Design and Experiment of a Single-Disk Silage Corn Harvester

Abstract

1. Introduction

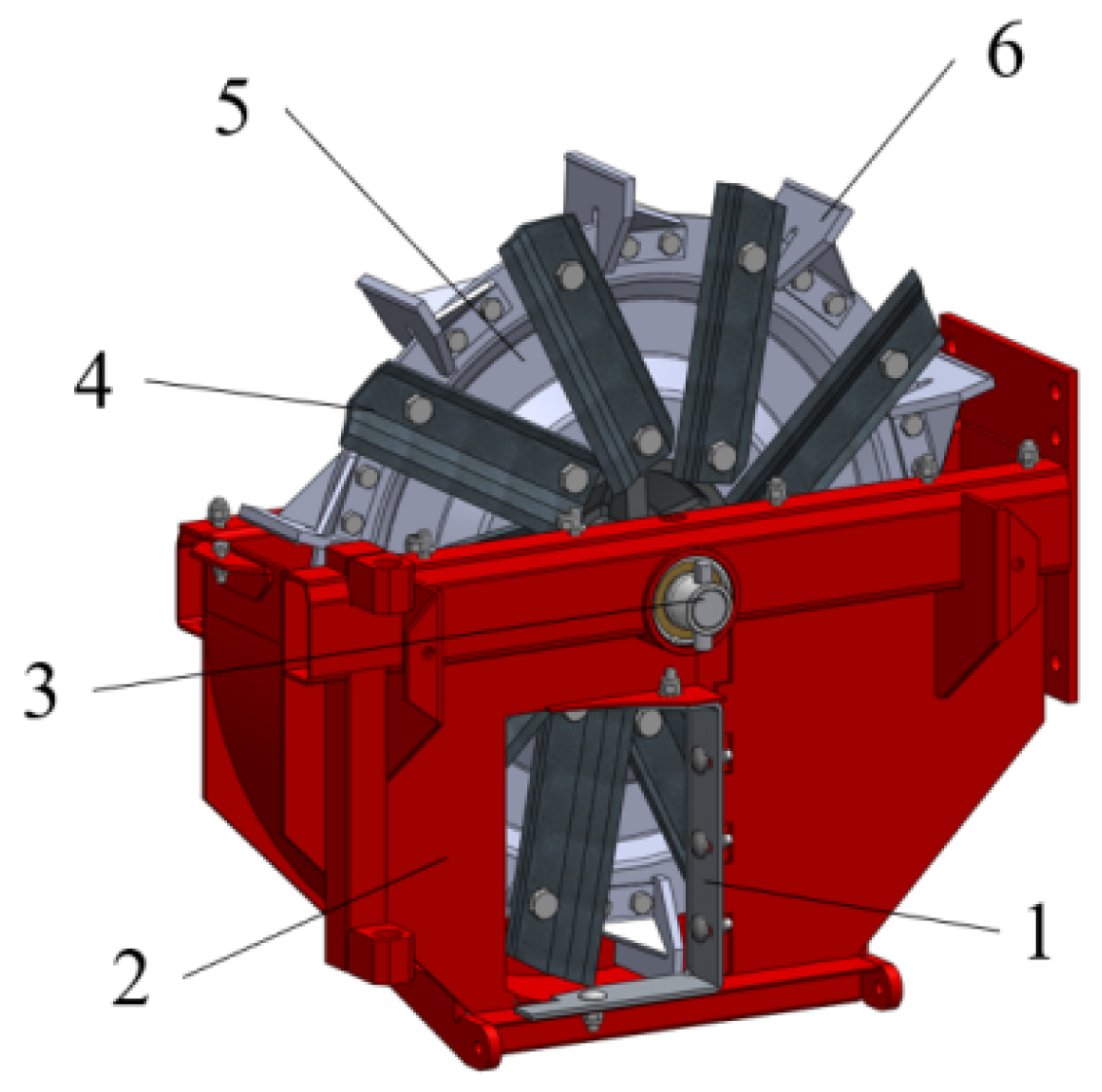

2. The Structure and Working Principle of the Whole Machine

2.1. Overall Structure of the Machine

2.2. Operating Principle

3. Structural Design of Key Components

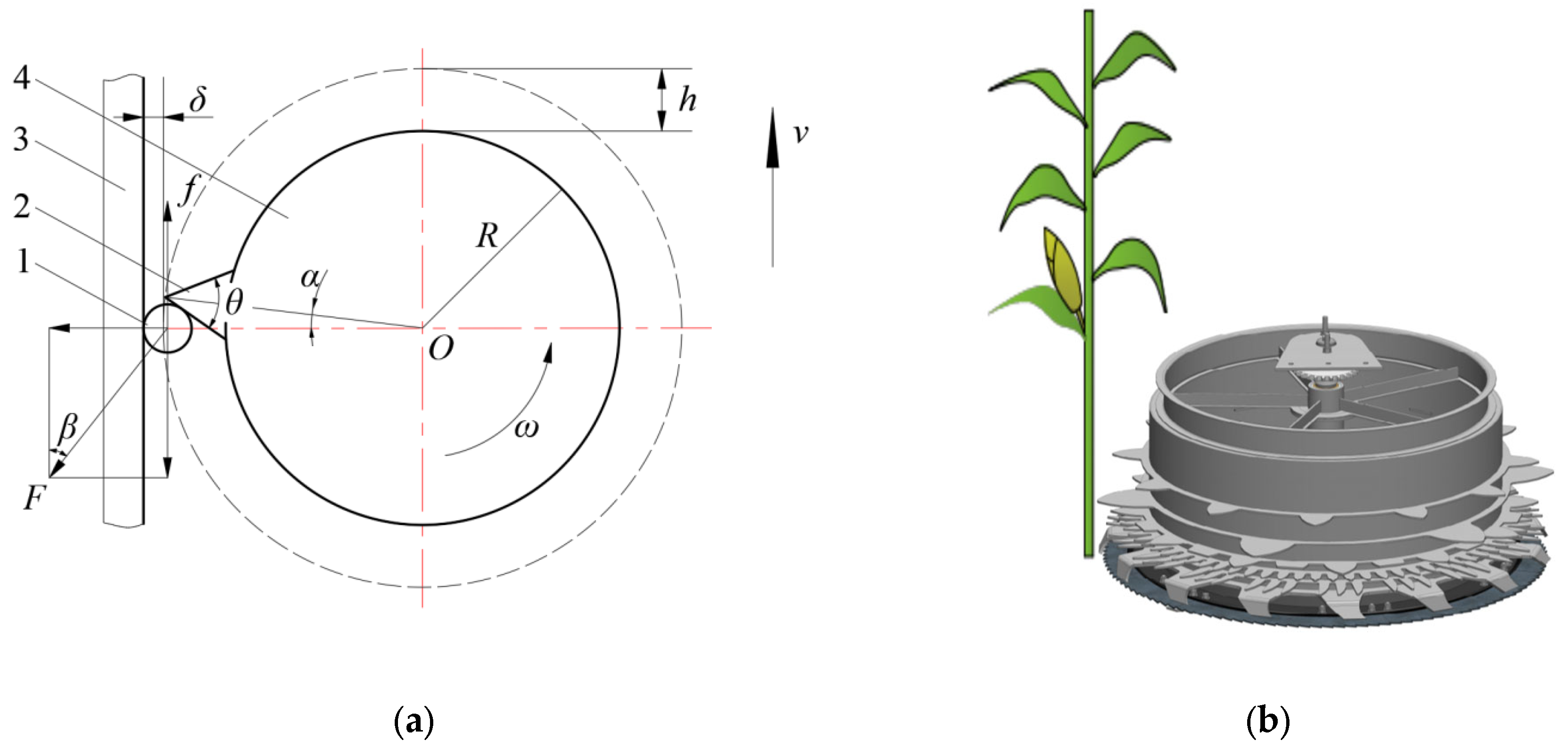

3.1. Feeding Device

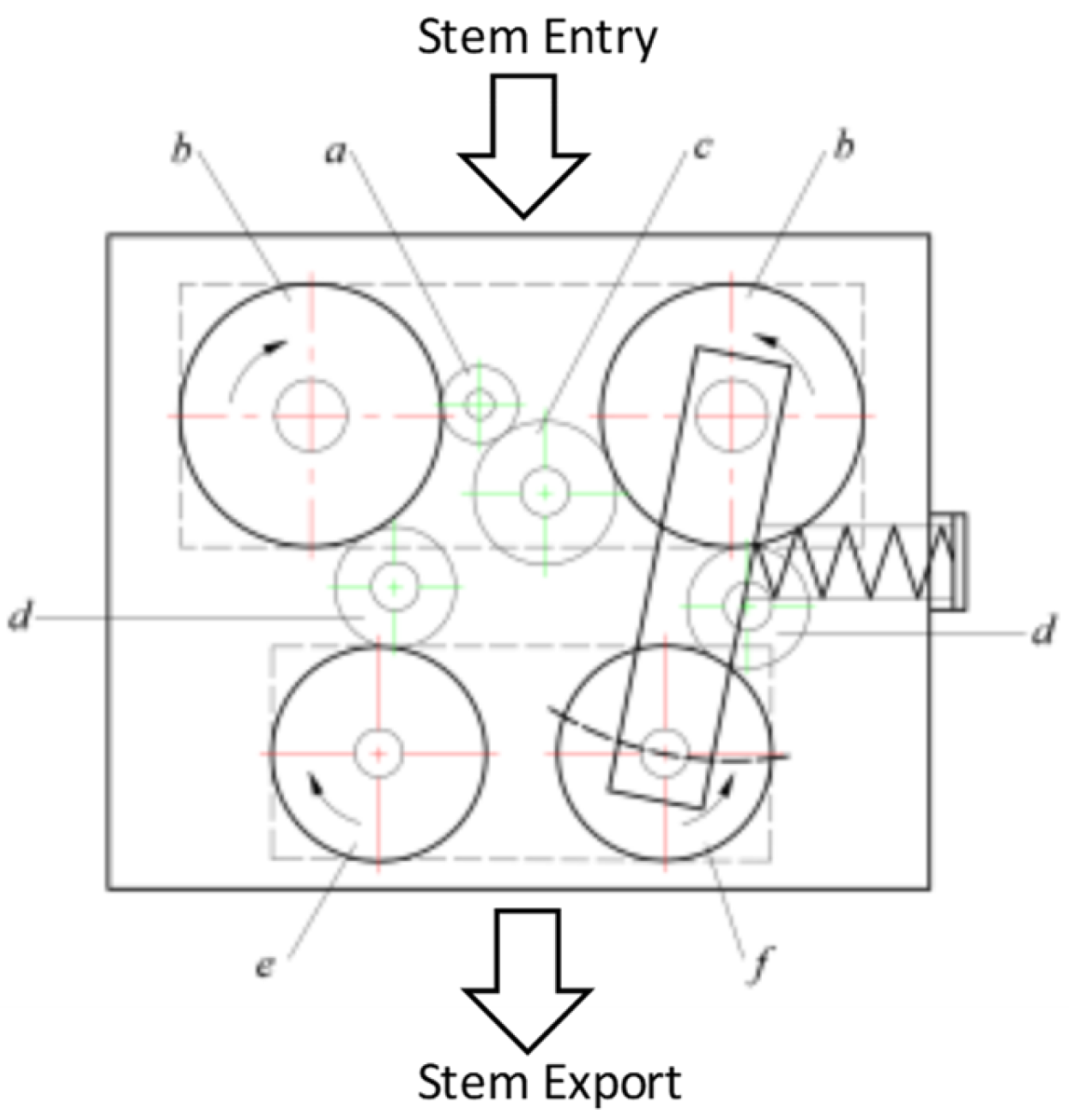

3.2. Flattening Device

Feeding Roller Material Selection and Surface Treatment

3.3. Cutting Device

The Hardness and Wear Resistance of the Blade and Its Influence on the Cutting Quality

4. Test Scheme Design

4.1. Performance Evaluation Indicators

4.1.1. Test Condition

4.1.2. Determination of Productivity Index

4.1.3. Determination of Standard Grass Length Rate

4.1.4. Determining the Qualified Stubble Cutting Rate

4.2. Design of Test Scheme

4.2.1. Design of Experimental Scheme Based on Latin Hypercube

4.2.2. Construction of Regression Equation and ANOVA Analysis

4.2.3. Particle Swarm Optimization Algorithm

5. Results Analysis

5.1. DOE Experimental Design

5.1.1. Design of Test Conditions

5.1.2. Design of Experimental Variables

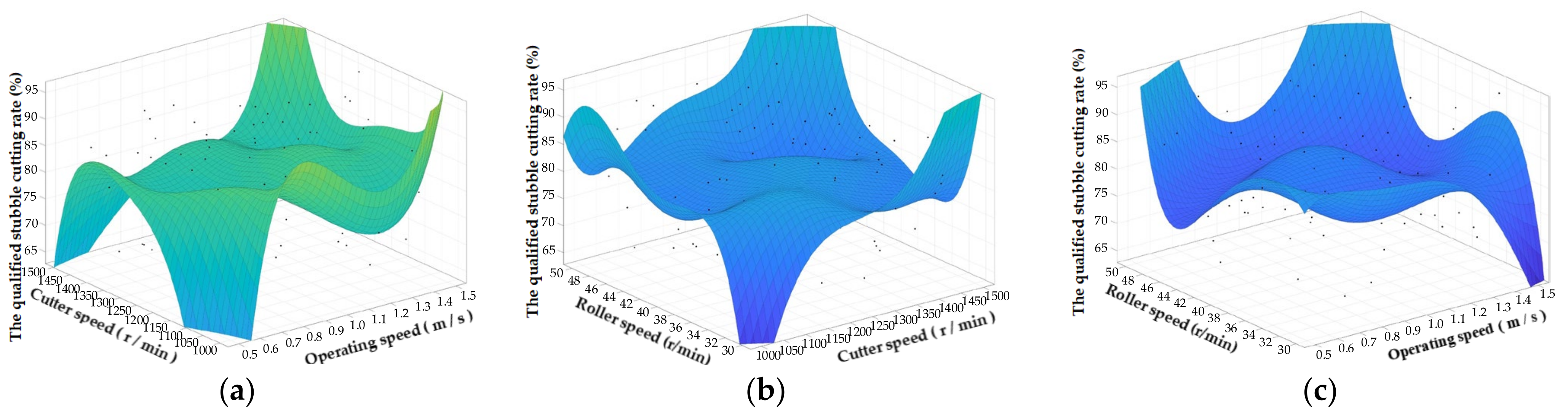

5.2. Analysis of Operation Performance Under the Interaction of Various Factors

5.2.1. Analysis of Operation Productivity

5.2.2. Standard Grass Length Rate Analysis

5.2.3. Analysis of the Qualified Stubble Cutting Rate

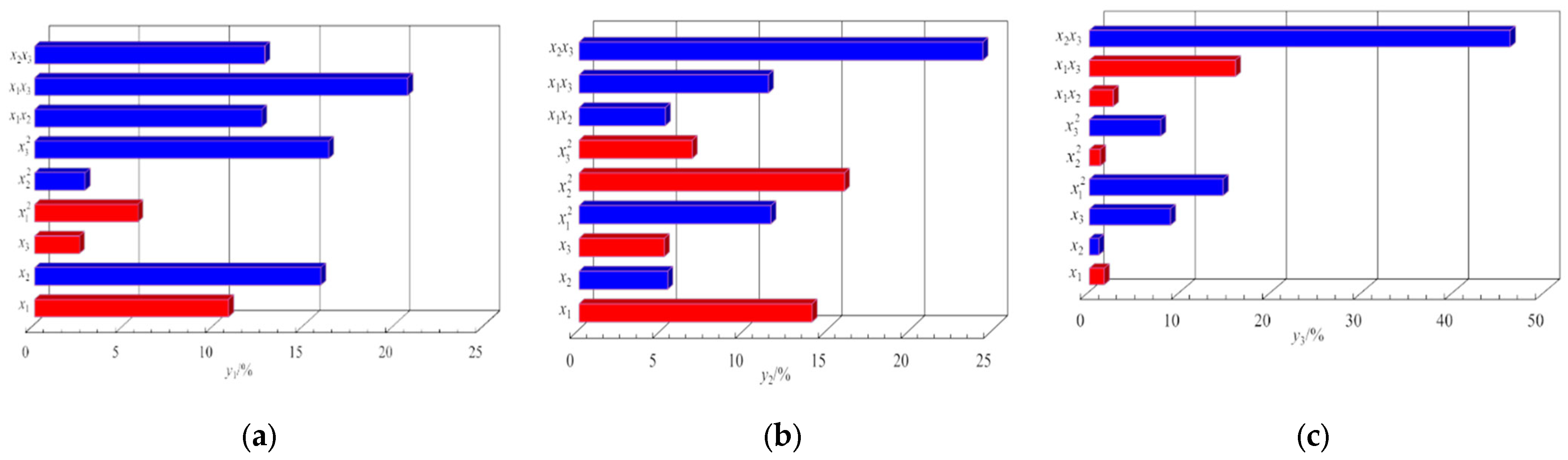

5.2.4. Analysis of Different Factors on the Performance of the Operation

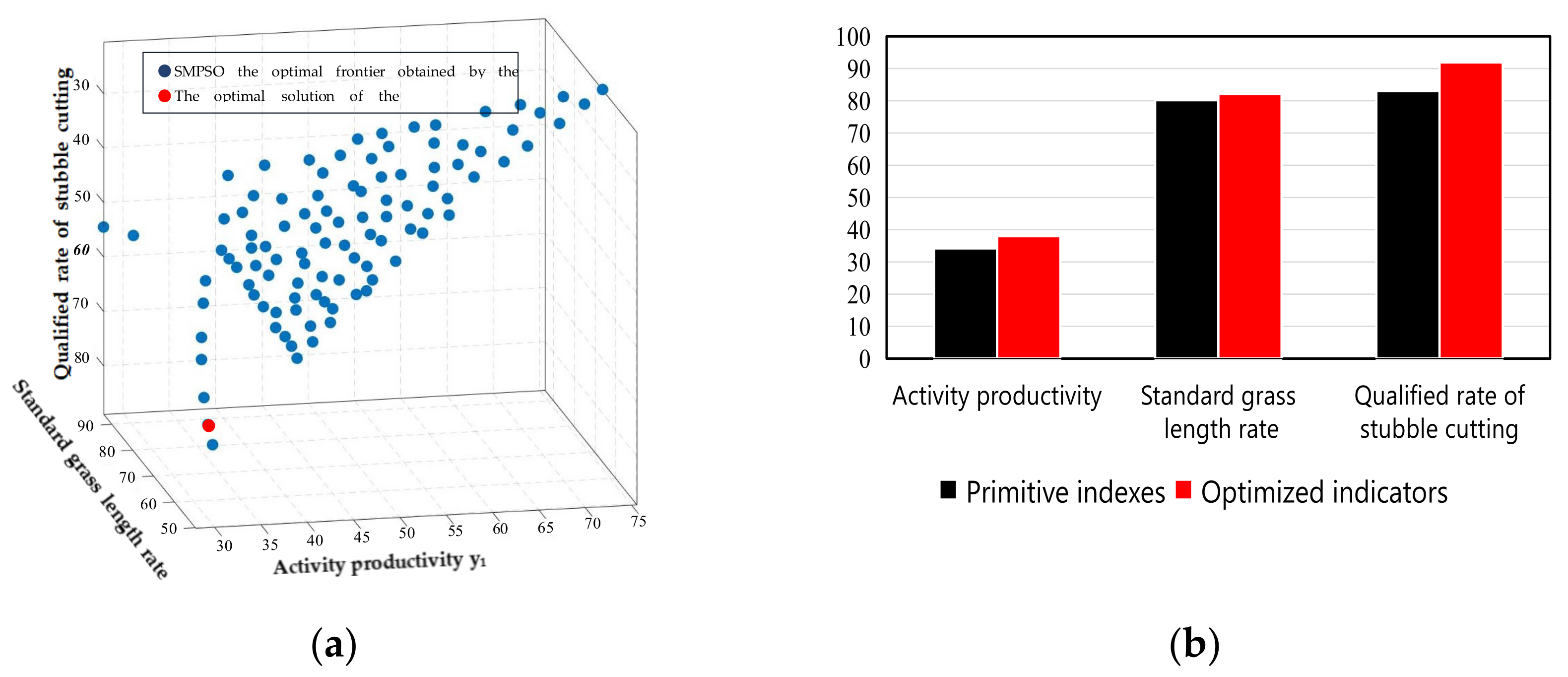

5.3. Multi-Objective Optimization Analysis

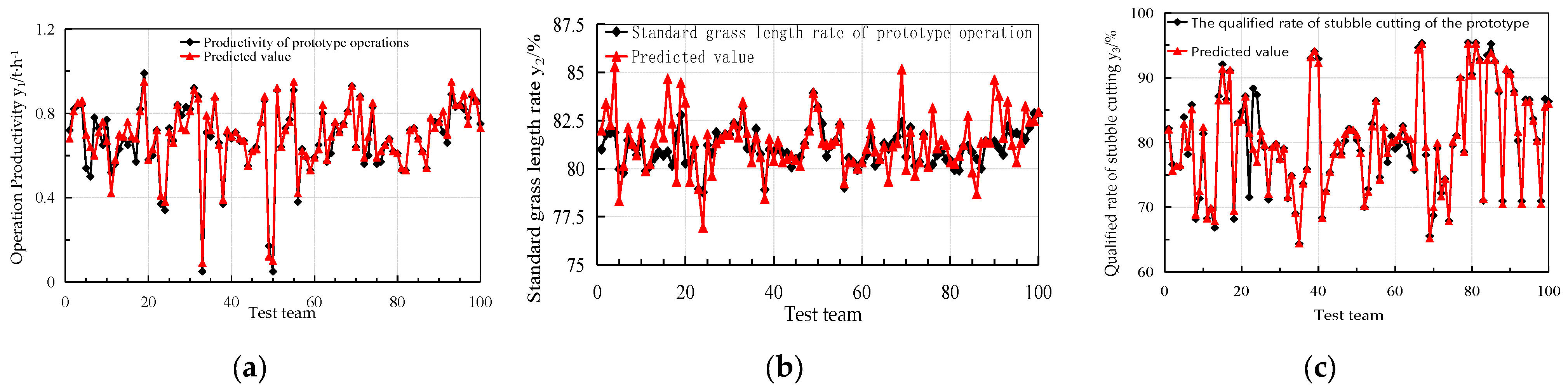

5.3.1. Construction of Regression Equation

5.3.2. Analysis of Variance

5.3.3. Multi-Objective Optimization

6. Results and Discussion

6.1. Discussion

6.1.1. Limitations of Related Research

6.1.2. Innovations of This Paper

6.1.3. Comparison of Research Results

6.1.4. Later Research Direction

6.2. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, X.; Li, X.; Zhang, F.; Li, X.; Shen, X. Design and experiment of feeding and shredding test bench for silage corn harvester. Chin. J. Agric. Mach. Chem. 2024, 45, 41–47. [Google Scholar]

- Wu, J.; Li, S.; Lin, H.; Ma, Y.; Pan, L.; Li, D.; Yang, G.; Sun, D. Comparative study on quality traits of different silage maize varieties. Anim. Husb. Feed Sci. 2021, 42, 48–51. [Google Scholar]

- Chen, M.; Xu, G.; Song, Z.; Wei, M.; Diao, P.; Xin, S. Design and experiment of automatic grinding device and control system for corn silage harvester. Acta Agric. Eng. 2022, 38, 22–33. [Google Scholar]

- Ye, H. Six factors lock the green forage harvester market. Contemp. Agric. Mach. 2021, 28–31. [Google Scholar]

- Zhang, L.; Luo, H.; Zhou, Y.; Qiu, Q.; Yuan, S.; Cai, J. Design and experiment of bionic crushing blade for the upper jaw of silage corn leaf-cutting ant. Acta Agric. Eng. 2022, 38, 48–56. [Google Scholar]

- Mu, X.D.; Jiang, H.X.; Sun, Y.C.; Xu, H.G.; Yao, Y.C.; Geng, D.Y. Simulation Optimization and Experiment of Disc Grain Crushing Device for Silage Corn Harvester. Trans. Chin. Soc. Agric. Mach. 2020, 51, 218–226. [Google Scholar]

- Li, X.; Zhang, J.; Han, S.; Shen, X. Design and experiment of 9QZL-1.8 self-propelled silage corn combine harvester. Chin. J. Agric. Mach. Chem. 2020, 41, 1–6+19. [Google Scholar]

- Jia, J. Use and maintenance of suspended silage harvester 4QS-1250. Agric. Eng. 2017, 7, 32–34. [Google Scholar]

- Yang, D.; Liu, W. Meddie 9QZ-3000 self-propelled silage harvester in Altay region. Xinjiang Agric. Mech. 2016, 36–37. [Google Scholar]

- Zhang, L.J. Application of Silage Corn Harvester. Agric. Mach. 2014, 89–90. [Google Scholar] [CrossRef]

- Zhang, S.Q.; Zhao, Q. Development status and prospects of domestic silage corn harvester. Agric. Mach. 2024, 64–67. [Google Scholar] [CrossRef]

- Duan, J.; Cheng, F.; He, C.; Liu, Y.; Wang, Y.; Guo, X. Research status and development trend of small and medium-sized silage corn harvesting machinery. Chin. J. Agric. Mach. Chem. 2024, 45, 305–310. [Google Scholar]

- Liu, P.W.; Yang, M.L.; Zhang, X.J.; Lin, J.; Peng, W.; Wang, Z. Evaluation of Mechanized Production Models in Southwest Hilly and Mountainous Areas Based on High Quality and Efficiency. Trans. Chin. Soc. Agric. Mach. 2022, 53 (Suppl. S1), 140–149. [Google Scholar]

- Li, Z.; Li, X.; Wang, Y.; Li, M.; Chen, Z. 9QZ-200 self-propelled crawler green fodder harvester design and experiment. Mech. Res. Appl. 2022, 35, 98–101. [Google Scholar]

- GB/T 10394.3-2002; Forage Harvesters—Part 3: Test Methods. China Standards Press: Beijing, China, 2002.

- GB/T 10394.4-2009; Forage Harvesters—Part 4: Safety and Performance. China Standards Press: Beijing, China, 2009.

- GB/T 21961-2008; Test Methods for Maize Combine Harvester. China Standards Press: Beijing, China, 2008.

- GB/T 8097-2008; Equipment for Harvesting—Combine Harvesters—Test Procedure. China Standards Press: Beijing, China, 2008.

- Moore; Chapman, R. Application of Particle Swarm to Multiobjective Optimization; Technical Report; Departament of Computer Science and Software Engineering, Auburn University: Auburn, AL, USA, 1999. [Google Scholar]

- Coello, C.A.C.; Lecsuga, M.S. MOPSO: A proposal for multiple objective particle swarm optimization. In Proceedings of the IEEE Congress on Evolutionary Computation, Honolulu, HI, USA, 12–17 May 2002; pp. 1051–1056. [Google Scholar]

- Dai, C.; Wang, Y.; Ye, M. A new multi-objective particle swarm optimization algorithm based on decomposition. Inf. Sci. 2015, 325, 541–557. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, X.; Cheng, R.; Qiu, J.; Jin, Y. A competitive mechanism based multi-objective particle swarm optimizer with fast convergence. Inf. Sci. 2017, 427, 63–76. [Google Scholar] [CrossRef]

- He, C.; Li, M.; Zhang, C.; Chen, H.; Li, X.; Li, J. A competitive swarm optimizer with probabilistic criteria for many-objective optimization problems. Complex Intell. Syst. 2022, 8, 4697–4725. [Google Scholar]

- Durillo, J.J.; Garc, J.; Nebro, A.J.; Coello, C.A.C.; Luna, F.; Alba, E. Multi-objective particle swarm optimizers: An experimental comparison. In 5th International Conference on Evolutionary MultiCriterion Optimization (EMO’ 2009); Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Nebro, A.J.; Durillo, J.J.; Nieto, J.G.; Coello, C.A.C.; Luna, F.; Alba, E. SMPSO: A new PSO-based metaheuristic for multiobjective optimization. In Proceedings of IEEE Symposium on Computational Intelligence in Miulti-Criteria Decision-Making, Nashville, TN, USA, 30 March–2 April 2009; pp. 66–73. [Google Scholar]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar]

- Zitzler, E.; Laumanns, M.; Thiele, L. SPEA2: Improving the Strength Pareto Evolutionary Algorithm; Giannakoglou, K., Ed.; Eurogen 2001: Athens, Greece, 2002; pp. 95–100. [Google Scholar]

| Parameter Type Check | Current Research Progress | Problems to Be Solved |

|---|---|---|

| Cutting qualified rate | The proportion of high-end models can reach 85~95% | Low-end models are only 60~75% |

| Stubble height stability | Hydraulic adjustment accuracy ±10 mm | When the ground is uneven, the stubble fluctuation is more than 30 mm |

| Feed preparation unit quantity | The double-disk machine can reach 8~12 kg/s | When the single-disk machine model > 3 kg/s, the blockage rate increases |

| Lodging adaptability | Some models are equipped with a dial chain (when the lodging angle is less than 30°, the leakage rate is less than 10%) | When the lodging angle > 45°, the missing cutting rate > 20% |

| Grain broken rate | Roller crusher > 95% | When the moisture content is more than 70%, the crushing effect decreases by 30% |

| Grain crushing uniformity | The high-end model adopts a double-roll design (CV < 5%) | Low-end models CV > 15%, affecting the consistency of fermentation |

| Parameter | Numerical Value |

|---|---|

| Total machine size (length × width × height)/mm | 3068 × 3350 × 4150 |

| Working width/mm | 1600 |

| Total machine mass/kg | 1295 |

| Matching power/kW | ≥96 |

| Operating speed/m·s−1 | 1–2 |

| Number of rows harvested/row | 4–8 |

| Project | Factor | ||

|---|---|---|---|

| Operating Speed x1 | Cutter Speed x2 | Drum Speed x3 | |

| Value | 1.0–2.0 | 1000–1600 | 30–60 |

| Serial Number | Factors | y1/t·h−1 | y2/% | y3/% | ||

|---|---|---|---|---|---|---|

| x1 | x2 | x3 | ||||

| 1 | 0.78 | 1378.79 | 41.31 | 28.608 | 81.00 | 82.18 |

| 2 | 0.89 | 1267.68 | 42.12 | 32.912 | 81.77 | 76.64 |

| 3 | 0.82 | 1292.93 | 37.88 | 33.448 | 81.85 | 76.36 |

| 4 | 1.14 | 1217.17 | 49.19 | 33.664 | 81.89 | 76.18 |

| 5 | 1.34 | 1434.34 | 30.4 | 21.456 | 79.98 | 83.91 |

| 6 | 1.49 | 1106.06 | 32.42 | 20.168 | 79.78 | 78.18 |

| 7 | 0.54 | 1398.99 | 47.78 | 31.088 | 81.48 | 85.82 |

| 8 | 1.46 | 1343.43 | 47.17 | 29.272 | 81.20 | 68.18 |

| 9 | 1.44 | 1176.77 | 36.67 | 26.168 | 80.71 | 71.36 |

| 10 | 0.80 | 1030.3 | 40.71 | 30.768 | 81.43 | 81.36 |

| 11 | 1.32 | 1439.39 | 46.97 | 20.816 | 79.88 | 68.27 |

| 12 | 0.62 | 1338.38 | 44.14 | 22.424 | 80.13 | 69.82 |

| 13 | 0.72 | 1409.09 | 36.87 | 25.096 | 80.55 | 66.82 |

| 14 | 1.41 | 1353.54 | 42.32 | 27.128 | 80.86 | 87.18 |

| 15 | 0.84 | 1393.94 | 30 | 25.952 | 80.68 | 92.09 |

| 16 | 1.24 | 1323.23 | 48.38 | 27.24 | 80.88 | 86.64 |

| 17 | 0.71 | 1202.02 | 35.86 | 22.632 | 80.16 | 91.09 |

| 18 | 1.08 | 1404.04 | 47.58 | 32.808 | 81.75 | 68.18 |

| 19 | 1.04 | 1131.31 | 34.24 | 39.44 | 82.79 | 83.09 |

| 20 | 1.00 | 1065.66 | 38.69 | 23.384 | 80.28 | 84.73 |

| 21 | 0.50 | 1419.19 | 35.25 | 23.816 | 80.35 | 87.18 |

| 22 | 0.92 | 1282.83 | 49.8 | 28.952 | 81.15 | 71.55 |

| 23 | 0.56 | 1318.18 | 31.82 | 14.816 | 78.94 | 88.36 |

| 24 | 0.64 | 1207.07 | 31.21 | 13.752 | 78.77 | 87.36 |

| 25 | 1.31 | 1025.25 | 32.83 | 29.376 | 81.22 | 80.27 |

| 26 | 1.26 | 1328.28 | 38.89 | 26.704 | 80.80 | 79.18 |

| 27 | 0.97 | 1151.52 | 41.72 | 33.664 | 81.89 | 71.18 |

| 28 | 1.15 | 1171.72 | 44.75 | 31.52 | 81.55 | 79.18 |

| 29 | 1.04 | 1333.33 | 30.61 | 33.016 | 81.78 | 79.82 |

| 30 | 0.63 | 1257.58 | 40.71 | 32.912 | 81.77 | 77.36 |

| 31 | 0.88 | 1489.9 | 33.43 | 36.656 | 82.35 | 79.09 |

| 32 | 1.22 | 1131.31 | 37.27 | 35.16 | 82.12 | 71.36 |

| 33 | 1.21 | 1015.15 | 37.47 | 2.12 | 83.21 | 74.91 |

| 34 | 1.42 | 1363.64 | 34.04 | 28.416 | 81.07 | 69.00 |

| 35 | 0.69 | 1459.6 | 45.15 | 27.56 | 80.93 | 64.36 |

| 36 | 0.68 | 1303.03 | 48.79 | 34.832 | 82.07 | 73.64 |

| 37 | 0.55 | 1156.57 | 42.93 | 26.488 | 80.76 | 75.91 |

| 38 | 0.52 | 1161.62 | 38.28 | 14.608 | 78.91 | 93.00 |

| 39 | 1.13 | 1232.32 | 40.3 | 27.992 | 81.00 | 94.09 |

| 40 | 0.86 | 1075.76 | 31.41 | 27.024 | 80.85 | 92.91 |

| 41 | 1.20 | 1035.35 | 45.76 | 28.528 | 81.08 | 68.36 |

| 42 | 0.83 | 1080.81 | 48.99 | 26.808 | 80.81 | 72.45 |

| 43 | 0.76 | 1111.11 | 44.55 | 26.808 | 80.81 | 75.36 |

| 44 | 0.57 | 1116.16 | 33.84 | 22.096 | 80.08 | 78.09 |

| 45 | 0.66 | 1479.8 | 40.51 | 24.776 | 80.50 | 79.91 |

| 46 | 1.39 | 1474.75 | 42.53 | 25.416 | 80.60 | 78.27 |

| 47 | 1.40 | 1020.2 | 47.98 | 29.912 | 81.30 | 80.27 |

| 48 | 1.28 | 1262.63 | 43.74 | 34.408 | 82.00 | 82.18 |

| Operational Productivity y1 (t·h−1) | Standard Grass Cutting Rate y2 (%) | Qualified Stubble Cutting Rate y3 (%) | |||

|---|---|---|---|---|---|

| Variable | Coefficient | Variable | Coefficient | Variable | Coefficient |

| Constant term a0 | 4.1637 | Constant term a0 | 84.575 | Constant term a0 | 81.049 |

| x1 | −1.1636 | x1 | −4.7757 | x1 | 4.423 |

| x2 | −0.001538 | x2 | 0.0041625 | x2 | −0.074185 |

| x3 | −0.10365 | x3 | −0.17225 | x3 | −2.7796 |

| −0.099564 | 0.83704 | 6.4574 | |||

| 0.00000019504 | −0.0000004632 | −0.0000021077 | |||

| 0.00070978 | −0.0012336 | 0.0086137 | |||

| x1x2 | 0.00043868 | x1x2 | 0.0007527 | x1x2 | −0.00237 |

| x1x3 | 0.018019 | x1x3 | 0.041308 | x1x3 | −0.352537 |

| x2x3 | 0.000022215 | x2x3 | 0.00017627 | x2x3 | 0.002036 |

| Evaluating Indicator | Source of Variance | Degree of Freedom | Square of the Deviation | Mean Square | F Ratio | R2 |

|---|---|---|---|---|---|---|

| Operational productivity y1 (t·h−1) | Model | 21 | 0.57546 | 0.02824 | 224.36 | 0.9508 |

| Error | 3 | 0.0003246 | 0.00032 | |||

| Standard grass cutting rate y2 (%) | Model | 26 | 0.58536 | 0.029349 | 216.07 | 0.9349 |

| Error | 6 | 0.00048903 | 0.00042604 | |||

| Qualified stubble cutting rate y3 (%) | Model | 23 | 0.54065 | 0.030026 | 235.09 | 0.9468 |

| Error | 5 | 0.000346 | 0.0003012 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Sun, W.; Li, H.; Li, X.; Yuan, Y. Design and Experiment of a Single-Disk Silage Corn Harvester. Agriculture 2025, 15, 751. https://doi.org/10.3390/agriculture15070751

Wang W, Sun W, Li H, Li X, Yuan Y. Design and Experiment of a Single-Disk Silage Corn Harvester. Agriculture. 2025; 15(7):751. https://doi.org/10.3390/agriculture15070751

Chicago/Turabian StyleWang, Wenxuan, Wei Sun, Hui Li, Xiaokang Li, and Yongwei Yuan. 2025. "Design and Experiment of a Single-Disk Silage Corn Harvester" Agriculture 15, no. 7: 751. https://doi.org/10.3390/agriculture15070751

APA StyleWang, W., Sun, W., Li, H., Li, X., & Yuan, Y. (2025). Design and Experiment of a Single-Disk Silage Corn Harvester. Agriculture, 15(7), 751. https://doi.org/10.3390/agriculture15070751