Development of Numerical Modelling Techniques for Composite Cylindrical Structures under External Pressure

Abstract

:1. Introduction

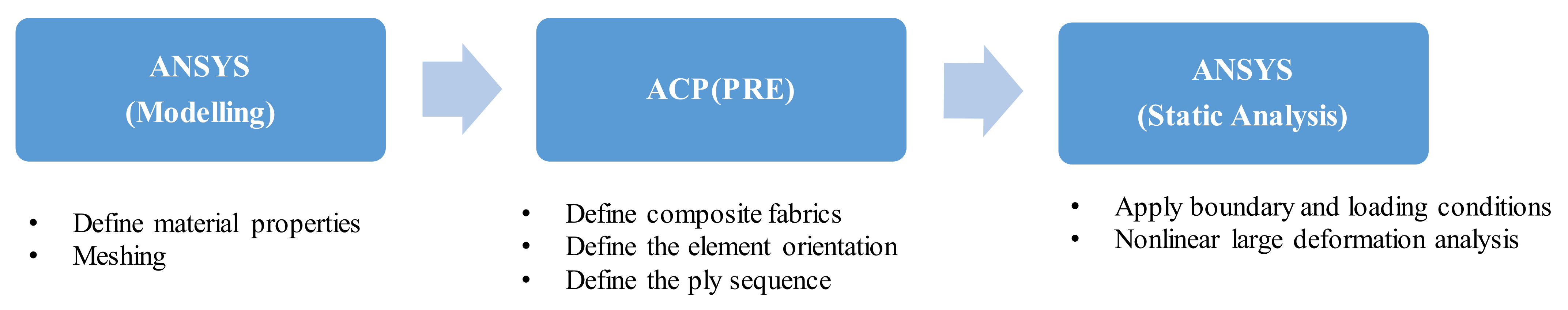

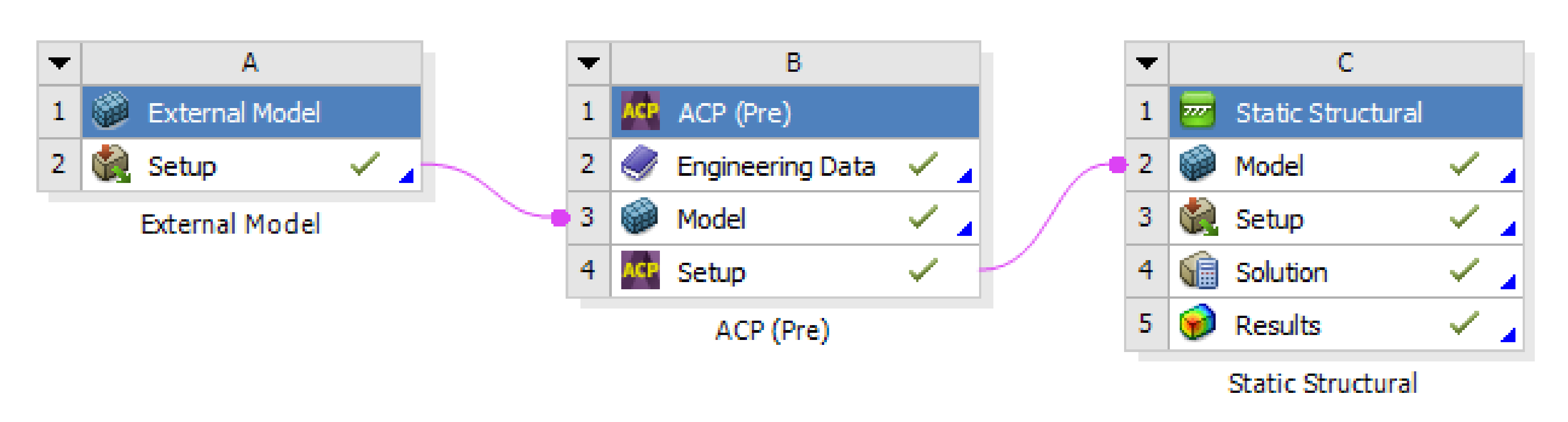

2. Computational Method

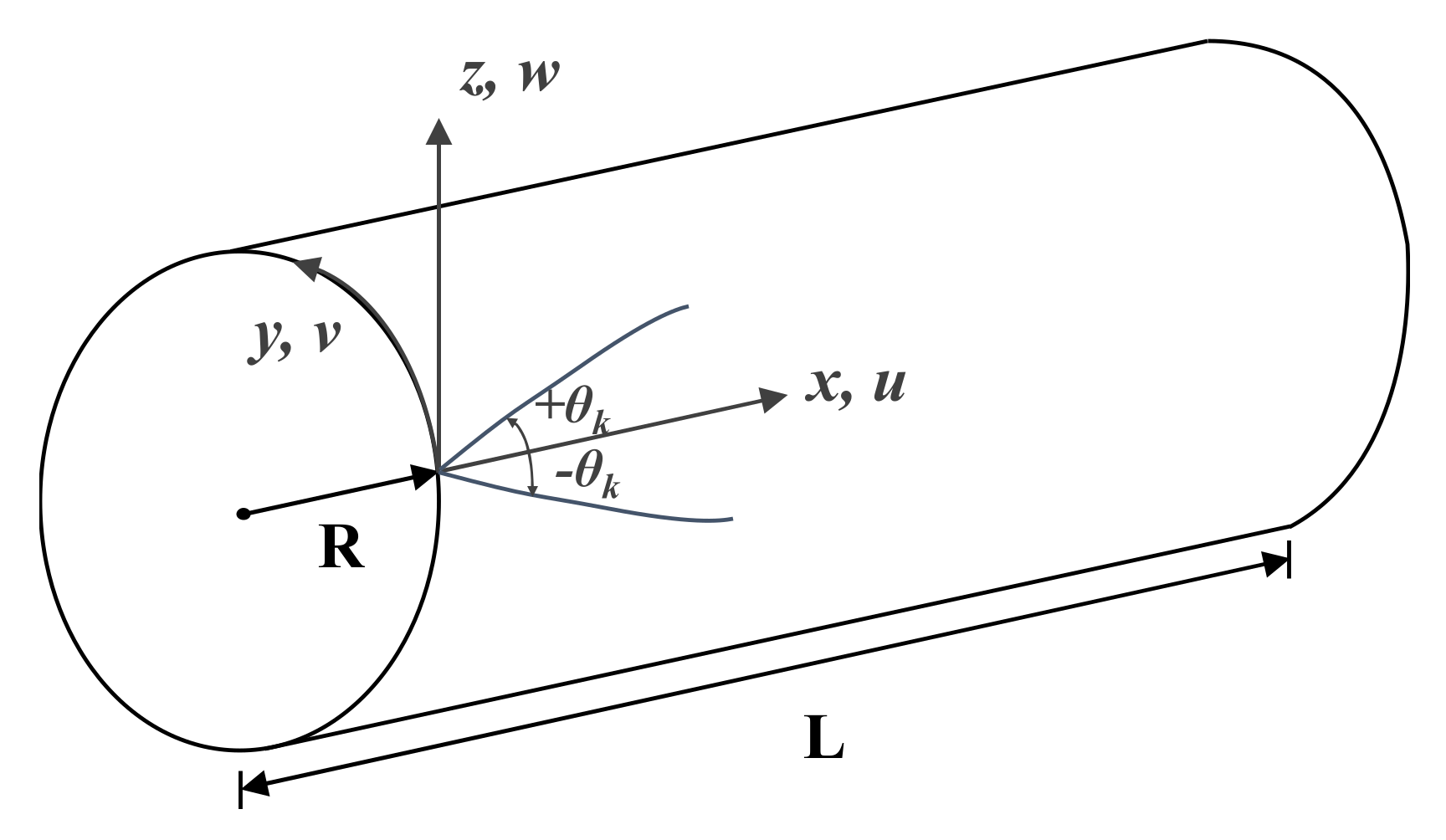

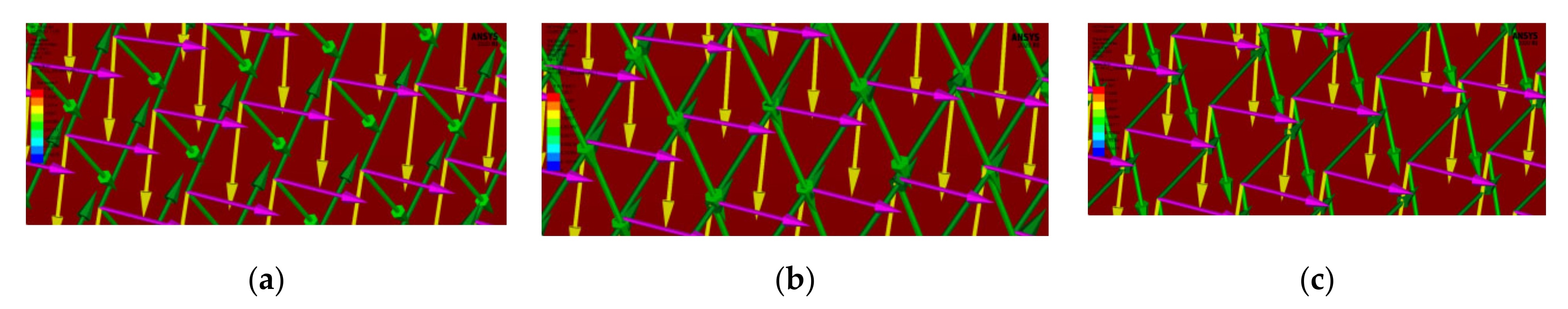

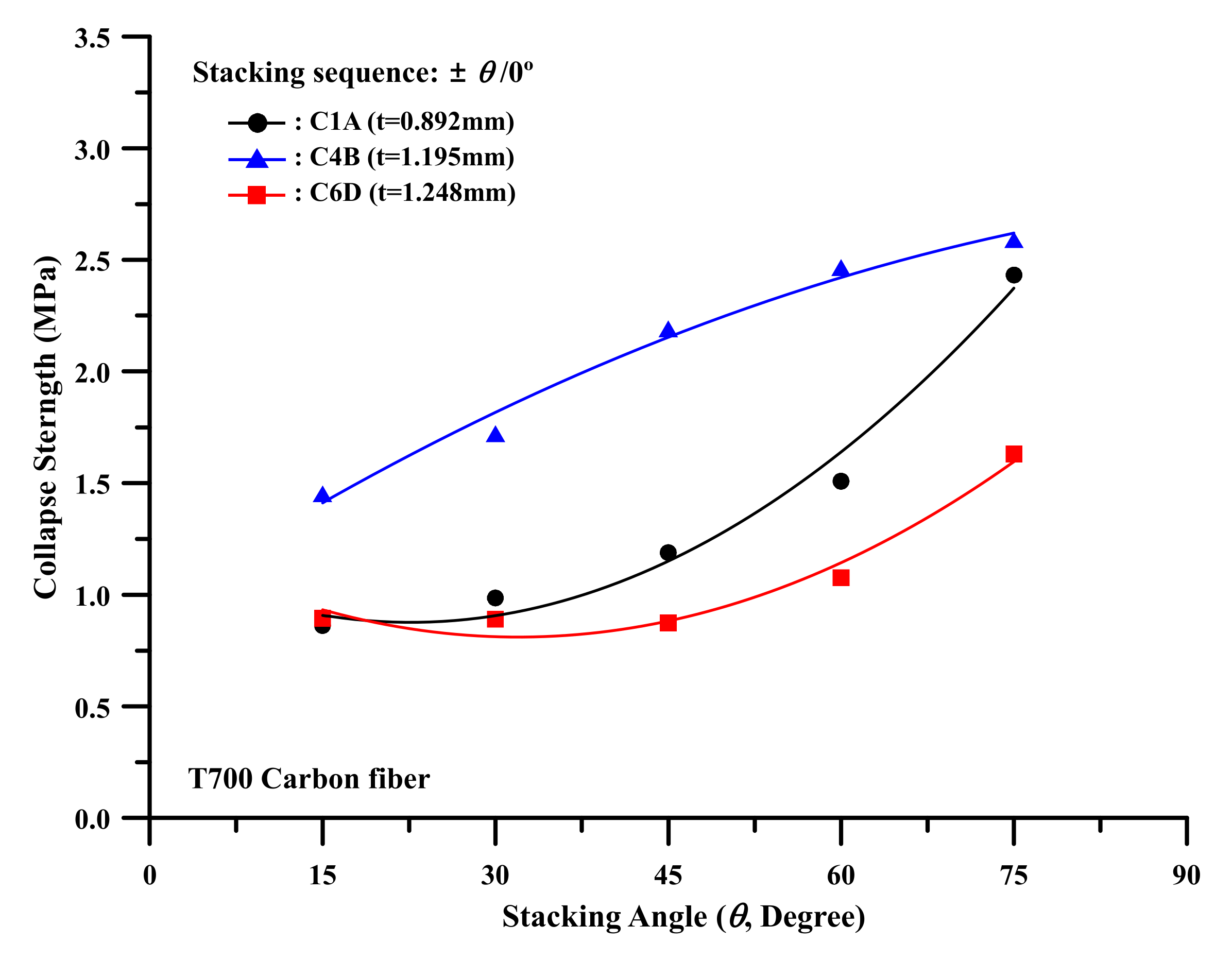

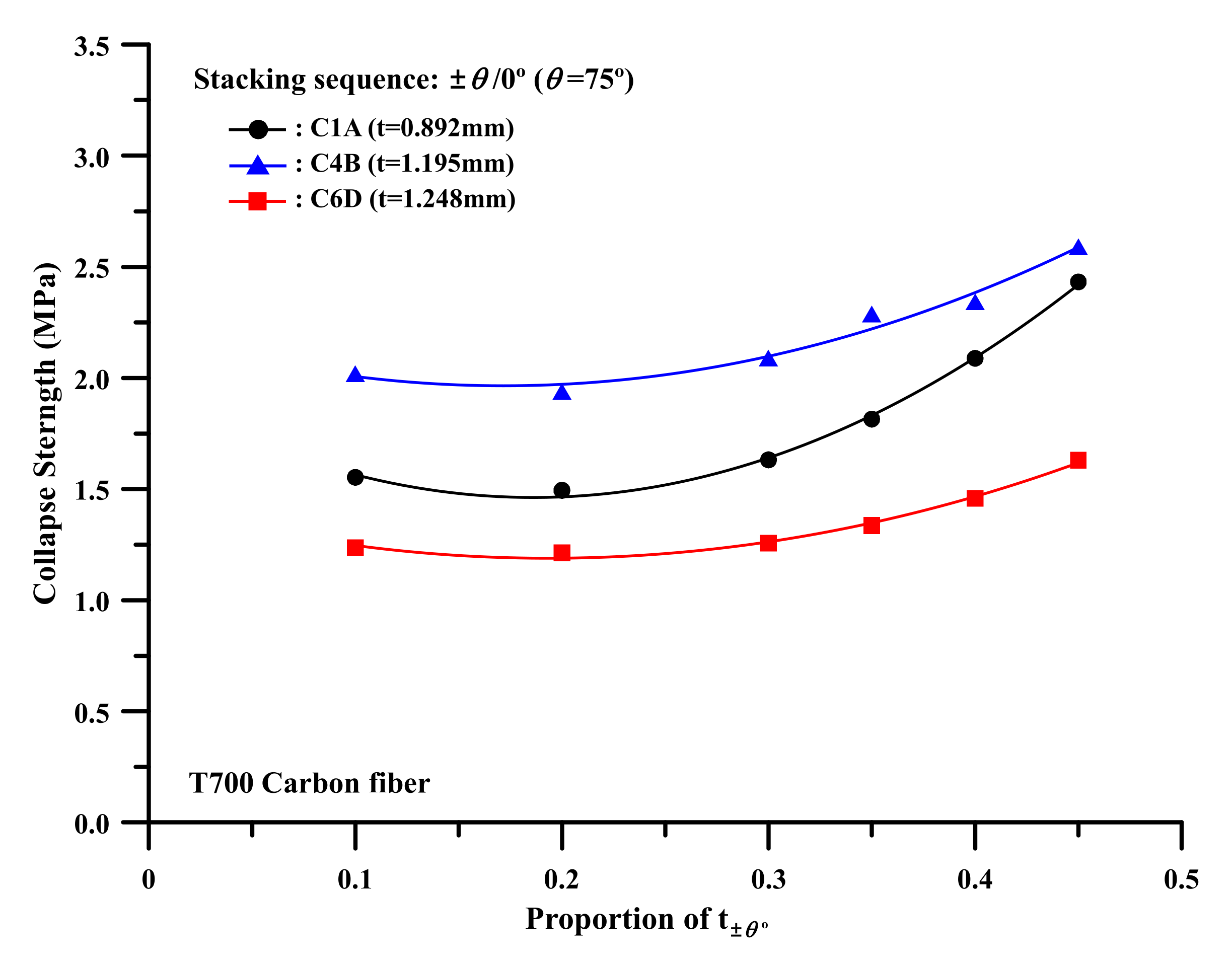

2.1. Numerical Modelling

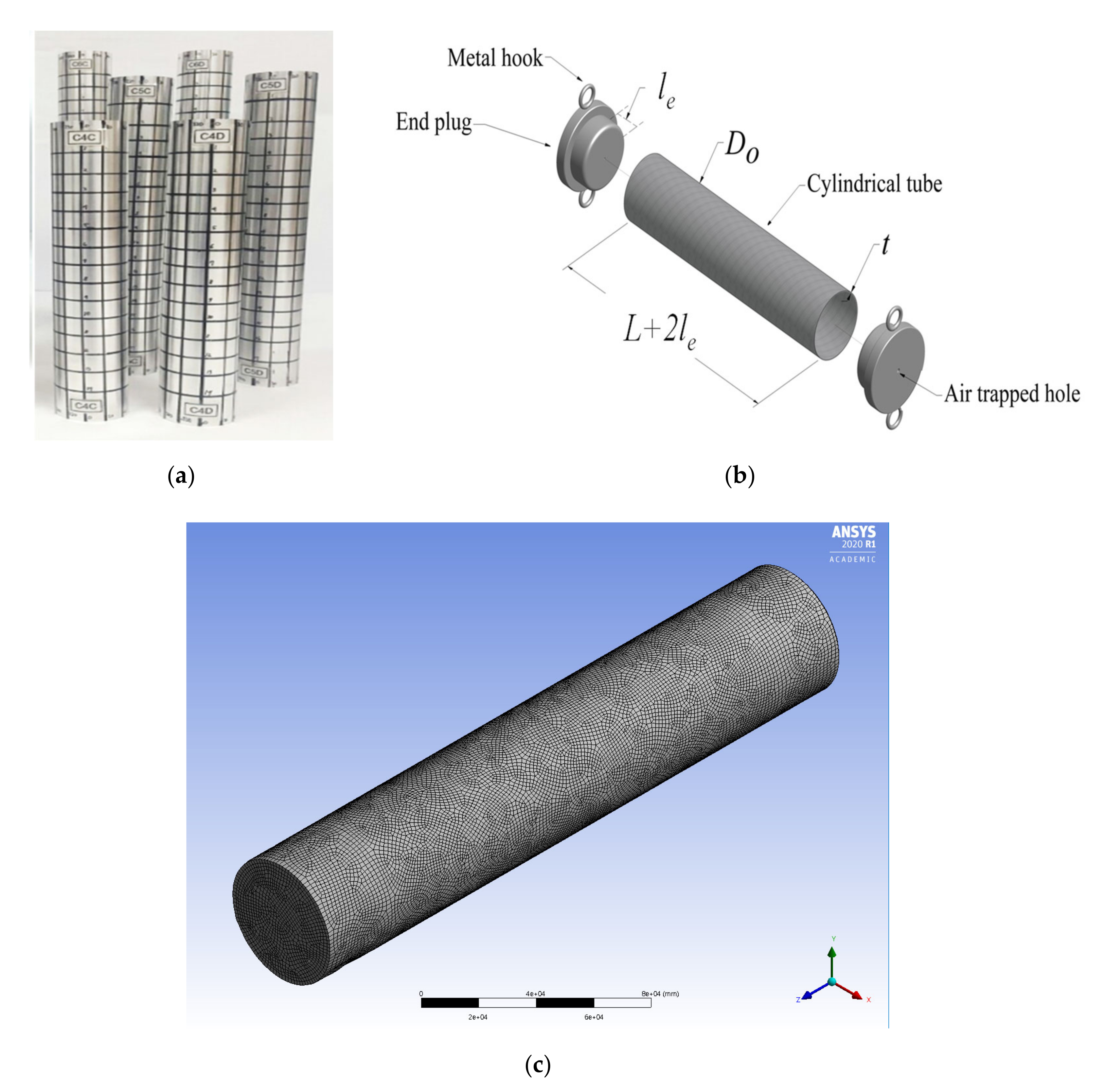

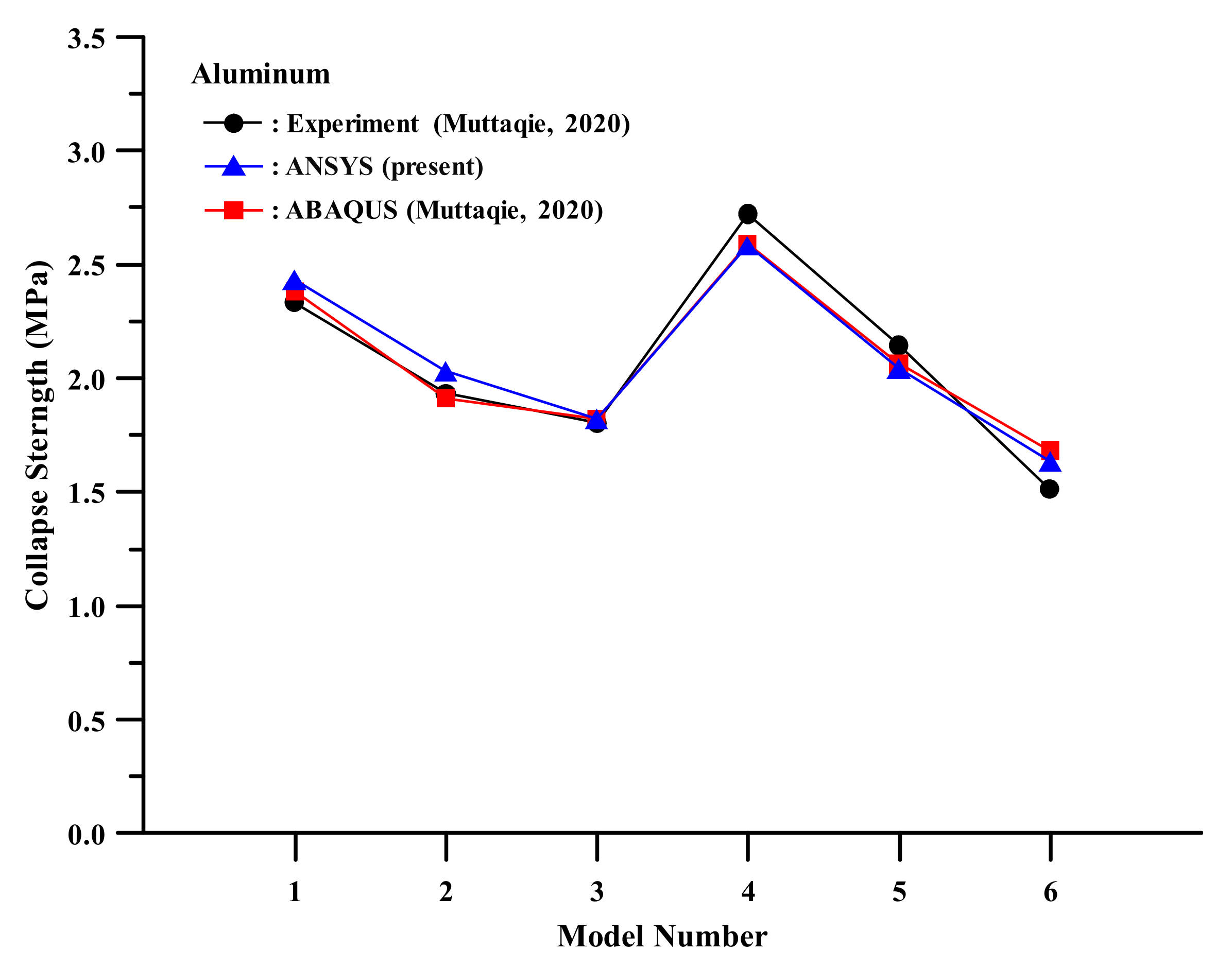

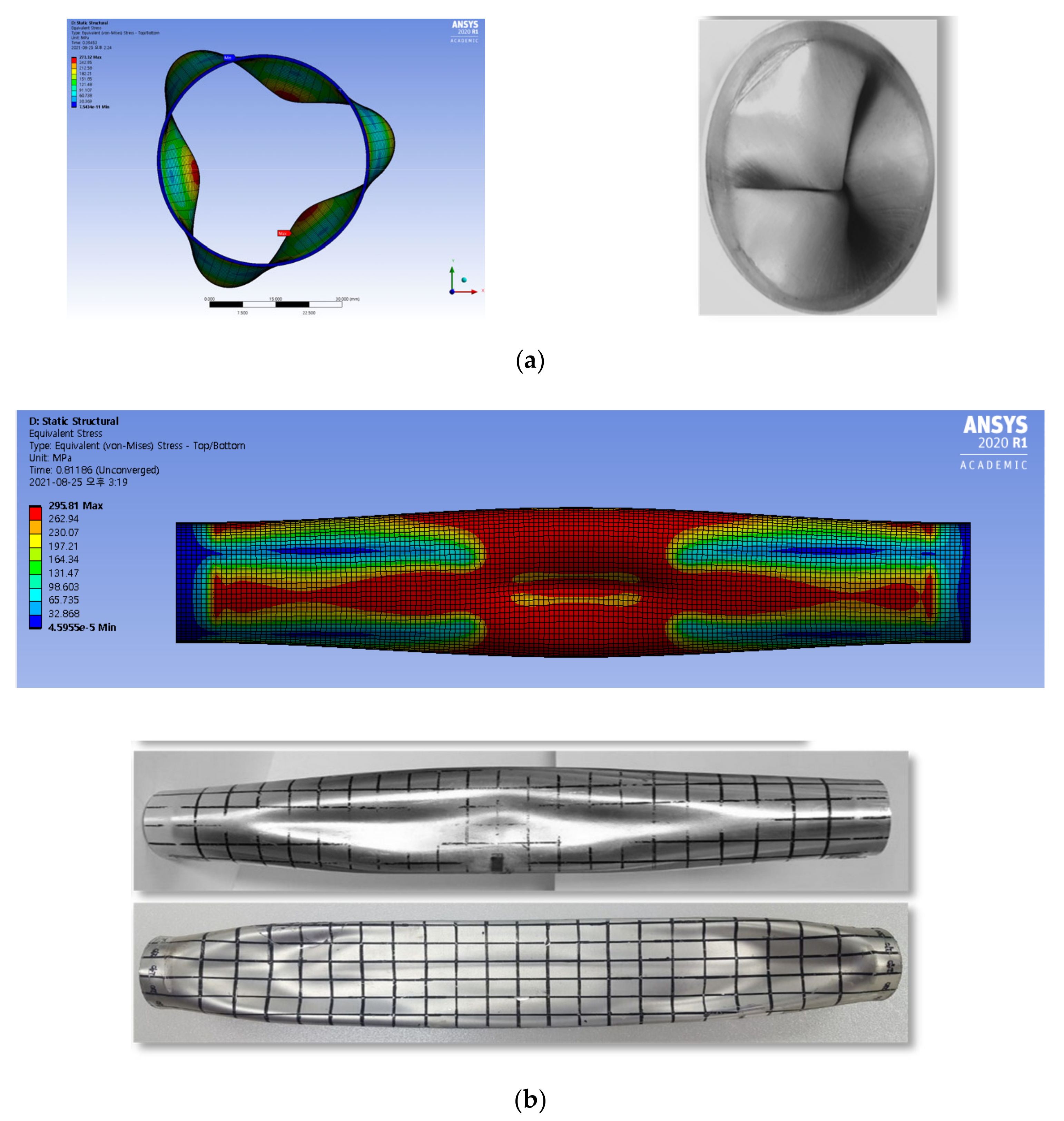

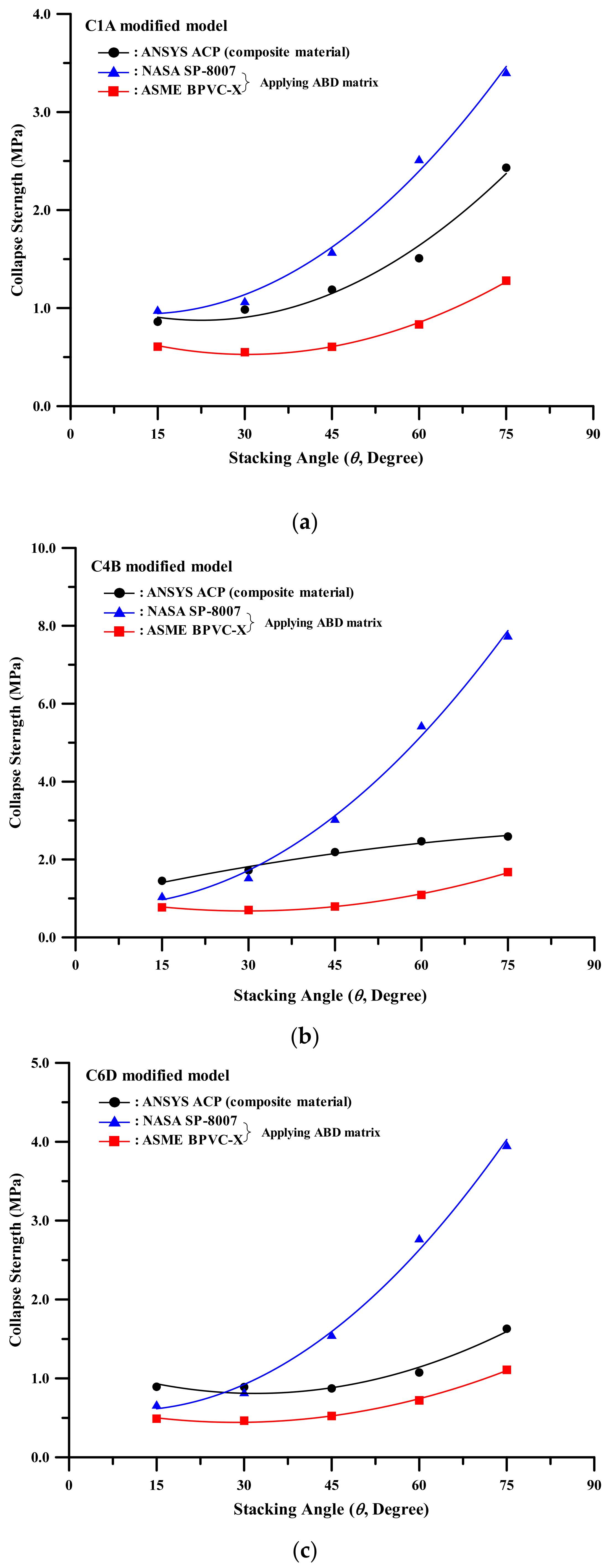

2.2. Numerical Validation

2.2.1. Aluminum Material

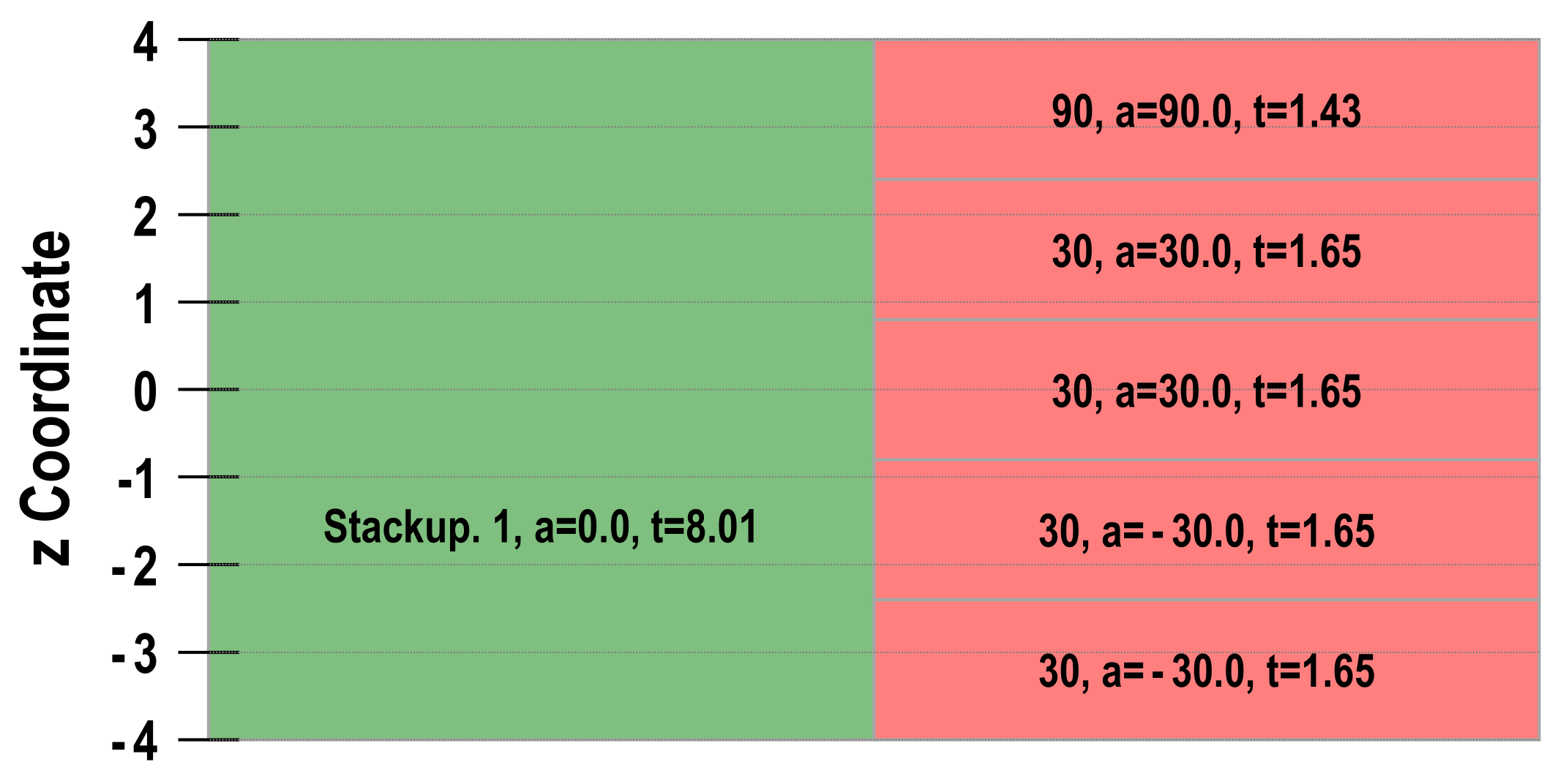

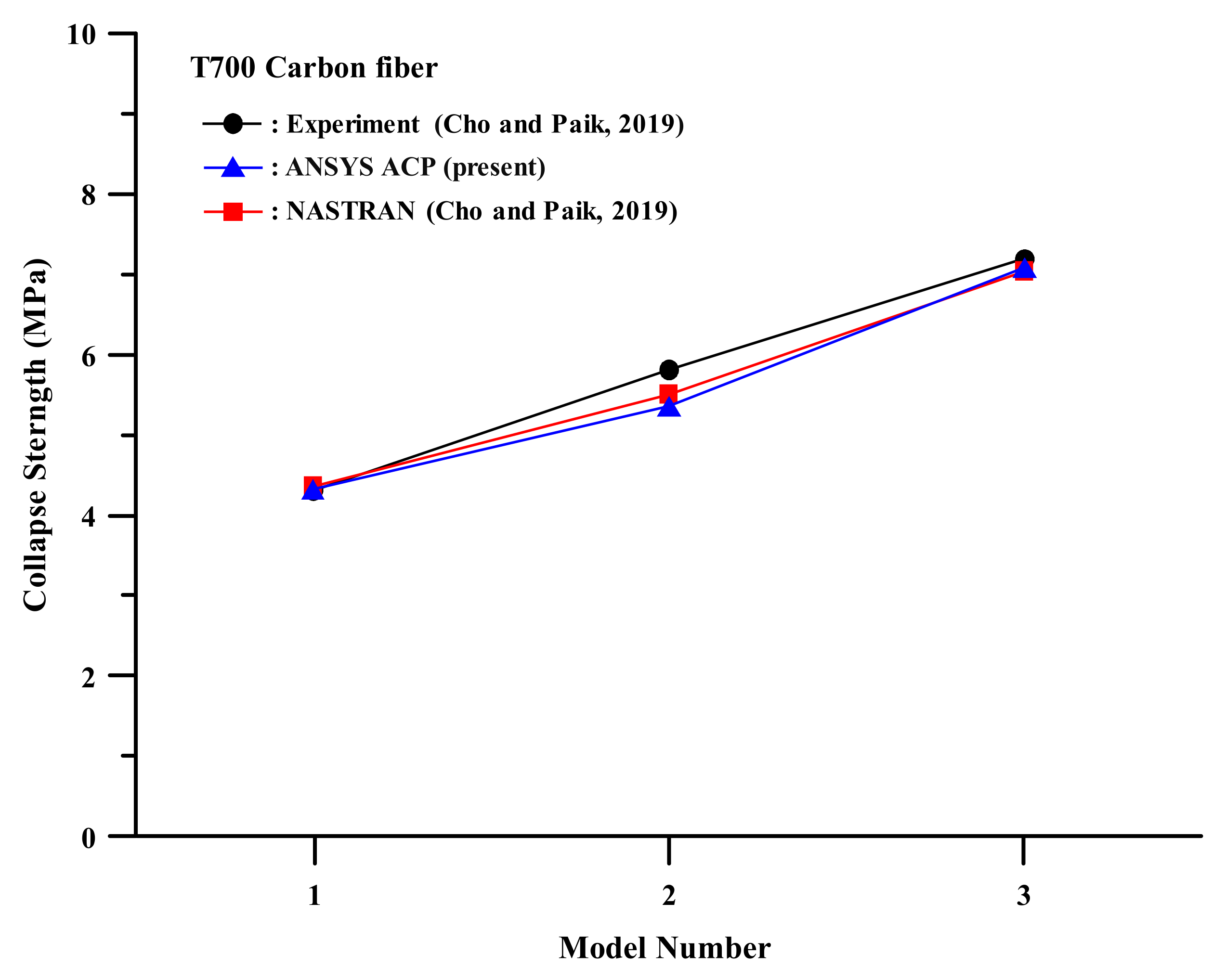

2.2.2. Composite Material

3. Comparison of Aluminum and Composite Materials

3.1. Application Model

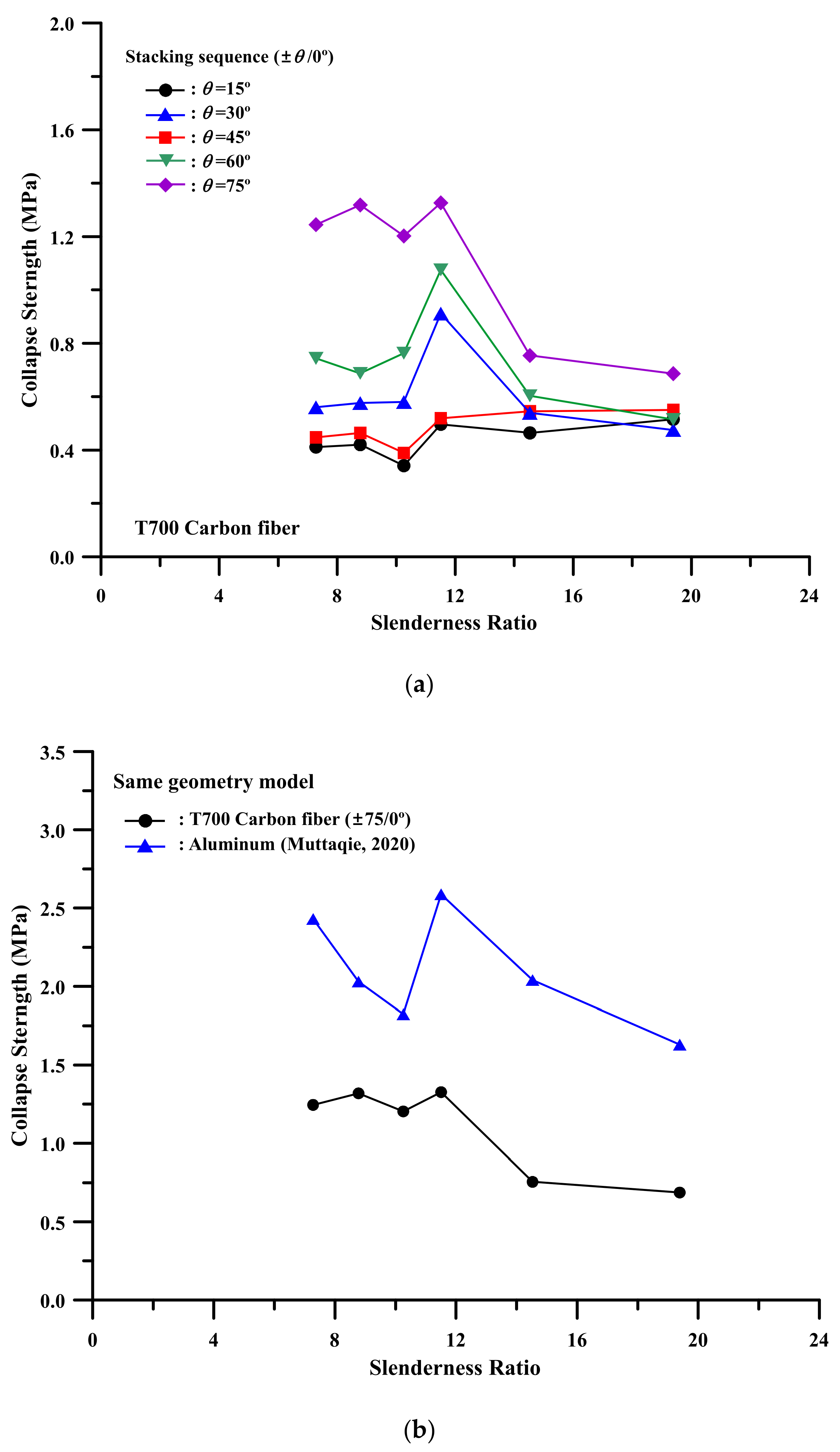

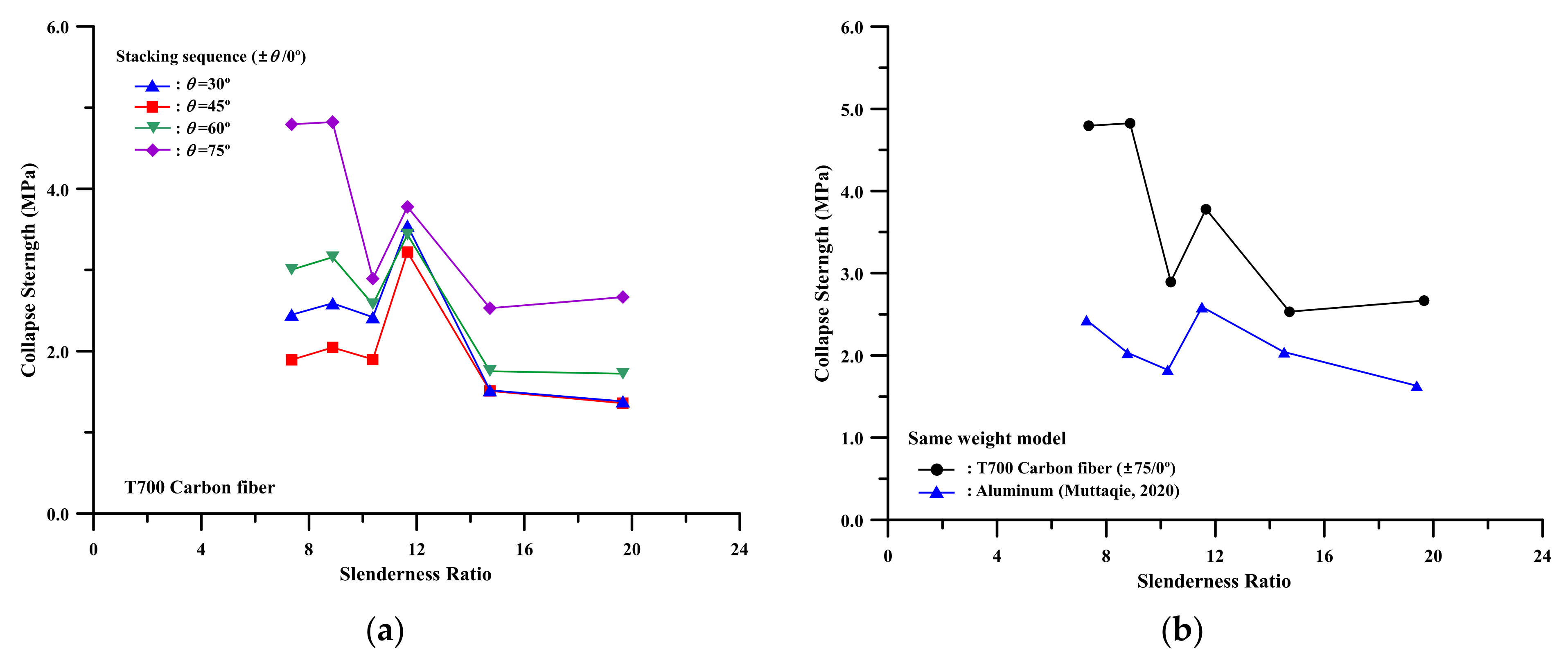

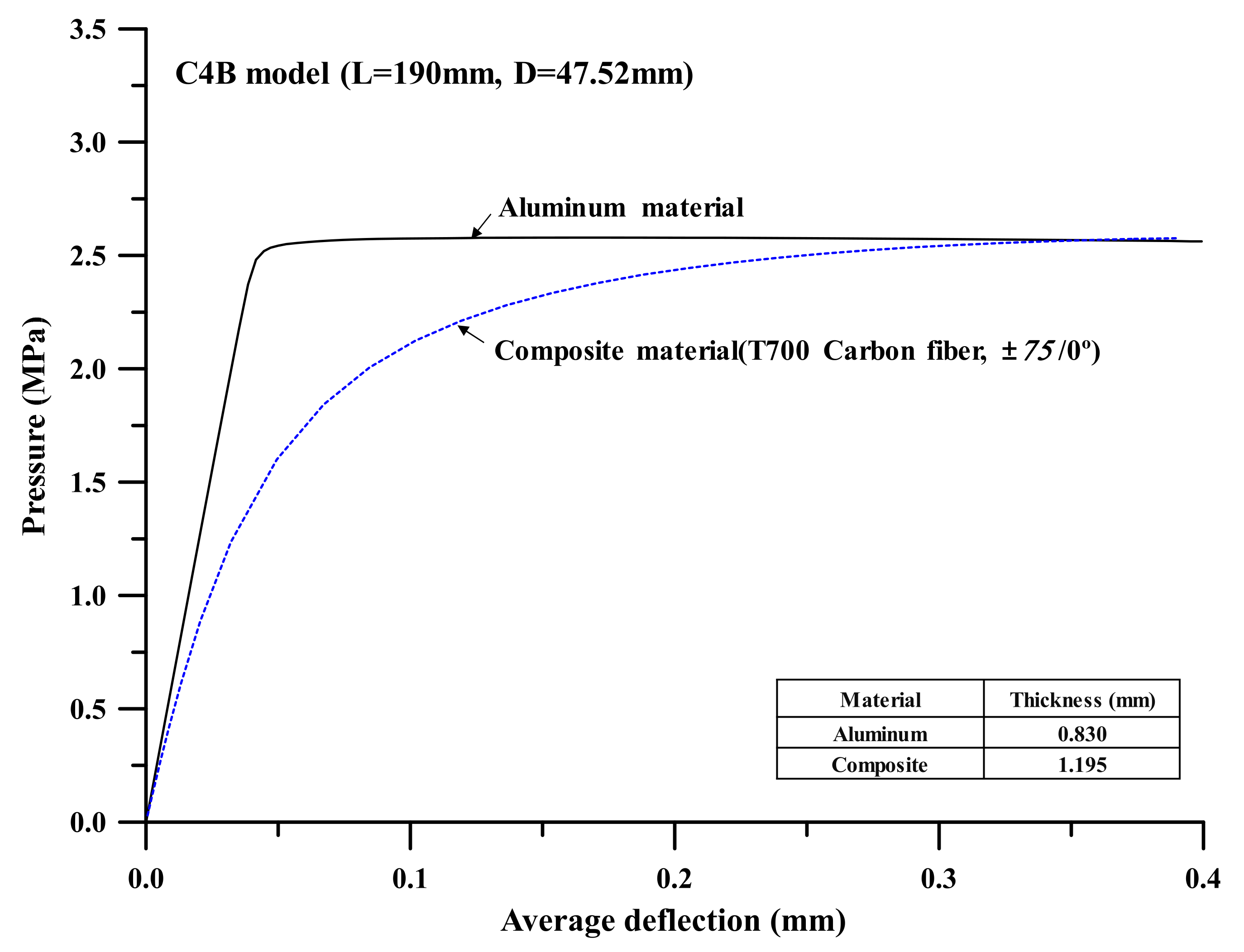

3.2. Results of Comparison

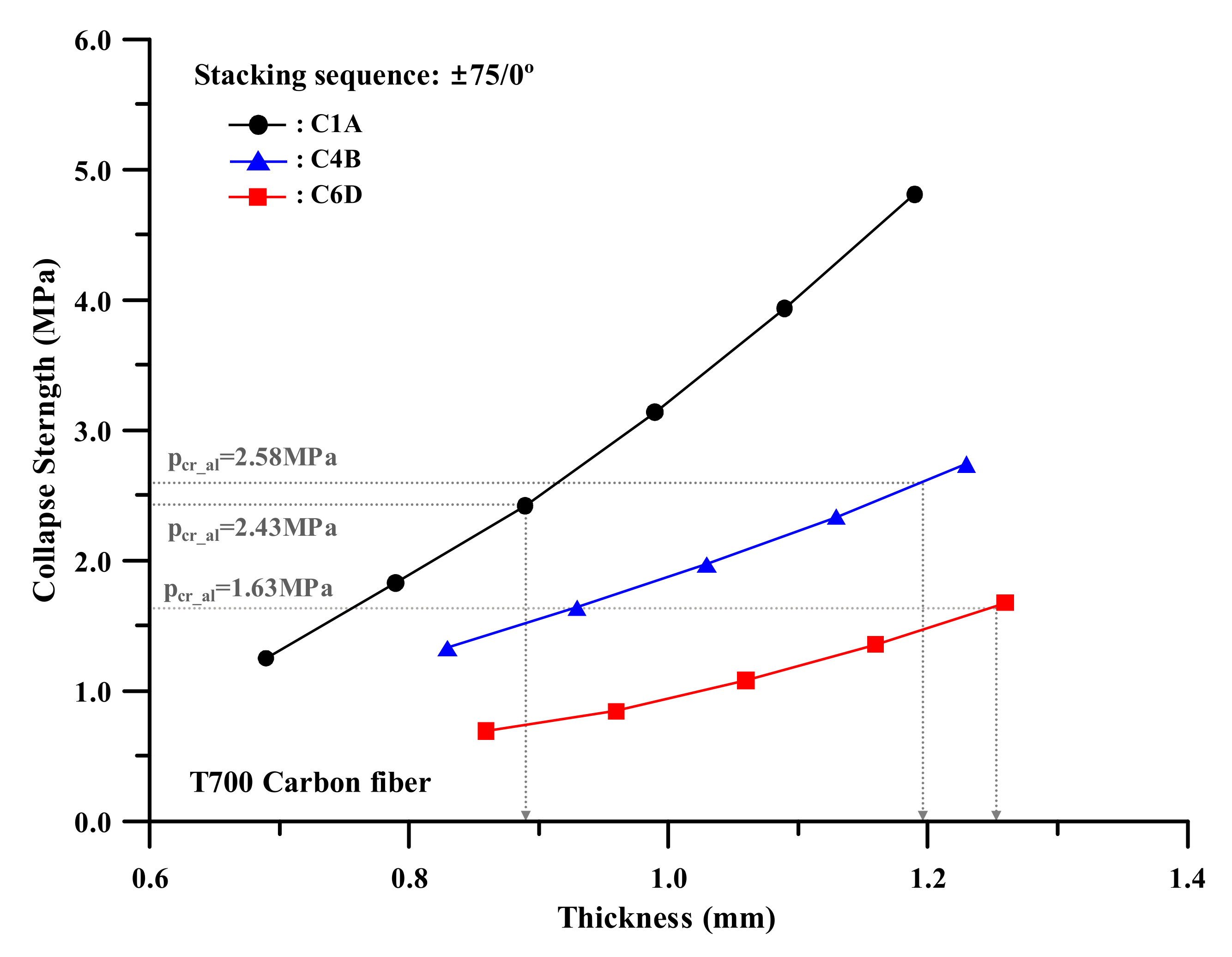

4. Parametric Studies

5. Comparison against Engineering Standards

- (1)

- The laminate thickness is very small;

- (2)

- The layers are perfectly bonded;

- (3)

- Vertical edges perpendicular to the cross-section surface of the small element in laminate remains straight after deformation;

- (4)

- The laminate is linear elastic;

- (5)

- The through-the-thickness stresses and strains are negligible.

6. Effective Engineering Constants of Laminate

6.1. Three-Dimensional Laminate Theory

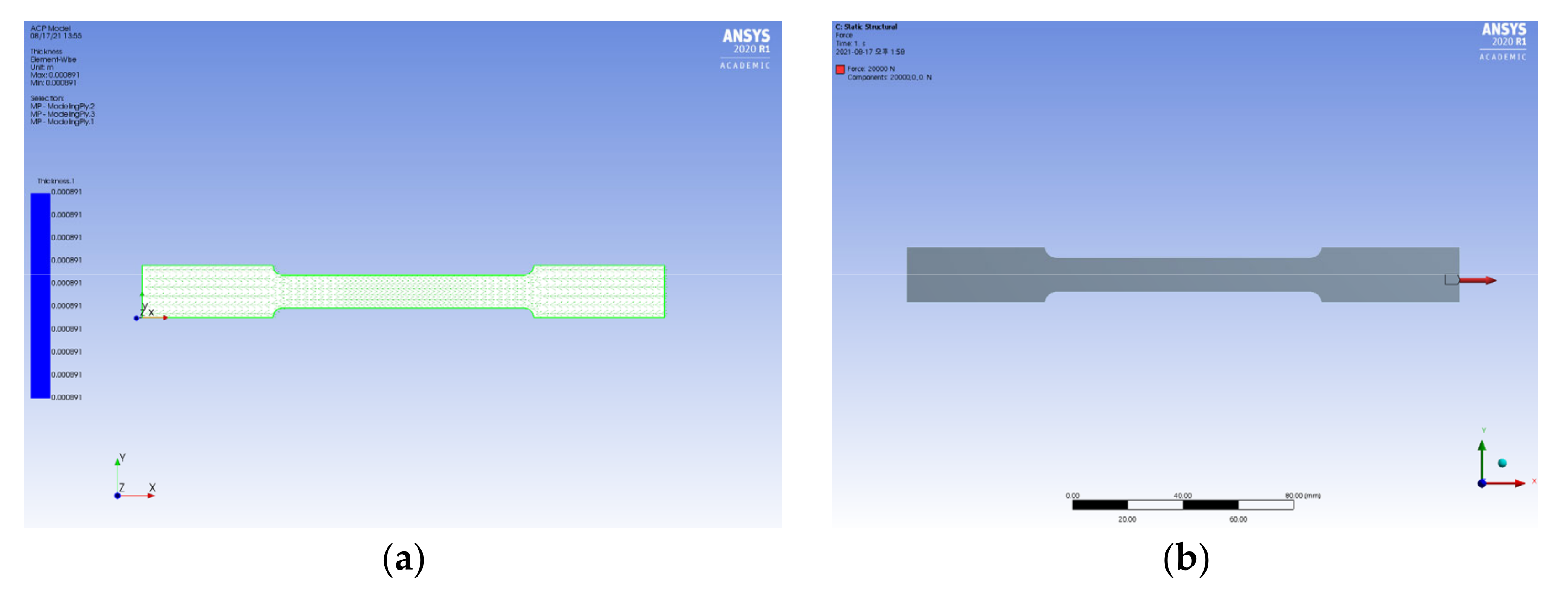

6.2. Numerical Analysis of Tensile Test

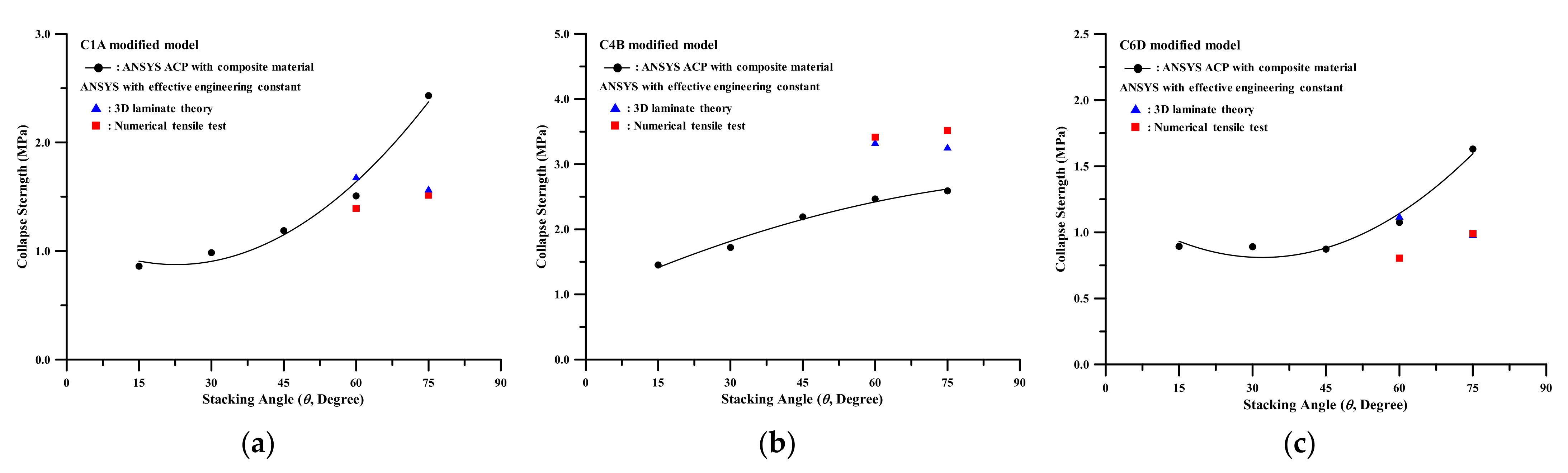

6.3. Application of Strength Analysis

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Do | Outer diameter of cylinder | t | Thickness |

| E | Elastic modulus | tk | Thickness of kth ply |

| Ei | Elastic modulus in ith-direction | tθ | Thickness for layer which has stacking angle of θ |

| F | Safety factor | Vk | Volume fraction of the kth ply |

| Gij | i and j axes shear modulus | zk | z-coordinate of the kth ply |

| KD | Knockdown factor, 0.84 | γ | Reduction factor |

| L | Length of cylinder | γxy | Shear strain |

| le | Length of end plug | εi | Normal strain in ith direction |

| m | Longitudinal wave no. of buckling | κ | Curvature in ith direction |

| n | Circumferential wave no. of buckling | θ | Stacking angle in helical layer |

| Mi | Moment resultant in ith direction | θk | Stacking angle in kth layer |

| Ni | Stress resultant in ith direction | λ | Slenderness ratio |

| Pa | Allowable external pressure | νij | Poisson’s ratio associated with loading in the ith direction and strain in the jth-direction |

| Lamina stiffness matrix | σY | Yield stress of material | |

| R | Radius of cylinder | σT | Tensile stress of material |

References

- Graham, D. Composite pressure hulls for deep ocean submersibles. Compos. Struct. 1995, 32, 331–343. [Google Scholar] [CrossRef]

- Helal, M.; Huang, H.; Wang, D.; Fathallah, E. Numerical analysis of sandwich composite deep submarine pressure hull considering failure criteria. J. Mar. Sci. Eng. 2019, 7, 377. [Google Scholar] [CrossRef] [Green Version]

- Franco, J.; Corz, A.; Peña, A. Optimization of pressure hulls of composite materials. In Proceedings of the 16th European Conference on Composite Materials, Seville, Spain, 22–26 June 2014. [Google Scholar]

- Craven, R.; Graham, D.; Dalzel-Job, J. Conceptual design of a composite pressure hull. Ocean Eng. 2016, 128, 153–162. [Google Scholar] [CrossRef]

- Wang, S.I. On Lightweight Design of Submarine Pressure Hulls. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2012. [Google Scholar]

- Khalili, F.; Showkati, H. T-ring stiffened cone cylinder intersection under internal pressure. Thin-Walled Struct. 2012, 54, 54–64. [Google Scholar] [CrossRef]

- Muttaqie, T.; Thang, D.Q.; Prabowo, A.R.; Cho, S.R.; Sohn, J.M. Numerical studies of the failure modes of ring-stiffened cylinders under hydrostatic pressure. Struct. Eng. Mech. 2019, 70, 431–443. [Google Scholar]

- Cho, S.R.; Muttaqie, T.; Lee, S.H.; Paek, J.; Sohn, J.M. Ultimate strength assessment of steel-welded hemispheres under external hydrostatic pressure. J. Mar. Sci. Appl. 2020, 19, 615–633. [Google Scholar] [CrossRef]

- Muttaqie, T.; Park, S.H.; Sohn, J.M.; Cho, S.R.; Nho, I.S.; Han, S.; Lee, P.S.; Cho, Y.S. Experimental investigations on the implosion characteristics of thin cylindrical aluminium-alloy tubes. Int. J. Solids Struct. 2020, 200–201, 64–82. [Google Scholar] [CrossRef]

- Muttaqie, T.; Park, S.H.; Sohn, J.M.; Cho, S.R.; Nho, I.S.; Han, S.; Cho, Y.S. Implosion tests of aluminium-alloy ring-stiffened cylinders subjected to external hydrostatic pressure. Mar. Struct. 2021, 78, 102980. [Google Scholar] [CrossRef]

- Waqas, H.M.; Shi, D.; Imran, M.; Khan, S.Z.; Tong, L.; Ahad, F.; Zaidi, A.A.; Iqbal, J.; Ahmed, W. Conceptual design of composite sandwich structure submarine radome. Materials 2019, 12, 1966. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jung, H.Y.; Cho, J.R.; Han, J.Y.; Lee, W.H.; Bae, W.B.; Cho, Y.S. A study on buckling of filament-wound cylindrical shells under hydrostatic external pressure using finite element analysis and buckling formula. Int. J. Precis. Eng. Manuf. 2012, 13, 731–737. [Google Scholar] [CrossRef]

- Chun, S.K.; Guang, P. Optimizing the buckling strength of filament winding composite cylinders under hydrostatic pressure. J. Reinf. Plast. Compos. 2018, 37, 892–904. [Google Scholar] [CrossRef]

- Cho, Y.S.; Paik, J.K. Optimal lamination design of composite cylinders using an empirical ultimate pressure load formula. J. Soc. Nav. Archit. Korea 2019, 56, 316–326. [Google Scholar] [CrossRef]

- Sun, C.T.; Li, S. Three-dimensional effective elastic constants for thick laminates. J. Compos. Mater. 1988, 22, 629–639. [Google Scholar] [CrossRef]

- ANSYS. User’s Manual of ANSYS; ANSYS Inc.: Canonsburg, PA, USA, 2020. [Google Scholar]

- NASA. Space Vehicle Design Criteria; NASA SP-8007. In Buckling of Thin-Walled Circular Cylinders; National Aeronautics and Space Administration: Washington, DC, USA, 1968. [Google Scholar]

- ASME. Boiler and Pressure & Vessel Code; Section X. In Fiber Reinforce Plastic Pressure Vessel; American Society for Testing and Materials: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Muttaqie, T. Ultimate Strength Investigations of Pressure Hull Structures Subjected to External Hydrostatic Pressure. Ph.D. Thesis, Pukyong National University, Busan, Korea, 2020. [Google Scholar]

- ABAQUS. Analysis User’s Manual Version 6.14; SIMULIA: Johnston, RI, USA, 2016. [Google Scholar]

- Wikia. Available online: https://military.wikia.org/wiki/Aluminaut (accessed on 2 February 2022).

- NASA. Space Vehicle Design Criteria; RP-1351. In Basic Mechanics of Laminated Composite Plates; National Aeronautics and Space Administration: Washington, DC, USA, 1994. [Google Scholar]

- Tavakoldavani, K. Composite Materials Equivalent Properties in Lamina, Laminate and Structure Levels. Master’s Thesis, University of Texas, Arlington, TX, USA, 2014. [Google Scholar]

- Hudisteanu, I.; Taranu, N.; Maxineasa, S.G.; Lupășteanu, V. Engineering constants of laminated composites. In Proceedings of the 15th International Scientific Conference VSU, Sofia, Bulgaria, 4–5 June 2015. [Google Scholar]

- Farooq, U.; Myler, P. Efficient determination of mechanical properties of carbon fibre-reinforced laminated composite Panels. J. Eng. Appl. Sci. 2017, 12, 1375–1392. [Google Scholar]

- Chou, P.C.; Carleone, J.; Hsu, C.M. Elastic constants of layered media. J. Compos. Mater. 1972, 6, 80–93. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Tension Testing of Metallic Materials; American Society for Testing and Materials: West Conshohocken, PA, USA, 2004. [Google Scholar]

- ANSYS. Theory Reference; ANSYS Inc.: Canonsburg, PA, USA, 2022. [Google Scholar]

| Material | Author (Year) | Pressure Hull | Method | Stacking Sequence (Case of Composite Material) | ||||

|---|---|---|---|---|---|---|---|---|

| Type | Feature | Lay-Up | Design Variable | t Variation | Effective Engineering Constant | |||

| Steel | Khalili and Showkati (2012) | Cone-cylinder | Stiffened structure | E, N | - | |||

| Muttaqie et al. (2019) | Cylinder | N | ||||||

| Cho et al. (2020) | Hemisphere | - | E, N, D | |||||

| Aluminum | Muttaqie et al. (2020) | Cylinder | E, N | - | ||||

| Muttaqie et al. (2021) | Cylinder | Stiffened structure | E, N | |||||

| GFRP CFRP | Waqas et al. (2019) | Hemisphere | Sandwich Structure | N | [±45i],[0j/90j] | i = 4, 5, 11 j = 3, 4, 11 | O | X |

| Carbon fibre | Jung et al. (2012) | Cylinder | N, D | [±θ/90] | θ = 30°, 45°, 60° | X | O | |

| Chun and Guang (2018) | Cylinder | - | N | [±θ10/904] | θ = 30°, 45°, 60° | X | X | |

| Cho and Paik (2019) | Cylinder | - | N | [90i/θ/15j/θ/90i] | θ = 30°, 45°, 60°, 75° i = 2,3, j = 2–6 | X | X | |

| Present | Cylinder | - | N, D | [±θ/0] | θ = 15°, 30°, 45°, 60°, 75° | O | O | |

| Model | Parameters (mm) | Material Properties (MPa) | |||||

|---|---|---|---|---|---|---|---|

| L | t | Do | E | σY | σT | ||

| C1A | 120 | 0.69 | 47.33 | 15 | 69,700 | 267 | 298 |

| C2A | 145 | 0.71 | 47.39 | 15 | |||

| C3C | 170 | 0.71 | 47.58 | 15 | |||

| C4B | 190 | 0.83 | 47.52 | 30 | 67,000 | 301 | 334 |

| C5C | 240 | 0.82 | 47.54 | 30 | 69,900 | 332 | 364 |

| C6D | 320 | 0.86 | 47.52 | 15 | 71,400 | 294 | 322 |

| No. | Collapse Strength (MPa) | Notation [19] | ||||

|---|---|---|---|---|---|---|

| Experiment | Finite Element Analysis | |||||

| ANSYS ACP | Error (%) | ABAQUS | Error (%) | |||

| 1 | 2.33 | 2.43 | 4.29 | 2.38 | 2.15 | C1A |

| 2 | 1.93 | 2.03 | 5.18 | 1.91 | 1.04 | C2A |

| 3 | 1.80 | 1.82 | 1.11 | 1.82 | 1.11 | C3C |

| 4 | 2.72 | 2.58 | 5.15 | 2.59 | 4.78 | C4B |

| 5 | 2.14 | 2.04 | 4.67 | 2.06 | 3.74 | C5C |

| 6 | 1.51 | 1.63 | 7.95 | 1.68 | 11.26 | C6D |

| Model | Stacking Angle (°) | Length (mm) | Inner Radius (mm) | Thickness (mm) | Hoop Thickness (mm) | Notation [14] |

|---|---|---|---|---|---|---|

| 1 | ±30/90 | 686 | 150 | 8.01 | 1.43 | FWT8 30/90-1 |

| 2 | ±45/90 | 695 | 150 | 8.12 | 0.97 | FWT8 45/90-1 |

| 3 | ±60/90 | 695 | 150 | 7.80 | 0.99 | FWT8 60/90-1 |

| Description | Direction | Values |

|---|---|---|

| Elastic modulus (GPa) | In-plane | 121.0 |

| Transverse | 8.6 | |

| Shear modulus (GPa) | In-plane | 3.35 |

| Transverse | 2.68 | |

| Poisson’s ratio | In-plane | 0.253 |

| Transverse | 0.421 | |

| Tensile strength (MPa) | In-plane | 2060 |

| Transverse | 32 | |

| Shear strength (MPa) | In-plane | 45 |

| Transverse | 64 |

| No. | Collapse Strength (MPa) | Notation [14] | ||||

|---|---|---|---|---|---|---|

| Experiment | Finite Elemetn Analysis | |||||

| ANSYS ACP | Error (%) | NASTRAN | Error | |||

| 1 | 4.30 | 4.31 | 0.23 | 4.351 | 1.19 | FWT8 30/90-1 |

| 2 | 5.80 | 5.35 | 7.76 | 5.498 | 5.21 | FWT8 45/90-1 |

| 3 | e7.18 | 7.07 | 1.53 | 7.034 | 2.03 | FWT8 60/90-1 |

| Notation [19] | Dimension (mm) | n | Slenderness Ratio | Ply Thickness (mm) | ||||

|---|---|---|---|---|---|---|---|---|

| L | D | t | +θ | −θ | 0° | |||

| C1A | 120 | 47.33 | 0.69 | 3 | 7.28 | 0.31 | 0.31 | 0.07 |

| C2A | 145 | 47.39 | 0.71 | 3 | 8.78 | 0.32 | 0.32 | 0.07 |

| C3C | 170 | 47.58 | 0.71 | 3 | 10.26 | 0.32 | 0.32 | 0.07 |

| C4B | 190 | 47.52 | 0.83 | 3 | 11.51 | 0.37 | 0.37 | 0.08 |

| C5C | 240 | 47.54 | 0.82 | 2 | 14.53 | 0.37 | 0.37 | 0.08 |

| C6D | 320 | 47.52 | 0.86 | 2 | 19.39 | 0.39 | 0.39 | 0.09 |

| Notation [19] | Dimension (mm) | λ | Weight (kg) | Weight Saving (%) | |||

|---|---|---|---|---|---|---|---|

| L | D | t | Aluminum | Composite (±75/0°) | |||

| C1A | 120 | 47.33 | 0.892 | 7.31 | 0.330 | 0.250 | 32 |

| C2A | 145 | 47.39 | 0.843 | 8.81 | 0.041 | 0.028 | 46 |

| C3C | 170 | 47.58 | 0.847 | 10.29 | 0.048 | 0.033 | 45 |

| C4B | 190 | 47.52 | 1.195 | 11.60 | 0.062 | 0.052 | 19 |

| C5C | 240 | 47.54 | 1.251 | 14.66 | 0.078 | 0.069 | 13 |

| C6D | 320 | 47.52 | 1.248 | 19.55 | 0.109 | 0.091 | 20 |

| Model | ttotal (mm) | Thickness in Helical Layers t±75 (mm) | Proportion (%) | Thickness in Hoop Layer t0 (mm) | Proportion (%) |

|---|---|---|---|---|---|

| C1A | 0.892 | 0.401 | 0.45 | 0.089 | 0.10 |

| 0.357 | 0.40 | 0.178 | 0.20 | ||

| 0.312 | 0.35 | 0.268 | 0.30 | ||

| 0.268 | 0.30 | 0.357 | 0.40 | ||

| 0.178 | 0.20 | 0.535 | 0.60 | ||

| 0.089 | 0.10 | 0.714 | 0.80 | ||

| C4B | 1.195 | 0.538 | 0.45 | 0.120 | 0.10 |

| 0.478 | 0.40 | 0.239 | 0.20 | ||

| 0.418 | 0.35 | 0.359 | 0.30 | ||

| 0.359 | 0.30 | 0.478 | 0.40 | ||

| 0.239 | 0.20 | 0.717 | 0.60 | ||

| 0.120 | 0.10 | 0.956 | 0.80 | ||

| C6D | 1.248 | 0.562 | 0.45 | 0.125 | 0.10 |

| 0.499 | 0.40 | 0.250 | 0.20 | ||

| 0.437 | 0.35 | 0.374 | 0.30 | ||

| 0.374 | 0.30 | 0.499 | 0.40 | ||

| 0.250 | 0.20 | 0.749 | 0.60 | ||

| 0.125 | 0.10 | 0.998 | 0.80 |

| Properties | Stacking Sequence | ||||

|---|---|---|---|---|---|

| ±15/0 | ±30/0 | ±45/0 | ±60/0 | ±75/0 | |

| Ex (GPa) | 100.48 | 47.46 | 23.32 | 19.54 | 19.61 |

| Ey (GPa) | 8.41 | 9.25 | 17.53 | 48.90 | 93.58 |

| Ez (GPa) | 8.70 | 9.31 | 9.99 | 9.85 | 9.60 |

| νxy | 0.934 | 1.405 | 0.823 | 0.321 | 0.087 |

| νyz | 0.394 | 0.309 | 0.160 | 0.055 | 0.195 |

| νxz | −0.033 | −0.205 | 0.070 | 0.282 | 0.383 |

| Gxy (GPa) | 9.67 | 22.32 | 28.65 | 22.32 | 9.67 |

| Gyz (GPa) | 2.71 | 2.81 | 2.95 | 3.10 | 3.22 |

| Gxz (GPa) | 3.30 | 3.17 | 3.01 | 2.87 | 2.77 |

| Properties | Stacking Sequence | ||||

|---|---|---|---|---|---|

| ±15/0 | ±30/0 | ±45/0 | ±60/0 | ±75/0 | |

| Ex (GPa) | 71.95 | 39.70 | 23.15 | 18.60 | 18.63 |

| Ey (GPa) | 8.42 | 8.28 | 9.37 | 15.14 | 32.86 |

| Ez (GPa) | 10.15 | 10.21 | 10.30 | 10.35 | 10.39 |

| νxy | 0.589 | 0.824 | 0.616 | 0.301 | 0.095 |

| νyz | 0.393 | 0.332 | 0.240 | 0.192 | 0.259 |

| νxz | 0.134 | 0.054 | 0.153 | 0.289 | 0.377 |

| Gxy (GPa) | 5.06 | 5.68 | 16.37 | 22.08 | 26.82 |

| Gyz (GPa) | 2.68 | 2.68 | 2.68 | 2.68 | 2.68 |

| Gxz (GPa) | 2.68 | 2.68 | 2.68 | 2.68 | 2.68 |

| Method | Stacking Sequence | ||||

|---|---|---|---|---|---|

| ±15/0 | ±30/0 | ±45/0 | ±60/0 | ±75/0 | |

| 3D laminate theory | −9.2921 | −8.5383 | −0.0021 | 0.7662 | 0.3015 |

| Numerical analysis of tensile test | −2.6608 | −2.4705 | −0.1427 | 0.6242 | 0.4950 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sohn, J.M.; Hirdaris, S.; Romanoff, J.; Kim, S.J. Development of Numerical Modelling Techniques for Composite Cylindrical Structures under External Pressure. J. Mar. Sci. Eng. 2022, 10, 466. https://doi.org/10.3390/jmse10040466

Sohn JM, Hirdaris S, Romanoff J, Kim SJ. Development of Numerical Modelling Techniques for Composite Cylindrical Structures under External Pressure. Journal of Marine Science and Engineering. 2022; 10(4):466. https://doi.org/10.3390/jmse10040466

Chicago/Turabian StyleSohn, Jung Min, Spyros Hirdaris, Jani Romanoff, and Sang Jin Kim. 2022. "Development of Numerical Modelling Techniques for Composite Cylindrical Structures under External Pressure" Journal of Marine Science and Engineering 10, no. 4: 466. https://doi.org/10.3390/jmse10040466