An Alternative to Field Retting: Fibrous Materials Based on Wet Preserved Hemp for the Manufacture of Composites

Abstract

:1. Introduction

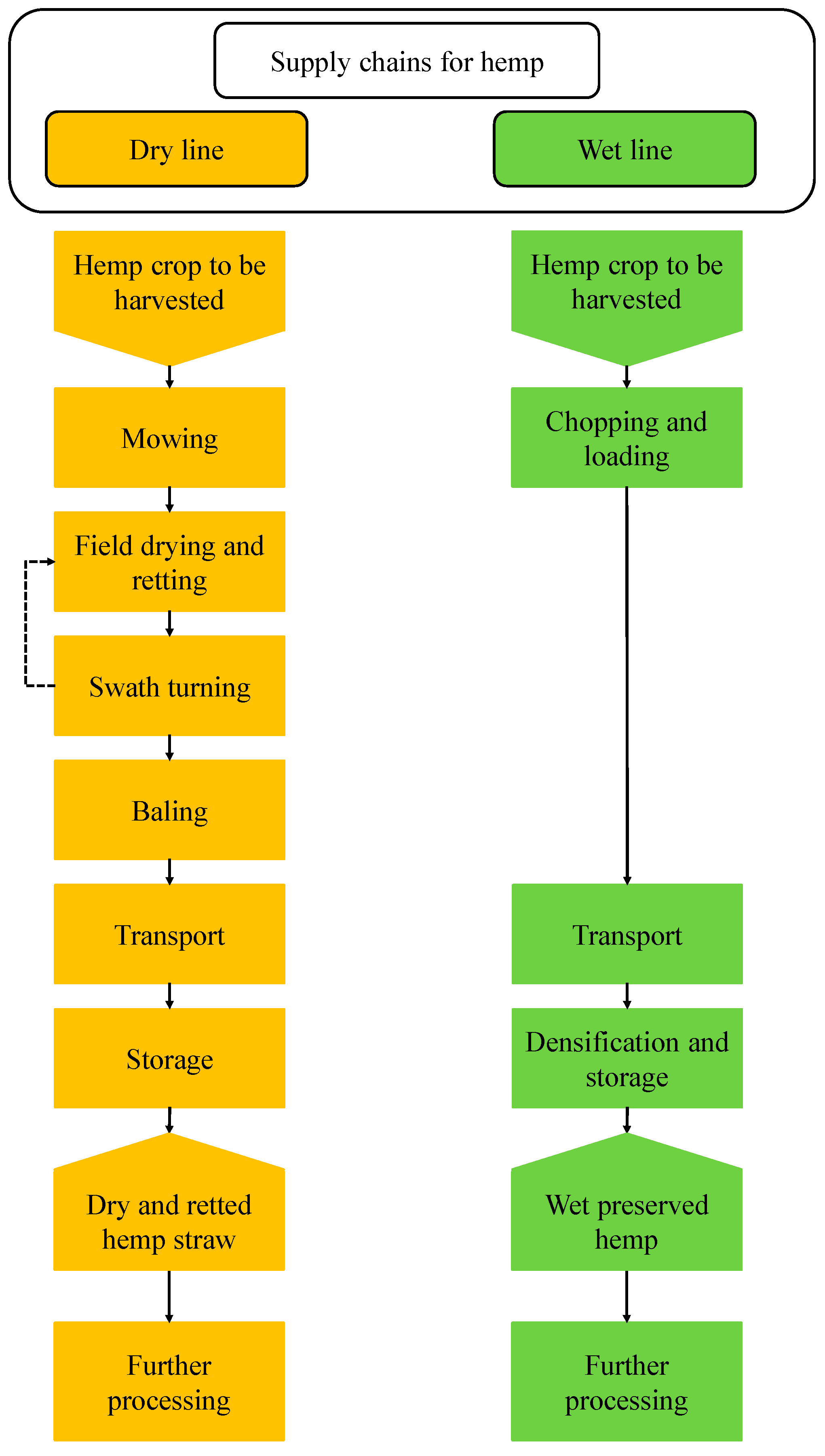

2. Materials—Raw Material Supply

2.1. Growing and Harvesting

2.2. Weather Related Risk of Harvesting Hemp

2.3. Storage Procedures

3. Experimental Procedures

3.1. Wet Preservation

3.2. Chemical Analysis

3.2.1. Characterization of Fresh Chopped Raw Material

3.2.2. Characterization of Wet Preserved Hemp

3.3. Further Raw Material Properties

3.3.1. Odor

3.3.2. Structural Characterization

3.4. Characterization of Intermediates and Final Products

4. Results on Processing and Products

4.1. Composites Reinforced with Fibrous Intermediates from Wet Preservation

4.1.1. Raw Materials and Composites Processing

4.1.2. Selected Mechanical Properties of Composites

4.2. Fiberboards Manufactured from Wet Preserved Hemp

4.2.1. Raw Material and Preparation

4.2.2. Manufacturing of Fiberboards

- mass of test specimen at normal climate (g)

- mass of test specimen after drying (g)

4.2.3. Characterization

- UL1-MDF (usually used as insulation boards with limited mechanical stiffness) and

- UL2-MDF (typically used as panels with a stiffening function. These products also have insulating properties).

5. Discussion and Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Kymäläinen, H.R.; Sjöberg, A.M. Flax and hemp fibres as raw materials for thermal insulations. Build. Environ. 2008, 43, 1261–1269. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibres: 2000–2010. Prog Polym Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Gomina, M. Flax and hemp composite applications. In Flax and Hemp Fibres: A natural Solution for the Composite Industry; Reux, F., Verpoest, I., Eds.; JEC Composites: Paris, France, 2012; pp. 141–162. ISBN 978-2-9526276-0-1. [Google Scholar]

- Shah, D.U. Natural fibre composites: Comprehensive Ashby-type materials selection charts. Mater. Des. 2014, 62, 21–31. [Google Scholar] [CrossRef]

- Pil, L.; Bensadoun, F.; Pariset, J.; Verpoest, I. Why are designers fascinated by flax and hemp fibre composites? Compos. Part A Appl. Sci. 2015, 83, 193–205. [Google Scholar] [CrossRef]

- Van Eynde, H. Comparative Life Cycle Assessment of Hemp and Cotton Fibres Used in Chinese Textile Manufacturing. Master thesis, University of Leuven, Leuven, Belgium, 2015. Available online: https://www.scriptiebank.be/sites/default/files/VanEyndeHannes_KUL_Eindwerk.pdf (accessed on 28 May 2018).

- Brzyski, P.; Barnat-Hunek, D.; Suchorab, Z.; Łagód, G. Composite materials based on hemp and flax for low-energy buildings. Materials 2017, 10, 510. [Google Scholar] [CrossRef]

- Placet, V.; François, C.; Day, A.; Beaugrand, J.; Ouagne, P. Industrial hemp transformation for composite applications: Influence of processing parameters on the fibre properties. In Advances in Natural Fibre Composites; Fangueiro, R., Rana, S., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 13–25. [Google Scholar]

- Stevulova, N.; Cigasova, J.; Schwarzova, I.; Sicakova, A.; Junak, J. Sustainable bio-aggregate-based composites containing hemp hurds and alternative binder. Buildings 2018, 8, 25. [Google Scholar] [CrossRef]

- Kremensas, A.; Kairytė, A.; Vaitkus, S.; Vėjelis, S.; Balčiūnas, G. Mechanical performance of biodegradable thermoplastic polymer-based biocomposite boards from hemp shivs and corn starch for the building industry. Materials 2019, 12, 845. [Google Scholar] [CrossRef]

- Hegazy, S.S.; Ahmed, K. Effect of date palm cultivar, particle size, panel density and hot water extraction on particleboards manufactured from date palm fronds. Agriculture 2015, 5, 267–285. [Google Scholar] [CrossRef]

- Ferrández-García, C.-E.; Ferrández-García, A.; Ferrández-Villena, M.; Hidalgo-Cordero, J.F.; García-Ortuño, T.; Ferrández-García, M.-T. Physical and mechanical properties of particleboard made from palm tree prunings. Forests 2018, 9, 755. [Google Scholar] [CrossRef]

- Papadopoulos, A.N.; Kyzas, G.Z.; Mitropoulos, A.C. Lignocellulosic composites from acetylated sunflower stalks. Appl. Sci. 2019, 9, 646. [Google Scholar] [CrossRef]

- Uitterhaegen, E.; Labonne, L.; Merah, O.; Talou, T.; Ballas, S.; Véronèse, T.; Evon, P. Impact of thermomechanical fiber pre-treatment using twin-screw extrusion on the production and properties of renewable binderless coriander fiberboards. Int. J. Mol. Sci. 2017, 18, 1539. [Google Scholar] [CrossRef] [PubMed]

- Amaducci, S.; Scordia, D.; Liu, F.H.; Zhang, Q.; Guo, H.; Testa, G.; Cosentino, S.L. Key cultivation techniques for hemp in Europe and China. Ind. Crops Prod. 2015, 68, 2–16. [Google Scholar] [CrossRef]

- Salentijn, E.; Zhang, Q.; Amaducci, S.; Yang, M.; Trindade, L. New developments in fibre hemp (Cannabis sativa L.) breeding. Ind. Crops Prod. 2014, 68, 32–41. [Google Scholar] [CrossRef]

- Carus, M. The Reintroduction of Industrial Hemp is in Full Swing Worldwide. Press Release of the European Industrial Hemp Association (EIHA). Available online: http://news.bio-based.eu/media/2018/05/ 18-05-17-PR-EIHA-Award-and-Conference.pdf (accessed on 8 June 2018).

- Carus, M.; Eder, A.; Dammer, L.; Korte, H.; Scholz, L.; Essel, R.; Breitmayer, E. WPC/NFC Market Study 2014-03 Wood-Plastic Composites (WPC) and Natural Fibre Composites (NFC): European and Global Markets 2012 and Future Trends; Nova-Institut: Hürth, Germany, 2014. [Google Scholar]

- Westerhuis, W. Hemp for Textiles: Plant Size Matters. PhD Thesis, Wageningen University, Wageningen, The Netherlands, 2016. [Google Scholar]

- Dickeduisberg, M.; Beckhaus, H. Hemp in Germany—Renaissance as winter cover crop for high quality textile hemp-fibres. In Proceedings of the 14th International Conference of the European Industrial Hemp Association (EIHA), Cologne, Germany, 7–8 June 2017. [Google Scholar]

- Moussa, T.; Maalouf, C.; Ingrao, C.; Scrucca, F.; Costantine, G.; Asdrubali, F. Bio-based and recycled-waste materials in buildings: A study of energy performance of hemp-lime concrete and recycled-polyethylene terephthalate façades for office facilities in France and Italy. Sci. Technol. Built Environ. 2018, 24, 492–501. [Google Scholar] [CrossRef]

- Viel, M.; Collet, F.; Lanos, C. Chemical and multi-physical characterization of agro-resources’ by-product as a possible raw building material. Ind. Crops Prod. 2018, 120, 214–237. [Google Scholar] [CrossRef]

- Amaducci, S.; Gusovius, H.-J. Hemp—Cultivation, extraction and processing. In Industrial Applications of Natural Fibres; Stevens, C.V., Müssig, J., Eds.; Wiley & Sons Ltd.: London, UK, 2010. [Google Scholar]

- Bouloc, P.; Allegret, S.; Arnaud, L. Hemp: Industrial Production and Uses; CABI: Wallingford, UK, 2013; p. 313. [Google Scholar]

- Pari, L.; Baraniecki, P.; Kaniewski, R.; Scarfone, A. Harvesting strategies of bast fibre crops in Europe and in China. Ind. Crops Prod. 2015, 68, 90–96. [Google Scholar] [CrossRef]

- Gusovius, H.-J.; Hoffmann, T.; Budde, J.; Lühr, C. Still special? Harvesting procedures for industrial hemp. Landtechnik 2016, 71, 14–24. [Google Scholar] [CrossRef]

- Hernandez-Estrada, A.; Gusovius, H.-J.; Müssig, J.; Hughes, M. Assessing the susceptibility of hemp fibre to the formation of dislocations during processing. Ind. Crops Prod. 2016, 85, 382–388. [Google Scholar] [CrossRef]

- Wang, S.; Gusovius, H.-J.; Lühr, C.; Musio, S.; Uhrlaub, B.; Amaducci, S.; Müssig, J. Assessment system to characterise and compare different hemp varieties based on a developed lab-scaled decortication system. Ind. Crops Prod. 2018, 117, 159–168. [Google Scholar] [CrossRef]

- Müssig, J.; Amaducci, S. Scanner based image analysis to characterise the influence of agronomic factors on hemp (Cannabis sativa L.) fibre width. Ind. Crops Prod. 2018, 113, 28–37. [Google Scholar] [CrossRef]

- Sisti, L.; Totaro, G.; Vannini, M.; Celli, A. Retting process as a pretreatment of natural fibres for the development of polymer composites. In Lignocellulosic Composite Materials; Kalia, S., Ed.; Springer: Cham, Switzerland, 2018; pp. 97–135. [Google Scholar]

- Sharma, H.S.S.; Lefevre, J.; Boucaud, J. Role of microbial enzymes during retting and their effect on fibre characteristics. In The biology and processing of flax; Sharma, H.S.S., Ed.; M Publications: Belfast, UK, 1992; pp. 199–212. ISBN 978-0951996300. [Google Scholar]

- Bacci, L.; Lonardo, S.; Albanese, L.; Mastromei, G.; Perito, B. Effect of different extraction methods on fibre quality of nettle (Urtica Dioica, L.). Text. Res. J. 2010, 81, 827–837. [Google Scholar] [CrossRef]

- Akin, D.E. Linen most useful: Perspective on structure, chemistry and enzyme for the retting flax. ISRN Biotechnol. 2013, 1–23. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, A.; Pochart, P.; Day, A.; Mennuni, S.; Bono, P.; Baret, J.L.; Spadoni, J.L.; Mangin, I. Microbial diversity observed during hemp retting. Appl. Microb. Biotechnol. 2015, 99, 4471–4484. [Google Scholar] [CrossRef] [PubMed]

- Jankauskienė, Z.; Butkutė, B.; Gruzdevienė, E.; Cesevičienė, J.; Fernando, A.-L. Chemical composition and physical properties of dew- and water-retted hemp fibres. Ind. Crops Prod. 2015, 75, 206–211. [Google Scholar] [CrossRef]

- Liu, M.; Fernando, D.; Daniel, G.; Madsen, B.; Meyer, A.S.; Ale, M.T.; Thygesen, A. Effect of harvest time and field retting duration on the chemical composition, morphology and mechanical properties of hemp fibres. Ind. Crops Prod. 2015, 69, 29–39. [Google Scholar] [CrossRef]

- Placet, V.; Day, A.; Beaugrand, J. The influence of unintended field retting on the physicochemical and mechanical properties of industrial hemp bast fibres. J. Mater. Sci. 2017, 52, 5759–5777. [Google Scholar] [CrossRef]

- Bleuze, L.; Lashermes, G.; Alavoine, G.; Recous, S.; Chabbert, B. Tracking the dynamics of hemp dew retting under controlled environmental conditions. Ind. Crops Prod. 2018, 123, 55–63. [Google Scholar] [CrossRef]

- Mazian, B.; Bergeret, A.; Benezet, J.C.; Malhautier, L. Influence of field retting duration on the biochemical, microstructural, thermal and mechanical properties of hemp fibres harvested at the beginning of flowering. Ind. Crops Prod. 2018, 116, 170–181. [Google Scholar] [CrossRef]

- Idler, C.; Ehlert, D.; Ackermann, I.; Kühne, G. Ernte, Konservierung und Erstverarbeitung von Hanf aus Einer Feuchtgutlinie, Harvesting, Conservation and First Processing of Hemp from a Moist Material Line. ATB-Projektabschlußbericht 2000/3; Institut für Agrartechnik: Potsdam, Germany, 2000; p. 43, In German. [Google Scholar]

- De Maeyer, E.A.A.; Huisman, W. New technology to harvest and store fibre hemp for paper pulp. J. Int Hemp Assoc. 1994, 1, 38–41. [Google Scholar]

- De Maeyer, E.A.A.; Huisman, W. Growing fibre hemp for pulp and paper: A new approach to harvesting and processing. In Alternative Oilseed and Fibre Crops for Cool and Wet Regions of Europe, Proccedings of the COST 814 Workshop Proc., Wageningen, The Netherlands, 7–8 April 1994; COST 814 Workshop Proc.: Wageningen, The Netherlands, 1994; pp. 157–162. Available online: http://edepot.wur.nl/412578 (accessed on 1 July 2018).

- De Maeyer, E.A.A.; Huisman, W. Oogst en Conserveringstechniek van Vezelhennep, Techniques for Harvesting and Storage of Fibre Hemp; IMAG-DLO and Wageningen Agricultural University: Wageningen, The Netherlands, 1995; p. 138, in Dutch with English summary. [Google Scholar]

- Einsiedel, R.; Bayer, R.; von Buttlar, H.B.; Scheffer, K. Fibres and composites from hemp silage. In Biomass for Energy and Industry, Proceedings of the 10th International Conference; Kopetz, H., Weber, T., Palz, W., Chartier, P., Ferrero, G.L., Eds.; Carmen Publ.: Würzburg, Germany, 1998; pp. 509–510. [Google Scholar]

- Hartinger, T.; Gresner, N.; Südekum, K.-H. Effect of wilting intensity, dry matter content and sugar addition on nitrogen fractions in lucerne silages. Agriculture 2019, 9, 11. [Google Scholar] [CrossRef]

- Szlachta, J.; Prask, H.; Fugol, M.; Luberański, A. Effect of mechanical pre-treatment of the agricultural substrates on yield of biogas and kinetics of anaerobic digestion. Sustainability 2018, 10, 3669. [Google Scholar] [CrossRef]

- Idler, C.; Pecenka, R.; Fürll, C.; Gusovius, H.-J. Wet processing of hemp: An overview. J. Nat. Fibers 2011, 8, 59–80. [Google Scholar] [CrossRef]

- Pecenka, R.; Idler, C.; Grundmann, P.; Fürll, C.; Gusovius, H.-J. Tube ensiling of hemp—Initial practical experience. Agric. Eng. Res. 2007, 13, 15–26. [Google Scholar] [CrossRef]

- Tahir, P.M.; Ahmed, A.A.; SaifulAzry, S.O.; Ahmed, Z. Retting process of some bast plant fibres and its effect on fibre quality: A review. BioResources 2011, 6, 5260–5281. [Google Scholar] [CrossRef]

- Gusovius, H.-J.; Prochnow, A.; Streßmann, U.; Hahn, J. The weather-determined process risk of harvesting fibre hemp. In Proceedings of the International Conference on Agricultural Engineering, Part 2, Warwick, UK, 2–7 July 2000; pp. 46–48. [Google Scholar]

- Hoffmann, T.; Pecenka, R.; Schemel, H.; Gusovius, H.-J. Process-technological evaluation of harvesting hemp in winter. J. Nat. Fibres 2013, 10, 159–175. [Google Scholar] [CrossRef]

- Pasila, A. The Dry-Line Method in Bast Fibre Production. Academic Dissertation, University of Helsinki, Faculty of Agriculture and Forestry, Helsinki, Finland, 2004. [Google Scholar]

- KTBL. Betriebsplanung Landwirtschaft 2016/17—Operational Planning in Agriculture; 25. Auflage; KTBL: Darmstadt, Germany, 2016; p. 768. ISBN 978-3-945088-19-7. In German. [Google Scholar]

- MultiHemp Deliverables Rated Public to Public. Available online: http://multihemp.eu/project/public-deliverables. (accessed on 5 July 2018).

- Wieringa, G.W.; Haan, S. Inkuillen—Ensiling; IBVL: Wageningen, The Netherlands, 1961; In Dutch. [Google Scholar]

- Mc Donald, P.; Henderson, A.R.; Heron, S.J.E. The Biochemistry of Silage, 2nd ed.; Marlow, Chalcombe Publication: Southampton, UK, 1991; p. 340. ISBN 978-0948617225. [Google Scholar]

- Akin, D.E.; Foulk, J.A.; Dodd, R.B.; McAlister III, D.D. Enzyme-retting of flax and characterization of processed fibers. J. Biotechnol. 2001, 89, 193–203. [Google Scholar] [CrossRef]

- Di Candilo, M.; Bonatti, P.M.; Guidetti, C.; Focher, B.; Grippo, C.; Tamburini, E.; Mastromei, G. Effects of selected pectinolytic bacterial strains on water-retting of hemp and fibre properties. J. Appl. Microbiol. 2010, 108, 194–203. [Google Scholar] [CrossRef]

- Fuentes, C.A.; Willekens, P.; Petit, J.; Thouminot, C.; Müssig, J.; Trindade, L.M.; Van Vuure, A.W. Effect of the middle lamella biochemical composition on the non-linear behaviour of technical fibres of hemp under tensile loading using strain mapping. Compos. Part A Appl. Sci. 2017, 101, 529–542. [Google Scholar] [CrossRef]

- Dreyer, J.; Müssig, J.; Koschke, N.; Ibenthal, W.-D.; Harig, H. Comparison of enzymatically separated hemp and nettle fibre to chemically separated and steam exploded hemp fibre. J. Ind. Hemp 2008, 7, 43–59. [Google Scholar] [CrossRef]

- DLG-Ausschuss für Futterkonservierung. Praxishandbuch Futter- und Substratkonservierung—Practical Manual for Feed and Substrate Conservation; 8. Auflage; DLG German Agricultural Society: Frankfurt, Germany, 2012; In German. [Google Scholar]

- VDLUFA. Die Chemische Untersuchung von Futtermitteln—The Chemical Analyses of Forage. Methodenbuch; Band III., 3. Auflage; 6. Ergänzungslieferung; VDLUFA-Verlag: Darmstadt, Germany, 2006. [Google Scholar]

- Herrmann, C.; Heiermann, M.; Idler, C.; Prochnow, A. Particle size reduction during harvesting of crop feedstock for biogas production: 1. Effects on ensiling process and me-thane yield. BioEnergy Res. 2012, 102, 5153–5161. [Google Scholar] [CrossRef]

- Herrmann, C.; Heiermann, M.; Idler, C. Effects of ensiling, silage additives and storage period on methane formation of biogas crops. Bioresour. Technol. 2011, 102, 5153–5161. [Google Scholar] [CrossRef] [PubMed]

- Weissbach, F.; Kuhla, S. Stoffverluste bei der Bestimmung des Trockemassegehaltes von Silagen und Grünfutter. Entstehende Fehler und Möglichkeiten der Korrektur—Losses in determining the dry matter content of silages and green fodder. Errors and possibilities of correction. Übersicht Tierernährung 1995, 23, 189–214, In German. [Google Scholar]

- Huisman, W.; Mayer, E.; Frerichs, L. Harvest and storage of hemp. In Proceedings of the Symposium “Bioressource Hemp”, Frankfurt, Germany, 2–5 May 1995. [Google Scholar]

- Cappelletto, P.; Brizzi, M.; Mongardini, F.; Barberi, B.; Sannibale, M.; Nenci, G. Italy-grown hemp: Yield, composition and cannabinoid content. Ind. Crops Prod. 2001, 13, 101–113. [Google Scholar] [CrossRef]

- Van der Werf, H.M.G.; Van Geel, W.C. Fibre Hemp as Raw Material for Paper. Agronomic Research 1990–1993. Verslag; Proefstation voor de Akkerbouw en de Groenteteelt in de Vollegrond: Lelystad, The Netherlands, 1994; Volume 177, p. 68. [Google Scholar]

- Liu, M.; Thygesen, A.; Summerscales, J.; Meyer, A.S. Targeted pre-treatment of hemp bast fibres for optimal performance in biocomposite materials: A review. Ind. Crops Prod. 2017, 108, 660–683. [Google Scholar] [CrossRef] [Green Version]

- Fischer, H.; Gerardi, H.; Knittel, D.; Antonov, V. Removal of odour from bast fibres in industrial scale by chemical and enzymatic treatment. In Proceedings of the 15th international conference STRUTEX, Technical University of Liberec, Liberec, Czech Republic, 1–3 December 2008; pp. 331–338. [Google Scholar]

- FNR. Schlussbericht zum Vorhaben Thema: FENAFA-Netzwerkverbund—Teilvorhaben 3: Zielgerichtete Weiterentwicklung und Anpassung der Verfahrensschritte zur Bereitstellung und Konditionierung von Naturfaserkonservat für den Einsatz in Verbundwerkstoffen (Schwerpunkt: Hanf), Final report on the Project Topic: FENAFA Network—Subproject 3: Targeted Further Development and Adaptation of the Process Steps for the Provision and Conditioning of Natural Fibre Conservation for Use in Composite Materials (Focus: Hemp). Available online: https://www.fnr.de/index.php?id=11150&fkz=22023808 (accessed on 02.07.2018).

- DIN EN. 13725:2003-07: Luftbeschaffenheit—Bestimmung der Geruchsstoffkonzentration mit dynamischer Olfaktometrie, Air quality—Determination of odour concentration by dynamic olfactometry; Beuth Verlag: Berlin, Germany, 2003; In German. [Google Scholar]

- VDI. 3882 Blatt 1:1992-10. Olfaktometrie; Bestimmung der Geruchsintensität—Olfactometry; Determination of Odour Intensity; Beuth Verlag: Berlin, Germany, 1992; In German. [Google Scholar]

- Wallot, G.; Gusovius, H.-J.; Pecenka, R.; Schierl, S.; Rinberg, R.; Nendel, W. Developments in the use of fibres from wet-preserved hemp for composite production. Agric. Eng. Int. CIGR J. 2012, 14, 218–223. [Google Scholar]

- Müssig, J.; Fischer, H.; Graupner, N.; Drieling, A. Testing methods for measuring physical and mechanical fibre properties (plant and animal fibres). In Industrial Applications of Natural Fibres; Stevens, C.V., Müssig, J., Eds.; Wiley & Sons Ltd.: London, UK, 2010. [Google Scholar]

- DIN EN ISO 527-1:2012-06. Kunststoffe—Bestimmung der Zugeigenschaften—Teil 1: Allgemeine Grundsätze—Plastics—Determination of Tensile Properties—Part 1: General Principles; Beuth Verlag GmbH: Berlin, Germany, In German.

- DIN EN ISO 527-4:1997-07. Kunststoffe—Bestimmung der Zugeigenschaften—Teil 4: Prüfbedingungen für isotrop und anisotrop faserverstärkte Kunststoffverbundwerkstoffe—Plastics—Determination of tensile properties—Part 4: Test Conditions for Isotropic and Anisotropic Fibre-Reinforced Plastic Composites; Beuth Verlag GmbH: Berlin, Germany, In German.

- DIN EN 319:1993. Span- und Faserplatten—Bestimmung der Zugfestigkeit Senkrecht zur Plattenebene—Particleboards and fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board; Beuth Verlag: Berlin, Germany, In German.

- DIN EN 310:1993. Holzwerkstoffe—Bestimmung des Biege-Elastizitätsmoduls und der Biegefestigkeit—Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength; Beuth Verlag: Berlin, Germany, In German.

- Pecenka, R.; Fürll, C.; Idler, C.; Grundmann, P.; Radosavljevic, L. Fibre boards and composites from wet preserved hemp. Int. J. Mater. Prod. Technol. 2009, 36, 208–220. [Google Scholar] [CrossRef]

- Gusovius, H.-J.; Pecenka, R.; Wallot, G.; Rinberg, R.; Nendel, W. An alternative processing technology for agricultural raw materials to supply fibrous materials for reinforced composites. In Proceedings of the BioComp 2010—10th Pacific Rim Bio-Based Composites Symposium, Banff, Canada, 5–8 October 2010. [Google Scholar]

- Gusovius, H.-J.; Wallot, G.; Schierl, S.; Rinberg, R.; Hartmann, T.; Kroll, L.; Jahn, I. Processing of wet preserved natural fibres with injection molding compounding (IMC). In Natural Fibres: Advances in Science and Technology Towards Industrial Applications from Science to Market; Fangueiro, R., Rana, S., Eds.; Proceedings of the 2nd International Conference on Natural Fibres ICNF 2015; Springer International Publishing: Cham, Switzerland, 2016; pp. 197–210. ISBN 978-94-017-7513-7. [Google Scholar]

- Lühr, C.; Pecenka, R.; Budde, J.; Hoffmann, T.; Gusovius, H.-J. Comparative investigations of fibreboards resulting from selected hemp varieties. Ind. Crops Prod. 2018, 118, 81–94. [Google Scholar] [CrossRef]

- Ogazi-Onyemaechi, B.C.; Nakamura, M.; Kitagawa, K.; Ichikawa, I.; Akahoshi, I.; Sahoo, S.; Nakai, A.; Kotaki, M.; Ishiaku, U.S.; Hamada, H. Mechanical properties of hemp fibre/poly olefin composites by injection molding. In Proceedings of the 22nd Annual Meeting of the Polymer Processing Society, Yamagata, Japan, 2–6 July 2006. [Google Scholar] [CrossRef]

- Tajvidi, M.; Motie, N.; Rassam, G.; Falk, R.H.; Felton, C. Mechanical performance of hemp fiber polypropylene composites at different operating temperatures. J. Reinf. Plast. Compos. 2010, 29, 664–674. [Google Scholar] [CrossRef]

- Haag, K.; Müssig, J. Ergebnisse der Untersuchungen. In Entwicklung einer industriellen Naturfaser-Pellet-Produktion zur Nutzung von Naturfasern als Verstärkung von (Bio-) Kunststoffen in Spritzguss und Extrusion”—Results of the investigations. In Development of an industrial natural fibre pellet production for the use of natural fibres as reinforcement of (bio-) plastics in injection moulding and extrusion. Projektabschlussbericht 2012, (AZ: 27717-34). Available online: https://www.dbu.de/OPAC/ab/DBU-Abschlussbericht-AZ-27717.pdf (accessed on 01 July 2018). In German.

- Pickering, K.L.; Aruan Efendy, M.G.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Kollmann, F. Holzspanwerkstoffe—Wood Chip Materials; Springer-Verlag: Berlin, Germany; Heidelberg, Germany; New York, NY, USA, 1966; p. 822, In German; ISBN 978-3-642-50247-7. [Google Scholar]

- Dunky, M.; Niemz, P. Holzwerkstoffe und Leime: Technologie und Einflussfaktoren—Wood Based Panels and Resins: Technology and Influence Parameters; Springer-Verlag: Berlin-Heidelberg, Germany, 2002; p. 954, In German; ISBN 978-3-642-55938-9. [Google Scholar]

- Müssig, J.; Schmid, H.G. Quality control of fibres along the value added chain by using scanning technique—From fibres to the final product. Microsc. Microanal. 2004, 10, 1332–1333. [Google Scholar] [CrossRef]

- Radosavljević, L. Ressourcenschonende Herstellung hochwertiger Faserplatten aus Hanfsilage, Optimierung der Bindemittelapplikation—Resource-Saving Production of High-Quality Fibre Boards from Hemp Silage, Optimisation of Binder Application. Dissertation, Brandenburgische Technische Universität Cottbus. 2010. Available online: https://opus4.kobv.de/opus4-btu/frontdoor/index/index/year/2010/docId/1742 (accessed on 05 July 2018). In German.

- Pizzi, A. Wood and fibre panel technology. In Research Developments in Wood Engineering and Technology; Aguilera, A., Davim, J.P., Eds.; IGI Global: Hershey, PA, USA, 2014; pp. 46–89. ISBN 978-1466645547. [Google Scholar]

- Ebnesajjad, S.; Landrock, A. Adhesives Technology Handbook; Elsevier Ltd.: Oxford, UK, 2014; p. 414. ISBN 978-0323355957. [Google Scholar]

- DIN EN 316:1999-12. Holzfaserplatten—Definition, Klassifizierung und Kurzzeichen—Fibreboards—Definition, Classification and Abbreviations; Beuth Verlag: Berlin, Germany, In German.

- DIN EN 622-5:2009-03. Anforderungen an Platten nach dem Trockenverfahren (MDF)—Requirements for Boards Using the Dry Process (MDF); Beuth Verlag: Berlin, Germany, In German.

- Dunky, M. Adhesives in the wood industry. In Handbook of Adhesive Technology, 3rd ed.; Pizzi, A., Mittal, K.L., Eds.; CRC Press: Boca Raton, FL, USA, 2018; pp. 511–574, ISBN-13: 9781498736442. [Google Scholar]

- Gruchot, M. In-situ-Untersuchungen des Rohdichteprofils von Holzwerkstoffen am Beispiel von MDF—In-situ Investigations of the Density Profile of Wood Materials Using MDF as an Example. Ph.D. Thesis, Universität Hamburg, Hmaburg, Germany, 2009. In German. [Google Scholar]

- Boehme, C. Die Bedeutung des Rohdichteprofils für MDF—The Importance of the Density Profile for MDF. Holz als Roh und Werkstoff 1992, 50, 18–24, In German. [Google Scholar] [CrossRef]

- Baets, J. Semi-Products with Flax and Hemp Fibres. In Flax and Hemp Fibres: A natural Solution for the Composite Industry; Reux, F., Verpoest, I., Eds.; JEC Composites: Paris, France, 2012; pp. 87–117. ISBN 978-2-9526276-0-1. [Google Scholar]

| Material | Parameter | Unit | Methods | References |

|---|---|---|---|---|

| Fresh chopped and wet preserved hemp | Dry matter | % FM | Gravimetry | VDLUFA MB Vol. 3 Chapter 3.1 [62] |

| pH | - | Electrode Sen Tix 41 | VDLUFA MB Vol. 3 Chapter 18.1 [62] | |

| Sugar | % DM | Reducing sugar | VDLUFA MB Vol. 3 Chapter 7.1.1 [62] | |

| Cellulose | % DM | Ankom2000 Fiber Analyser system, filter bag technology | Herrmann et al. (2012) [63] | |

| Hemicellulose | % DM | |||

| Lignin | % DM | |||

| Wet preserved hemp | Ethanol, propanol, acetic, propionic, i-butyric, n -butyric, i-valeric, n-valeric, capronic acids | % DM | Gas chromatography | Herrmann et al. (2011) [64] |

| Lactic acid | % DM | Liquid chromatography | Herrmann et al. (2011) [64] | |

| Mass losses | % DM | Calculation | Weissbach and Kuhla (1995) [65] |

| Hemp Variety | Harvest Date | DM % FM | Sugar % DM | Cellulose % DM | Hemicellulose % DM | Lignin % DM |

|---|---|---|---|---|---|---|

| Fedora 17 | 1 October 2009 | 38.80 | 2.01 | 38.93 | 15.81 | 8.75 |

| USO-34 | 28 September 2010 | 28.50 | 1.58 | 49.76 | 8.33 | 7.96 |

| Santhica 27 | 2 September 2011 | 29.25 | 3.89 | 44.50 | 13.04 | 7.84 |

| Santhica 27 | 12 September 2012 | 32.21 | n.e. | 53.47 | 7.29 | 11.33 |

| Fedora 17 | 25 September 2013 | 36.05 | 1.75 | 54.21 | 6.24 | 10.90 |

| Futura 75 | 28 September 2014 | 40.54 | 1.16 | 60.66 | 10.43 | 11.60 |

| Parameter | Dimension | Santhica | Santhica | Santhica | Santhica | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Additives | - | Without | LUPROSIL | NATUZYM MAX | LUPROSIL and NATUZYM MAX | ||||||||

| Storage time | months | 0 | 6 | 12 | 0 | 6 | 12 | 0 | 6 | 12 | 0 | 6 | 12 |

| DM | % FM | 29.25 | 28.19 | 27.23 | 28.86 | 28.49 | 27.48 | 29.87 | 27.78 | 26.90 | 29.04 | 28.75 | 26.42 |

| pH | - | 6.87 | 6.30 | 5.82 | 5.14 | 4.86 | 4.49 | 6.86 | 4.75 | 4.43 | 5.39 | 4.39 | 4.19 |

| Sugar | % DM | 3.89 | n.e. | 0.21 | 3.83 | n.e. | 0.76 | 3.70 | n.e. | 1.16 | 4.31 | n.e. | 1.81 |

| Cellulose | % DM | 44.50 | 49.04 | 58.34 | 42.83 | 44.53 | 56.56 | 41.38 | 44.32 | 47.08 | 41.47 | 41.92 | 48.13 |

| Hemicellulose | % DM | 13.04 | 11.76 | 4.84 | 17.74 | 10.30 | 3.80 | 15.37 | 8.28 | 5.06 | 16.16 | 12.51 | 4.79 |

| Lignin | % DM | 7.84 | 7.70 | 10.83 | 7.95 | 9.41 | 9.74 | 7.07 | 8.63 | 11.67 | 7.52 | 8.45 | 10.63 |

| Ethanol | % DM | n.e. | 0.69 | 1.18 | n.e. | 0.26 | 0.73 | n.e. | 0.69 | 3.02 | n.e. | 0.41 | 1.82 |

| Propanol | % DM | n.e. | 0.08 | 0.47 | n.e. | 0.04 | 0.12 | n.e. | 0.02 | 0.19 | n.e. | 0.04 | 0.21 |

| Acetic acid | % DM | n.e. | 1.74 | 10.84 | n.e. | 1.24 | 4.68 | n.e. | 1.56 | 8.39 | n.e. | 1.33 | 6.74 |

| Lactic acid | % DM | n.e. | 1.52 | n.d. | n.e. | 3.76 | 4.05 | n.e. | 6.34 | 7.02 | n.e. | 4.52 | 5.78 |

| Propionic acid | % DM | n.e. | 0.17 | 2.49 | n.e. | 4.01 | 12.42 | n.e. | 0.20 | 0.89 | n.e. | 3.83 | 12.31 |

| i-butyric acid | % DM | n.e. | n.d. | 0.63 | n.e. | n.d. | n.d. | n.e. | n.d. | n.d. | n.e. | n.d. | 0.03 |

| n-butyric acid | % DM | n.e. | 1.13 | 6.45 | n.e. | 0.01 | 0.02 | n.e. | 0.63 | 3.25 | n.e. | 0.01 | 0.22 |

| i-valerian acid | % DM | n.e. | 0.03 | 0.57 | n.e. | 0.02 | n.d. | n.e. | n.d. | n.d. | n.e. | 0.01 | 0.03 |

| n-valerian acid | % DM | n.e. | n.d. | 0.34 | n.e. | n.d. | n.d. | n.e. | n.d. | n.d. | n.e. | n.d. | 0.01 |

| Caproic acid | % DM | n.e. | 0.04 | 1.17 | n.e. | 0.01 | n.d. | n.e. | 0.03 | 0.12 | n.e. | 0.02 | 0.10 |

| Sum of VFA ** | % DM | n.e. | 4.63 | 22.49 | n.e. | 9.05 | 21.18 | n.e. | 8.77 | 19.67 | n.e. | 9.72 | 25.22 |

| Mass losses | % DM | n.e. | 2.85 | 2.97 | n.e. | 2.61 | 2.64 | n.e. | 2.79 | 2.91 | n.e. | 2.60 | 2.69 |

| Parameter | Dimension | USO-34 | USO-34 | USO-34 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Additives | - | Without | LUPROSIL | NATUZYM MAX | ||||||

| Storage time | months | 0.5 | 1 | 6 | 0.5 | 1 | 6 | 0.5 | 1 | 6 |

| Sum of VFA * | %DM | 3.11 | 3.92 | 10.02 | 7.84 | 6.71 | 10.54 | 6.57 | 6.41 | 9.63 |

| Sum of butyric acid ** | % DM | 0.50 | 0.75 | 3.86 | 0.06 | n.d. | 0.23 | 1.28 | 2.42 | 6.01 |

| Sum of alcohols *** | % DM | 1.00 | 0.96 | 0.75 | 0.33 | 0.41 | 0.46 | 2.30 | 2.75 | 1.99 |

| Odour | 103 GEE/m3 | 364.91 | 516.06 | 421.60 | 325.10 | 250.696 | n.e. | 729.82 | 386.61 | 546.75 |

| Hedonic odour | −4 to +4 | +0.42 | −0.21 | +0.33 | +0.08 | −0.04 | n.e. | +0.25 | ±0.00 | +0.04 |

| Material | Parameter | Unit | Methods | References |

|---|---|---|---|---|

| Natural fiber reinforced composites | Tensile modulus | MPa | Tensile test of respective specimens (rods) | DIN EN ISO 527-1:2012-06 [76] DIN EN ISO 527-4:1997-07 [77] |

| Breaking elongation | % | Tensile test of respective specimens (rods) | DIN EN ISO 527-1:2012-06 [76] DIN EN ISO 527-4:1997-07 [77] | |

| Fiberboards | Tensile strength | MPa * | Tensile test perpendicular to the plane of the board | DIN EN 319:1993 [78] |

| Modulus of elasticity in bending | MPa * | Three-point bending test | DIN EN 310:1993 [79] |

| Density (kg m−3) | Fiber Material | Gluing Factor (%) | Ct/T/M/B/Cb |

|---|---|---|---|

| 500 | Standard | 10 | 0/1/0/8/1 |

| 500 | Standard | 20 | 0/0/10/0/0 |

| 500 | Dedusted | 10 | 0/4/0/6/0 |

| 750 | Standard | 10 | 0/0/0/0/10 |

| 750 | Standard | 20 | 0/0/10/0/0 |

| 750 | Dedusted | 10 | 0/5/0/5/0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gusovius, H.-J.; Lühr, C.; Hoffmann, T.; Pecenka, R.; Idler, C. An Alternative to Field Retting: Fibrous Materials Based on Wet Preserved Hemp for the Manufacture of Composites. Agriculture 2019, 9, 140. https://doi.org/10.3390/agriculture9070140

Gusovius H-J, Lühr C, Hoffmann T, Pecenka R, Idler C. An Alternative to Field Retting: Fibrous Materials Based on Wet Preserved Hemp for the Manufacture of Composites. Agriculture. 2019; 9(7):140. https://doi.org/10.3390/agriculture9070140

Chicago/Turabian StyleGusovius, Hans-Jörg, Carsten Lühr, Thomas Hoffmann, Ralf Pecenka, and Christine Idler. 2019. "An Alternative to Field Retting: Fibrous Materials Based on Wet Preserved Hemp for the Manufacture of Composites" Agriculture 9, no. 7: 140. https://doi.org/10.3390/agriculture9070140