Smart Pig Farms: Integration and Application of Digital Technologies in Pig Production

Abstract

:1. Introduction

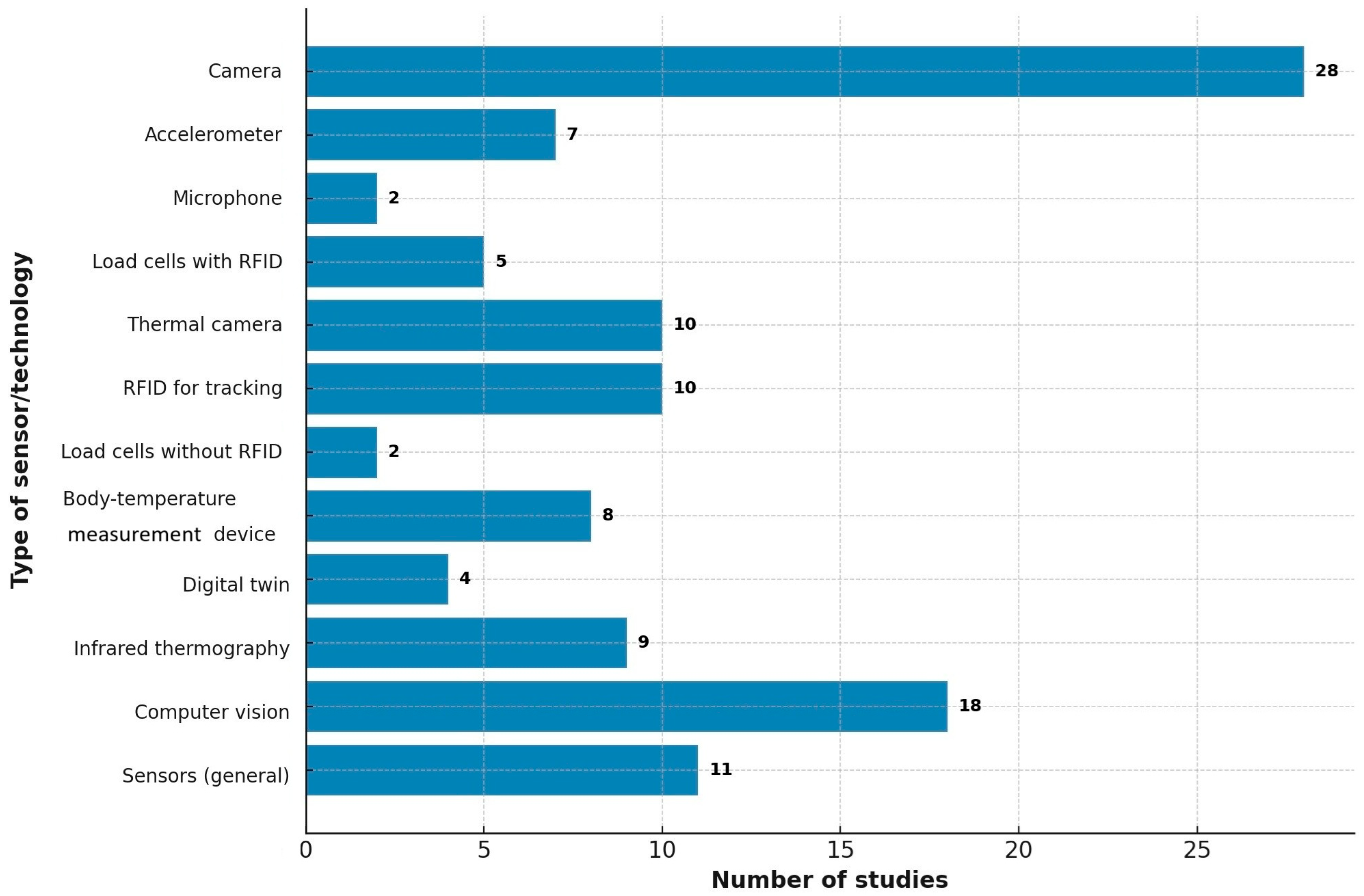

- Species: pigs.

- Technology: precise livestock farming, IoT, sensors, digital twin, thermal imaging, cameras and computer vision.

- Application: monitoring, feeding, welfare assessment, automation and digitalization.

2. Precision Livestock Farming: How Did It All Begin?

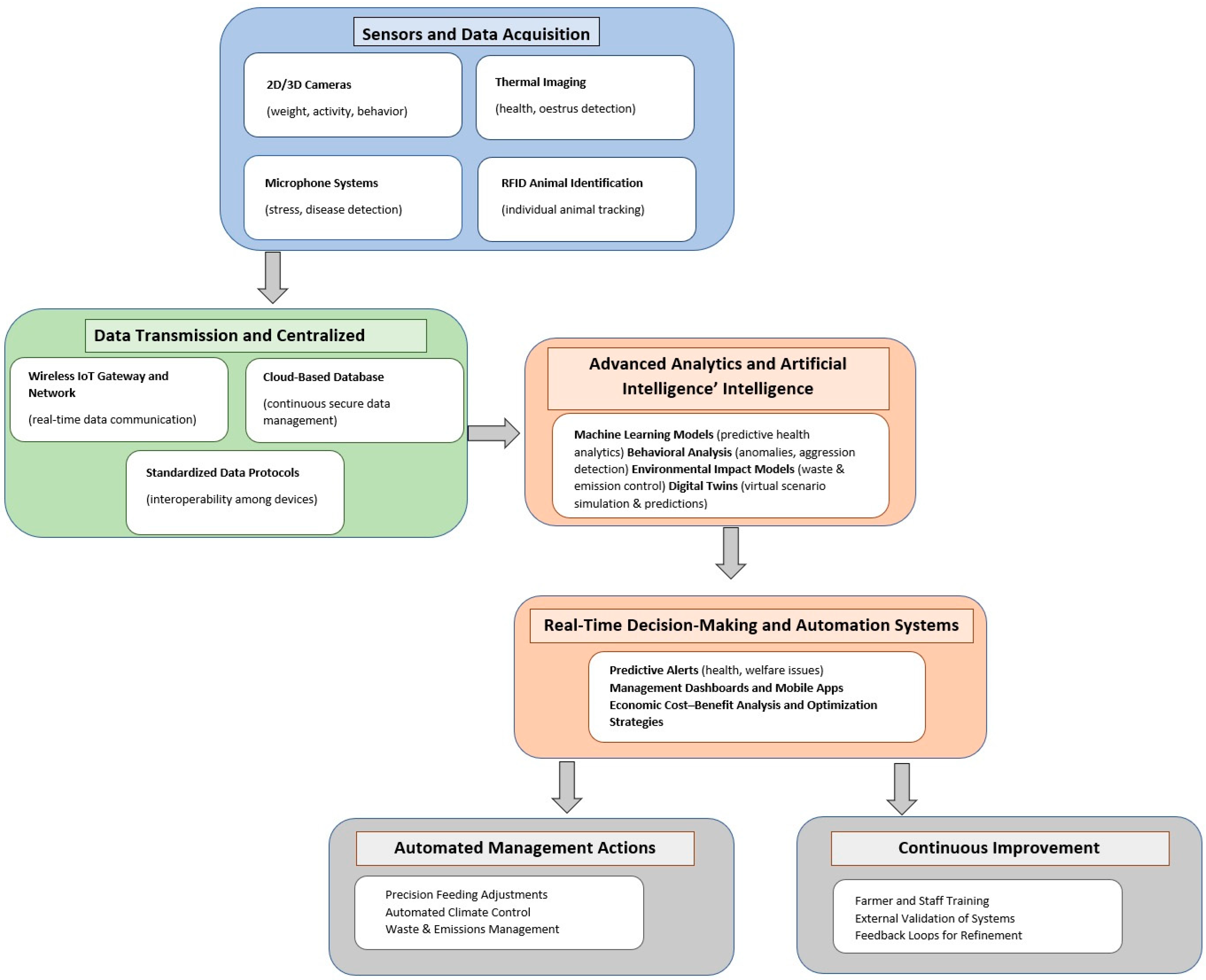

3. Implementation of Technologies

3.1. Pig Identification

3.2. Body Weight Estimation

3.3. Body Temperature

3.4. Precise Feeding

4. Future Perspectives

| Parameter | Applied Technology | Application Context | Reference(s) |

|---|---|---|---|

| Weight estimation | 2D/3D cameras, computer vision, depth sensors | Non-invasive daily monitoring of growth and weight gain | [25,48,65,68,71,77] |

| Sound-based stress detection | Microphones, AI-based acoustic classification systems | Acoustic monitoring for signs of stress, pain or disease | [28,45,61] |

| Behavior monitoring | Accelerometers, microphones, posture/sound detection | Detection of stress, illness and abnormal behavior patterns | [27,28,57,61,63] |

| Thermal status/fever detection | Infrared thermography, thermal cameras, ear-based sensors | Continuous monitoring of body temperature and detection of fever or heat stress | [26,80,81,82,88,96] |

| Welfare optimization using early warning systems | AI algorithms with integrated video, audio and motion data, anomaly detection systems | Real-time alerts based on abnormal patterns to prevent welfare deterioration | [28,45,53,57,61,90] |

| Individual identification | RFID, facial recognition, biometric systems | Tracking and managing pigs at the individual level | [30,36,45,51,54] |

| Digital twin systems | Simulations of animal–environment interaction | Predictive models for management and scenario planning | [40,41,42,43] |

| Monitoring health and welfare | AI stress detection, facial expression and movement analysis | Real-time indicators of animal comfort, illness or distress | [60,62,63,73] |

| Locomotion analysis | Computer vision, accelerometers, pressure-sensing mats | Detection of lameness and mobility-related welfare issues | [69,74,75] |

| Estrus detection | Infrared cameras, temperature and ultrasonic sensors | Early and automated detection of reproductive status in sows | [83,84,94] |

| Feeding | Precision feeding systems, RFID-based feeders, smart feeders | Individualized feeding strategies to optimize nutrient use and minimize waste | [20,97,101,103,106] |

| Environmental monitoring | IoT sensors, smart ventilation, climate sensors | Adjusting housing conditions to maintain optimal animal welfare | [103,110,111] |

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- OECD. Meat Consumption (Indicator). 2024. Available online: https://www.oecd.org/en/data/indicators/meat-consumption.html (accessed on 15 May 2024).

- Tzanidakis, C.; Simitzis, P.; Arvanitis, K.; Panagakis, P. An overview of the current trends in precision pig farming technologies. Livest. Sci. 2021, 249, 104530. [Google Scholar] [CrossRef]

- Kopler, I.; Marchaim, U.; Tikász, I.E.; Opaliński, S.; Kokin, E.; Mallinger, K.; Banhazi, T. Farmers’ perspectives of the benefits and risks in precision livestock farming in the EU pig and poultry sectors. Animals 2023, 13, 2868. [Google Scholar] [CrossRef] [PubMed]

- Schillings, J.; Bennett, R.; Rose, D.C. Exploring the potential of precision livestock farming technologies to help address farm animal welfare. Front. Anim. sci. 2021, 2, 639678. [Google Scholar] [CrossRef]

- Benjamin, M.; Yik, S. Precision livestock farming in swine welfare: A review for swine practitioners. Animals 2019, 9, 133. [Google Scholar] [CrossRef]

- Schillings, J.; Bennett, R.; Wemelsfelder, F.; Rose, D.C. Digital Livestock Technologies as boundary objects: Investigating impacts on farm management and animal welfare. Anim. Welf. 2023, 32, e17. [Google Scholar] [CrossRef]

- Wang, M.; Norton, T.; Rault, J.L. Development of Automatic Physiological and Behavioural Monitoring Systems for Pigs. Ph.D. Thesis, KU Leuven, Leuven, Belgium, 2022. [Google Scholar]

- Larsen, M.L.V.; Pedersen, L.J.; Norton, T. Precision livestock farming. In Tail Biting in Pigs; O’Driscoll, K., Valros, A., Eds.; Brill, Wageningen Academics: Wageningen, The Netherlands, 2024; pp. 330–347. [Google Scholar]

- Hasan, M.K.; Mun, H.S.; Ampode, K.M.B.; Lagua, E.B.; Park, H.R.; Kim, Y.H.; Yang, C.J. Transformation toward precision large-scale operations for sustainable farming: A review based on China’s pig industry. J. Adv. Vet. 2024, 11, 1076. [Google Scholar] [CrossRef]

- Aquilani, C.; Confessore, A.; Bozzi, R.; Sirtori, F.; Pugliese, C. Precision Livestock Farming technologies in pasture-based livestock systems. Animal 2022, 16, 100429. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, X.; Feng, H.; Huang, Q.; Xiao, X.; Zhang, X. Wearable Internet of Things enabled precision livestock farming in smart farms: A review of technical solutions for precise perception, biocompatibility, and sustainability monitoring. J. Clean. Prod. 2021, 312, 127712. [Google Scholar] [CrossRef]

- Kleen, J.L.; Guatteo, R. Precision Livestock Farming: What Does It Contain and What Are the Perspectives? Animals 2023, 13, 779. [Google Scholar] [CrossRef]

- Ruiz-Garcia, L.; Lunadei, L. The role of RFID in agriculture: Applications, limitations and challenges. Comput. Electron. Agric. 2011, 79, 42–50. [Google Scholar] [CrossRef]

- Norton, T.; Chen, C.; Larsen, M.L.V.; Berckmans, D. Precision livestock farming: Building ‘digital representations’ to bring the animals closer to the farmer. Animal 2019, 13, 3009–3017. [Google Scholar] [CrossRef] [PubMed]

- Ndue, K.; Pál, G. Life cycle assessment perspective for sectoral adaptation to climate change: Environmental impact assessment of pig production. Land 2022, 11, 827. [Google Scholar] [CrossRef]

- Hörtenhuber, S.J.; Schauberger, G.; Mikovits, C.; Schönhart, M.; Baumgartner, J.; Niebuhr, K.; Piringer, M.; Anders, I.; Andre, K.; Hennig-Pauka, I.; et al. The effect of climate change-induced temperature increase on performance and environmental impact of intensive pig production systems. Sustainability 2020, 12, 9442. [Google Scholar] [CrossRef]

- Tullo, E.; Finzi, A.; Guarino, M. Environmental impact of livestock farming and Precision Livestock Farming as a mitigation strategy. Sci. Total Environ. 2019, 650, 2751–2760. [Google Scholar] [CrossRef]

- Rauw, W.M.; Rydhmer, L.; Kyriazakis, I.; Øverland, M.; Gilbert, H.; Dekkers, J.C.; Gomez-Raya, L. Prospects for sustainability of pig production in relation to climate change and novel feed resources. J. Sci. Food Agric. 2020, 100, 3575–3586. [Google Scholar] [CrossRef]

- Balafoutis, A.; Beck, B.; Fountas, S.; Vangeyte, J.; Van der Wal, T.; Soto, I.; Eory, V. Precision agriculture technologies positively contributing to GHG emissions mitigation, farm productivity and economics. Sustainability 2017, 9, 1339. [Google Scholar] [CrossRef]

- Pomar, C.; van Milgen, J.; Remus, A. Precision livestock feeding, principle and practice. In Poultry and Pig Nutrition: Challenges for the 21st Century; Wageningen Academic: Wageningen, The Netherlands, 2019; pp. 397–418. [Google Scholar]

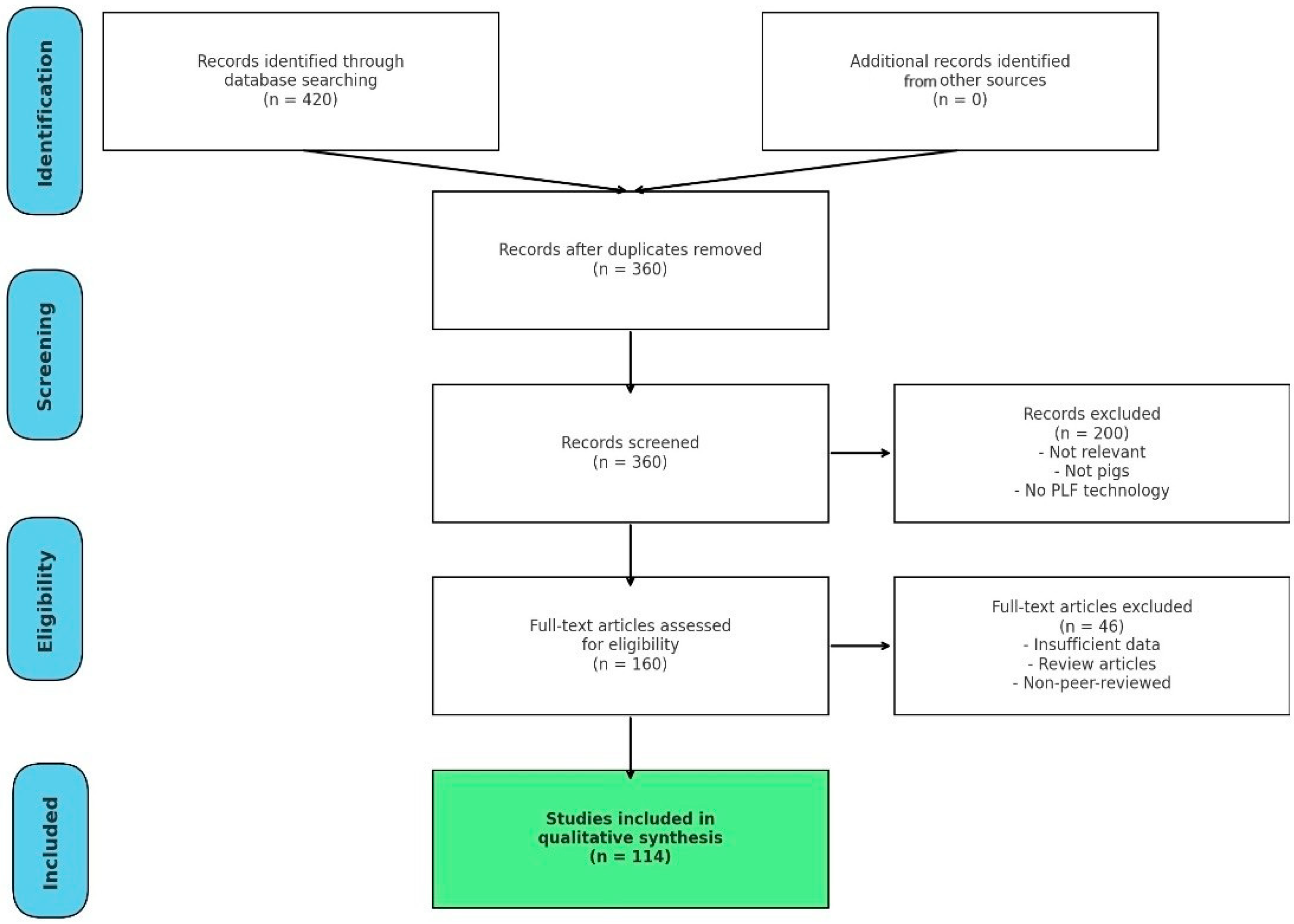

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. Int. J. Surg. 2021, 88, 105906. [Google Scholar] [CrossRef]

- Collins, L.M.; Smith, L.M. Smart agri-systems for the pig industry. Animal 2022, 16, 100518. [Google Scholar] [CrossRef]

- Halachmi, I.; Guarino, M. Precision livestock farming: A ‘per animal’approach using advanced monitoring technologies. Animal 2016, 10, 1482–1483. [Google Scholar] [CrossRef]

- Berckmans, D. General introduction to precision livestock farming. Anim. Front. 2017, 7, 6–11. [Google Scholar] [CrossRef]

- Arulmozhi, E.; Bhujel, A.; Moon, B.E.; Kim, H.T. The application of cameras in precision pig farming: An overview for swine-keeping professionals. Animals 2021, 11, 2343. [Google Scholar] [CrossRef] [PubMed]

- Franchi, G.A.; Bus, J.D.; Boumans, I.J.; Bokkers, E.A.; Jensen, M.B.; Pedersen, L.J. Estimating body weight in conventional growing pigs using a depth camera. Smart Agric. Technol. 2023, 3, 100117. [Google Scholar] [CrossRef]

- Xie, Q.; Wu, M.; Bao, J.; Zheng, P.; Liu, W.; Liu, X.; Yu, H. A deep learning-based detection method for pig body temperature using infrared thermography. Comput. Electron. Agric. 2023, 213, 108200. [Google Scholar] [CrossRef]

- Angarita, B.K.; Han, J.; Cantet, R.J.; Chewning, S.K.; Wurtz, K.E.; Siegford, J.M.; Steibel, J.P. Estimation of direct and social effects of feeding duration in growing pigs using records from automatic feeding stations. J. Anim. Sci. 2021, 99, skab042. [Google Scholar] [CrossRef]

- van Erp-van der Kooij, E.; de Graaf, L.F.; de Kruijff, D.A.; Pellegrom, D.; de Rooij, R.; Welters, N.I.; van Poppel, J. Using Sound Location to Monitor Farrowing in Sows. Animals 2023, 13, 3538. [Google Scholar] [CrossRef]

- Azarpajouh, S.; Díaz, J.A.C.; Taheri, H. Precision livestock farming: Automatic lameness detection in intensive livestock systems. CABI Rev. 2020. [Google Scholar] [CrossRef]

- Kapun, A.; Adrion, F.; Gallmann, E. Evaluating the Activity of Pigs with Radio-Frequency Identification and Virtual Walking Distances. Animals 2023, 13, 3112. [Google Scholar] [CrossRef]

- Maselyne, J.; Van Nuffel, A.; Briene, P.; Vangeyte, J.; De Ketelaere, B.; Millet, S.; Saeys, W. Online warning systems for individual fattening pigs based on their feeding pattern. Biosyst. Eng. 2018, 173, 143–156. [Google Scholar] [CrossRef]

- Alexy, M.; Horvath, T.; Reich, C.; Felfoldi, J.; Tarcsi, A. Adaption of data-intensive monitoring and tracking systems in outdoor pig production for better decision-making, literature review, and project idea. In Precision Livestock Farming 2019-Papers, Proceedings of the 9th European Conference on Precision Livestock Farming, Cork, Ireland, 26–29 August 2019; ECPLF: Cork, Ireland, 2019. [Google Scholar]

- Alexy, M.; Pai, R.R.; Ferenci, T.; Haidegger, T. The potential of RFID technology for tracking Mangalica pigs in the extensive farming system—A research from Hungary. Pastor. Res. Policy Pract. 2024, 14, 12854. [Google Scholar] [CrossRef]

- Ma, C.; Wang, Y.; Ying, G. The pig breeding management system based on RFID and WSN. In Proceedings of the 2011 Fourth International Conference on Information and Computing, Phuket, Thailand, 25–27 April 2011. [Google Scholar]

- Pandey, S.; Kalwa, U.; Kong, T.; Guo, B.; Gauger, P.C.; Peters, D.J.; Yoon, K.J. Behavioral monitoring tool for pig farmers: Ear tag sensors, machine intelligence, and technology adoption roadmap. Animals 2021, 11, 2665. [Google Scholar] [CrossRef]

- Kashiha, M.; Bahr, C.; Ott, S.; Moons, C.P.; Niewold, T.A.; Ödberg, F.O.; Berckmans, D. Automatic identification of marked pigs in a pen using image pattern recognition. Comput. Electron. Agric. 2013, 93, 111–120. [Google Scholar] [CrossRef]

- Van der Zande, L.E.; Guzhva, O.; Rodenburg, T.B. Individual detection and tracking of group housed pigs in their home pen using computer vision. Front. Anim. sci. 2021, 2, 669312. [Google Scholar] [CrossRef]

- Yin, J.; Xie, X.; Mao, H.; Guo, S. Efficient Missing Key Tag Identification in Large-scale RFID Systems: An Iterative Verification and Selection Method. IEEE Trans. Mob. Comput. 2024, 24, 3. [Google Scholar] [CrossRef]

- Mora, M.; Piles, M.; David, I.; Rosa, G.J. Integrating computer vision algorithms and RFID system for identification and tracking of group-housed animals: An example with pigs. Anim. Sci. J. 2024, 102, skae174. [Google Scholar] [CrossRef]

- Neethirajan, S.; Kemp, B. Digital twins in livestock farming. Animals 2021, 11, 1008. [Google Scholar] [CrossRef]

- Verdouw, C.; Tekinerdogan, B.; Beulens, A.; Wolfert, S. Digital twins in smart farming. Agric. Syst. 2021, 189, 103046. [Google Scholar] [CrossRef]

- Pylianidis, C.; Osinga, S.; Athanasiadis, I.N. Introducing digital twins to agriculture. Comput. Electron. Agric. 2021, 184, 105942. [Google Scholar] [CrossRef]

- Purcell, W.; Neubauer, T. Digital Twins in Agriculture: A State-of-the-art review. Smart Agric. Technol. 2023, 3, 100094. [Google Scholar] [CrossRef]

- Madec, F.; Geers, R.; Vesseur, P.; Kjeldsen, N.; Blaha, T. Traceability in the pig production chain. Rev. Sci. Tech. 2001, 20, 523–537. [Google Scholar] [CrossRef]

- Bergqvist, A.S.; Forsberg, F.; Eliasson, C.; Wallenbeck, A. Individual identification of pigs during rearing and at slaughter using microchips. Livest. Sci. 2015, 180, 233–236. [Google Scholar] [CrossRef]

- Zhou, H.; Li, Q.; Xie, Q. Individual Pig Identification Using Back Surface Point Clouds in 3D Vision. Sensors 2023, 23, 5156. [Google Scholar] [CrossRef] [PubMed]

- Berckmans, D. Precision livestock farming technologies for welfare management in intensive livestock systems. Rev. Sci. Tech. 2014, 33, 189–196. [Google Scholar] [CrossRef] [PubMed]

- Riekert, M.; Klein, A.; Adrion, F.; Hoffmann, C.; Gallmann, E. Automatically detecting pig position and posture by 2D camera imaging and deep learning. Comput. Electron. Agric. 2020, 174, 105391. [Google Scholar] [CrossRef]

- Tscharke, M.; Banhazi, T.M. Integrating radio frequency identification into the piGUI system to recognise sampling bias and detect feeding behaviour. Aust. J. Mech. Eng. 2013, 10, 94–107. [Google Scholar]

- Thölke, H.; Wolf, P. Economic advantages of individual animal identification in fattening pigs. Agriculture 2022, 12, 126. [Google Scholar] [CrossRef]

- Hansen, M.F.; Smith, M.L.; Smith, L.N.; Salter, M.G.; Baxter, E.M.; Farish, M.; Grieve, B. Towards on-farm pig face recognition using convolutional neural networks. Comput. Ind. 2018, 98, 145–152. [Google Scholar] [CrossRef]

- Gómez, Y.; Stygar, A.H.; Boumans, I.J.; Bokkers, E.A.; Pedersen, L.J.; Niemi, J.K.; Llonch, P. A systematic review on validated precision livestock farming technologies for pig production and its potential to assess animal welfare. Front. Vet. Sci. 2021, 8, 660565. [Google Scholar] [CrossRef]

- Chen, C.; Zhu, W.; Steibel, J.; Siegford, J.; Han, J.; Norton, T. Recognition of feeding behaviour of pigs and determination of feeding time of each pig by a video-based deep learning method. Comput. Electron. Agric. 2020, 176, 105642. [Google Scholar] [CrossRef]

- Marsot, M.; Mei, J.; Shan, X.; Ye, L.; Feng, P.; Yan, X.; Zhao, Y. An adaptive pig face recognition approach using Convolutional Neural Networks. Comput. Electron. Agric. 2020, 173, 105386. [Google Scholar] [CrossRef]

- Kang, M.H.; Oh, S.H. Research trends in livestock facial identification—A review. J. Anim. Sci. Technol. 2025, 67, 43–55. [Google Scholar] [CrossRef]

- Shvets, Y.; Morkovkin, D.; Basova, M.; Yashchenko, A.; Petrusevich, T. Robotics in agriculture: Advanced technologies in livestock farming and crop cultivation. E3S Web Conf. 2024, 480, 03024. [Google Scholar] [CrossRef]

- Cowton, J.; Kyriazakis, I.; Bacardit, J. Automated individual pig localisation, tracking and behaviour metric extraction using deep learning. IEEE Access 2019, 7, 108049–108060. [Google Scholar] [CrossRef]

- McGlone, J.J. A quantitative ethogram of aggressive and submissive behaviors in recently regrouped pigs. J. Anim. Sci. 1985, 61, 556–566. [Google Scholar] [CrossRef]

- Gašpar, D.; Gvozdanović, K.; Galović, D.; Samac, D.; Jurčević, J.; Margeta, V. Ponašanje svinja u različitim sustavima uzgoja. In Proceedings of the 59th Croatian & 19th International Symposium on Agriculture, Dubrovnik, Croatia, 11–16 February 2024; pp. 310–315. [Google Scholar]

- Vitali, M.; Santolini, E.; Bovo, M.; Tassinari, P.; Torreggiani, D.; Trevisi, P. Behavior and welfare of undocked heavy pigs raised in buildings with different ventilation systems. Animals 2021, 11, 2338. [Google Scholar] [CrossRef]

- Vranken, E.; Berckmans, D. Precision livestock farming for pigs. Anim. Front. 2017, 7, 32–37. [Google Scholar] [CrossRef]

- Wei, J.; Tang, X.; Liu, J.; Zhang, Z. Detection of pig movement and aggression using deep learning approaches. Animals 2023, 13, 3074. [Google Scholar] [CrossRef]

- Shao, H.; Pu, J.; Mu, J. Pig-posture recognition based on computer vision: Dataset and exploration. Animals 2021, 11, 1295. [Google Scholar] [CrossRef]

- Li, G.; Shi, G.; Jiao, J. YOLOv5-KCB: A new method for individual pig detection using optimized K-means, CA attention mechanism and a bi-directional feature pyramid network. Sensors 2023, 23, 5242. [Google Scholar] [CrossRef]

- Nguyen, A.H.; Holt, J.P.; Knauer, M.T.; Abner, V.A.; Lobaton, E.J.; Young, S.N. Towards rapid weight assessment of finishing pigs using a handheld, mobile RGB-D camera. Biosyst. Eng. 2023, 226, 155–168. [Google Scholar] [CrossRef]

- Lagua, E.; Mun, H.S.; Ampode, K.M.B.; Park, H.R.; Kim, Y.H.; Yang, C.J. Monitoring using artificial intelligence reveals critical links between housing conditions and respiratory health in pigs. J. Anim. Behav. Biometeorol. 2024, 12, 2024008. [Google Scholar] [CrossRef]

- Racewicz, P.; Ludwiczak, A.; Skrzypczak, E.; Składanowska-Baryza, J.; Biesiada, H.; Nowak, T.; Ślósarz, P. Welfare health and productivity in commercial pig herds. Animals 2021, 11, 1176. [Google Scholar] [CrossRef] [PubMed]

- Pezzuolo, A.; Guarino, M.; Sartori, L.; González, L.A.; Marinello, F. On-barn pig weight estimation based on body measurements by a Kinect v1 depth camera. Comput. Electron. Agric. 2018, 148, 29–36. [Google Scholar] [CrossRef]

- Wang, Z.; Li, Q.; Yu, Q.; Qian, W.; Gao, R.; Wang, R.; Li, X. A Review of Visual Estimation Research on Live Pig Weight. Sensors 2024, 24, 7093. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.A.; Kong, C.; Adeola, O.; Kim, B.G. Different coefficients and exponents for metabolic body weight in a model to estimate individual feed intake for growing-finishing pigs. Asian-Australas. J. Anim. Sci. 2016, 29, 1756. [Google Scholar] [CrossRef]

- Thapar, G.; Biswas, T.K.; Bhushan, B.; Naskar, S.; Kumar, A.; Dandapat, P.; Rokhade, J. Accurate estimation of body weight of pigs through smartphone image measurement app. Smart Agric. Technol. 2023, 4, 100194. [Google Scholar] [CrossRef]

- Bhoj, S.; Tarafdar, A.; Chauhan, A.; Singh, M.; Gaur, G.K. Image processing strategies for pig liveweight measurement: Updates and challenges. Comput. Electron. Agric. 2022, 193, 106693. [Google Scholar] [CrossRef]

- Mluba, H.S.; Atif, O.; Lee, J.; Park, D.; Chung, Y. Pattern Mining-Based Pig Behavior Analysis for Health and Welfare Monitoring. Sensors 2024, 24, 2185. [Google Scholar] [CrossRef]

- Schofield, C.P. Evaluation of image analysis as a means of estimating the weight of pigs. J. Agric. Eng. Res. 1990, 47, 287–296. [Google Scholar] [CrossRef]

- Wang, M.; Li, X.; Larsen, M.L.; Liu, D.; Rault, J.L.; Norton, T. A computer vision-based approach for respiration rate monitoring of group housed pigs. Comput. Electron. Agric. 2023, 210, 107899. [Google Scholar] [CrossRef]

- Lei, K.; Tang, X.; Li, X.; Lu, Q.; Long, T.; Zhang, X.; Xiong, B. Research and Preliminary Evaluation of Key Technologies for 3D Reconstruction of Pig Bodies Based on 3D Point Clouds. Agriculture 2024, 14, 793. [Google Scholar] [CrossRef]

- Win, K.D.; Kawasue, K.; Tokunaga, T. Robust pig extraction using ground base depth images for automatic weight estimation. Artif. Life Robot. 2025, 30, 42–50. [Google Scholar] [CrossRef]

- Fernandes, A.F.A.; Dorea, J.R.R.; Fitzgerald, R.; Herring, W.O. PSXIII-16 Comparison of models for prediction of pig body weight using features from an autonomous 3D computer vision system. J. Anim. Sci. 2019, 97, 475–476. [Google Scholar] [CrossRef]

- Abner, V.A. Accurate and Rapid Weight Assessment of Finishing Pigs. Master’s Thesis, North Carolina State University, Raleigh, NC, USA, 2021, 2021; p. 28814862. [Google Scholar]

- Zhang, Z.; Zhang, H.; Liu, T. Study on body temperature detection of pig based on infrared technology: A review. Artif. Intell. Agric. 2019, 1, 14–26. [Google Scholar] [CrossRef]

- Reza, M.N.; Ali, M.R.; Kabir, M.S.N.; Karim, M.R.; Ahmed, S.; Kyoung, H.; Chung, S.O. Thermal imaging and computer vision technologies for the enhancement of pig husbandry: A review. J. Anim. Sci. Technol. 2014, 66, 31–56. [Google Scholar] [CrossRef]

- Chem, V.; Mun, H.S.; Ampode, K.M.B.; Mahfuz, S.; Chung, I.B.; Dilawar, M.A.; Yang, C.J. Heat detection of gilts using digital infrared thermal imaging camera. Adv. Anim. Vet. Sci. 2022, 10, 2142–2147. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, D.H.; Yun, W.; Oh, H.J.; An, J.S.; Kim, Y.G.; Cho, J.H. Quantifiable and feasible estrus detection using the ultrasonic sensor array and digital infrared thermography. J. Anim. Sci. Technol. 2019, 61, 163. [Google Scholar] [CrossRef]

- Schmidt, M.; Lahrmann, K.H.; Ammon, C.; Berg, W.; Schön, P.; Hoffmann, G. Assessment of body temperature in sows by two infrared thermography methods at various body surface locations. J. Swine Health Prod. 2013, 21, 203–209. [Google Scholar] [CrossRef]

- Zhang, B.; Xiao, D.; Liu, J.; Huang, S.; Huang, Y.; Lin, T. Pig eye area temperature extraction algorithm based on registered images. Comput. Electron. Agric. 2024, 217, 108549. [Google Scholar] [CrossRef]

- Sánchez-Giménez, P.; Martínez-Nicolas, A.; Madrid, J.A.; Fernández, R.; Martínez-Alarcón, L.; Murciano, F.; Munoz, A.; Ramis, G. Circadian temperature rhythm in breeding sows: Differences between days in oestrus and anoestrus after weaning. Porc. Health Manag. 2024, 10, 20. [Google Scholar] [CrossRef]

- Mostaço, G.M.; Miranda, K.O.D.S.; Condotta, I.C.D.S.; Salgado, D.D.A. Determination of piglets’ rectal temperature and respiratory rate through skin surface temperature under climatic chamber conditions. Eng. Agríc. 2015, 35, 979–989. [Google Scholar] [CrossRef]

- Rocha, L.M.; Devillers, N.; Maldague, X.; Kabemba, F.Z.; Fleuret, J.; Guay, F.; Faucitano, L. Validation of anatomical sites for the measurement of infrared body surface temperature variation in response to handling and transport. Animals 2019, 9, 425. [Google Scholar] [CrossRef] [PubMed]

- Himu, H.A.; Raihan, A. Digital transformation of livestock farming for sustainable development. J. Vet. Med. 2024, 1, 1–8. [Google Scholar]

- Glencorse, D.; Grupen, C.G.; Bathgate, R. A Review of the Monitoring Techniques Used to Detect Oestrus in Sows. Animals 2025, 15, 331. [Google Scholar] [CrossRef]

- Papadopoulos, G.; Papantonatou, M.Z.; Uyar, H.; Kriezi, O.; Mavrommatis, A.; Psiroukis, V.; Kasimati, A.; Tsiplakou, E.; Fountas, S. Economic and Environmental Benefits of Digital Agricultural Technological Solutions in Livestock Farming: A Review. Smart Agric. Technol. 2025, 10, 100783. [Google Scholar] [CrossRef]

- Chung, T.H.; Jung, W.S.; Nam, E.H.; Kim, J.H.; Park, S.H.; Hwang, C.Y. Comparison of rectal and infrared thermometry for obtaining body temperature of gnotobiotic piglets in conventional portable germ free facility. Asian-Australas. J. Anim. Sci. 2010, 23, 1364–1368. [Google Scholar] [CrossRef]

- Štukelj, M.; Hajdinjak, M.; Pušnik, I. Stress-free measurement of body temperature of pigs by using thermal imaging–Useful fact or wishful thinking. Comput. Electron. Agric. 2022, 193, 106656. [Google Scholar] [CrossRef]

- Sharifuzzaman, M.; Mun, H.S.; Ampode, K.M.B.; Lagua, E.B.; Park, H.R.; Kim, Y.H.; Hasan, M.K.; Yang, C.J. Technological Tools and Artificial Intelligence in Estrus Detection of Sows—A Comprehensive Review. Animals 2024, 14, 471. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H.; He, Y.; Liu, T. A Review in the automatic detection of pigs behavior with sensors. J. Sens. 2022, 2022. [Google Scholar] [CrossRef]

- Wang, G.; Ma, Y.; Huang, J.; Fan, F.; Wang, Z. Measurement of pig body temperature based on ear segmentation and multi-factor infrared temperature compensation. IEEE Trans. Instrum. Meas. 2025, 74, 5008415. [Google Scholar]

- Gaillard, C.; Brossard, L.; Dourmad, J.Y. Improvement of feed and nutrient efficiency in pig production through precision feeding. Anim. Feed. Sci. Technol. 2020, 268, 114611. [Google Scholar] [CrossRef]

- Morrone, S.; Dimauro, C.; Gambella, F.; Cappai, M.G. Industry 4.0 and precision livestock farming (PLF): An up to date overview across animal productions. Sensors 2022, 22, 4319. [Google Scholar] [CrossRef] [PubMed]

- Pomar, C.; Hauschild, L.; Zhang, G.H.; Pomar, J.; Lovatto, P.A. Applying precision feeding techniques in growing-finishing pig operations. Rev. Bras. Zootecn. 2009, 38, 226–237. [Google Scholar] [CrossRef]

- Burns, R.T.; Spajić, R. Precision Livestock Farming in Swine Production. In Tracing the Domestic Pig; Kušec, G., Djurkin Kušec, I., Eds.; IntechOpen: London, UK, 2024. [Google Scholar] [CrossRef]

- Andretta, I.; Pomar, C.; Kipper, M.; Hauschild, L.; Rivest, J. Feeding behavior of growing–finishing pigs reared under precision feeding strategies. J. Anim. Sci. 2016, 94, 3042–3050. [Google Scholar] [CrossRef]

- Aparicio, M.; Yeste-Vizcaíno, N.; Morales, J.; Soria, N.; Isabel, B.; Piñeiro, C.; González-Bulnes, A. Use of Precision Feeding during Lactation Improves the Productive Yields of Sows and Their Piglets under Commercial Farm Conditions. Animals 2024, 14, 2863. [Google Scholar] [CrossRef]

- Perez Garcia, C.A.; Bovo, M.; Torreggiani, D.; Tassinari, P.; Benni, S. Indoor Temperature Forecasting in Livestock Buildings: A Data-Driven Approach. Agriculture 2024, 14, 316. [Google Scholar] [CrossRef]

- Andretta, I.; Hauschild, L.; Kipper, M.; Pires, P.G.S.; Pomar, C. Environmental impacts of precision feeding programs applied in pig production. Animal 2018, 12, 1990–1998. [Google Scholar] [CrossRef]

- Llorens, B.; Pomar, C.; Goyette, B.; Rajagopal, R.; Andretta, I.; Latorre, M.A.; Remus, A. Precision feeding as a tool to reduce the environmental footprint of pig production systems: A life-cycle assessment. Anim. Sci. J. 2024, 102, skae225. [Google Scholar] [CrossRef]

- Mielke, S.; Stein, A. Excretion Detection in Pigsties Using Convolutional and Transformerbased Deep Neural Networks. arXiv 2024, arXiv:2412.00256. [Google Scholar]

- Maes, D.G.; Dewulf, J.; Piñeiro, C.; Edwards, S.; Kyriazakis, I. A critical reflection on intensive pork production with an emphasis on animal health and welfare. J. Anim. Sci. 2020, 98, S15–S26. [Google Scholar] [CrossRef]

- Norton, T.; Vranken, E.; Exadaktylos, V.; Berckmans, D.; Lehr, H.; Vessier, I.; Berckmans, D. Implementation of Precision Livestock Farming (PLF) Technology on EU Farms: Results from the EU-PLF Project; Wageningen Academic Publishers: Wageningen, The Netherlands, 2016. [Google Scholar]

- Bordignon, F.; Provolo, G.; Riva, E.; Caria, M.; Todde, G.; Sara, G.; Pezzuolo, A. Smart technologies to improve the management and resilience to climate change of livestock housing: A systematic and critical review. Ital. J. Anim. Sci. 2025, 24, 376–392. [Google Scholar] [CrossRef]

- Renaudeau, D.; Dourmad, J.Y. Future consequences of climate change for European Union pig production. Animal 2022, 16, 100372. [Google Scholar] [CrossRef] [PubMed]

- Niu, K.; Zhong, J.; Hu, X. Impacts of climate change-induced heat stress on pig productivity in China. Sci. Total Environ. 2024, 908, 168215. [Google Scholar] [CrossRef] [PubMed]

- de Oliveira, M.J.K.; Polycarpo, G.V.; Andretta, I.; Melo, A.D.B.; Marçal, D.A.; Létourneau-Montminy, M.P.; Hauschild, L. Effect of constant and cyclic heat stress on growth performance, water intake, and physiological responses in pigs: A meta-analysis. Anim. Feed. Sci. Technol. 2024, 309, 115904. [Google Scholar] [CrossRef]

| Technology | Advantages | Limitations | Application | Future Improvements | Implementation Challenges |

|---|---|---|---|---|---|

| 2D/3D Cameras | Accurate body weight estimation, behavioral monitoring, activity tracking | Sensitivity to environmental conditions (lighting, dust) | Large-scale pig farms for automated monitoring | Improved AI for better accuracy in poor lighting conditions | High initial setup cost, require technical expertise |

| Thermal Imaging | Non-invasive body temperature monitoring, estrus detection | Expensive, calibration needed for accuracy | Health monitoring and early disease detection | Cost reduction and integration with AI-based alerts | High cost of thermal cameras, requires regular maintenance |

| RFID-Based Feeders | Individualized feeding, reduced feed waste | High initial cost, infrastructure | Precision feeding strategies in intensive production system | Increased affordability, integration with cloud-based analytics | Require RFID infrastructure, potential signal interference |

| Sound Analysis Systems | Early detection of respiratory problems and stress | Advanced AI models needed for accurate interpretation | Large farms with high number of pigs | Enhanced deep learning models | Require extensive labeled sound datasets |

| Automated Waste Management | Reduces environmental footprint, optimizes nutrient recycling | Initial setup costs, requires suitable maintenance | Production farms aiming for sustainability | Smart waste processing units | Requires space and regulatory compliance |

| AI-Driven Predictive Models | Enable early intervention in health and nutrition management | Large datasets needed for accuracy, need for continuous refinement | Farms leveraging big data for predictive analytics | Expansion of real-time data collection and self-learning systems | Data privacy concerns, high computing power requirements |

| Digital Twin Technology | Simulates and predicts farm conditions in real time | Integration of multiple sensors and high computing power | Precision monitoring of farm environments | Enhanced AI-driven decision-making with real-time optimization | Computationally demanding, integration complexity |

| IoT-Based Smart Barns | Automate climate control, feeding and monitoring | High installation cost, network dependency | Large-scale automated pig production | Integration with blockchain for data security and transparency | Stable internet, cybersecurity risks |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marić, K.; Gvozdanović, K.; Djurkin Kušec, I.; Kušec, G.; Margeta, V. Smart Pig Farms: Integration and Application of Digital Technologies in Pig Production. Agriculture 2025, 15, 937. https://doi.org/10.3390/agriculture15090937

Marić K, Gvozdanović K, Djurkin Kušec I, Kušec G, Margeta V. Smart Pig Farms: Integration and Application of Digital Technologies in Pig Production. Agriculture. 2025; 15(9):937. https://doi.org/10.3390/agriculture15090937

Chicago/Turabian StyleMarić, Katarina, Kristina Gvozdanović, Ivona Djurkin Kušec, Goran Kušec, and Vladimir Margeta. 2025. "Smart Pig Farms: Integration and Application of Digital Technologies in Pig Production" Agriculture 15, no. 9: 937. https://doi.org/10.3390/agriculture15090937

APA StyleMarić, K., Gvozdanović, K., Djurkin Kušec, I., Kušec, G., & Margeta, V. (2025). Smart Pig Farms: Integration and Application of Digital Technologies in Pig Production. Agriculture, 15(9), 937. https://doi.org/10.3390/agriculture15090937