.; Zhang, H.; Yin, X.; Chen, F. Broadcasting Winter Wheat Can Increase Grain Yield without Reducing the Kernels per Spike and the Kernel Weight. Sustainability 2018, 10, 4858. [Google Scholar] [CrossRef]

- Bochtis, D.D.; Sørensen, C.G.C.; Busato, P. Advances in Agricultural Machinery Management: A Review. Biosyst. Eng. 2014, 126, 69–81. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Y.; Wu, M.; Wu, Z. Sowing Performance of the Seeder Drill for the 2BYG-220 Type Combined Rapeseed Planter under Vibration Conditions. Appl. Sci. 2024, 14, 5091. [Google Scholar] [CrossRef]

- Cujbescu, D.; Găgeanu, I.; Persu, C.; Matache, M.; Vlăduț, V.; Voicea, I.; Paraschiv, G.; Biriș, S.Ș.; Ungureanu, N.; Voicu, G.; et al. Simulation of Sowing Precision in Laboratory Conditions. Appl. Sci. 2021, 11, 6264. [Google Scholar] [CrossRef]

- Xiong, D.; Wu, M.; Xie, W.; Liu, R.; Luo, H. Design and Experimental Study of the General Mechanical Pneumatic Combined Seed Metering Device. Appl. Sci. 2021, 11, 7223. [Google Scholar] [CrossRef]

- GB/T 6973-2005; Testing Methods of Single Seed Drills. Standardization Administration of the P.R.C.: Beijing, China, 2005.

- Fang, Z.; Zhang, J.; Chen, J.; Pan, F.; Wang, B.; Ji, C. Design and Experimental Analysis of an Air-Suction Wheat Precision Hill-Seed Metering Device. Agriculture 2024, 14, 1931. [Google Scholar] [CrossRef]

- ISO 7256-1:1984; Sowing Equipment-Test Methods. Part 1. Single Seed Drills (Precision Drills). International Organization for Standardization: Geneva, Switzerland, 1984.

- Kamgar, S.; Noei-Khodabadi, F.; Shafaei, S.M. Design, development and field assessment of a controlled seed metering unit to be used in grain drills for direct seeding of wheat. Inf. Process. Agric. 2015, 2, 169–176. [Google Scholar] [CrossRef]

- Xi, X.; Gu, C.; Shi, Y.; Zhao, Y.; Zhang, Y.; Zhang, Q.; Jin, Y.; Zhang, R. Design and experiment of no-tube seeder for wheat sowing. Soil Tillage Res. 2020, 204, 104724. [Google Scholar] [CrossRef]

- Jafari, M.; Hemmat, A.; Sadeghi, M. Comparison of coefficient of variation with non-uniformity coefficient in evaluation of grain drills. J. Agric. Sci. Technol. 2011, 13, 643–654. [Google Scholar]

- Poncet, A.M.; Fulton, J.P.; McDonald, T.P.; Knappenberger, T.; Shaw, J.N.; Bridges, R.W. Effect of heterogeneous field conditions on corn seeding depth accuracy and uniformity. Appl. Eng. Agric. 2018, 34, 819–830. [Google Scholar] [CrossRef]

- Nielsen, S.K.; Munkholm, L.J.; Lamandé, M.; Nørremark, M.; Skou-Nielsen, N.; Edwards, G.T.; Green, O. Seed drill instrumentation for spatial coulter depth measurements. Comput. Electron. Agric. 2017, 141, 207–214. [Google Scholar] [CrossRef]

- Nielsen, S.K.; Munkholm, L.J.; Lamandé, M.; Nørremark, M.; Edwards, G.T.; Green, O. Seed drill depth control system for precision seeding. Comput. Electron. Agric. 2018, 144, 174–180. [Google Scholar] [CrossRef]

- Galibjon, M.; Dimitris, S.; Hans, W. Implementation of a magnetorheological damper on a no-till seeding assembly for optimising sowing depth. Comput. Electron. Agric. 2018, 150, 465–475. [Google Scholar]

- Carman, K.; Çıtıl, E.; Marakoğlu, T.; Gür, K.; Kırılmaz, H. Comparison of strip tillage systems for sillage maize production in middle anatolia. Selcuk J. Agric. Food Sci. 2018, 32, 430–435. [Google Scholar]

- Lv, H.; Ren, J.; Liu, X.; Li, S.; Wu, G.; Zheng, Y. Review of the Monitoring Systems of the Machine for Precision Sowing and Fertilization of Wheat. In Proceedings of the 2018 ASABE Annual International Meeting, Detroit, MI, USA, 29 July–1 August 2018; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2018; p. 1800736. [Google Scholar]

- Jin, M.F.; Ding, Y.Q.; Yu, H.F.; Liu, H.T.; Jiang, Y.Z.; Fu, X.Q. Optimal Structure Design and Performance Tests of Seed metering Device with Fluted Rollers for Precision Wheat Seeding Machine. IFAC-PapersOnLine 2018, 51, 509–514. [Google Scholar]

- Yu, H.; Ding, Y.; Liu, Z.; Fu, X.; Dou, X.; Yang, C. Development and Evaluation of a Calibrating System for the Application Rate Control of a Seed-Fertilizer Drill Machine with Fluted Rollers. Appl. Sci. 2019, 9, 5434. [Google Scholar] [CrossRef]

- Yu, H.; Ding, Y.; Fu, X.; Liu, H.; Jin, M.; Yang, C.; Liu, Z.; Sun, G.; Dou, X. A solid fertilizer and seed application rate measuring system for a seed-fertilizer drill machine. Comput. Electron. Agric. 2019, 162, 836–844. [Google Scholar] [CrossRef]

- Adilet, S.; Zhao, K.; Liu, G.; Sayakhat, N.; Jun, C.; Hu, G.; Bu, L.; Chen, Y.; Jin, H.; Zhang, S.; et al. Investigation of the pin-roller metering device and tube effect for wheat seeds and granular fertilizers based on DEM. Int. J. Agric. Biol. Eng. 2023, 16, 103–114. [Google Scholar] [CrossRef]

| Parameter | Unit | Average | Minimum | Maximum | Standard Deviation | Coefficient of Variation (%) | Standard Error |

|---|---|---|---|---|---|---|---|

| Laboratory tests | |||||||

| Sowing grain | kg | 13.82 | 13.30 | 14.06 | 0.31 | 2.24 | 0.10 |

| Fertiliser application | kg | 13.55 | 13.38 | 13.73 | 0.11 | 0.84 | 0.04 |

| Field tests | |||||||

| Sowing grain | kg | 13.61 | 12.98 | 14.25 | 0.48 | 3.49 | 0.15 |

| Fertiliser application | kg | 14.05 | 13.52 | 14.58 | 0.35 | 2.52 | 0.11 |

| Sowing depth | cm | 2.76 | 2.64 | 2.89 | 0.07 | 2.58 | 0.02 |

| Number of plants | pcs./m | 80.38 | 78.36 | 83.18 | 1.50 | 1.87 | 0.48 |

| Parameter | Assembly | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | |

| Laboratory tests | |||||||||||

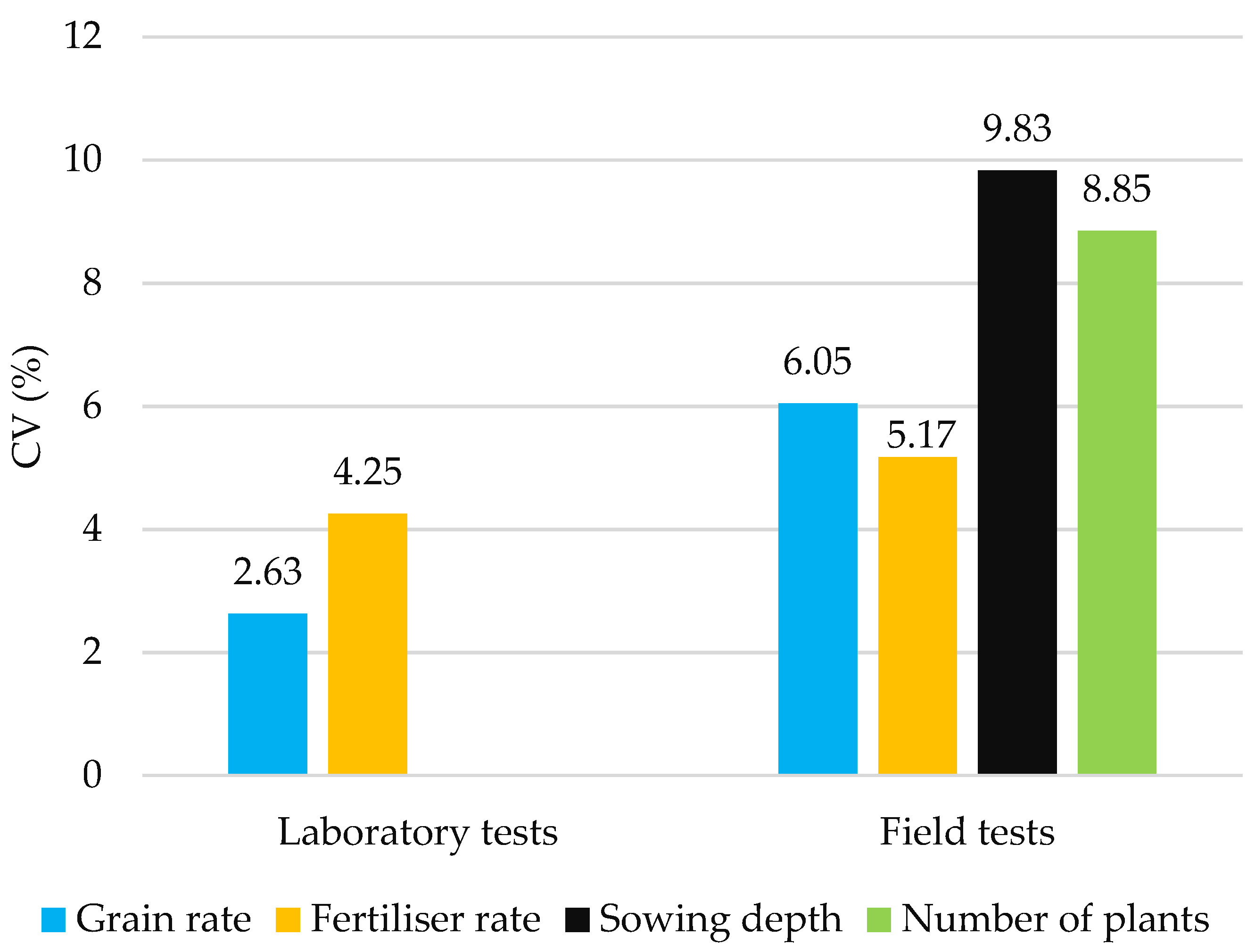

| Sowing grain | 2.19 | 2.40 | 2.59 | 3.06 | 2.43 | 2.57 | 2.25 | 3.22 | 2.61 | 3.46 | 2.59 |

| Fertiliser application | 2.49 | 4.67 | 4.26 | 5.05 | 4.83 | 5.36 | 3.11 | 3.04 | 3.91 | 4.98 | 3.49 |

| Field tests | |||||||||||

| Sowing grain | 5.00 | 5.98 | 7.27 | 5.77 | 4.27 | 6.59 | 6.31 | 5.88 | 6.06 | 7.29 | 6.09 |

| Fertiliser application | 5.45 | 6.71 | 5.06 | 6.43 | 3.74 | 6.90 | 3.92 | 3.92 | 4.77 | 4.87 | 4.92 |

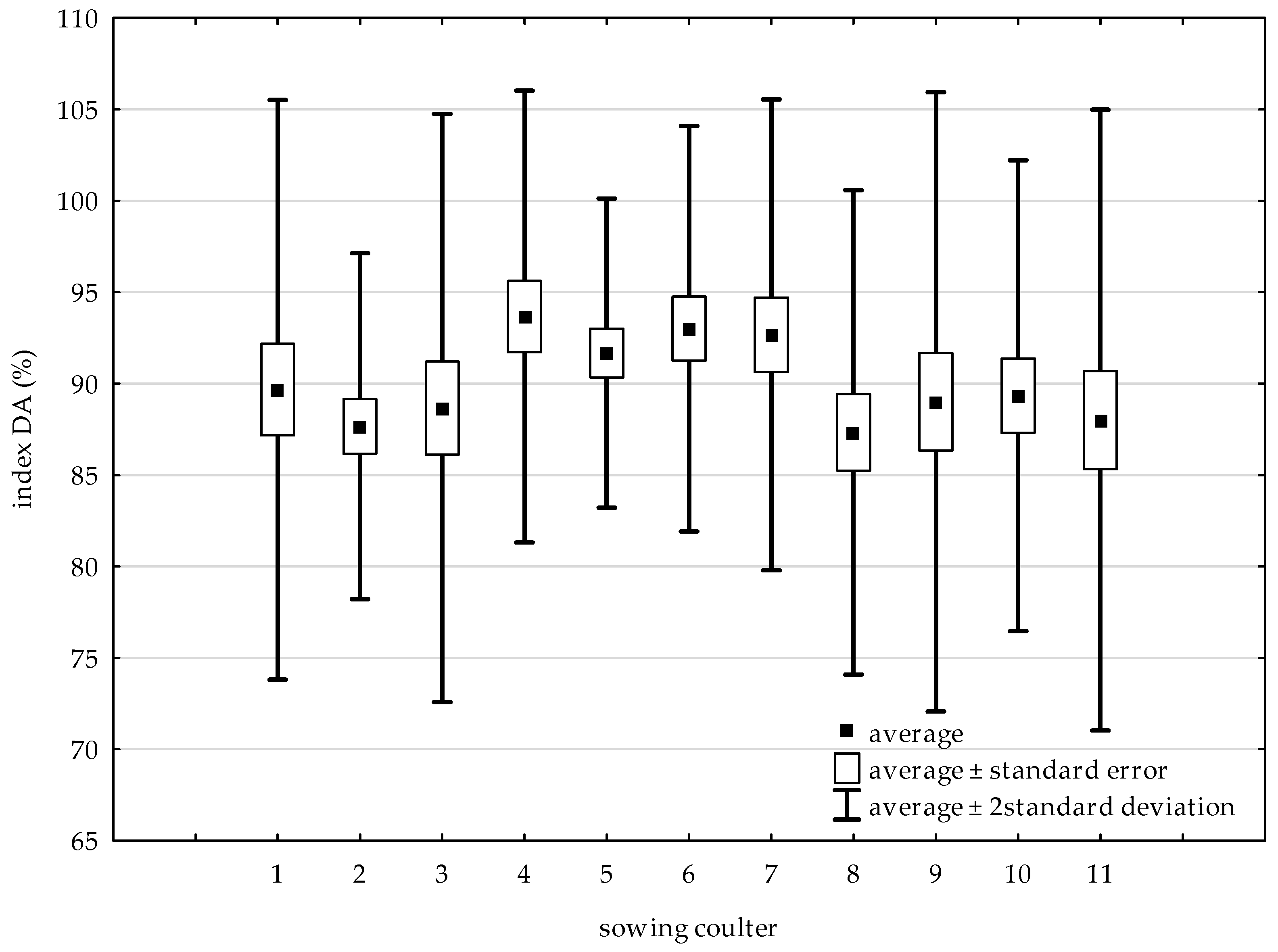

| Sowing depth | 9.76 | 9.51 | 10.07 | 8.55 | 9.51 | 7.98 | 8.32 | 11.71 | 11.20 | 10.06 | 10.66 |

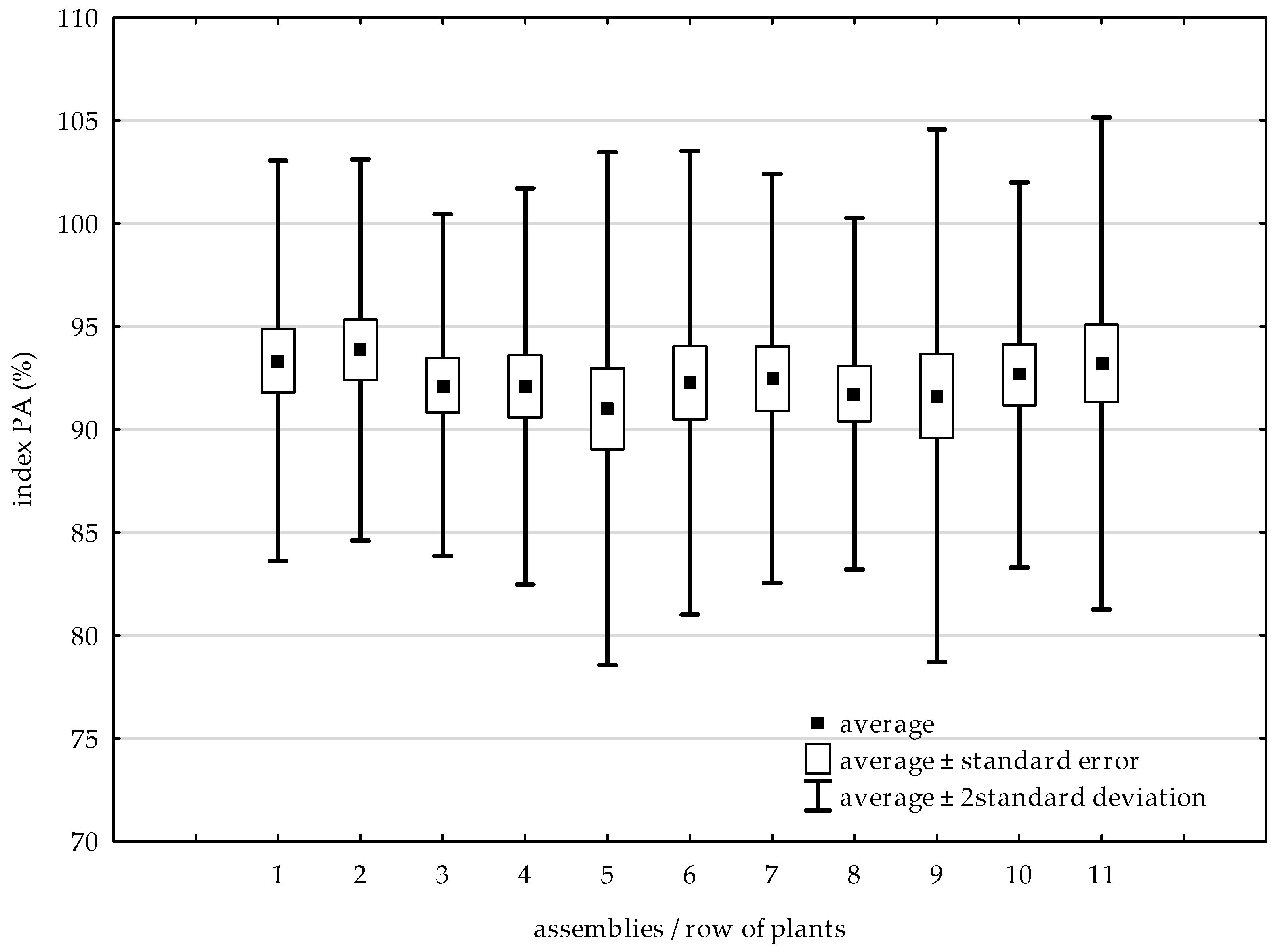

| Number of plants | 8.45 | 5.63 | 8.74 | 7.24 | 10.43 | 9.79 | 8.23 | 6.76 | 6.00 | 8.50 | 8.33 |

| Index | Average | Minimum | Maximum | Standard Deviation | Coefficient of Variation (%) | Standard Error |

|---|---|---|---|---|---|---|

| Laboratory tests | ||||||

| Sowing grain—GA | 97.44 | 96.59 | 99.53 | 0.83 | 0.86 | 0.26 |

| Fertiliser Application—FA | 99.21 | 98.40 | 99.67 | 0.43 | 0.43 | 0.14 |

| Field tests | ||||||

| Sowing grain—GA | 96.91 | 95.19 | 98.80 | 1.25 | 1.30 | 0.40 |

| Fertiliser application—FA | 96.52 | 92.78 | 99.67 | 2.32 | 2.40 | 0.73 |

| Sowing depth—DA | 92.00 | 87.88 | 96.36 | 2.37 | 2.58 | 0.75 |

| Number of plants—PA | 98.05 | 94.84 | 99.90 | 1.52 | 1.55 | 0.48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaskulski, D.; Jaskulska, I.; Różniak, E.; Radziemska, M.; Klik, B.; Brtnický, M. Smart Strip-Till One-Pass Machine: Winter Wheat Sowing Accuracy Assessment. Agriculture 2025, 15, 411. https://doi.org/10.3390/agriculture15040411

Jaskulski D, Jaskulska I, Różniak E, Radziemska M, Klik B, Brtnický M. Smart Strip-Till One-Pass Machine: Winter Wheat Sowing Accuracy Assessment. Agriculture. 2025; 15(4):411. https://doi.org/10.3390/agriculture15040411

Chicago/Turabian StyleJaskulski, Dariusz, Iwona Jaskulska, Emilian Różniak, Maja Radziemska, Barbara Klik, and Martin Brtnický. 2025. "Smart Strip-Till One-Pass Machine: Winter Wheat Sowing Accuracy Assessment" Agriculture 15, no. 4: 411. https://doi.org/10.3390/agriculture15040411

APA StyleJaskulski, D., Jaskulska, I., Różniak, E., Radziemska, M., Klik, B., & Brtnický, M. (2025). Smart Strip-Till One-Pass Machine: Winter Wheat Sowing Accuracy Assessment. Agriculture, 15(4), 411. https://doi.org/10.3390/agriculture15040411