An Efficient Method for Water Treatment of Artificial Ponds in Jordan Valley Based on Photovoltaic Pumping System

Abstract

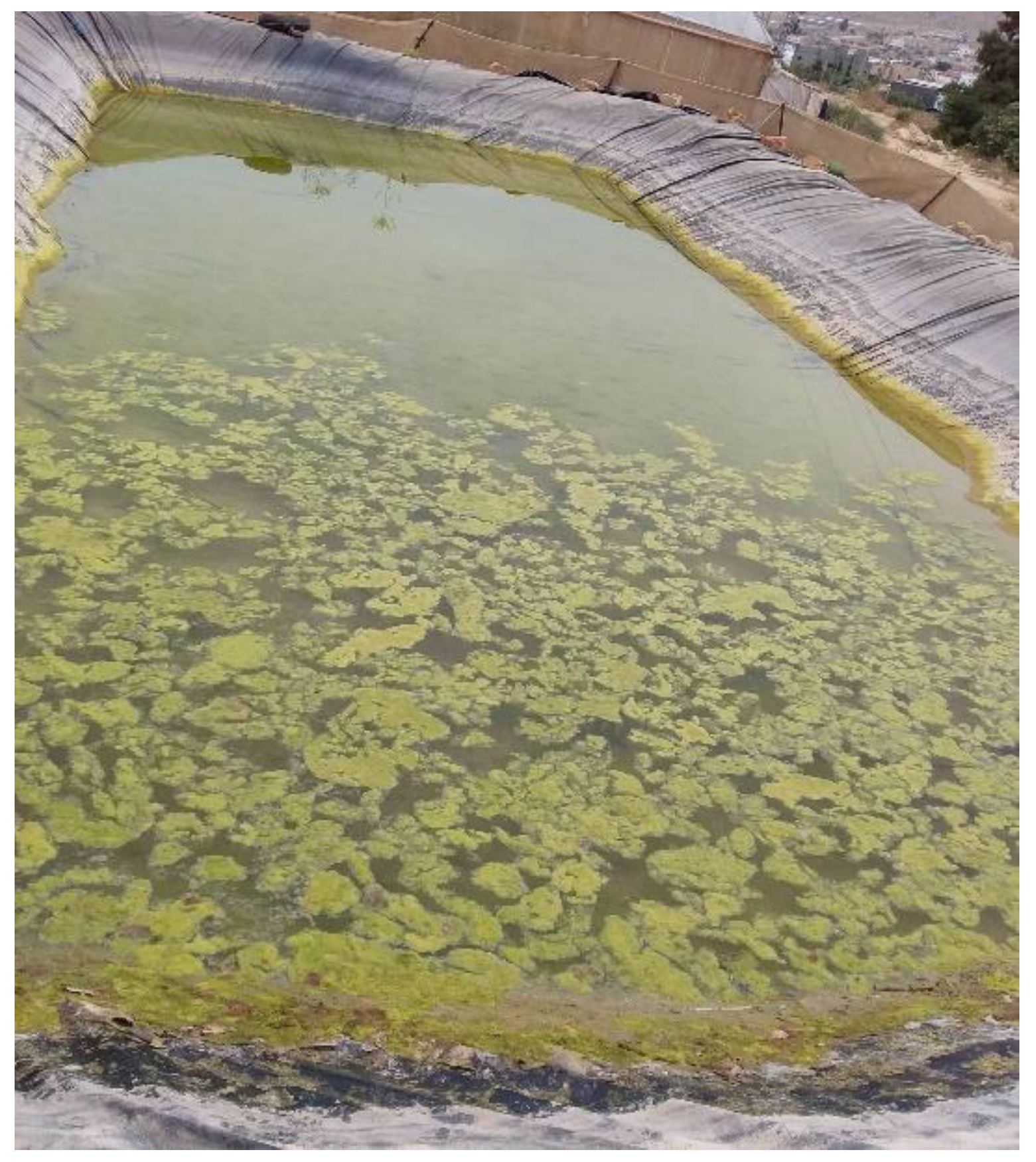

:1. Introduction

2. Proposed Chemical Material for Water Treatment

2.1. Sample Collection and Analysis

2.2. Proposed Treating Material

3. Materials and Methods

3.1. Materials Selection

3.2. Flow Rate Estimation

3.3. Total Dynamic Head Estimation

3.4. Pump Selection and PV Sizing

3.5. Control System

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Isaac, J.; Sabbah, W. The Intensifying Water Crisis in Palestine; Applied Research Institute–Jerusalem (ARIJ): Bethlehem, Palestine, 1994. [Google Scholar]

- Final Palestinian Water Authority Status Report of Water Resources in the Occupied State of Palestine-2012; Palestinian Water Authority: Ramallah, Palestine, 2013.

- Scott, M.J.; Gould, F.; Lorenzen, M.; Grubbs, N.; Edwards, O.; O’Brochta, D. Agricultural production: Assessment of the potential use of Cas9-mediated gene drive systems for agricultural pest control. J. Responsib. Innov. 2018, 5, S98–S120. [Google Scholar] [CrossRef]

- Raheja, A.K. Assessment of Losses Caused by Insect Pests to Cowpeas in Northern Nigeria. PANS 1976, 22, 229–233. [Google Scholar] [CrossRef]

- Nanninga, H.J.; Tyrrell, T. Importance of light for the formation of algal blooms by Emiliania huxleyi. Mar. Ecol. Prog. Ser. 1996, 136, 195–203. [Google Scholar] [CrossRef]

- Thronson, A.; Quigg, A. Fifty-Five Years of Fish Kills in Coastal Texas. Estuaries Coasts 2008, 31, 802–813. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, P.; Wang, B.; Liu, H. Ultrasonic frequency effects on the removal of Microcystis aeruginosa. Ultrason. Sonochem. 2006, 13, 446–450. [Google Scholar] [CrossRef] [PubMed]

- Heng, L.; Jun, N.; Wen-jie, H.; Guibai, L. Algae removal by ultrasonic irradiation–coagulation. Desalination 2009, 239, 191–197. [Google Scholar] [CrossRef]

- Li, J.; Long, H.; Song, C.; Wu, W.; Yeabah, T.O.; Qiu, Y. Study on the removal of algae from lake water and its attendant water quality changes using ultrasound. Desalin. Water Treat. 2014, 52, 4762–4771. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, B.; Zhang, P.; Wang, L.; Wang, H. Removal of Algae by Sonication-Coagulation. J. Environ. Sci. Health Part A 2006, 41, 1379–1390. [Google Scholar] [CrossRef] [PubMed]

- Ghernaout, B.; Ghernaout, D.; Saiba, A. Algae and cyanotoxins removal by coagulation/flocculation: A review. Desalin. Water Treat. 2010, 20, 133–143. [Google Scholar] [CrossRef] [Green Version]

- Hu, W.C.; Wu, C.D.; Jia, A.Y.; Chen, F. Enhanced coagulation for treating slightly polluted algae-containing raw water of the Pearl River combining ozone pre-oxidation with polyaluminum chloride (PAC). Desalin. Water Treat. 2015, 56, 1698–1703. [Google Scholar] [CrossRef]

- Hoko, Z.; Makado, P.K. Optimization of algal removal process at Morton Jaffray water works, Harare, Zimbabwe. Phys. Chem. Earth Parts A/B/C 2011, 36, 1141–1150. [Google Scholar] [CrossRef]

- Shen, Q.; Zhu, J.; Cheng, L.; Zhang, J.; Zhang, Z.; Xu, X. Enhanced algae removal by drinking water treatment of chlorination coupled with coagulation. Desalination 2011, 271, 236–240. [Google Scholar] [CrossRef]

- Phoochinda, W.; White, D.A. Removal of algae using froth flotation. Environ. Technol. 2003, 24, 87–96. [Google Scholar] [CrossRef] [PubMed]

- Kwon, D.Y.; Kwon, J.H.; Jo, G.J. Removal of algae and turbidity by floating-media and sand filtration. Desalin. Water Treat. 2014, 52, 1007–1013. [Google Scholar] [CrossRef]

- Shehata, S.; Badr, S.; Wahba, S. Drinking Water Treatment Options for Eliminating Freshwater Algae. Int. J. Environ. Stud. 2002, 59, 679–688. [Google Scholar] [CrossRef]

- Lembi, C.A. Control of nuisance algae. Freshw. Algae N. Am. 2003, 805–834. [Google Scholar] [CrossRef]

- Blottiere, L. The Effects of Wind-Induced Mixing on the Structure and Functioning of Shallow Freshwater Lakes in a Context of Global Change; Archive Ouverte HAL: Lyon, France, 2016. [Google Scholar]

- Kirke, B.K. Pumping downwards to prevent algal blooms. Presented at the IWA 2nd World Water Congress, Berlin, German, 15–29 October 2001. [Google Scholar]

- Murphy, C.F.; Allen, D.T. Energy-Water Nexus for Mass Cultivation of Algae. Environ. Sci. Technol. 2011, 45, 5861–5868. [Google Scholar] [CrossRef] [PubMed]

- Brune, D.E.; Schwartz, G.; Eversole, A.G.; Collier, J.A.; Schwedler, T.E. Intensification of pond aquaculture and high rate photosynthetic systems. Aquac. Eng. 2003, 28, 65–86. [Google Scholar] [CrossRef]

- Klemenčič, A.K.; Griessler-Bulc, T. The efficiency of ultrasound on algal control in a closed loop water treatment system for cyprinid fish farms. Fresenius Environ. Bull. 2010, 19, 919–931. [Google Scholar]

- Middlebrooks, E.J.; Porcella, D.B.; Gearheart, R.A.; Marshall, G.R.; Reynolds, J.H.; and Grenney, W.J. Review Paper: Evaluation of Techniques for Algae Removal from Wastewater Stabilization Ponds; Utah Water Research Laboratory: Logan, UT, USA, 1974. [Google Scholar]

- De Godos, I.; Guzman, H.O.; Soto, R.; García-Encina, P.A.; Becares, E.; Muñoz, R.; Vargas, V.A. Coagulation/flocculation-based removal of algal–bacterial biomass from piggery wastewater treatment. Bioresour. Technol. 2011, 102, 923–927. [Google Scholar] [CrossRef]

- Ma, X.Y.; Zhang, Z.H.; Li, Q.S.; Hu, S.F.; Wang, H.Y.; Li, J.; Chen, J.M. Simultaneous removal of algae and its odor metabolites in raw water by potassium ferrate. Desalin. Water Treat. 2014, 52, 357–364. [Google Scholar] [CrossRef]

- Gopal, C.; Mohanraj, M.; Chandramohan, P.; Chandrasekar, P. Renewable energy source water pumping systems—A literature review. Renew. Sustain. Energy Rev. 2013, 25, 351–370. [Google Scholar] [CrossRef]

- Khatib, T. Deign of Photovoltaic Water Pumping Systems at Minimum Cost for Palestine: A Review Optimal modeling and sizing of photovoltaic water pumping system View project Rural Electrification View project. Artic. J. Appl. Sci. 2010, 10, 2773–2784. [Google Scholar]

- Mahmoud, N.; Hogland, W.; Sokolov, M.; Rud, V.; Myazin, N. Assessment of rainwater harvesting for domestic water supply in palestinian rural areas. In Proceedings of the MATEC Web Conference, Saint-Petersburg, Russia, 5 December 2018; Volume 245, p. 06012. [Google Scholar]

- Parry, R. Agricultural Phosphorus and Water Quality: A U.S. Environmental Protection Agency Perspective. J. Environ. Qual. 1998, 27, 258–261. [Google Scholar] [CrossRef]

- Peterson, F.; Risberg, J. Nutrients: Phosphorus, Nitrogen Sources, Impact on Water Quality—A General Overview; Pollution Control Agenc: Sao Paulo, MN, USA, 2008. [Google Scholar]

- Potash–An Overview|ScienceDirect Topics; Science Direct: Amsterdam, The Netherlands. Available online: https://www.sciencedirect.com/topics/chemical-engineering/potash (accessed on 13 April 2019).

- Prajapati, K.; Modi, H.A. The Importance of potassium in plant growth—A review. Indian J. Plant Sci. 2012, 1, 177–186. [Google Scholar]

- Raghuwanshi, S.S.; Khare, V. Sizing and modelling of stand-alone photovoltaic water pumping system for irrigation. Energy Environ. 2018, 29, 473–491. [Google Scholar] [CrossRef]

- Robert, L. Applied Fluid Mechanics, 6th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2006. [Google Scholar]

- Schweitzer, P.A. Corrosion Resistance Tables: Metals, Nonmetals, Coatings, Mortars, Plastics, Elastomers and Linings, and Fabrics; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Spellman, F.R. Spellman’s Standard Handbook for Wastewater Operators; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Jenkins, T. Designing Solar Water Pumping Systems for Livestock; Mexico State University: Las Cruces, NM, USA, 2014. [Google Scholar]

- Neutrium. Pressure Loss from Fittings–Excess Head (K) Method. 12 October 2012. Available online: https://neutrium.net/fluid_flow/pressure-loss-from-fittings-excess-head-k-method/ (accessed on 23 March 2019).

- Ahemed, N. The Mathematics of Pumping Water AECOM Design Build Civil, Mechanical Engineering; AECOM: Los Angeles, CA, USA, 2010. [Google Scholar]

| Test | Units | Results | Ref |

|---|---|---|---|

| pH | -- | 6.76 | SMWW * |

| Nitrate (NO3) | mg/L | 1.3 | SMWW * |

| Sulfate (SO4) | mg/L | 30.1 | SMWW * |

| Phosphate (PO4) | mg/L | 0.8 | SMWW * |

| Chloride (Cl) | mg/L | 100 | SMWW * |

| Total alkalinity (as CaCO3) | mg/L | 240 | SMWW * |

| Total Hardness (as CaCO3) | mg/L | 290 | SMWW * |

| Total Dissolved Solid (TDS) | mg/L | 454.5 | SMWW * |

| Calcium (Ca) | mg/L | 56 | SMWW * |

| Magnesium (Mg) | mg/L | 36.5 | SMWW * |

| Sodium (Na) | mg/L | 36 | SMWW * |

| Potassium (K) | mg/L | 27 | SMWW * |

| Chemical Oxygen Demand (COD) | mg/L | 7200 | SMWW * |

| Estimated Parts | Required Parts/Unit | Cost/Parts |

|---|---|---|

| Centrifugal Pump | 1 | $50.00 |

| Plastic tank (20 L) | 1 | $4.96 |

| Pex pipes (16 mm, PE) | 18 m | $4.96 |

| 90° elbows (elbow joiner) | 7 | $1.65 |

| T-elbow | 3 | $1.65 |

| Non-return valve | 1 | $3.31 |

| Nozzles (rotor sprinkler) | 3 | $9.92 |

| Chemical material (KAl(SO4)2)/Bottle | 2.8 kg | $32.40 |

| Tank stand | 1 | $5.56 |

| End line | 1 | $0.28 |

| Screw | 4 | $1.10 |

| Arduino, Relay and switch | 1 | $16.53 |

| Sensor flow meter | 1 | $13.77 |

| Clipper | 1 | $0.28 |

| CB, DC Surge Arrestor and Fuse | 1 | $13.77 |

| Joints at inlet and outlet of the pump (coupling) | 2 | $1.10 |

| Foldable 50 Watt solar panel | 1 | $50.00 |

| Total Price = $213 | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khatib, T.; Qalalweh, S.; Ameerah, R.; Warad, I. An Efficient Method for Water Treatment of Artificial Ponds in Jordan Valley Based on Photovoltaic Pumping System. Agriculture 2019, 9, 151. https://doi.org/10.3390/agriculture9070151

Khatib T, Qalalweh S, Ameerah R, Warad I. An Efficient Method for Water Treatment of Artificial Ponds in Jordan Valley Based on Photovoltaic Pumping System. Agriculture. 2019; 9(7):151. https://doi.org/10.3390/agriculture9070151

Chicago/Turabian StyleKhatib, Tamer, Sora Qalalweh, Raghad Ameerah, and Ismail Warad. 2019. "An Efficient Method for Water Treatment of Artificial Ponds in Jordan Valley Based on Photovoltaic Pumping System" Agriculture 9, no. 7: 151. https://doi.org/10.3390/agriculture9070151

APA StyleKhatib, T., Qalalweh, S., Ameerah, R., & Warad, I. (2019). An Efficient Method for Water Treatment of Artificial Ponds in Jordan Valley Based on Photovoltaic Pumping System. Agriculture, 9(7), 151. https://doi.org/10.3390/agriculture9070151