Holistic Energy Efficiency and Environmental Friendliness Model for Short-Sea Vessels with Alternative Power Systems Considering Realistic Fuel Pathways and Workloads

Abstract

:1. Introduction

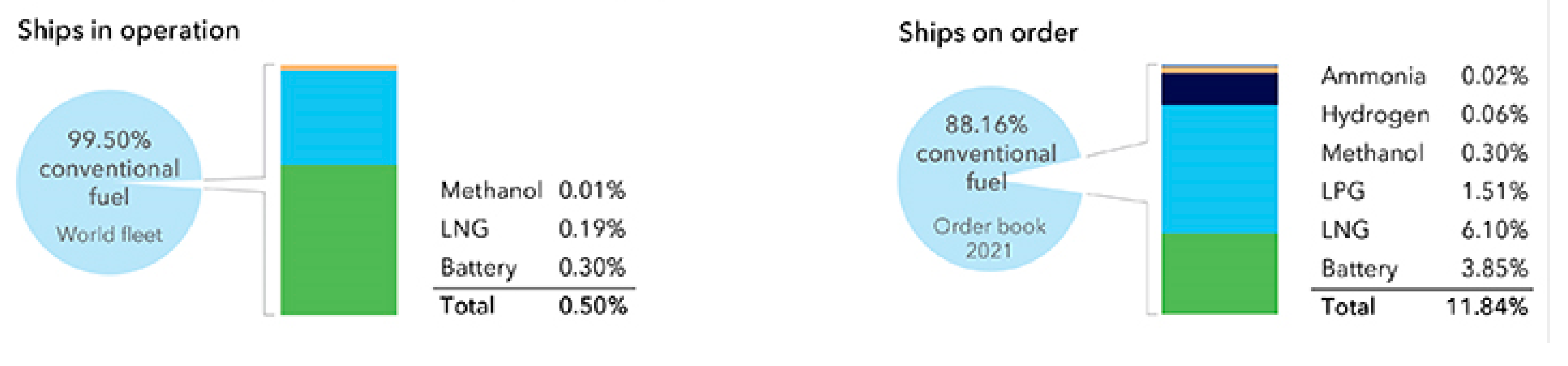

1.1. Regulatory Framework for Energy Efficiency and the Environmental Footprint in the Shipping Sector

1.2. Environmental Impact Reduction Measures

1.3. Research Gap and the Aim of the Paper

- Development of the energy efficiency index applicable for ships with alternative power systems, which considers different impact categories of ships’ environmental footprint and life-cycle emissions.

- Identification of a combination of optimal technical and operational measures that results in lower costs, emissions, and ultimately a lower energy efficiency index compared to currently used diesel power system configurations.

2. Methodology

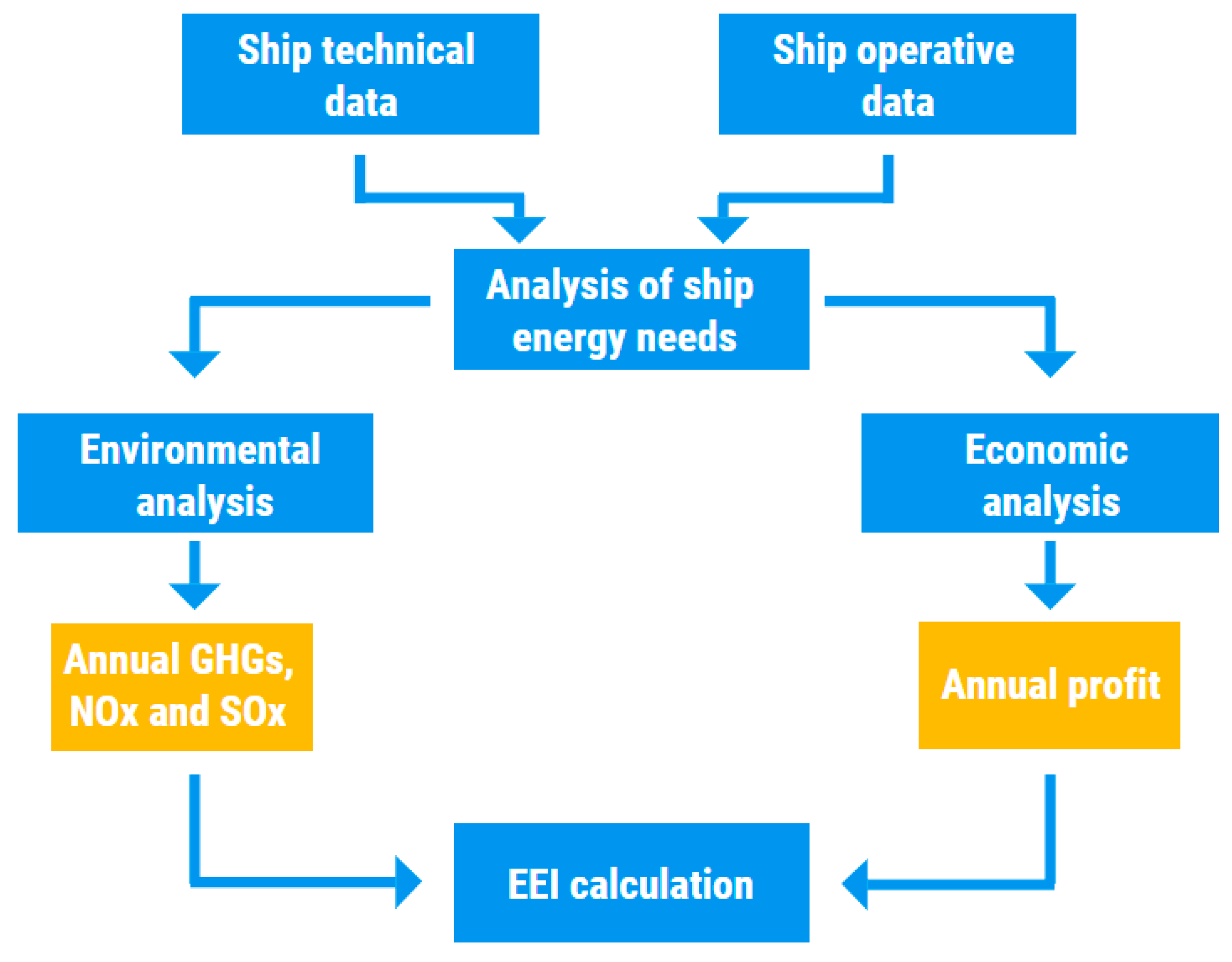

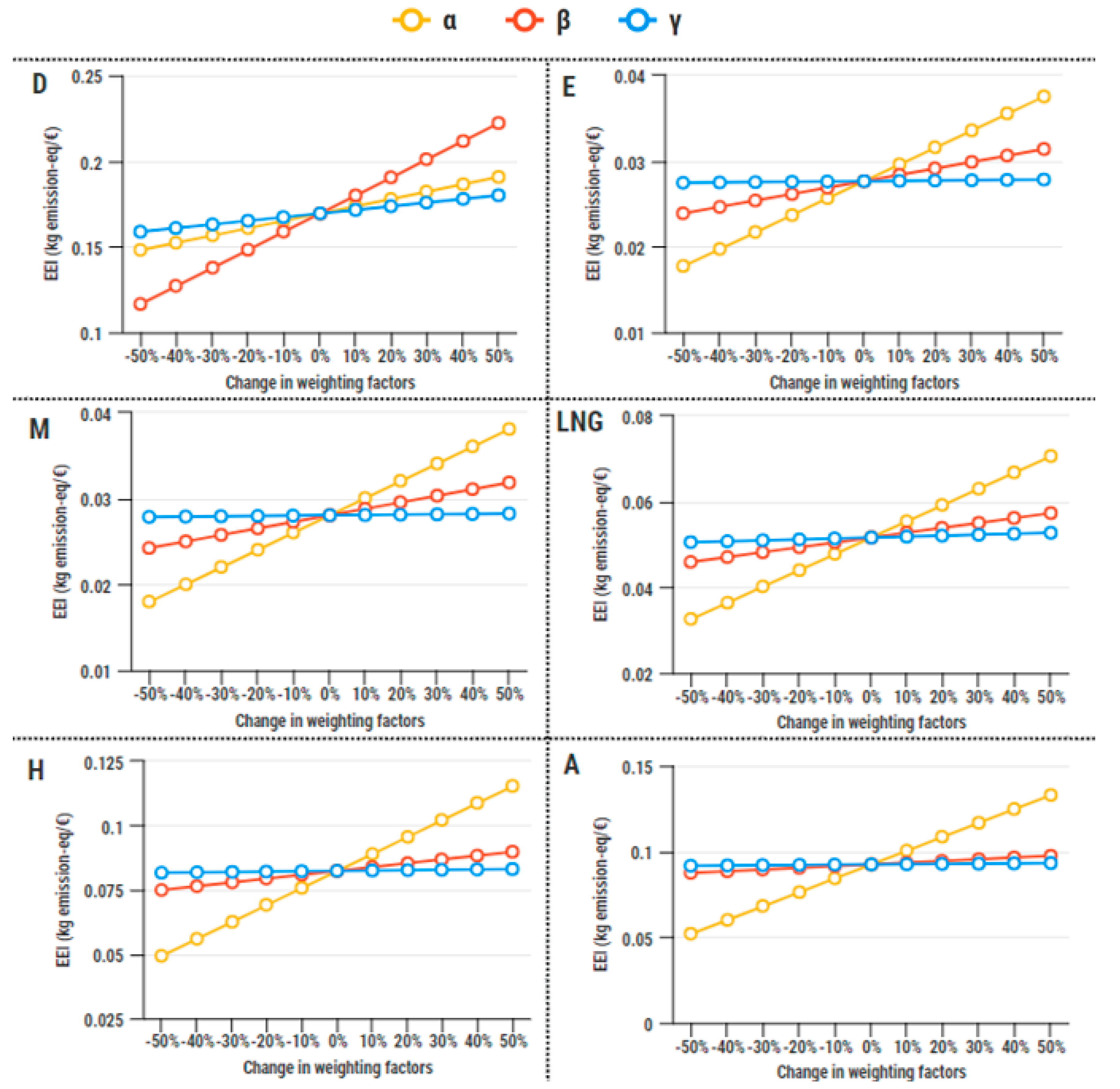

2.1. Formulation of Energy Efficiency Index for Ships with Alternative Powering Options

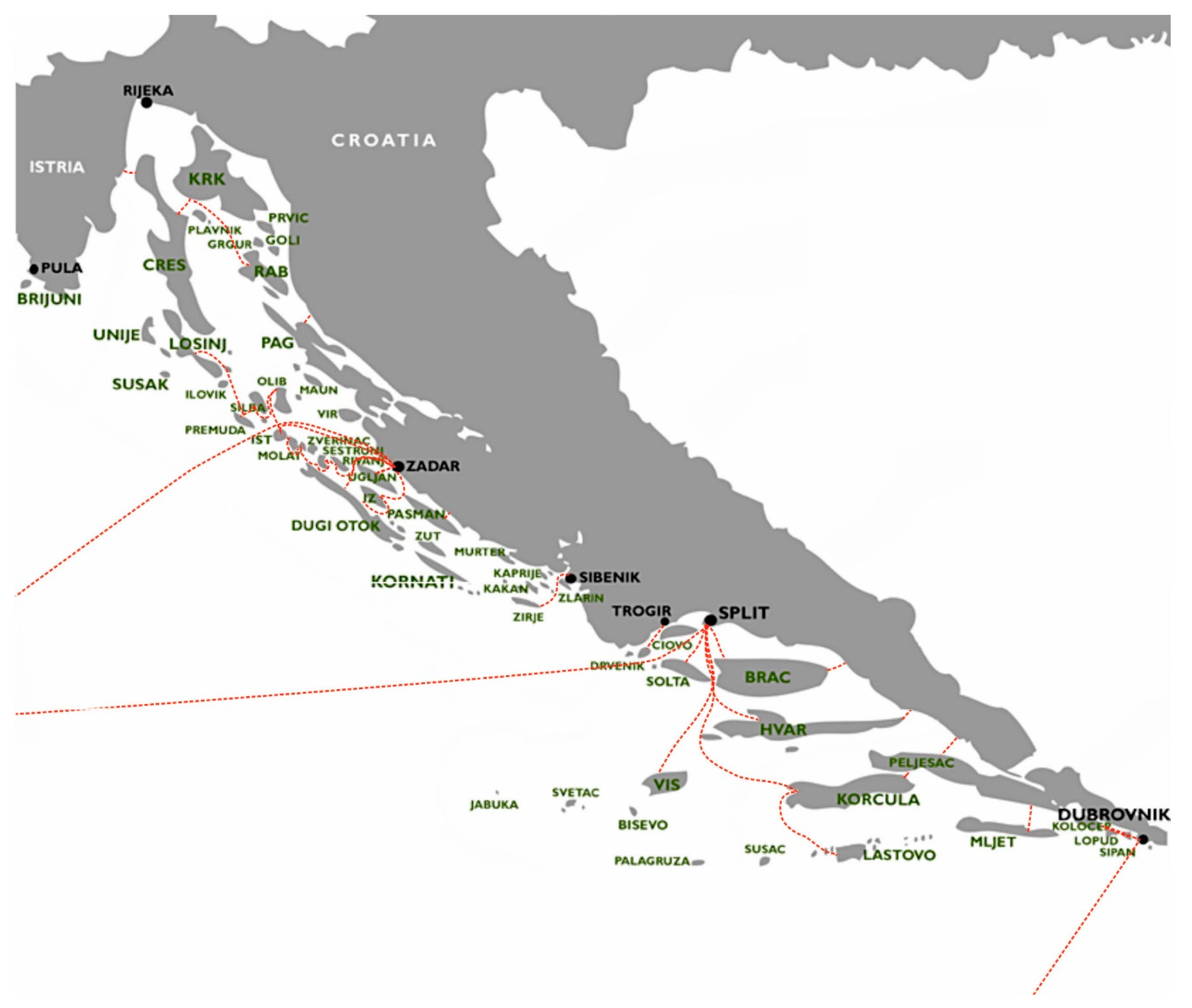

2.2. The Croatian Ro-Ro Passenger Fleet

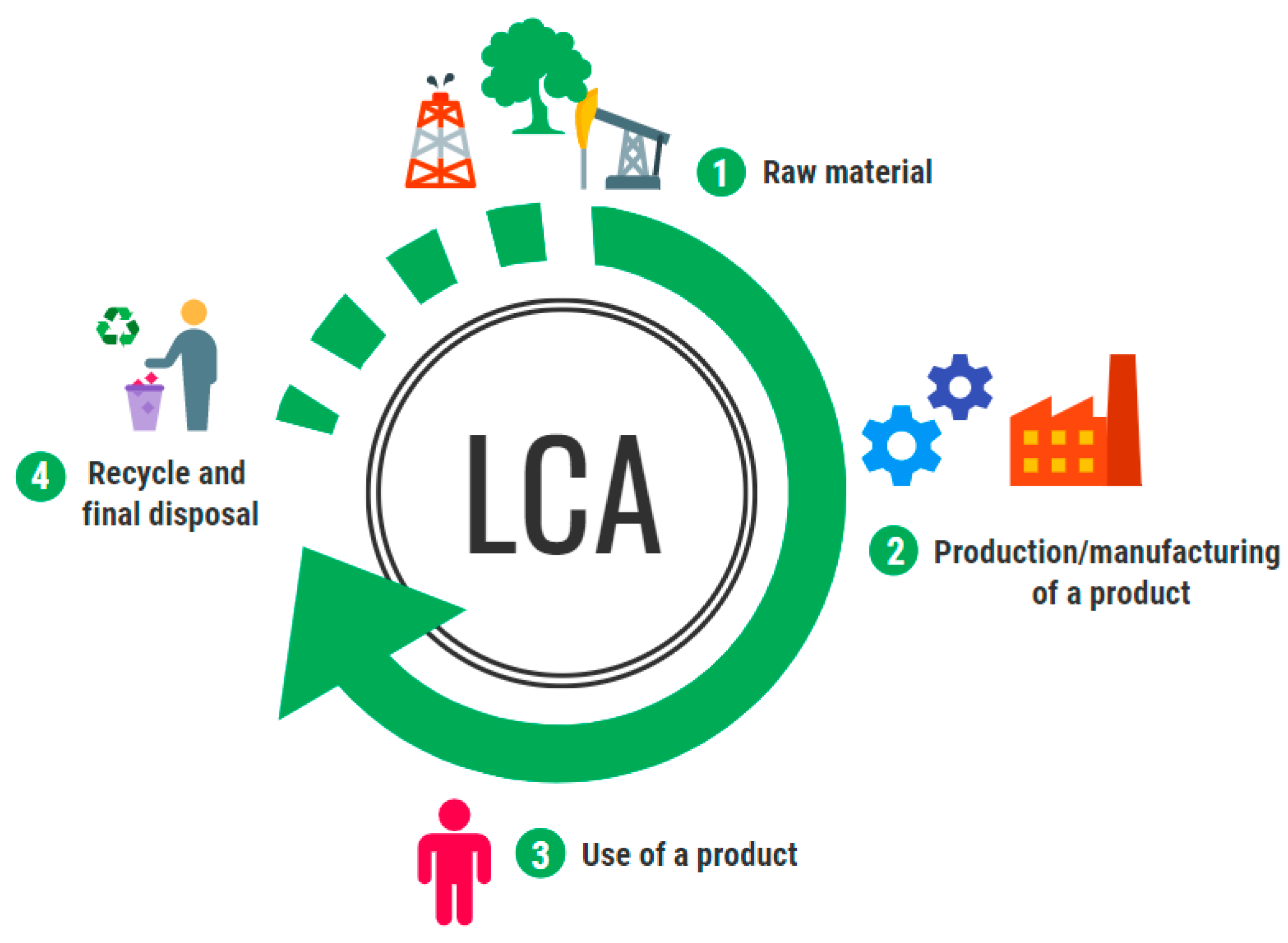

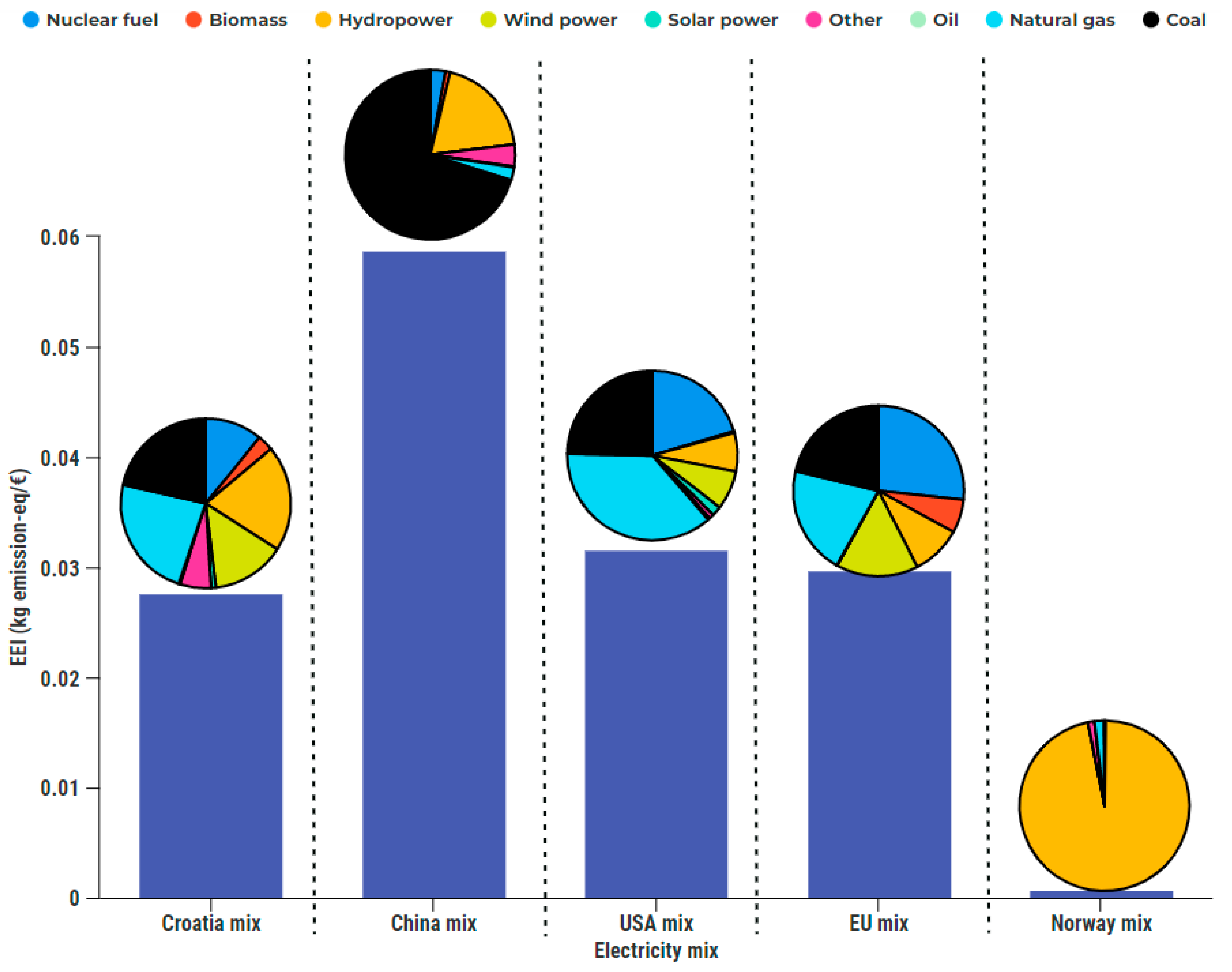

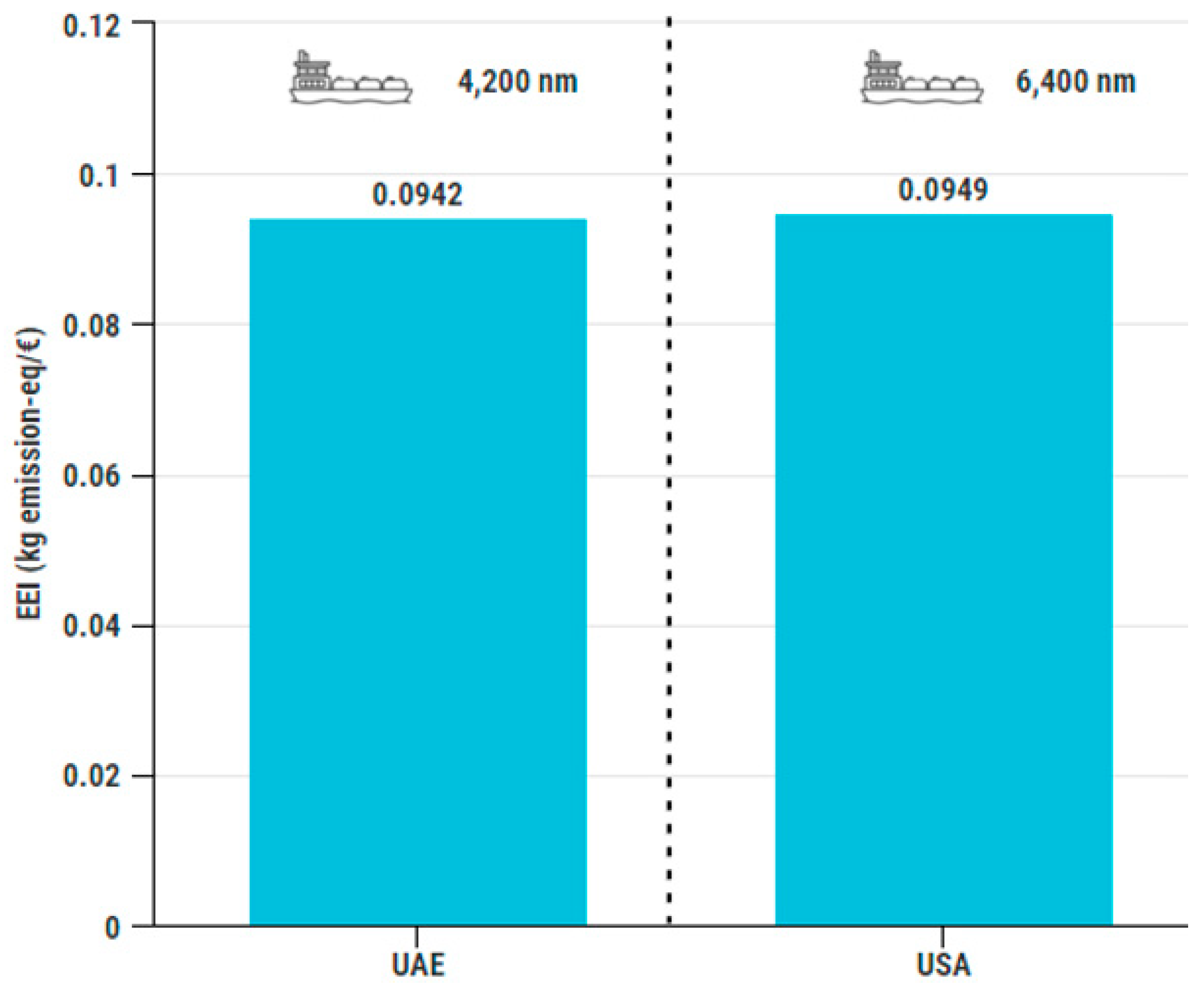

2.3. Environmental Analysis

2.4. Economic Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Nomenclature

| Variables | Abbreviations | ||

| AP | acidification potential (kg SO2-eq) | A | Ammonia |

| BS | benefit for the society (mil. €) | CII | Carbon Intensity Indicator |

| E | emission (kg) | D | Diesel |

| EC | energy consumption (kWh/nm) | E | Electricity |

| EEI | energy efficiency and emission index (kg emission-eq/€) | ECA | Emission Control Area |

| EP | eutrophication potential (kg PO4-eq) | EEDI | Energy Efficiency Design Index |

| FC | fuel consumption (kg/nm) | EEXI | Energy Efficiency Existing Ship Index |

| GWP | global warming potential (kg CO2-eq) | EU | European Union |

| l | trip length (nm) | GHG | Greenhouse Gas |

| NP | annual number of passengers (-) | Gn-H | Green hydrogen |

| NRT | annual number of round trips (-) | Gy-H | Grey hydrogen |

| NV | annual number of vehicles (-) | H | Hydrogen |

| P | power (kW) | HFO | Heavy Fuel Oil |

| PR | price (€) | HPS | Hybrid Power System |

| SFC | specific fuel consumption (kg/kWh) | I4E | Energy Efficiency and Environmental Eligibility Index |

| t | trip duration (h) | IMO | International Maritime Organization |

| v | speed (kn) | IPS | Integrated Power System |

| LCA | Life-Cycle Assessment | ||

| Subscripts | LNG | Liquefied Natural Gas | |

| AE | auxiliary engine | M | Methanol |

| An | annual | MARPOL | International Convention for the prevention of Pollution from Ships |

| ave | average | MDO | Marine Diesel Oil |

| d | design | RES | Renewable Energy Source |

| ME | main engine | SEEMP | Ship Energy Efficiency Management Plan |

| P | passenger | UAE | United Arab Emirates |

| V | vehicles | USA | United States of America |

| Units | Greek letters | ||

| kn | knot (nm/h) | α | weighting factor for GWP |

| nm | nautical mile (1 nm = 1.852 km) | β | weighting factor for AP |

| γ | weighting factor for EP | ||

References

- United Nations Framework Convention Climate Change (UNFCCC). Climate Change Information Kit. Available online: https://unfccc.int/resource/iuckit/cckit2001en.pdf (accessed on 5 March 2021).

- Odeh, N.A.; Cockerill, T.T. Life cycle GHG assessment of fossil fuel power plants with carbon capture and storage. Energy Policy 2008, 36, 367–380. [Google Scholar] [CrossRef]

- Ait Allal, A.; Mansouri, K.; Youssfi, M.; Qbadou, M. Toward an evaluation of marine fuels for a clean and efficient autonomous ship propulsion energy. Mater. Today Proc. 2019, 13, 486–495. [Google Scholar] [CrossRef]

- International Maritime Organization. Resolution MEPC.176(58); International Maritime Organization: London, UK, 2008. [Google Scholar]

- Chen, L.; Yip, T.L.; Mou, J. Provision of Emission Control Area and the impact on shipping route choice and ship emissions. Transp. Res. Part D Transp. Environ. 2018, 58, 280–291. [Google Scholar] [CrossRef]

- Emission Standards: IMO Marine Engine Regulations. Available online: https://dieselnet.com/standards/inter/imo.php#s (accessed on 5 October 2021).

- International Maritime Organization. Resolution MEPC. 203(62); International Maritime Organization: London, UK, 2011. [Google Scholar]

- Ozaki, Y.; Larkin, J.; Tikka, K.; Michel, K. An Evaluation of the Energy Efficiency Design Index (EEDI) Baseline for Tankers, Containerships, and LNG Carriers. In Proceedings of the SNAME & Marine Board Symposium 2010—Climate Change and Ships: Increasing Energy Efficiency, Linthicum Heights, MD, USA, 16–17 February 2010. [Google Scholar]

- DNV. Energy Efficiency Existing Ship Index (EEXI). Available online: https://www.dnv.com/maritime/insights/topics/eexi/index.html (accessed on 1 March 2022).

- Marine Environment Protection Committee. Resolution MEPC.334(76)—Annex 8—Guidelines on Survey and Certification of the Attained Energy Efficiency Existing Ship Index (EEXI); Marine Environment Protection Committee: London, UK, 2021. [Google Scholar]

- DNV. Carbon Intensity Indicator. Available online: https://www.dnv.com/maritime/insights/topics/CII-carbon-intensity-indicator/index.html (accessed on 18 March 2022).

- Lindstad, E.; Borgen, H.; Eskeland, G.S.; Paalson, C.; Psaraftis, H.; Turan, O. The Need to Amend IMO’s EEDI to Include a Threshold for Performance in Waves (Realistic Sea Conditions) to Achieve the Desired GHG Reductions. Sustainability 2019, 11, 3668. [Google Scholar] [CrossRef] [Green Version]

- Ančić, I.; Vladimir, N.; Cho, D.S. Determining environmental pollution from ships using Index of Energy Efficiency and Environmental Eligibility (I4E). Mar. Policy 2018, 95, 1–7. [Google Scholar] [CrossRef]

- Ančić, I.; Vladimir, N.; Runko Luttenberger, L. Energy efficiency of ro-ro passenger ships with integrated power system. Ocean Eng. 2018, 16, 350–357. [Google Scholar] [CrossRef]

- Trivyza, N.L.; Rentizelas, A.; Theotokatos, G. A Comparative Analysis of EEDI Versus Lifetime CO2 Emissions. J. Mar. Sci. Eng. 2020, 8, 61. [Google Scholar] [CrossRef] [Green Version]

- International Maritime Organization. Fourth IMO GHG Study-Final Report 2020. Available online: https://safety4sea.com/wp-content/uploads/2020/08/MEPC-75-7-15-Fourth-IMO-GHG-Study-2020-Final-report-Secretariat.pdf (accessed on 14 January 2022).

- Hüffmeier, J.; Johanson, M. State-of-the-Art Methods to Improve Energy Efficiency of Ships. J. Mar. Sci. Eng. 2021, 9, 447. [Google Scholar] [CrossRef]

- Xing, H.; Spence, S.; Chen, H. A comprehensive review on countermeasures for CO2 emissions from ships. Renew. Sustain. Energy Rev. 2020, 134, 110222. [Google Scholar] [CrossRef]

- Bouman, E.A.; Lindstad, E.; Rialland, A.I.; Strømman, A.H. State-of-the-art technologies, measures, and potential for reducing GHG emissions from shipping—A review. Transp. Res. Part D Transp. Environ. 2017, 52, 408–421. [Google Scholar] [CrossRef]

- Ančić, I.; Perčić, M.; Vladimir, N. Alternative power options to reduce carbon footprint of ro-ro passenger fleet: A case study of Croatia. J. Clean. Prod. 2020, 271, 122638. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Q.; Qi, X.; Han, Y.; Lu, F. Estimation of PV output power in moving and rocking hybrid energy marine ships. Appl. Energy 2017, 204, 362–372. [Google Scholar] [CrossRef]

- Perčić, M.; Vladimir, N.; Koričan, M. Electrification of inland waterway ships considering power system lifetime emissions and costs. Energies 2021, 14, 7046. [Google Scholar] [CrossRef]

- Hansson, J.; Månsson, S.; Brynolf, S.; Grahn, M. Alternative marine fuels: Prospects based on multi-criteria decision analysis involving Swedish stakeholders. Biomass Bioenergy 2019, 126, 159–173. [Google Scholar] [CrossRef]

- Vladimir, N.; Bakica, A.; Perčić, M.; Jovanović, I. Modular approach in the design of small passenger vessels for Mediterranean. J. Mar. Sci. Eng. 2022, 10, 117. [Google Scholar] [CrossRef]

- Wan, C.; Yan, X.; Zhang, D.; Yang, Z. A novel policy making aid model for the development of LNG fuelled ships. Transp. Res. Part A Policy Pract. 2019, 119, 29–44. [Google Scholar] [CrossRef]

- Ammar, N.R. An environmental and economic analysis of methanol fuel for a cellular container ship. Transp. Res. Part D 2019, 69, 66–76. [Google Scholar] [CrossRef]

- Jovanović, I.; Vladimir, N.; Perčić, M.; Koričan, M. The feasibility of autonomous low-emission ro-ro passenger shipping in the Adriatic Sea. Ocean Eng. 2022, 247, 110712. [Google Scholar] [CrossRef]

- Wang, H.; Boulougouris, E.; Theotokatos, G.; Zhou, P.; Priftis, A.; Shi, G. Life cycle analysis and cost assessment of a battery powered ferry. Ocean Eng. 2021, 241, 110029. [Google Scholar] [CrossRef]

- Gagatsi, E.; Estrup, T.; Halatsis, A. Exploring the potentials of electrical waterborne transport in Europe: The E-ferry concept. Transp. Res. Procedia 2016, 14, 1571–1580. [Google Scholar] [CrossRef] [Green Version]

- Perčić, M.; Vladimir, N.; Jovanović, I.; Koričan, M. Application of fuel cells with zero-carbon fuels in short-sea shipping. Appl. Energy 2022, 309, 118463. [Google Scholar] [CrossRef]

- Perčić, M.; Ančić, I.; Vladimir, N. Life-cycle cost assessments of different power system configurations to reduce the carbon footprint in the Croatian short-sea shipping sector. Renew. Sustain. Energy Rev. 2020, 131, 110028. [Google Scholar] [CrossRef]

- Degiuli, N.; Martić, I.; Farkas, A.; Gospić, I. The impact of slow steaming on reducing CO2 emissions in the Mediterranean Sea. Energy Rep. 2021, 7, 8131–8141. [Google Scholar] [CrossRef]

- Ritari, A.; Spoof-Tuomi, K.; Huotari, J.; Niemi, S.; Tammi, K. Emission Abatement Technology Selection, Routing and Speed Optimization of Hybrid Ships. J. Mar. Sci. Eng. 2021, 9, 944. [Google Scholar] [CrossRef]

- DNV. Uptake of Alternative Fuels for the World Fleet as of June 2021 including Ships in Operation and on Order. Available online: https://www.dnv.com/maritime/hub/decarbonize-shipping/fuels/bridging-fuels.html (accessed on 10 April 2022).

- Kim, T.; Chae, C. Environmental Impact Analysis of Acidification and Eutrophication Due to Emissions from the Production of Concrete. Sustainability 2016, 8, 578. [Google Scholar] [CrossRef] [Green Version]

- Environmental Protection Agency. Understanding Global Warming Potentials. Available online: https://www.epa.gov/ghgemissions/understanding-global-warming-potentials (accessed on 20 December 2021).

- Gonçalves Castro, M.; Mestemaker, B.; Van Den Heuvel, H. Towards zero emission work vessels: The case of a dredging vessel. Proceedings of 2nd International Conference on Modelling and Optimisation of Ship Energy Systems (MOSES2019), Glasgow, Scotland, UK, 8–10 May 2019. [Google Scholar]

- Monteiro, A.; Russo, M.; Gama, C.; Borrego, C. How important are maritime emissions for the air quality: At European and national scale. Environ. Pollut. 2018, 242, 565–575. [Google Scholar] [CrossRef]

- Sofiev, M.; Winebrake, J.J.; Johansson, L.; Carr, E.W.; Prank, M.; Soares, J.; Vira, J.; Kouznetsov, R.; Jalkanen, J.-P.; Corbett, J.J. Cleaner fuels for ships provide public health benefits with climate tradeoffs. Nat. Commun. 2018, 9, 406. [Google Scholar] [CrossRef] [Green Version]

- Croatian Register of Shipping. Web Report of a Ship. Available online: http://report.crs.hr/hrbwebreports/Default.aspx (accessed on 10 December 2021).

- Jadrolinija. Ferry Lines Schedule. Available online: https://www.jadrolinija.hr/redovi-plovidbe-i-cijene/lokalne-linije-2022 (accessed on 15 December 2021).

- Coastal Liner Services Agency. Traffic of Passengers and Vehicles on Ferry Lines. Available online: http://agencija-zolpp.hr/wp.content/uploads/2022/02/PROMET_PUTNIKA_I_VOZILA_2020-2021.pdf (accessed on 17 February 2022).

- Adland, R.; Cariou, P.; Wolff, F.C. Optimal ship speed and the cubic law revisited: Empirical evidence from an oil tanker fleet. Transp. Res. Part E Logist. Transp. Rev. 2020, 140, 101972. [Google Scholar] [CrossRef]

- ISO 14040. Available online: https://www.iso.org/standard/37456.html (accessed on 21 April 2021).

- GREET 2020. Available online: https://greet.es.anl.gov/ (accessed on 30 June 2021).

- Perčić, M.; Vladimir, N.; Fan, A. Life-cycle cost assessment of alternative marine fuels to reduce the carbon footprint in short-sea shipping: A case study of Croatia. Appl. Energy 2020, 279, 115848. [Google Scholar] [CrossRef]

- Perčić, M.; Vladimir, N.; Fan, A. Techno-economic assessment of alternative marine fuels for inland shipping in Croatia. Renew. Sustain. Energy Rev. 2021, 148, 111363. [Google Scholar] [CrossRef]

| Ship Route | PME (kW) | PAE (kW) | vd (kn) | t (h) | l (nm) | NRT | NP | NV | PRP (€) | PRV (€) |

|---|---|---|---|---|---|---|---|---|---|---|

| Biograd-Tkon | 806 | 824 | 7.5 | 0.33 | 1.35 | 3,900 | 417,713 | 123,104 | 1.6 | 13.33 |

| Prizna-Žigljen | 792 | 84 | 8 | 0.25 | 1.61 | 1,590 | 777,360 | 320,409 | 1.87 | 17.87 |

| Orebić-Dominče | 1790 | 444 | 12 | 0.33 | 1.83 | 5,520 | 602,838 | 253,184 | 1.73 | 13.87 |

| Brestova-Porozina | 1616 | 444 | 11 | 0.33 | 2.81 | 3,540 | 467,932 | 198,565 | 2 | 23.73 |

| Sućuraj-Drvenik | 806 | 824 | 7.5 | 0.58 | 3.40 | 2760 | 337,608 | 126,888 | 1.73 | 20.67 |

| Zadar-Preko | 1968 | 532 | 13 | 0.42 | 3.45 | 5700 | 1,159,218 | 417,384 | 2 | 17.73 |

| Valbiska-Merag | 1968 | 272 | 12 | 0.42 | 3.62 | 3960 | 974,081 | 431,391 | 2 | 23.73 |

| Sobra-Prapratno | 2352 | 480 | 12 | 0.33 | 5.72 | 1560 | 137,499 | 55,189 | 3.07 | 29.73 |

| Sumartin-Makarska | 882 | 102 | 10 | 0.83 | 6.96 | 1260 | 118,589 | 32,118 | 3.2 | 30.67 |

| Suđurađ-Dubrovnik | 1986 | 1921 | 12.5 | 0.42 | 8.10 | 480 | 17,744 | 4.636 | 2.53 | 30.67 |

| Ploče-Trpanj | 1764 | 840 | 12.3 | 1 | 8.14 | 1740 | 390,170 | 164.022 | 3.6 | 25.07 |

| Split-Supetar | 1968 | 630 | 13 | 0.83 | 8.85 | 3720 | 1,667,571 | 423.232 | 3.73 | 30.67 |

| Split-Rogač | 1788 | 645 | 12 | 1 | 8.90 | 1620 | 347,536 | 93.122 | 3.73 | 30.67 |

| Drvenik Veli- Trogir | 794 | 102 | 11.5 | 1.17 | 9.66 | 600 | 109,161 | 5674 | 1.73 | 30.67 |

| Šibenik-Žirje | 882 | 72 | 11 | 1.33 | 11.60 | 540 | 43,090 | 7270 | 2.53 | 35.33 |

| Valbiska-Lopar | 1764 | 1080 | 12.3 | 1.33 | 15.29 | 960 | 125,715 | 47,221 | 4.13 | 24 |

| Zadar-Brbinj | 1764 | 840 | 12.3 | 1.67 | 15.76 | 870 | 189,905 | 78,205 | 3.33 | 35.33 |

| Zadar- M. Rava | 1648 | 270 | 14 | 2 | 19.16 | 152 | 39,061 | 14,532 | 3.07 | 17.73 |

| Split-Stari Grad | 1968 | 630 | 13.2 | 2 | 22.88 | 1740 | 612,601 | 180,621 | 5.2 | 61.33 |

| Zadar-Ist | 1140 | 200 | 11 | 2.67 | 27.42 | 240 | 19,667 | 7566 | 2.67 | 35.33 |

| Split-Vis | 3600 | 1944 | 15.75 | 2.33 | 30.18 | 800 | 244,589 | 64,879 | 6 | 62.67 |

| Zadar-M.Lošinj | 2646 | 348 | 16 | 5.25 | 63.68 | 240 | 28,828 | 9373 | 3.47 | 30.67 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perčić, M.; Vladimir, N.; Fan, A.; Jovanović, I. Holistic Energy Efficiency and Environmental Friendliness Model for Short-Sea Vessels with Alternative Power Systems Considering Realistic Fuel Pathways and Workloads. J. Mar. Sci. Eng. 2022, 10, 613. https://doi.org/10.3390/jmse10050613

Perčić M, Vladimir N, Fan A, Jovanović I. Holistic Energy Efficiency and Environmental Friendliness Model for Short-Sea Vessels with Alternative Power Systems Considering Realistic Fuel Pathways and Workloads. Journal of Marine Science and Engineering. 2022; 10(5):613. https://doi.org/10.3390/jmse10050613

Chicago/Turabian StylePerčić, Maja, Nikola Vladimir, Ailong Fan, and Ivana Jovanović. 2022. "Holistic Energy Efficiency and Environmental Friendliness Model for Short-Sea Vessels with Alternative Power Systems Considering Realistic Fuel Pathways and Workloads" Journal of Marine Science and Engineering 10, no. 5: 613. https://doi.org/10.3390/jmse10050613

APA StylePerčić, M., Vladimir, N., Fan, A., & Jovanović, I. (2022). Holistic Energy Efficiency and Environmental Friendliness Model for Short-Sea Vessels with Alternative Power Systems Considering Realistic Fuel Pathways and Workloads. Journal of Marine Science and Engineering, 10(5), 613. https://doi.org/10.3390/jmse10050613