Experimental Study on Motion Characterisation of CALM Buoy Hose System under Water Waves

Abstract

:1. Introduction

2. Materials and Methods

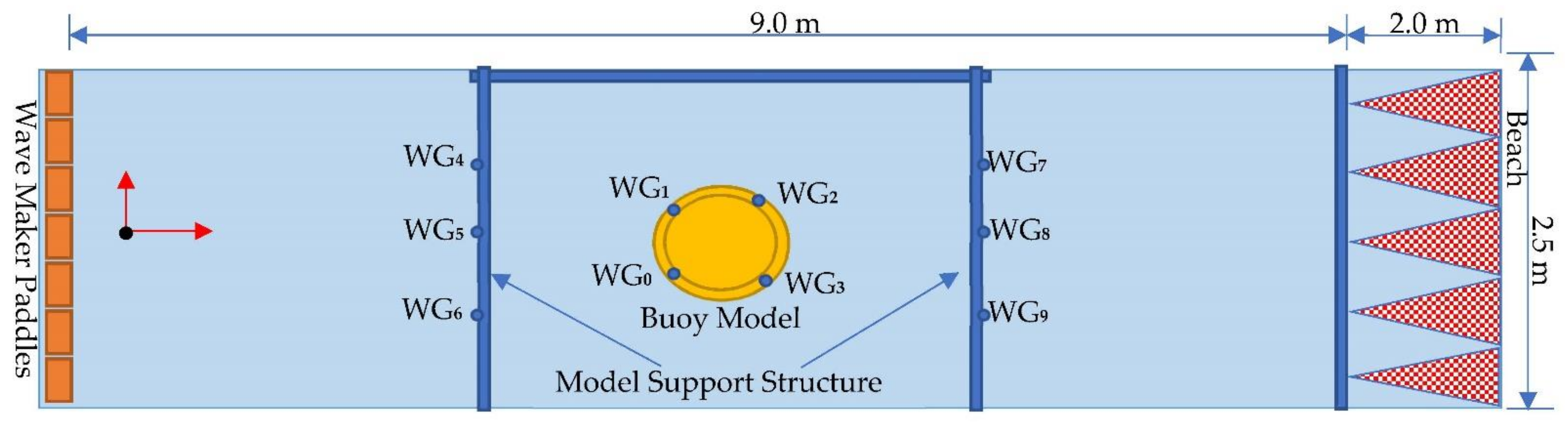

2.1. Experimental Setup

2.2. Lancaster University’s Wave Tank

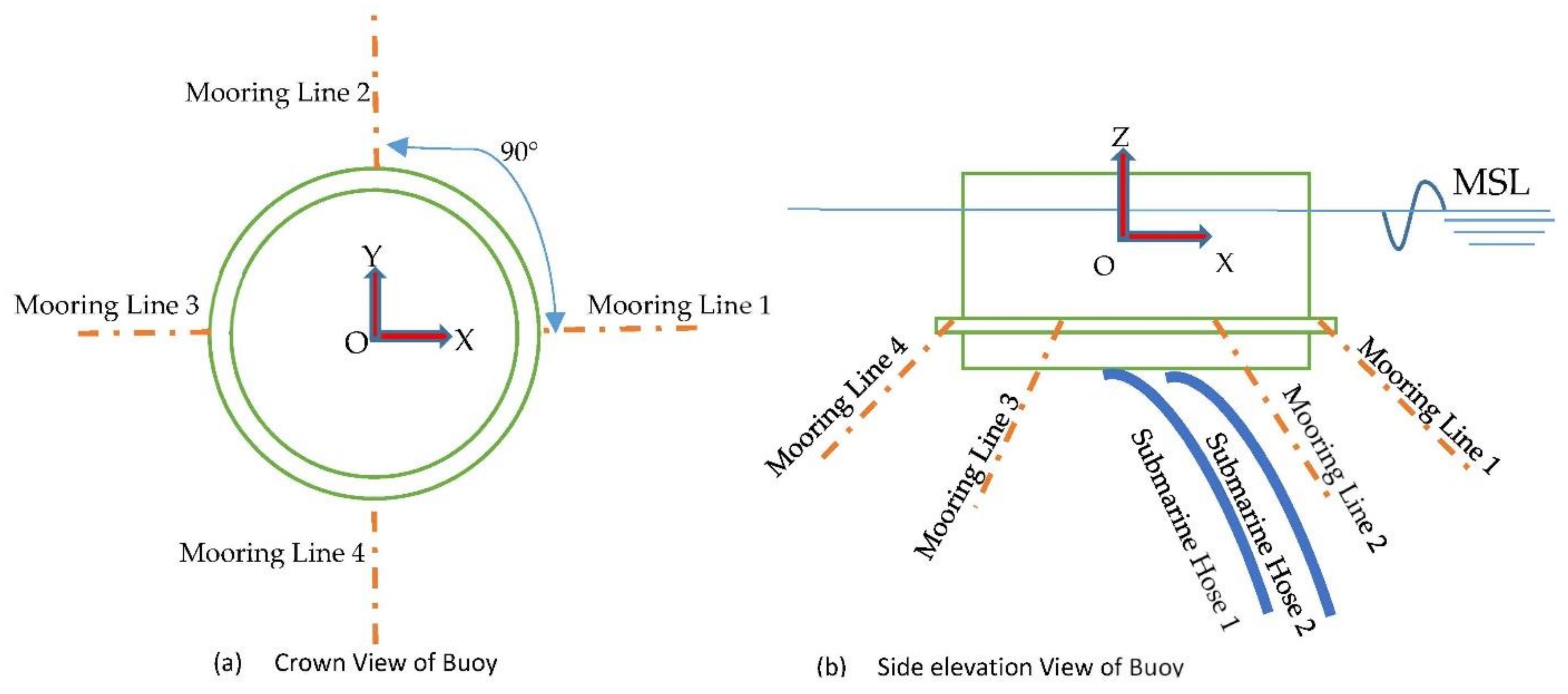

2.3. The Buoy Model

2.4. Mooring Lines & Fittings

2.5. Hoses and End Fittings

2.6. Imetrum DIC (Digital Image Correlation) System

2.7. Wave Gauges and Readouts

2.8. WIT Bluetooth Gyro Underwater Motion Sensors

2.9. Underwater 4K Camera

2.10. Methodology

2.11. Engineering Application: Numerical Studies

2.12. Experimental Data Postprocessing

3. Results and Discussion

3.1. Results from Wave Gauges and Readout

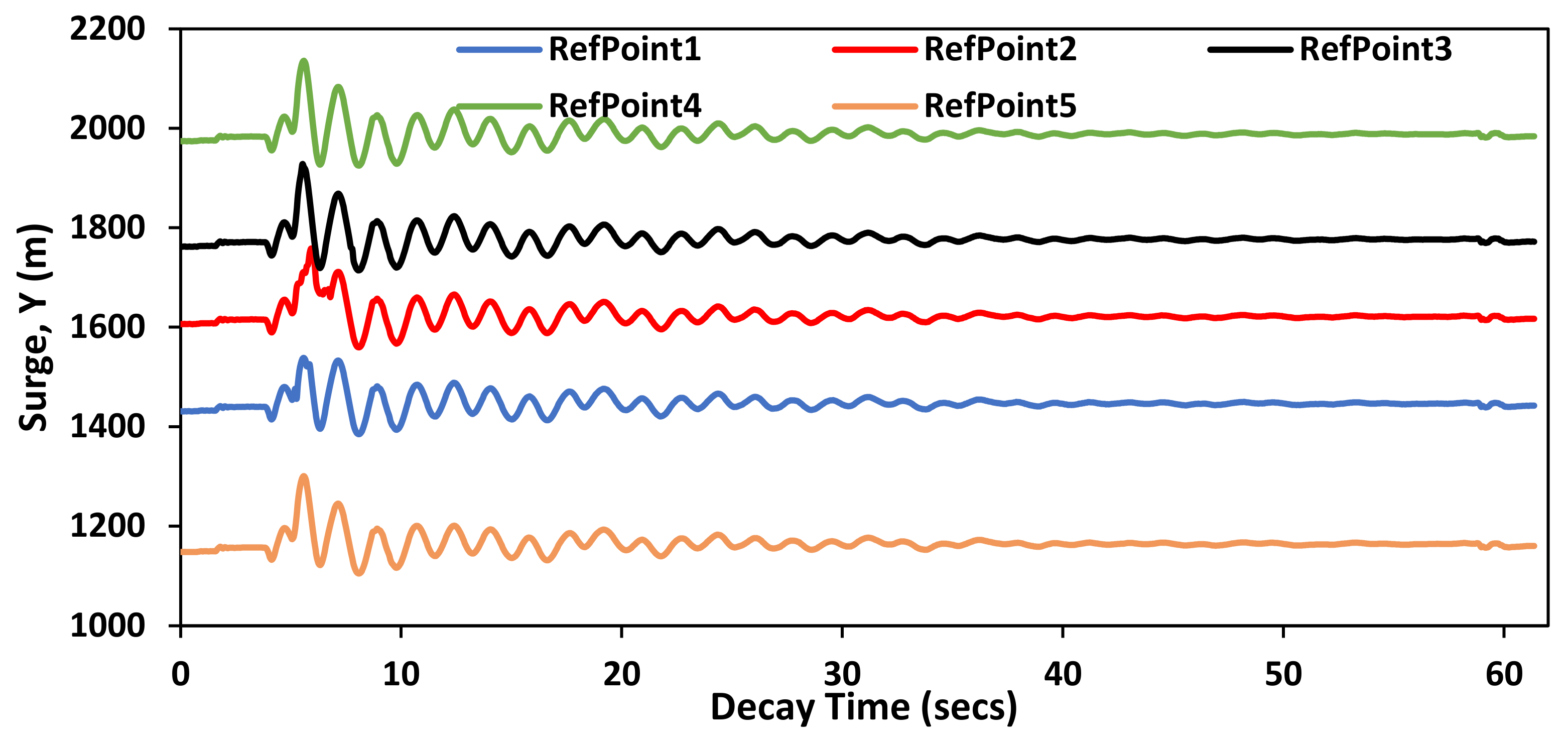

3.2. Results from Wave Tank’s Underwater Motion Sensors

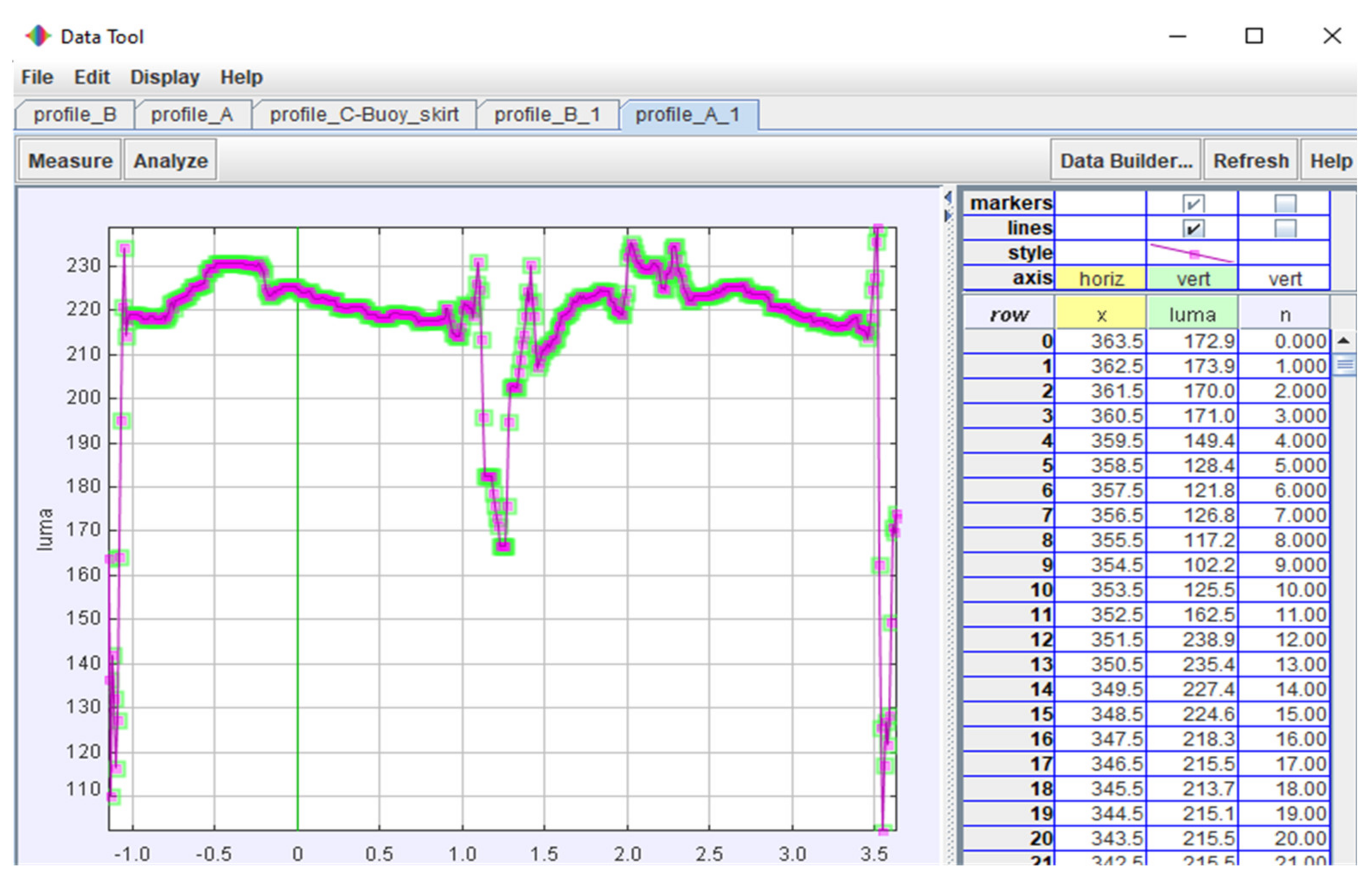

3.3. Results from DIC Using Imetrum System

3.4. Results from Tracker Postprocessing

3.5. Discussion

4. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| θ | Angle to the Horizontal Axis |

| 3D | Three-Dimensional |

| 6DoF | Six Degrees of Freedom |

| ABS | American Bureau of Shipping |

| ASPM | Articulated Single Point Moorings |

| BEM | Boundary Element Method |

| CALM | Catenary Anchor Leg Mooring |

| CB | Cylindrical Buoy |

| CCS | Cartesian Coordinate System |

| CFD | Computational Fluid Dynamics |

| CMS | Conventional Mooring Systems |

| DIC | Digital Image Correlation |

| DNVGL | Det Norkse Veritas & Germanischer Lloyd |

| F.C.T | Federal Capital Territory |

| FEM | Finite Element Model |

| FOS | Floating Offshore Structure |

| FPSO | Floating Production Storage and Offloading |

| FSO | Floating Storage and Offloading |

| GMPHOM | Guide to Manufacturing and Purchasing Hoses for Offshore Moorings |

| ID | Inner Diameter |

| IEFG | Interpolating Element Free Galerkin |

| MSL | Mean Sea Level |

| OCIMF | Oil Companies International Marine Forum |

| OD | Outer Diameter |

| RAO | Response Amplitude Operator |

| SALM | Single Anchor Leg Moorings |

| SON | Standards Organisation of Nigeria |

| SPM | Single-Point Mooring |

| UHD | Ultra-High Definition |

| U.K | United Kingdom |

| VIM | Vortex-Induced Motion |

References

- Islam, A.S.M.S.; Jameel, M.; Jumaat, M.Z.; Shirazi, S.; Salman, F.A. Review of offshore energy in Malaysia and floating Spar platform for sustainable exploration. Renew. Sustain. Energy Rev. 2012, 16, 6268–6284. [Google Scholar] [CrossRef] [Green Version]

- Sadeghi, K. An Overview of Design, Analysis, Construction and Installation of Offshore Petroleum Platforms Suitable for Cyprus Oil/Gas Fields. GAU J. Soc. Appl. Sci. 2007, 2, 1–16. Available online: https://cemtelecoms.iqpc.co.uk/media/6514/786.pdf (accessed on 6 January 2022).

- Amaechi, C.V.; Ye, J. A review of state-of-the-art and meta-science analysis on composite risers for deep seas. Ocean Eng. 2022. under review. [Google Scholar]

- Odijie, A.C.; Wang, F.; Ye, J. A review of floating semisubmersible hull systems: Column stabilized unit. Ocean. Eng. 2017, 144, 191–202. [Google Scholar] [CrossRef] [Green Version]

- Yu, L.C.; King, L.S.; Hoon, A.T.C.; Yean, P.C.C. A Review Study of Oil and Gas Facilities for Fixed and Floating Offshore Platforms. Res. J. Appl. Sci. Eng. Technol. 2015, 10, 672–679. [Google Scholar] [CrossRef]

- Hirdaris, S.E.; Bai, W.; Dessi, D.; Ergin, A.; Gu, X.; Hermundstad, O.A.; Huijsmans, R.; Iijima, K.; Nielsen, U.; Parunov, J.; et al. Loads for use in the design of ships and offshore structures. Ocean Eng. 2014, 78, 131–174. [Google Scholar] [CrossRef]

- Sorensen, R.M. Basic Coastal Engineering, 3rd ed.; Springer: New York, NY, USA, 2006. [Google Scholar]

- Sorensen, R.M. Basic Wave Mechanics: For Coastal and Ocean Engineers; John Wiley and Sons: Hoboken, NJ, USA, 1993. [Google Scholar]

- Amaechi, C.V.; Wang, F.; Odijie, A.C.; Ye, J. Numerical investigation on mooring line configurations of a Paired Column Semisubmersible for its global performance in deep water condition. Ocean. Eng. 2022. [Google Scholar] [CrossRef]

- Boccotti, P. Chapter 11 Analysis of The Wave Forces on Offshore Structures. In Wave Mechanics for Ocean Engineering, 1st ed.; Elsevier Oceanography Series; Elsevier Science Publishers: London, UK, 2000; Volume 64, pp. 361–392. [Google Scholar] [CrossRef]

- Boccotti, P. Wave Mechanics and Wave Loads on Marine Structures, 1st ed.; Elsevier Science Publishers, Imprint of Butterworth-Heinemann Inc.: Woburn, MA, USA, 2015. [Google Scholar] [CrossRef]

- Dean, R.G.; Dalrymple, R.A. Water Wave Mechanics for Engineers and Scientists; Advanced Series on Ocean Engineering; World Scientific Publishers: Toh Tuck Link, Singapore, 1991; Volume 2. [Google Scholar] [CrossRef]

- McCormick, M.E. Ocean Engineering Mechanics: With Applications; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Amaechi, C.V.; Gillett, N.; Odijie, A.C.; Hou, X.; Ye, J. Composite risers for deep waters using a numerical modelling approach. Compos. Struct. 2019, 210, 486–499. [Google Scholar] [CrossRef] [Green Version]

- Amaechi, C.V.; Ye, J. Local tailored design of deep water composite risers subjected to burst, collapse and tension loads. Ocean. Eng. 2022. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Ye, J. A numerical modeling approach to composite risers for deep waters. In Proceedings of the International Conference on Composite Structures (ICCS20) Proceedings, Paris, France, 4–7 September 2017; Società Editrice Esculapio: Bologna, Italy, 2017. [Google Scholar]

- Amaechi, C.V.; Gillett, N.; Odijie, A.C.; Wang, F.; Hou, X.; Ye, J. Local and Global Design of Composite Risers on Truss SPAR Platform in Deep waters. In Proceedings of the 5th International Conference on Mechanics of Composites, Instituto Superior de Tecnico, Lisbon, Portugal, 1–4 July 2019; Volume 20005, pp. 1–3. [Google Scholar]

- Amaechi, C.V.; Gillet, N.; Ye, J. Tailoring the local design of deep water composite risers to minimise structural weight. J. Compos. Sci. 2022, 6. under review. [Google Scholar]

- Sun, L.; Zhang, X.; Kang, Y.; Chai, S. Motion Response Analysis of FPSO’s CALM Buoy Offloading System. In Proceedings of the ASME 2015 34th International Conference on Ocean, Offshore and Arctic Engineering, St. John’s, NL, Canada, 31 May–5 June 2015; Volume 11, p. V011T12A008. [Google Scholar] [CrossRef]

- Amaechi, C.V. Novel Design, Hydrodynamics and Mechanics of Marine Hoses in Oil/Gas Applications. Ph.D. Thesis, Lancaster University, Engineering Department, Lancaster, UK, 2022. [Google Scholar]

- Kang, Y.; Sun, L.; Kang, Z.; Chai, S. Coupled Analysis of FPSO and CALM Buoy Offloading System in West Africa. In Proceedings of the ASME 2014 33rd International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014; Volume 8A, p. V08AT06A010. [Google Scholar] [CrossRef]

- Qi, X.; Chen, Y.; Yuan, Q.; Xu, G.; Huang, K. CALM Buoy and Fluid Transfer System Study. In Proceedings of the 27th International Offshore and Polar Engineering Conference, San Francisco, CA, USA, 25–30 June 2017; ISOPE: Lisbon, Portugal, 2017; pp. 128–932. Available online: https://onepetro.org/ISOPEIOPEC/proceedings-abstract/ISOPE17/All-ISOPE17/ISOPE-I-17-128/17225 (accessed on 13 November 2021).

- Wang, H.; Ma, G.; Sun, L.; Hu, K. Model test and coupled dynamic analysis of a deepwater FPSO with internal turret mooring system. Brodogradnja 2017, 68, 42–55. [Google Scholar] [CrossRef] [Green Version]

- Gu, H.; Chen, H.-C.; Zhao, L. Coupled CFD-FEM simulation of hydrodynamic responses of a CALM buoy. Ocean. Syst. Eng. 2019, 9, 21–42. [Google Scholar] [CrossRef]

- Gu, H. Coupled Mooring Analysis of a CALM Buoy by a CFD Approach. Master’s Thesis, Texas A&M University, Texas, TX, USA, 2016. [Google Scholar]

- Gu, H.; Chen, H.-C.; Zhao, L. Coupled Mooring Analysis of a CALM Buoy by a CFD Approach. In Proceedings of the 27th International Ocean and Polar Engineering Conference, San Francisco, CA, USA, 25–30 June 2017; Paper Number: ISOPE-I-17-223. Available online: https://www.researchgate.net/publication/320044188_Coupled_Mooring_Analysis_of_a_CALM_Buoy_by_a_CFD_Approach (accessed on 23 January 2022).

- Amaechi, C.V.; Chesterton, C.; Butler, H.O.; Gu, Z.; Odijie, A.C.; Wang, F.; Hou, X.; Ye, J. Finite Element Model on the mechanical behaviour of Marine Bonded Composite Hose under internal pressure and external pressure. J. Mar. Sci. Eng. 2022, 10, 151. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Wang, F.; Ja’e, I.A.; Aboshio, A.; Odijie, A.C.; Ye, J. A literature review on the technologies of bonded hoses for marine applications. Ships Offshore Struct. 2022. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Chesterton, C.; Butler, H.O.; Wang, F.; Ye, J. An Overview on Bonded Marine Hoses for sustainable fluid transfer and (un)loading operations via Floating Offshore Structures (FOS). J. Mar. Sci. Eng. 2021, 9, 1236. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Chesterton, C.; Butler, H.O.; Wang, F.; Ye, J. Review on the design and mechanics of bonded marine hoses for Catenary Anchor Leg Mooring (CALM) buoys. Ocean Eng. 2021, 242, 110062. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Wang, F.; Ye, J. Mathematical Modelling of Bonded Marine Hoses for Single Point Mooring (SPM) Systems, with Catenary Anchor Leg Mooring (CALM) Buoy Application—A Review. J. Mar. Sci. Eng. 2021, 9, 1179. [Google Scholar] [CrossRef]

- Le Cunff, C.; Ryu, S.; Duggal, A.; Ricbourg, C.; Heurtier, J.M.; Heyl, C.; Liu, Y.; Beauclair, O. Derivation of CALM Buoy coupled motion RAOs in Frequency Domain and Experimental Validation. In Proceedings of the Seventeenth International Offshore and Polar Engineering Conference, Lisbon, Portugal, 1–6 July 2007; Paper Number: ISOPE-I-07-402. ISOPE: Lisbon, Portugal, 2007; pp. 1–8. Available online: https://www.sofec.com/wp-content/uploads/white_papers/2007-ISOPE-Derivation-of-CALM-Buoy-Coupled-Motion-RAOs-in-Frequency-Domain.pdf (accessed on 23 January 2022).

- Zhang, S.-F.; Chen, C.; Zhang, Q.-X.; Zhang, N.-M.; Zhang, F. Wave Loads Computation for Offshore Floating Hose Based on Partially Immersed Cylinder Model of Improved Morison Formula. Open Pet. Eng. J. 2015, 8, 130–137. [Google Scholar] [CrossRef] [Green Version]

- ABS. Rules for Building and Classing—Single Point Moorings; American Bureau of Shipping: Houston, TX, USA, 2021; Available online: https://ww2.eagle.org/content/dam/eagle/rules-and-guides/current/offshore/8_rules-forbuildingandclassingsinglepointmoorings_2021/spm-rules-jan21.pdf (accessed on 13 November 2021).

- API. API RP 2SK—Design and Analysis of Stationkeeping Systems for Floating Structures, 3rd ed.; American Petroleum Institute (API): Texas, TX, USA, 2005. [Google Scholar]

- API. API 17K—Specification for Bonded Flexible Pipe. ISO 13628-10 (Identical), Petroleum and Natural Gas Industries—Design and Operation of Subsea Production Systems-Part 10: Specification for Bonded Flexible Pipe, 3rd ed.; American Petroleum Institute (API): Texas, TX, USA, 2017. [Google Scholar]

- OCIMF. Guide to Manufacturing and Purchasing Hoses for Offshore Moorings (GMPHOM); Witherby Seamanship International Ltd.: Livingstone, UK, 2009. [Google Scholar]

- DNVGL. DNVGL-RP-F205 Global Performance Analysis of Deepwater Floating Structures; Det Norske Veritas & Germanischer Lloyd: Oslo, Norway, 2017. [Google Scholar]

- DNVGL. DNVGL-OS-E403. Offshore Laoding Buoys; Det Norske Veritas & Germanischer Lloyd: Oslo, Norway, 2016; Available online: https://rules.dnv.com/docs/pdf/DNV/os/2015-07/DNVGL-OS-E403.pdf (accessed on 13 November 2021).

- Bridgestone, J. Study of Causes of Kinking in Floating Hoses at Petrobras/Tefran Terminal. Report No. 6YMT-0011; Bridgestone: Kurume, Japan, 1976. [Google Scholar]

- Brown, M.; Elliott, L. A design tool for static underbuoy hose-systems. Appl. Ocean Res. 1987, 9, 171–180. [Google Scholar] [CrossRef]

- OCIMF. A Study into Crane Loads Associated with Hose Handling at Offshore Terminals, OCIMF Info Paper, Version 6; Oil Companies International Marine Forum (OCIMF): London, UK, 2020; Available online: https://www.ocimf.org/media/58339/OC_INFOPAPER2961_CRANE_V6.pdf (accessed on 14 February 2021).

- Liu, B.; Fu, D.; Zhang, Y.; Chen, X. Experimental and numerical study on the wave force calculation of a partially immersed horizontal cylindrical float. Int. J. Nav. Arch. Ocean Eng. 2020, 12, 733–742. [Google Scholar] [CrossRef]

- Roveri, F.E.; Volnei, L.S.S.; Cicilia, F.B. A Case Study on the Evaluation of Floating Hose Forces in a C.A.L.M. System. In Proceedings of the Twelfth International Offshore and Polar Engineering Conference, Kitakyushu, Japan, 26–31 May 2002; ISOPE: Lisbon, Portugal, 2002; pp. 190–197. Available online: https://www.academia.edu/26568632/A_Case_Study_on_the_Evaluation_of_Floating_Hose_Forces_in_a_C.A.L.M._System (accessed on 21 January 2022).

- Ryu, S.; Duggal, A.S.; Heyl, C.N.; Liu, Y. Prediction of Deepwater Oil Offloading Buoy Response and Experimental Validation. Int. J. Offshore Polar Eng. 2006, 16, 1–7. Available online: https://www.sofec.com/wp-content/uploads/white_papers/2006-ISOPE-Prediction-of-DW-Oil-Offloading-Buoy-Response.pdf (accessed on 21 January 2022).

- Ricbourg, C.; Berhault, C.; Camhi, A.; Lecuyer, B.; Marcer, R. Numerical and Experimental Investigations on Deepwater CALM Buoys Hydrodynamics Loads. In Proceedings of the Offshore Technology Conference Proceeding, Houston, TX, USA, 1–4 May 2006; OnePetro: Houston, TX, USA, 2006; pp. 1–8, OTC 18254-P. [Google Scholar] [CrossRef]

- Quash, J.E.; Burgess, S. Improving underbuoy hose system design using relaxed storm design criteria. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 1979; OnePetro: Houston, TX, USA, 1979; pp. 1827–1836. [Google Scholar] [CrossRef]

- Brady, I.; Williams, S.; Golby, P. A study of the Forces Acting on Hoses at a Monobuoy Due to Environmental Conditions. In Proceedings of the Offshore Technology Conference Proceeding, Dallas, TX, USA, 6–8 May 1974; OnePetro: Houston, TX, USA, 1974; pp. 1–10, OTC 2136. [Google Scholar]

- Saito, H.; Mochizuki, T.; Fukai, T.; Okui, K. Actual measurement of external forces on marine hoses for SPM. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–8 May ; OnePetro: Houston, TX, USA, 1980; pp. 89–97, OTC 3803. [Google Scholar] [CrossRef]

- Young, R.A.; Brogren, E.E.; Chakrabarti, S.K. Behavior of Loading Hose Models in Laboratory Waves and Currents. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–8 May 1980; pp. 421–428, OTC-3842-MS. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Wang, F.; Ye, J. Investigation on Hydrodynamic Characteristics, Wave–Current Interaction and Sensitivity Analysis of Submarine Hoses Attached to a CALM Buoy. J. Mar. Sci. Eng. 2022, 10, 120. [Google Scholar] [CrossRef]

- Duggal, A.; Ryu, S. The dynamics of deepwater offloading buoys. In WIT Transactions on The Built Environment; Paper FSI05026FU; WIT Press: Singapore, 2005; Available online: https://www.witpress.com/Secure/elibrary/papers/FSI05/FSI05026FU.pdf (accessed on 21 January 2022).

- O’Donoghue, T.; Halliwell, A. Vertical bending moments and axial forces in a floating marine hose-string. Eng. Struct. 1990, 12, 124–133. [Google Scholar] [CrossRef]

- O’Donoghue, T.; Halliwell, A.R. Floating Hose-Strings Attached to a Calm Buoy. Available online: https://onepetro.org/OTCONF/proceedings-abstract/88OTC/All-88OTC/OTC-5717-MS/49540 (accessed on 21 January 2022). [CrossRef]

- Ziccardi, J.J.; Robins, H.J. Selection of the hose systems for SPM tanker terminals. In Proceedings of the Offshore Technology Conference (OTC), Houston, TX, USA, 21–23 April 1970. OTC-1152-MS. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Wang, F.; Ye, J. Understanding the fluid–structure interaction from wave diffraction forces on CALM buoys: Numerical and analytical solutions. Ships Offshore Struct. 2022. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Wang, F.; Ye, J. Numerical studies on CALM buoy motion responses and the effect of buoy geometry cum skirt dimensions with its hydrodynamic waves-current interactions. Ocean Eng. 2021, 244, 110378. [Google Scholar] [CrossRef]

- Kang, Z.; Zhang, C.; Ni, W.; Xu, X. Research on Hydrodynamic Calculation Method of Deepwater CALM Buoy. In Proceedings of the 27th International Ocean and Polar Engineering Conference, San Francisco, CA, USA, 25–30 June 2017; pp. 217–224. Available online: https://onepetro.org/ISOPEIOPEC/proceedings-abstract/ISOPE17/All-ISOPE17/ISOPE-I-17-144/17298 (accessed on 21 January 2022).

- Edward, C.; Dev, A.K. Assessment of CALM Buoys Motion Response and Dominant OPB/IPB Inducing Parameters on Fatigue Failure of Offshore Mooring Chains. In Practical Design of Ships and Other Floating Structures. PRADS 2019. Lecture Notes in Civil Engineering; Okada, T., Suzuki, K., Kawamura, Y., Eds.; Springer: Singapore, 2021; Volume 64. [Google Scholar] [CrossRef]

- Wang, D.J.; Sun, S.P. An Analytical Solution of Wave Exciting Loads on CALM Buoy with Skirt. Appl. Mech. Mater. 2013, 477–478, 254–258. [Google Scholar] [CrossRef]

- Cozijn, J.L.; Bunnik, T.H.J. Coupled Mooring Analysis for a Deep water CALM Buoy. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering (OMAE), Vancouver, BC, Canada, 20–25 June 2004; Volume 1, pp. 663–673. [Google Scholar] [CrossRef] [Green Version]

- Cozijn, H.; Uittenbogaard, R.; Brake, E.T. Heave, Roll and Pitch Damping of a Deepwater CALM Buoy with a Skirt. In Proceedings of the International Society of Offshore and Polar Engineering Conference, Seoul, Korea, 19–24 June 2005; pp. 388–395. Available online: https://www.researchgate.net/publication/267364857_Heave_Roll_and_Pitch_Damping_of_a_Deepwater_CALM_Buoy_with_a_Skirt (accessed on 22 December 2021).

- Woodburn, P.; Gallagher, P.; Naciri, M.; Borleteau, J.-P. Coupled CFD Simulation of the Response of a Calm Buoy in Waves. In Proceedings of the ASME 2005 24th International Conference on Offshore Mechanics and Arctic Engineering, Halkidiki, Greece, 12–17 June 2005; Volume 3, pp. 793–803. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Wang, F.; Ye, J. An investigation on the vortex effect of a CALM buoy under water waves using Computational Fluid Dynamics (CFD). Inventions 2022, 7, 23. [Google Scholar] [CrossRef]

- Monroy, C.; Ducrozet, G.; Bonnefoy, F.; Babarit, A.; Gentaz, L.; Ferrant, P. RANS Simulations of a Calm Buoy in Regular and Irregular Seas using the SWENSE Method. Int. J. Offshore Polar Eng. 2011, 21, 264–271. Available online: https://hal.archives-ouvertes.fr/hal-01145146/document (accessed on 13 November 2021).

- Abbaszadeh, M.; Dehghan, M.; Khodadadian, A.; Heitzinger, C. Analysis and application of the interpolating element free Galerkin (IEFG) method to simulate the prevention of groundwater contamination with application in fluid flow. J. Comput. Appl. Math. 2019, 368, 112453. [Google Scholar] [CrossRef]

- Mirsian, S.; Khodadadian, A.; Hedayati, M.; Manzour-Ol-Ajdad, A.; Kalantarinejad, R.; Heitzinger, C. A new method for selective functionalization of silicon nanowire sensors and Bayesian inversion for its parameters. Biosens. Bioelectron. 2019, 142, 111527. [Google Scholar] [CrossRef]

- Abbaszadeh, M.; Dehghan, M.; Khodadadian, A.; Noii, N.; Heitzinger, C.; Wick, T. A reduced-order variational multiscale interpolating element free Galerkin technique based on proper orthogonal decomposition for solving Navier–Stokes equations coupled with a heat transfer equation: Nonstationary incompressible Boussinesq equations. J. Comput. Phys. 2020, 426, 109875. [Google Scholar] [CrossRef]

- Bluewater. Bluewater Turret Buoy- Technical Description; Bluewater Energy Services: Amsterdam, The Netherlands, 2011; Available online: https://www.bluewater.com/wp-content/uploads/2013/04/digitale-brochure-TurretBouy-Tech-description.pdf. (accessed on 13 November 2021).

- EDesign. Edinburgh Designs Ltd., Edinburgh, UK. 2016. Available online: http://www4.edesign.co.uk/product/wave-generating-software/ (accessed on 26 September 2021).

- Zhang, D.; George, A.; Wang, Y.; Gu, X.; Li, W.; Chen, Y. Wave tank experiments on the power capture of a multi-axis wave energy converter. J. Mar. Sci. Technol. 2015, 20, 520–529. [Google Scholar] [CrossRef]

- Zhang, D.; Aggidis, G.; Wang, Y.; McCabe, A.; Li, W. Experimental results from wave tank trials of a multi-axis wave energy converter. Appl. Phys. Lett. 2013, 103, 103901. [Google Scholar] [CrossRef]

- Doyle, S.; Aggidis, G.A. Experimental investigation and performance comparison of a 1 single OWC, array and M-OWC. Renew. Energy 2020, 168, 365–374. [Google Scholar] [CrossRef]

- MARINET D2 27 Manual of Wave Instrumentation Survey of Laboratories. WP2: Marine Energy System Testing—Standardisation and Best Practice. MARINET (Marine Renewables Infrastrcuture Network for Emerging Energy Technologies). 2015. Available online: https://www.marinet2.eu/wp-content/uploads/2017/04/D2.27-Manual-of-Wave-Instrumentation-1.pdf (accessed on 13 November 2021).

- Imetrum Digital Image Correlation in Video Gauge™. 2017. Available online: https://www.imetrum.com/documents/product-sheets/digital-image-correlation.pdf (accessed on 24 April 2021).

- Imetrum. Video Gauge User Manual: Version 5.4.0.; Imetrum Limited: Bristol, UK, 2016; pp. 1–153. [Google Scholar]

- Milad, M.; Green, S.; Ye, J. Mechanical properties of reinforced composite materials under uniaxial and planar tension loading regimes measured using a non-contact optical method. Compos. Struct. 2018, 202, 1145–1154. [Google Scholar] [CrossRef] [Green Version]

- Aboshio, A.; Green, S.; Ye, J. Experimental investigation of the mechanical properties of neoprene coated nylon woven reinforced composites. Compos. Struct. 2014, 120, 386–393. [Google Scholar] [CrossRef]

- Odijie, A.C. Design of Paired Column Semisubmersible Hull. Ph.D. Thesis, Lancaster University, Lancaster, UK, 2016. [Google Scholar] [CrossRef]

- NI. LabView: Getting Started with LabView; National Instruments: Austin, TX, USA, 2003; Available online: https://www.ni.com/pdf/manuals/323427a.pdf (accessed on 6 January 2022).

- Klinger, T. Image Processing with LabVIEW and IMAQ Vision, 1st. ed.; National Instruments Virtual Instrumentation Series; Prentice Hall Professional: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- WIT. WIT Motion User Manual. WIT Motion (Xingji Jia Yuan), Shenzhen City, Guangdong Province, China. 2019. Available online: https://wiki.wit-motion.com/english (accessed on 26 September 2021).

- WIT. Wit Motion Bluetooth Sensor. WIT Motion (Xingji Jia Yuan), Shenzhen City, Guangdong Province, China. 2020. Available online: http://www.wit-motion.com/english.php (accessed on 26 September 2021).

- Samsung. Samsung Galaxy S8|S8+ Smartphone User Manual; Samsung Electronics America Inc.: Ridgefield Park, NJ, USA, 2017; Available online: http://files.customersaas.com/files/Samsung_G950U_Galaxy_S8_User_Manual.pdf (accessed on 26 September 2021).

- Samsung. Samsung Galaxy S8- Support, Warranty Information, Solutions Tips; Samsung Electronics America Inc.: Ridgefield Park, NJ, USA, 2021; Available online: https://www.samsung.com/uk/support/model/SM-G950FZVABTU/ (accessed on 26 September 2021).

- AKASO. AKASO Action Camera EK7000 User Manual; Akaso Tech LLC: Frederick, MD, USA, 2020; Available online: https://www.akasotech.com/usermanual/detail?category=1&product=11&name=EK7000 (accessed on 26 September 2021).

- Amaechi, C.V.; Wang, F.; Ye, J. Numerical Assessment on the Dynamic Behaviour of Submarine Hoses Attached to CALM Buoy Configured as Lazy-S under Water Waves. J. Mar. Sci. Eng. 2021, 9, 1130. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Wang, F.; Hou, X.; Ye, J. Strength of submarine hoses in Chinese-lantern configuration from hydrodynamic loads on CALM buoy. Ocean Eng. 2018, 171, 429–442. [Google Scholar] [CrossRef] [Green Version]

- Amaechi, C.V.; Ye, J.; Hou, X.; Wang, F.-C. Sensitivity Studies on Offshore Submarine Hoses on CALM Buoy with Comparisons for Chinese-Lantern and Lazy-S Configuration OMAE2019-96755. In Proceedings of the 38th International Conference on Ocean, Offshore and Arctic Engineering, Glasgow, Scotland, 9–14 June 2019; Available online: https://eprints.lancs.ac.uk/id/eprint/134404 (accessed on 24 April 2021).

- Orcina. OrcaFlex Manual, Version 9.8; Orcina Ltd.: Ulverton, Cumbria, UK, 2014. [Google Scholar]

- Orcina. OrcaFlex Manual, Version 11.0f [Electronic Online Version of Manual and Documentation); Orcina Ltd.: Ulverton, Cumbria, UK, 2022; Available online: https://www.orcina.com/SoftwareProducts/OrcaFlex/Documentation/index.php (accessed on 4 January 2022).

- Orcina. Orcaflex Documentation, Version 11.0f. 2021. Available online: https://www.orcina.com/webhelp/OrcaFlex/Default.htm (accessed on 24 April 2021).

- Wang, F.; Chen, J.; Gao, S.; Tang, K.; Meng, X. Development and sea trial of real-time offshore pipeline installation monitoring system. Ocean Eng. 2017, 146, 468–476. [Google Scholar] [CrossRef]

- Tracker Tracker Video Analysis and Modeling Tool- Tracker Home Page. 2016. Available online: https://physlets.org/tracker/ (accessed on 4 January 2022).

- Tracker Tracker Video Analysis and Modeling Tool- Tracker 6.0.2. 2016. Available online: http://www.opensourcephysics.org/items/detail.cfm?ID=7365 (accessed on 4 January 2022).

- Brown, D.; Hanson, R.; Christian, W. Tracker Video Analysis and Modeling Tool. O.S.P- Open Source Physics. 2016. Available online: https://www.compadre.org/osp/items/detail.cfm?ID=7365 (accessed on 4 January 2022).

| Parameters | Model Test |

|---|---|

| Shape of buoy | Cylindrical |

| Depth of Water (m) | 0.90 |

| Diameter of Skirt (m) | 0.68 |

| Draft size (m) | 0.15 |

| Mass of Buoy (kg) | 0.25 |

| Buoy’s Height (m) | 0.20 |

| Diameter of Buoy’s body (m) | 0.50 |

| Parameters | Amplitude | Angle | Frequency | Distance | Max Runtime |

|---|---|---|---|---|---|

| Value | 0.078 | 0.0 | 1.0 | 5.0 | 64.0 |

| Unit | m | Degree (o) | Hz | m | secs |

| Parameters for the Wave | Max Displacement | ||

|---|---|---|---|

| Frequency, f (Hz) | Period, T (s) | Surge (m) | Heave (m) |

| 0.5 | 2.0 | 0.01506 | 0.04660 |

| 0.6 | 1.6 | 0.01301 | 0.02640 |

| 0.7 | 1.4 | 0.01150 | 0.00190 |

| 0.8 | 1.2 | 0.00825 | 0.00240 |

| 0.9 | 1.1 | 0.00633 | 0.00260 |

| 1.0 | 1.0 | 0.00465 | 0.00220 |

| Horizontal, n | Vertical, x | Vertical, Luna |

|---|---|---|

| 0 | 363.5 | 172.9 |

| 1 | 362.5 | 173.9 |

| 2 | 361.5 | 170.0 |

| 3 | 360.5 | 171.0 |

| 4 | 359.5 | 149.4 |

| 5 | 358.5 | 128.4 |

| 6 | 357.5 | 121.8 |

| 7 | 356.5 | 126.8 |

| 8 | 355.5 | 117.2 |

| 9 | 354.5 | 102.2 |

| 10 | 353.5 | 125.5 |

| 11 | 352.5 | 162.5 |

| 12 | 351.5 | 238.9 |

| 13 | 350.5 | 235.4 |

| 14 | 349.5 | 227.4 |

| 15 | 348.5 | 224.6 |

| 16 | 347.5 | 218.3 |

| 17 | 346.5 | 215.5 |

| 18 | 345.5 | 213.7 |

| 19 | 344.5 | 215.1 |

| 20 | 343.5 | 215.5 |

| 21 | 342.5 | 215.6 |

| 22 | 341.5 | 212.8 |

| Horizontal, n | Vertical, x | Vertical, Luna |

|---|---|---|

| 0 | 441.5 | 239.2 |

| 1 | 440.5 | 250.3 |

| 2 | 439.5 | 250.0 |

| 3 | 438.5 | 245.2 |

| 4 | 437.5 | 238.6 |

| 5 | 436.5 | 235.6 |

| 6 | 435.5 | 227.6 |

| 7 | 434.5 | 220.6 |

| 8 | 433.5 | 214.6 |

| 9 | 432.5 | 212.6 |

| 10 | 431.5 | 206.4 |

| 11 | 430.5 | 203.4 |

| 12 | 429.5 | 201.4 |

| 13 | 428.5 | 199.4 |

| 14 | 427.5 | 199.6 |

| 15 | 426.5 | 199.6 |

| 16 | 425.5 | 192.5 |

| 17 | 424.5 | 188.5 |

| 18 | 423.5 | 180.4 |

| 19 | 422.5 | 180.4 |

| 20 | 421.5 | 175.6 |

| 21 | 420.5 | 179.6 |

| 22 | 419.5 | 184.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amaechi, C.V.; Wang, F.; Ye, J. Experimental Study on Motion Characterisation of CALM Buoy Hose System under Water Waves. J. Mar. Sci. Eng. 2022, 10, 204. https://doi.org/10.3390/jmse10020204

Amaechi CV, Wang F, Ye J. Experimental Study on Motion Characterisation of CALM Buoy Hose System under Water Waves. Journal of Marine Science and Engineering. 2022; 10(2):204. https://doi.org/10.3390/jmse10020204

Chicago/Turabian StyleAmaechi, Chiemela Victor, Facheng Wang, and Jianqiao Ye. 2022. "Experimental Study on Motion Characterisation of CALM Buoy Hose System under Water Waves" Journal of Marine Science and Engineering 10, no. 2: 204. https://doi.org/10.3390/jmse10020204

APA StyleAmaechi, C. V., Wang, F., & Ye, J. (2022). Experimental Study on Motion Characterisation of CALM Buoy Hose System under Water Waves. Journal of Marine Science and Engineering, 10(2), 204. https://doi.org/10.3390/jmse10020204