Study on the Effect of the Guide Vane Opening on the Band Clearance Sediment Erosion in a Francis Turbine

Abstract

:1. Introduction

2. Study Methods

2.1. Mathematical Model

2.1.1. Governing Equations

2.1.2. Lagrangian Tracking of Particle Motions

2.1.3. Erosion Model

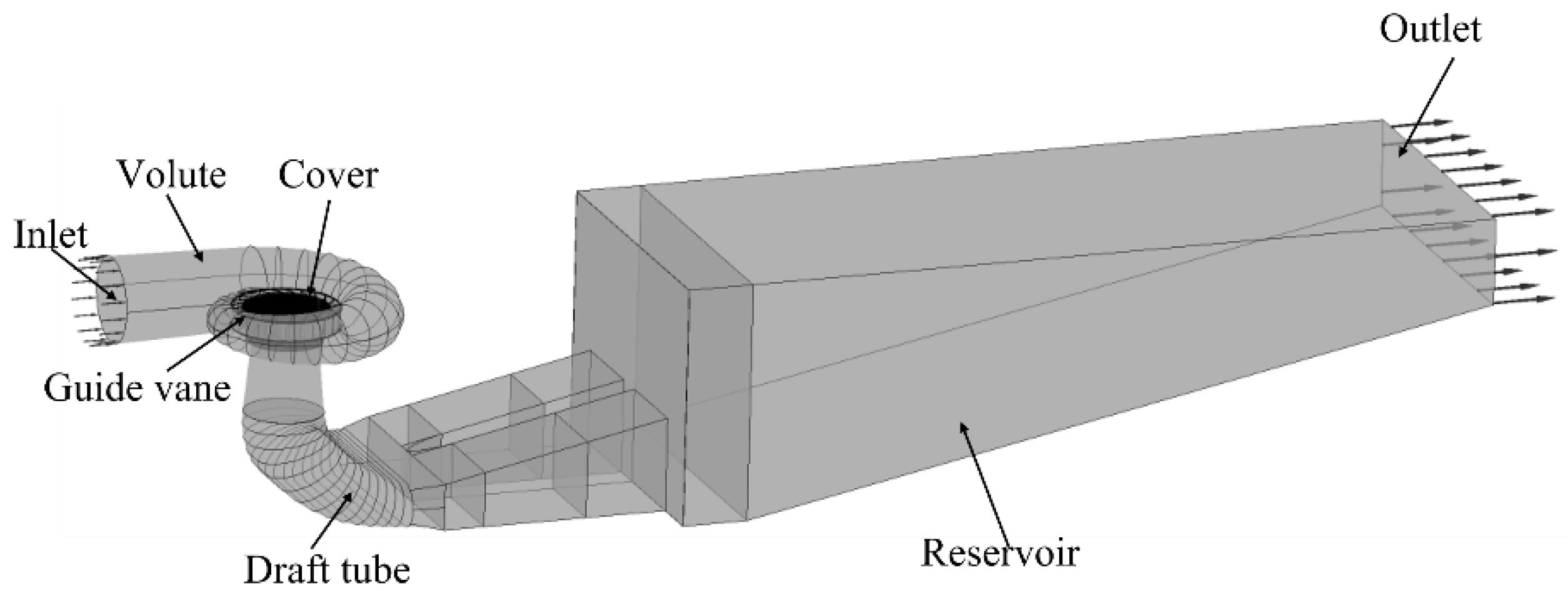

2.2. Simulation Geometry Model

2.2.1. Geometric Model Set Up

2.2.2. Parameter Setting in Calculation Model

- (1)

- Particle parameters

- (2)

- Boundary condition

- (3)

- Calculation parameters

3. Results

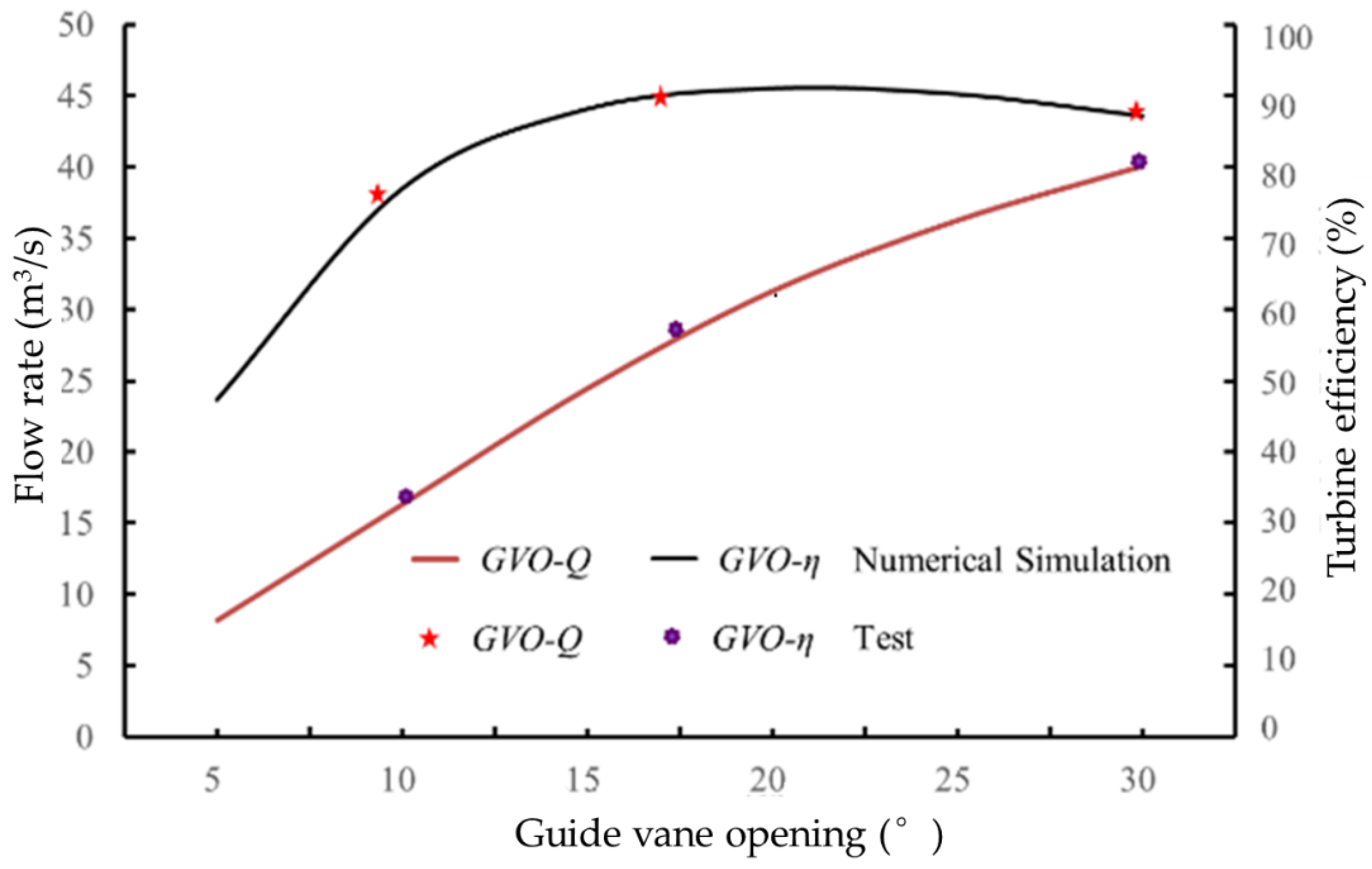

3.1. Reliability Verification of Calculation Model

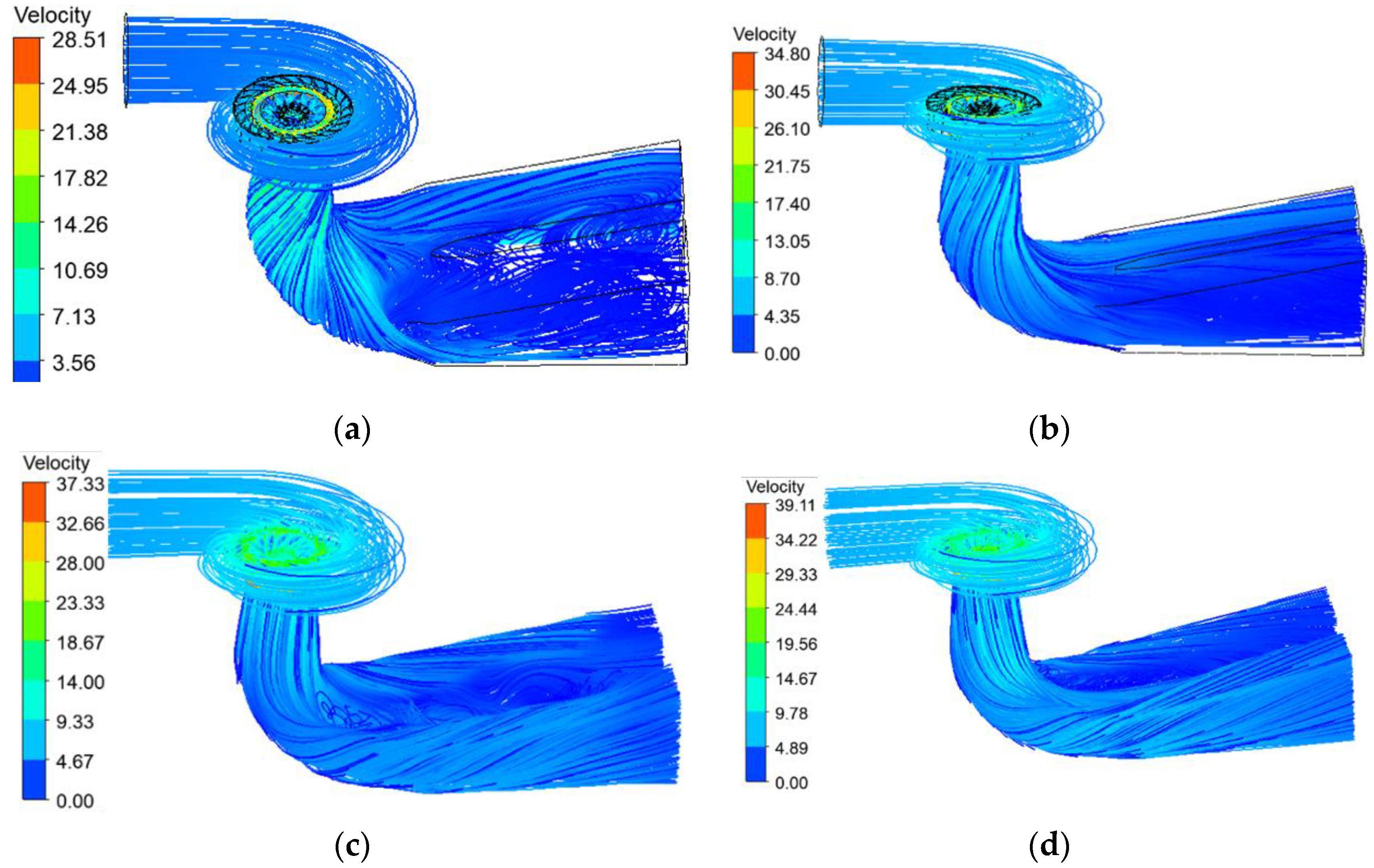

3.2. Flow Analysis under Different Guide Vane Opening

3.3. Analysis of Runner Wear under Different Guide Vane Opening

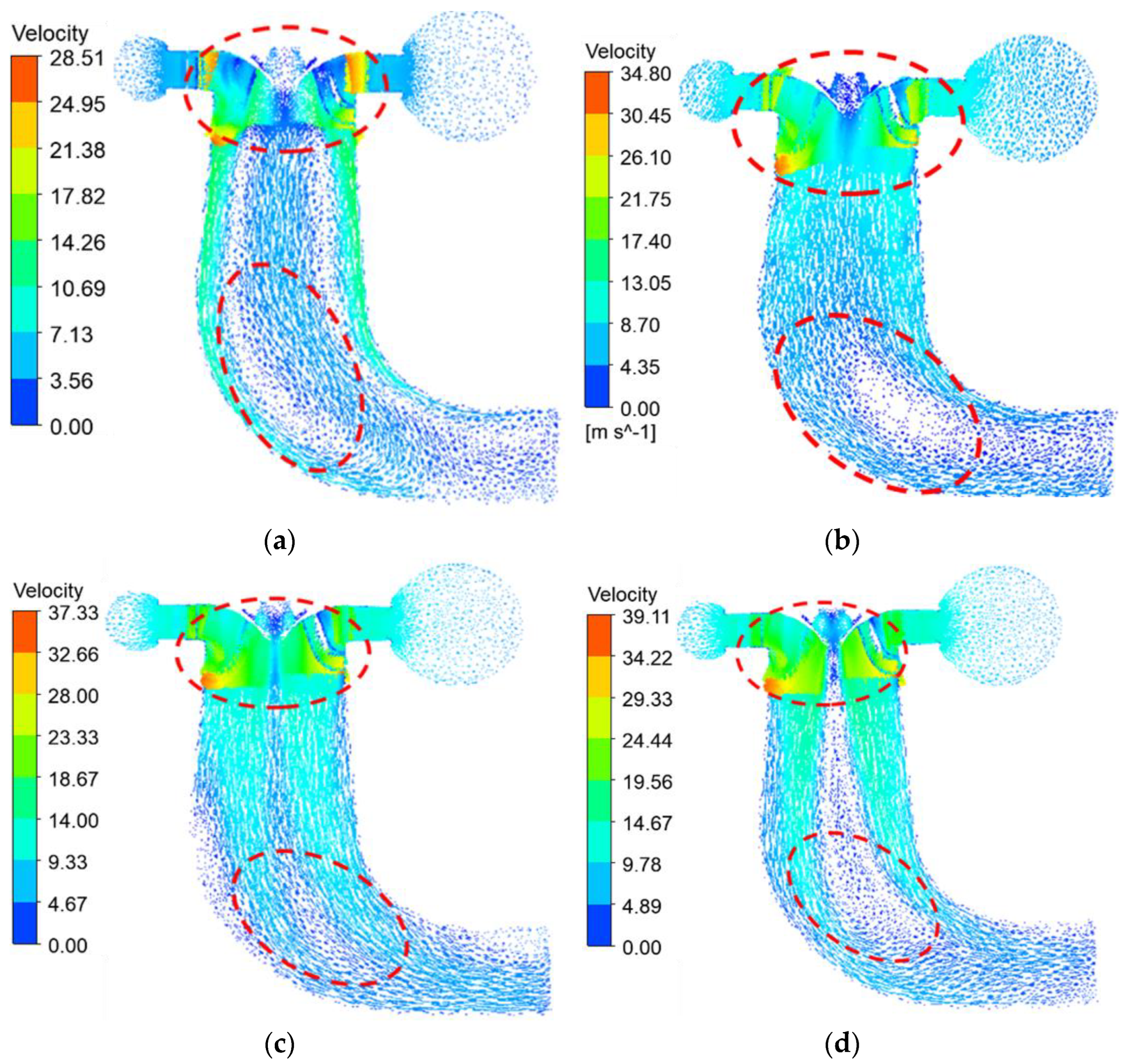

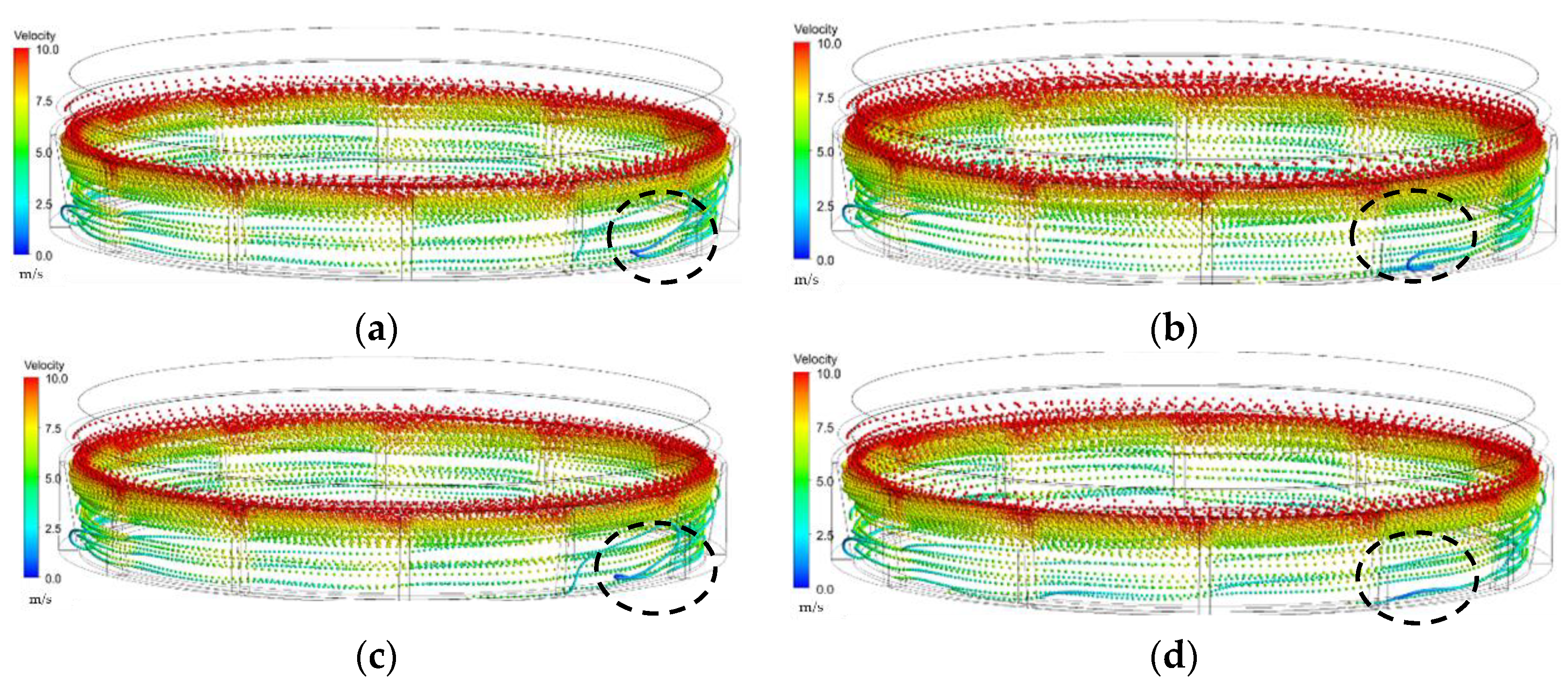

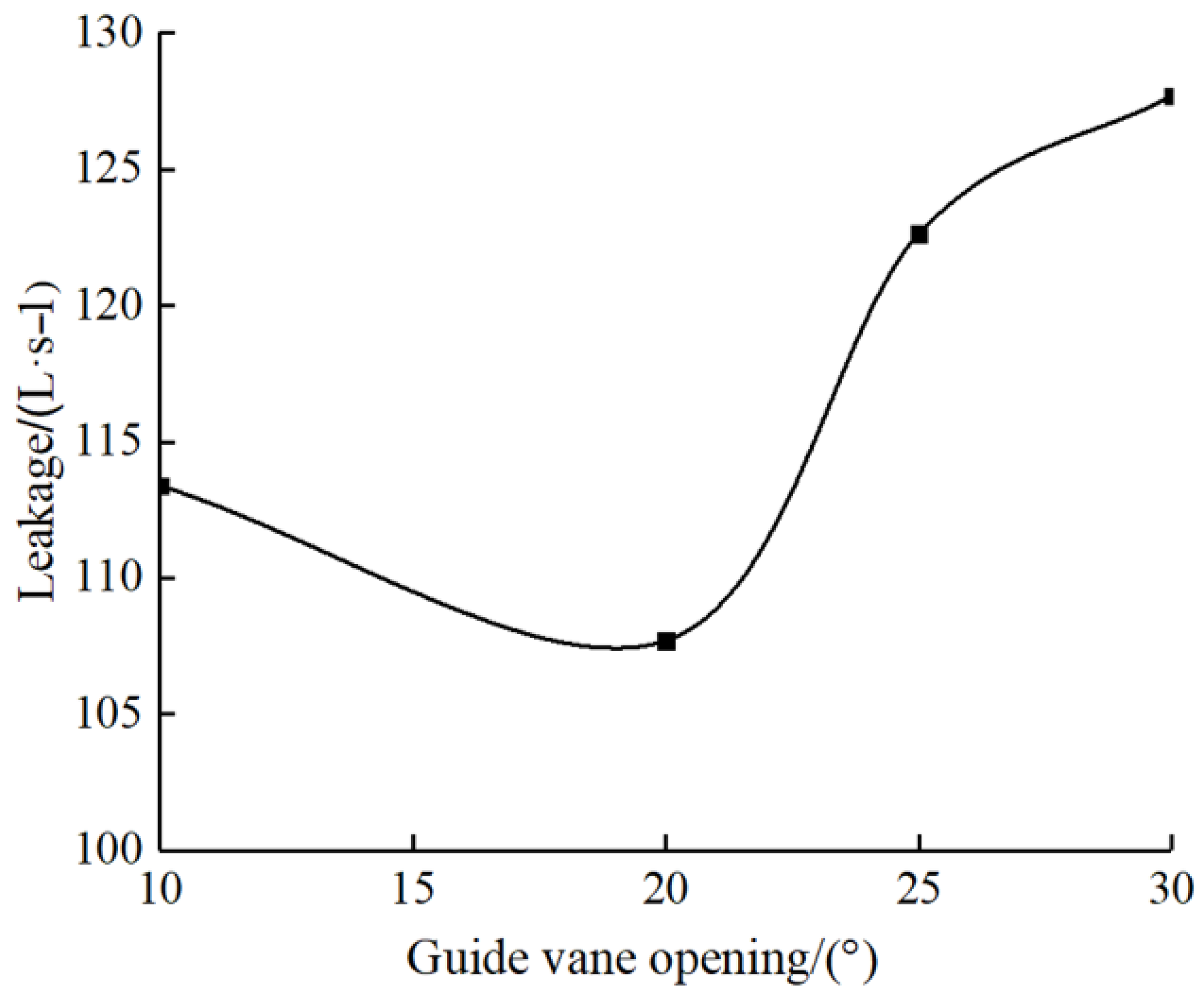

3.4. Particle Flow in the Lower Annulus under Different Guide Vane Opening

3.5. Erosion in the Band Clearance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ansari, B.; Aligholami, M.; Khosroshahi, A.R. An experimental and numerical investigation into using hydropower plant on oil transmission lines. Energy Sci. Eng. 2022. [Google Scholar] [CrossRef]

- Takaffoli, M.; Papini, M. Numerical simulation of solid particle impacts on Al6061-T6 part I: Three-dimensional representation of angular particles. Wear 2012, 292, 100–110. [Google Scholar] [CrossRef]

- Song, X.; Liu, C. Zhengwei Wang. Prediction on the pressure pulsation induced by the free surface vortex based on experimental investigation and Biot-Saval Law. Ocean Eng. 2022, 250, 110934. [Google Scholar] [CrossRef]

- Song, X.; Luo, Y.; Wang, Z. Numerical prediction of the influence of free surface vortex air-entrainment on pump unit performance. Ocean Eng. 2022, 256. [Google Scholar] [CrossRef]

- Cheng, X.; Dong, F.; Yang, C. The influence of particle diameter on friction loss intensity and collision wear loss intensity along blades of centrifugal pump. J. Lanzhou Univ. Technol. 2015, 41, 44. [Google Scholar]

- Song, X.; Liu, C. Experimental investigation of floor-attached vortex effects on the pressure pulsation at the bottom of the axial flow pump sump. Renew. Energy 2019, 145, 2327–2336. [Google Scholar] [CrossRef]

- Matsumura, T.; Shirakashi, T.; Usui, E. Identification of Wear Characteristics in Tool Wear Model of Cutting Process. Int. J. Mater. Form. 2008, 1, 555–558. [Google Scholar] [CrossRef]

- Koirala, R.; Thapa, B.; Neopane, H.P.; Zhu, B. A review on flow and sediment erosion in guide vanes of Francis turbines. Renew. Sustain. Energy Rev. 2017, 75, 1054–1065. [Google Scholar] [CrossRef]

- Qian, Z.; Gao, Y.; Zhang, K.; Huai, W.; Wu, Y. Influence of dynamic seals on silt abrasion of the impeller ring in a centrifugal pump. Proc. Inst. Mech. Eng. Part A J. Power Energy 2013, 227, 557–566. [Google Scholar] [CrossRef]

- Zhang, Y.; Qian, Z.; Ji, B.; Wu, Y. A review of microscopic interactions between cavitation bubbles and particles in silt-laden flow. Renew. Sustain. Energy Rev. 2016, 56, 303–318. [Google Scholar] [CrossRef]

- Smirnov, P.E. Sensitization of the SST turbulence model to rotation and curvature by applying the Spalart–Shur correction term. J. Turbomach. 2009, 131, 1407–1419. [Google Scholar] [CrossRef]

- Guo, B.; Xiao, Y.; Rai, A.K.; Zhang, J.; Liang, Q. Sediment-laden flow and erosion modeling in a Pelton turbine injector. Renew. Energy 2020, 162, 30–42. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Xianbei, H.; Qiang, G.; Baoyun, Q. Prediction of Air-Entrained Vortex in Pump Sump: Influence of Turbulence Models and In-terface-Tracking Methods. J. Hydraul. Eng. 2020, 146, 04020010. [Google Scholar]

- Celik, I.B.; Ghia, U.; Roache, P.J. Procedure for estimation and reporting of uncertainty due to discretization in CFD applications. J. Fluids Eng. 2008, 130, 078001-1–078001-4. [Google Scholar]

- Zeise, B.; Liebich, R.; Prölß, M. Simulation of fretting wear evolution for fatigue endurance limit estimation of assemblies. Wear 2014, 316, 49–57. [Google Scholar] [CrossRef]

- Shrestha, U.; Chen, Z.; Park, S.H.; Choi, Y.D. Numerical studies on sediment erosion due to sediment characteristics in Francis hydro turbine. IOP Conf. Ser. Earth Environ. Sci. 2019, 240, 042001. [Google Scholar] [CrossRef]

- Shen, Z.; Chu, W.; Li, X.; Dong, W. Sediment erosion in the impeller of a double-suction centrifugal pump—A case study of the Jingtai Yellow River Irrigation Project, China. Wear 2019, 422–423, 269–279. [Google Scholar] [CrossRef]

- Gautam, S.; Neopane, H.P.; Thapa, B.S.; Chitrakar, S.; Zhu, B. Numerical Investigation of the Effects of Leakage Flow From Guide Vanes of Francis Turbines using Alternative Clearance Gap Method. J. Appl. Fluid Mech. 2020, 13, 1407–1419. [Google Scholar]

- Xijie, S.; Chao, L. Experiment study of the floor-attached vortices in pump sump using V3V. Renew. Energy 2021, 164, 752–766. [Google Scholar] [CrossRef]

- Fan, M.; Yanjun, L.; Ji, P. Energy Characteristics of Full Tubular Pump Device with Different Backflow Clearances Based on Entropy Production. Appl. Sci. 2021, 11, 3376. [Google Scholar]

- Karakas, E.S.; Watanabe, H.; Aureli, M.; Evrensel, C.A. Cavitation Performance of Constant and Variable Pitch Helical Inducers for Centrifugal Pumps: Effect of Inducer Tip Clearance. J. Fluids Eng. 2020, 142, 1–19. [Google Scholar] [CrossRef]

- Daqiq Shirazi, M.; Torabi, R.; Riasi, A. The effect of wear ring clearance on flow field in the impeller sidewall gap and efficiency of a low specific speed centrifugal pump. Proc. Inst. Mech. Eng. Part C (J. Mech. Eng. Sci.) 2018, 232, 3062–3073. [Google Scholar] [CrossRef]

- Takaffoli, M.; Papini, M. Numerical simulation of solid particle impacts on Al6061-T6 Part II: Materials removal mechanisms for impact of multiple angular particles. Wear 2012, 296, 648–655. [Google Scholar] [CrossRef]

- Zhu, Y.; Lu, J.; Liao, H.; Wang, J.; Fan, B.; Yao, S. Research on cohesive sediment erosion by flow: An overview. Sci. China Technol. Sci. 2008, 51, 2001–2012. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, X.; Zhou, X.; Song, H.; Deng, J.; Wang, Z. Study on the Effect of the Guide Vane Opening on the Band Clearance Sediment Erosion in a Francis Turbine. J. Mar. Sci. Eng. 2022, 10, 1396. https://doi.org/10.3390/jmse10101396

Song X, Zhou X, Song H, Deng J, Wang Z. Study on the Effect of the Guide Vane Opening on the Band Clearance Sediment Erosion in a Francis Turbine. Journal of Marine Science and Engineering. 2022; 10(10):1396. https://doi.org/10.3390/jmse10101396

Chicago/Turabian StyleSong, Xijie, Xuhui Zhou, Huating Song, Jianhua Deng, and Zhengwei Wang. 2022. "Study on the Effect of the Guide Vane Opening on the Band Clearance Sediment Erosion in a Francis Turbine" Journal of Marine Science and Engineering 10, no. 10: 1396. https://doi.org/10.3390/jmse10101396

APA StyleSong, X., Zhou, X., Song, H., Deng, J., & Wang, Z. (2022). Study on the Effect of the Guide Vane Opening on the Band Clearance Sediment Erosion in a Francis Turbine. Journal of Marine Science and Engineering, 10(10), 1396. https://doi.org/10.3390/jmse10101396