1. Introduction

The maritime industry is increasingly aware of its environmental impact and is always looking for a cleaner alternative marine fuel [

1,

2]. Among alternative marine fuels, liquefied natural gas (LNG) is one of the most popular alternative marine fuels because it is one of the cleanest fossil marine fuels and can significantly reduce ship exhaust emissions, including sulfur oxides, nitrogen oxides, particulate matter, and greenhouse gases [

1,

3]. Specifically, compared to conventional heavy fuel oils, the use of LNG means a 100% reduction in sulfur dioxide (

) and fine particle (

) emissions, a 90% reduction in nitrogen oxide (

) emissions, and a 25% reduction in carbon dioxide (

) emissions [

4]. Fueling ships with LNG can bring many benefits, such as less fuel consumption and fewer air emissions. The density of LNG is roughly in the range of 410 kg/

to 500 kg/

[

5], and the density of conventional heavy fuel oils is greater than 900 kg/

at 15 °C [

6]. The calorific value of LNG is around 54 MJ/kg to 56 MJ/kg [

7], and the calorific value of conventional heavy fuel oils is around 46 MJ/kg [

8]. Therefore, since LNG is about half the density of conventional heavy fuel oils but has about 20% higher calorific value, [

9] stated that it takes about 1.8 times as much LNG to achieve the same distance compared to conventional heavy fuel oils on a volume (

) basis. Since our problem is very complex, we simplify the problem by assuming that the combustion efficiencies of LNG and conventional fuel oil are equal and assume that it takes about 1.8 times as much LNG to achieve the same distance compared to conventional heavy fuel oils on a volume (

) basis. This feature of LNG is essential to achieve green shipping and helps shipping liners meet increasingly stringent environmental regulations. As a result, more and more shipping liners, such as German shipping company Hapag-Lloyd [

10], and China shipping company China Ocean Shipping Company (COSCO) [

11], purchase dual-fuel ships which can burn both conventional fuel oil, i.e., low-sulphur fuel oil (LSFO) and LNG.

A serious problem faced by dual-fuel ships is methane slip (unburned fuel is expelled in the exhaust) from the main and auxiliary engines of the ship. This phenomenon is because LNG primarily consists of methane (85% to 99%) [

12], and engines using LNG as a fuel are usually designed to have a combustion efficiency of at least 98%, which means the other 2% of unburned methane is expelled in the exhaust [

4]. As a potent greenhouse gas, methane has more than 25 times the global warming potential of carbon dioxide after it reaches the atmosphere [

13]. Especially in the first 20 years after entering the atmosphere, methane is more than 80 times more potent than

[

14]. Although methane is up to 25 times more potent as a greenhouse gas than

, methane has a relatively short lifespan of 12 years compared to

which can hang around for hundreds or even thousands of years [

15]. In addition, LNG can significantly reduce ship emissions, including sulfur oxides, nitrogen oxides, particulate matter, and greenhouse gases. Therefore, dual-fuel ships are becoming more and more popular. Although carbon dioxide has a more lasting effect, methane determines the pace of global warming in the near term. Therefore, how to schedule dual-fuel ships is a vital issue for the decarbonization of the shipping industry.

This study is motivated by the above real-world problem encountered in sustainable development. LNG can allow the shipping industry to significantly reduce , , , and , but it results in the leakage of more potent greenhouse gas, i.e., methane. Therefore, for the dual-fuel ships which become more and more popular, how to schedule them is particularly important. Since sailing speed affects the fuel consumption of both main and auxiliary engines and further affects ship refueling and fleet deployment, this study aims to integrate fleet deployment, ship refueling, and speed optimization into a comprehensive problem for dual-fuel ships with the consideration of fuel consumption of both main and auxiliary engines, ship carbon emissions, availability of LNG at different ports of call, and methane slip from ships’ main engines. Specifically, this study formulates a nonlinear mixed-integer programming (MIP) model for the integrated problem to optimally determine the number of deployed ships, at which port and how much fuel (and which fuel) the deployed ships should be refueled, and sailing speeds of deployed ships during each voyage leg. A large number of numerical experiments with different route compositions are carried out to evaluate the proposed model after linearization transformation. Sensitivity analyses with crucial parameters, including the price difference between LSFO and LNG, carbon tax, and methane slip amount, are then conducted to investigate the influence of these factors on the operational decisions to seek managerial insights. Therefore, this study provides shipping liners with scientific methods to optimize fleet deployment, ship refueling, and speed optimization for dual-fuel ships with the consideration of methane slip to minimize the total weekly cost which contains three parts, namely weekly fixed operating cost, weekly fuel purchase cost, and weekly carbon emissions cost. In summary, this study may contribute to liner operations management by proposing an integrated optimization method and seeking managerial insights for the joint planning problem of fleet deployment, ship refueling, and speed optimization for dual-fuel ships considering methane slip.

The fleet deployment problem is generally based on the container liner shipping mode. For a comprehensive overview of the container liner fleet deployment, readers can refer to [

16]. This study focuses on the joint optimization problem of fleet deployment, ship refueling, and speed optimization to minimize the total weekly cost, including the fixed operating cost, fuel purchase cost, and carbon emissions cost based on a weekly service frequency. Speed optimization is the issue most closely related to fleet deployment because different speeds directly affect the number of ships that need to be deployed. Therefore, the fleet deployment problem considering speed optimization is widely studied, and this study first reviews related research on the fleet deployment problem considering speed optimization. This study then reviews related research on joint optimization of fleet deployment, ship refueling, and speed optimization.

The first perspective is related to fleet deployment considering speed optimization. On the one hand, container cargos are usually transported by ships along fixed ship routes at a regular service frequency. Therefore, optimizing speeds is equivalent to determining the number of ships deployed on various routes. To maintain a fixed service frequency, the higher the sailing speed is, the smaller the number of deployed ships. [

17] developed a generalized nonlinear MIP model to allocate different types of ships on each route. They found that the optimal service frequency leads to fewer operating costs than the fixed service frequency. [

18] studied a joint optimization problem of service frequency, sailing speed, and the number of ships deployed on a service route for a long-haul liner service route. They used a piecewise linear function to approximate the fuel consumption function. [

19] considered service time windows for ports of call, and balanced low sailing speeds and high schedule reliability in their model. On the other hand, bunker fuel cost can significantly impact the daily operating cost of a container ship. In practice, sailing speed, cargo load, displacement, voyage length, and sea and weather conditions could significantly impact fuel consumption. Lower fuel consumption causes lower daily operating costs. Considering a general fuel consumption function, [

20] integrated fleet deployment, speed optimization, and cargo allocation to maximize the total profit at the strategic level. [

21] fitted the fuel consumption rate based on shipping log data and proposed two bunker fuel consumption rate functions for shipping liners under different scenarios. To reduce the sulfur emissions, [

22] proposed a joint ship path, speed, and deployment problem to minimize the total cost of all routes, including fuel cost, carbon tax, and fixed operating cost. They considered relationships between ship speed and low-sulfur fuel consumption in international Emission Control Areas (ECAs) where ships must use low-sulfur fuels.

Refueling policy is another issue that could significantly influence the total operating costs of fleet deployment, especially when the fuel price is uncertain [

23,

24,

25]. Thus, some studies integrate both speed optimization and refueling policy into the fleet deployment problem [

26]. Proposed a nonlinear MIP model, which optimized refueling policy, speed selection, and fleet deployment. They aimed to minimize the sum of transportation, fuel consumption, and carbon emissions costs. In practice, the fuel consumption of ships on different sailing legs and the fuel prices at each port are uncertain. To mitigate the impacts of uncertainty, [

23] investigated a dynamic bunker fuel management and ship operation problem. They developed a nonlinear MIP model to determine refueling ports, refueling amount, sailing speed, and the number of deployed ships on a route based on a weekly service. Recently, sustainable shipping development have also drawn much attention [

27,

28,

29,

30]. To reduce emissions from ships, such as carbon emissions, some scholars consider using low-carbon or low-sulfur fuels in compliance with international regulations. Some studies, such as [

22,

31], differentiated the sulfur content of the fuels when ships sail within ECAs and outside ECAs in their mathematical model. In addition to shipping deployment, sailing speed, and bunkering optimization, some studies included route selection as one of the decisions, such as [

32,

33,

34,

35].

To sum up, fleet deployment, ship refueling, and speed optimization are three main factors for shipping liners to control daily costs. However, most studies focus on only one or two aspects of them. Specifically, the prevailing literature on the fleet deployment problem considering speed optimization mainly focuses on balancing the service frequency, the number of deployed ships, and sailing speeds. Research on comprehensive optimization of fleet deployment, ship refueling, and speed optimization is still limited, especially in the domain of sustainable shipping development. To fill this research gap, this paper studies an integrated optimization problem of fleet deployment, ship refueling, and speed optimization. Since LNG is viewed as a cleaner alternative to fuel oil and coal, this study considers dual-fuel ships which could use LSFO and LNG for the main engine of the ship along a fixed route and proposes a nonlinear MIP model to minimize the total weekly cost by simultaneously optimizing fleet deployment, ship refueling policy (LSFO or LNG), and sailing speed. In addition, the problem studied in this paper could be seen as a lower-level decision of the problem involving routing, and can be easily extended to incorporate the route selection.

The remainder of this paper is organized as follows.

Section 2 describes the problem, formulates a nonlinear MIP model for the problem, and applies several linearization techniques to linearize the model.

Section 3 reports the results of computational experiments including the basic analysis to evaluate the model and sensitivity analyses to seek managerial insights. Conclusions including contributions and limits of our paper are summarized in

Section 4.

2. Materials and Methods

This study focuses on an integrated optimization problem of fleet deployment, ship refueling, and speed optimization for dual-fuel ships, with the consideration of fuel consumption of both main and auxiliary engines, ship carbon emissions, availability of LNG at different ports of call, and methane slip from ships’ main engines. This section first elaborates on the detailed background of the problem in

Section 2.1, formulates the mathematical model in

Section 2.2, and linearizes nonlinear parts in the proposed model line in

Section 2.3.

2.1. Problem Background

We consider a shipping liner which operates a fleet of container ships to provide a fixed liner shipping service at a weekly service frequency. The shipping service is described as a loop ship route consisting of a set

of ports of call. The voyage from port of call

to port of call

is called leg

. In this case, ship route is described as port 1

port 2

port

port 1, implying that the route has

legs. To maintain weekly visits for every port of call on the route, a fleet of ships needs to be deployed on the route, and the total time for a ship finishing the travel along the route is

h, where

represents the number of deployed ships on the route. Sailing speeds of all deployed ships need to be between the feasible speed range of ships, and let

represent the set of all possible sailing speeds. The total time for a ship finishing the travel along the route consists of two parts, namely sailing time and dwell time. Specifically, the total sailing time can be calculated by

, where

,

, and

are length (

n mile) of the

leg, sailing speed (knot) during the

leg, and a binary variable which equals 1 if, and only if, the speed of the ship sailing during leg

is

, and 0 otherwise, respectively. In reality, port dwell time is usually predetermined based on contracts between shipping liners and the port operator, so this study assumes the dwell duration (hour) of a ship at port of call

, represented by

, is deterministic. Hence, the total number of deployed ships and the total time for each deployed ship finishing the travel along the route should have the following relationship:

.

All ships operated by the shipping liner are dual-fuel ships that consume either LNG or LSFO. Each ship contains a main engine which provides propulsion power for the ship, and an auxiliary engine which provides power for uses except propulsion. Because of the news from [

36] which indicates that auxiliary engines of LNG ships leak more climate-warming methane than main engines, this study assumes that auxiliary engines of the ships only burn LSFO, and main engines of the ships can burn LSFO or LNG. Hence, let

represent a binary variable which equals 1 if and only if the fuel option of the main engine of deployed ships during leg

,

, is LSFO, and 0 LNG. In terms of fuel consumption of auxiliary engines, this study assumes the auxiliary engine of each deployed ship consumes

amount of LSFO per hour. However, fuel consumption of the main engine is more complicated because the main engine can burn LSFO or LNG. The speed of a ship has a nonlinear relationship with fuel consumption. Specifically, engine theory and empirical data show that the daily fuel consumption of a ship is roughly proportional to the cube of the speed [

37]. Furthermore, [

38] calibrated the relationship between fuel consumption and sailing speed for container ships by using realistic historical data. Therefore, in the case of LSFO burning on the main engine, most of existing fuel consumption models in the literature agreed that bunker consumption rate (ton/n mile) of main engines is assumed to be a power function of sailing speed

, i.e.,

, where

is sailing speed (knot), and

and

are positive coefficients. Therefore, the total amount of LSFO consumed by the main engine of a ship completing the travel along the route is

. Furthermore, in the case of LNG burning on the main engine, we define two more positive coefficients

and

for the calculation of fuel consumption because LNG has a lower density and higher calorific value than LSFO [

39]. In addition, from the news from [

36], when burning LNG, ships’ main engines leak 2% unburned LNG in the exhaust. This phenomenon, also known as methane slip, is because engines using LNG as a fuel are usually designed to have a combustion efficiency of at least 98%, which means the other 2% of unburned methane is expelled in the exhaust [

4]. Hence, the total amount of LNG consumed by the main engine of a ship completing the travel along the route is

, where

represents the amount of LNG leaked from the main engine of a deployed ship per hour when burning LNG (ton/h).

At some ports, deployed ships have to refill LSFO or LNG to sustain the voyage. This study assumes all ports of call can offer LSFO bunkering facilities, but only several ports of call can offer LNG bunkering facilities because this assumption is close to reality, and let a binary parameter

,

, to represent the availability of LNG refueling at port of call

which equals 1 if, and only if, port of call

offers LNG bunkering facilities, and 0 otherwise. At each port of call, the amount of fuel added should be determined (we assume that bunkering time is short and can thus be ignored, and that bunker is refilled as soon as the ship arrives at the port of call). We denote by

and

the amount of LSFO and the amount of LNG refueled at port of call

(ton), respectively. If

port of call does not offer LNG bunkering facilities, i.e.,

, the value of

must equal 0. In addition, the bunker amount in the tank after refilling should not exceed the tank capacity. The capacity limit of tanks in ships for storing LNG is a factor that cannot be ignored and has been considered in the existing literature, such as [

1,

40]. The capacity of the tank for storing LNG is denoted by

, and the capacity of the tank for storing LSFO is assumed to be infinite. Let

, and

represent ship LSFO inventory level, and ship LNG inventory level when arriving at port of call

(ton), respectively. Hence, after refueled at port of call

, ship LSFO inventory level (

) or LNG inventory level (

) should be larger than fuel consumption during sailing time of leg

and dwell time at port of call

. In addition, fuel switch of the main engine is not allowed during each voyage, that is, the main engine of each deployed ships can only use one kind of fuel (LSFO or LNG) during each voyage, and cannot switch the fuel back and forth. The remaining LSFO amount of the ship (i.e.,

), and the remaining LNG amount of the ship (i.e.,

) arriving at the next port of call can thus be calculated by Equations (2) and (3), respectively. Finally, because the ship sails in a round trip, for sustainability purpose, we consider that the bunker level after finishing the round trip should be equal to the initial bunker level, i.e., Equations (4) and (5).

Finally, this study aims to minimize the total weekly cost which contains three parts, namely weekly fixed operating cost, weekly fuel purchase cost, and weekly carbon emissions cost. Specifically, first part is the weekly fixed operating cost of deployed ships. Because a fleet of homogeneous ships is deployed on the route to maintain a weekly service frequency, the total fixed operating cost for all deployed ships on all routes during one week can be calculated as

, where

represents the weekly fixed operating cost for deploying one ship on the ship route. Next is the weekly fuel purchase cost. Recall that

and

represent the amount of LSFO and the amount of LNG refueled at port of call

(ton), respectively. Hence, the weekly fuel purchase cost can be calculated by

, where

, and

represent unit price of LSFO (USD/ton), and unit price of LNG (USD/ton) at port of call

, respectively. The final part is the weekly carbon emissions cost of all deployed ships on the ship route. [

26] stated that ship carbon emissions are mostly from engine fuel consumption. Recall that each ship contains a main engine and an auxiliary engine. First, let

,

, and

represent the amount of

(ton) generated when burning one ton of LSFO, the amount of

generated (ton) when burning one ton of LNG, and carbon tax per ton (USD/ton), respectively. Weekly fuel consumption of auxiliary engines of all deployed ships on the ship route is

because a week contains

h. In addition, weekly fuel consumption of ships’ main engines on the ship route can be calculated by

. Hence, the weekly carbon emissions cost of all deployed ships on the ship route can be calculated by

.

In summary, this study considers fuel consumption of both main and auxiliary engines, ship carbon emissions, availability of LNG at different ports of call, and methane slip from ships’ main engines. From the perspective of the shipping liner, this study develops a nonlinear MIP model to minimize the total weekly cost by determining fleet deployment, ship refueling strategies including LNG and LSFO, and sailing speed of all deployed ships.

2.2. Model Formulation

Based on the above analysis of the problem, we formulate a nonlinear MIP model in this section. The following two assumptions are considered in this study.

- (I)

The ships are homogenous in terms of the LNG tank capacity and cost structure.

- (II)

The ships’ dwell time at each port of call on the ship route is deterministic.

Before formulating the mathematical model for this problem, we list the notation used in this paper as follows.

Indices and sets:

set of all ports of call (legs) on the ship route, .

set of all possible sailing speeds, , , where and represent the minimum and maximum speeds of ships on ship routes, respectively.

set of all non-negative integers.

Parameters

unit price of LSFO at port of call (USD/ton).

unit price of LNG at port of call (USD/ton).

binary coefficient to represent the availability of LNG refueling at port of call which equals 1 if and only if port of call offers LNG bunkering facilities, and 0 otherwise.

coefficients to calculate the unit fuel consumption for travelling per n mile, which mainly depends on sailing speed (ton/ n mile).

amount of LSFO consumed by the auxiliary engine of a ship deployed on the ship route per hour (ton/h).

amount of LNG leaked from the main engine of a deployed ship when burning LNG per hour (ton/h).

amount of generated when burning one ton of LSFO (ton).

amount of generated when burning one ton of LNG (ton).

length (n mile) of the th () leg on the ship route.

capacity of the tank for storing LNG.

weekly fixed operating cost of one ship deployed on the ship route.

carbon tax per ton (USD/ton).

maximum number of ships that can be deployed on the ship route.

dwell duration (hour) of a ship at port of call on the ship route.

Variables

binary, equals 1 if and only if the speed of the ship sailing during leg on the ship route is ; 0 otherwise.

binary, equals 1 if and only if the fuel option of the main engine of deployed ships during leg , , on the ship route is LSFO; 0 LNG.

integer, number of ships deployed on the ship route.

continuous, amount of LSFO refueled at port of call (ton).

continuous, amount of LNG refueled at port of call (ton).

continuous, ship LSFO inventory level when arriving at port of call (ton).

continuous, ship LNG inventory level when arriving at port of call (ton).

Mathematical model

Based on the above definition of parameters and variables, a nonlinear MIP model is formulated as follows.

subject to:

Objective (6) minimizes the total weekly cost considered in this study, namely the sum of weekly fixed operating cost, weekly fuel purchase cost, and weekly carbon emissions cost. Constraint (7) guarantees that at least one ship and at most ships should be deployed on the ship route. Constraint (8) ensures the weekly arrival pattern for each port of call. Constraints (9) ensure that sailing speeds of deployed ships during each leg should be within the feasible speed range of ships. Constraints (10) guarantee that deployed ships can only refuel LNG at ports of call where LNG bunkering facilities are provided and that the LNG amount in the tank after refilling should not exceed the LNG tank capacity. Constraints (11) and (12) calculate the remaining LSFO amount, and the remaining LNG amount of the ship arriving at the next port of call, respectively. Constraints (13) and (14) ensure that the LSFO level, and LNG level at the tank after finishing the round trip should be equal to the initial LSFO level, and initial LNG level, respectively. Constraints (15)–(18) state the ranges of the defined decision variables.

2.3. Model Linearization

It is challenging to solve the nonlinear model [M1], which contains multiple nonlinear parts including objective function (6), constraints (11)–(14). Therefore, some linearization techniques are applied to constraints (11)–(14) and objective function (6). Several newly defined variables and constraints are summarized as follows:

Newly defined variables

→binary, equals 1 if and only if both variables and are equal to one; 0 otherwise.

Newly defined constraints Then, nonlinear constraints (11)–(14) are replaced by linear constraints (23)–(26), respectively.

Next, we linearize the nonlinear part

in objective function (6), which can be rewritten as

. Because of constraints (19)–(22),

can be further rewritten as

. In addition, constraints (8) need to be transformed to constraints (27) because sailing speeds of ships are discrete.

As a result, the final version of the model [M1] becomes:

subject to: Constraints (7), (9), (10), (15), and (27).

4. Conclusions

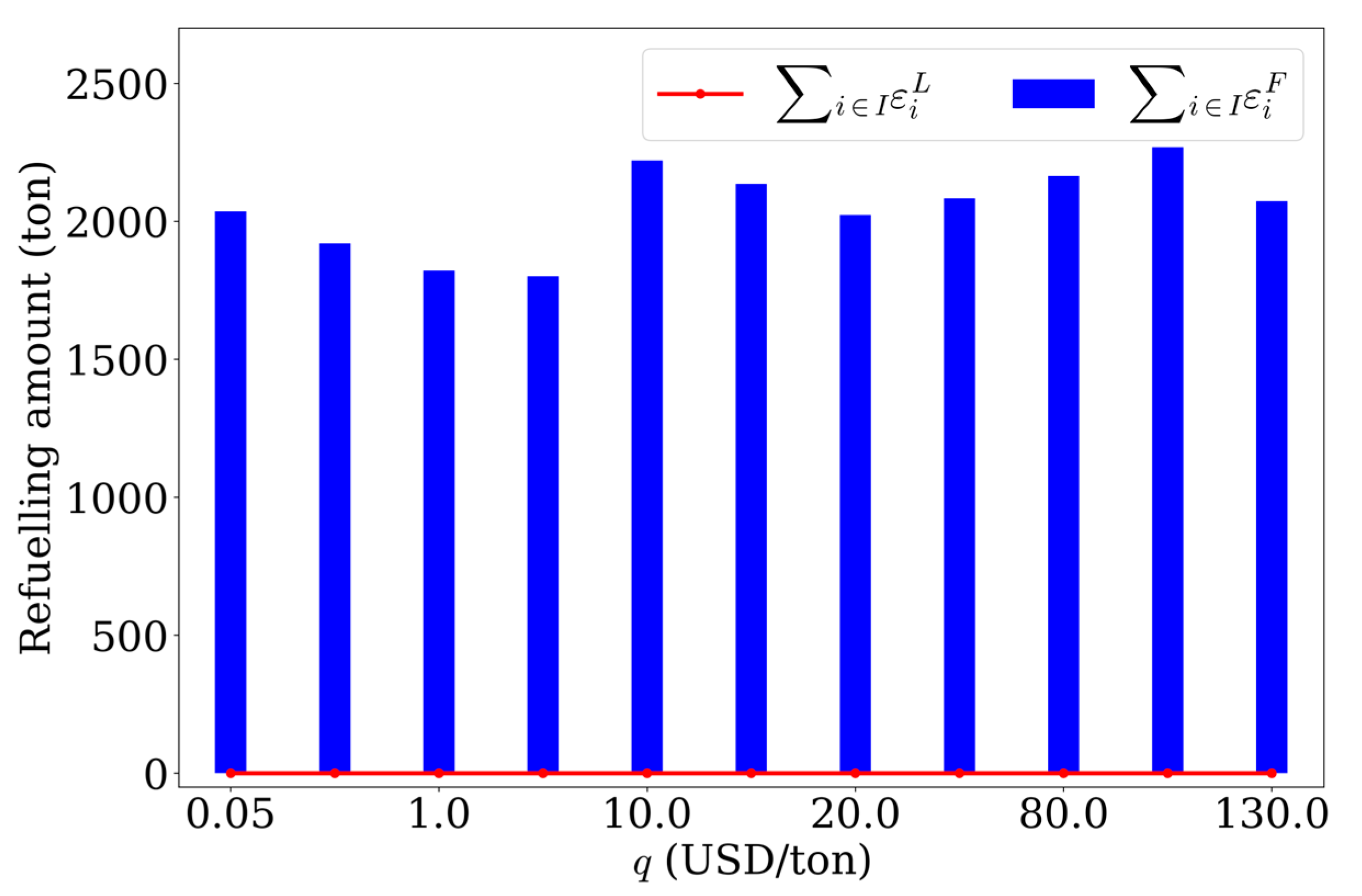

Growing environmental awareness and strict regulations from international organizations are forcing shipping liners to reduce pollution. Faced with this phenomenon, the use of dual-fuel ships is one of the most promising options for reducing pollution from the shipping industry. However, existing literature lacks research on the comprehensive optimization problem of fleet deployment, ship refueling, and speed optimization for dual-fuel ships considering methane slip. To fill this research gap, this study formulates a nonlinear MIP model for dual-fuel ships with the consideration of fuel consumption of both main and auxiliary engines, ship carbon emissions, availability of LNG at different ports of call, and methane slip from ships’ main engines. Contributions of this paper are summarized from the following two aspects: first, a nonlinear MIP model is proposed for the integrated optimization problem of fleet deployment, ship refueling, and speed optimization for dual-fuel ships to optimally determine the number of deployed ships, at which port and how much fuel (and which fuel) the deployed ships should be refueled, and sailing speeds of deployed ships during each voyage leg. To deal with the challenge of solving a nonlinear MIP model, several linearization techniques are applied to transform it to a linear model which can be solved directly by off-the-shelf solvers. The proposed linearized model can be solved quickly by Gurobi, namely shorter than 0.12 s, which implies the possibility of applying the proposed model to practical problems to help decision-makers of shipping liners make operational plans. Secondly, sensitivity analyses with important parameters, such as the price difference between LSFO and LNG, carbon tax, and methane slip amount, are conducted to show the influences of these factors on the results to seek managerial insights. For example, when the price difference between LSFO and LNG varies from 0 to 500 USD/ton, there is no need to deploy more ships in order to save the fuel cost by choosing slow steaming. Additionally, even under the existing strictest carbon tax policy, shipping liners do not need to deploy more ships and slow steaming to reduce the total weekly cost. In addition, methane slip affects the choice of oil types for ships. When methane slip exceeds 0.27 ton/h, ships no longer burn LNG.

However, there are some limitations for the current methodology. This study does not consider uncertainty. Since fuel prices change dramatically from time to time, uncertain fuel prices may be incorporated into the problem in the future. In addition, although shipping inevitably produces

, how to utilize the

produced can be investigated to reduce the environmental impact of shipping [

50]. Moreover, advanced sustainability assessment tools, e.g., life cycle assessment and exergy analysis, may be used when studying sustainability features of the shipping industry [

51]. Finally, other alternative marine fuels, such as hydrogen and biofuels [

52,

53,

54], can be investigated to seek more managerial insights. In general, this study provides a scientific approach to help manage liner operations for dual-fuel ships in in the context of maritime decarbonization.