1. Introduction

One of the most popular hull systems for deep-water drilling and production platforms around the world is the semi-submersible. Because of its excellent hydrodynamic performance in adverse weather, structural performance is always one of the key concerns throughout the course of its service life. It is generally agreed upon that a system reliability approach should be used to design such structures. This approach can be used to optimize design parameters throughout the design process and can take into account the effects of uncertainties in materials, loading parameters, and other factors.

The American Society of Civil Engineers (ASCE) structural reliability committee [

1] summarized the reliability in a publication at the time and discussed a solution to the problem of the system reliability of marine structures in 1983. Following that, numerous studies focused on using reliability theory to address reliability issues in marine structures.

It typically takes extensive numerical simulations and significant computational effort to assess the reliability of large structures. A novel method for the system reliability analysis of offshore structures was proposed by Cocconel. et al. (2017) [

2] makes use of the dominant failure modes found through selective searching. The development of an artificial neural network model for the reliability analysis of steel structures was studied by Chojaczyk et al. [

3] in 2015. This research revealed that, for complex structures, the artificial neural network-based reliability analysis method is a useful alternative to the conventional reliability analysis method. Using Monte Carlo simulation (MCS), Vazirizade et al. (2017) [

4] trained an ANN and assessed the seismic reliability of the suggested structures. The techniques for choosing training sets are crucial for neural network-based approaches to structural reliability problems (Chojaczyk et al., 2015). To create samples for regression analysis and create the response surface, Latin hypercube sampling (LHS) has been widely used (Kang et al., 2015 [

5]; Gaspar and Guedes Soares, 2013 [

6]). In structural reliability analysis, the Monte Carlo method and response surface techniques have also been widely employed (Sadoughi et al., 2018 [

7]); Pan and Dias, 2017 [

8]; Gaspar et al., 2015 [

9]). An ideal reliability-based design method for complex structural systems was put forth by Ang et al. [

10] in 2021.

Moan and his students have conducted extensive research on the dependability of marine structures over the past 40 years. Their works include ship reliability analysis [

11]. (Jia and Moan 2009), the reliability-based design of the ultimate hull girder strength [

12] (Amlashi et al., 2011), fatigue reliability analysis of the jacket structure [

13] (Dong et al., 2012), the fatigue reliability-based inspection and maintenance planning of gearbox components [

14] (Rasekhi Nejad et al., 2014), the time-variant reliability assessment of FPSO reliability [

15] (Yala-Uraga and Moan 2015), and uncertainty in forecasted environmental conditions [

16]. Their work has had a significant impact on the methodology for calculating marine structure reliability as well as the calibration and calculation examples for various marine structures.

Researchers have looked into the pile–soil interaction and system reliability of jacket platforms (Asgarian et al., 2019 [

17]; Bai et al., 2016 [

18]; Zhao et al., 2020 [

19]). A strength reliability analysis method for the local joint of a tension leg platform was published in 2012 by Shaoet. al. [

20]. Ye et al.’s (2013) [

21] investigation into the system reliability of a typical semi-submersible drilling rig showed that this issue had not yet been adequately addressed, according to additional research.

A semi-submersible platform is a very complex structural form, as opposed to ship-like structures. Typically, a systematic analysis plan should be created in accordance with a specified structure in order to conduct the structural analysis of a complex structure (Murotsuetal., 1984 [

22]; Feng, 1988 [

23]). First and foremost, when considering a semi-submersible platform, it is important to build both well-represented hydrodynamic and structural simulation models that correspond to the dimensions of a real semi-submersible platform. Second, the most unfavorable load conditions are frequently determined using the DNV (2005) [

24] and ABS (2008) [

25] rules. Finally, a semi-submersible platform system reliability model should be presented, and the system reliability of a typical semi-submersible platform was examined, taking into account the contribution of the main nodes.

The fundamental ideas of the system reliability assessment are introduced in

Section 2. In

Section 3, South China Sea-based semi-submersible platforms are illustrated with useful numerical examples.

Section 4 and

Section 5 present a case study that utilizes a typical semi-submersible platform while discussing the system reliability analysis method using the established numerical model. Finally,

Section 6 presents the conclusions and summarizes them.

3. Numerical Simulation Model of Selected Semi-Submersible Platform

This paper focuses on a typical drilling semi-submersible platform that is braced between columns and has two parallel pontoons for column stabilization. Using the finite element software packages, ANSYS, a well-represented, nonlinear finite element model, was constructed to accurately predict the behavior of the structure [

26].

3.1. Geometric Dimensions of the Object Platform

Figure 3 depicts the main components of the structure, including the pontoons, columns, horizontal braces, and deck, while

Table 1 summarizes the platform’s main dimensions.

3.2. Material Properties

The strength of the structure is largely determined by the constitutive relation model, which depicts the relationship between stress and strain. The ideal elastic-plastic model is used in this paper, and strain hardening is not taken into account. The numerical model, EQ36, is used and has the following parameters: a Poisson’s ratio of = 0.3, Young’s modulus of E = 206 GPa, and yield stress of = 315 MPa = 315 MPa.

3.3. Environment Load Calculation

The environmental loads that are induced by waves traveling normally toward a semi-submersible platform are the most significant. The hydrodynamic software program WAMIT [

27] is typically used to calculate the wave loads on a hull structure. A hydrodynamic model should be constructed in accordance with the platform dimensions shown in

Figure 3 in order to generate the wave loading on the chosen platform. Following the generation of the wave loads, the most unfavorable load cases can be found by scanning thousands of wave parameters using the selection criteria that are strictly adhered to by the DNV [

24] and ABS [

25] rules.

Table 2 lists the responses that correspond to each characteristic. The wave statistics in

Table 3 are the foundation for the environmental criteria. Four different types of load cases, including split force (

), shear force (

)), torsion moment (

), and bending moment (

), are used as candidate load cases for nonlinear finite element computations.

Table 3 provides a list of the final wave parameters. The wave amplitudes

are based on the maximum value obtained over a hundred years, and the wave direction angles are from the bow. The South China Sea’s statistical wave steepness was used to calculate the wave amplitudes in

Table 3, which are used as a guide for the ULS analysis. The maximum values for the response amplitude operators (RAOs), which make up the main section load

, are shown in

Table 3. They represent the load per unit of wave amplitude for the corresponding design wave.

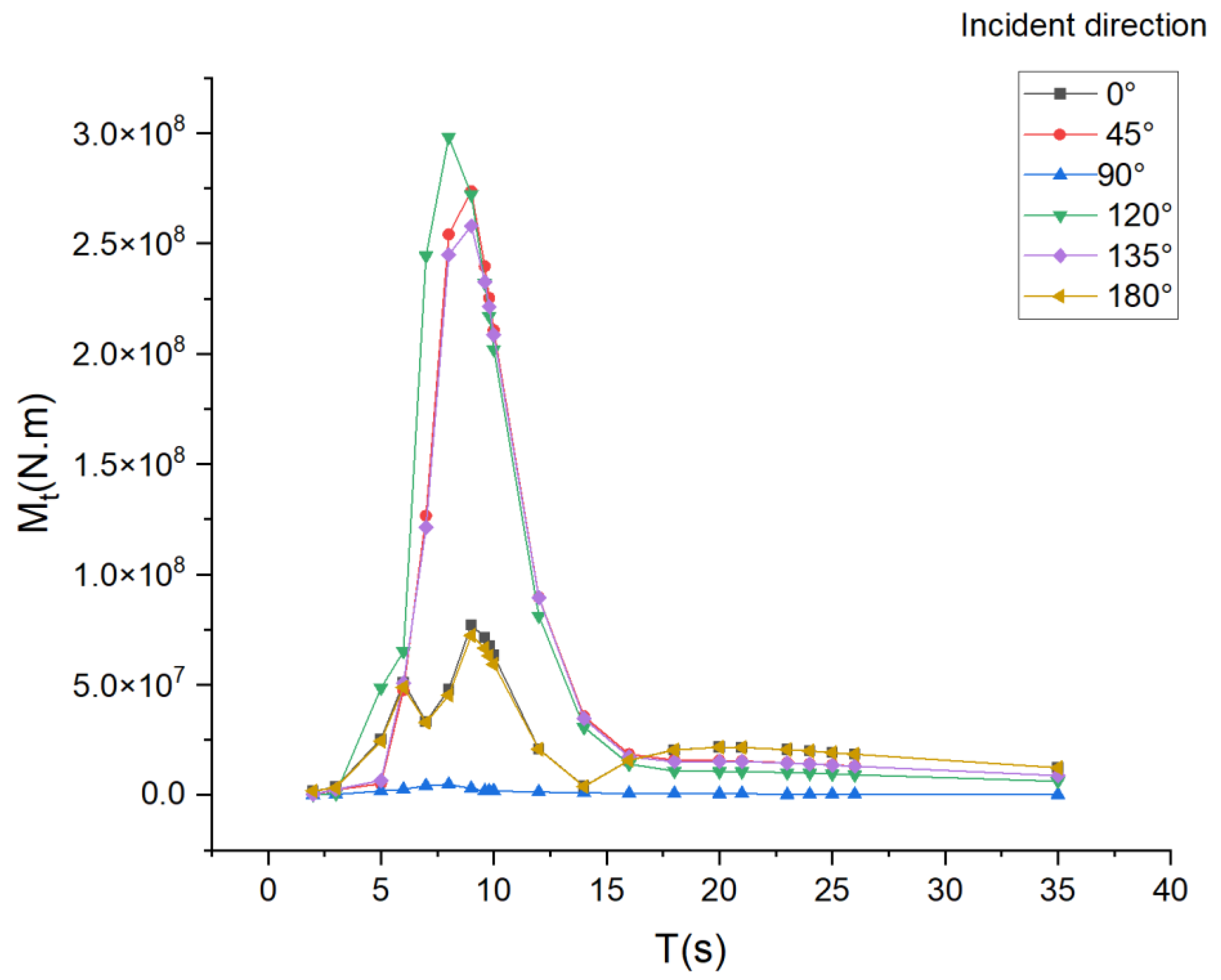

Figure 4,

Figure 5,

Figure 6 and

Figure 7 depict the ROA of a regular wave condition under various wave conditions.

3.4. Nonlinear Finite Element Mesh Modeling

A finite element model is created using ANSYS [

26] software in accordance with the general outline in

Figure 3, as shown in

Figure 8. As can be seen, the semi-submersible platform’s main support system is made up of pontoons, columns, a deck, and braces. Each of them is made up of sub-structural components similar to the stiffener, girder, and bulkhead. A large volume thin-walled three-dimensional shell combined with the beam is used to represent the global stiffness of the structure in the global FE model. Each component’s connections must be sufficiently detailed in the models.

It is necessary to consider computation time and memory size. However, a coarse mesh in crucial locations leads to irrational stresses. Mesh convergence studies were run on the entire simulation model before it was finished. The DNV and ABS rules’ recommendations for mesh size, elements, and element types were followed in this study [

24,

25]. We used four different element types (shell181, mass21, beam188, and solid65). It is obvious that the semi-connection submersible is crucial, and these parts use fine mesh with a mesh size of approximately 0.5 m. The remainder of the platform’s grid measures roughly one to fifteen meters.

This mesh strategy, which has practical and reasonable computational time and computer capacity requirements, is sufficient to capture the real structural behavior of the platform through trial-and-error test analysis. There are approximately 240,000 total elements in the model, and there are 835,344 total degrees of freedom.

Six degrees of freedom boundary conditions are employed in accordance with the DNV rule [

24], consisting of three vertical restraints (Z), two transversal horizontal restraints (Y), and one longitudinal horizontal restraint (X).

3.5. Main Nodes of the Object Platform

As shown in

Figure 9, the platform connection nodes, which include the deck and column connection nodes (upper node) and the nodes of the columns and pontoon connection nodes (lower node), are being taken into consideration.

A precise method of computing the fine structure based on the Saint-Venant principle is sub-model technology. Sub-model technology is used to analyze the platform’s reliability for the local node, and it can increase accuracy and cut down on computational work. The cutting boundary can only pass-through body or shell elements according to conventional sub-model technology. Large calculation errors result from the presence of other types of elements, such as beam units, at the cutting boundary. A Beaml88 element serves as the reinforcement in the body model, and a SHELLl81 element serves as the reinforcement in the local node model. The traditional sub-model technology is currently being used to analyze which local node structures will result in inaccurate or even incorrect results. These can be avoided by selecting two or more cutting boundaries in the local node model that are farther from the area of concern, saving the nodes on the two cutting edges and the nodes in between them to create node files, and then performing displacement interpolation.