Bionic Optimal Design and Performance Study of Soil Loosening Shovels for Degraded Grasslands

Abstract

:1. Introduction

2. Materials and Methods

2.1. Mechanized Soil Loosening Requirements

- To minimize damage to the growth environment of Leymus chinensis and soil microorganisms, the fragmentation of soil in the loosening area should be reduced, and soil turning should be avoided.

- To minimize damage to the roots by the loosening shovels, the loosening depth should exceed the depth of root concentration.

- To provide an appropriate growth space for the roots of Leymus chinensis and enhance water and nutrient absorption, the deeper soil should be loosened appropriately.

- Excessive disturbance may further loosen the root-soil layer, increasing wind and water erosion and damaging surface vegetation. Therefore, the disturbance of the root-soil layer during loosening should be minimized.

- To reduce mechanical energy consumption and improve operational efficiency, the loosening resistance of the shovel should be minimized.

2.2. Bionic Optimal Design of Loosening Shovels

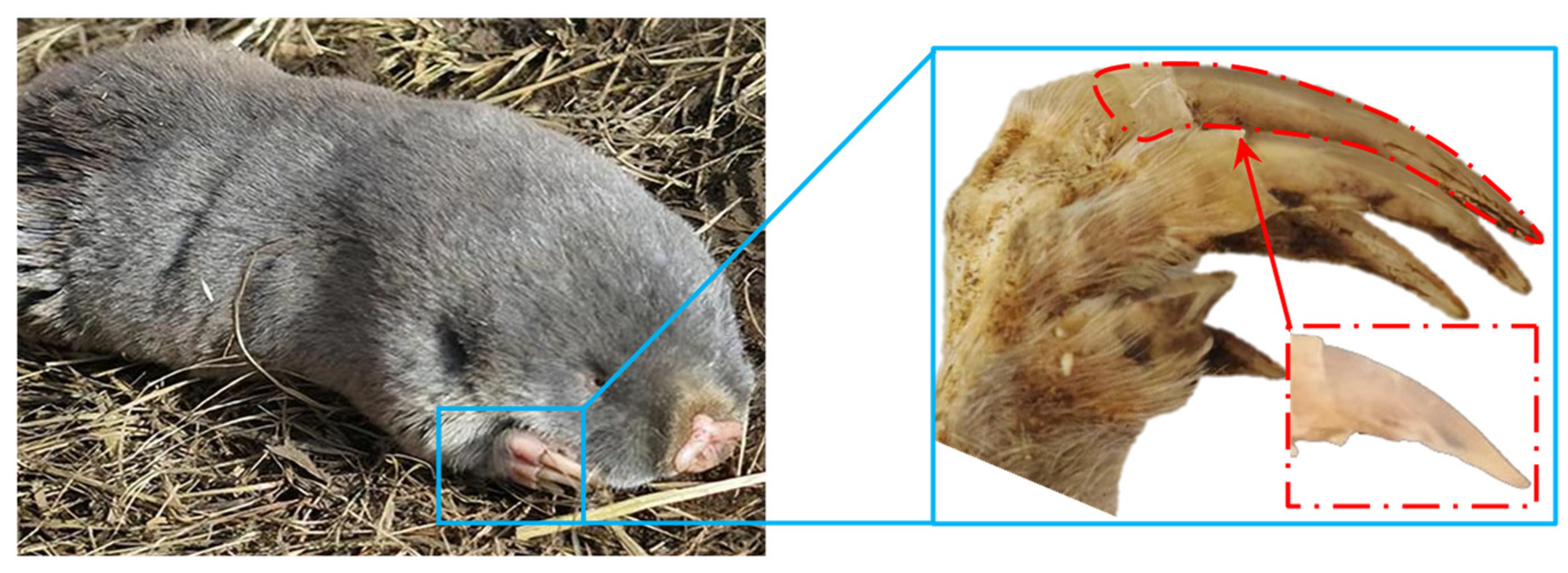

2.2.1. Basic Characteristics of Prairie Zokor

2.2.2. Contour Feature Extraction and Fitting

- The largest toe of the prairie zokor’s paw is shaved off using scissors, then cleaned with an ultrasonic instrument and disinfected with a high-concentration ethanol solution. It is rinsed with water, air-dried naturally, and finally prepared as a sample for spare use.

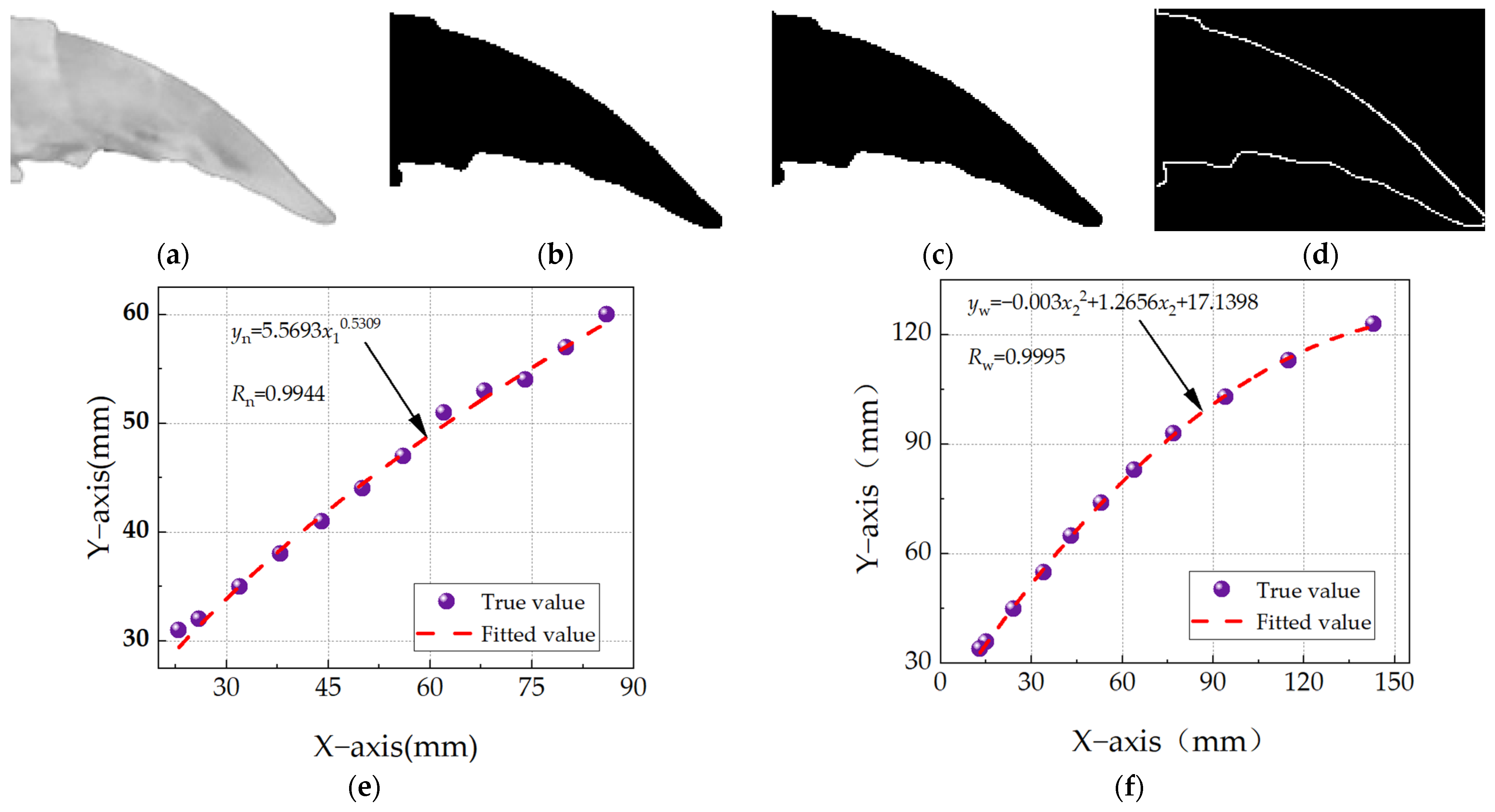

- A high-definition camera is used to capture an image of the largest toe of the prairie zokor’s paw, which is imported into MATLAB R2021a. Then, the image undergoes grayscale processing (Figure 2a), binarization processing (Figure 2b), and filtering processing (Figure 2c). MATLABs Canny operator is used to detect the edges of the toe (Figure 2d) and extract the point cloud data of the inner and outer contours from the processed images, and point cloud data for both the inner and outer contours are extracted from the processed image.

- The point cloud data obtained were imported into Origin 2021, where the trajectories of the inner and outer contours of the toe are fitted. Then, the fitting equations were obtained. During the fitting process, the effectiveness of the fitting is evaluated using the coefficients of determination, Rn and Rw. The closer these coefficients were to 1, the better the fit. The fitted trajectories of the inner and outer contours of the toe are shown in Figure 2e,f. The fitting coefficients of the inner and outer trajectories were 0.9944 and 0.9995. The results indicated that the fitted equations accurately characterized the inner and outer contours of the toe.

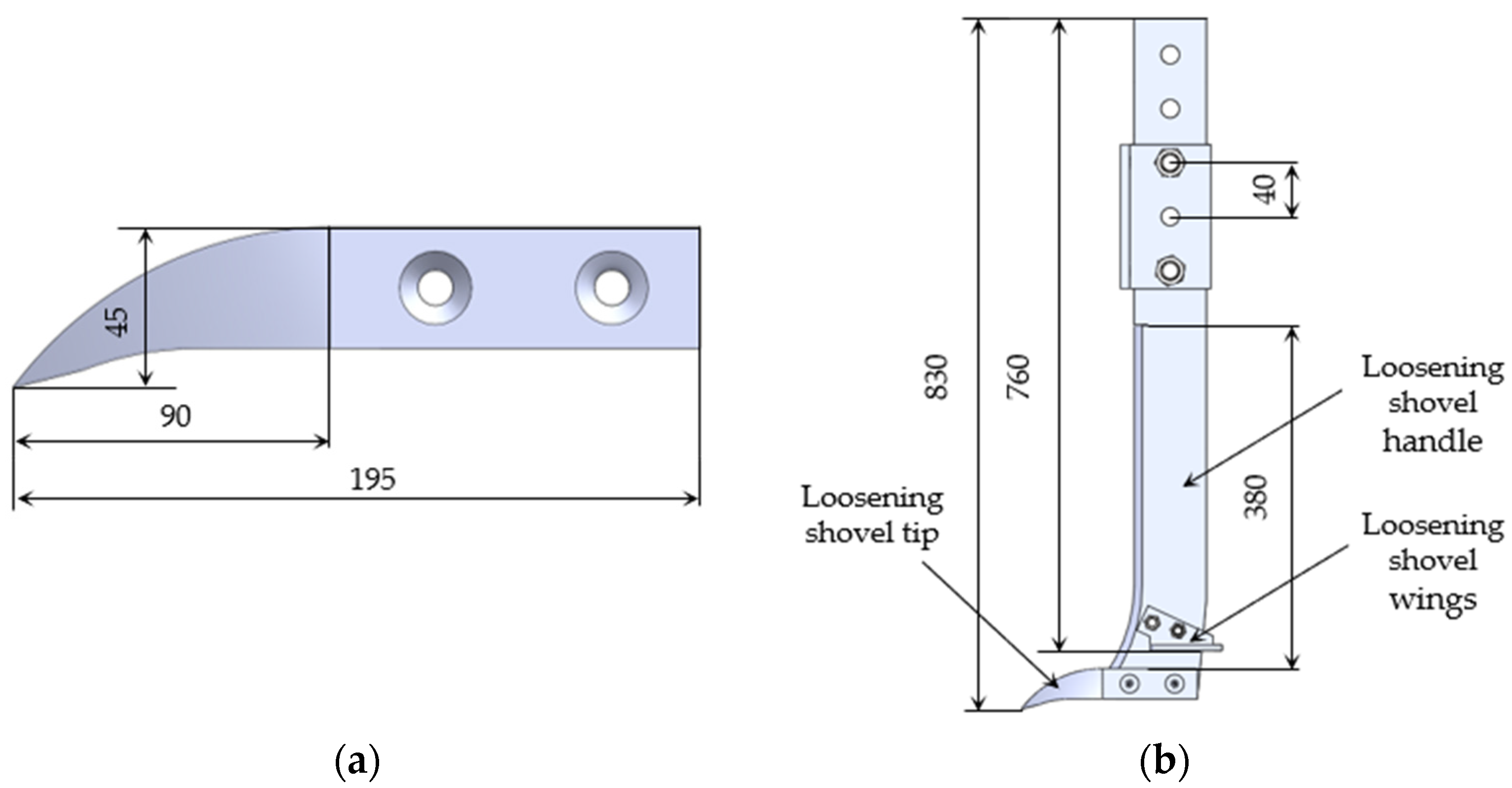

2.2.3. Three-Dimensional Modeling of the Bionic Loosening Shovel

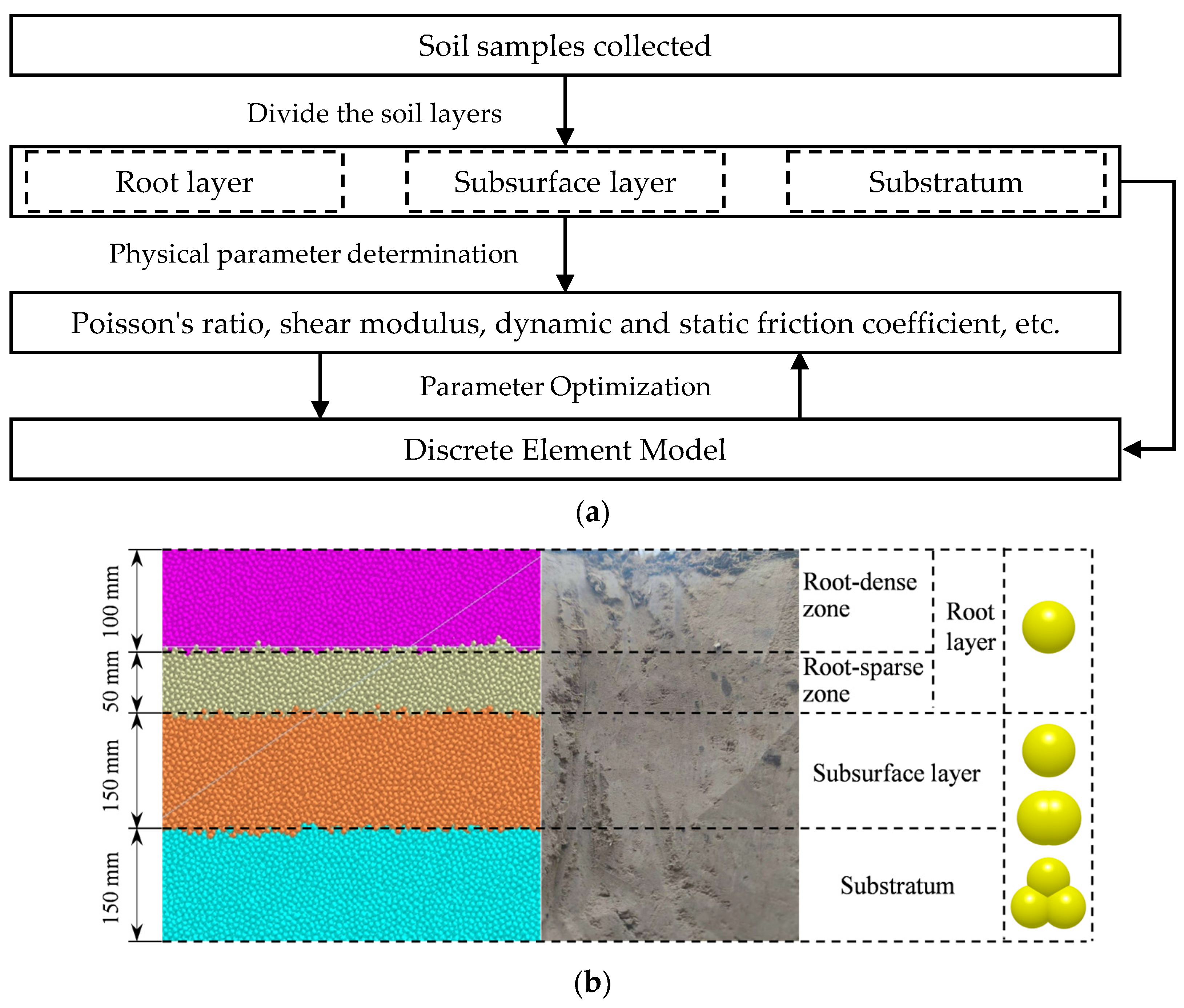

2.3. Discrete Element Simulation

2.3.1. Simulation Model Construction

2.3.2. Design and Process of Simulation Tests

2.4. Field Test Design and Parameter Acquisition

2.4.1. Description of Test Environment

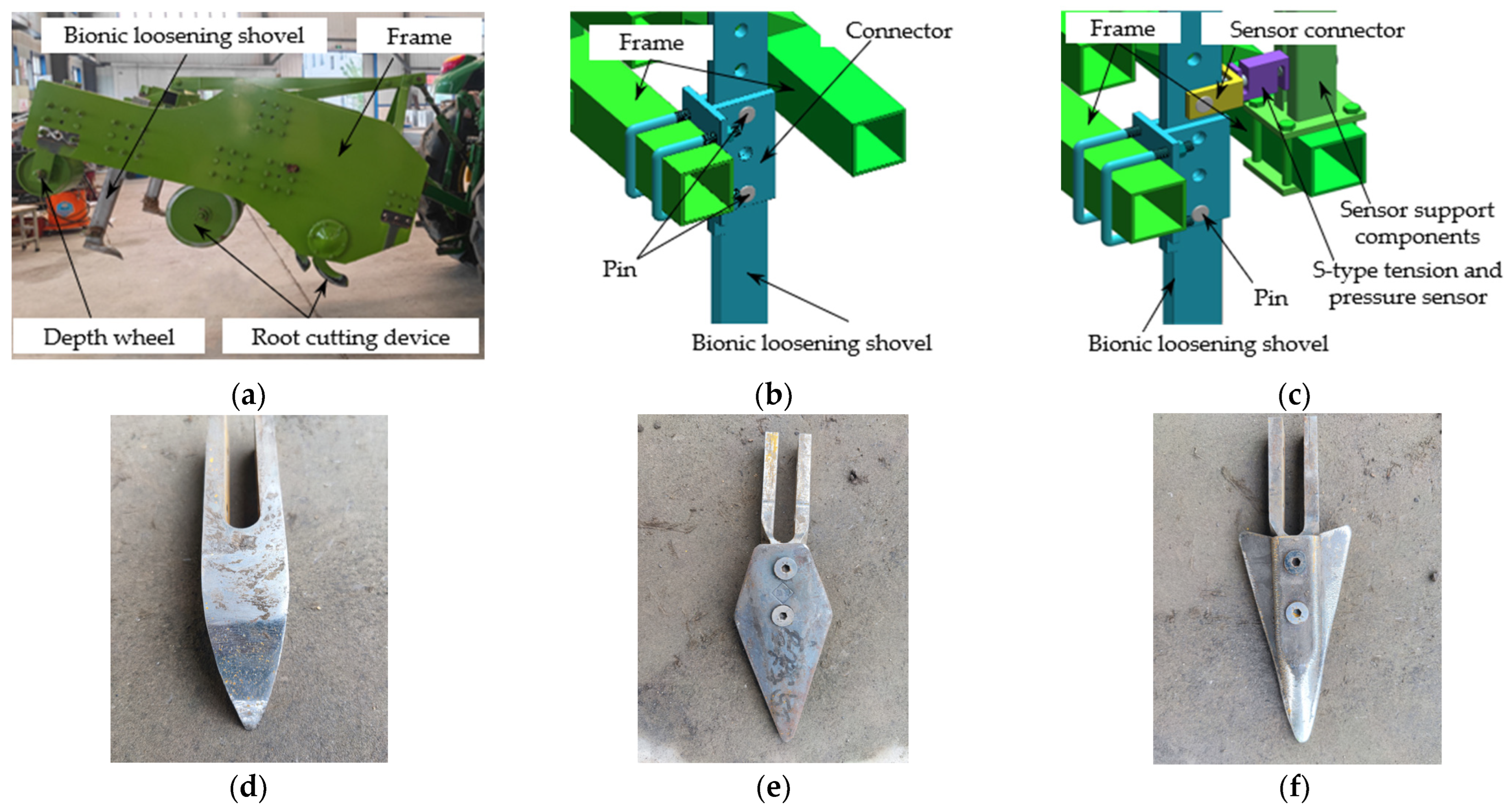

2.4.2. Test Equipment

2.4.3. Design of Field Tests

2.4.4. Data Collection and Processing

3. Results and Discussion

3.1. Simulation Results and Analysis

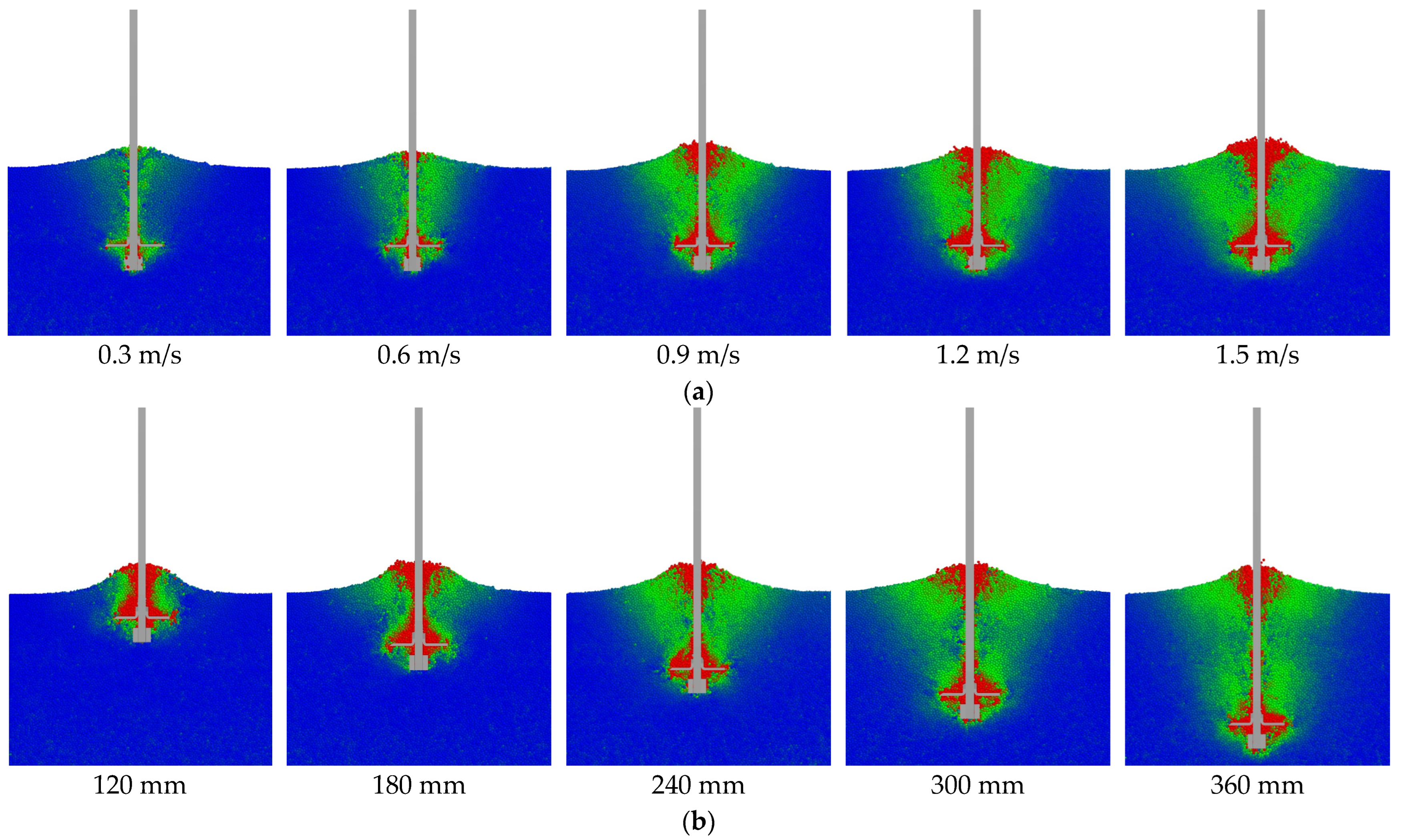

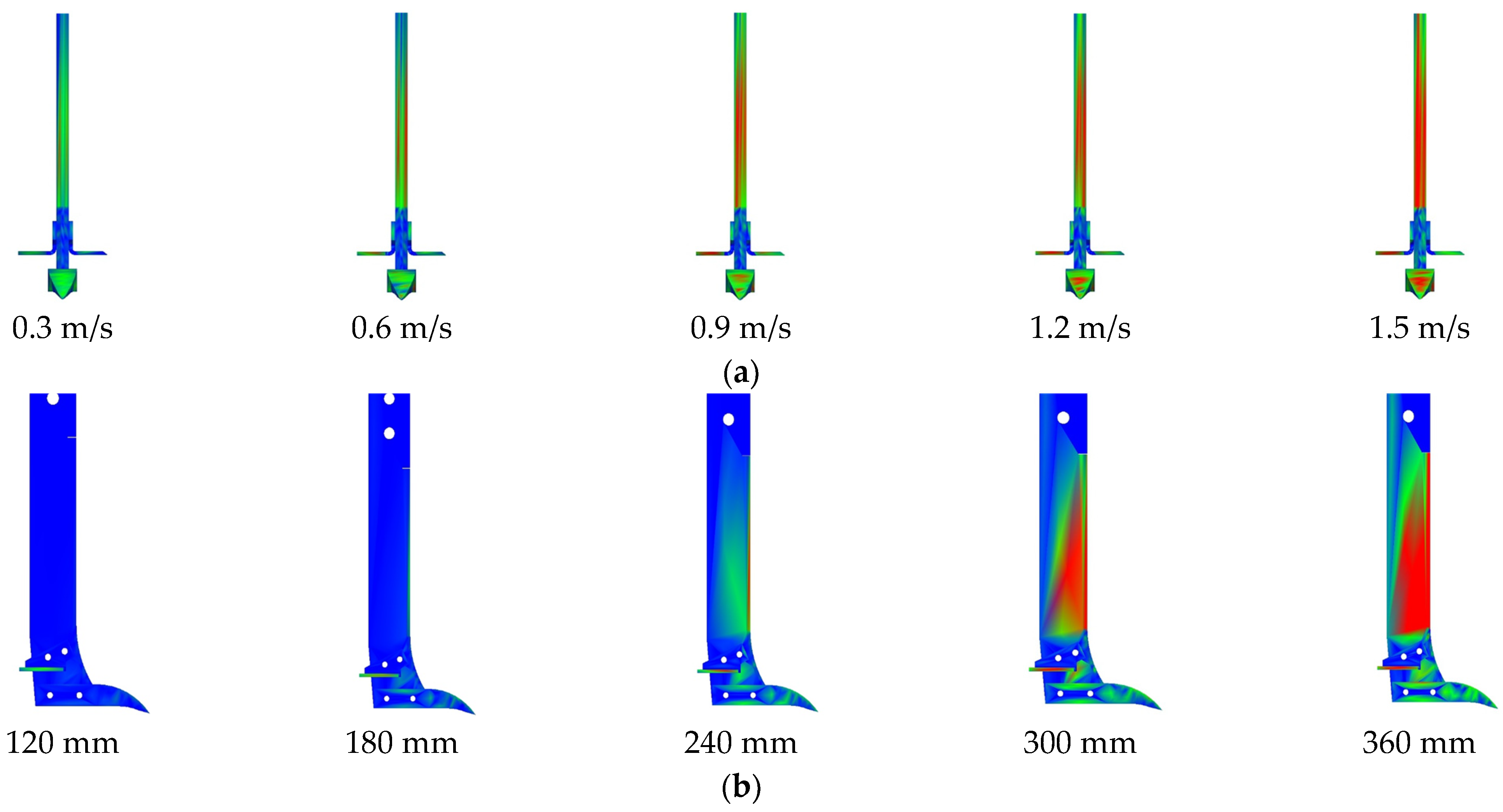

3.1.1. Soil Disturbance Status

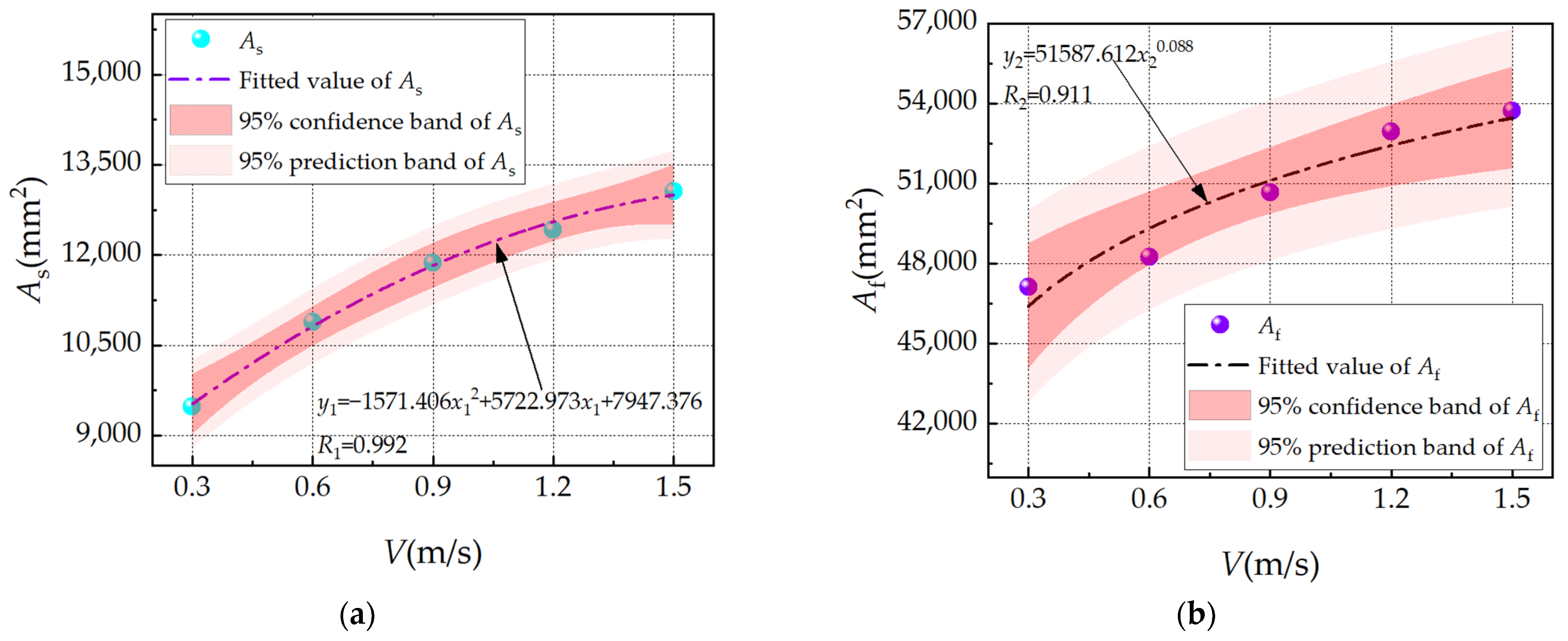

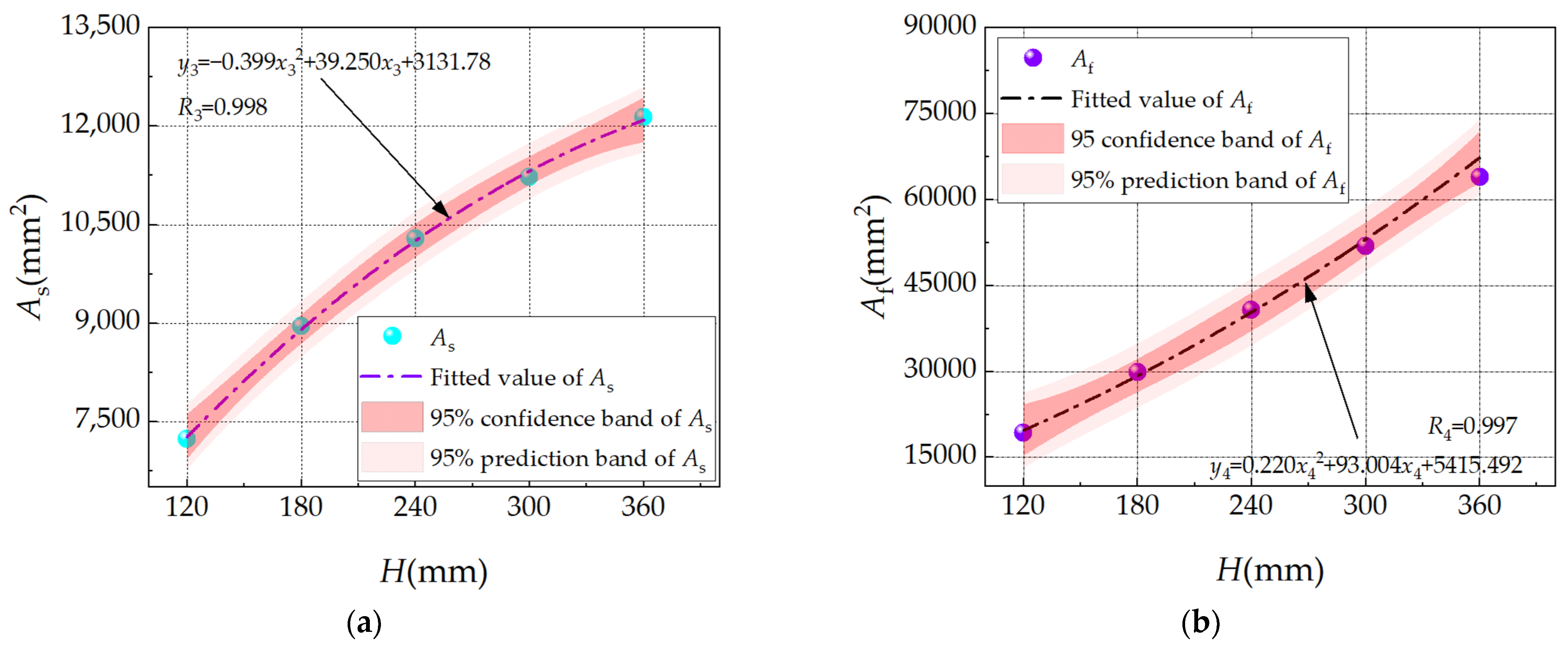

3.1.2. Effects of Operating Parameters on the Soil Disturbance Area

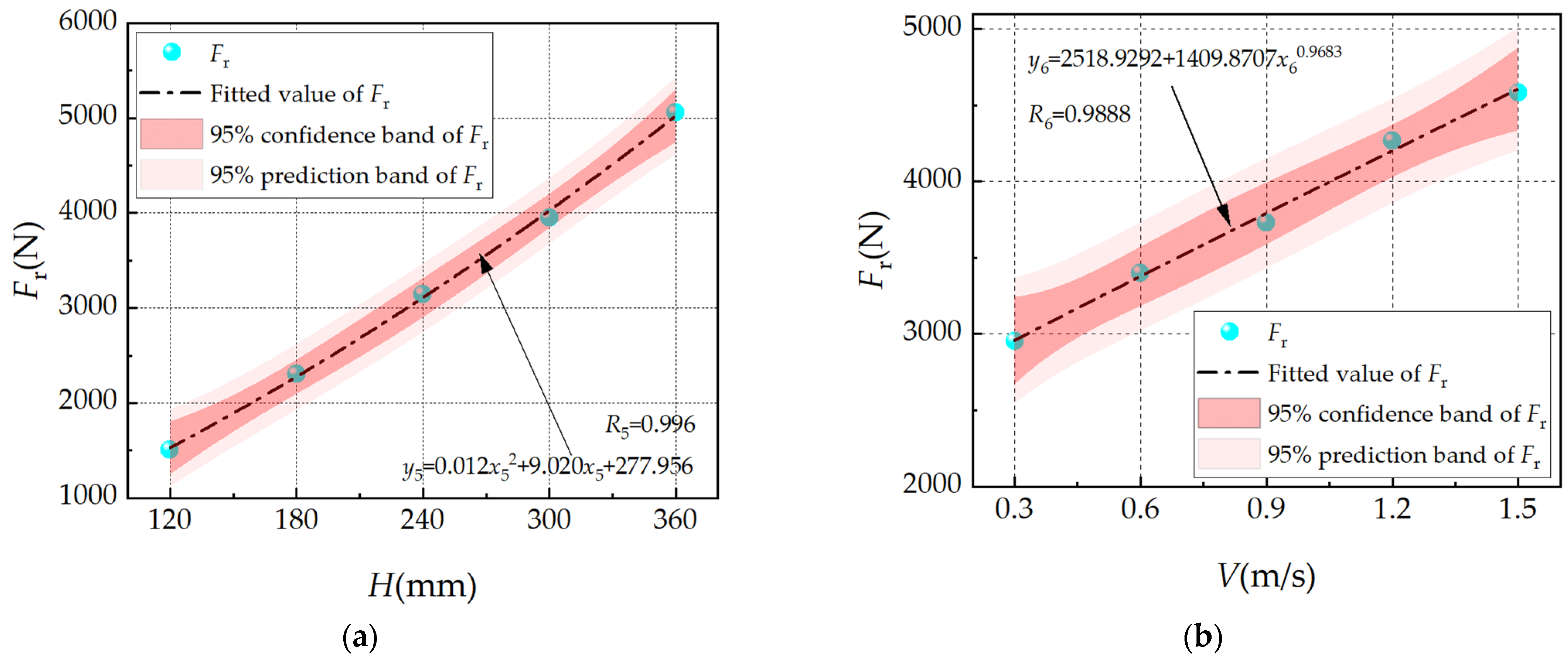

3.1.3. Effect of Operating Parameters on Loosening Resistance and Specific Resistance

3.2. Field Test Results and Analysis

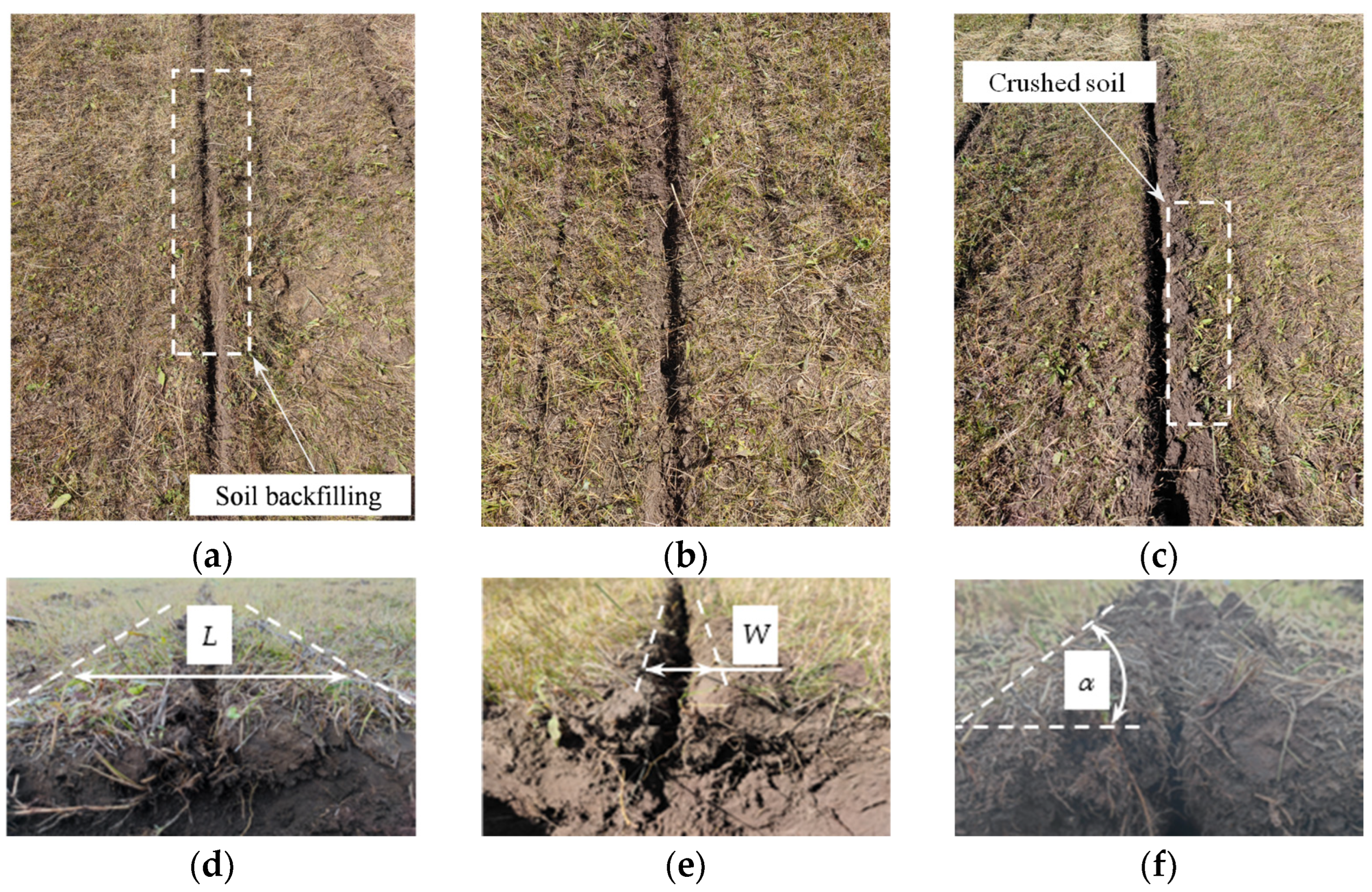

3.2.1. Disturbance Feature Analysis

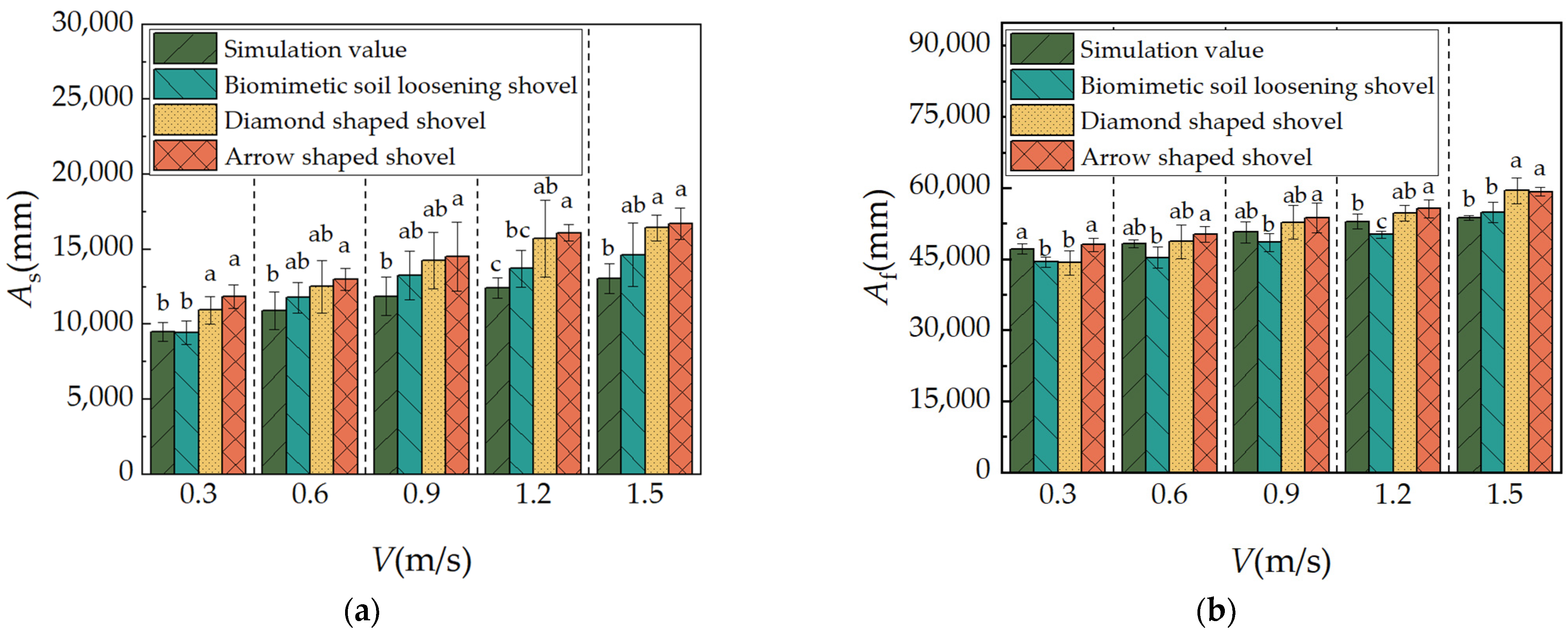

3.2.2. Comparison Values of As and Af Among Three Types of Loosening Shovels

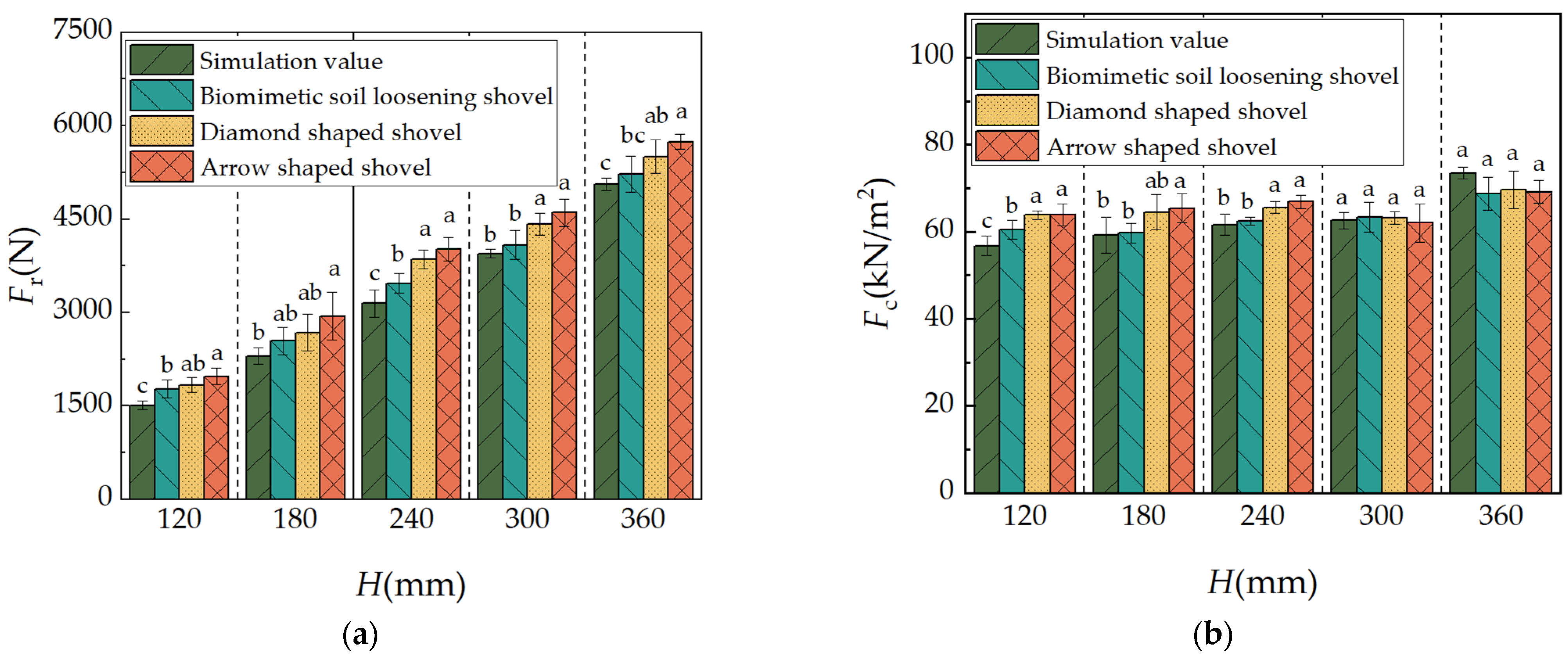

3.2.3. Effects of Operating Parameters on Fr and Fc

4. Conclusions

- The simulation results indicate that As, Af, Fr, and Fc all show a nonlinear increase as V and H increase. As V increases, the growth rate of Fc rises gradually, while the growth rate of Fr remains relatively stable, and the growth rates of As and Af decrease. As H increases, the growth rates of Af and Fr tend to increase, while the growth rates of As and Fc decrease.

- The field tests, conducted with varying values of V and H, show that the changes in As, Af, Fr, and Fc align closely with the trends observed in the simulation results. The Da1 between the test and simulation values for As, Af, Fr, and Fc is less than 10%, indicating that the simulation model can reliably predict the performance of the bionic loosening shovel.

- After using the bionic loosening shovel, the values of α and W were the smallest, with an average α of 18.56° and an average W of 46.33 mm. In contrast, after using the arrow-shaped loosening shovel, α and W were the largest, with an average α of 27.53° and an average W of 84.77 mm. L was the largest with the arrow-shaped loosening shovel and the smallest with the bionic loosening shovel. Overall, the bionic loosening shovel demonstrated a better disturbance effect on the surface soil compared to both the diamond-shaped and arrow-shaped loosening shovels.

- The comparative test results show that the bionic loosening shovel has the smallest As, Fr, and Fc values, while the arrow-shaped loosening shovel has the largest. Specifically, compared with the arrow-shaped loosening shovel, As the bionic loosening shovel is reduced by 15.41% and 20.25%, Fr is reduced by 20.55% and 8.97%, and Fc is reduced by 9.16% and 4.69%. However, the bionic loosening shovel does not significantly improve Af. Considering the requirements for loosening soil in degraded grasslands, the bionic loosening shovel outperforms both the diamond-shaped and arrow-shaped loosening shovels, making it more suitable for this purpose.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Petermann, J.S.; Buzhdygan, O.Y. Grassland biodiversity. Curr. Biol. 2021, 31, R1195–R1201. [Google Scholar] [CrossRef] [PubMed]

- Gu, C.; Jia, Z.; Du, B.; He, L.; Li, Q. Reviews and prospects of ecological restoration measures for degraded grasslands of China. Ecol. Environ. 2022, 31, 1465. [Google Scholar] [CrossRef]

- Wang, Z.; Li, L.; Han, X.; Dong, M. Do rhizome severing and shoot defoliation affect clonal growth of Leymus chinensis at ramet population level? Acta Oecol. 2004, 26, 255–260. [Google Scholar] [CrossRef]

- Zhang, X.; You, Y.; Wang, D.; Wang, Z.; Liao, Y.; Li, S. Soil failure characteristics and loosening effectivity of compacted grassland by subsoilers with different plough points. Biosyst. Eng. 2024, 237, 170–181. [Google Scholar] [CrossRef]

- Han, J.G.; Zhang, Y.J.; Wang, C.J.; Bai, W.M.; Wang, Y.R.; Han, G.D.; Li, L.H. Rangeland degradation and restoration management in China. Rangel. J. 2008, 30, 233. [Google Scholar] [CrossRef]

- Pulido, M.; Schnabel, S.; Lavado Contador, J.F.; Lozano-Parra, J.; Gómez-Gutiérrez, Á.; Brevik, E.C.; Cerdà, A. Reduction of the frequency of herbaceous roots as an effect of soil compaction induced by heavy grazing in rangelands of SW spain. CATENA 2017, 158, 381–389. [Google Scholar] [CrossRef]

- Zhang, Z.; Gong, J.; Wang, B.; Li, X.; Ding, Y.; Yang, B.; Zhu, C.; Liu, M.; Zhang, W. Regrowth strategies of Leymus chinensis in response to different grazing intensities. Ecol. Appl. 2020, 30, e02113. [Google Scholar] [CrossRef]

- Liu, Y.; Meng, L.; Huang, Z.; Shi, Z.; Wu, G. Contribution of fine roots mechanical property of poaceae grasses to soil erosion resistance on the loess plateau. Geoderma 2022, 426, 116122. [Google Scholar] [CrossRef]

- Zhang, X.; You, Y.; Wang, D.; Zhu, L. Quality evaluation of the soil-root composites layer of Leymus chinensis grassland based on different degradation degrees. CATENA 2022, 215, 106330. [Google Scholar] [CrossRef]

- Sang, H.; He, C.; Bi, Y.; Liu, M.; Wang, X. Evaluation of the performance of very narrow tines with different geometrical structures for tilling natural grassland. Biosyst. Eng. 2022, 224, 34–48. [Google Scholar] [CrossRef]

- You, Y.; Wang, D.; Liu, J. A device for mechanical remediation of degraded grasslands. Soil Tillage Res. 2012, 118, 1–10. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, T.; Guo, R.; Li, H.; Zhang, R.; Degen, A.A.; Huang, K.; Wang, X.; Bai, Y.; Shang, Z. Fencing enclosure alters nitrogen distribution patterns and tradeoff strategies in an alpine meadow on the Qinghai-Tibetan Plateau. CATENA 2021, 197, 104948. [Google Scholar] [CrossRef]

- Xu, L.; Nie, Y.; Chen, B.; Xin, X.; Yang, G.; Xu, D.; Ye, L. Effects of fence enclosure on vegetation community characteristics and productivity of a degraded temperate meadow steppe in northern China. Appl. Sci. 2020, 10, 2952. [Google Scholar] [CrossRef]

- De Boer, H.C.; Deru, J.G.C.; Van Eekeren, N. Sward lifting in compacted grassland: Contrasting effects on two different soils. Soil Tillage Res. 2020, 201, 104564. [Google Scholar] [CrossRef]

- Drewry, J.J.; Lowe, J.A.H.; Paton, R.J. Effect of subsoiling on soil physical properties and pasture production on a Pallic Soil in Southland, New Zealand. N. Z. J. Agric. Res. 2000, 43, 269–277. [Google Scholar] [CrossRef]

- Głąb, T.; Kacorzyk, P. Root distribution and herbage production under different management regimes of mountain grassland. Soil Tillage Res. 2011, 113, 99–104. [Google Scholar] [CrossRef]

- Zhang, H.; Araya, K.; Kudoh, M.; Zhang, C.; Jia, H.; Liu, F.; Sawai, T.; Yang, S. An explosive subsoiler for the improvement of meadow soil, part 3: Field experiments. J. Agric. Eng. Res. 2000, 75, 327–332. [Google Scholar] [CrossRef]

- Ning, T.; Liu, Z.; Hu, H.; Li, G.; Kuzyakov, Y. Physical, chemical and biological subsoiling for sustainable agriculture. Soil Tillage Res. 2022, 223, 105490. [Google Scholar] [CrossRef]

- Zhang, L.; Zhai, Y.; Chen, J.; Zhang, Z.; Huang, S. Optimization design and performance study of a subsoiler underlying the tea garden subsoiling mechanism based on bionics and EDEM. Soil Tillage Res. 2022, 220, 105375. [Google Scholar] [CrossRef]

- Huang, Y.; Si, Z.J.; Teng, Y.; Wang, B. Research on the improved effect of grassland desertification salinity-alkalinity by vibration deep loosening integration technology. In Proceedings of the 2011 International Conference on New Technology of Agricultural, Zibo, China, 27–29 May 2011. [Google Scholar] [CrossRef]

- De Boer, H.C.; Deru, J.G.C.; Van Eekeren, N. Sward lifting in compacted grassland: Effects on soil structure, grass rooting and productivity. Soil Tillage Res. 2018, 184, 317–325. [Google Scholar] [CrossRef]

- He, C.; You, Y.; Wang, D.; Wu, H.; Ye, B. An experimental investigation of soil layer coupling failure characteristics on natural grassland by passive subsoiler-type openers. INMATEH-Agric. Eng. 2020, 61, 49–58. [Google Scholar] [CrossRef]

- Wang, X.; Gao, P.; Yue, B.; Shen, H.; Fu, Z.; Zheng, Z.; Zhu, R.; Huang, Y. Optimization of installation parameters of subsoiler’ wing using the discrete element method. Comput. Electron. Agric. 2019, 162, 523–530. [Google Scholar] [CrossRef]

- Liu, K.; Sozzi, M.; Gasparini, F.; Marinello, F.; Sartori, L. Combining simulations and field experiments: Effects of subsoiling angle and tillage depth on soil structure and energy requirements. Comput. Electron. Agric. 2023, 214, 108323. [Google Scholar] [CrossRef]

- Sasaki, C.M.; Gonçalves, J.L.d.M.; da Silva, Á.P. Ideal subsoiling moisture content of Latosols used in forest plantations. For. Ecol. Manag. 2007, 243, 75–82. [Google Scholar] [CrossRef]

- Wang, S.; Wang, H.; Hafeez, M.B.; Zhang, Q.; Yu, Q.; Wang, R.; Wang, X.; Li, J. No-tillage and subsoiling increased maize yields and soil water storage under varied rainfall distribution: A 9-year site-specific study in a semi-arid environment. Field Crops Res. 2020, 255, 107867. [Google Scholar] [CrossRef]

- Zhang, X.; You, Y.; Wang, D.; Lv, J. Design and experiment of a combined root-cutting and ditching device. INMATEH-Agric. Eng. 2022, 66, 383–392. [Google Scholar] [CrossRef]

- Wang, Y.; Li, N.; Ma, Y.; Tong, J.; Pfleging, W.; Sun, J. Field experiments evaluating a biomimetic shark-inspired (BioS) subsoiler for tillage resistance reduction. Soil Tillage Res. 2020, 196, 104432. [Google Scholar] [CrossRef]

- Song, W.; Jiang, X.; Li, L.; Ren, L.; Tong, J. Increasing the width of disturbance of plough pan with bionic inspired subsoilers. Soil Tillage Res. 2022, 220, 105356. [Google Scholar] [CrossRef]

- Li, B.; Chen, Y.; Chen, J. Modeling of soil–claw interaction using the discrete element method (DEM). Soil Tillage Res. 2016, 158, 177–185. [Google Scholar] [CrossRef]

- Hilal, M.G.; Ji, C.; Li, Y.; Tang, K.; Li, H.; Liu, X.; Lin, K.; Wang, D. Deciphering the role of rodents in grassland degradation; A review. J. Environ. Manag. 2024, 370, 122618. [Google Scholar] [CrossRef]

- Guo, Z.G.; Li, X.F.; Liu, X.Y.; Zhou, X.R. Response of alpine meadow communities to burrow density changes of plateau pika (Ochotona curzoniae) in the Qinghai-Tibet Plateau. Acta Ecol. Sin. 2012, 32, 44–49. [Google Scholar] [CrossRef]

- Ucgul, M.; Saunders, C.; Fielke, J.M. Discrete element modelling of top soil burial using a full scale mouldboard plough under field conditions. Biosyst. Eng. 2017, 160, 140–153. [Google Scholar] [CrossRef]

- Zhao, J.; Lu, Y.; Wang, X.; Zhuang, J.; Han, Z. A bionic profiling-energy storage device based on MBD-DEM coupled simulation optimization reducing the energy consumption of deep loosening. Soil Tillage Res. 2023, 234, 105824. [Google Scholar] [CrossRef]

- Tamás, K.; Jóri, I.J.; Mouazen, A.M. Modelling soil–sweep interaction with discrete element method. Soil Tillage Res. 2013, 134, 223–231. [Google Scholar] [CrossRef]

- Tamás, K.; Bernon, L. Role of particle shape and plant roots in the discrete element model of soil–sweep interaction. Biosyst. Eng. 2021, 211, 77–96. [Google Scholar] [CrossRef]

- Yang, Y.; Li, M.; Tong, J.; Ma, Y. Study on the interaction between soil and the five-claw combination of a mole using the discrete element method. Appl. Bionics Biomech. 2018, 2018, 7854052. [Google Scholar] [CrossRef]

- Hang, C.; Gao, X.; Yuan, M.; Huang, Y.; Zhu, R. Discrete element simulations and experiments of soil disturbance as affected by the tine spacing of subsoiler. Biosyst. Eng. 2018, 168, 73–82. [Google Scholar] [CrossRef]

- Hang, C.; Huang, Y.; Zhu, R. Analysis of the movement behaviour of soil between subsoilers based on the discrete element method. J. Terramech. 2017, 74, 35–43. [Google Scholar] [CrossRef]

- Chen, M.; Ma, L.; Shao, M.; Wei, X.; Jia, Y.; Sun, S.; Zhang, Q.; Li, T.; Yang, X.; Gan, M. Chinese zokor (Myospalax fontanierii) excavating activities lessen runoff but facilitate soil erosion—A simulation experiment. CATENA 2021, 202, 105248. [Google Scholar] [CrossRef]

- Mamman, E. The effects of tool width and rake angle on draught and soil failure patterns of model chisels furrowers. In Proceedings of the 2019 ASABE Annual International Meeting, Boston, MA, USA, 7–10 July 2019; ASABE: St. Joseph, MI, USA, 2019. [Google Scholar] [CrossRef]

- JB/T 9788–1999; Subsoiler and Share Shaft. China Machine Press: Beijing, China, 1999.

- Wu, P.; Zhang, X.; Zeng, Z.; Chen, Y. DEM simulation of subsoiling for soil disturbance as affected by soil layering and working speed. Smart Agric. Technol. 2024, 7, 100385. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, J.; Yin, B.; Ma, Z.; Hao, J.; Yang, X.; Feng, X.; Ma, Y. Discrete element modelling of the yam root–soil complex and its verification. Biosyst. Eng. 2022, 220, 55–72. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, H.; Wang, X.; Dong, J.; Zhao, P.; Yang, F.; Chen, X.; Liu, F.; Huang, Y. Discrete element modeling and shear properties of the maize stubble-soil complex. Comput. Electron. Agric. 2023, 204, 107519. [Google Scholar] [CrossRef]

- Xie, K.; Zhang, Z.; Wang, F.A.; Yu, X.; Wang, C.; Jiang, S. Calibration and experimental verification of discrete element parameters of Panax notoginseng root. Int. J. Agric. Biol. Eng. 2024, 17, 12–23. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, S.; Pan, H.; Zheng, Z.; Huang, Y.; Zhu, R. Effect of soil particle size on soil-subsoiler interactions using the discrete element method simulations. Biosyst. Eng. 2019, 182, 138–150. [Google Scholar] [CrossRef]

- GB/T 50123–2019; Standard for Geotechnical Testing Method. China Planning Press: Beijing, China, 2019.

- Zhou, L.; Gao, J.; Hu, C.; Li, Q. Numerical simulation and testing verification of the interaction between track and sandy ground based on discrete element method. J. Terramech. 2021, 95, 73–88. [Google Scholar] [CrossRef]

- Li, J.; Xie, S.; Liu, F.; Guo, Y.; Liu, C.; Shang, Z.; Zhao, X. Calibration and testing of discrete element simulation parameters for sandy soils in potato growing areas. Appl. Sci. 2022, 12, 10125. [Google Scholar] [CrossRef]

- Raper, R.L. Force requirements and soil disruption of straight and bentleg subsoilers for conservation tillage systems. Appl. Eng. Agric. 2005, 21, 787–794. [Google Scholar] [CrossRef]

- GB/T 34751-2017; Utilization Site Classification of Rangeland. Administration for Quality Supervision, Inspection and Quarantine of the People’s Republic of China & Standardization Administration of the People’s Republic of China: Beijing, China, 2017.

- NY/T 1121.4–2006; Soil Testing—Part 4: Method for Determination of Soil Bulk Density. China Agriculture Press: Beijing, China, 2006.

- Aikins, K.A.; Antille, D.L.; Ucgul, M.; Barr, J.B.; Jensen, T.A.; Desbiolles, J.M.A. Analysis of effects of operating speed and depth on bentleg opener performance in cohesive soil using the discrete element method. Comput. Electron. Agric. 2021, 187, 106236. [Google Scholar] [CrossRef]

- McKyes, E.; Maswaure, J. Effect of design parameters of flat tillage tools on loosening of a clay soil. Soil Tillage Res. 1997, 43, 195–204. [Google Scholar] [CrossRef]

- Ibrahmi, A.; Bentaher, H.; Hbaieb, M.; Maalej, A.; Mouazen, A.M. Study the effect of tool geometry and operational conditions on mouldboard plough forces and energy requirement: Part 1. Finite element simulation. Comput. Electron. Agric. 2015, 117, 258–267. [Google Scholar] [CrossRef]

| Material | Parameter | Value |

|---|---|---|

| 65Mn steel | Density (kg/m3) | 7830 [45] |

| Poisson’s ratio | 0.35 [45] | |

| Shear modulus (Pa) | 7.27 × 1010 [45] | |

| Soil particles | Density (kg/m3) | 2650 |

| Poisson’s ratio | 0.4 | |

| Shear modulus (Pa) | 1.15 × 106 | |

| Restitution coefficient between soil particles | 0.50 | |

| Coefficient of static friction between soil particles | 0.45 | |

| Coefficient of rolling friction between soil particles | 0.51 | |

| Restitution coefficient between soil particles and composite particles | 0.50 | |

| Coefficient of static friction between soil particles and composite particles | 0.44 | |

| Coefficient of rolling friction between soil particles and composite particles | 0.51 | |

| Restitution coefficient between soil particles and 65Mn steel | 0.42 | |

| Coefficient of static friction between soil particles and 65Mn steel | 0.61 | |

| Coefficient of rolling friction between soil particles and 65Mn steel | 0.65 | |

| Composite particles | Density (kg/m3) | 2500 |

| Poisson’s ratio | 0.4 | |

| Shear modulus (Pa) | 3.0 × 106 | |

| Restitution coefficient between composite particles | 0.58 | |

| Coefficient of static friction between composite particles | 0.55 | |

| Coefficient of rolling friction between composite particles | 0.49 | |

| Restitution coefficient between composite particles and 65Mn steel | 0.47 | |

| Coefficient of static friction between composite particles and 65Mn steel | 0.54 | |

| Coefficient of rolling friction between composite particles and 65Mn steel | 0.49 |

| Factor | Parameter Value | ||||

|---|---|---|---|---|---|

| V (m/s) | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 |

| H (mm) | 120 | 180 | 240 | 300 | 360 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; You, Y.; Zhang, X.; Wang, D.; Pan, C. Bionic Optimal Design and Performance Study of Soil Loosening Shovels for Degraded Grasslands. Agriculture 2025, 15, 487. https://doi.org/10.3390/agriculture15050487

Wang Z, You Y, Zhang X, Wang D, Pan C. Bionic Optimal Design and Performance Study of Soil Loosening Shovels for Degraded Grasslands. Agriculture. 2025; 15(5):487. https://doi.org/10.3390/agriculture15050487

Chicago/Turabian StyleWang, Zhaoyu, Yong You, Xuening Zhang, Decheng Wang, and Chengzhong Pan. 2025. "Bionic Optimal Design and Performance Study of Soil Loosening Shovels for Degraded Grasslands" Agriculture 15, no. 5: 487. https://doi.org/10.3390/agriculture15050487

APA StyleWang, Z., You, Y., Zhang, X., Wang, D., & Pan, C. (2025). Bionic Optimal Design and Performance Study of Soil Loosening Shovels for Degraded Grasslands. Agriculture, 15(5), 487. https://doi.org/10.3390/agriculture15050487