Design and Test of a Bionic Auxiliary Soil-Crushing Device for Strip-Tillage Machines

Abstract

1. Introduction

2. Materials and Methods

2.1. Structure and Working Principle of Auxiliary Soil-Crushing Device

2.2. Design and Analysis of Key Components

2.2.1. Design and Analysis of the Soil-Crushing Blade Structure

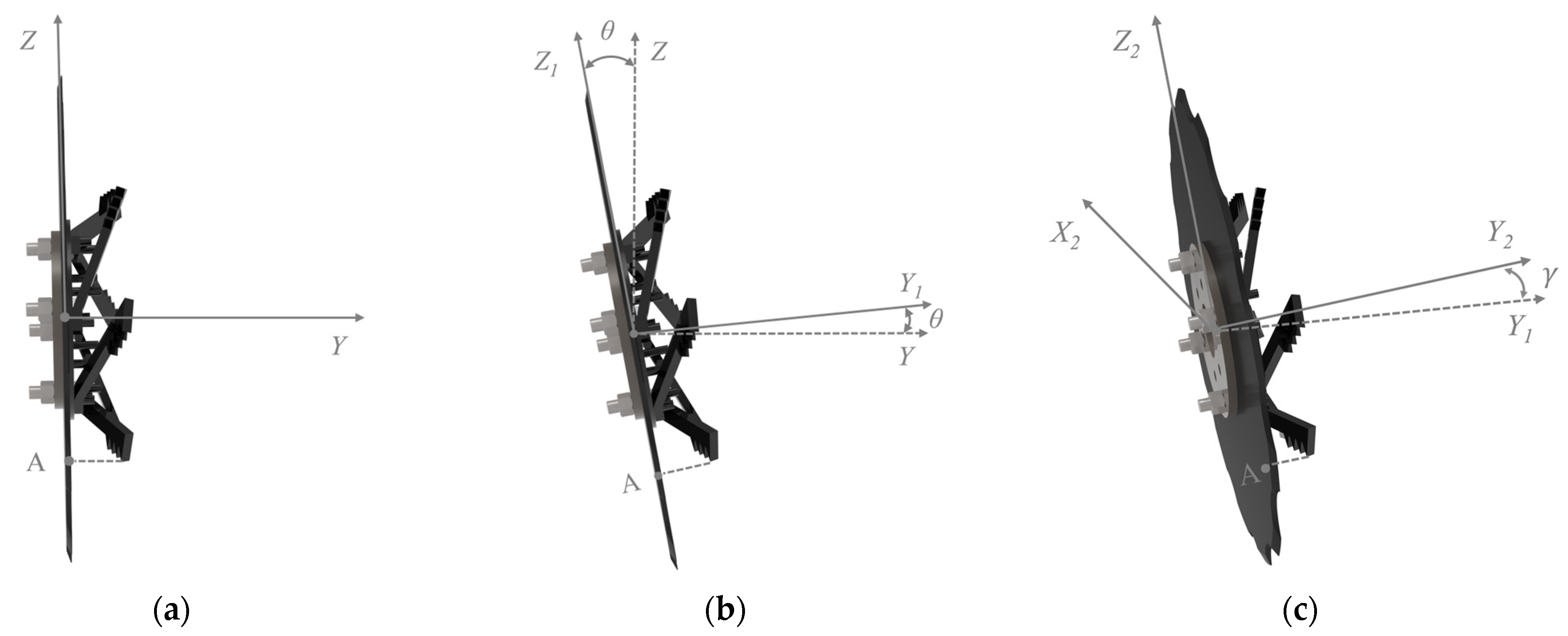

2.2.2. Determination of Soil-Crushing Blade Parameter Ranges

2.2.3. Determination the Number of Soil-Crushing Blades to Be Installed

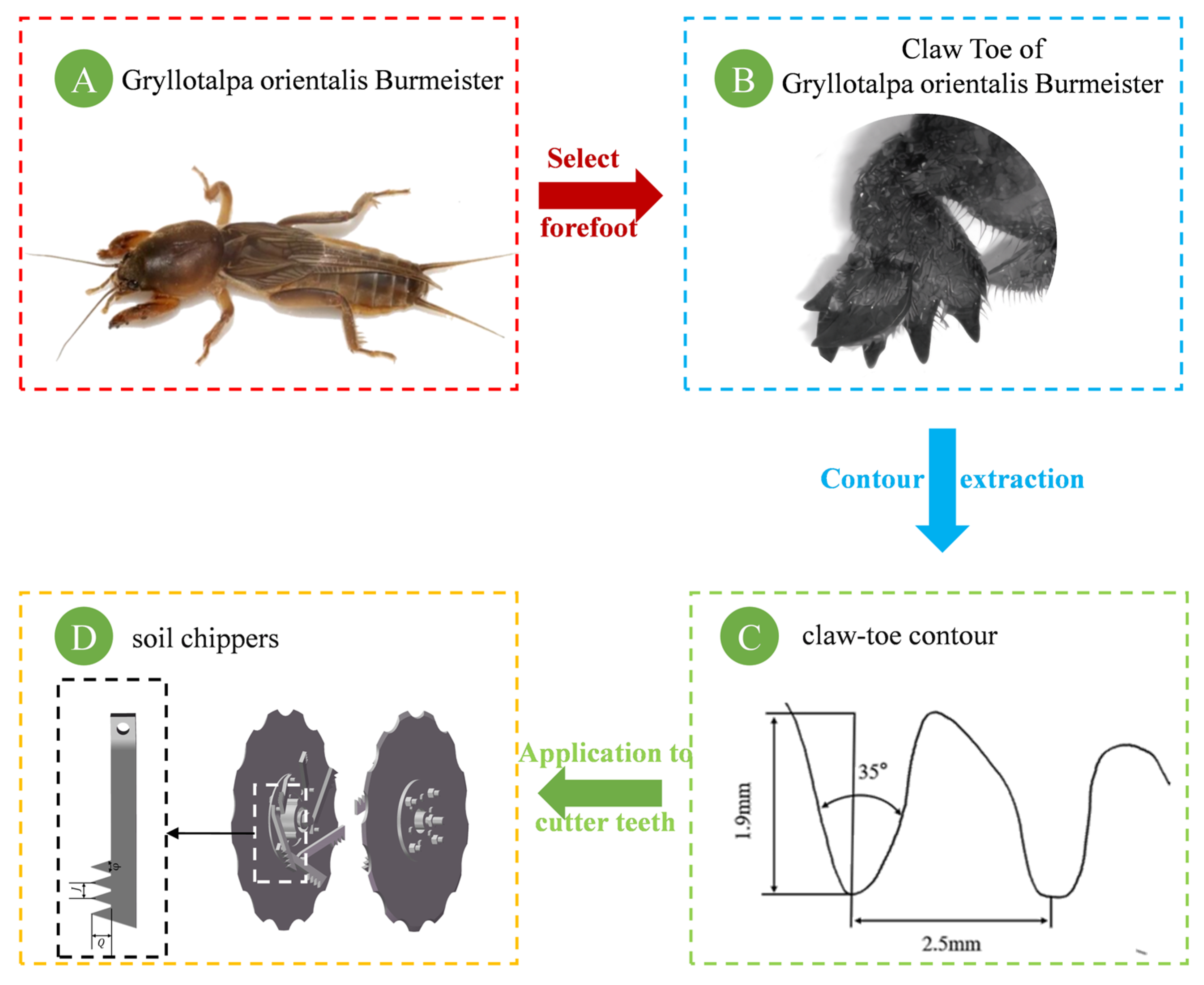

2.3. Bionic Design of Soil-Crushing Blade

2.4. Simulation Test Based on DEM

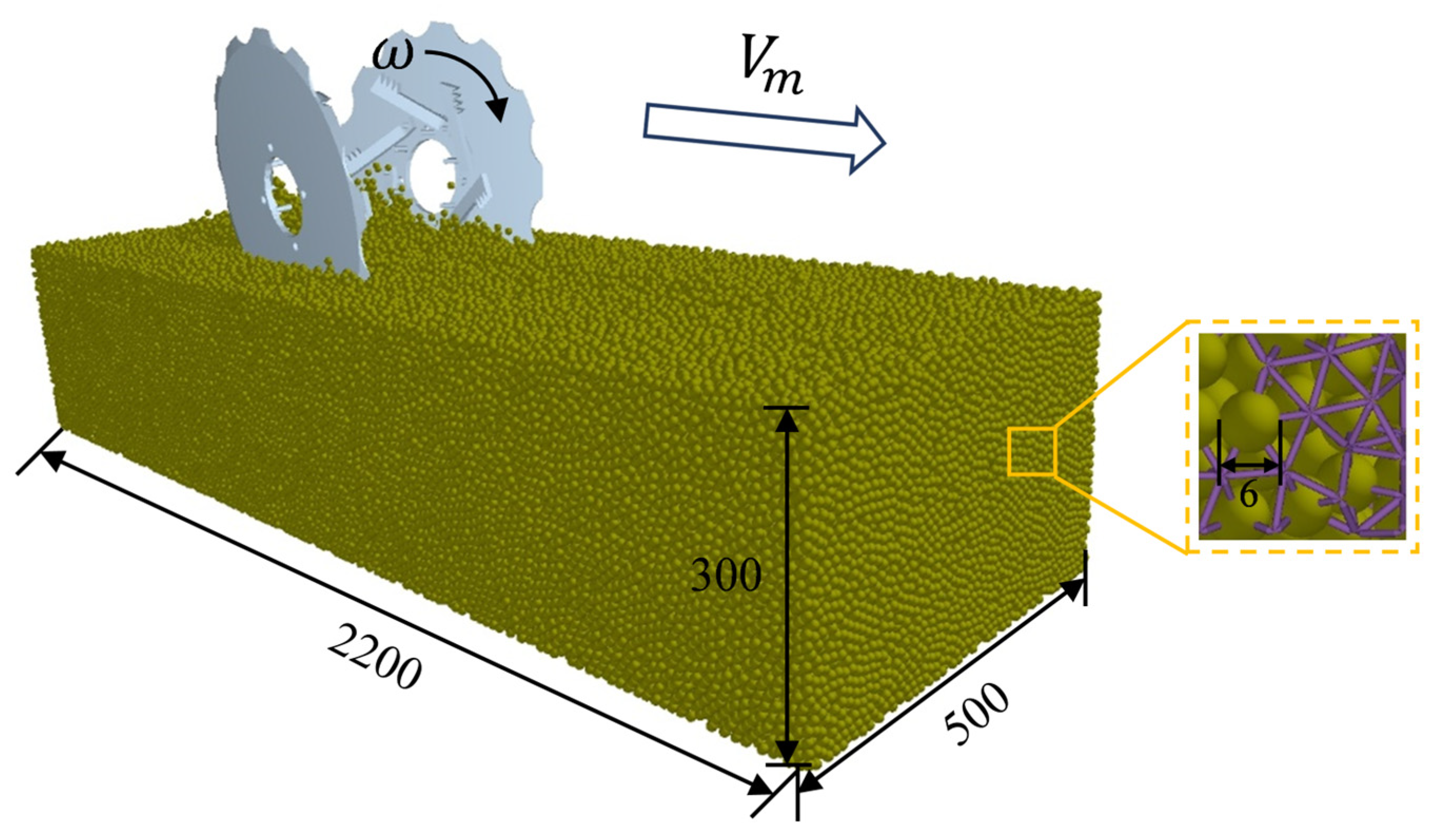

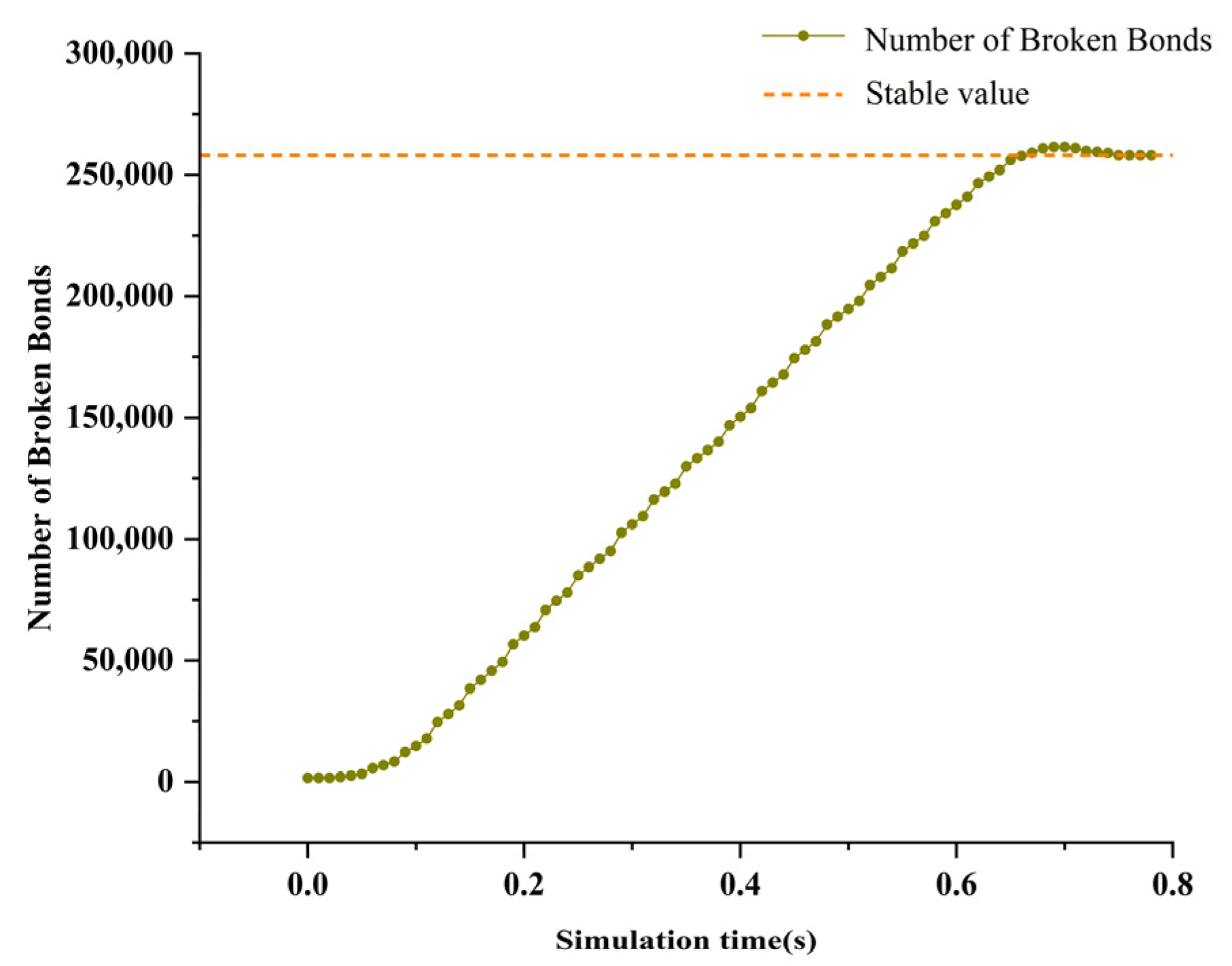

2.4.1. Establishment of EDEM Discrete Element Model

2.4.2. Simulation Test Measurement Methods

2.4.3. Simulation Test Design

2.5. Field Experiment

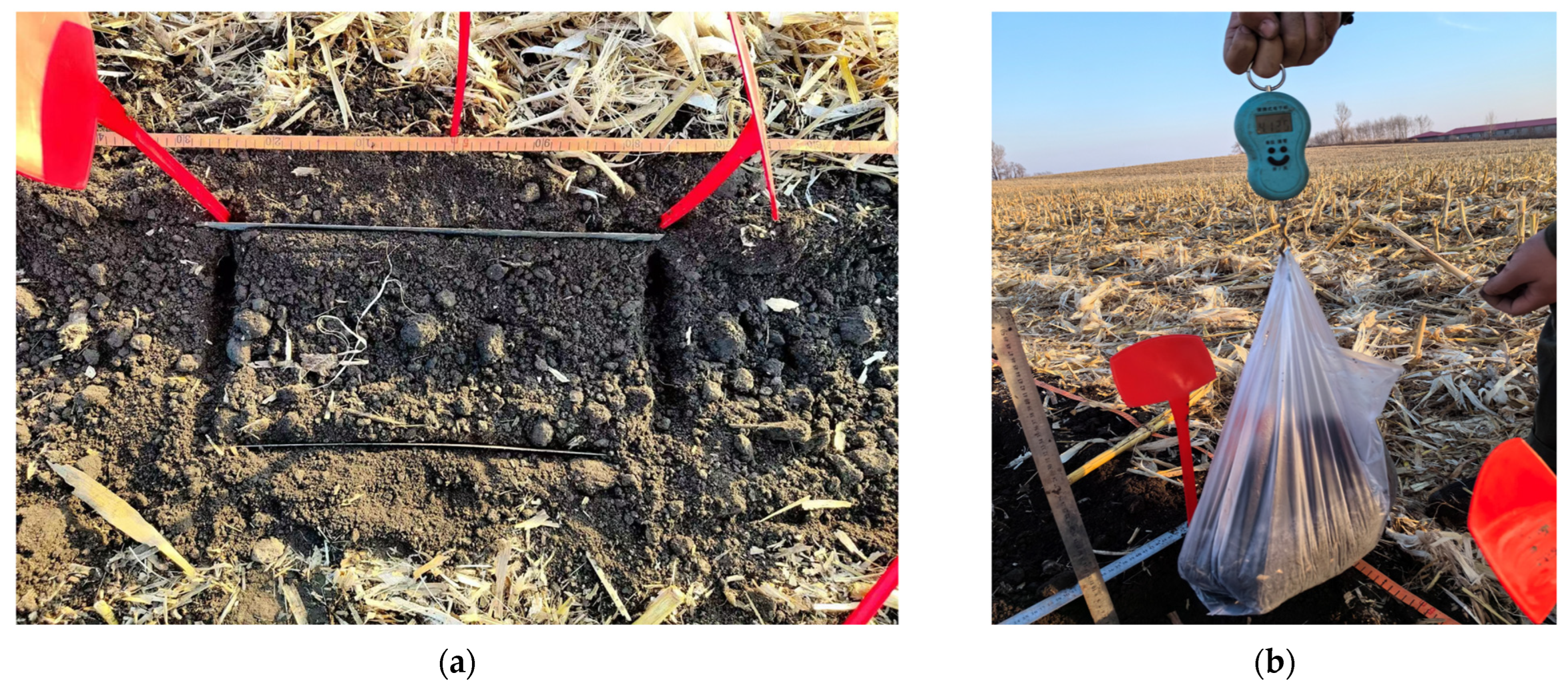

2.5.1. Field Experiment Method

2.5.2. Bionic Auxiliary Soil-Crushing Device Field Operation

2.6. Statistical Methods

3. Results and Discussion

3.1. Optimization and Analysis of CCD Experiment

3.1.1. ANOVA

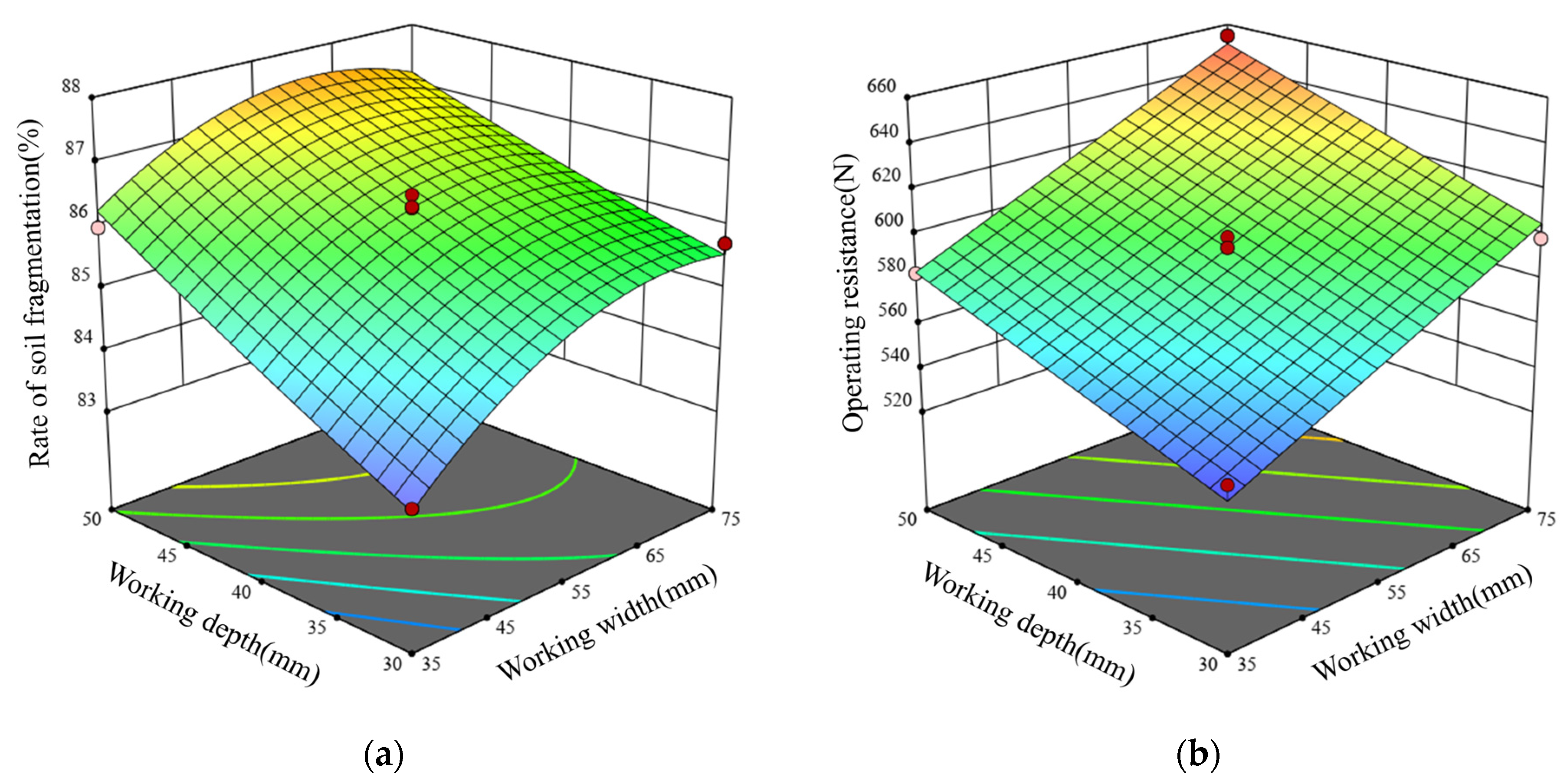

3.1.2. Response Surface Analysis

3.2. Blade Tooth Structure Comparison Test

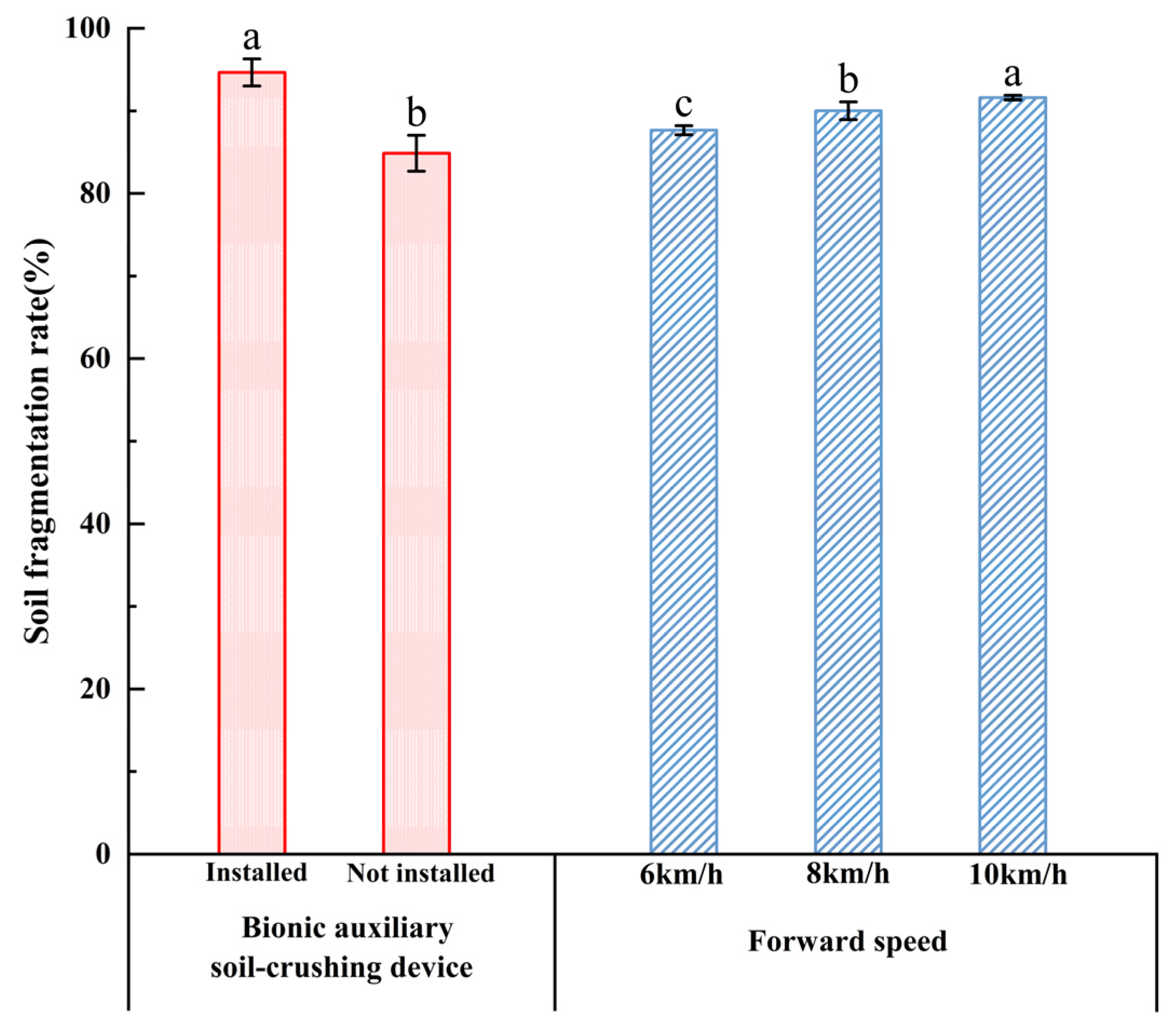

3.3. Field Experiment Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Blanco-Canqui, H.; Lal, R. Crop residue removal impacts on soil productivity and environmental quality. Crit. Rev. Plant Sci. 2009, 28, 139–163. [Google Scholar] [CrossRef]

- Ren, Z.J.; Han, X.J.; Feng, H.X.; Wang, L.F.; Ma, G.; Li, J.H.; Lv, J.J.; Tian, W.Z.; He, X.H.; Zhao, Y.N.; et al. Long-term conservation tillage improves soil stoichiometry balance and crop productivity based on a 17-year experiment in a semi-arid area of northern china. Sci. Total Environ. 2024, 908, 168283. [Google Scholar] [CrossRef] [PubMed]

- Nunes, M.R.; Karlen, D.L.; Veum, K.S.; Moorman, T.B.; Cambardella, C.A. Biological soil health indicators respond to tillage intensity: A us meta-analysis. Geoderma 2020, 369, 114335. [Google Scholar] [CrossRef]

- Xu, X.Z.; Xu, Y.; Chen, S.C.; Xu, S.G.; Zhang, H.W. Soil loss and conservation in the black soil region of northeast china: A retrospective study. Environ. Sci. Policy 2010, 13, 793–800. [Google Scholar] [CrossRef]

- Tagar, A.A.; Adamowski, J.; Memon, M.S.; Do, M.C.; Mashori, A.S.; Soomro, A.S.; Bhayo, W.A. Soil fragmentation and aggregate stability as affected by conventional tillage implements and relations with fractal dimensions. Soil. Till Res. 2020, 197, 104494. [Google Scholar] [CrossRef]

- Guan, C.S.; Fu, J.J.; Xu, L.; Jiang, X.Z.; Wang, S.L.; Cui, Z.C. Study on the reduction of soil adhesion and tillage force of bionic cutter teeth in secondary soil crushing. Biosyst. Eng. 2022, 213, 133–147. [Google Scholar] [CrossRef]

- Wang, J.W.; Wen, N.; Liu, Z.M.; Zhou, W.Q.; Tang, H.; Wang, Q.; Wang, J.F. Coupled bionic design of liquid fertilizer deep application type opener based on sturgeon streamline to enhance opening performance in cold soils of northeast China. Agriculture 2022, 12, 615. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, B.; Sun, M.J.; Sun, X.B.; Zhou, W.Q.; Tang, H.; Wang, J.W. Design and testing of an automatic strip-till machine for conservation tillage of corn. Agronomy 2023, 13, 2357. [Google Scholar] [CrossRef]

- Wu, B.; Huang, T.C.; Qiu, X.X.; Zuo, T.L.; Wang, X.S.; Xie, F.P. Design and experimental study of potato-soil separation device for sticky soils condition. Appl. Sci. 2021, 11, 10959. [Google Scholar] [CrossRef]

- Tukhtakuziyev, A.; Ishmuradov, S.U.; Abdumajidov, R. Researching the parameters of the disc plough and its smooth run throughout the tillage depth. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; p. 012058. [Google Scholar]

- Han, C.J.; Liu, Z.; Mao, H.P.; Ma, X.; Wang, S. Design and experiment of variable rate fertilization combined soil preparation machine. Trans. Chin. Soc. Agric. Mach. 2024, 55, 250–261, 284. [Google Scholar]

- Li, F.; Yang, H.J.; Zheng, X.; Hu, H.Y. Development of the soil layer construction device for the cotton seedbed in sandy soil of arid areas. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2024, 40, 55–65. [Google Scholar]

- Kayombo, B.; Lal, R. Effects of soil compaction by rolling on soil structure and development of maize in no-till and disc ploughing systems on a tropical alfisol. Soil. Tillage Res. 1986, 7, 117–134. [Google Scholar] [CrossRef]

- Ucgul, M. Simulating soil–disc plough interaction using discrete element method–multi-body dynamic coupling. Agriculture 2023, 13, 305. [Google Scholar] [CrossRef]

- Onwualu, A.; Watts, K. Draught and vertical forces obtained from dynamic soil cutting by plane tillage tools. Soil. Tillage Res. 1998, 48, 239–253. [Google Scholar] [CrossRef]

- Zhong, G.Y.; Li, H.W.; He, J.; Wang, Q.J.; Lu, C.Y.; Wang, C.; Tong, Z.W.; Cui, D.D.; He, D. Design and test of single-disc opener for no-till planter based on support cutting. Agriculture 2023, 13, 1635. [Google Scholar] [CrossRef]

- Zeng, Z.W.; Chen, Y. Performance evaluation of fluted coulters and rippled discs for vertical tillage. Soil. Till Res. 2018, 183, 93–99. [Google Scholar] [CrossRef]

- Li, J.W.; Li, X.Y.; Hu, B.; Gu, T.L.; Wang, Z.J.; Wang, H.L. Analysis of the resistance reduction mechanism of potato bionic digging shovels in clay and heavy soil conditions. Comput. Electron. Agr. 2023, 214, 108315. [Google Scholar] [CrossRef]

- Jia, H.L.; Wang, W.J.; Wang, W.P.; Zheng, J.; Wang, Q.; Zhuang, J. Application of anti-adhesion structure based on earthworm motion characteristics. Soil. Till Res. 2018, 178, 159–166. [Google Scholar] [CrossRef]

- Sun, J.Y.; Wang, Y.M.; Ma, Y.H.; Tong, J.; Zhang, Z.J. Dem simulation of bionic subsoilers (tillage depth >40 cm) with drag reduction and lower soil disturbance characteristics. Adv. Eng. Softw. 2018, 119, 30–37. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, Z.M.; Zhang, Z.H.; Zhang, K.; Yao, S.; Zhou, W.Q.; Sun, X.B.; Wang, J.W. Design and test of bionic elastic row cleaner with improved straw cleaning performance. Agriculture 2024, 14, 186. [Google Scholar] [CrossRef]

- Zhao, J.L.; Lu, Y.; Wang, X.G.; Zhuang, J.; Han, Z.W. A bionic profiling-energy storage device based on mbd-dem coupled simulation optimization reducing the energy consumption of deep loosening. Soil. Till Res. 2023, 234, 105824. [Google Scholar] [CrossRef]

- Tan, H.C.; Shen, C.C.; Ma, J.L.; Wu, C.L.; Xu, L.M.; Ma, S. The reduction of energy consumption and soil disturbance mechanisms in trenching using biomimetic blades. Comput. Electron. Agr. 2025, 230, 109887. [Google Scholar] [CrossRef]

- Zhang, Z.J.; Jia, H.L.; Sun, J.Y. Review of application of biomimetics for designing soil-engaging tillage implements in northeast china. Int. J. Agric. Biol. Eng. 2016, 9, 12–21. [Google Scholar]

- Xiao, M.; Wang, K.; Yang, W.; Wang, W.; Jinag, F. Design and experiment of bionic rotary blade based on claw toe of Gryllotalpa orientalis burmeister. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2021, 52, 55–63. [Google Scholar]

- Liu, S.H.; Weng, S.J.; Liao, Y.L.; Zhu, D.Y. Structural bionic design for digging shovel of cassava harvester considering soil mechanics. Appl. Bionics Biomech. 2014, 11, 1–11. [Google Scholar] [CrossRef]

- Shibusawa, S. Reverse-rotational rotary tiller for reduced power requirement in deep tillage. J. Terramechanics 1993, 30, 205–217. [Google Scholar] [CrossRef]

- Salokhe, V.; Ramalingam, N. Effects of direction of rotation of a rotary tiller on properties of bangkok clay soil. Soil. Tillage Res. 2001, 63, 65–74. [Google Scholar] [CrossRef]

- Wang, J.; Yang, D.; Wang, Z.; Fu, Z.; Wang, J.; Weng, W. Design and experiment of rice straw biaxial deep-buried returning machine. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2023, 54, 21–30. [Google Scholar]

- Zhang, X.Y.; Yu, S.Y.; Hu, X.; Zhang, L.X. Study on rotary tillage cutting simulations and energy consumption predictions of sandy ground soil in a xinjiang cotton field. Comput. Electron. Agr. 2024, 217, 108646. [Google Scholar] [CrossRef]

- O’Dogherty, M.; Godwin, R.; Hann, M.; Al-Ghazal, A. A geometrical analysis of inclined and tilted spherical plough discs. J. Agric. Eng. Res. 1996, 63, 205–217. [Google Scholar] [CrossRef]

- Kogut, Z.; Sergiel, L.; Żurek, G. The effect of the disc setup angles and working depth on disc harrow working resistance. Biosyst. Eng. 2016, 151, 328–337. [Google Scholar] [CrossRef]

- Cheng, Y.; Yan, X.; Zhu, R.; Li, C.; Liu, Y.; Liu, Z.; Lu, Q. Design and experiment of testing device for passive disc. J. Northwest Univ. Nat. Sci. Ed. 2016, 44, 228–234. [Google Scholar]

- Yang, Z.; Zhang, K.; Zhang, Y.; An, J. Discrete element method–multibody dynamics coupling simulation and experiment of rotary tillage and ridging process for chili pepper cultivation. Agronomy 2024, 14, 446. [Google Scholar] [CrossRef]

- Tisdall, J.M.; Oades, J.M. Organic matter and water-stable aggregates in soils. J. Soil Sci. 1982, 33, 141–163. [Google Scholar] [CrossRef]

- Bao, P.; Wu, M.; Guan, C.; Luo, H.; He, Y.; Xiang, W. Design of plow-rotary style ditching and ridging device for rapeseed seeding. Trans. Chin. Soc. Agric. Eng. 2017, 33, 23–31. [Google Scholar]

- Zhu, H.; Wang, D.; He, X.; Shang, S.; Zhao, Z.; Wang, H.; Tan, Y.; Shi, Y. Study on plant crushing and soil throwing performance of bionic rotary blades in cyperus esculentus harvesting. Machines 2022, 10, 562. [Google Scholar] [CrossRef]

- Zhang, Z.; Sun, X.; Jin, Z.; Bing, Z.; Sun, J.; Tong, J. Design and test of crushing bionic soil covering device of soybean seeder. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2018, 49, 34–40. [Google Scholar]

- Zhu, A.W.; Xu, C.T.; Liu, Y.F.; Wang, J.S.; Tan, X.D. Design and experiment of oblique stubble-cutting side-throwing anti-blocking device for no-tillage seeder. Agriculture 2024, 14, 2250. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, X.W.; Chen, J.N.; Wang, H.Y.; Cao, Y.G. Analysis and optimization of low-resistance animal bionic subsoiling shovel based on edem. Agriculture 2024, 14, 2046. [Google Scholar] [CrossRef]

- Zhao, S.; Gao, L.; Yuan, Y.; Hou, L.; Zhang, X.; Yang, Y. Maize straw motion law in subsoiling operation using discrete element method. Trans. Chin. Soc. Agric. Eng. 2021, 37, 53–62. [Google Scholar]

- Hasimu, A.; Chen, Y. Soil disturbance and draft force of selected seed openers. Soil. Till Res. 2014, 140, 48–54. [Google Scholar] [CrossRef]

- Jia, H.L.; Li, C.Y.; Zhang, Z.H.; Wang, G. Design of bionic saw blade for corn stalk cutting. J. Bionic Eng. 2013, 10, 497–505. [Google Scholar] [CrossRef]

- Kheiralla, A.F.; Yahya, A.; Zohadie, M.; Ishak, W. Modelling of power and energy requirements for tillage implements operating in serdang sandy clay loam, malaysia. Soil. Till Res. 2004, 78, 21–34. [Google Scholar] [CrossRef]

- Matin, M.A.; Fielke, J.M.; Desbiolles, J.M.A. Torque and energy characteristics for strip-tillage cultivation when cutting furrows using three designs of rotary blade. Biosyst. Eng. 2015, 129, 329–340. [Google Scholar] [CrossRef]

| Parameter | Values |

|---|---|

| Structure type | Three-point suspension |

| Dimension (length × width × height)/mm | 1800 × 920 × 300 |

| Machine quality (kg) | 300 |

| Row spacing (mm) | 450–950 |

| Working width (mm) | 180–240 |

| Tillage depth (mm) | 60–120 |

| Material | Parameter | Value |

|---|---|---|

| Soil particle—soil particle | Coefficient of restitution | 0.5 |

| Static friction coefficient | 0.3 | |

| Rolling friction coefficient | 0.2 | |

| Soil particle—65 Mn steel | Coefficient of restitution | 0.6 |

| Static friction coefficient | 0.6 | |

| Rolling friction coefficient | 0.05 |

| Code | Factor | |

|---|---|---|

| X1 Working Width s (mm) | X2 (mm) | |

| −1 | 35 | 30 |

| 0 | 55 | 40 |

| 1 | 75 | 50 |

| Trial No. | Experimental Factors | Evaluation Indicators | ||

|---|---|---|---|---|

| Working Width X1 | Working Depth X2 | Soil Fragmentation Rate Y1 (%) | Operational Resistance Y2 (N) | |

| 1 | 35 | 30 | 83.53 | 544.67 |

| 2 | 75 | 30 | 85.73 | 598.68 |

| 3 | 35 | 50 | 85.98 | 583.15 |

| 4 | 75 | 50 | 87.06 | 654.68 |

| 5 | 26.7157 | 40 | 83.88 | 539.27 |

| 6 | 83.2843 | 40 | 85.83 | 640.48 |

| 7 | 55 | 25.8579 | 84.70 | 565.88 |

| 8 | 55 | 54.1421 | 88.24 | 627.90 |

| 9 | 55 | 40 | 86.03 | 590.97 |

| 10 | 55 | 40 | 86.31 | 594.66 |

| 11 | 55 | 40 | 86.30 | 593.56 |

| 12 | 55 | 40 | 86.5 | 599.39 |

| 13 | 55 | 40 | 86.29 | 594.63 |

| Source of Variation | Y1 | Y2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sum of Squares | Degree of Squares | Mean square | F | p | Sum of Squares | Degree of Squares | Mean Square | F | p | |

| Model | 18.50 | 5 | 3.70 | 74.10 | <0.0001 ** | 13,298.48 | 5 | 2659.70 | 209.35 | <0.0001 ** |

| 4.56 | 1 | 4.56 | 91.26 | <0.0001 ** | 9023.12 | 1 | 9023.12 | 710.24 | <0.0001 ** | |

| 9.65 | 1 | 9.65 | 193.27 | <0.0001 ** | 4149.13 | 1 | 4149.13 | 326.59 | <0.0001 ** | |

| 0.3136 | 1 | 0.3136 | 6.28 | 0.0406 * | 76.74 | 1 | 76.74 | 6.04 | 0.0436 * | |

| 3.78 | 1 | 3.78 | 75.75 | <0.0001 ** | 25.26 | 1 | 25.26 | 1.99 | 0.2014 | |

| 0.0342 | 1 | 0.0342 | 0.6851 | 0.4351 | 17.86 | 1 | 17.86 | 1.41 | 0.2745 | |

| Residual | 0.3495 | 7 | 0.0499 | 88.93 | 7 | 12.70 | ||||

| Lack of Fit | 0.2374 | 3 | 0.0791 | 2.82 | 0.1709 | 51.73 | 3 | 17.24 | 1.85 | 0.2779 |

| Corrected Total | 18.85 | 12 | 13,387.41 | 12 | ||||||

| 0.9815 | 0.9934 | |||||||||

| Type of Blade Tooth Structure | Operational Resistance (N) | Soil Fragmentation Rate (%) |

|---|---|---|

| Bs | 604.68 | 86.59 |

| Os | 652.87 | 85.49 |

| Comparison | Reduced by 48.19 | Upgraded by 1.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, K.; Zhang, Y.-Y.; Zhao, X.; Zhao, Y.; Feng, X.; Wang, Q.; Wang, J. Design and Test of a Bionic Auxiliary Soil-Crushing Device for Strip-Tillage Machines. Agriculture 2025, 15, 944. https://doi.org/10.3390/agriculture15090944

Zhang K, Zhang Y-Y, Zhao X, Zhao Y, Feng X, Wang Q, Wang J. Design and Test of a Bionic Auxiliary Soil-Crushing Device for Strip-Tillage Machines. Agriculture. 2025; 15(9):944. https://doi.org/10.3390/agriculture15090944

Chicago/Turabian StyleZhang, Kui, Yong-Ying Zhang, Xinliang Zhao, Yun Zhao, Xin Feng, Qi Wang, and Jinwu Wang. 2025. "Design and Test of a Bionic Auxiliary Soil-Crushing Device for Strip-Tillage Machines" Agriculture 15, no. 9: 944. https://doi.org/10.3390/agriculture15090944

APA StyleZhang, K., Zhang, Y.-Y., Zhao, X., Zhao, Y., Feng, X., Wang, Q., & Wang, J. (2025). Design and Test of a Bionic Auxiliary Soil-Crushing Device for Strip-Tillage Machines. Agriculture, 15(9), 944. https://doi.org/10.3390/agriculture15090944