Influence of Stern Rudder Type on Flow Noise of Underwater Vehicles

Abstract

:1. Introduction

2. Numerical Approach

2.1. Large Eddy Simulation(LES)

2.2. FW-H Acoustic Analogy Method

3. Verification and Validation

4. Influence of Sail on Flow Noise

5. Influence of Stern Rudders on the Flow Noise

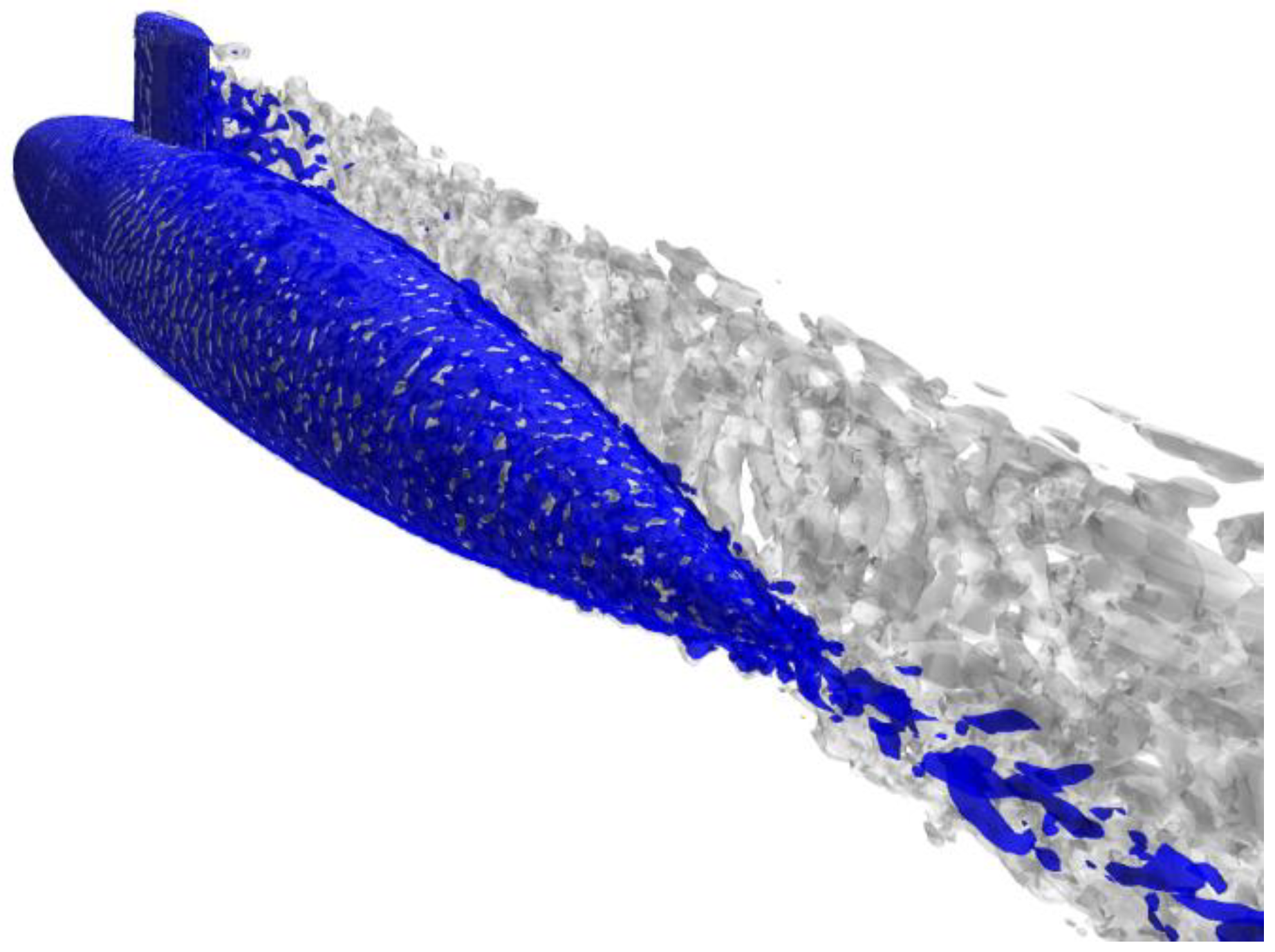

5.1. Flow Field Simulation Results

5.2. Simulation Results of Flow Noise of Underwater Vehicle with Full Appendages

5.3. Simulation Results of Flow Noise at Stern Rudders

6. Conclusions

- The results of the flow noise simulation of an underwater vehicle with a sail showed that the existence of a sail significantly increases the sound energy in the horizontal section, and the sound pressure level increases by 10–15 dB.

- The velocity fields and Q-contour figures of different stern rudder types showed that the stern rudders were observed in the disturbance generated by the sail. The degree of impact was as follows: cross-type rudders is greater than X-type rudders, and X-type is greater than T-type rudders.

- The flow noise simulation results showed that the sound pressure level of the flow noise was also larger for the stern rudder types, which were heavily influenced by sail vortex shedding. This was evident from the sound pressure level directivity of the three sections and sound pressure level of all monitoring points. The relationship of sound pressure level of the three types of stern rudders was as follows: cross-type rudders is greater than X-type rudders, and X-type is greater than T-type rudders.

- The flow noise simulation results for each single rudder surface showed that the sound pressure level of the upper rudder of the cross-type rudder was significantly larger than that of the lower rudder and left rudder. The sound pressure level of the upper left rudder of the X-type rudder was significantly higher than that of the lower left rudder. Furthermore, T-type rudders exhibited lower sound pressure levels on the left and lower rudders. The results showed that X-type rudders, particularly T-type rudders, could significantly reduce the sound pressure level of stern rudder noise.

- The noise frequencies generated by the sail and stern rudders were mainly concentrated at low frequencies, whereas the peak frequency of the noise generated by the vehicle body was mainly in the middle frequency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bechara, W.; Bailly, C.; Lafon, P.; Candel, S.M. Stochastic approach to noise modeling for free turbulent flows. AIAA J. 1994, 32, 455–463. [Google Scholar] [CrossRef] [Green Version]

- Ewert, R. Broadband slat noise prediction based on CAA and stochastic sound sources from a fast random particle-mesh (RPM) method. Comput. Fluids 2008, 37, 369–387. [Google Scholar] [CrossRef]

- Kolb, A.; Mancini, S.; Rossignol, K.-S.; Ewert, R. Flap Side-Edge Noise Simulation Using RANS-based Source Modelling. In Proceedings of the AIAA Aviation 2020 Forum, Reston, VA, USA, 15–19 June 2020; p. 2581. [Google Scholar]

- Skudrzyk, E.; Haddle, G. Noise production in a turbulent boundary layer by smooth and rough surfaces. J. Acoust. Soc. Am. 1960, 32, 19–34. [Google Scholar] [CrossRef]

- Cottet, G.-H.; Koumoutsakos, P.D. Vortex Methods: Theory and Practice; Cambridge University Press: Cambridge, UK, 2000; Volume 8. [Google Scholar]

- Powell, A. Theory of vortex sound. J. Acoust. Soc. Am. 1964, 36, 177–195. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, T.; Hou, G. Noise prediction of submerged free jet based on theory of vortex sound. J. Ship Mech. 2010, 14, 670–677. [Google Scholar]

- Huang, C.; Yang, K.; Li, H.; Zhang, Y. The flow noise calculation for an axisymmetric body in a complex underwater environment. J. Mar. Sci. Eng. 2019, 7, 323. [Google Scholar] [CrossRef] [Green Version]

- Luo, X.; Li, Q.; Zhang, Z.; Zhang, J. Research on the underwater noise radiation of high pressure water jet propulsion. Ocean Eng. 2021, 19, 108438. [Google Scholar] [CrossRef]

- Zhang, Z.; Gao, W.; Wang, S.; Ma, B.; Luo, J.; Deng, J. Flow noise around underwater axisymmetric models with Bio-Inspired Coating. In Proceedings of the 2020 IEEE SENSORS, Rotterdam, The Netherlands, 25 October 2020; pp. 1–4. [Google Scholar]

- Wang, Y.; Jia, L.; Guo, X. Experimental and Simulation Research on Flow Noise of Underwater High Speed Vehicles. In Proceedings of the 2021 OES China Ocean Acoustics (COA), Harbin, China, 14 July 2021; pp. 415–419. [Google Scholar]

- Liu, Y.W.; Li, Y.L.; Shang, D.J. The Generation Mechanism of the Flow-Induced Noise from a Sail Hull on the Scaled Submarine Model. Appl. Sci. 2019, 9, 106. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.; Zhang, T.; Zhang, Y.O.; Liu, J.M.; Wang, C.Z. Numerical simulations of hydrodynamic noise of an underwater vehicle. In Proceedings of the OCEANS 2014-TAIPEI, Taipei, China, 7–10 April 2014; pp. 1–9. [Google Scholar]

- Yao, H.; Zhang, H.; Liu, H.; Jiang, W. Numerical study of flow-excited noise of a submarine with full appendages considering fluid structure interaction using the boundary element method. Eng. Anal. Bound. Elem. 2017, 77, 1–9. [Google Scholar] [CrossRef]

- Qu, D.; Zhang, Z.; Lou, J. Analysis of hydrodynamic noise characteristics of rudder-wing. Vibroeng. Procedia 2017, 11, 155–160. [Google Scholar] [CrossRef] [Green Version]

- Tu, J.; Gan, L.; Ma, S.; Zhang, H. Flow noise characteristics analysis of underwater high-speed vehicle based on LES/FW-H coupling model. Acoust. Aust. 2019, 47, 91–104. [Google Scholar] [CrossRef]

- Sezen, S.; Atlar, M.; Fitzsimmons, P. Prediction of cavitating propeller underwater radiated noise using RANS & DES-based hybrid method. Ships Offshore Struct. 2021, 16, 93–105. [Google Scholar]

- Hu, J.; Ning, X.; Zhao, W.; Li, F.; Ma, J.; Zhang, W.; Sun, S.; Zou, M.; Lin, C. Numerical simulation of the cavitating noise of contra-rotating propellers based on detached eddy simulation and the Ffowcs Williams–Hawkings acoustics equation. Phys. Fluids 2021, 33, 115117. [Google Scholar] [CrossRef]

- Kolahan, A.; Roohi, E.; Pendar, M.-R. Wavelet analysis and frequency spectrum of cloud cavitation around a sphere. Ocean Eng. 2019, 182, 235–247. [Google Scholar] [CrossRef]

- Pendar, M.-R.; Páscoa, J.; Roohi, E. Cavitating Flow Structure and Noise Suppression Analysis of a Hydrofoil with Wavy Leading Edges. In Proceedings of the 11th International Symposium on Cavitation CAV2021, Daejeon, Korea, 10–13 May 2021; pp. 10–13. [Google Scholar]

- Pendar, M.R.; Pascoa, J.C. Numerical Investigation of Plasma Actuator Effects on Flow Control Over a Three-Dimensional Airfoil with a Sinusoidal Leading Edge. J. Fluids Eng. Trans. ASME 2022, 144, 081208. [Google Scholar] [CrossRef]

- Yao, S.; Guang, P.; Gao, H.Q. Les-Based Numerical Simulation of Flow Noise for Uuv with Full Appendages. In Advanced Materials Research; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2013; pp. 879–884. [Google Scholar]

- Zhang, H.; Duan, K. Flow noise computation and tail wing optimization of the underwater vehicle based on computational fluid dynamics. J. Vibroeng. 2015, 17, 2633–2644. [Google Scholar]

- Xiao, X.; Liang, Q.; Ke, L.; Hu, Y.; Zhang, L. Effects of X Rudder Area on the Horizontal Mechanical Properties and Wake Flow Field of Submarines. J. Phys. Conf. Ser. 2021, 2095, 012089. [Google Scholar] [CrossRef]

- Jeon, M.; Yoon, H.K.; Park, J.; You, Y. Analysis of maneuverability of X-rudder submarine considering environmental disturbance and jamming situations. Appl. Ocean Res. 2022, 121, 103079. [Google Scholar] [CrossRef]

- Lighthill, M.J. On sound generated aerodynamically I. General theory. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1952, 211, 564–587. [Google Scholar]

- Lighthill, M.J. On sound generated aerodynamically II. Turbulence as a source of sound. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1954, 222, 1–32. [Google Scholar]

- Williams, J.F.; Hawkings, D.L. Sound generation by turbulence and surfaces in arbitrary motion. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 1969, 264, 321–342. [Google Scholar]

- Yuntao, L. Numerical Simulation of the Flow-Field and Flow-Noise of Fully Appendage Submarine; Shanghai Jiao Tong University: Shanghai, China, 2008. (In Chinese) [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Huang, L.; Zhao, Y.; Dai, J.; Jiang, Y. Influence of Stern Rudder Type on Flow Noise of Underwater Vehicles. J. Mar. Sci. Eng. 2022, 10, 1866. https://doi.org/10.3390/jmse10121866

Wang C, Huang L, Zhao Y, Dai J, Jiang Y. Influence of Stern Rudder Type on Flow Noise of Underwater Vehicles. Journal of Marine Science and Engineering. 2022; 10(12):1866. https://doi.org/10.3390/jmse10121866

Chicago/Turabian StyleWang, Chunxu, Lei Huang, Yue Zhao, Jinchi Dai, and Yichen Jiang. 2022. "Influence of Stern Rudder Type on Flow Noise of Underwater Vehicles" Journal of Marine Science and Engineering 10, no. 12: 1866. https://doi.org/10.3390/jmse10121866