Recent Research Progress on Key Technologies and Equipment for Mechanized Potato Harvesting

Abstract

:1. Introduction

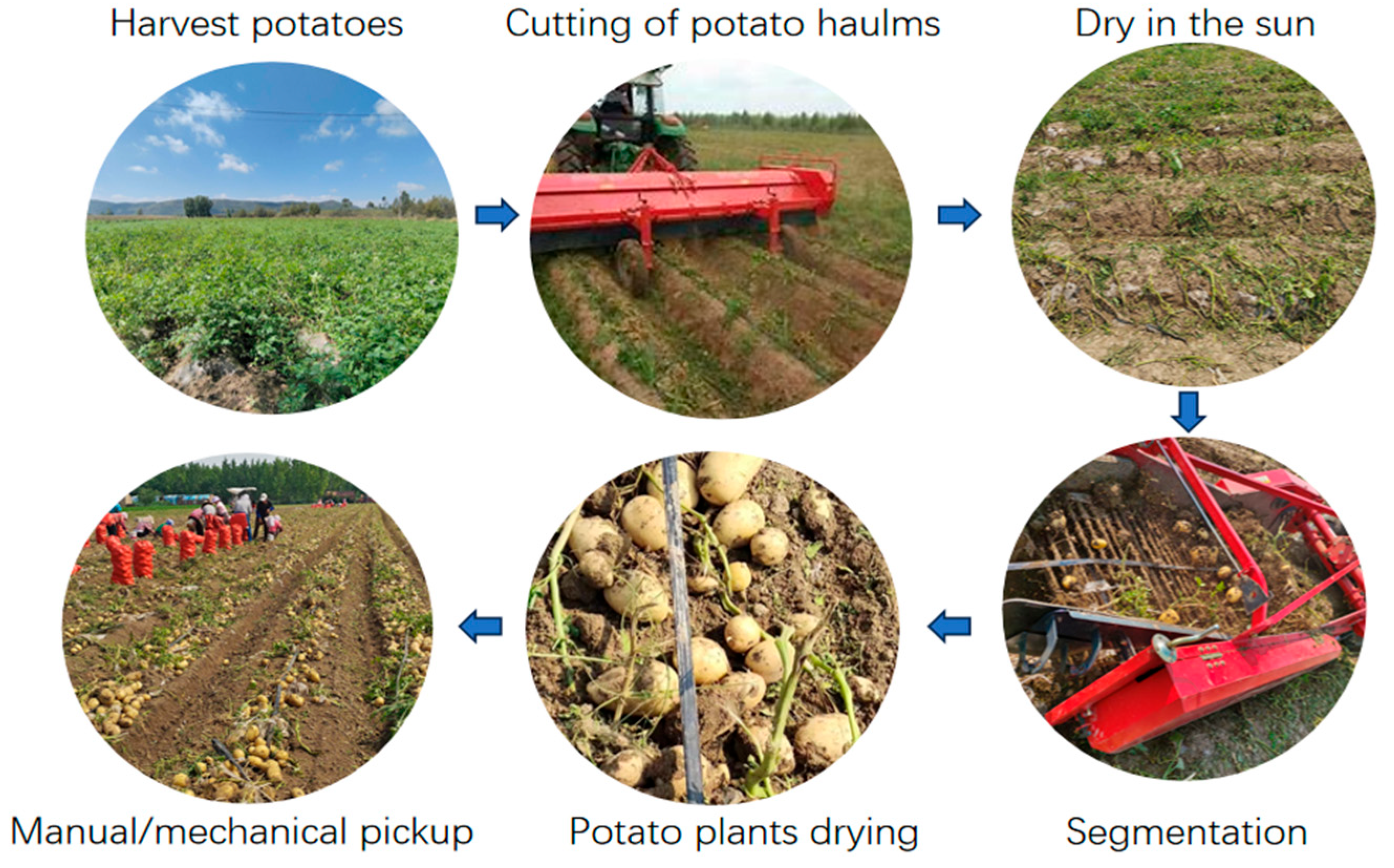

2. Mechanized Potato Harvesting Operation Modes

2.1. Potato Harvesting Operation Mode

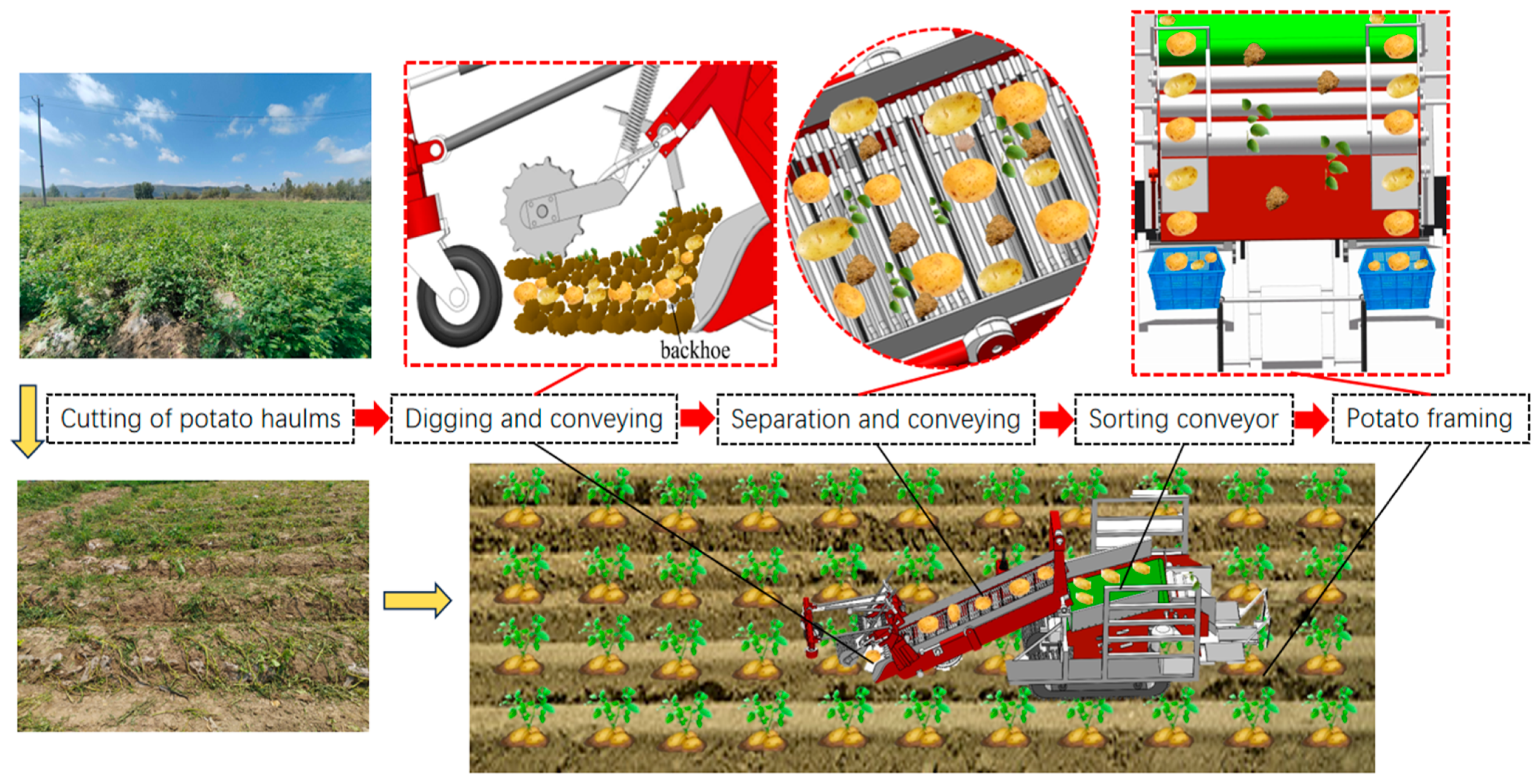

2.2. Potato Combine Harvester Operation Mode

3. Key Technologies for Mechanized Potato Harvesting

3.1. Potato Haulms Removal Technology

3.2. Potato-Digging Techniques

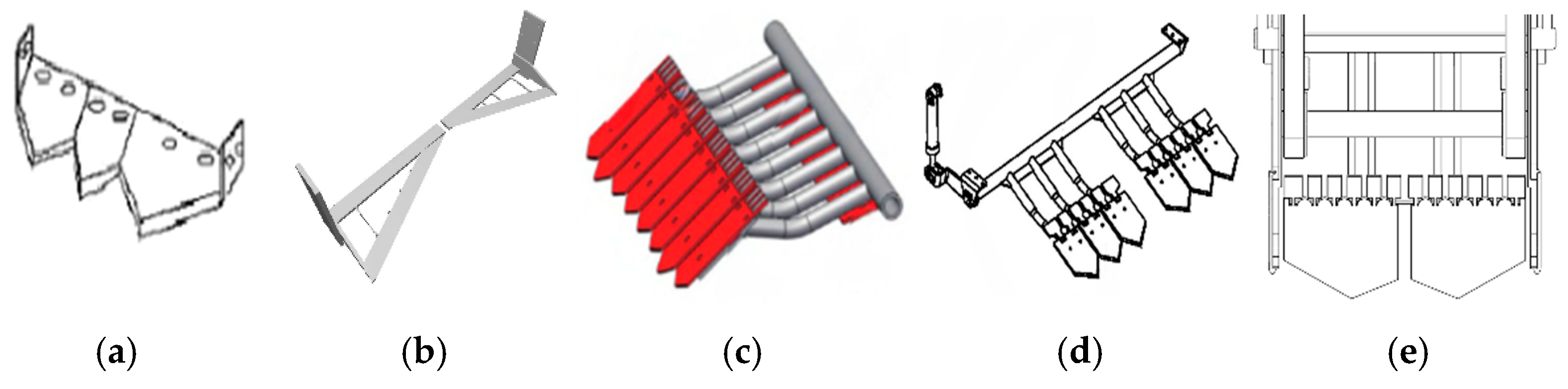

3.2.1. Flat Excavator Shovel

3.2.2. Vibratory Digging Shovel

3.2.3. Hybrid Bionic Digging Shovel

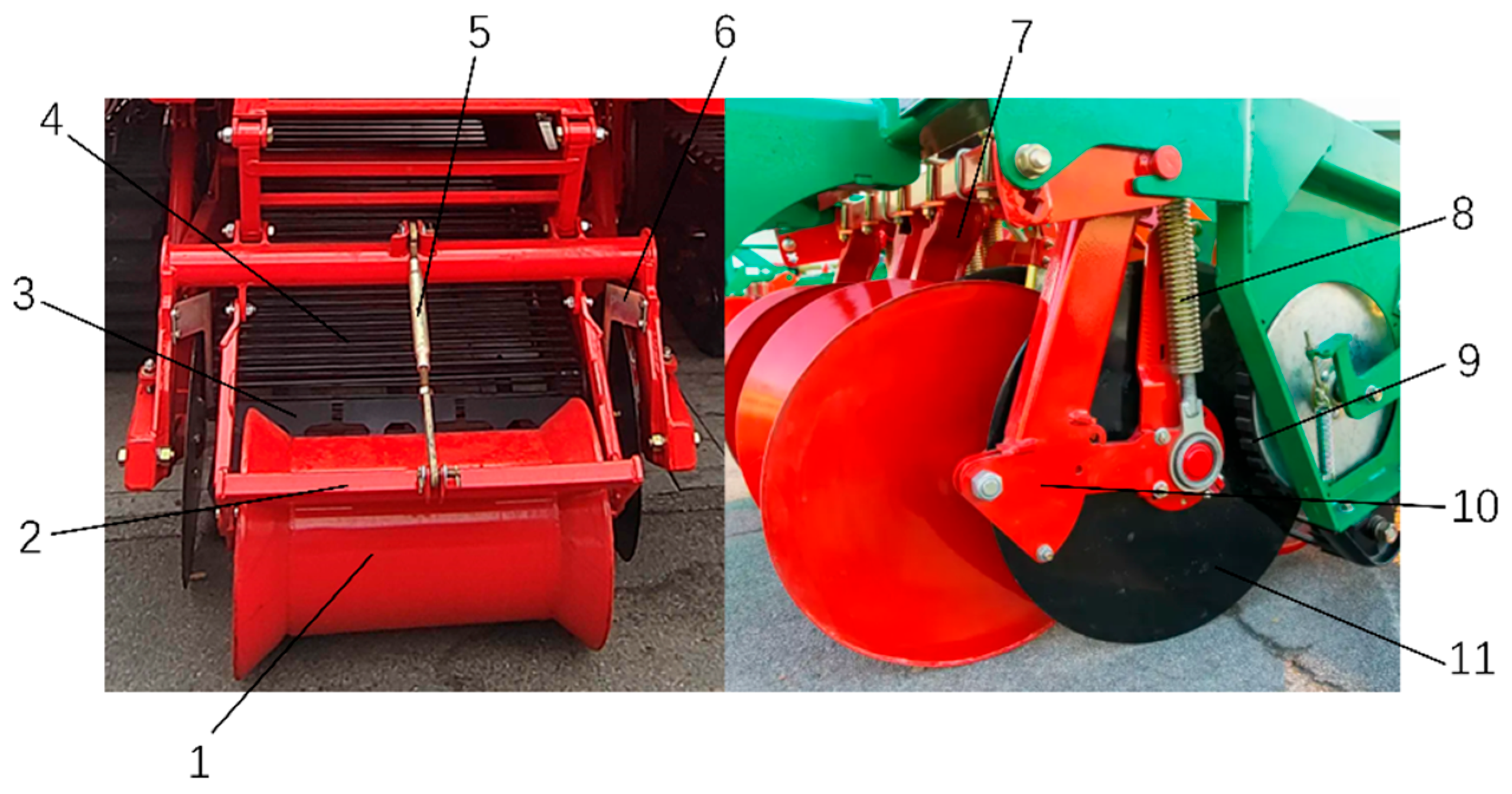

3.3. Potato Depth-Limiting Technology

3.4. Potato Separation Technology

3.4.1. Segmented Harvest Separation Technology

3.4.2. Combined Harvest Separation Technology

3.5. Impurity Separation Technology

3.6. Potato-Sorting Tonnage Technology

3.7. Intelligent Harvesting Technology

4. Mechanized Potato-Harvesting Equipment

4.1. Small- and Medium-Sized Potato-Harvesting Equipment

4.1.1. Small- and Medium-Sized Segmented Harvesting Equipment

4.1.2. Small- and Medium-Sized Combined Harvesting Equipment

4.2. Large Potato-Harvesting Equipment

4.3. Characteristics of Potato-Harvesting Equipment at Home and Abroad

- (1)

- The application rate of domestic Chinese large-scale potato-harvesting equipment is low. Europe, the United States, and other developed countries have fully achieved entirely mechanized potato harvesting in both large fields and small plots, as well as other varied terrains. In Japan, South Korea, and other countries that are characterized by hilly and mountainous areas with a lack of plains, their research into and use of small- and medium-sized potato-harvesting equipment has led to a high mechanization utilization rate and an advanced level of intelligence technology used. Due to the terrain and unique planting pattern restrictions in China, the application rate of large potato-harvesting equipment is low; simple structures with a low level of intelligence, i.e., small- and medium-sized potato-harvesting equipment, are more commonly used.

- (2)

- Creating new key harvesting technologies is difficult, and the equipment has a short service life. There has been much domestic Chinese research conducted on key potato-harvesting technology, but less research has been carried out on intelligent potato digging and transportation, low-loss flexible separation, efficient and clean sorting, and other innovative research. The output results are insufficient, and the adaptability to different terrains and soil environments is poor. The manufacturing processes for commonly used equipment, such as digging shovels, seedling-cutting disks, elevating and transporting separation screens, conveying and sorting belts, and other materials, should be improved, and these components should be characterized by wear resistance, a high level of toughness, and low clay resistance to improve their service life.

- (3)

- In China, the degree of technology integration is insufficient, and the utilization rate of intelligent technology is low. Foreign joint harvesting equipment, digging devices, and separating and conveying equipment are applicable to different planting modes, and the potato collection device parameters can be adjusted in real time, which greatly improves the utilization rate of the equipment. Domestic potato-harvesting equipment more often follows a purely mechanical design, meaning that fewer adjustments can be made via adaptive control equipment to the limit depth, conveying speed, vibration frequency amplitude, and other key parameters; this equipment relies on the manual adjustment of these parameters.

4.4. Comparative Economic Efficiency of Potato-Harvesting Equipment

5. Summary and Development Recommendations

5.1. Problems with Mechanized Potato Harvesting

- (1)

- The development of mechanization is unbalanced, with great regional differences. China’s potato-planting area is vast and covers plains, mountains, terraces, and so on. In areas with plains, the uptake of potato-harvesting equipment is higher, including segmented potato harvesters and various other types of potato combine harvesters [9]. In hilly and mountainous areas, areas with terraces, and other complex terrains, flat crops, ridge crop intercropping, and other planting modes are common, making mechanized harvesting more difficult; for example, in the Yunnan–Guizhou Plateau potato-planting zone, the mechanized harvesting rate is less than 5%. In Qinghai, Inner Mongolia, Gansu, and other places where the soil moisture content varies greatly, there are more planting areas with slate and slopes; using mechanized harvesting in these areas requires changing the working parameters of the equipment more often and thereby reducing the harvester’s efficiency. At the same time, it is difficult to take into account the rate of potato loss, the skin-breaking rate, and the rate of impurities. Compared with the plains, the inability to provide high-quality potato harvesters in these areas is a major bottleneck problem faced at this stage.

- (2)

- High-quality potato–soil separation and potato–impurity separation is difficult, and there is a lack of high-efficiency and low-loss separation devices. High-quality harvesting, namely, mechanized potato harvesting, has been used to solve this core problem; the potato mechanical damage is low, the soil content on the surfaces of the harvested potatoes is lower, and the harvesting equipment recycling rate is high. There is not a large difference in potato harvest quality between automatically and manually sorted potatoes, and automatic harvesting often has a more flexible clean-up. In many major production areas, in order to improve the potato yield and to ensure weed prevention, mulch planting is used, which requires potato-harvesting equipment. Mechanical harvesting has a good potato–impurity separation function, whereas, when using most of the current harvesting equipment, it is difficult to separate residual impurities, prompting the potato harvester to harvest a high rate of impurities.

- (3)

- The harvesting of fresh potatoes accounts for a large proportion of the total yield, which is difficult to achieve using mechanical harvesting. There are two main uses for potatoes after harvesting; some are used as starch potatoes, which are sent to factories for processing and selling, but their rate of return is low. Others are used as fresh potatoes, which are sold in vegetable wholesale markets, supermarkets, and so on; their rate of return is high. Many merchants and farmers naturally favor fresh potatoes and choose fresh potatoes for both planting and selling, so fresh potatoes have in the past accounted for more than 65% of the domestic potato harvest [131,132]. Fresh potatoes should be high-quality, and the surface layers of these potatoes need to be completely lignified during the harvesting period to prevent surface or internal damage caused by the mechanical harvesting process.

- (4)

- There are many bottleneck technologies and few high-quality harvesting machines. The manufacturing process for domestic potato-harvesting machinery is rough, and the application rate of special flexible materials is low, among other problems. The main reason for this is that domestic high-precision processing equipment is insufficient and that special flexible materials incur high costs. The existing processing equipment in small factories is not able to meet the precision requirements of high-quality potato-harvesting equipment, and they find it difficult to bear the huge cost of selecting special high-quality materials. Secondly, many aspects of harvesting technology research are currently insufficient, including harvesting bottleneck technology, intelligent technology, digging and conveying device technology, the development of automatic depth regulation technology, low-loss and high-efficiency potato–soil separation technology, adaptive regulation technology, machine identification application technology, and human–machine interaction technology.

5.2. Recommendations for Mechanized Potato Harvesting

- (1)

- We should harmonize unbalanced development regions and develop multiple models collaboratively. Potatoes are planted in the main production areas in plain and hilly mountainous areas. The utilization rate of potato-harvesting equipment models in plain areas can be introduced to hilly mountainous areas and improved. For hilly and mountainous areas, small plots, and other terrains, users can pick from a variety of models according to their needs, including potato diggers, pickers, and small self-propelled potato harvesters; these models can provide minimum potato damage and high harvesting efficiency.

- (2)

- The research and development of high-quality harvesting and separation equipment should be increased. High-quality potato soil separation and potato–impurity separation are the core problems that potato-harvesting equipment research needs to solve. At the same time, potato soil–separation devices and potato–impurity separation devices affect the potato damage rate, broken skin rate, and impurity rate of the direct parts. From a mechanical design perspective, adding buffer damage reduction devices, flexible low-loss materials, and adaptive control systems are research directions for potato-harvesting and separation equipment. When adding key devices, low-loss-material selection is an important way to meet potato-harvesting objectives. In medium- and large-scale harvesting equipment, the separation equipment should offer automatic cleaning, overload protection, parameter adjustment, real-time matching of rotational speed, and other key functions for in-depth research.

- (3)

- Intelligent technology needs to be integrated in order to solve the bottleneck problem. The structural innovations of existing equipment make it difficult to solve the practical problems faced in potato harvesting. Machine vision and other technologies should be used to identify the differences between potatoes, soil, and impurities; intelligent control systems and the precise control of the separation device should be used to achieve the efficient separation of potatoes; sensors should be installed to monitor the number of potatoes conveyed and the conveyor belt speed; and an intelligent control system should be used to automatically adjust the speed of the conveyor belt in order to avoid the accumulation of potatoes or clogging. In the future, the focus should be on integrating soil sensors, crop sensors, position sensors, and other information using a central control system for the real-time intelligent regulation of digging depth, separation parameters, conveying speed, and other operating parameters so that the harvester can be automatically adjusted to the optimal state of operation, in accordance with the different soil conditions and crop growth, thereby improving the quality and efficiency of the operation.

- (4)

- The government should optimize industrial infrastructure and strengthen quality supervision. The government should also help to solve the current problems with the manufacturing processes of potato-harvesting machinery by providing a number of subsidies to support important production enterprises in updating these processes. At the same time, the government should encourage research institutes and agricultural enterprises to join forces and to combine innovative theories and production practices to enhance the driving force of innovation. In addition, the government should improve the social service systems for agricultural machinery and promote potato-harvesting equipment diversification reform.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.G.; Li, Y.B.; Wang, H.Y.; Zhang, Z.D.; Liu, X.C. Progress of key technologies and equipment for mechanized potato harvesting. J. Yunnan Agric. Univ. Nat. Sci. 2021, 36, 1092–1103. [Google Scholar]

- Dou, Q.Q.; Sun, Y.G.; Sun, Y.T.; Shen, J.X.; Li, Q.L. Current status and development of potato harvesting machinery at home and abroad. Chin. J. Agric. Mech. Chem. 2019, 40, 206–210. [Google Scholar]

- Xu, N.; Zhang, H.L.; Zhang, R.H.; Xu, Y.K. Current situation and outlook of potato farming in China. China Potato 2021, 35, 81–96. [Google Scholar]

- Li, Y.; Wang, J.; Tang, J.Z.; Zhang, J.; Hu, Q.; Pan, Z.H.; Pan, X.B. Analysis of production characteristics, limiting factors and countermeasures in major potato producing areas in China. China Potato 2020, 34, 374–382. [Google Scholar]

- Almady, S.S.; Al-Hamed, S.A.; Marey, S.A.; Al-Sager, S.M.; Aboukarima, A.M. An Assessment of Some Mechanical Properties of Harvested Potato Tubers Cv. Spunta. Agronomy 2024, 14, 1116. [Google Scholar] [CrossRef]

- Pszczółkowski, P.; Barbaś, P.; Sawicka, B.; Krochmal-Marczak, B. Biological and Agrotechnical Aspects of Weed Control in the Cultivation of Early Potato Cultivars under Cover. Agriculture 2020, 10, 373. [Google Scholar] [CrossRef]

- Wang, H.C.; Zhao, W.Y.; Sun, W.; Zhang, H.; Liu, X.L.; Li, H. Research progress on mechanized potato harvesting technology and equipment. J. Agric. Eng. 2023, 39, 1–22. [Google Scholar]

- Wei, Z.C.; Li, X.Q.; Zhang, Y.F.; Li, H.W.; Sun, C.Z. Progress in research on mechanized potato production technology and equipment for the whole potato production process. Agric. Mech. Res. 2017, 39, 1–6. [Google Scholar]

- Li, Z.H.; Wen, X.Y.; Lv, J.Q.; Li, J.C.; Yi, S.J.; Qiao, D. Analysis and Prospect of the Progress of Research on Key Technologies and Equipment for Mechanization of Potato Planting. J. Agric. Mach. 2019, 50, 1–16. [Google Scholar]

- Wei, Z.C.; Wang, Y.W.; Su, G.L.; Zhang, X.G.; Wang, X.L.; Cheng, X.P.; Li, X.Q.; Jin, C.Q. Progress in potato mechanized harvesting and debris removal technology and equipment. J. Agric. Eng. 2024, 40, 1–13. [Google Scholar]

- Kayad, A.; Paraforos, D.S.; Marinello, F.; Fountas, S. Latest Advances in Sensor Applications in Agriculture. Agriculture 2020, 10, 362. [Google Scholar] [CrossRef]

- Li, G.; Zhou, S.; Deng, G.; Zheng, S.; He, F.; Cui, Z.; Dai, Y.; Li, L.; Yan, B.; Qin, S.; et al. Research Progress on Mechanization Technology and Equipment for Cassava Field Production. Agriculture 2024, 14, 1926. [Google Scholar] [CrossRef]

- Zhou, B.; Li, Y.; Zhang, C.; Cao, L.; Li, C.; Xie, S.; Niu, Q. Potato Planter and Planting Technology: A Review of Recent Developments. Agriculture 2022, 12, 1600. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhu, X.; Li, J.; Lyu, J.; Qi, Y.; Liu, J. Design and Test of an Arc-Shaped Tooth Press Device for Combined Soil Preparation Equipment for Growing Potatoes. Agriculture 2023, 13, 1193. [Google Scholar] [CrossRef]

- Wei, H.G.; Zhang, J.L.; Yang, X.P.; Huang, X.P.; Dai, L.X.; Sun, G.H.; Liu, X. Improved design and experiment of 4UFD-1400 potato combine harvester. Trans. Chin. Soc. Agric. Eng. 2014, 30, 12–17. [Google Scholar]

- Zhang, X.; Liu, J.; Zhang, C.; Zhao, Y.; Du, X. Design and Experimentation of Small Potato Harvester for Heavy Soil in Hilly and Mountainous Areas. Agronomy 2024, 14, 2131. [Google Scholar] [CrossRef]

- Yang, X.; Wu, Y.; Wang, L.; Liu, F.; Zhao, X.; Bai, H.; Dong, W.; Kong, X.; Hu, H.; Zhong, W.; et al. Design and Performance Test of 4UJ-180A Potato Picking and Bagging Machine. Agriculture 2024, 14, 454. [Google Scholar] [CrossRef]

- Xie, S.S.; Wang, C.G.; Deng, W.G.; Li, X.; Qi, S.H. Analysis on the mechanism of potato-soil separation and parameter optimization experiment of swing separation screen. Trans. Chin. Soc. Agric. Mach. 2017, 48, 156–164. [Google Scholar]

- Xie, S.S.; Wang, C.G.; Deng, W.G. Potato collision damage test and collision acceleration characterization. J. China Agric. Univ. 2020, 25, 163–169. [Google Scholar]

- Shen, H.Y.; Luo, W.W.; Wu, F.; Gu, F.W.; Yang, H.G.; Hu, Z.C. Research progress on equipment and technology of mechanized peanut harvesting. Trans. Chin. Soc. Agric. Mach. 2024, 55, 21–38. [Google Scholar]

- Shen, H.Y.; Wang, B.; Hu, L.L.; Wang, G.P.; Ji, L.L.; Shen, G.W.; Wu, T. Design of potato tuber transfer and conveying mechanism for 4UZL-1 sweet potato combine harvester. J. Agric. Eng. 2020, 36, 9–17. [Google Scholar]

- Li, Y.; Fan, J.; Hu, Z.; Luo, W.; Yang, H.; Shi, L.; Wu, F. Calibration of Discrete Element Model Parameters of Soil around Tubers during Potato Harvesting Period. Agriculture 2022, 12, 1475. [Google Scholar] [CrossRef]

- Li, Z.; Sun, W.; Wang, H.; Wang, J.; Simionescu, P.A. Study on the Process of Soil Clod Removal and Potato Damage in the Front Harvesting Device of Potato Combine Harvester. Agriculture 2024, 14, 1947. [Google Scholar] [CrossRef]

- Shen, H.Y.; Ji, L.L.; Hu, L.L.; Wang, B.; Wang, G.P.; Bao, G.C. Study on mechanical and physical properties parameters of sweet potato tubers during harvest period. Chin. J. Agric. Mech. 2020, 41, 55–61. [Google Scholar]

- Wei, Z.C.; Wang, Y.W.; Li, X.Q.; Wang, J.M.; Su, G.L.; Meng, P.C.; Han, M.; Jin, C.Q.; Li, Z.H. Design and test of flexible kneading potato combine harvester. J. Agric. Eng. 2023, 39, 60–69. [Google Scholar]

- Yang, R.B.; Tian, G.B.; Shang, S.Q.; Wang, B.J.; Zhang, J.; Zhai, Y.M. Design and experiment of roller-type potato-soil separation device for potato harvester. Trans. Chin. Soc. Agric. Mach. 2023, 54, 107–118. [Google Scholar]

- Zhang, Z.G.; Zhang, Z.D.; Li, G.N.; Wang, H.Y.; Li, Y.B.; Li, D.H. Detection of potato in complex environments using improved YoloV4 model. J. Agric. Eng. 2021, 37, 170–178. [Google Scholar]

- Li, J.; Li, X.; Hu, B.; Gu, T.; Wang, Z.; Wang, H. Analysis of the Resistance Reduction Mechanism of Potato Bionic Digging Shovels in Clay and Heavy Soil Conditions. Comput. Electron. Agric. 2023, 214, 108315. [Google Scholar]

- Zhao, Z.; Deng, W.; Hu, X.; Yu, H.; Li, Q. Investigation of Impact Contact Force Testing and Damage Analysis on Potatoes. Agriculture 2024, 14, 1740. [Google Scholar] [CrossRef]

- Xie, Q.; Song, M.; Wen, T.; Cao, W.; Zhu, Y.; Ni, J. A Hob-Type Smart Weeding Machine for Use in Wheat Fields: Towards a Low Power Consumption and High-Efficiency Design. Comput. Electron. Agric. 2024, 227, 109519. [Google Scholar]

- Wang, X.; Wang, Q.; Qiao, Y.; Zhang, X.; Lu, C.; Wang, C. Precision Weed Management for Straw-Mulched Maize Field: Advanced Weed Detection and Targeted Spraying Based on Enhanced YOLO V5s. Agriculture 2024, 14, 2134. [Google Scholar] [CrossRef]

- Lü, J.Q.; Yu, J.; Li, Z.Y. Design of key components of potato seedling killer. In Proceedings of the Potato Industry and Green Development, Yulin, China, 24 July 2021; Potato Committee of the Chinese Society of Crop Science: Beijing, China, 2021; p. 9. [Google Scholar]

- Zhu, X.X.; Lü, Y.N.; Yu, J.; Li, J.C. Design and experiment of potato stem and leaf chopping knife roller in full ridge. Trans. Chin. Soc. Agric. Mach. 2022, 53, 140–150. [Google Scholar]

- Feng, B.; Sun, W.; Wang, D.; Zhang, J.L.; Zhang, H.; Shi, L.R.; Wu, J.M. Design and experiment of potato vine seedling killer with flailing knife. Agric. Res. Arid Areas 2014, 32, 269–274. [Google Scholar]

- Lü, J.Q.; Shang, Q.Q.; Yang, Y.; Li, Z.H.; Li, J.C.; Liu, Z.Y. Design optimization and experiment of potato seedling killer. Trans. Chin. Soc. Agric. Mach. 2016, 47, 106–114+98. [Google Scholar]

- Peng, M.M.; Lv, J.Q.; Sun, H.; Yu, J.Y. Design of a four-row potato seedling cutting machine. Agric. Mech. Res. 2019, 2, 41. [Google Scholar]

- Kwinda, M.; Siebert, S.J.; Van Coller, H.; Masehela, T.S. Identifying Plant Functional Traits of Weeds in Fields Planted with Glyphosate-Tolerant Maize for Preferable Weed Management Practices. Agriculture 2024, 14, 223. [Google Scholar] [CrossRef]

- Jiao, J.; Hu, L.; Chen, G.; Chen, C.; Zang, Y. Development and Experimentation of Intra-Row Weeding Device for Organic Rice. Agriculture 2024, 14, 146. [Google Scholar] [CrossRef]

- Goyal, R.; Nath, A.; Niranjan, U. Weed Detection Using Deep Learning in Complex and Highly Occluded Potato Field Environment. Crop Prot. 2025, 187, 106948. [Google Scholar]

- Chen, P.; Xia, T.; Yang, G. A New Strategy for Weed Detection in Maize Fields. Eur. J. Agron. 2024, 159, 127289. [Google Scholar]

- Yang, R.; Zhai, Y.; Zhang, J.; Zhang, H.; Tian, G.; Zhang, J.; Huang, P.; Li, L. Potato Visual Navigation Line Detection Based on Deep Learning and Feature Midpoint Adaptation. Agriculture 2022, 12, 1363. [Google Scholar] [CrossRef]

- Goyal, R.; Nath, A.; Niranjan, U.; Sharda, R. Analyzing the Performance of Deep Convolutional Neural Network Models for Weed Identification in Potato Fields. Crop Prot. 2025, 188, 107035. [Google Scholar] [CrossRef]

- Ruysschaert, G.; Poesen, J.; Verstraeten, G.; Govers, G. Soil Losses Due to Mechanized Potato Harvesting. Soil Tillage Res. 2006, 86, 52–72. [Google Scholar] [CrossRef]

- Jia, J.X.; Zhang, D.X.; Sang, Y.Y.; Yang, X. Computer-aided analysis and simulation of potato digging shovel experimental study. J. Agric. Eng. 2006, 22, 106–110. [Google Scholar]

- Wang, Z.D.; Wang, S.S.; Zhu, P.Y.; Zhu, D.G. Research on key parameters of ginger rhizome excavation shovel based on discrete element method. J. Northwest Agric. For. Univ. Nat. Sci. Ed. 2025, 1–13. [Google Scholar] [CrossRef]

- Sun, W.; Wang, H.C.; Zhao, W.Y.; Zhang, H.; Liu, S.; Wu, J. Residual film recycling-type full-film soil-covered ridge-sown potato digger design and test. J. Agric. Mach. 2018, 49, 105–114. [Google Scholar]

- Zhou, J.; Cai, H.X.; Hu, G.R.; Chen, Y.; Chen, J. Design and testing of potato digging shovels based on monoculture two-row planting agronomy. Agric. Mech. Res. 2024, 46, 191–195. [Google Scholar]

- Han, L.; Liu, X.Z. Optimization design of digging shovel for potato harvester. Mech. Eng. 2023, 67–68+71. [Google Scholar]

- Wang, D.W.; Wang, J.S.; Shang, S.Q. Experimental study on vibration-based soil excavation resistance and energy consumption characteristics. J. Agric. Mach. 2020, 51, 267–272. [Google Scholar]

- Wu, T.; Huang, W.F.; Huang, J.B.; Liu, Q.T. Design and test of potato vibratory excavation test rig. Agric. Mech. Res. 2020, 42, 44–50. [Google Scholar]

- Liu, B.; Zhang, D.X.; Li, J. Design of MZPH-820 single-row potato harvester. Trans. Chin. Soc. Agric. Mach. 2009, 40, 81–86. [Google Scholar]

- Yang, H.G.; Yang, R.B.; Shang, S.Q.; Liu, Z.S.; Ni, Z.W. Design and experiment of vibrating digging potato harvester. China Agric. Sci. Technol. Rev. 2017, 19, 55–62. [Google Scholar]

- Jia, H.L.; Wang, W.P.; Chen, Z.; Zheng, T.Z.; Zhang, P.; Zhuang, J. Current Status and Prospects of Research on Optimization of Soil-Touching Components of Agricultural Machinery. J. Agric. Mach. 2017, 48, 1–13. [Google Scholar]

- Lv, J.Q.; Tian, Z.E.; Wu, J.E.; Yang, Y.; Shang, Q.Q.; Wang, Y.B.; Liu, Z.X. Design and test of a 4U1Z vibratory potato digger. J. Agric. Eng. 2015, 31, 39–47. [Google Scholar]

- Chen, K.; Gao, Y.Y.; Yang, L.Q.; Zhao, Y.Q. Design and simulation analysis of vibrating shovel potato harvester. Agric. Mech. Res. 2018, 40, 44–50. [Google Scholar]

- Liu, X.; He, B.T.; Duan, A.G.; Li, Y.P.; Qi, J.T.; Yu, F. Design of key components of vibratory potato digging device. Chin. J. Agric. Mech. Chem. 2020, 41, 6–12. [Google Scholar]

- Zhang, Y.; Qiao, C.X.; Wang, T.Q.; Cao, J.F.; Wang, P.F.; Shi, L. The mechanism of drag reduction in the three-dimensional geometric conformation of the claw toes of mole crickets (Gryllotalpa crickets) forefoot. J. Agric. Eng. 2021, 37, 309–315. [Google Scholar]

- Wang, S.W.; Li, S.J.; Zhang, Y.L.; Wan, Q.; Chen, H.; Meng, L. Mole Toe Bionics and Surface Heat Treatment to Improve Resistance Reduction and Wear Resistance of Toothed Trenching Knives. J. Agric. Eng. 2019, 35, 10–20. [Google Scholar]

- Zhang, Z.G.; Xue, H.T.; Wang, Y.C.; Jie, K.T.; Deng, Y.X. Design and experiment of a Sanqi bionic excavator shovel based on discrete element method. Trans. Chin. Soc. Agric. Mach. 2022, 53, 100–111. [Google Scholar]

- Li, J.W.; Gu, T.L.; Li, X.Y.; Wang, Z.J.; Hu, B.; Ma, Y.H. Bionic drag reduction characteristics of potato digging shovels under clay-heavy black soil conditions analyzed and tested. J. Agric. Eng. 2023, 39, 1–9. [Google Scholar]

- Li, X.P.; Liao, M.; Hu, B.; Pan, Q.L.; Tao, J.J. Potato bionic digging shovel blade and its drag reduction characteristics. Agric. Mech. Res. 2019, 41, 19–25+31. [Google Scholar]

- Fan, Y. Research on Potato Digging Mechanism and Bionic Shovel Design Based on Discrete Element Method. Ph.D. Thesis, Shenyang Agricultural University, Shenyang, China, 2020. [Google Scholar]

- Bao, J.L. Design and Test of Bionic Self-Sharpening Sharp Potato Digging Shovel. Master’s Thesis, Jilin University, Changchun, China, 2022. [Google Scholar]

- Yu, J.; Ma, Y.; Wang, S.; Xu, Z.; Liu, X.; Wang, H.; Qi, H.; Han, L.; Zhuang, J. 3D Finite Element Simulation and Experimental Validation of a Mole Rat’s Digit Inspired Biomimetic Potato Digging Shovel. Appl. Sci. 2022, 12, 1761. [Google Scholar] [CrossRef]

- Wei, Z.C.; Li, H.W.; Sun, C.Z.; Li, X.Q.; Su, G.L.; Liu, W.Z. Design and test of potato combine harvester based on multi-stage separation process. J. Agric. Mach. 2019, 50, 129–140+112. [Google Scholar]

- Yue, R.C. Research on the Decompression System of Potato Combine Harvester on the Ridge. Master’s Thesis, Shandong University of Technology, Zibo, China, 2020. [Google Scholar]

- Wu, H.C.; Hu, Z.C.; Peng, B.L.; Gu, F.W.; Wang, H.O.; Wang, B.K. Development of automatic row alignment system for towed sugar beet combine harvester. J. Agric. Eng. 2013, 29, 17–24. [Google Scholar]

- Li, T.; Zhou, J.; Xu, W.Y.; Zhang, H.; Liu, C.G.; Jiang, W. Design and test of automatic row alignment system for root and tuber crop harvester. J. Agric. Mach. 2019, 50, 102–110. [Google Scholar]

- Wang, S.Y.; Hu, Z.C.; Chen, Y.Q.; Gu, F.W.; Peng, B.L.; Lv, X.L. Development of automatic row-to-row digging and harvesting test bed for subsoil crops. J. Agric. Eng. 2020, 36, 29–37. [Google Scholar]

- Wu, J.M.; Li, F.; Sun, W.; Huang, X.P.; Zhang, W. Experimentation of a finger-wheel potato digger. J. Agric. Eng. 2011, 27, 173–177. [Google Scholar]

- Chen, S.D.; Hu, Z.C.; Wang, B.; You, S.Y.; Peng, B.L.; Hu, L.L. Design and parameter optimization of potato and seedling separating mechanism of monorow single-row sweet potato combine harvester. J. Agric. Eng. 2019, 35, 12–21. [Google Scholar]

- Lv, J.Q.; Sun, H.; Tui, H.; Yang, X.H.; Liu, Z.F. Design and test of a two-row towed potato digger. Agric. Mech. Res. 2019, 41, 98–103. [Google Scholar] [CrossRef]

- Wei, Z.C.; Su, G.L.; Li, X.Q.; Wang, F.M.; Sun, C.Z.; Meng, P.X. Optimization and experimentation of wavy screen surface parameters of potato harvester based on discrete elements. J. Agric. Mach. 2020, 51, 109–122. [Google Scholar]

- Wei, Z.C.; Han, M.; Su, G.L.; Zhang, H.; Li, X.Q.; Jin, C.Q. 4UL-2 potato tonnage bale combine harvester design and test. J. Agric. Mach. 2023, 1–12. [Google Scholar]

- Wei, Z.C.; Li, H.W.; Su, G.L.; Sun, C.Z.; Liu, W.Z.; Li, X.Q. Development of buffer sieve-type potato harvester for separating potato impurities. J. Agric. Eng. 2019, 35, 1–11. [Google Scholar]

- Wei, Z.C.; Li, H.W.; Su, G.L.; Sun, C.Z.; Liu, W.Z.; Li, X.Q. Design and test of low spreading double buffer potato harvester. J. Agric. Mach. 2019, 50, 140–152. [Google Scholar]

- Feng, B.; Sun, W.; Sun, B.G.; Zhang, T.; Wu, J. Study on the impact characteristics of potato tuber drop and damage law during harvesting in Shilinrong. Vib. Shock. 2019, 38, 267–274. [Google Scholar]

- Feng, B. Research on physical characteristics and damage mechanism of potato tubers during harvest. Ph.D. Thesis, Gansu Agricultural University, Lanzhou, China, 2018. [Google Scholar]

- Feng, B.; Wang, H.C.; Wang, G.P.; Sun, W.; Shi, L.R.; Tian, B. Optimization and experimentation of separation sieve operating parameters of a small potato harvester. Agric. Mech. Res. 2024, 46, 138–144+152. [Google Scholar]

- Feng, B.; Sun, W.; Shi, L.Y.; Sun, B.G.; Zhang, T.; Wu, J.M. Determination of collision recovery coefficient of potato tubers at harvest time and analysis of influencing factors. J. Agric. Eng. 2017, 33, 50–57. [Google Scholar]

- Lü, J.Q.; Zhao, Z.M.; Yang, D.Q.; Zhu, X.X.; Qi, Y. Research on screening and conveying device of potato harvester. In Proceedings of the Potato Industry and Seed Industry Innovation, Qiqihar, China, 16 July 2023; Potato Industry and Seed Innovation: Qiqihar, China, 2023; p. 7. [Google Scholar]

- Lü, J.Q.; Sun, H.; Dui, H.; Li, Z.H. Research and experiment on the configuration of lifting bars of potato harvester. In Proceedings of the Potato Industry and Poverty Alleviation, Zhaotong, China, 8 July 2018; Potato Committee of the Chinese Society of Crop Science: Beijing, China, 2018; p. 8. [Google Scholar]

- Lv, J.Q.; Wang, P.R.; Liu, Z.F.; Li, Z.H.; Zou, F.Y.; Yang, D.Q. Potato Harvester Potato Seedling Separation Device Design and Test. J. Agric. Mach. 2019, 50, 100–109. [Google Scholar]

- Lv, J.Q.; Yang, X.H.; Lv, Y.N.; Li, Z.H.; Li, J.C.; Du, C.L. Analysis and test of tuber damage mechanism during potato digger lifting and transportation separation. J. Agric. Mach. 2020, 51, 103–113. [Google Scholar]

- Lv, J.Q.; Liu, J.N.; Zhu, S.X.; Li, J.C.; Qi, Y. Design and test of digging device of potato harvester under clay-heavy black soil conditions. J. Northeast Agric. Univ. 2024, 55, 76–89. [Google Scholar]

- Lv, J.Q.; Sun, H.; Tui, H.; Peng, M.M.; Yu, J.Y. Improved design and test of separating and conveying device of potato digger under clay soil. J. Agric. Mach. 2017, 48, 146–155. [Google Scholar]

- Chen, M.; Liu, X.; Hu, P.; Zhai, X.; Han, Z.; Shi, Y.; Zhu, W.; Wang, D.; He, X.; Shang, S. Study on Rotor Vibration Potato-Soil Separation Device for Potato Harvester Using DEM-MBD Coupling Simulation. Comput. Electron. Agric. 2024, 218, 108638. [Google Scholar]

- Liang, Z.; Huang, Y.; Li, D.; Wada, M.E. Parameter Determination of a Viscoelastic–Plastic Contact Model for Potatoes during Transient Collisions. Biosyst. Eng. 2023, 234, 156–171. [Google Scholar] [CrossRef]

- Bentini, M.; Caprara, C.; Martelli, R. Harvesting Damage to Potato Tubers by Analysis of Impacts Recorded with an Instrumented Sphere. Biosyst. Eng. 2006, 94, 75–85. [Google Scholar] [CrossRef]

- Wang, B. Research on the mechanism and screening characteristics of fruit picking in four-row semi-fed peanut combine harvesting. Ph.D. Thesis, Chinese Academy of Agricultural Sciences, Beijing, China, 2018. [Google Scholar]

- Wang, J.; Liao, M.; Xia, H.; Chen, R.; Li, J.; Li, J.; Yang, J. Study on a Novel Reseeding Device of a Precision Potato Planter. Agriculture 2024, 14, 1824. [Google Scholar] [CrossRef]

- Wei, Z.C.; Han, M.; Su, G.L.; Zhang, H.; Li, X.Q.; Jin, C.Q. Design and test of bale-loading and bale-unloading potato combine harvester. J. Agric. Mach. 2023, 54, 92–104. [Google Scholar]

- Ouyang, A.; Cui, T.; Lin, L. Status quo of intelligent agricultural machinery and equipment industry and development suggestions. Sci. Technol. Her. 2022, 40, 55–66. [Google Scholar]

- Chen, X.G.; Wen, H.J.; Zhang, W.R.; Pan, F.D.; Zhao, Y. Current status and direction of the development of integration of agricultural machinery and information technology. Smart Agric. 2020, 2, 1–16, (In Chinese and English). [Google Scholar]

- Zhai, C.Y.; Yang, S.; Wang, X.; Zhang, C.F.; Song, J. Current Status and Prospect of Research on Intelligent Measurement and Control Technology for Agricultural Machinery and Equipment. J. Agric. Mach. 2022, 53, 1–20. [Google Scholar]

- Dong, S.; Yuan, C.H.; Gu, C.; Yang, F. A review of research on intelligent agricultural machine control platform based on multidisciplinary technology integration. J. Agric. Eng. 2017, 33, 1–11. [Google Scholar]

- Zhou, Z.; Huang, Y.; Li, X.Y.; Wen, D.D.; Wang, C.L.; Tao, H.L. An automatic potato grading method based on machine vision. J. Agric. Eng. 2012, 28, 178–183. [Google Scholar]

- Wang, H.J.; Xiong, J.T.; Li, Z.Z.; Deng, J.M.; Zou, X.J. A method for grading potato quality and shape based on machine vision image feature parameters. J. Agric. Eng. 2016, 32, 272–277. [Google Scholar]

- Jin, C.Q.; Yang, T.X.; Liu, G.W.; Wang, T.E.; Chen, M.; Liu, Z. Crawler Combine Harvester Omnidirectional Leveling Chassis Design and Test. J. Agric. Mach. 2020, 51, 393–402. [Google Scholar]

- Liu, H.X.; Li, J.L.; Guo, L.F.; Zhang, G.F. Research on knowledge organization and knowledge base system of combine harvester. J. Agric. Mach. 2021, 52, 381–393. [Google Scholar]

- Yao, M.; Lv, J.; Wang, L.; Yue, R.; Hu, J. Cooperative Operation Method of Seedling Conveying and Picking by Full-Automatic Transplanter Based on Multi-Sensor Combination. Comput. Electron. Agric. 2024, 225, 109311. [Google Scholar]

- Yang, L.; Li Zhang, X.; Yaoming, L.; Liya, L.; Maolin, S. Modeling and Control Methods of a Multi-Parameter System for Threshing and Cleaning in Grain Combine Harvesters. Comput. Electron. Agric. 2024, 225, 109251. [Google Scholar]

- Zheng, G.N.; Tan, Y.Z.; Zhang, J.X.; Li, W. Automatic detection and grading of potato based on computer vision. J. Agric. Mach. 2009, 40, 166–168+156. [Google Scholar]

- Rady, A.M.; Guyer, D.E. Rapid and/or Nondestructive Quality Evaluation Methods for Potatoes: A Review. Comput. Electron. Agric. 2015, 117, 31–48. [Google Scholar]

- Al-Mallahi, A.; Kataoka, T.; Okamoto, H. Discrimination between Potato Tubers and Clods by Detecting the Significant Wavebands. Biosyst. Eng. 2008, 100, 329–337. [Google Scholar]

- Yang, Q.; Huang, G.; Shi, X.; He, M.; Ahmad, I.; Zhao, X.; Addy, M. Design of a Control System for a Mini-Automatic Transplanting Machine of Plug Seedling. Comput. Electron. Agric. 2020, 169, 105226. [Google Scholar]

- Wang, B.; Hu, Z.C.; Hu, L.L.; Peng, B.L.; Wang, G.F.; Wang, B.K. Research status and development of sweet potato combine harvester. Jiangsu Agric. Sci. 2018, 46, 11–16. [Google Scholar]

- Wang, G.F.; Jiang, J.L.; Tian, Y.Q.; Zhou, S. Current status and development trend of potato mechanical harvesting technology. China Agric. Mach. Chem. J. 2014, 35, 11–15+21. [Google Scholar]

- Yang, H.G.; Hu, Z.C.; Wang, B.; Peng, B.L.; Wang, G.P. Progress of potato harvest mechanization technology research. Chin. J. Agric. Mech. Chem. 2019, 40, 27–34. [Google Scholar]

- Wang, L.; Liu, F.; Wang, Q.; Zhou, J.; Fan, X.; Li, J.; Zhao, X.; Xie, S. Design of a Spring-Finger Potato Picker and an Experimental Study of Its Picking Performance. Agriculture 2023, 13, 945. [Google Scholar] [CrossRef]

- Yang, R.B.; Yang, H.G.; Shang, S.Q.; Xu, P.X.; Cui, G.P.; Liu, L.H. Design and test of paddle roller push potato harvester. J. Agric. Mach. 2016, 47, 119–126. [Google Scholar]

- Li, Y.B.; Zhang, Z.G.; Wang, Y.M.; Wang, H.Y.; Pang, Y.L.; Zhang, Z.D. Design and test of multistage conveying and separating device for potato harvester. J. Shenyang Agric. Univ. 2021, 52, 758–768. [Google Scholar]

- Lv, J.Q.; Du, C.L.; Liu, Z.Y.; Li, J.C.; Li, Z.H.; Li, Z.Y. Design and test of potato hopper machine debris removal device. J. Agric. Mach. 2021, 52, 82–90+61. [Google Scholar]

- Chen, X.S.; Chen, T.; Wu, T.; Ma, X.; Zeng, L.C.; Chen, L.C. Mulching and winter planting potato harvester straw separation mechanism design and test. J. Jilin Univ. Eng. Ed. 2020, 50, 749–757. [Google Scholar]

- Hu, Z.C.; Peng, B.L.; Yin, W.Q.; Wang, H.O.; Ji, F.L.; Xie, H.X. Multi-functional Roots and Tubers Combined Harvester Design and Test. J. Agric. Mach. 2008, 39, 58–61. [Google Scholar]

- New breakthrough in small self-propelled potato combine harvester. China Agric. Mach. Chem. J. 2020, 41, 237.

- Wang, F.A.; Cao, Q.Z.; Li, Y.B.; Pang, Y.L.; Xie, T.; Zhang, Z.G. Design and passability test of self-propelled potato combine harvester in hilly mountainous area. J. Agric. Mach. 2023, 54, 10–19. [Google Scholar]

- Wei, H.A.; Wang, T.; Lian, W.H.; Shao, S.L.; Yang, S.; Huang, X.P. Development of 4UFD-1400 potato combine harvester. J. Agric. Eng. 2013, 29, 11–17. [Google Scholar]

- Wang, H.; Zhao, W.; Sun, W.; Liu, X.; Shi, R.; Zhang, H.; Chen, P.; Gao, K. The Design and Experimentation of a Wheeled-Chassis Potato Combine Harvester with Integrated Bagging and Ton Bag-Lifting Systems. Agriculture 2024, 14, 1461. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Z.; Zhang, H.; Liu, X.; Li, H.; Sun, W.; Li, H. Investigation of the Traveling Performance of the Tracked Chassis of a Potato Combine Harvester in Hilly and Mountainous Areas. Agriculture 2024, 14, 1625. [Google Scholar] [CrossRef]

- Fan, J.; Li, Y.; Luo, W.; Yang, K.; Yu, Z.; Wang, S.; Hu, Z.; Wang, B.; Gu, F.; Wu, F. An Experimental Study of Stem Transported-Posture Adjustment Mechanism in Potato Harvesting. Agronomy 2023, 13, 234. [Google Scholar] [CrossRef]

- Tang, H.; Zhu, G.; Wang, Z.; Xu, W.; Xu, C.; Wang, J. Prediction Method for Maize Kernel Impact Breakage Based on High-Speed Camera and FEM. Powder Technol. 2024, 444, 120002. [Google Scholar] [CrossRef]

- Yang, R.B.; Yang, H.G.; Shang, S.Q.; Ni, Z.W.; Liu, Z.S.; Guo, D. Design and test of vertical ring separation conveyor for potato combine harvester. J. Agric. Eng. 2018, 34, 10–18. (In English) [Google Scholar]

- Yang, B.; Guo, W.; Huang, X.; Du, R.; Liu, Z. A Portable, Low-Cost and Sensor-Based Detector on Sweetness and Firmness Grades of Kiwifruit. Comput. Electron. Agric. 2020, 179, 105831. [Google Scholar] [CrossRef]

- Zhang, W.; Zhu, Q.; Zhang, T.; Liu, H.; Mu, G. Design and Control of a Side Dense Transplanting Machine for Sweet Potato Seedlings on Mulch Film. Comput. Electron. Agric. 2024, 224, 109193. [Google Scholar]

- Wang, H.Y. Design and test of self-propelled potato combine harvester in mountainous area. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2022. [Google Scholar]

- Jia, J.X.; Zhang, D.X.; Hao, X.M.; Liu, H.W. Parametric modeling of potato harvester and simulation of key components of virtual prototype. J. Agric. Mach. 2005, 36, 70–73. [Google Scholar]

- Liu, W.J.; Luo, X.W.; Zeng, S.; Zeng, L. Performance test and analysis of adaptive profiling cutter for regenerated rice based on fuzzy PID control. J. Agric. Eng. 2022, 38, 1–9. [Google Scholar]

- Wang, B. Analysis and discussion of mechanized sowing and harvesting of garlic at home and abroad. Agric. Dev. Equip. 2020, 159–161. [Google Scholar]

- Liu, C.; Wu, N.; Cheng, G.; Wu, F.; Gu, F.; Shi, L.; Wang, B. Design and Optimization of a Lightweight and Simple Self-Propelled Crawler Potato Combine Harvester. Agronomy 2025, 15, 65. [Google Scholar] [CrossRef]

- Li, W.H.; Lv, D.Q.; Min, F.X. Comparative analysis of potato production profiles in China, the Netherlands and Belgium. China Potato 2018, 32, 54–60. [Google Scholar]

- Yang, B.N.; Zhang, S.Y.; Zhao, F.M.; Liu, W.; Yang, Y.C.; Li, S.J. Characterization of common potato varieties and classification of processing suitability. J. Food Sci. Technol. 2016, 34, 28–36. [Google Scholar]

| Brand/Model | Line Spacing | Number of Rows | Throwing Form | Technical Features |

|---|---|---|---|---|

| GRIMME/HT-400 | 75/90 | 4 | Lateral delivery of potato vines. | The machine is characterized by its smooth operation and clean cutting of potato seedlings. A seedling divider can be optionally installed on the machine to distribute the potato seedlings on the harvested land [31]. |

| GRIMME/HT-200 | 75/90 | 2 | Lateral delivery of potato vines. | The potato vines are mechanically shredded by the blade shaft and transported laterally to the side of the ridge, significantly reducing the risk of clogging the digging unit [37]. |

| Xisen/4JM360B | 90 | 4 | The seedlings and weeds are diverted to the ditches on both sides. | The seedling-cutting knives are symmetrically distributed in a double helix on the seedling-cutting axis, and their movement trajectory is basically consistent with the ridge shape, ensuring a crushing effect [38,39]. |

| China Machinery Mino/1084 | 80/90 | 4 | The seedlings, leaves, and weeds are diverted to the ditches on both sides. | The swing knives are arranged in a double helix on the cutter roller shaft to ensure uniform force on the cutter roller; the transmission belts on both sides are equipped with overrunning clutches to effectively protect the transmission system [40,41]. |

| Hongzhu/1JH-360 | 90 | 4 | Spread evenly on the furrows. | The special blades designed according to the ridge shape rotate at high speed, generating negative pressure, which sucks up and crushes the seedlings at the bottom of the ridge without damaging the potatoes [42]. |

| Name | Bionic Prototype | Structural Diagram | Performance Characteristics |

|---|---|---|---|

| Bionic longitudinal wave shovel |  |  | The surface texture of earthworms and scallops is bionic, with good soil flow performance, a bionic reduction rate of 14.45%, and a potato damage rate of 0.736% [28,60]. |

| Double bionic surface excavating shovel |  |  | The robot is inspired by the excellent digging ability of the mole cricket’s front claws; it has a good digging ability, reduces drag by about 27.5%, and reduces energy consumption by about 9% [61]. |

| Bionic digging shovel |  |  | Due to the unique advantages of the wild boar’s snout, the digging shovel is subject to less resistance and deformation, and the stress it is subjected to is reduced by nearly 59% compared to the triangular flat shovel, with a significant drag reduction effect [62]. |

| Low-resistance bionic excavator shovel |  |  | The low resistance of rabbit incisors to soil is simulated by the self-sharpening effect; this is improved by 8.33%, and the drag reduction effect is improved by 12.82% [63]. |

| Potato curved bionic shovel |  |  | By imitating the low-drag characteristics of mole fingers, traction and fuel consumption were reduced by more than 13.33% and 9.18%, respectively [64]. |

| Separation Principle | Characteristic Index and Utilization Method | Representative Separation Device Type |

|---|---|---|

| Geometry | Separation using sieve holes and gaps | Bar elevators, separation screens, drum screens, etc. |

| Plasticity | Separability without causing damage | Centrifugal (drum, four-disk) |

| Surface physical properties | Friction coefficient | Inclined conveyor belt |

| Absolute mass, inertia | Gravity | Brush roller |

| Hardness | Ease of insertion of the finger | Finger conveyor belt |

| Density | Separation in liquid or bulk media | Suspension |

| Aerodynamic properties | Separation using air flow | Airflow type, jet type |

| Electrical properties | Separation using capacitance and conductivity | Electrical |

| Color and gloss | Light reflectance, spectral intensity of luminescence | Photoelectric |

| Damage Reduction Devices and Materials | |||||

|---|---|---|---|---|---|

| Damage reduction buffer roller | Annular potato collection and lifting device | Double-cushioning loss reduction curtain | Low-loss polyurethane material | Wave-shaped loss reduction device | Loss-free roller conveyor |

|  |  |  |  |  |

| Name | Type | Features |

|---|---|---|

| Double-headed vibrating wheel |  | The vibration frequency of the shaking wheel gradually increases from front to back, and the shaking effect is large and damages the potatoes. |

| Cylindrical vibrating wheel |  | This wheel is driven by the lifter chain during operation and has a simple structure, but adjusting the amplitude and frequency must be conducted by using different shapes of the shaking wheel. |

| Passive vibration wheel |  | Driven by the chain of the lifter during operation, it shakes well but damages the connecting belt. |

| Eccentric vibrating wheel |  | It is driven by the drive shaft during operation, and its amplitude and frequency are determined by the motor, which can accomplish stepless speed change. |

| Circular shaking wheel |  | This wheel has a small jittering effect, a low impact on the lift chain, and high support. |

| Intelligent Application Objects | Application Methods | Representative Models |

|---|---|---|

| Chassis device | An adaptive electromagnetic hydraulic leveling system is used, equipped with sensors to control the left and right swing and tilt of the chassis structure, ensuring that the harvester can perform harvesting operations on a limited slope [99]. | GRIMME4150, SE, EVO series, AVR Puma4. |

| Separation–conveying device | It uses a fully hydraulic drive and is equipped with a load-sensitive proportional control system. The separation device can adjust the working parameters of the separation device in real time according to the minimum potato damage rate, skin breakage rate, and impurity rate required for harvesting [100]. | GRIMMESE, EVO series. |

| Machine working environment | Utilizing multiple sensors combined with multiple sets of imaging devices, the whole machine working environment is monitored in real time [101,102]. It is characterized by the automatic switching of the fault screen and an automatic alarm to reduce the operational burden on staff [103]. | GRIMME4150, AVR Puma4. |

| Potato movement | Using an acceleration sensor combined with a speed receiver, real-time detection of potato collisions, and slip movement, it uses USB output potato movement data to adjust the working parameters based on the potato damage rate [104,105]. Simultaneously, a combination of mass and slope sensors is utilized to automatically measure the yield. | GRIMME’s quality mapping system, AVRPuma4. |

| Human–computer interaction | Both a human and a computer use certain language and interactions to complete information exchange. This integrates electromechanical instrumentation and liquidity, real-time control of the harvester forward state, digging state, separating state, removing state, etc., to maximize operational efficiency and reduce the loss of the harvester [87,106]. | GRIMM’s ErgoDrive, SmartView human–computer interaction system, and Belgium’s AVR’s Connect platform. |

| Type | Prototype Photos | Basic Structure and Technical Features |

|---|---|---|

| Flick potato picker |  | It is rear-suspended and utilizes the design of finger-snapping with different lengths, which can effectively separate the potatoes. It is mainly composed of a spindle, a finger-snapping shaft, a crank, a crank cover, and so on. It can solve the problems of a low pickup rate and a high rate of potato injury during mechanized potato pickup [110]. |

| Small potato harvester for hilly mountainous areas and heavy soil |  | This is rear-suspended equipment designed for heavy-soil-type potato harvesting in hilly and mountainous areas. The matched power is 20–30 kW, the digging depth is 150–220 mm, and the total length of the separating screen is 1552 mm. It performs well in hilly and mountainous areas with sticky soil [16]. |

| Roller push potato harvester |  | It is rear-suspended and is mainly composed of an excavating shovel, a conveying fence, a roller push-type conveying and separating device, etc. It uses a five-level rubber push roller set, each of which has three teeth and a radius of 230 mm. The unit operating speed is 1.0 m/s and the roller speed is 60 r/min [111]. |

| Multi-stage conveyor separator for potato harvesters |  | It is rear-suspended and uses multi-stage separation and transportation to improve the quality of potato harvesting and separation. The weight of the whole machine is 860 kg, the supporting power is 36.7–51.5 kW, the working width is 900 mm, and the digging depth is 100–260 mm. It can be used for potato harvesting operations in hilly and mountainous areas with soil slabs [112]. |

| Loss-reducing low-level potato harvester |  | It uses a three-point suspension structure, with an equipment mass of 1500 kg, a supporting power of no less than 68 kw, an operating width of 2100 mm, a row spacing of 900 mm, and two working rows. It can effectively solve the problem of a short growing season, make harvesting easier, and achieve better soil and debris separation [113]. |

| Potato diggers in clayey soils |  | This equipment is rear-suspended. The rear end of the separation conveyor adopts wheeled walking, which reduces the digging resistance. At the same time, wheeled walking is used to ensure automatic row alignment. The separation device adopts two-stage separation, so the potatoes are completely separated from the potato seedlings and weeds [114]. |

| Type | Prototype Photos | Basic Structure and Technical Features |

|---|---|---|

| 4UZL-1 self-propelled potato combine harvester |  | It adopts a traveling crawler chassis system and multi-stage conveying and separating, and the end sorting platform adopts a grading design to increase the separating effect. The matching power is 21 kW, the operating width is 1000 mm, and the digging depth is no less than 200 mm. It has the technical advantages of hydraulic drive, high-efficiency separation and transportation, and manually assisted sorting [115,116]. |

| Self-propelled potato combine harvester for hilly areas |  | This walk-behind self-propelled harvester includes a chassis walking system, a digging shovel, depth-limiting ground wheels, a conveying and separating device, a potato-collecting plate, etc. The machine has a total weight of 600 kg, an engine power of 19 kW, an operating width of 600 mm, an adapted ridge spacing of no more than 800 mm, and a travel speed of 0.2–0.8 m/s [117]. |

| 4UFD-1400A1 potato combine harvester |  | This is rear-suspended and can complete the operational processes of digging, separating, and bagging at the same time. Its structural mass is 2300 kg, its supporting power is 44–58.8 kW, its operating width is 1400 mm, its operating depth is 0–300 mm (adjustable), and its transportation clearance is ≥300 mm [118]. |

| Wheeled-chassis potato combine harvester |  | This is driven by a wheeled chassis. The operating width is 1100 mm, the digging depth is 0–240 mm, the engine power is 73.5 kW, the rated engine speed is 2600 r/min, and the minimum turning radius is 2.8 m. The whole machine has a compact structure, small longitudinal dimensions, a low center of gravity, and a good climbing performance [119]. |

| 4UJ-180A potato harvester and bagger |  | It uses a wheeled chassis and multi-stage conveying and separation machinery. The machine weighs 2500 kg and has a working width of 1600 mm and a power range of 66.1–88.2 kW. It is equipped with a flexible conveying system and hydraulic control system to minimize damage to the potato skins [17]. |

| Self-propelled crawler potato combine harvester |  | This adopts crawler-type walking, with convenient speed adjustment and stable driving. The total machine weight is 3100 kg, the operating width is 1500 mm, the digging depth is 200–300 mm, and the engine power is 54 kW. It is able to climb vertical walls up to 450 mm high and cross trenches up to 1200 mm wide [120]. |

| Type | Prototype Photos | Basic Structure and Technical Features |

|---|---|---|

| SE 150-60 UB |  | This is rear-mounted traction-type equipment, the external dimensions (L × W × H) of which are 11,650 × 3300 × 4000 mm. The machine mass is 9500 kg and its matching power is no less than 95 kW. The number of working rows is two, the width of the two-stage screen is 1700 mm, and the output speed of PTO is 540/1000 r/min. The machine can be equipped with a simple picking unit for delayed, discontinuous harvesting processes [23,121]. |

| 4ULZ-170 |  | This is rear-suspended traction equipment and requires a matching power of no less than 88.2 kW. The overall dimensions (L × W × H) are 9795 × 3300 × 3360 mm, the machine mass is 5960 kg, its working width is 1700 mm, it is adaptable to a ridge width of more than 700 mm, its digging depth is 150–300 mm, and its PTO input speed is 540 r/min. It contains a multi-stage star-roller soil-clearing and debris-removal device, which removes soil and debris from the potato surface [122]. |

| 4UZ-95 |  | This is a self-propelled crawler chassis design; its external dimensions (L × W × H) are 6900 × 3000 × 3200, the machine mass is 7300 kg, and its supporting power is 88 kW. The working width is 950 mm, the digging depth is 150–300 mm, and the PTO output speed is 2400 r/min. The rear-end separating and conveying device adopts three-dimensional separation, which has a low potato damage rate [123,124,125]. |

| AVR-PUMA3 |  | This equipment adopts a self-propelled wheeled chassis system with four-wheel drive and needs to be equipped with 345 kW. The machine size (L × W × H) is 14,500 × 3480 × 4000 mm, the machine weight is 22,000 kg, and there are four operating rows, supporting an 8 t storage capacity. The whole machine adopts full hydraulic drive, which can realize the stepless regulation of several operating parameters, and the potato collection section uses adaptive height adjustment technology [126,127]. |

| GRIMMEEVO280 |  | This is rear-suspended traction-type equipment, with a minimum supporting power of 115 kW, a machine size (L × W × H) of 12,000 × 3900 × 3990 mm, and a machine weight of 12,400 kg. The screen width is 1700 mm and the PTO input speed is 1000 r/min. It is fully hydraulic-driven and can be adjusted independently of the engine speed (power output shaft speed) of the tractor [128]. |

| Harvesting Technology | Operating Efficiency (ha/day) | Labor Cost | Equipment Costs | Potato Damage rate | Harvest Costs Per Hectare (USD) | Applicable Scenario |

|---|---|---|---|---|---|---|

| Manual harvest | 0.1–0.2 | High | Low | High | 1500–3000 | Small-scale planting [2] |

| Semi-mechanized harvest | 0.5–1 | Medium | Medium | Medium | 800–1500 | Medium- and small-scale planting [8,9] |

| Fully mechanized harvest | 2–5 | Low | High | Low | 500–1000 | Large-scale planting [13,14] |

| Intelligent harvest | 5–10 | Very low | Very high | Very low | 300–800 | Super-large-scale modernized farms [32] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Wu, F.; Gu, F.; Cao, M.; Yang, H.; Shi, L.; Wang, B.; Wang, B. Recent Research Progress on Key Technologies and Equipment for Mechanized Potato Harvesting. Agriculture 2025, 15, 675. https://doi.org/10.3390/agriculture15070675

Liu C, Wu F, Gu F, Cao M, Yang H, Shi L, Wang B, Wang B. Recent Research Progress on Key Technologies and Equipment for Mechanized Potato Harvesting. Agriculture. 2025; 15(7):675. https://doi.org/10.3390/agriculture15070675

Chicago/Turabian StyleLiu, Caichao, Feng Wu, Fengwei Gu, Mingzhu Cao, Hongguang Yang, Lili Shi, Bokai Wang, and Bing Wang. 2025. "Recent Research Progress on Key Technologies and Equipment for Mechanized Potato Harvesting" Agriculture 15, no. 7: 675. https://doi.org/10.3390/agriculture15070675

APA StyleLiu, C., Wu, F., Gu, F., Cao, M., Yang, H., Shi, L., Wang, B., & Wang, B. (2025). Recent Research Progress on Key Technologies and Equipment for Mechanized Potato Harvesting. Agriculture, 15(7), 675. https://doi.org/10.3390/agriculture15070675