Impact of Biofuel on the Environmental and Economic Performance of Marine Diesel Engines

Abstract

:1. Introduction

2. Literature Review

- Establish optimal configuration schemes for marine fuel systems, in which the use of alternative fuel is possible;

- Define the criteria for evaluating the efficiency of using alternative fuels;

- Set the optimal concentration of alternative fuel in a mixture with diesel fuel.

3. Materials and Methods

- The sulfur content of marine fuel must not exceed 0.5% by weight;

- In special areas, to control SOX emissions, the sulfur content in the marine fuel supplied to the ship and used on it should not exceed 0.10% by weight;

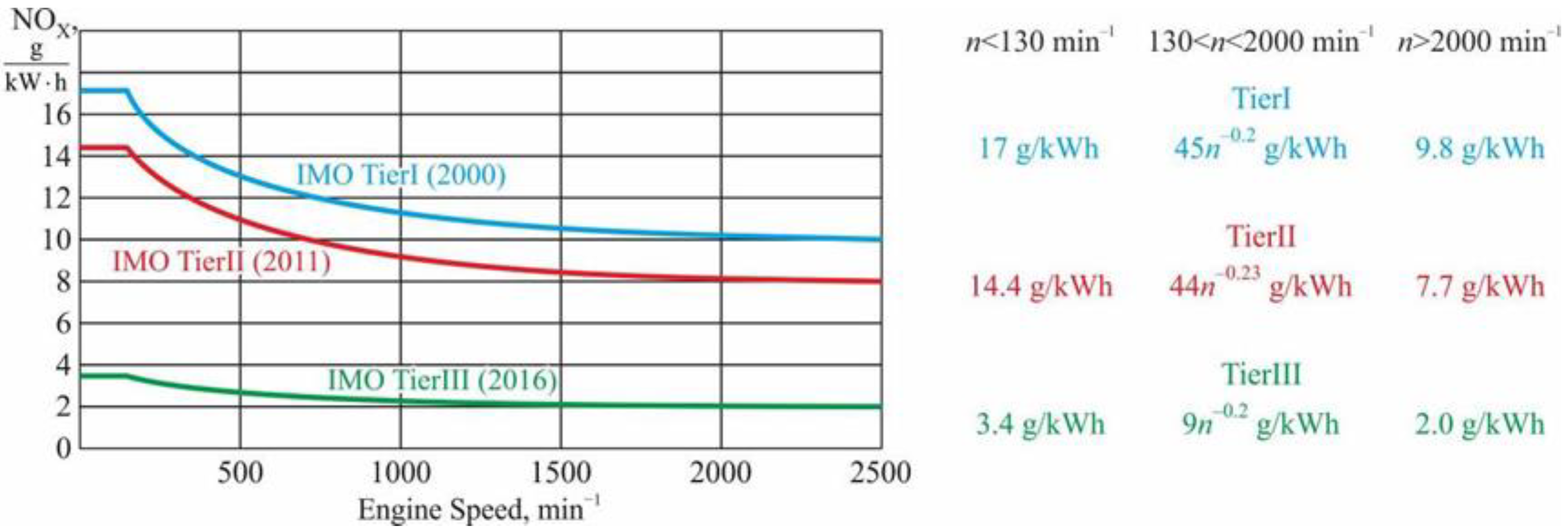

- The emissions of nitrogen oxides in exhaust gases must comply with Tier-I, Tier-II, Tier-III standards (which apply to diesel engines of ships built after 2000, 2011, and 2016), but the maximum amount of NOX in exhaust gases depends on the speed of the diesel engine and should not exceed the values determined by special expressions (Figure 1) [60,63,64].

- Content of biodiesel fuel—99.7%;

- Diesel fuel content—0.3%;

- Diesel fuel class—ultra-low-sulfur diesel fuel;

- Sulfur content in diesel fuel—0.02%;

- Viscosity at 40 °C—15 sSt;

- Density at 15 °C—850 kg/m3.

- Viscosity at 40 °C—12 sSt;

- Density at 15 °C—865 kg/m3;

- Sulfur content—0.09%.

- Vf—the amount of fuel that has passed through the flow meter, m3;

- ρ—density of the fuel at the appropriate temperature, kg/m3;

- t—the time during which the experiment was carried out in the corresponding operating mode of the diesel engine, h;

- Nework—power of the diesel in different modes of operation, kW.

4. Results

- where —emission of nitrogen oxide during diesel operation on RMA10 fuel and the mixture of RMA10 fuel with FAME biofuel, g/(kWh);

- —emission of carbon during diesel operation on RMA10 fuel and the mixture of RMA10 fuel with FAME biofuel, %;

- —the specific useful diesel fuel consumption during diesel operation on RMA10 fuel and the mixture of RMA10 fuel with FAME biofuel, g/(kWh).

5. Discussion

6. Conclusions

- The fuel mixture can be based on the diesel fuel which it contains (80–95%); the rest will take place in the form of biodiesel. It is easier to make a mixture with diesel and biodiesel directly before injection using a special dosing unit. The needed proportion of biodiesel will be automatically added to the system and the mixture will be ready directly before injection. The close or equal viscosity and density of diesel fuel and biofuel allow the injection of the fuel mixture through a common nozzle. It does not require the installation of an additional biofuel supply system to the diesel engine cylinder.

- It is advisable to carry out, on the basis of environmental and economic criteria, the efficient use of a fuel mixture consisting of diesel fuel and biofuel. It is also necessary to calculate the specific effective fuel consumption as an economic criterion.

- The best proportion between biodiesel and diesel can be found during the test and experiment for each type of diesel engine.

- During the experimental research performed on 6N165LW Yanmar marine medium-speed diesel engines in the range of their operating loads of 50–80% with a fuel mixture that included 80–95% RMA10 diesel fuel and 5–20% FAME biofuel, the environmental friendliness of marine diesel operation was shown to increase. At the same time (depending on the diesel load and the content of biofuel in the fuel mixture), the emission of nitrogen oxides within exhaust gases was reduced by 8.7–23.4% and the emission of carbon oxides within exhaust gases was reduced by 3.1–24%. It was also found that when using biofuels, the efficiency of diesel operation was reduced. At the same time (depending on the load of the diesel engine and the content of biofuel in the fuel mixture), the specific effective fuel consumption increased by 0.5–9.3%.

- The concentration of biofuel in the fuel mixture has an optimal value. It has been experimentally established that the highest environmental efficiency was achieved when using a fuel mixture which includes 10–15% of biofuel. At the same time, in the modes of 80% of the diesel load, the emission of nitrogen oxides decreased (by 21–23.5%) and the emission of carbon oxides decreased (by 16.5–19.2%). The increase in the specific effective consumption for the specified composition of the fuel mixture and diesel load was 1–1.55%.A fuel mixture containing 20% of biofuel significantly reduced the efficiency of a diesel engine. At the same time, at loads of 50–60% (the most common range of operating conditions for marine auxiliary engines), the specific fuel consumption increased by 8.46–9.31%. Despite an almost twenty percent reduction in carbon oxide emissions and an almost sixteen percent reduction in nitrogen oxide emissions, the operation of marine diesel engines with such a fuel mixture composition is not advisable. The highest economic efficiency for any concentration of biofuel in the fuel mixture belongs to the modes of 70–80% of the load. At the same time, at the load of 70%, the specific effective fuel consumption increased by 1–6.6%; at the load of 80%, it showed an increase of 0.5–3.1%. The fuel mixture containing 5% biofuel only provided the minimum environmental efficiency of the diesel engine—the emission of nitrogen oxides was reduced by 8.7–9.6%, and the emission of carbon oxides was reduced by 3.0–12.3% (relative to the diesel load). In this regard, the operation of diesel engines using such a fuel mixture can only be performed in certain cases (for example, with a small amount of biofuel on board).

- The proposed option for using biofuel in marine medium-speed diesel engines is based on practical experience. Taking into account that bunkering by biofuel is not possible in all ports, it is better to bunker in a convenient port with the needed quantity of biofuel to reach the next convenient port.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Smyshlyaeva, K.I.; Rudko, V.A.; Kuzmin, K.A.; Povarov, V.G. Asphaltene genesis influence on the low-sulfur residual marine fuel sedimentation stability. Fuel 2022, 328, 125291. [Google Scholar] [CrossRef]

- Sagin, S.; Kuropyatnyk, O.; Sagin, A.; Tkachenko, I.; Fomin, O.; Píštěk, V.; Kučera, P. Ensuring the Environmental Friendliness of Drillships during Their Operation in Special Ecological Regions of Northern Europe. J. Mar. Sci. Eng. 2022, 10, 1331. [Google Scholar] [CrossRef]

- Sagin, S.; Madey, V.; Sagin, A.; Stoliaryk, T.; Fomin, O.; Kučera, P. Ensuring Reliable and Safe Operation of Trunk Diesel Engines of Marine Transport Vessels. J. Mar. Sci. Eng. 2022, 10, 1373. [Google Scholar] [CrossRef]

- Kaminski, P. Experimental Investigation into the Effects of Fuel Dilution on the Change in Chemical Properties of Lubricating Oil Used in Fuel Injection Pump of Pielstick PA4V185 Marine Diesel Engine. Lubricants 2022, 10, 162. [Google Scholar] [CrossRef]

- Maryanov, D. Development of a method for maintaining the performance of drilling fluids during transportation by Platform Supply Vessel. Technol. Audit. Prod. Reserves 2021, 5, 15–20. [Google Scholar] [CrossRef]

- Maryanov, D. Control and regulation of the density of technical fluids during their transportation by sea specialized vessels. Technol. Audit. Prod. Reserves 2022, 1, 19–25. [Google Scholar] [CrossRef]

- Lovska, A.; Fomin, O.; Pistek, V.; Kucera, P. Dynamic load modelling within combined transport trains during transportation on a railway ferry. Appl. Sci. 2020, 10, 5710. [Google Scholar] [CrossRef]

- Gorb, S.; Levinskyi, M.; Budurov, M. Sensitivity Optimisation of a Main Marine Diesel Engine Electronic Speed Governor. Sci. Horiz. 2021, 24, 9–19. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Li, J.; Wang, S.; Zhong, Y.; Dong, R.; Gao, S.; Cao, C.; Tan, D. Investigation on combustion, performance and emission characteristics of a diesel engine fueled with diesel/alcohol/n-butanol blended fuels. Fuel 2022, 320, 123975. [Google Scholar] [CrossRef]

- Komać, A.; Mohović, Đ.; Strabić, M. Impact of High Speed of Vessels on Narrow and Shallow Waterways with Reference to the Adriatic Sea. Naše more 2022, 69, 84–91. [Google Scholar] [CrossRef]

- Ren, H.; Ding, Y.; Sui, C. Influence of EEDI (Energy Efficiency Design Index) on Ship-Engine-Propeller Matching. J. Marit. Sci. Eng. 2019, 7, 425. [Google Scholar] [CrossRef] [Green Version]

- Lu, R.; Ringsberg, J.W. Ship energy performance study of three wind-assisted ship propulsion technologies including a parametric study of the Flettner rotor technology. Ships Offshore Struct. 2020, 15, 249–258. [Google Scholar] [CrossRef] [Green Version]

- Öztürk, E.; Can, Ö. Effects of EGR, injection retardation and ethanol addition on combustion, performance and emissions of a DI diesel engine fueled with canola biodiesel/diesel fuel blend. Energy 2020, 244, 123129. [Google Scholar] [CrossRef]

- Aditya, N.D.; Sandhya, K.G.; Harikumar, R. Development of small vessel advisory and forecast services system for safe navigation and operations at sea. J. Oper. Oceanogr. 2020, 15, 52–67. [Google Scholar] [CrossRef]

- Shen, F.; Li, X. Effects of fuel types and fuel sulfur content on the characteristics of particulate emissions in marine low-speed diesel engine. Environ. Sci. Pollut. Res. 2020, 27, 37229–37236. [Google Scholar] [CrossRef]

- Sagin, S.V.; Kuropyatnyk, O.A. The Use of Exhaust Gas Recirculation for Ensuring the Environmental Performance of Marine Diesel Engines. Naše More Int. J. Marit. Sci. Technol. 2018, 65, 78–86. [Google Scholar] [CrossRef] [Green Version]

- Van, T.G.; Ramirez, J.; Ristovskim, Z.; Brown, R.J. Global impact of recent IMO regulation on marine fuel oil refining processes and ship emissions. Transp. Res. Part D Transp. Environ. 2019, 70, 123–134. [Google Scholar] [CrossRef]

- Labeckas, G.; Slavinskas, S.; Mickevicius, T. Experimental investigation of biodiesel-n-butanol fuels blends on performance and emissions in a diesel engine. Combust. Engines 2022, 188, 90–95. [Google Scholar] [CrossRef]

- Ingaldi, M.; Klimecka-Tatar, D. People’s Attitude to Energy from Hydrogen—From the Point of View of Modern Energy Technologies and Social Responsibility. Energies 2020, 13, 6495. [Google Scholar] [CrossRef]

- Fomin, O.; Lovska, A.; Kučera, P.; Píštěk, V. Substantiation of Improvements for the Bearing Structure of an Open Car to Provide a Higher Security during Rail/Sea Transportation. J. Mar. Sci. Eng. 2021, 9, 873. [Google Scholar] [CrossRef]

- Maryanov, D.M. Maintaining the efficiency of drilling fluids when they are transported by platform supply vessels class offshore vessels. Austrian J. Tech. Nat. Sci. Sci. J. 2021, 7–8, 22–28. [Google Scholar] [CrossRef]

- Karthic, S.; Kumar, M. Experimental investigations on hydrogen biofueled reactivity controlled compression ignition engine using open ECU. Energy 2021, 229, 120787. [Google Scholar] [CrossRef]

- Sahar, M.; Kassem, H.; Driss, Z.; Abid, M. Effects of hydrogen enrichment and injection location on in-cylinder flow characteristics, performance and emissions of gaseous LPG engine. Energy 2021, 150, 92–108. [Google Scholar] [CrossRef]

- Zincira, B.; Deniz, C.; Tunér, M. Investigation of environmental, operational and economic performance of methanol partially premixed combustion at slow speed operation of a marine engine. J. Clean. Prod. 2019, 235, 1006–1019. [Google Scholar] [CrossRef]

- Chen, C.; Yao, A.; Yao, C.; Wang, D.; Lu, H.; Fen, J. Study of the characteristics of PM and the correlation of soot and smoke opacity on the diesel methanol dual fuel engine. Appl. Therm. Eng. 2019, 148, 391–403. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Xie, G.; Li, J.; Xu, W.; Jiang, F.; Huang, Y.; Tan, D. Investigation on the combustion and emission characteristics of diesel engine fueled with diesel/methanol/n-butanol blends. Fuel 2022, 314, 123088. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Tian, J.; Dong, R.; Zou, Z.; Gao, S.; Tan, D. Performance, combustion and emission characteristics investigations on a diesel engine fueled with diesel/ethanol/n-butanol blends. Energy 2022, 249, 123733. [Google Scholar] [CrossRef]

- Madey, V.V. Usage of biodiesel in marine diesel engines. Austrian J. Tech. Nat. Sci. Sci. J. 2021, 7–8, 18–21. [Google Scholar] [CrossRef]

- Tabatabaeiab, M.; Aghbashlo, M.; Dehhaghice, M.; Kazem, H.; Panahic, S.; Mollahosseini, A.; Hosseini, M.; Soufiya, M. Reactor technologies for biodiesel production and processing. Prog. Energy Combust. Sci. 2019, 74, 239–303. [Google Scholar] [CrossRef]

- Melnyk, O.; Onishchenko, O.; Onyshchenko, S.; Voloshyn, A.; Kalinichenko, Y.; Rossomakha, O.; Naleva, G.; Rossomakha, O. Autonomous Ships Concept and Mathematical Models Application in their Steering Process Control. TransNav 2022, 16, 553–559. [Google Scholar] [CrossRef]

- Alanen, J.; Saukko, E.; Lehtoranta, K.; Murtonen, T. The formation and physical properties of the particle emissions from a natural gas engine. Fuel 2015, 162, 155–161. [Google Scholar] [CrossRef]

- Povarov, V.G.; Efimov, I.; Smyshlyaeva, K.I.; Rudko, V.A. Application of the UNIFAC Model for the Low-Sulfur Residue Marine Fuel Asphaltenes Solubility Calculation. J. Mar. Sci. Eng. 2022, 10, 1017. [Google Scholar] [CrossRef]

- Likhanov, V.A.; Lopatin, O.P. Dynamics of soot formation and burnout in a gas diesel cylinder. IOP Conf. Ser. Mater. Sci. Eng. 2020, 862, 062033. [Google Scholar] [CrossRef]

- Lopez, J.A.; Alvarez, P.; Onur, B.; Kiliciris, A.; Vis, F.A. An inventory control policy for liquefied natural gas as a transportation fuel. Omega 2020, 90, 101985. [Google Scholar] [CrossRef]

- Chen, C.; Yao, A.; Yao, C.; Wang, H.; Liu, M.; Li, Z. Selective catalytic reduction of nitrogen oxides with methanol over the (Cobalt-Molybdenum)/Alumina dual catalysts under the diesel methanol dual fuel conditions. Chem. Eng. Sci. 2020, 211, 115320. [Google Scholar] [CrossRef]

- Kuropyatnyk, O.A.; Sagin, S.V. Exhaust Gas Recirculation as a Major Technique Designed to Reduce NOx Emissions from Marine Diesel Engines. Naše More Int. J. Marit. Sci. Technol. 2019, 66, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Sagin, S.V. Decrease in mechanical losses in high-pressure fuel equipment of marine diesel engines. Mater. Int. Conf. Sci. Res. SCO Ctries. Synerg. Integr. 2019, 1, 139–145. [Google Scholar] [CrossRef]

- Jalava, P.I.; Aakko-Saksa, P.; Murtonen, T.; Happo, M.S.; Markkanen, A.; Yli-Pirilä, P.; Hakulinen, P.; Hillamo, R.; Mäki-Paakkanen, J.; Salonen, R.O.; et al. Toxicological properties of emission particles from heavy duty engines powered by conventional and bio-based diesel fuels and compressed natural gas. Part Fibre Toxicol. 2012, 9, 37. [Google Scholar] [CrossRef]

- Millo, F.; Vlachos, T.; Piano, A. Physicochemical and mutagenic analysis of particulate matter emissions from an automotive diesel engine fuelled with fossil and biofuel blends. Fuel 2021, 285, 119092. [Google Scholar] [CrossRef]

- Kowalska, M.; Wegierek-Ciuk, A.; Brzoska, K.; Wojewodzka, M.; Meczynska-Wielgosz, S.; Gromadzka-Ostrowska, J.; Mruk, R.; Øvrevik, J.; Kruszewski, M.; Lankoff, A. Genotoxic potential of diesel exhaust particles from the combustion of first- and second-generation biodiesel fuels—The Fuel Health project. Environ. Sci. Pollut. Res. 2017, 24, 24223–24234. [Google Scholar] [CrossRef]

- Ju, H.-J.; Jeon, S.-K. Analysis of Characteristic Changes of Blended Very Low Sulfur Fuel Oil on Ultrasonic Frequency for Marine Fuel. J. Mar. Sci. Eng. 2022, 10, 1254. [Google Scholar] [CrossRef]

- Vilke, S.; Tadic, F.; Ostović, I.; Debelić, B. The use of hydrogen as an alternative fuel in urban transport. Sci. J. Marit. Res. 2020, 34, 376–386. [Google Scholar] [CrossRef]

- Likhanov, V.A.; Lopatin, O.P.; Yurlov, A.S.; Anfilatova, N.S. Simulation of soot formation in a tractor diesel engine running on rapeseed oil methyl ether and methanol. IOP Conf. Ser. Earth Environ. Sci. 2021, 839, 052057. [Google Scholar] [CrossRef]

- Wanderley Neto, A.O.; Rodrigues, D.V.; De Oliveira Freitas, J.C.; Da Silva, V.L.; Ribeiro, L.S.; Nunes Da Silva, D.N. A novel oil-in-water microemulsion as a cementation flushing fluid for removing non-aqueous filter cake. J. Pet. Sci. Eng. 2020, 184, 106536. [Google Scholar] [CrossRef]

- Zablotsky, Y.V.; Sagin, S.V. Maintaining Boundary and Hydrodynamic Lubrication Modes in Operating High-pressure Fuel Injection Pumps of Marine Diesel Engines. Indian J. Sci. Technol. 2016, 9, 208–216. [Google Scholar] [CrossRef]

- Chena, Z.; Chena, H.; Wang, L.; Geng, L.; Zen, K. Parametric study on effects of excess air/fuel ratio, spark timing, and methanol injection timing on combustion characteristics and performance of natural gas/methanol dual-fuel engine at low loads. Energy Convers. Manag. 2020, 210, 112742. [Google Scholar] [CrossRef]

- Sagin, S.V.; Semenov, O.V. Motor Oil Viscosity Stratification in Friction Units of Marine Diesel Motors. Am. J. Appl. Sci. 2016, 13, 200–208. [Google Scholar] [CrossRef] [Green Version]

- Kneba, Z.; Stepanenko, D.; RudnickiI, J. Numerical methodology for evaluation the combustion and emissions characteristics on WLTP in the light duty dual-fuel diesel vehicle. Combust. Engines 2022, 189, 94–102. [Google Scholar] [CrossRef]

- Temizer, I.; Cihan, O.; Eskici, B. Numerical and experimental investigation of the effect of biodiesel/diesel fuel on combustion characteristics in CI engine. Fuel 2020, 270, 117523. [Google Scholar] [CrossRef]

- Yadav, P.; Athanassiadis, D.; Yacout, D.; Tysklind, M.; Upadhyayula, V. Environmental Impact and Environmental Cost Assessment of Methanol Production from wood biomass. Environ. Pollut. 2020, 265, 114990. [Google Scholar] [CrossRef]

- Kuropyatnyk, O.A. Reducing the emission of nitrogen oxides from marine diesel engines. Int. Conf. Sci. Res. SCO Ctries. Synerg. Integr. 2020, 154–160. [Google Scholar] [CrossRef]

- Likhanov, V.A.; Lopatin, O.P.; Yurlov, A.S.; Anfilatova, N.S. Investigation of the effective performance of diesel engines running on methanol and rapeseed oil methyl ether. J. Phys. Conf. Ser. 2021, 1889, 042067. [Google Scholar] [CrossRef]

- Sagin, S.V.; Solodovnikov, V.G. Estimation of Operational Properties of Lubricant Coolant Liquids by Optical Methods. Int. J. Appl. Eng. Res. 2017, 12, 8380–8391. [Google Scholar]

- Popovskii, Y.M.; Sagin, S.V.; Khanmamedov, S.A.; Grebenyuk, M.N.; Teregerya, V.V. Designing, calculation, testing and reliability of machines: Influence of anisotropic fluids on the operation of frictional components. Russ. Eng. Res. 1996, 16, 1–7. [Google Scholar]

- Sagin, S.V.; Solodovnikov, V.G. Cavitation Treatment of High-Viscosity Marine Fuels for Medium-Speed Diesel Engines. Mod. Appl. Sci. 2015, 9, 269–278. [Google Scholar] [CrossRef]

- Kondrasheva, N.K.; Rudko, V.A.; Kondrashev, D.O.; Shakleina, V.S.; Smyshlyaeva, K.I.; Konoplin, R.R.; Shaidulina, A.A.; Ivkin, A.S.; Derkunskii, I.O.; Dubovikov, O.A. Application of a ternary phase diagram to describe the stability of residual marine fuel. Energy Fuels 2019, 33, 4671–4675. [Google Scholar] [CrossRef]

- Sagin, S.V.; Semenov, O.V. Marine Slow-Speed Diesel Engine Diagnosis with View to Cylinder Oil Specification. Am. J. Appl. Sciences. 2016, 13, 618–627. [Google Scholar] [CrossRef] [Green Version]

- Sagin, S.; Madey, V.; Stoliaryk, T. Analysis of mechanical energy losses in marine diesels. Technol. Audit. Prod. Reserves 2021, 5, 26–32. [Google Scholar] [CrossRef]

- Zablotsky, Y.V.; Sagin, S.V. Enhancing Fuel Efficiency and Environmental Specifications of a Marine Diesel When using Fuel Additives. Indian J. Sci. Technol. 2016, 9, 353–362. [Google Scholar] [CrossRef]

- Sagin, S.V.; Kuropyatnyk, O.A.; Zablotskyi, Y.V.; Gaichenia, O.V. Supplying of Marine Diesel Engine Ecological Parameters. Naše More Int. J. Marit. Sci. Technol. 2022, 69, 53–61. [Google Scholar] [CrossRef]

- Strus, M.; Poprawski, W. Efficiency of the Diesel engine fuelled with the advanced biofuel Bioxdiesel. Combust. Engines 2021, 186, 89–95. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhong, Y.; Wang, J.; Tan, D.; Zhang, Z.; Yang, D. Effects of Different Biodiesel-Diesel Blend Fuel on Combustion and Emission Characteristics of a Diesel Engine. Processes 2021, 9, 1984. [Google Scholar] [CrossRef]

- Dhyani, V.; Subramanian, K.A. Control of backfire and NOX emission reduction in a hydrogen fueled mylti-cylinder spark ignition engine using cooled EGR and water injection strategies. Int. J. Hydrogen Energy 2019, 44, 6287–6298. [Google Scholar] [CrossRef]

- Husnain, N.; Wang, E.; Li, K.; Anwar, M.T. Iron oxide based catalysts for low temperature selective catalytic reduction NOX with NH3. Rev. Chem. Eng. 2019, 35, 239–264. [Google Scholar] [CrossRef]

- Madey, V. Assessment of the efficiency of biofuel use in the operation of marine diesel engines. Technol. Audit. Prod. Reserves 2022, 2, 34–41. [Google Scholar] [CrossRef]

- Hunicz, J.; Krzaczek, P.; Gęca, M.; Rybak, A.; Mikulski, M. Comparative study of combustions and emission of diesel engine fuelled with FAME and HVO. Combust. Engines 2021, 184, 72–78. [Google Scholar] [CrossRef]

- Jiaqi, H.; Helin, X.; Xiaolong, Y.; Fengyun, G.; Xiuqing, H. Effects of methanol blending on combustion characteristics and various emissions of a diesel engine fueled with soybean biodiesel. Fuel 2020, 15, 118734. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Tian, J.; Xie, G.; Tan, D.; Qin, B.; Huang, Y.; Cui, S. Effects of Different Diesel-Ethanol Dual Fuel Ratio on Performance and Emission Characteristics of Diesel Engine. Processes 2021, 9, 1135. [Google Scholar] [CrossRef]

- Wang, Y.; Wright, L.A. A Comparative Review of Alternative Fuels for the Maritime Sector: Economic, Technology, and Policy Challenges for Clean Energy Implementation. World 2020, 2, 29. [Google Scholar] [CrossRef]

- Smyshlyaeva, K.I.; Rudko, V.A.; Povarov, V.G.; Shaidulina, A.A.; Efimov, I.; Gabdulkhakov, R.R.; Pyagay, I.N.; Speight, J.G. Influence of Asphaltenes on the Low-Sulphur Residual Marine Fuels’ Stability. J. Mar. Sci. Eng. 2021, 9, 1235. [Google Scholar] [CrossRef]

- Feng, C.; Deng, Y.; Chen, L.; Han, W.; Jiaqiang, E.; Wei, K.; Han, D.; Zhang, B. Hydrocarbon emission control of a hydrocarbon adsorber and converter under cold start of the gasoline engine. Energy 2022, 239, 122138. [Google Scholar] [CrossRef]

- Cruz-Peragón, F.; Torres-Jiménez, E.; Lešnik, L.; Arma, O. Methodology improvements to simulate performance and emissions of engine transient cycles from stationary operating modes. A case study applied to biofuels. Fuel 2022, 312, 122977. [Google Scholar] [CrossRef]

- Lee, T.; Cho, J.; Lee, J. Mixing Properties of Emulsified Fuel Oil from Mixing Marine Bunker-C Fuel Oil and Water. J. Mar. Sci. Eng. 2022, 10, 1610. [Google Scholar] [CrossRef]

- Abdu Ahmed, S.; Zhou, S.; Yuanqing, Z.; Yongming, F.; Adil, M.; Naseem, A. Influence of Injection Timing on Performance and Exhaust Emission of CI Engine Fuelled with Butanol-Diesel Using a 1D GT-Power Model. Processes 2019, 7, 299. [Google Scholar] [CrossRef] [Green Version]

- Aydın, S. Detailed evaluation of combustion, performance and emissions of ethyl proxitol and methyl proxitol-safflower biodiesel blends in a power generator diesel engine. Fuel 2020, 270, 117492. [Google Scholar] [CrossRef]

- Likhanov, V.A.; Lopatin, O.P.; Vylegzhanin, P.N. Calculation of geometric parameters of diesel fuel ignition flares. IOP Conf. Ser. Mater. Sci. Eng. 2020, 862, 062074. [Google Scholar] [CrossRef]

- Hoekman, S.K.; Robbins, C. Review of the effects of biodiesel on NOx emissions. Fuel Process. Technol. 2012, 96, 237–249. [Google Scholar] [CrossRef]

| Type of Fuel | Lower Caloric Value, kJ/kg | Density at 20 °C, kg/m3 |

|---|---|---|

| Natural gas | 50,000 | 0.7 |

| Petroleum gas | 47,500–48,500 | 1.8–2.5 |

| Hydrogen | 120,000–140,000 | 0.1 |

| Methanol and ethanol | 22,500–23,000 | 790–800 |

| Rapeseed oil | 37,000–37,500 | 900–920 |

| Characteristics | Value |

|---|---|

| Bore, mm | 165 |

| Stroke, mm | 232 |

| Speed, min–1 | 1200 |

| Output power, kW | 530 |

| Specific fuel oil consumption, g/(kWh) | 194 |

| Diesel Load, % | Type of Fuel Blend | ||||

|---|---|---|---|---|---|

| RMA10 | RMA10 + 5% Biofuel | RMA10 + 10% Biofuel | RMA10 + 15% Biofuel | RMA10 + 20% Biofuel | |

| Emission of nitrogen oxide NOX in exhaust gases, g/(kWh) | |||||

| 50 | 7.32 | 6.62 | 6.02 | 5.93 | 6.15 |

| 60 | 7.56 | 6.88 | 6.22 | 6.12 | 6.33 |

| 70 | 7.88 | 7.17 | 6.32 | 6.18 | 6.58 |

| 80 | 8.16 | 7.45 | 6.45 | 6.25 | 6.84 |

| Emission of carbon oxides CO in exhaust gases, volume % | |||||

| 50 | 6.22 | 6.03 | 5.68 | 5.25 | 5.06 |

| 60 | 6.31 | 6.07 | 5.71 | 5.32 | 5.1 |

| 70 | 6.73 | 6.22 | 6.03 | 5.52 | 5.21 |

| 80 | 7.33 | 6.43 | 6.12 | 5.92 | 5.57 |

| Specific useful fuel consumption be, g/(kWh) | |||||

| 50 | 204 | 209 | 215 | 219 | 223 |

| 60 | 201 | 204 | 207 | 211 | 218 |

| 70 | 196 | 198 | 200 | 203 | 209 |

| 80 | 193 | 194 | 195 | 196 | 199 |

| Diesel Load, % | Type of Fuel Blend | |||

|---|---|---|---|---|

| RMA10 + 5% Biofuel | RMA10 + 10% Biofuel | RMA10 + 15% Biofuel | RMA10 + 20% Biofuel | |

| Reducing the emission of nitrogen oxides ∆NOX in exhaust gases, % | ||||

| 50 | 9.56 | 17.76 | 18.99 | 15.98 |

| 60 | 8.99 | 17.72 | 19.05 | 16.27 |

| 70 | 9.01 | 19.80 | 21.57 | 16.5 |

| 80 | 8.70 | 20.96 | 23.41 | 16.18 |

| Reducing the emission of carbon monoxide ∆CO in exhaust gases, % | ||||

| 50 | 3.05 | 8.68 | 15.59 | 18.65 |

| 60 | 3.80 | 9.51 | 15.69 | 19.18 |

| 70 | 7.58 | 10.4 | 17.98 | 22.59 |

| 80 | 12.30 | 16.51 | 19.24 | 24.01 |

| Increase in specific useful fuel consumption ∆be, % | ||||

| 50 | 2.45 | 5.39 | 7.35 | 9.31 |

| 60 | 1.49 | 2.99 | 4.98 | 8.46 |

| 70 | 1.02 | 2.04 | 3.57 | 6.63 |

| 80 | 0.52 | 1.04 | 1.55 | 3.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sagin, S.; Karianskyi, S.; Madey, V.; Sagin, A.; Stoliaryk, T.; Tkachenko, I. Impact of Biofuel on the Environmental and Economic Performance of Marine Diesel Engines. J. Mar. Sci. Eng. 2023, 11, 120. https://doi.org/10.3390/jmse11010120

Sagin S, Karianskyi S, Madey V, Sagin A, Stoliaryk T, Tkachenko I. Impact of Biofuel on the Environmental and Economic Performance of Marine Diesel Engines. Journal of Marine Science and Engineering. 2023; 11(1):120. https://doi.org/10.3390/jmse11010120

Chicago/Turabian StyleSagin, Sergii, Sergey Karianskyi, Volodymyr Madey, Arsenii Sagin, Tymur Stoliaryk, and Ivan Tkachenko. 2023. "Impact of Biofuel on the Environmental and Economic Performance of Marine Diesel Engines" Journal of Marine Science and Engineering 11, no. 1: 120. https://doi.org/10.3390/jmse11010120

APA StyleSagin, S., Karianskyi, S., Madey, V., Sagin, A., Stoliaryk, T., & Tkachenko, I. (2023). Impact of Biofuel on the Environmental and Economic Performance of Marine Diesel Engines. Journal of Marine Science and Engineering, 11(1), 120. https://doi.org/10.3390/jmse11010120