A Study on the Control Solution of Ship’s Central Fresh Water-Cooling System for Efficient Energy Control Based on Merchant Training Ship

Abstract

:1. Introduction

1.1. Background

1.2. Research Content and Composition

1.3. Actual Vessel Composition

1.4. Research Procedures

2. System Modeling

2.1. Heat Exchanger Modeling

2.2. Seawater Pump Modeling

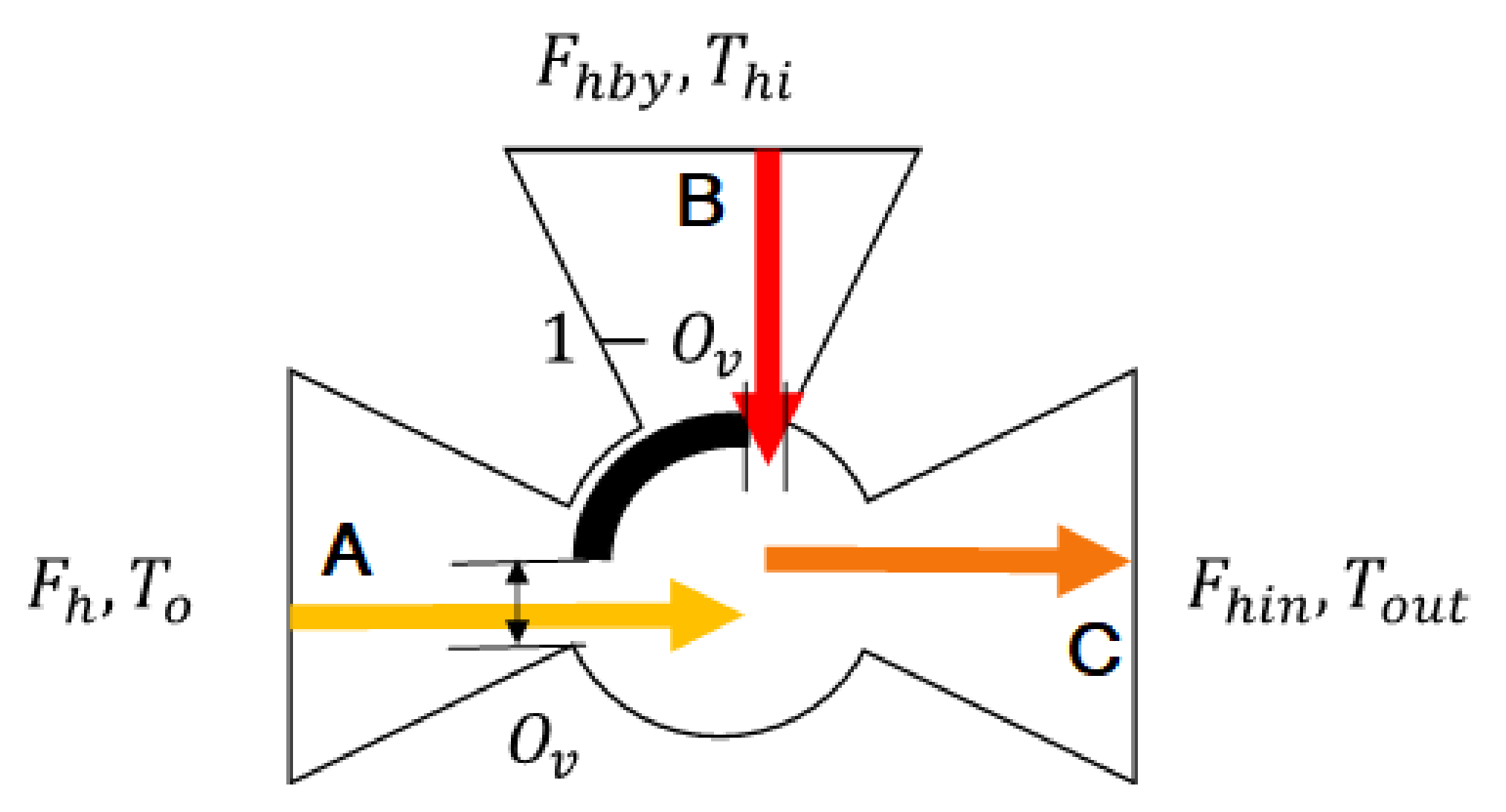

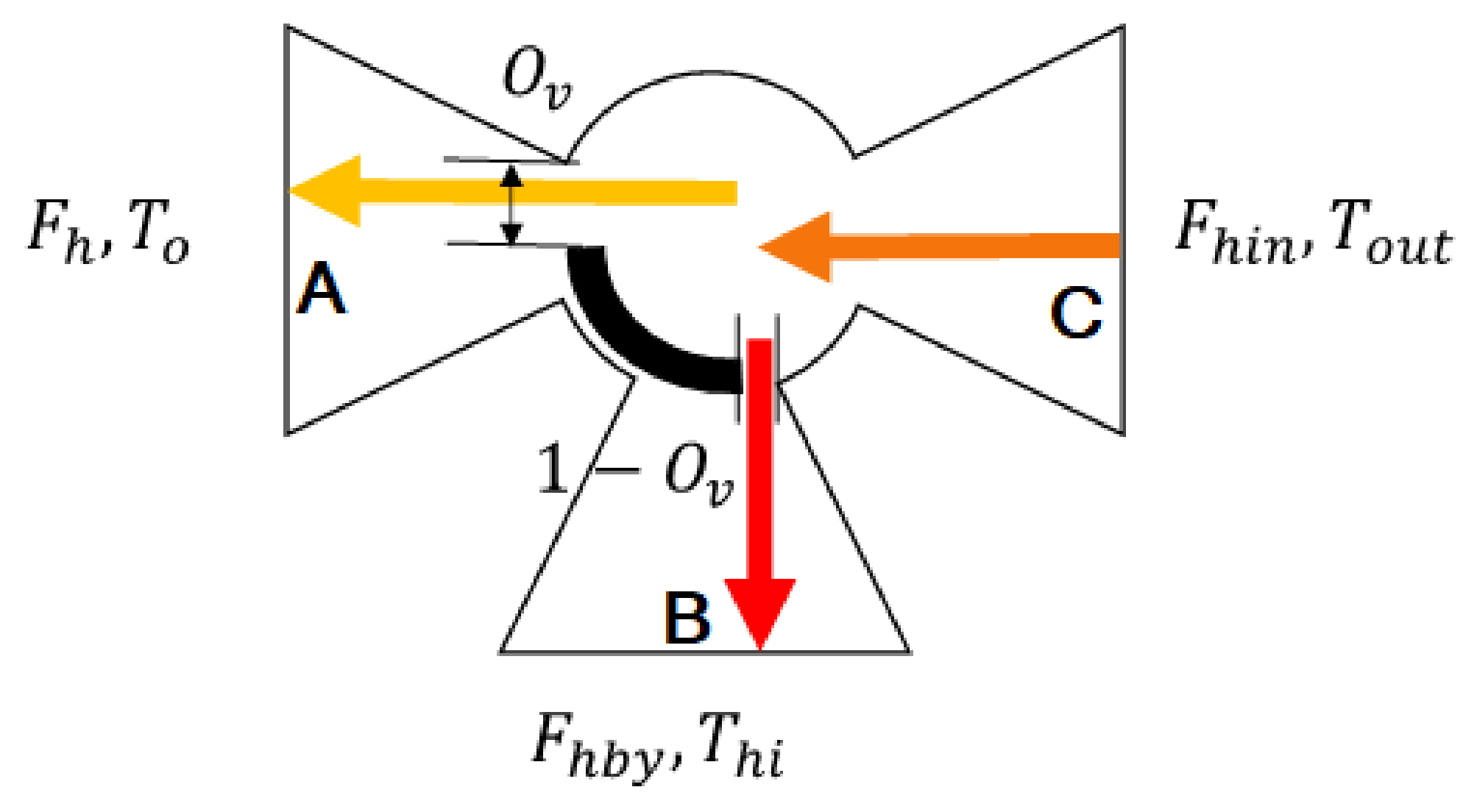

2.3. 3-Way Valve Modeling

2.4. Linearization Model at the Operating Point

3. Simulation

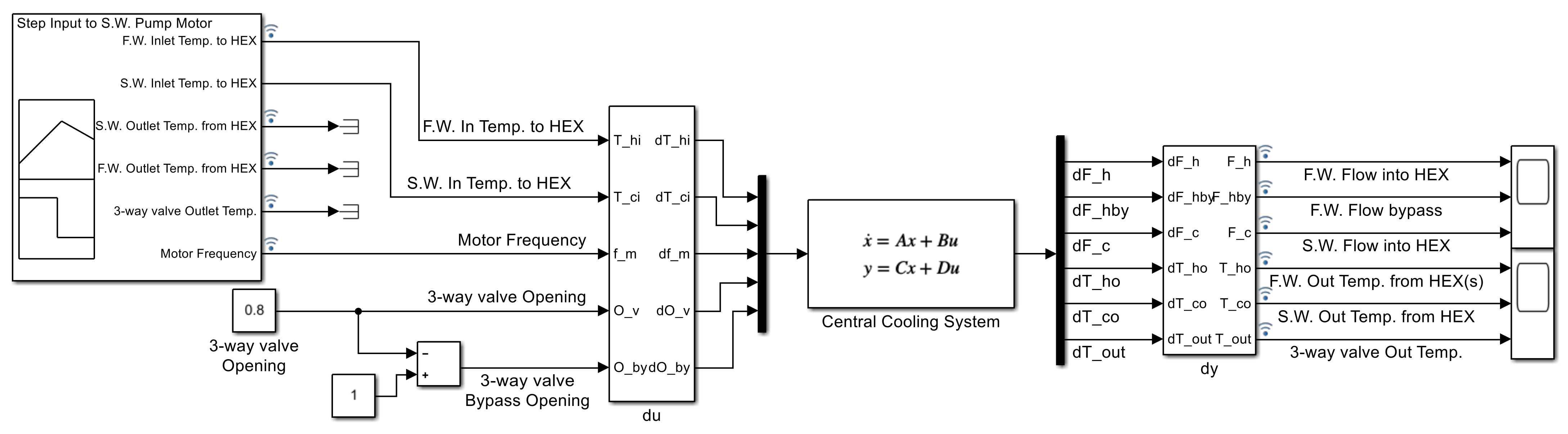

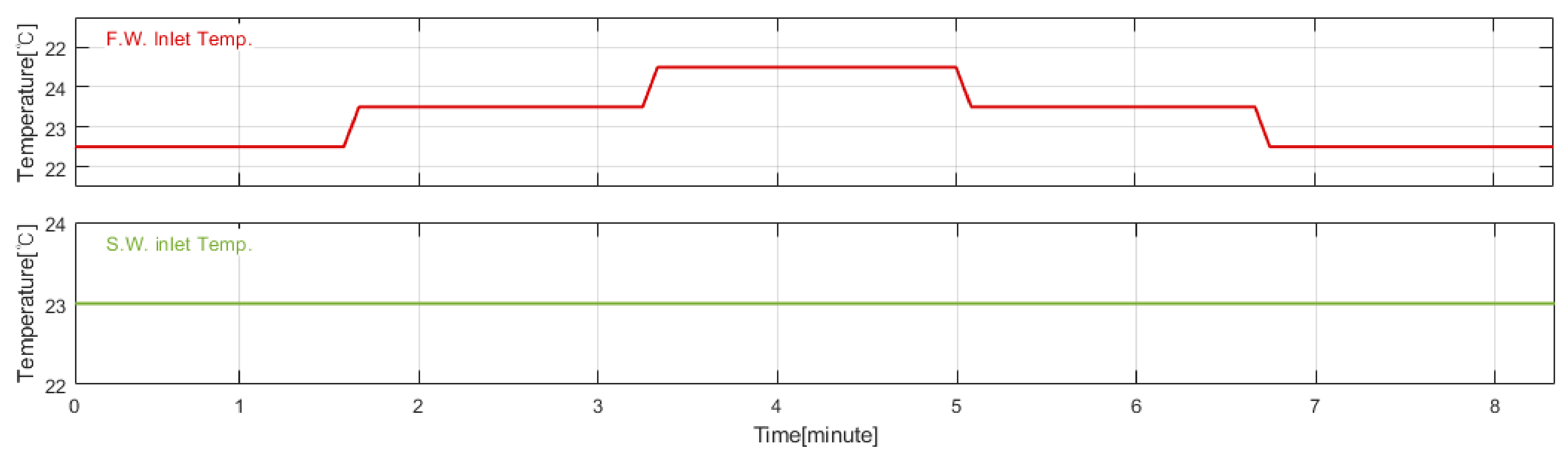

3.1. Simulation Configuration for Steady State

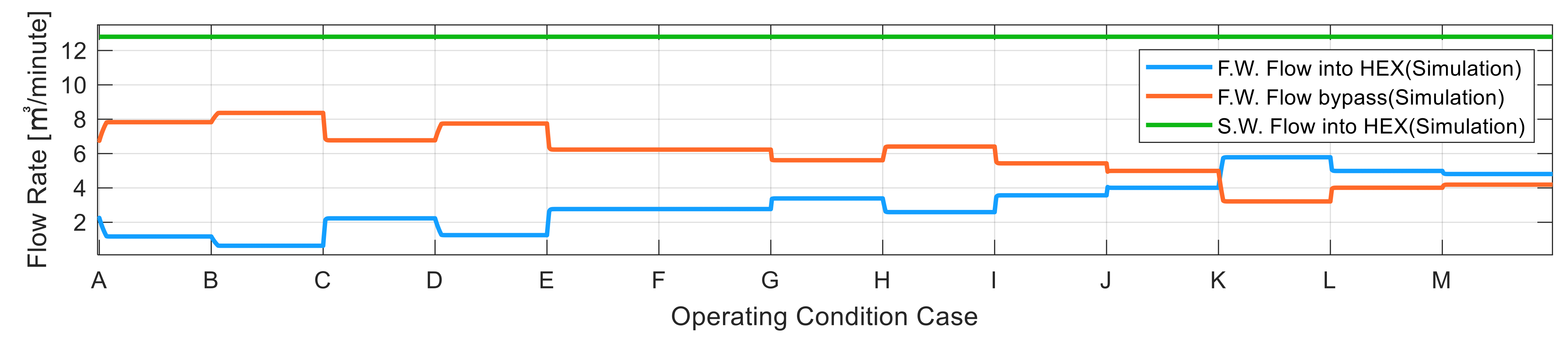

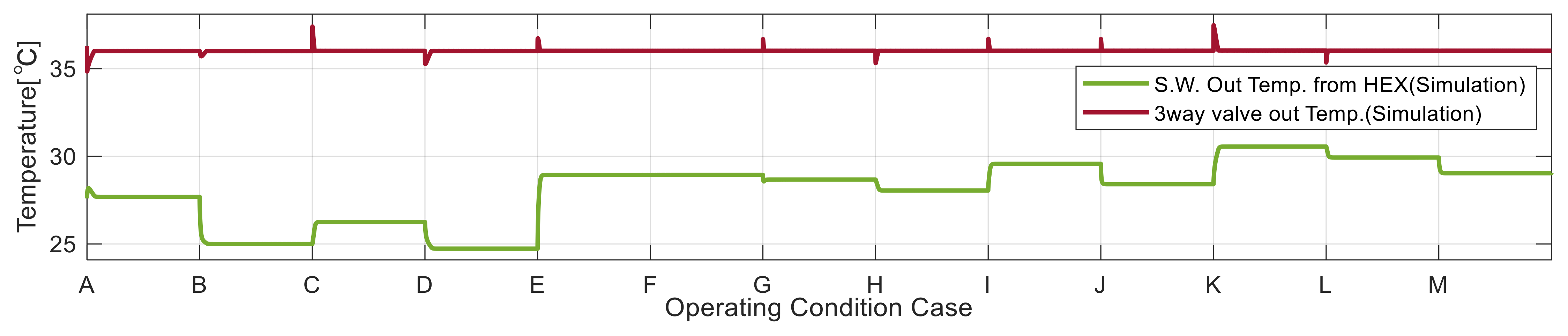

3.2. Simulation Results

3.3. Simulation Configuration for Dynamic Response

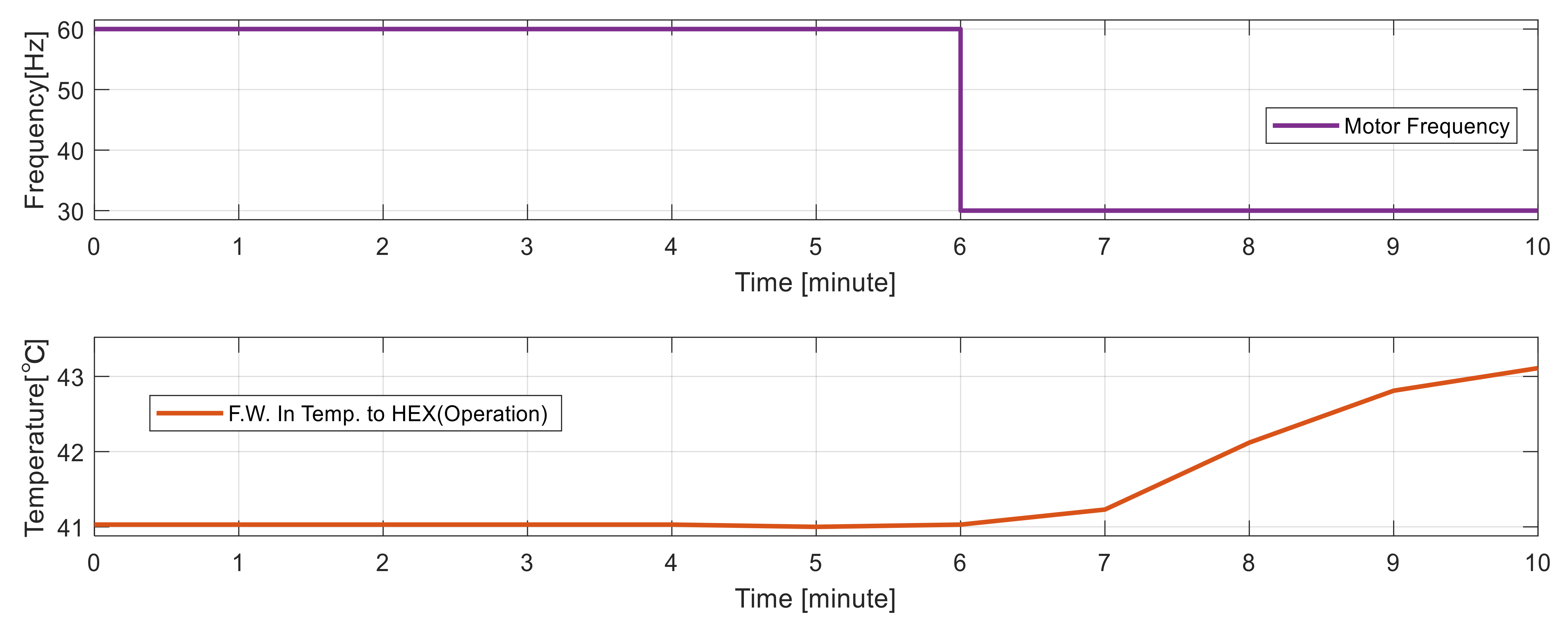

3.4. Simulation Result of Step Input

4. Step Input Simulation for Finding Inefficient Operation Case

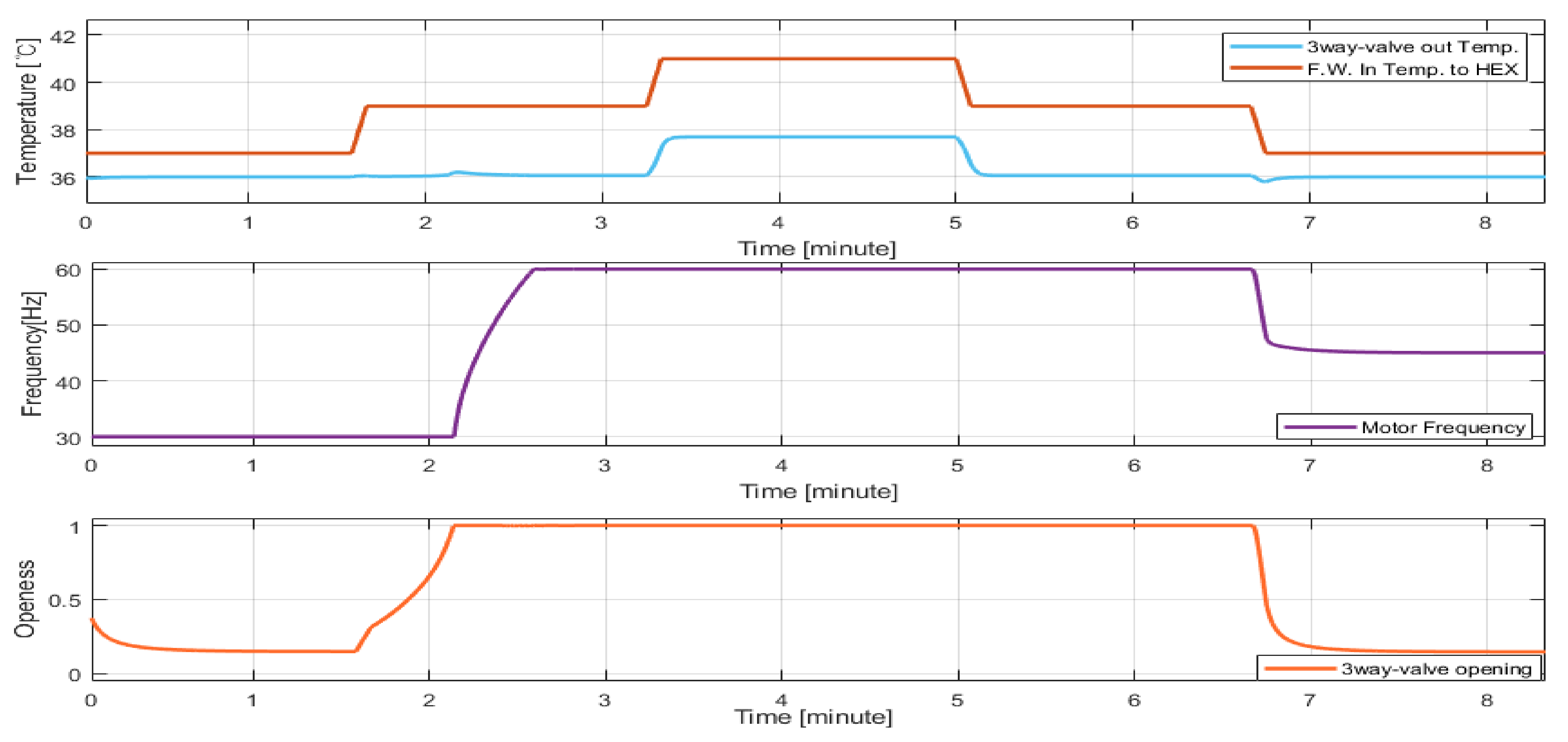

4.1. Test Condition of A Typical Control Method

4.2. Test Result of a Typical Control Method

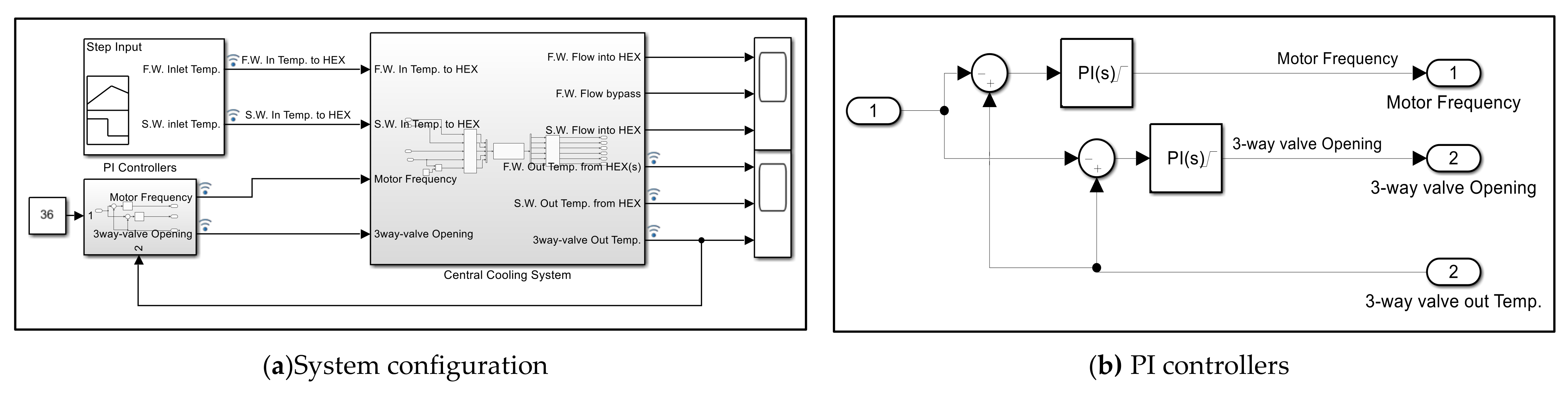

4.3. A Suggested PI Control Method (Separated the Feed-Back Points)

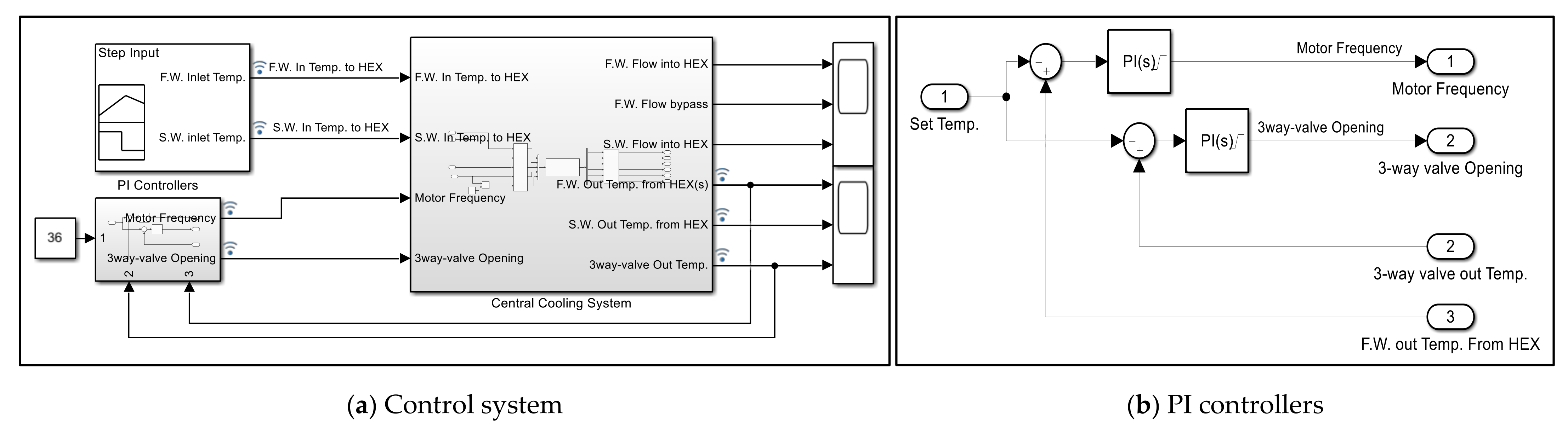

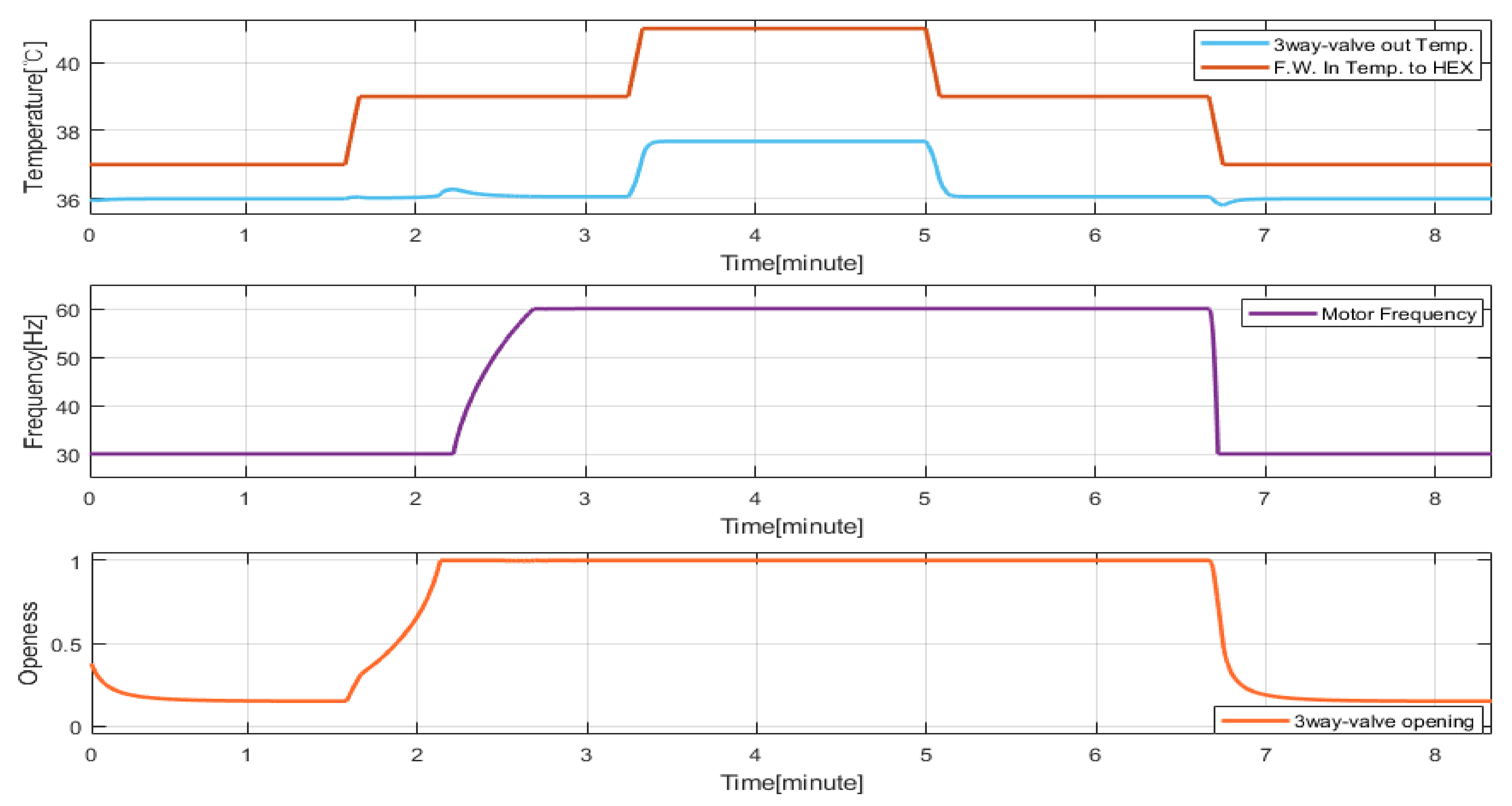

4.3.1. The Simulation Configuration for the Suggested Control Method

4.3.2. The Simulation Result for the Suggested Control Method

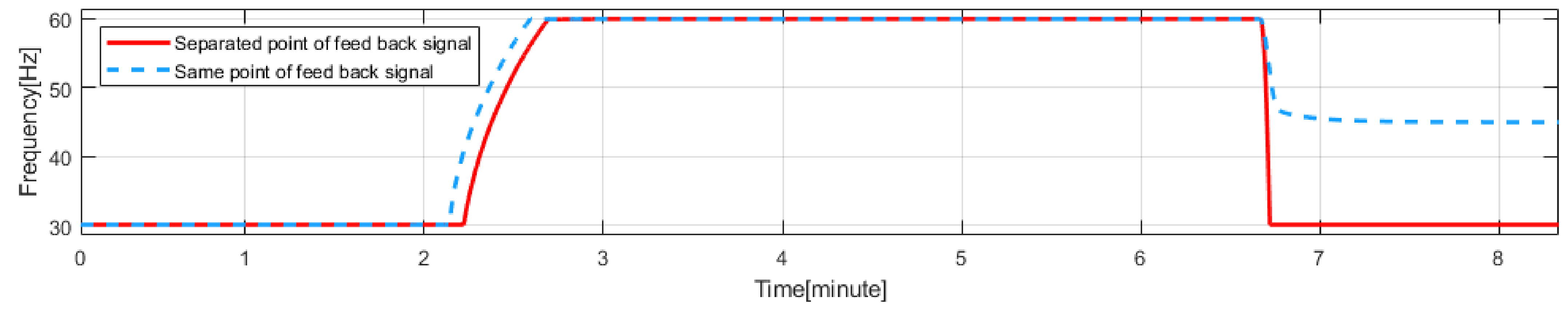

4.4. Comparing the Typical PI Control Method and Separated Feed-Back Signal Control Method

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Global 4 Ports Average Prices Singapore-Rotterdam-LA/LB Houston. Available online: https://shipandbunker.com/prices/av (accessed on 27 April 2022).

- Frischmann, T.; Hinz, O.; Skiera, B. Retailers’ use of shipping cost strategies: Free shipping or partitioned prices? Int. J. Electron. Commer. 2012, 16, 65–88. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.-Y.; Lee, H.L.; Zhang, J. The impact of slow ocean steaming on delivery reliability and fuel consumption. Transp. Res. Part E Logist. Transp. Rev. 2015, 76, 176–190. [Google Scholar] [CrossRef]

- Lindstad, H.; Asbjørnslett, B.E.; Strømman, A.H. Reductions in greenhouse gas emissions and cost by shipping at lower speeds. Energy Policy 2011, 39, 3456–3464. [Google Scholar] [CrossRef]

- Chang, C.C.; Wang, C.-M. Evaluating the effects of speed reduce for shipping costs and CO2 emission. Transp. Res. Part D Transp. Environ. 2014, 31, 110–115. [Google Scholar] [CrossRef]

- Notteboom, T.E.; Vernimmen, B. The effect of high fuel costs on liner service configuration in container shipping. J. Transp. Geogr. 2009, 17, 325–337. [Google Scholar] [CrossRef]

- Dewan, M.H.; Yaakob, O.; Suzana, A. Barriers for adoption of energy efficiency operational measures in shipping industry. WMU J. Marit. Aff. 2018, 17, 169–193. [Google Scholar] [CrossRef]

- The Marine Environment Protection Committee. Guidelines for the Development of a Ship Energy Efficiency Management Plan (SEEMP). 2012. Available online: https://wwwcdn.imo.org/localresources/en/OurWork/Environment/Documents/213(63).pdf (accessed on 2 May 2022).

- Hou, Y.H.; Kang, K.; Liang, X. Vessel speed optimization for minimum EEOI in ice zone considering uncertainty. Ocean Eng. 2019, 188, 106240. [Google Scholar] [CrossRef]

- Hou, Y.H. Hull form uncertainty optimization design for minimum EEOI with influence of different speed perturbation types. Ocean Eng. 2017, 140, 66–72. [Google Scholar] [CrossRef]

- Cheng, X.; Feng, B.; Liu, Z.; Chang, H. Hull surface modification for ship resistance performance optimization based on Delaunay triangulation. Ocean Eng. 2018, 153, 333–344. [Google Scholar] [CrossRef]

- Abramowski, T.; Żelazny, K.; Szelangiewicz, T. Numerical analysis of influence of ship hull form modification on ship resistance and propulsion characteristics Part III Influence of hull form modification on screw propeller efficiency. Pol. Marit. Res. 2010, 17, 10–13. [Google Scholar] [CrossRef]

- Yu, Y.; Yang, C.; Li, J.; Zhu, Y.; Yan, Z.; Zhang, H. Screening of inexpensive and efficient catalyst for microwave-assisted pyrolysis of ship oil sludge. J. Anal. Appl. Pyrolysis 2020, 152, 104971. [Google Scholar] [CrossRef]

- Lützen, M.; Mikkelsen, L.L.; Jensen, S.; Rasmussen, H.B. Energy efficiency of working vessels–A framework. J. Clean. Prod. 2017, 143, 90–99. [Google Scholar] [CrossRef]

- Johnson, H.; Johansson, M.; Andersson, K. Barriers to improving energy efficiency in short sea shipping: An action research case study. J. Clean. Prod. 2014, 66, 317–327. [Google Scholar] [CrossRef]

- Lai, C.; Tsao, Y.; Tsai, C. Modeling, analysis, and realization of permanent magnet synchronous motor current vector control by MATLAB/Simulink and FPGA. Machines 2017, 5, 26. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Zhang, H.; Han, Z.; Ni, X. Optimization design of centrifugal pump flow control system based on adaptive control. Processes 2021, 9, 1538. [Google Scholar] [CrossRef]

- Dere, C.; Deniz, C. Load optimization of central cooling system pumps of a container ship for the slow steaming conditions to enhance the energy efficiency. J. Clean. Prod. 2019, 222, 206–217. [Google Scholar] [CrossRef]

- Koegler, A.F.; Evert, A.; Alt, N.S.; Schluecker, E. Parallel Operation of Centrifugal Pumps: Effects of Rotational Speed Differences due to Motor Slip. Chem. Eng. Technol. 2014, 37, 951–956. [Google Scholar] [CrossRef]

- Kim, Y.-H. A Study on Suitable Electric Energy Saving System for the Cooling System of Vessel. Master’s Thesis, Korea Maritime and Ocean University, Seoul, Korea, 2008. [Google Scholar]

- Hernandez-Solis, A.; Carlsson, F. Diagnosis of submersible centrifugal pumps: A motor current and power signature approaches. EPE J. 2010, 20, 58–64. [Google Scholar] [CrossRef]

- Qi, X.; Jiao, J.; Zheng, G. Research on optimize design method of ship sea water cooling system. In Proceedings of the 2016 13th International Computer Conference on Wavelet Active Media Technology and Information Processing (ICCWAMTIP), Chengdu, China, 16–18 December 2016; pp. 440–443. [Google Scholar]

- Theotokatos, G.; Sfakianakis, K.; Vassalos, D. Investigation of ship cooling system operation for improving energy efficiency. J. Mar. Sci. Technol. 2017, 22, 38–50. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.-Y.; Yoo, H.-H.; Kim, Y.-H.; Oh, J.-S. A Study on the Energy Saving Method by controlling Capacity of Sea Water Pump in Central Cooling System for Vessel. J. Adv. Mar. Eng. Technol. 2007, 31, 592–598. [Google Scholar] [CrossRef]

- Deniz, C. Thermodynamic and Environmental Analysis of Low-Grade Waste Heat Recovery System for a Ship Power Plant. Int. J. Energy Sci. 2015, 5, 23–34. [Google Scholar] [CrossRef] [Green Version]

- De Almeida, A.T.; Ferreira, F.J.T.E.; Both, D. Technical and Economical Considerations in the Application of Variable-Speed Drives With Electric Motor Systems. IEEE Trans. Ind. Appl. 2005, 41, 188–199. [Google Scholar] [CrossRef]

- Simpson, A.R.; Marchi, A. Evaluating the approximation of the affinity laws and improving the efficiency estimate for variable speed pumps. J. Hydraul. Eng. 2013, 139, 1314–1317. [Google Scholar] [CrossRef] [Green Version]

- Chantasiriwan, S. Performance of variable-speed centrifugal pump in pump system with static head. Int. J. Power Energy Syst. 2013, 33, 15–21. [Google Scholar] [CrossRef]

- Kocak, G.; Durmusoglu, Y. Energy efficiency analysis of a ship’s central cooling system using variable speed pump. J. Mar. Eng. Technol. 2018, 17, 43–51. [Google Scholar] [CrossRef] [Green Version]

- Qi, X.; Jiao, J.; Tang, T.; Chu, Y.; Shi, S. Study on optimize design of central cooling system. In Proceedings of the 2017 IEEE 2nd Information Technology, Networking, Electronic and Automation Control Conference (ITNEC), Chengdu, China, 15–17 December 2017; pp. 1512–1515. [Google Scholar] [CrossRef]

- Lee, C.C.; Yeh, T.K.; Chang, Y.H. Research on energy-saving control of the sea-water cooling pump in ships. In Proceedings of the 32th Symposium on Electrical Power Engineering, New Taipei City, Taiwan, 2–3 December 2011. [Google Scholar]

- Yimchoy, S.; Supatti, U. An Energy-Savings Evaluation Method for Variable-Frequency-Drive Applications on Water Pump Systems. In Proceedings of the 2021 24th International Conference on Electrical Machines and Systems (ICEMS), Gyeongju, Korea, 31 October–3 November 2021; pp. 603–608. [Google Scholar]

- Su, C.-L.; Chung, W.-L.; Yu, K.-T. An energy-savings evaluation method for adjustable-frequency drives on sea water cooling pumps on ships. In Proceedings of the 49th IEEE/IAS Industrial & Commercial Power Systems Technical Conference, Stone Mountain, GA, USA, 30 April–3 May 2013; pp. 1–10. [Google Scholar]

- Pariotis, E.G.; Zannis, T.C.; Katsanis, J.S. An Integrated Approach for the Assessment of Central Cooling Retrofit Using Variable Speed Drive Pump in Marine Applications. J. Mar. Sci. Eng. 2019, 7, 253. [Google Scholar] [CrossRef] [Green Version]

- Giannoutsos, S.V.; Manias, S.N. A Data-Driven Process Controller for Energy-Efficient Variable-Speed Pump Operation in the Central Cooling Water System of Marine Vessels. IEEE Trans. Ind. Electron. 2014, 62, 587–598. [Google Scholar] [CrossRef]

- Lee, C.-M.; Jeon, T.-Y.; Jung, B.-G.; Lee, Y.-C. Design of Energy Saving Controllers for Central Cooling Water Systems. J. Mar. Sci. Eng. 2021, 9, 513. [Google Scholar] [CrossRef]

- Irshad, K. Performance Improvement of Thermoelectric Air Cooler System by Using Variable-Pulse Current for Building Applications. Sustainability 2021, 13, 9682. [Google Scholar] [CrossRef]

- Tsamatsoulis, D. Optimizing the Control System of Clinker Cooling: Process Modeling and Controller Tuning. ChemEngineering 2021, 5, 50. [Google Scholar] [CrossRef]

- Cui, X.; Chua, K.J.; Islam, M.R.; Yang, W.M. Fundamental formulation of a modified LMTD method to study indirect evaporative heat exchangers. Energy Convers. Manag. 2014, 88, 372–381. [Google Scholar] [CrossRef]

- Hanjin Heavy Industry. Heat Balance Calculation; T/S Hannara, Korea Maritime & Ocean University: Seoul, Korea, 2018. [Google Scholar]

- Hanjin Heavy Industry. Plate Cooler Final; T/S Hannara, Korea Maritime & Ocean University: Seoul, Korea, 2018. [Google Scholar]

- Bequette, W.B. Process Control: Modeling, Design, and Simulation; Prentice Hall PTR: New Jersey, NJ, USA, 2003; p. 65. [Google Scholar]

- Vega, D.M.; Acevedo, H.G. Advanced Control System Design for a Plate Heat Exchanger. In Proceedings of the 2020 IX International Congress of Mechatronics Engineering and Automation (CIIMA), Cartagena, Colombia, 4–6 November 2020; pp. 1–6. [Google Scholar]

- Wang, Y.; You, S.; Zheng, W.; Zhang, H.; Zheng, X.; Miao, Q. State space model and robust control of plate heat exchanger for dynamic performance improvement. Appl. Therm. Eng. 2018, 128, 1588–1604. [Google Scholar] [CrossRef]

- Chaabane, N.; Wajdi, S.; Derbel, N. On the Modeling of a Centrifugal Pump. 2007. Available online: https://www.researchgate.net/publication/333292922_On_the_modeling_of_a_centrifugal_pump (accessed on 2 May 2022).

- Ogata, K. System Dynamics, 4th ed.; Pearson Prentice Hall: Seoul, Korea, 2016; p. 399. [Google Scholar]

| Operating Condition Case | Fresh Water Temp. to Heat Exchanger (°C) | Fresh Water Temp. from Heat Exchanger (°C) | Seawater Temp. to Heat Exchanger (°C) |

|---|---|---|---|

| A | 37 | 27.6 | 27 |

| B | 37 | 25.8 | 24 |

| C | 39 | 28 | 24 |

| D | 38 | 26 | 23 |

| E | 39 | 28.6 | 27 |

| F | 39 | 28.4 | 27 |

| G | 40 | 29.3 | 26 |

| H | 39 | 27.2 | 26 |

| I | 40 | 28.8 | 27 |

| J | 41 | 28.3 | 25 |

| K | 43 | 31.2 | 26 |

| L | 42 | 30.6 | 26 |

| M | 42 | 29.8 | 25 |

| N | 42 | 30.5 | 27 |

| Symbols | Subscripts |

|---|---|

| heat transfer area of the heat exchanger | |

| specific heats of fresh water | |

| specific heats of sea water | |

| fluid capacitance | |

| fluid capacitance number of poles of motor | |

| seawater pump motor power frequency | |

| seawater pump motor power frequency rotational speed of pump flow rates of sea water | |

| flow rates of sea water | |

| flow rates of fresh water | |

| flow rate of fresh water bypassing the heat exchanger | |

| steady-state flow rate of fresh water output flow rate in steady state of cooling pump | |

| flow rate of fresh water bypassing the heat exchanger opening degree of the 33-way valve | |

| flow rate of fresh water passing through heat exchanger flowrate of fresh water passing through the heat exchanger | |

| flow rate of cooling pump fluid capacitance number of poles of motor | |

| output flow rate in steady state of cooling pump flow resistance fluid capacitance | |

| flow rate of fresh water passing through the heat exchanger flow rate of cooling pump flow resistance | |

| steady-state flow rate of fresh water output flow rate in steady state of cooling pump flow rate of cooling pump | |

| flow rate of cooling pump flow resistance number of poles of motor | |

| output flow rate in steady state of cooling pump flow rate of cooling pump fluid capacitance | |

| flow rate of fresh water passing through the heat exchanger output flow rate in steady state of cooling pump flow resistance | |

| flow rate of fresh water passing through heat exchanger flow rate of fresh water passing through the heat exchanger output flow rate in steady state of cooling pump | |

| flow rate of fresh water bypassing the heat exchanger flow rate of fresh water passing through heat exchanger steady-state flow rate of fresh water | |

| the flow rate per one rotate of pump flow rates of sea waterflow rates of fresh water density of fresh water | |

| the flow rate per one rotate of pump flow rates of fresh water density of sea water density of fresh water specific heats of fresh water | |

| the mass of sea water | |

| sea water input flow rate | |

| the mass of fresh water | |

| fresh water input flow rate | |

| sea water input flow rate heat transfer area of the heat exchanger | |

| the rate of change in mass of fresh water at the outlet side of the 33-way valve. | |

| the mass of fresh water inside the 33-way valve amount of heat of fresh water bypassing the central cooling heat fresh water input flow rate | |

| the mass of fresh water inside the 33-way valve amount of heat of fresh water cooled through central cooling heat exchanger the rate of change in mass of fresh water at the outlet side of the 33-way valve the mass of fresh water | |

| the mass of fresh water inside the 33-way valve amount of heat of fresh water cooled through central cooling heat exchanger | |

| the rate of change in mass of fresh water at the outlet side of the 33-way valve amount of heat at the outlet side of the 33-way valve flow rate of fresh water bypassing the heat exchanger | |

| the rate of change in mass of fresh water at the outlet side of the 33-way valve flow rate of fresh water bypassing the heat exchanger opening degree of the 33-way valve fresh water input flow rate | |

| the mass of fresh water inside the 33-way valve amount of heat of fresh water bypassing the central cooling heat | |

| opening degree of the 33-way valve steady-state flow rate of fresh waterflow rate of fresh water passing through the heat exchanger | |

| number of poles of motor seawater pump motor power frequency the flow rate per one rotate of pump | |

| number of poles of motor rotational speed of pump the flow rate per one rotate of pump flow rates of sea water density of sea water | |

| amount of heat of fresh water cooled through central cooling heat exchanger the rate of change in mass of fresh water at the outlet side of the 33-way valve. | |

| amount of heat of fresh water bypassing the central cooling heat amount of heat of fresh water cooled through central cooling heat exchanger | |

| amount of heat of fresh water bypassing the central cooling heat the rate of change in mass of fresh water at the outlet side of the 33-way valve amount of heat at the outlet side of the 33-way valve flow rate of fresh water bypassing the heat exchanger opening degree of the 33-way valve | |

| amount of heat of fresh water cooled through central cooling heat exchanger amount of heat at the outlet side of the 33-way valve flow rate of fresh water bypassing the heat exchanger opening degree of the 33-way valve flow rate of fresh water passing through heat exchanger steady-state flow rate of fresh water | |

| heat transfer rate | |

| amount of heat at the outlet side of the 33-way valve | |

| amount of heat at the outlet side of the 33-way valve opening degree of the 33-way valve | |

| amount of heat at the outlet side of the 33-way valve flow rate of fresh water bypassing the heat exchanger low rate of fresh water passing through heat exchanger | |

| amount of heat at the outlet side of the 33-way valve opening degree of the 33-way valve flow rate of fresh water passing through heat exchanger steady-state flow rate of fresh waterflow rate of fresh water passing through the heat exchanger flow rate of cooling pump | |

| flow resistance fluid capacitance seawater pump motor power frequency | |

| flow resistance number of poles of motor seawater pump motor power frequency rotational speed of pump the flow rate per one rotate of pump flow rates of fresh water | |

| sea water input temperature | |

| sea water outlet temperature | |

| fresh water input temperature | |

| outlet temperature of the 33-way valve | |

| sea water input temperature the mass of sea water | |

| sea water outlet temperature sea water input flow rate | |

| fresh water outlet temperature fresh water input temperature | |

| outlet temperature of the 33-way valve the mass of fresh water inside the 33-way valve | |

| outlet temperature of the 33-way valve amount of heat of fresh water bypassing the central cooling heat | |

| outlet temperature of the 33-way valve the mass of fresh water inside the 33-way valve amount of heat of fresh water bypassing the central cooling heat | |

| outlet temperature of the 33-way valve the mass of fresh water inside the 33-way valve amount of heat of fresh water cooled through central cooling heat exchanger | |

| outlet temperature of the 33-way valve the mass of fresh water inside the 33-way valve amount of heat of fresh water bypassing the central cooling heat amount of heat of fresh water cooled through central cooling heat exchanger | |

| outlet temperature of the 33-way valve amount of heat of fresh water bypassing the central cooling heat amount of heat of fresh water cooled through central cooling heat exchanger the rate of change in mass of fresh water at the outlet side of the 33-way valve amount of heat at the outlet side of the 33-way valve opening degree of the 33-way valve | |

| overall heat transfer coefficient of the heat exchanger heat transfer area of the heat exchanger | |

| rotational speed of pump | |

| rotational speed of pump flow rates of sea waterflow rates of fresh water density of sea water specific heats of sea water | |

| density of fresh water specific heats of fresh water fresh water outlet temperature | |

| density of sea water specific heats of sea water specific heats of fresh water fresh water input temperature | |

| density of sea water density of fresh water specific heats of sea water fresh water outlet temperature |

| Symbol | Value | Unit | Symbol | Value | Unit |

|---|---|---|---|---|---|

| 180.8 | m2 | 0.5 | min/kJ | ||

| 3.93 | kJ/kg°C | 1025 | kg/m3 | ||

| 4.18 | kJ/kg°C | 1000 | kg/m3 | ||

| 3.344 | kJ/°C | 25.7 | °C | ||

| 60 | Hz | 39 | °C | ||

| 9 | m3/min | 27.7 | °C | ||

| 12.8 | m3/min | 36.3 | °C | ||

| 2.25 | m3/min | 28.3 | °C | ||

| 6.75 | m3/min | 450.6 | kJ/m2 min°C | ||

| 0.0071 | m3/rpm | 0.014 | m3 | ||

| 4 | pole | 0.27 | m3 | ||

| 0.5 | min/°C | 0.27 | m3 |

| Time (min) | SW Inlet Temp. to Heat Exchanger (°C) | SW Outlet Temp. from Heat Exchanger (°C) | FW Inlet Temp. to Heat Exchanger (°C) | FW Outlet Temp. from Heat Exchanger (°C) | 3-Way Valve Outlet Temp. (°C) |

|---|---|---|---|---|---|

| 0 | 24.5 | 33.4 | 41.0 | 34.0 | 34.8 |

| 1 | 24.5 | 33.4 | 41.0 | 34.0 | 34.8 |

| 2 | 24.5 | 33.4 | 41.0 | 34.0 | 34.8 |

| 3 | 24.5 | 33.4 | 41.0 | 34.0 | 34.8 |

| 4 | 24.5 | 33.4 | 41.0 | 34.0 | 34.8 |

| 5 | 24.5 | 33.5 | 41.0 | 34.0 | 34.9 |

| 6 | 24.5 | 33.6 | 41.0 | 34.1 | 34.8 |

| 7 | 24.5 | 34.4 | 41.2 | 35.1 | 36.2 |

| 8 | 24.5 | 35.6 | 42.1 | 35.6 | 37.2 |

| 9 | 24.6 | 36.4 | 42.8 | 35.9 | 37.6 |

| 10 | 24.6 | 36.8 | 43.1 | 36.1 | 37.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, T.-Y.; Lee, C.-M.; Hur, J.-J. A Study on the Control Solution of Ship’s Central Fresh Water-Cooling System for Efficient Energy Control Based on Merchant Training Ship. J. Mar. Sci. Eng. 2022, 10, 679. https://doi.org/10.3390/jmse10050679

Jeon T-Y, Lee C-M, Hur J-J. A Study on the Control Solution of Ship’s Central Fresh Water-Cooling System for Efficient Energy Control Based on Merchant Training Ship. Journal of Marine Science and Engineering. 2022; 10(5):679. https://doi.org/10.3390/jmse10050679

Chicago/Turabian StyleJeon, Tae-Youl, Chang-Min Lee, and Jae-Jung Hur. 2022. "A Study on the Control Solution of Ship’s Central Fresh Water-Cooling System for Efficient Energy Control Based on Merchant Training Ship" Journal of Marine Science and Engineering 10, no. 5: 679. https://doi.org/10.3390/jmse10050679

APA StyleJeon, T.-Y., Lee, C.-M., & Hur, J.-J. (2022). A Study on the Control Solution of Ship’s Central Fresh Water-Cooling System for Efficient Energy Control Based on Merchant Training Ship. Journal of Marine Science and Engineering, 10(5), 679. https://doi.org/10.3390/jmse10050679