Applying Hierarchical Task Analysis to Depict Human Safety Errors during Pesticide Use in Vineyard Cultivation

Abstract

1. Introduction

- The safe use of pesticide application equipment and its maintenance.

- Specific risks linked to the use of pesticide application equipment and the relevant risk management measures.

- Safe working practices for storing, handling and mixing pesticides, and disposing of empty packaging, other contaminated materials and surplus pesticides.

- The proper selection and use of personal protection equipment (PPE) to reduce the exposure of users.

2. Materials and Methods

2.1. Context of the Study

2.2. Methods

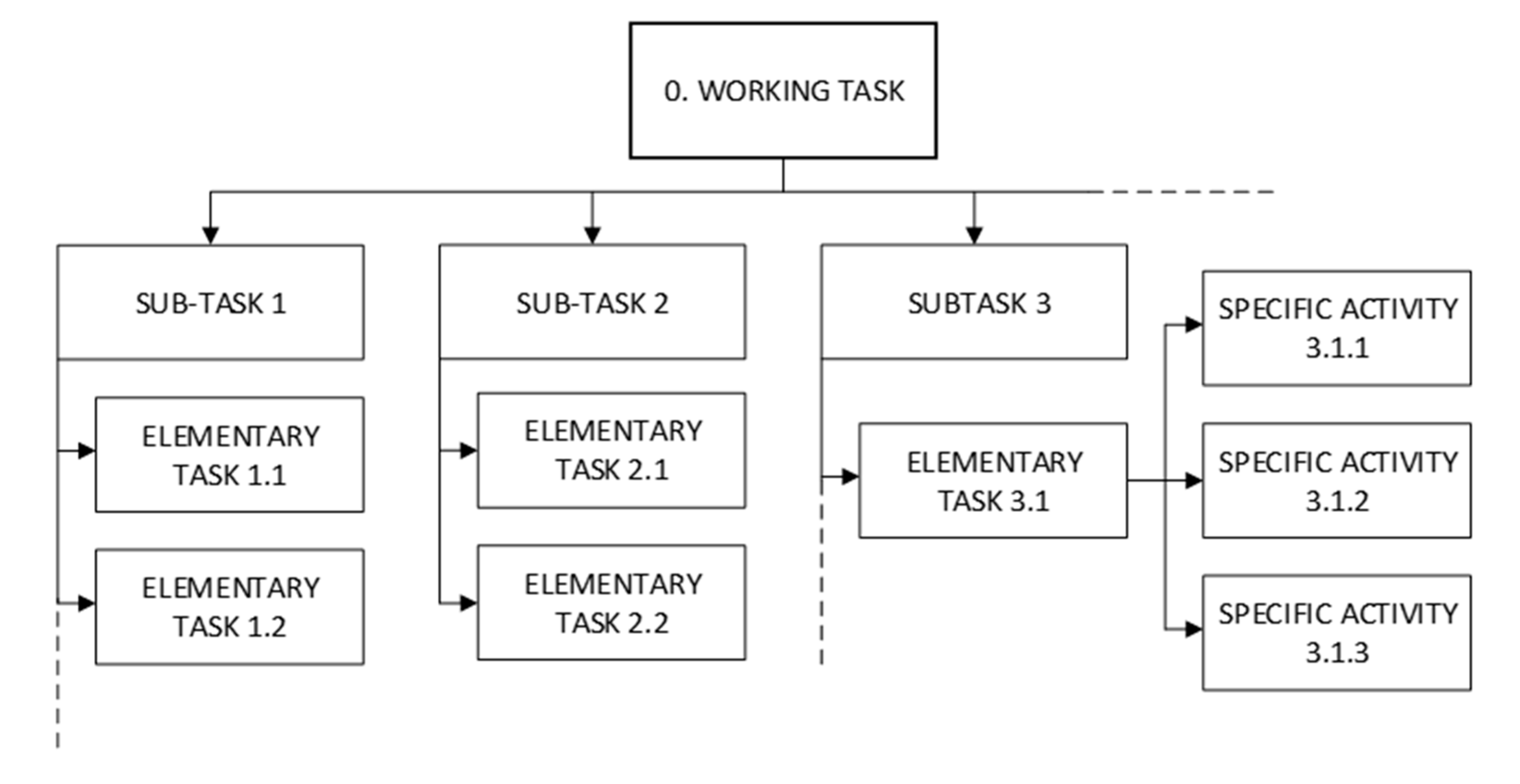

2.2.1. Hierarchical Task Analysis (HTA)

2.2.2. Systematic Human Error Reduction and Prediction Approach (SHERPA)

2.2.3. Research Methodology

- Analysis of the working activities: for this purpose, the HTA method can be used in order to break the working task down into its components [35]. The definition of the hierarchical framework of the working activities can be carried out considering references including technical standards, safety manuals and the experts’ opinions [53].

- Classification of the working task components: for each task step (considering the lowest level of each tree branch), the possible error modes are defined and classified in accordance with the criteria illustrated in Table 1. For this purpose, interviews with operators are a key factor for depicting how accidents, incidents and near-misses might occur when performing each specific activity.

- Consequences definition: the potential consequences of each error mode are defined.

- Errors assessment: each error is evaluated in a qualitative manner considering its probability of occurrence (P) and its criticality (C). For this purpose, the risk matrix [60] criteria can be used, where the probability of occurrence can be estimated on a 1–5 scale (from 1 = very unlikely to 5 = very likely);and the criticality of consequences can be estimated by means of a 1–5 scale (from 1 = minor effects to 5 = catastrophic effects). It should be noted that in this context, we considered that the latter factor mainly referred to occupational health and safety consequences.

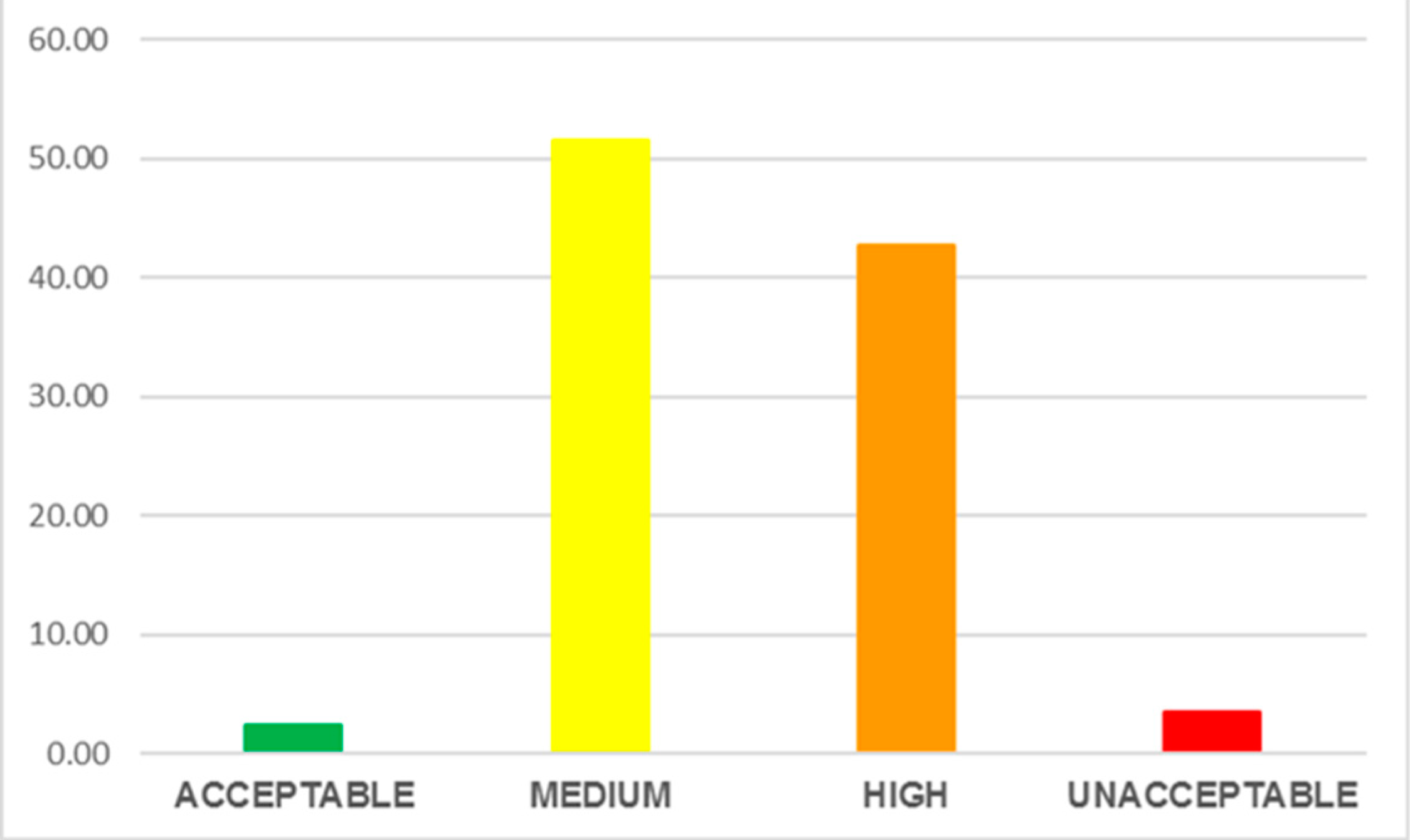

- Risk level definition: the estimation of the risk level (R) related to each error type is performed by combining the probability of occurrence (P) and its criticality (C) by means of the following equation:R = P × C,The output consists of the classification of the human error risk level based on the criteria shown in Table 2.

3. Case Study

4. Discussion of Results

4.1. Case Study Results

- A2. The operator mistimes the activity, especially when dealing with the equipment, for instance, when getting in/out of the tractor, driving and maneuvering it.

- A3. The operator performs the activity incorrectly, as when an operation is carried out without following the instructions, e.g., when performing maintenance activities on the atomizer without switching off the tractor.

- A7. The operator performs the wrong operation on the right object, as for example, when they activate the tractor or the equipment, mix the product’s components incorrectly, miscounts the dose of components, puts the product in the wrong place, parks the tractor in a wrong manner, or uses PPE incorrectly.

- A8. The operator does not perform a requested activity, as for example, they omit to update the treatments’ register, to label the equipment with the information of the pesticide used, fill the tank with supplementary water for hand-washing, etc.

- C1. The operator omits checking important elements that characterize the activity, for example, checking the weather conditions (e.g., the wind speed), checking the information reported on the products’ label (e.g., safety information, expiry date), as well as checking the “three points” attachment between the tractor and the atomizer, or the PTO (power take off) protection.

- C5. The information acquired during checking operations is mistimed, as for example, when the operator fails to pay attention to the equipment parameters, e.g., the tractor speed when driving or the atomizer pressure when applying the product.

- R1. Important information on the specific activity is not obtained, as when the operator fails to read the pesticide labels or the PPE instructions check the correct PPE; check the atomizer pressure, etc.

- R2. Wrong information is obtained, for example, when the operator reads the pesticide labels and the safety instructions incorrectly.

- S2. The operator makes a wrong selection, for example, when the wrong pesticide is selected to prepare the product, the wrong PPE is used, or an unsafe area to park the tractor for loading or maintenance operations is selected.

4.2. Research Insights

4.3. Limitations

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Appendix A

| Subtask | Elementary Task | Specific Activity |

|---|---|---|

| 1. Preparation Plan 1: do 1.4 or 1.3 then 1.1, 1.2 | 1.1. Product preparation Plan 1.1: do 1.1.1, 1.1.2, 1.1.3, 1.1.4, 1.1.5, 1.1.6, 1.1.7, 1.1.8, 1.1.9 in order | 1.1.1. Check the treatment register |

| 1.1.2. Check the weather conditions | ||

| 1.1.3. Take the product out of store | ||

| 1.1.4. Read the product label | ||

| 1.1.5. Check the expiry date | ||

| 1.1.6. Check safety instructions | ||

| 1.1.7. Dose the product | ||

| 1.1.8. Store the product not used | ||

| 1.1.9. Update the treatment register | ||

| 1.2. Loading Plan 1.2: do 1.2.1, 1.2.2, 1.2.3 or 1.2.4, then 1.2.5, 1.2.6 | 1.2.1. Fill the tank with the water | |

| 1.2.2. Fill the tank with the product | ||

| 1.2.3. Mix the components (if present) | ||

| 1.2.4. Fill the supplementary water tank | ||

| 1.2.5. Check the tank tap | ||

| 1.2.6. Update the tank label | ||

| 1.3. Equipment preparation: Plan 1.3: do 1.3.1, 1.3.2, then 1.3.3, 1.3.4, 1.3.5, 1.3.6, 1.3.7, 1.3.8 | 1.3.1. Verify the parking in the loading area | |

| 1.3.2. Check the connection between tractor and equipment | ||

| 1.3.3. Check the PTO (if used) | ||

| 1.3.4. Check the pump | ||

| 1.3.5. Check the sprayer | ||

| 1.3.6. Regulate the sprayer | ||

| 1.3.7. Check the product tank | ||

| 1.3.8. Check the supplementary water tank | ||

| 1.4. Protective measures Plan 1.4: do 1.4.1, then 1.4.2, 1.4.3, 1.4.4 | 1.4.1. Read safety instructions | |

| 1.4.2. Check the PPE | ||

| 1.4.3. Wear the PPE | ||

| 1.4.4. Check the cabin filters (if present) | ||

| 2. Transit Plan 2: do 2.1, 2.2 and/or 2.3 then 2.4 | 2.1. Start Plan 2.1: do 2.1.1, 2.1.2, 2.1.3, in order | 2.1.1. Get in the tractor |

| 2.1.2. Activate the tractor | ||

| 2.1.3. Check the presence of obstacles | ||

| 2.1.4. Start the transit | ||

| 2.2. Road transit Plan 2.2: do 2.2.1, 2.2.2, 2.2.3 | 2.2.1. Drive on the public road | |

| 2.2.2. Check the speed | ||

| 2.2.3. Check the road traffic | ||

| 2.3. In-field transit Plan 2.3: do 2.3.1, 2.3.2, 2.3.3 | 2.3.1. Drive in the field | |

| 2.3.2. Check the presence of obstacles | ||

| 2.3.3. Check the speed | ||

| 2.4. Stop Plan 2.4: do 2.4.1, 2.4.2, 2.4.3, 2.4.4, 2.4.5 | 2.4.1. Check the presence of obstacles | |

| 2.4.2. Park the tractor | ||

| 2.4.3. Switch off the tractor | ||

| 2.4.4. Brake the tractor | ||

| 2.4.4. Get out of the tractor | ||

| 3. Application Plan 3: do 3.1 then 3.2 or 3.3 then 3.2 | 3.1. Checking Plan 3.1: do 3.1.1, 3.1.2, 3.1.3 in order | 3.1.1. Check weather condition |

| 3.1.2. Check the field condition | ||

| 3.1.3. Check the PPE | ||

| 3.2. Product application Plan 3.2: do 3.2.1, 3.2.2, 3.2.3 and 3.2.4 then 3.2.5, 3.2.6 then 3.2.1, 3.2.2, 3.2.3 and 3.2.4 | 3.2.1. Reach the vineyard row | |

| 3.2.2. Activate the equipment | ||

| 3.2.3. Apply the product | ||

| 3.2.4. Check the speed of the tractor | ||

| 3.2.5. Stop the equipment | ||

| 3.2.6. Change the vineyard row | ||

| 3.3. In-field setting/maintenance: Plan 3.3: do 3.3.1, 3.3.2, 3.3.3, 3.3.4, 3.3.5, 3.3.6, 3.3.7 and/or 3.3.8, then 3.3.9, 3.3.10, 3.3.11 | 3.3.1. Reach a parking area | |

| 3.3.2. Park the tractor | ||

| 3.3.3. Switch off the equipment | ||

| 3.3.4. Switch off the tractor | ||

| 3.3.5. Get out the tractor | ||

| 3.3.6. Check the equipment | ||

| 3.3.7. Regulate the sprayer | ||

| 3.3.8. Regulate the pump | ||

| 3.3.9. Get in the tractor | ||

| 3.3.10. Activate the tractor | ||

| 3.3.11. Reach the vineyard rows | ||

| 4. Final operations Plan 4: do 4.1 then 4.2 | 4.1. External cleaning Plan 4.1: do 4.1.1, 4.1.2, 4.1.3, 4.1.4, 4.1.5, 4.1.6, 4.1.7, 4.1.8, 4.1.9, 4.1.10, 4.1.11 in order | 4.1.1. Reach the cleaning area |

| 4.1.2. Park the tractor | ||

| 4.1.3. Switch off the equipment | ||

| 4.1.4. Switch off the tractor | ||

| 4.1.5. Get out the tractor | ||

| 4.1.6. Wash the equipment | ||

| 4.1.9. Get in the tractor | ||

| 4.1.10. Activate the tractor | ||

| 4.2. Disposal of residuals Plan 4.2: do 4.2.1, 4.2.2, 4.2.3. | 4.2.1. Read instruction | |

| 4.2.2. Collect residuals | ||

| 4.2.3. Dispose residuals | ||

| 4.2.4. Dispose package | ||

| 4.2.5. Update the register |

References

- Schreinemachers, P.; Tipraqsa, P. Agricultural pesticides and land use intensification in high, middle and low income countries. Food Policy 2012, 37, 616–626. [Google Scholar] [CrossRef]

- Wesseler, J. Perspective: Regulation of pest and disease control strategies and why (many) economists are concerned. Pest Manag. Sci. 2019, 75, 578–582. [Google Scholar] [CrossRef] [PubMed]

- Bondori, A.; Bagheri, A.; Allahyari, M.S.; Damalas, C.A. Pesticide waste disposal among farmers of Moghan region of Iran: Current trends and determinants of behavior. Environ. Monit. Assess. 2019, 191, 30. [Google Scholar] [CrossRef] [PubMed]

- Wumbei, A.; Bawa, J.K.A.; Akudugu, M.A.; Spanoghe, P. Absence of Effects of Herbicides Use on Yam Rots: A Case Study in Wulensi, Ghana. Agriculture 2019, 9, 95. [Google Scholar] [CrossRef]

- Emery, S.B.; Hart, A.; Butler-Ellis, C.; Gerritsen-Ebben, M.G.; Machera, K.; Spanoghe, P.; Frewer, L.J. A review of the use of pictograms for communicating pesticide hazards and safety instructions: Implications for EU policy. Hum. Ecol. Risk Assess. Int. J. 2015, 21, 1062–1080. [Google Scholar] [CrossRef]

- Jess, S.; Kildea, S.; Moody, A.; Rennick, G.; Murchie, A.K.; Cooke, L.R. European Union policy on pesticides: Implications for agriculture in Ireland. Pest Manag. Sci. 2014, 70, 1646–1654. [Google Scholar] [CrossRef]

- Dugger-Webster, A.; LePrevost, C.E. Following pesticide labels: A continued journey toward user comprehension and safe use. Curr. Opin. Environ. Sci. Health 2018, 4, 19–26. [Google Scholar] [CrossRef]

- Directive 2009/128/EC of the European Parliament and of the Council of 21 October 2009 Establishing a Framework for Community Action to Achieve the Sustainable Use of Pesticides. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=celex%3A32009L0128 (accessed on 30 April 2019).

- Jess, S.; Matthews, D.; Murchie, A.; Lavery, M. Pesticide Use in Northern Ireland’s Arable Crops from 1992–2016 and Implications for Future Policy Development. Agriculture 2018, 8, 123. [Google Scholar] [CrossRef]

- Biocca, M.; Gallo, P.; Imperi, G. Periodical Inspections and Controls of Agricultural Sprayers Already in Use in Italy Looking at the Directive CE 128/09. In Proceedings of the International Conference Work Safety and Risk Prevention in Agro-Food and Forest Systems, Ragusa SHWA 2010, Ragusa, Italy, 16–18 September 2010; pp. 517–520. [Google Scholar]

- Zhang, X.; Guo, Q.; Shen, X.; Yiu, S.; Qiu, G. Water quality, agriculture and food safety in China: Current situation, trends, interdependencies, and management. J. Integr. Agric. 2015, 14, 2365–2379. [Google Scholar] [CrossRef]

- McCauley, L.A.; Anger, W.K.; Keifer, M.; Langley, R.; Robson, M.G.; Rohlman, D. Studying health outcomes in farmworker populations exposed to pesticides. Environ. Health Perspect. 2006, 114, 953–960. [Google Scholar] [CrossRef]

- Biocca, M.; Pochi, D.; Fanigliulo, R.; Gallo, P.; Pulcini, P.; Marcovecchio, F.; Perrino, C. Evaluating a filtering and recirculating system to reduce dust drift in simulated sowing of dressed seed and abraded dust particle characteristics. Pest Manag. Sci. 2017, 73, 1134–1142. [Google Scholar] [CrossRef]

- Damalas, C.A.; Eleftherohorinos, I.G. Pesticide exposure, safety issues, and risk assessment indicators. Int. J. Environ. Res. Public Health 2011, 8, 1402–1419. [Google Scholar] [CrossRef]

- Bagheri, A.; Emami, N.; Allahyari, M.S.; Damalas, C.A. Pesticide handling practices, health risks, and determinants of safety behavior among Iranian apple farmers. Hum. Ecol. Risk Assess. Int. J. 2018, 24, 2209–2223. [Google Scholar] [CrossRef]

- Damalas, C.A.; Koutroubas, S.D. Farmers’ exposure to pesticides: Toxicity types and ways of prevention. Toxics 2016, 4, 1. [Google Scholar] [CrossRef]

- Khan, M.; Damalas, C.A. Factors preventing the adoption of alternatives to chemical pest control among Pakistani cotton farmers. Int. J. Pest Manag. 2015, 61, 9–16. [Google Scholar] [CrossRef]

- Palis, F.G.; Flor, R.J.; Warburton, H.; Hossain, M. Our farmers at risk: Behaviour and belief system in pesticide safety. J. Public Health 2006, 28, 43–48. [Google Scholar] [CrossRef]

- Yang, X.; Wang, F.; Meng, L.; Zhang, W.; Fan, L.; Geissen, V.; Ritsema, C.J. Farmer and retailer knowledge and awareness of the risks from pesticide use: A case study in the Wei River catchment, China. Sci. Total Environ. 2014, 497, 172–179. [Google Scholar] [CrossRef]

- Mubushar, M.; Aldosari, F.O.; Baig, M.B.; Alhafi, B.M.; Kassem, H.S.; Khan, A.Q. Assessment of farmers on their knowledge regarding pesticide usage and biosafety. Saudi J. Biol. Sci. 2019. [Google Scholar] [CrossRef]

- Sharifzadeh, M.S.; Abdollahzadeh, G.; Damalas, C.A.; Rezaei, R.; Ahmadyousefi, M. Determinants of pesticide safety behavior among Iranian rice farmers. Sci. Total Environ. 2019, 651, 2953–2960. [Google Scholar] [CrossRef]

- Caffaro, F.; Micheletti Cremasco, M.; Roccato, M.; Cavallo, E. It does not occur by chance: A mediation model of the influence of workers’ characteristics, work environment factors, and near misses on agricultural machinery-related accidents. Int. J. Occup. Environ. Health 2017, 23, 52–59. [Google Scholar] [CrossRef]

- Moradhaseli, S.; Ataei, P.; Farhadian, H.; Ghofranipour, F. Farmers’ Preventive Behavior Analysis Against Sunlight Using the Health Belief Model: A Study from Iran. J. Agromed. 2019, 24, 110–118. [Google Scholar] [CrossRef]

- Fan, L.; Niu, H.; Yang, X.; Qin, W.; Bento, C.P.; Ritsema, C.J.; Geissen, V. Factors affecting farmers’ behaviour in pesticide use: Insights from a field study in northern China. Sci. Total Environ. 2015, 537, 360–368. [Google Scholar] [CrossRef]

- Yuantari, M.G.; Van Gestel, C.A.; Van Straalen, N.M.; Widianarko, B.; Sunoko, H.R.; Shobib, M.N. Knowledge, attitude, and practice of Indonesian farmers regarding the use of personal protective equipment against pesticide exposure. Environ. Monit. Assess. 2015, 187, 142. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lombardi, M.; Haber, N.; Puri, D. The Impact of Human Error in the Use of Agricultural Tractors: A Case Study Research in Vineyard Cultivation in Italy. Agriculture 2018, 8, 82. [Google Scholar] [CrossRef]

- Irwin, A.; Poots, J. Investigation of UK farmer go/no-go decisions in response to tractor-based risk scenarios. J. Agromed. 2018, 23, 154–165. [Google Scholar] [CrossRef]

- Abadi, B. The determinants of cucumber farmers’ pesticide use behavior in central Iran: Implications for the pesticide use management. J. Clean. Prod. 2018, 205, 1069–1081. [Google Scholar] [CrossRef]

- Caffaro, F.; Schmidt, S.; Murphy, D.J.; Cavallo, E. Comprehension rates of safety pictorials affixed to agricultural machinery among Pennsylvania rural population. Saf. Sci. 2018, 103, 162–171. [Google Scholar] [CrossRef]

- Irwin, A.; Caruso, L.; Tone, I. Thinking ahead of the tractor: Driver safety and situation awareness. J. Agromed. 2019, 1–10. [Google Scholar] [CrossRef]

- Sharafi, K.; Pirsaheb, M.; Maleki, S.; Arfaeinia, H.; Karimyan, K.; Moradi, M.; Safari, Y. Knowledge, attitude and practices of farmers about pesticide use, risks, and wastes; a cross-sectional study (Kermanshah, Iran). Sci. Total Environ. 2018, 645, 509–517. [Google Scholar] [CrossRef]

- Damalas, C.A.; Koutroubas, S.D. Farmers’ behaviour in pesticide use: A key concept for improving environmental safety. Curr. Opin. Environ. Sci. Health 2018, 4, 27–30. [Google Scholar] [CrossRef]

- Sadeghi, L.; Dantan, J.Y.; Siadat, A.; Marsot, J. Design for human safety in manufacturing systems: Applications of design theories, methodologies, tools and techniques. J. Eng. Des. 2016, 27, 844–877. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lombardi, M. Preliminary Human Safety Assessment (PHSA) for the Improvement of the Behavioral Aspects of Safety Climate in the Construction Industry. Buildings 2019, 9, 69. [Google Scholar] [CrossRef]

- Lane, R.; Stanton, N.A.; Harrison, D. Applying hierarchical task analysis to medication administration errors. Appl. Ergon. 2006, 37, 669–679. [Google Scholar] [CrossRef]

- Strand, G.O.; Haskins, C. On Linking of Task Analysis in the HRA Procedure: The Case of HRA in Offshore Drilling Activities. Safety 2018, 4, 39. [Google Scholar] [CrossRef]

- Olivares, R.D.C.; Rivera, S.S.; Mc Leod, J.E.N. A novel qualitative prospective methodology to assess human error during accident sequences. Saf. Sci. 2018, 103, 137–152. [Google Scholar] [CrossRef]

- Mitropoulos, P.; Cupido, G.; Namboodiri, M. Cognitive approach to construction safety: Task demand-capability model. J. Constr. Eng. Manag. 2009, 135, 881–889. [Google Scholar] [CrossRef]

- Shepherd, A. HTA as a framework for task analysis. Ergonomics 1998, 41, 1537–1552. [Google Scholar] [CrossRef]

- Mandal, S.; Singh, K.; Behera, R.K.; Sahu, S.K.; Raj, N.; Maiti, J. Human error identification and risk prioritization in overhead crane operations using HTA, SHERPA and fuzzy VIKOR method. Expert Syst. Appl. 2015, 42, 7195–7206. [Google Scholar] [CrossRef]

- Embrey, D. Qualitative and quantitative evaluation of human error in risk assessment. In Human Factors for Engineers; Sandom, C., Harvey, R.S., Eds.; IET: London, UK, 2004; pp. 151–202. ISBN 0863413293. [Google Scholar]

- Amato, V.; Valletta, M. Wine landscapes of Italy. In Landscapes and Landforms of Italy; Soldati, M., Marchetti, M., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 523–536. [Google Scholar] [CrossRef]

- OIV (The International Organisation of Vine and Wine). State of the Vitiviniculture World Market Report—State of the Sector 2018. Available online: http://www.oiv.int/public/medias/6679/en-oiv-state-of-the-vitiviniculture-world-market-2019.pdf (accessed on 20 May 2019).

- Tegli, S.; Santilli, E.; Bertelli, E.; Surico, G. Genetic variation within Phaeoacremonium aleophilum and P. chlamydosporum in Italy. Phytopathol. Mediterr. 2000, 39, 125–133. [Google Scholar]

- Pretorius, I.S.; Bauer, F.F. Meeting the consumer challenge through genetically customized wine-yeast strains. Trends Biotechnol. 2002, 20, 426–432. [Google Scholar] [CrossRef]

- EUROSTAT. Agriculture, Forestry and Fishery Statistics, 2018th Edition ed. Available online: https://ec.europa.eu/eurostat/documents/3217494/9455154/KS-FK-18-001-EN-N.pdf (accessed on 30 April 2019).

- Cividino, S.R.S.; Pergher, G.; Gubiani, R.; Moreschi, C.; Da Broi, U.; Vello, M.; Rinaldi, F. Definition of a Methodology for Gradual and Sustainable Safety Improvements on Farms and Its Preliminary Applications. Agriculture 2018, 8, 7. [Google Scholar] [CrossRef]

- Vitali, M.; Protano, C.; Del Monte, A.; Ensabella, F.; Guidotti, M. Operative modalities and exposure to pesticides during open field treatments among a group of agricultural subcontractors. Arch. Environ. Contam. Toxic. 2009, 57, 193–202. [Google Scholar] [CrossRef]

- Cecchini, M.; Colantoni, A.; Monarca, D.; Cossio, F.; Riccioni, S. Survey on the status of enforcement of European directives on health and safety at work in some farms of central Italy. Chem. Eng. Trans. 2017, 58, 103–108. [Google Scholar] [CrossRef]

- Lombardi, M.; Fargnoli, M. Prioritization of hazards by means of a QFD-based procedure. Int. J. Saf. Secur. Eng. 2018, 8, 342–353. [Google Scholar] [CrossRef]

- Harris, D.; Stanton, N.A.; Marshall, A.; Young, M.S.; Demagalski, J.; Salmon, P. Using SHERPA to predict design-induced error on the flight deck. Aerosp. Sci. Technol. 2005, 9, 525–532. [Google Scholar] [CrossRef]

- Ghasemi, M.; Khoshakhlagh, A.H.; Mahmudi, S.; Fesharaki, M.G. Identification and assessment of medical errors in the triage area of an educational hospital using the SHERPA technique in Iran. Int. J. Occup. Saf. Ergon. 2015, 21, 382–390. [Google Scholar] [CrossRef]

- Di Pasquale, V.; Miranda, S.; Iannone, R.; Riemma, S. A simulator for human error probability analysis (SHERPA). Reliab. Eng. Syst. Saf. 2015, 139, 17–32. [Google Scholar] [CrossRef]

- Salvendy, G. Handbook of Human Factors and Ergonomics, 4th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; pp. 1–1732. [Google Scholar]

- Ainsworth, L.K. Task analysis. In Human Factors for Engineers; Sandom, C., Harvey, R.S., Eds.; IET: London, UK, 2004; pp. 81–112. ISBN 0863413293. [Google Scholar]

- Stanton, N.A. Hierarchical task analysis: Developments, applications, and extensions. Appl. Ergon. 2006, 37, 55–79. [Google Scholar] [CrossRef]

- Salmon, P.; Jenkins, D.; Stanton, N.; Walker, G. Hierarchical task analysis vs. cognitive work analysis: Comparison of theory, methodology and contribution to system design. Theor. Issues Ergon. Sci. 2010, 11, 504–531. [Google Scholar] [CrossRef]

- Baber, C.; Stanton, N.A. Human error identification techniques applied to public technology: Predictions compared with observed use. Appl. Ergon. 1996, 27, 119–131. [Google Scholar] [CrossRef]

- Ghasemi, M.; Nasleseraji, J.; Hoseinabadi, S.; Zare, M. Application of SHERPA to identify and prevent human errors in control units of petrochemical industry. Int. J. Occup. Saf. Ergon. 2013, 19, 203–209. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). Safety of Machinery—Risk Assessment—Part 2: Practical Guidance and Examples of Methods; ISO/TR 14121-2:2012; International Organization for Standardization: Geneva, Switzerland, 2012. [Google Scholar]

- PANE (Pesticide Action Network Europe). NAP Best Practice—Sustainable Use of Pesticides: Implementing a National Action Plan. 2010. Available online: https://www.pan-europe.info/old/Resources/Reports/NAP_best_practice.pdf (accessed on 30 April 2019).

- Balsari, P.; Marucco, P. The new EU Directives requirements and the innovation in pesticide application techniques. J. ASTM Int. 2011, 8, 1–21. [Google Scholar] [CrossRef]

- Cerruto, E.; Emma, G.; Failla, S.; Manetto, G. Survey on vineyards treatment and pesticide remnant management in Sicilian vine-growing farms. In Proceedings of the International Conference Work Safety and Risk Prevention in Agro-Food and Forest Systems, Ragusa SHWA 2010, Ragusa, Italy, 16–18 September 2010; pp. 389–395. [Google Scholar]

- Pinto, A.; Nunes, I.L.; Ribeiro, R.A. Occupational risk assessment in construction industry—Overview and reflection. Saf. Sci. 2011, 49, 616–624. [Google Scholar] [CrossRef]

- Hollnagel, E. Reliability analysis and operator modelling. Reliab. Eng. Syst. Saf. 1996, 52, 327–337. [Google Scholar] [CrossRef]

- Elkind, P.D. Perceptions of Risk, Stressors, and Locus of Control Influence Intentions to Practice Safety Behaviors in Agriculture. J. Agromed. 2008, 12, 7–25. [Google Scholar] [CrossRef]

- Caffaro, F.; Lundqvist, P.; Micheletti Cremasco, M.; Nilsson, K.; Pinzke, S.; Cavallo, E. Machinery-Related Perceived Risks and Safety Attitudes in Senior Swedish Farmers. J. Agromed. 2018, 23, 78–91. [Google Scholar] [CrossRef]

- Allahyari, M.; Damalas, C.; Ebadattalab, M. Farmers’ technical knowledge about integrated pest management (IPM) in olive production. Agriculture 2017, 7, 101. [Google Scholar] [CrossRef]

- Bagagiolo, G.; Laurendi, V.; Cavallo, E. Safety Improvements on Wood Chippers Currently in Use: A Study on Feasibility in the Italian Context. Agriculture 2017, 7, 98. [Google Scholar] [CrossRef]

- Damalas, C.A.; Koutroubas, S.D.; Abdollahzadeh, G. Drivers of Personal Safety in Agriculture: A Case Study with Pesticide Operators. Agriculture 2019, 9, 34. [Google Scholar] [CrossRef]

- Rezaei, R.; Damalas, C.A.; Abdollahzadeh, G. Understanding farmers’ safety behaviour towards pesticide exposure and other occupational risks: The case of Zanjan, Iran. Sci. Total Environ. 2018, 616, 1190–1198. [Google Scholar] [CrossRef]

- Caffaro, F.; Mirisola, A.; Cavallo, E. Safety signs on agricultural machinery: Pictorials do not always successfully convey their messages to target users. Appl. Ergon. 2017, 58, 156–166. [Google Scholar] [CrossRef]

- Vigoroso, L.; Caffaro, F.; Cavallo, E. Warning against critical slopes in agriculture: Comprehension of targeted safety signs in a group of machinery operators in Italy. Int. J. Environ. Res. Public Health 2019, 16, 611. [Google Scholar] [CrossRef]

- Kapeleka, J.; Mwaseba, D.L. Effectiveness of Pesticide Labels as A Communication Tool for Smallholder Farmers on Pesticides Handling. Int. J. Sci. Technol. Res. 2017, 6, 50–60. [Google Scholar]

- Rother, H.A. Pesticide labels: Protecting liability or health?—Unpacking “misuse” of pesticides. Curr. Opin. Environ. Sci. Health 2018, 4, 10–15. [Google Scholar] [CrossRef]

- Fargnoli, M.; Vita, L.; Gattamelata, D.; Laurendi, V.; Tronci, M. A reverse engineering approach to enhance machinery design for safety. In DS 70, Proceedings of the DESIGN 2012 12th International Design Conference, Dubrovnik, Croatia, 21–24 May 2012; Marjanovic, D., Storga, M., Pavkovic, N., Bojcetic, N., Eds.; The Design Society: Glasgow, UK, 2012; pp. 627–636. ISBN 978-953-7738-17-4. [Google Scholar]

- Bhandari, G.; Atreya, K.; Yang, X.; Fan, L.; Geissen, V. Factors affecting pesticide safety behaviour: The perceptions of Nepalese farmers and retailers. Sci. Total Environ. 2018, 631, 1560–1571. [Google Scholar] [CrossRef]

- Lyons, M. Towards a framework to select techniques for error prediction: Supporting novice users in the healthcare sector. Appl. Ergon. 2009, 40, 379–395. [Google Scholar] [CrossRef]

- Damalas, C.A.; Khan, M. Farmers’ attitudes towards pesticide labels: Implications for personal and environmental safety. Int. J. Pest. Manag. 2016, 62, 319–325. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lombardi, M.; Puri, D.; Casorri, L.; Masciarelli, E.; Mandić-Rajčević, S.; Colosio, C. The safe use of pesticides: A risk assessment procedure for the enhancement of occupational health and safety (OHS) management. Int. J. Environ. Res. Public Health 2019, 16, 310. [Google Scholar] [CrossRef]

- Hughes, C.M.; Baber, C.; Bienkiewicz, M.; Worthington, A.; Hazell, A.; Hermsdörfer, J. The application of SHERPA (Systematic Human Error Reduction and Prediction Approach) in the development of compensatory cognitive rehabilitation strategies for stroke patients with left and right brain damage. Ergonomics 2015, 58, 75–95. [Google Scholar] [CrossRef]

- Baxter, P.; Jack, S. Qualitative case study methodology: Study design and implementation for novice researchers. Qualit. Rep. 2008, 13, 544–559. [Google Scholar]

- Cooper, R.J.; Fitt, P.; Hiscock, K.M.; Lovett, A.A.; Gumm, L.; Dugdale, S.J.; Rambohul, J.; Williamson, A.; Noble, L.; Beamish, J.; et al. Assessing the effectiveness of a three-stage on-farm biobed in treating pesticide contaminated wastewater. J. Eniron. Manag. 2016, 181, 874–882. [Google Scholar] [CrossRef]

- Roettele, M.; Balsari, P.; Doruchowski, G.; Petersen, P.H. Sprayer development needs more focus on mitigation of environmental risks arising from point source water pollution (Results from the TOPPS project). Asp. Appl. Biol. 2010, 99, 123–132. [Google Scholar]

- Thouvenin, I.; Bouneb, F.; Mercier, T. Operator dermal exposure and protection provided by personal protective equipment and working coveralls during mixing/loading, application and sprayer cleaning in vineyards. Int. J. Occup. Saf. Ergon. 2017, 23, 229–239. [Google Scholar] [CrossRef]

- Suciu, N.A.; Ferrari, T.; Ferrari, F.; Trevisan, M.; Capri, E. Pesticide removal from waste spray-tank water by organoclay adsorption after field application to vineyards. Environ. Sci. Pollut. Res. 2011, 18, 1374–1383. [Google Scholar] [CrossRef]

- Andersen, P.G.; Jørgensen, M.K.; Nilsson, E.; Wehmann, H.J. Towards efficient sprayer cleaning in the field and minimum point source pollution. Asp. Appl. Biol. 2010, 99, 49–53. [Google Scholar]

- Doerpmund, M.; Cai, X.; Walgenbach, M.; Vondricka, J.; Lammers, P.S. Assessing the cleanability of a direct nozzle injection system. Biosyst. Eng. 2011, 110, 49–56. [Google Scholar] [CrossRef]

| Error Type | Error Mode |

|---|---|

| Action errors (A), when the human action changes the status of the system | A1 Operation too long/short A2 Operation mistimed A3 Operation in wrong direction A4 Operation too little/much A5 Misalign A6 Right operation on wrong object A7 Wrong operation on right object A8 Operation omitted A9 Operation incomplete A10 Wrong operation on wrong object |

| Checking errors (C), when the operator fails to verify, check the status of the system | C1 Check omitted C2 Check incomplete C3 Right check on wrong object C4 Wrong check on right object C5 Check mistimed C6 Wrong check on wrong object |

| Retrieval errors (R), if the operator fails to retrieve information, e.g., from a work procedure | R1 Information not obtained R2 Wrong information obtained R3 Information retrieval incomplete |

| Communication errors (I), when the operator fails to transfer information to another person | I1 Information not communicated I2 Wrong information communicated I3 Information communication incomplete |

| Selection errors (S), when the operator makes the wrong choice among different alternatives | S1 Selection omitted S2 Wrong selection made |

| R | Level | Meaning |

|---|---|---|

| ≤5 | I | Acceptable level risk |

| 6–9 | II | Medium level of risk |

| 10–15 | III | High level of risk |

| 16–25 | IV | Unacceptable level of risk |

| Subtask | Elementary Task | Specific Activity |

|---|---|---|

| 1. Preparation Plan 1: do 1.4 or 1.3 then 1.1, 1.2 | 1.1. Product preparation Plan 1.1: do 1.1.1, 1.1.2, 1.1.3, 1.1.4, 1.1.5, 1.1.6, 1.1.7, 1.1.8, 1.1.9 in order | 1.1.1. Check the treatment register |

| 1.1.2. Check the weather conditions | ||

| 1.1.3. Take the product out of store | ||

| 1.1.4. Read the product label | ||

| 1.1.5. Check the expiry date | ||

| 1.1.6. Check safety instructions | ||

| 1.1.7. Dose the product | ||

| 1.1.8. Store the product not used | ||

| 1.1.9. Update the treatment register | ||

| 1.2. Loading Plan 1.2: do 1.2.1, 1.2.2, 1.2.3 or 1.2.4, then 1.2.5, 1.2.6 | 1.2.1. Fill the tank with the water | |

| 1.2.2. Fill the tank with the product | ||

| 1.2.3. Mix the components (if present) | ||

| 1.2.4. Fill the supplementary water tank | ||

| 1.2.5. Check the tank tap | ||

| 1.2.6. Update the tank label |

| Specific Activity | Error Mode | Description | Consequences | P | C | Remedial Measures |

|---|---|---|---|---|---|---|

| 1.1.3. Take the product out of store | A6 | The operator takes the wrong product from the storage closet | A wrong product is used for the treatment | 2 | 4 | Preserve the package integrity of the products |

| S1 | Select the wrong product | A wrong product is used for the treatment | 2 | 4 | Specific operator training | |

| 1.1.4. Read the product label | R1 | The operator fails in reading the label | A wrong product/dose is used for the treatment Inappropriate safety measures are implemented | 3 | 4 | Preserve the package integrity of the products Specific operator training |

| R2 | The operator reads the label incorrectly | A wrong product/dose is used for the treatment Inappropriate safety measures are implemented | 3 | 4 | Preserve the package integrity of the products Specific operator training |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fargnoli, M.; Lombardi, M.; Puri, D. Applying Hierarchical Task Analysis to Depict Human Safety Errors during Pesticide Use in Vineyard Cultivation. Agriculture 2019, 9, 158. https://doi.org/10.3390/agriculture9070158

Fargnoli M, Lombardi M, Puri D. Applying Hierarchical Task Analysis to Depict Human Safety Errors during Pesticide Use in Vineyard Cultivation. Agriculture. 2019; 9(7):158. https://doi.org/10.3390/agriculture9070158

Chicago/Turabian StyleFargnoli, Mario, Mara Lombardi, and Daniele Puri. 2019. "Applying Hierarchical Task Analysis to Depict Human Safety Errors during Pesticide Use in Vineyard Cultivation" Agriculture 9, no. 7: 158. https://doi.org/10.3390/agriculture9070158

APA StyleFargnoli, M., Lombardi, M., & Puri, D. (2019). Applying Hierarchical Task Analysis to Depict Human Safety Errors during Pesticide Use in Vineyard Cultivation. Agriculture, 9(7), 158. https://doi.org/10.3390/agriculture9070158