Results of the tests carried out on sunflower cultivation and sunflower oil extraction are reported separately as follows.

3.1. Sunflower Seed Production

The multiannual thermo-pluviometric trends and differences of the yearly trends for each year and location are reported in

Figure 2.

The selected locations showed similar thermo-pluviometric trends. Cesa is characterized by lower temperatures (1 °C in average), while Papiano by lower rainfall (100 mm in average), especially in June and July. With respect to the multiannual trend, in 2015 there is an increase of 1 °C with a peak of +4 °C in July. Rainfall in 2015 showed a decrease, especially in the period related to flowering.

In 2016, there was a general increase in rainfall (from +104 mm in Papiano to +395 mm in Monteleone), with a significant amount in Spring with the only exception of Monteleone.

In 2017, rainfall was limited in all the locations, mainly in the Marche region and in June and July, with a temperature increase of more than 3 °C in Summer.

The results are reported not only as hybrid yield per year, but also as location per year and hybrid per location to highlight the significant effect of these interactions.

According to results (

Table 1), 2016 is characterized by the highest crop yield because temperature and rainfall were more favorable to the sunflower crop along the entire cultivation cycle. In all the locations, crop yield was near or over 4 t ha

−1 in 2016, with average differences of 15% and 21% from 2015 and 2017, respectively. Cesa in general showed the best production results in 2016 and 2017, while in 2015 it was the worst one among all the locations.

Similarly, plant height results were also dependent by year and location. 2016 was the best year, showing, on average, 11 and 31 cm more with respect to 2015 and 2017. Monteleone and Osimo presented the highest values in 2015 and 2016, because of the abundant rainfall promoting an important vegetative growth. This growth, if not adequately supported, is not translated into good yield [

11].

It is also interesting to analyze the interaction between years and hybrids (

Table 2).

As mentioned before, the 2016 showed the best crop yield for all the hybrids. In absolute terms NK Stradi resulted the best (3.70 t ha−1 in average), with +0.12 t ha−1 with respect to SY Excellio, +0,24 to MAS 86.OL, and +0.27 to MAS 85.SU.

Crop yield of different hybrids was affected also by location (

Table 3), but with limited differences.

Mas 85.SU showed the highest yield at Cesa, but the result is not significantly different from the other hybrids. Similar results have been obtained in the other locations, while a statistically different result has been reported in Monteleone for MAS 85.OL.

The oil content of sunflower seed is generally more linked to genotype than location [

12], but resulted, in this case, being dependent on both location and year (

Table 4). Consequently, the same resulted for the potential oil yield, where the oil content is a component together with crop yield. The best year in terms of potential oil content (48.3%) resulted the 2016, in line with the crop yield. The differences with the other two years are 3.2% and 2.1%, with 2015 and 2017, respectively. Monteleone is the location where the highest value of potential oil content was registered, with differences of 0.8% and 1.6% from Cesa and Osimo, respectively.

NK Stradi and SY Excellio showed the highest oil content, more than 47%. The lowest oil content was recorded in Papiano in 2015 for MAS 86.OL; the highest for NK Stradi in 2016 in the same location.

The highest potential oil yield was obviously recorded in 2016, by far the best year of the study. In line with the crop yield, Cesa is the best location also for potential oil yield (1.66 t ha−1 on average), with mean differences of 13%, 9%, and 5% with Monteleone, Osimo, and Papiano, respectively. NK Stradi was the most productive (1.62 t ha−1 on average), followed by SY Excellio (1.56 t ha−1), MAS 85.SU (1.51), and MAS 86.OL (1.49). The best production performances were achieved in Cesa by MAS 85.SU, MAS 86.OL, and SY Excellio, while in Papiano by NK Stradi, (more than 2 t ha−1 of potential oil yield); the worst performances were achieved in Monteleone in 2017.

In

Table 5 the analytical results of oleic and linoleic acid contents are reported. The contents of the different hybrids are perfectly in line with the values declared by the producers.

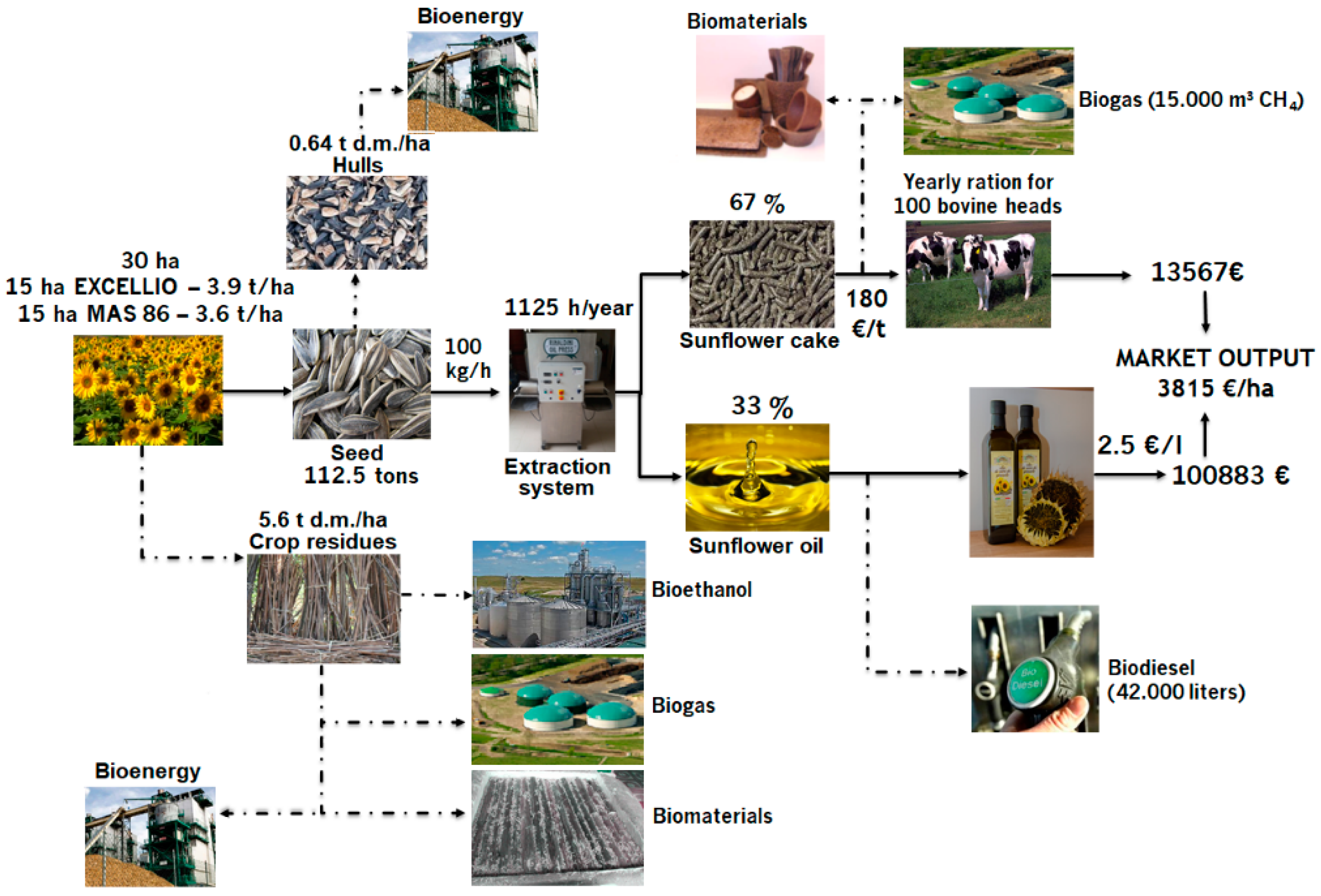

3.3. By-Products and Residues Characterization

The results of the energy characterization of by-products and residues are reported in

Table 7, while the results of additional analysis carried out on extraction cake, and importantly also for animal feeding purposes, are reported in

Table 8.

The results are in line with a previous study carried out by the authors [

8] in previous years. The sunflower cake could be used as feedstock for anaerobic digestion, showing a C/N ratio over 10, in line with the results of a study carried out by other authors [

13]. The performance of this residue for biogas production can also be enhanced by pre-treatments [

14,

15]. The sunflower cake could also be employed for biofuel production in co-pyrolysis, as suggested by Shie [

16], or for producing biomaterials by extrusion [

17].

According to results and previous studies, the stalks can be used as feedstock for bioethanol production [

18], for biogas production [

19], and for biomaterials production [

20]. Sunflower seed hulls can be employed by cofiring for energy production [

21] or for obtaining bio-oil [

22].

The results highlight how the extraction cake can be used for energy and other applications, but should be better valorized for feeding purposes as reported by different authors [

23,

24,

25].