Human Error Analysis and Fatality Prediction in Maritime Accidents

Abstract

:1. Introduction

2. Materials and Methods

2.1. Overview of Accident Causation Models

- Social environment;

- Human error (negligence);

- Unsafe acts or mechanical and physical conditions;

- Accidents;

- Injuries.

- Unsafe acts;

- Preconditions for unsafe acts;

- Unsafe supervision;

- Organisational influences.

- Latent failures—Hidden threats stemming from organisational issues, like misaligned priorities, culture, or procedures. These can exist in the system for a long time before the accident, representing unforeseen hazards;

- Active failures—Errors in judgment or decision-making by operators, which are easier to identify and are often the primary cause of accidents [7].

- Software (S)—processes, training, support, etc.;

- Hardware (H)—equipment, devices, technical equipment, etc.;

- Environment (E)—operating environment in which other components must work;

- Liveware (L)—people in the work environment (human performance, communication, interpersonal relations, etc.).

- DREAM (Driver Reliability and Error Analysis Method) for traffic accident analysis;

- BREAM (Board Reliability and Error Analysis Method) for use in marine casualty analysis [10].

- Equivalence of successes and failures—Failures and successes share the same origin, occurring for similar reasons;

- Principle of approximate adjustments—Socio-technical systems are complex, often underspecified, and subject to daily adjustments to match system conditions;

- Principle of emergence—Normal performance variability alone is generally insufficient to cause accidents or malfunctions, but when multiple functions’ variability combines unexpectedly, non-linear effects can occur;

- Functional resonance—Variability in a group of functions can resonate, leading to an excessive amount of variability that the system cannot manage, potentially resulting in an accident.

- Development of a hierarchical control structure that includes identification of interactions between system components and identification of security requirements and constraints;

- Classification and analysis of mismanagement, which includes classification of causal factors followed by reasons for mismanagement and dysfunctional interactions.

- Government—activities of government, controlling safety practices in society through legislation;

- Regulators—activities of regulators, industrial associations and unions that are responsible for legislation implementation in various sectors;

- Company—activities of a particular company;

- Management—activities of the management body in a particular company that lead, manage and control the performance of employees;

- Staff member—individuals’ activities interacting directly with technology or processes being controlled;

- Engineering disciplines—design of potentially risky equipment and operating procedures for process control.

2.2. Research Method: Human Factor Analysis and Classification System

2.3. Risk Matrix

- Acceptable (green) area;

- Acceptable area (under certain circumstances; yellow and orange area—yellow risks are closer to the acceptable area, orange risks are closer to the unacceptable area);

- Unacceptable (red) area.

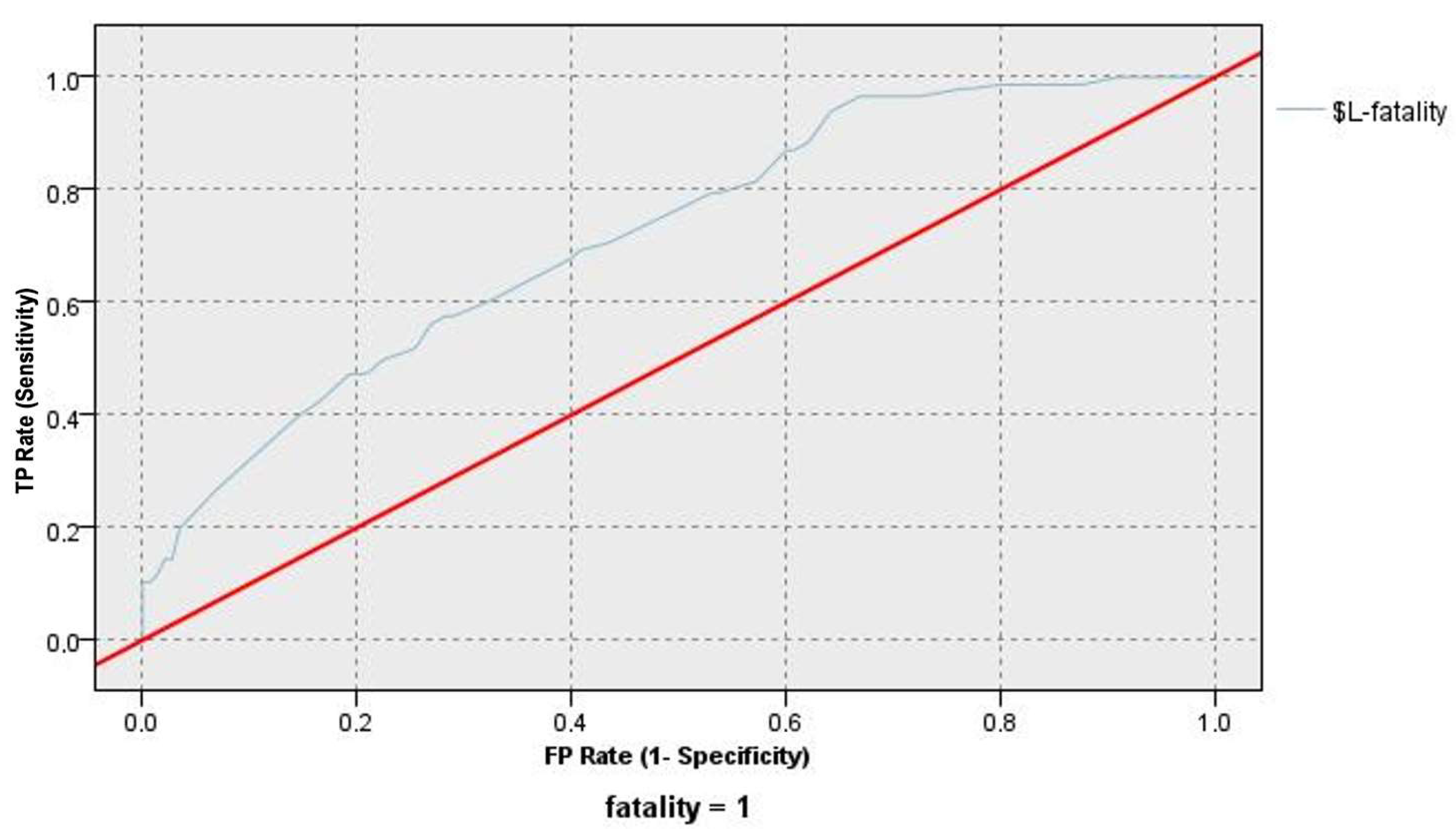

2.4. Logistic Regression

- Using the created model, we predict the occurrence of a fatality, and in reality, a fatality did occur—true positive rate;

- Conversely, using the created model, we predict that no fatalities will occur, and in reality, no fatalities occurred—true negative rate.

- Predicting a fatality during accident where no fatality occurred in reality—false positive rate;

- Conversely, predicting an accident without fatalities where, in reality, a fatality did occur—false negative rate [35].

Data Description

- Meteorological factor—waves/current;

- Technical—ship construction/devices for navigation/communication.

3. Application

3.1. Causal Factors Identification

3.1.1. Maritime Accidents Based on MAIB Reports

3.1.2. Maritime Accidents Based on TSB Reports

3.2. Application of HFACS

Example of Coding Process

- The vessel grounded when the Officer of the Watch lost situational awareness as a result of being under the influence of alcohol;

- The effective administration of the owner’s zero alcohol policy might have prevented the development of a culture in which the chief officer considered it acceptable to consume alcohol before his watch;

- Had a lookout been on the bridge, he would have been well placed to prevent the accident by alerting the master to the chief officer’s condition and that navigational waypoints had been missed;

- Had the BNWAS been switched on it is probable that the OOW would have realised at an earlier stage that a navigation waypoint had been missed;

- Had the passage plan been appropriately entered into the ECS, the available safety features would have been available, and the alarms could have alerted the OOW to potential dangers at an early stage;

- Had an appropriate and detailed passage plan been prepared and implemented in a professional and precautionary manner, it is unlikely that the voyage would have ended with the vessel hard aground;

- The abuse of alcohol was a symptom of systemic non-compliance with the SMS on Lysblink Seaways, which had gone unchallenged despite regular audits [37].

- Change of voyage because of adverse weather;

- The chief officer made a private telephone call that caused him anxiety, after which he consumed about 0.5 litre of rum (off duty);

- At midnight the chief officer took over as OOW, then sat in a chair located to starboard of the central manoeuvring station, from where he monitored the systems, but was sleepy and turned off the audio;

- The vessel’s steering was in autopilot mode;

- Deviation from planned route until grounding (vessel passes wrong route because of wind and alarms turned off);

- No lookout was posted during the hours of darkness;

- The emergency checklist for grounding was not consulted;

- The master advised that the vessel was not damage and that there was no pollution or injuries, but the vessel’s hull had been breached and its steering gear was damaged;

- Poor navigational practices, and defences/control measures for the Officer of the Watch becoming incapacitated were being ignored;

- Delay in contacting the coastal state;

- Neither the master nor the chief officer had received training in the use of the ECS and available safety features.

- The only alarm that had been enabled was for cross-track error, but this had been inappropriately set up and the audio alarm had been silenced.

| UNSAFE ACTS | |

|---|---|

| Decision errors | |

| Skill-based errors | |

| Perceptual errors | |

| Routine violations | |

| Exceptional violations | The audible alarm for cross track deviation had been silenced BNWAS switched off |

| PRECONDITIONS FOR UNSAFE ACTS | |

| Physical environment | Darkness Adverse weather (wind) |

| Technological environment | Cross-track error of alarm (not set) |

| Adverse mental state | Loss of situational awareness as a result of being under the influence of alcohol |

| Adverse physiological state | |

| Physical/mental limitations | |

| Crew resource management | |

| Personal readiness | Influence of alcohol |

| UNSAFE SUPERVISION | |

| Inadequate supervision | Chief officer considered it acceptable to consume alcohol before the watch. Master and chief officer did not received training in the use of the ECS and available safety features |

| Planned inappropriate operations | No lookout on the bridge to prevent the accident by alerting the master to the chief officer’s condition and that navigational waypoints had been missed Unprepared and unimplemented appropriate and detailed passage plan Passage plan not entered into the ECS |

| Failed to correct problem | |

| Supervisory violations | Systemic non-compliance with the SMS on Lysblink Seaways |

| ORGANISATIONAL INFLUENCES | |

| Resource management | |

| Organisational climate | |

| Organisational process | |

3.3. Summary

4. Results

4.1. Coding Process Results

4.2. Evaluation of Critical Areas

- Decision errors (14.2%);

- Routine violations (13.3%);

- Inadequate supervision (11.7%);

- Crew resource management (7.3%);

- Organisational process (7.3%).

- Exceptional violations;

- Crew resource management;

- Personal readiness;

- Planned inappropriate operations;

- Failure to correct the known problem;

- Supervisory violations.

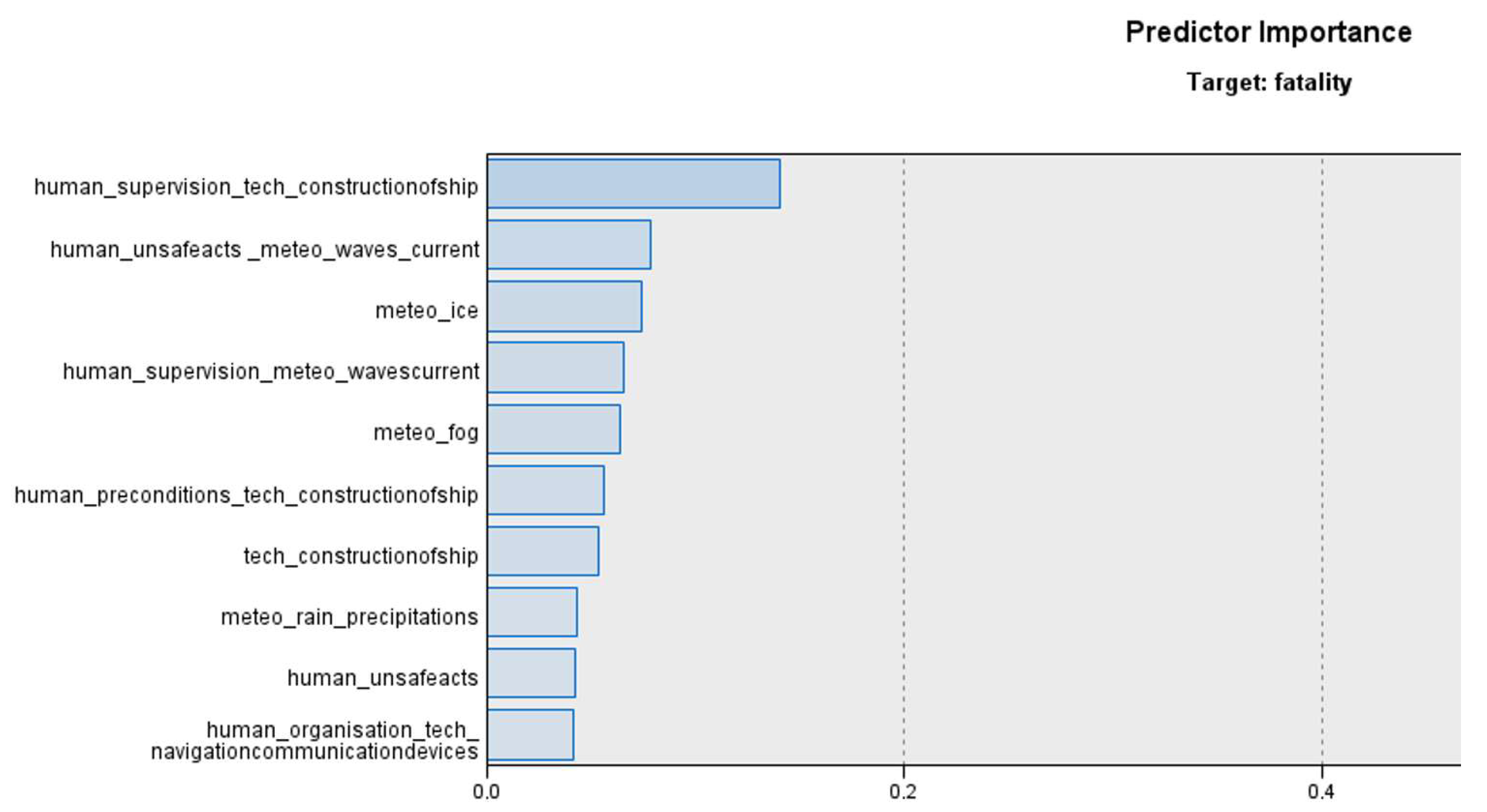

4.3. Modeling the Prediction of the Probability of Fatality in a Maritime Accident

- Meteorological/hydrological factors—ice, precipitation, fog;

- Technical failures—improper vessel construction;

- Human factors—unsafe acts (most commonly decision errors and skill-based errors).

5. Proposal of Measures for Critical Areas for Increasing Maritime Safety

- Safety and environmental protection policy;

- Instructions and procedures to ensure the ship’s safe operation and environmental protection in compliance with international and flag state law;

- Clear delineation of authority levels and communication channels between shore authorities and crewmembers;

- Protocols for reporting accidents/incidents and non-compliance with the code’s provisions;

- Procedures for emergency preparedness and response;

- Guidelines for international audits and management controls [39].

- Positive motivation involves financial rewards beyond regular salaries for performing safe navigation without incidents;

- Negative motivation can also increase safety by imposing sanctions for non-compliance with rest periods, consuming alcohol during duty, or neglecting training obligations.

6. Discussion

- The research includes the analysis of 247 maritime accident investigation reports from MAIB and TSB databases in the period 2015–2022;

- Determining causal factors involved categorisation into four groups—meteorological, technical, human, and other factors;

- The HFACS method classified human errors and failures into four main categories: unsafe acts, preconditions for unsafe acts, unsafe supervision, and organisational influences;

- By employing the coding process of the HFACS method, repetitive errors within each category were identified. This allowed for identifying specific areas requiring monitoring and implementing preventive measures to enhance maritime safety;

- Risk assessment methods were used to analyse and evaluate critical areas in the context of improving maritime transport safety;

- The most critical causal factors causing maritime accidents with fatalities are identified and assessed, based on the prediction model using linear regression;

- Limitations of the study lie in two aspects—firstly, only full investigation reports on maritime accidents were used. The authors focused on these accidents because such reports offer a thorough understanding of the causes. In contrast, accidents with less severe consequences tend to have less detailed reports (if any), posing challenges in data acquisition. For this reason, the coding process and regression model were based on the 232 accidents instead of 247. The second limitation lies in the subjectivity of the HFACS method. The categorisation of unsafe events using HFACS is based on individual, subjective opinions of experts and/or researchers using it. However, this limitation can be greatly reduced when HFCAS analysis is carried out by an expert with experience in safety investigations;

- By identifying the most significant threats, the paper has proposed preventive measures and the introduction of new safety processes. These initiatives aim to reduce the incentives for engaging in dangerous behaviour.

- The SOLAS convention (International Convention for the Safety of Life at Sea, 1974) developed in response to the Titanic accident [46]. The sinking of the Titanic in 1912 marked a crucial moment in maritime safety, leading to a shift from national attempts to regulating maritime safety independently [47];

- The main objective of the SOLAS convention is to specify minimum standards for the construction, equipment and operation of ships, compatible with their safety;

- The MARPOL convention (International Convention for the Prevention of Pollution from Ships, 1978), dealing with the prevention of pollution of the marine environment by ships from operational or accidental causes. The MARPOL Convention was adopted on 2 November 1973 at IMO. The Protocol of 1978 was adopted in response to a spate of tanker accidents in 1976–1977 [48];

- The ISM Code (International Safety Management Code, 1993) was adopted in response to the Herald of Free Enterprise incident. The ISM Code provides an international standard for the safe management and operation of ships and for pollution prevention [49].

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

| 1 | Sequential models, which aim to eliminate the causes of accidents, work reliably for accidents caused by technical and physical component failures along with human failures in relatively simple systems. However, they are limited if they are to explain the cause of accidents in more complex systems. Epidemiological models (e.g., Reason’s model) are used to investigate causal factors in more complex systems. Therefore, the Human Factor Analysis and Classification System (HFACS) method was chosen for research, which is based on Reason’s model. The HFACS method is tool used for the evaluation of human failure and is directly applicable to the research needs of causal factors in maritime transport. |

| 2 | A measure of a ship’s overall internal volume and is determined by dividing by 100 the contents, in cubic feet, of the vessel’s enclosed spaces [40]. |

References

- United Nations Conference on Trade and Development (UNCTAD). Review of Maritime Transport 2021. Available online: https://unctad.org/publication/review-maritime-transport-2021 (accessed on 12 August 2023).

- IMO. Contribution of the International Maritime Organization (IMO). To the Secretary-General’s Report on Oceans and the Law of the Sea, 2008. Maritime Safety and Security. Functions and Current Activities of IMO and Its Achievements Covering Technical Fields of Shipping Engaged in International Trade; United Nations: New York, NY, USA, 2008. [Google Scholar]

- European Maritime Safety Agency. Safety Analysis of EMCIP Data. Analysis of Navigation Accidents. Summary Report. 2022. Available online: https://safety4sea.com/wp-content/uploads/2022/09/EMSA-EMCIP-Navigation-Accidents-2022_09.pdf (accessed on 23 November 2023).

- Wróbel, K. Searching for the origins of the myth: 80% human error impact on maritime safety. Reliab. Eng. Syst. Saf. 2021, 216, 107942. [Google Scholar] [CrossRef]

- Galieriková, A. The human factor and maritime safety. Transp. Res. Procedia 2019, 40, 1319–1326. [Google Scholar] [CrossRef]

- Hollnagel, E.; Woods, D.D. Cognitive Systems Engineering: New wine in new bottles. Int. J. Man-Mach. Stud. 1983, 18, 583–600. [Google Scholar] [CrossRef]

- Reason, J.T. Human Error, 1st ed.; Cambridge University Press: Cambridge, UK, 1990. [Google Scholar]

- Lee, Y.C. A study on maritime casualty investigations combining the SHEL and Hybrid model methods. J. Adv. Mar. Eng. Technol. 2016, 40, 721–725. [Google Scholar] [CrossRef]

- Wu, B.; Yan, X.; Wang, Y.; Soares, C.G. An evidential reasoning-based CREAM to human reliability analysis in maritime accident process. Risk Anal. 2017, 37, 1936–1957. [Google Scholar] [CrossRef]

- Reason, J.T.; Hollnagel, E.; Paries, J. Revisiting the Swiss cheese model of accidents. J. Clin. Eng. 2006, 27, 110–115. [Google Scholar]

- Hollnagel, E. FRAM: The Functional Resonance Analysis Method: Modelling Complex Socio-Technical Systems; Ashgate Publishing Limited: Farnham, UK, 2012; p. 37. [Google Scholar]

- Leveson, N.; Daouk, M.; Dulac, N.; Marais, K. Applying STAMP in Accident Analysis; NASA Conference Publication; MIT: Cambridge, MA, USA, 1998; pp. 177–198. [Google Scholar]

- Rasmussen, J. Risk management in a dynamic society: A modelling problem. Saf. Sci. 1997, 27, 182–213. [Google Scholar] [CrossRef]

- Swain, A.D. THERP. The Symposium of the Quantification of Human Performance: A Symposium and Workshop jointly sponsored by the University of New Mexico and the M-5; 7 Subcommittee on Human Factors, Electronic Industries Association, University of New Mexico: Albuquerque, New Mexico, 1964. [Google Scholar]

- Schroeder-Hinrichs, J.U.; Graziano, A.; Kataria, A.; Praetorius, G. TRACEr-MAR-applying TRACEr in a maritime context. In Proceedings of the Risk, Reliability and Safety: Innovating Theory and Practice, 26th Conference on European Safety and Reliability (ESREL), Glasgow, Scotland, 25–29 September 2016; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: Abingdon, UK, 2017; WOS:000414164700018. [Google Scholar]

- Graziano, A.; Teixeira, A.; Soares, C.G. Classification of human errors in grounding and collision accidents using the TRACEr taxonomy. Saf. Sci. 2016, 86, 245–257. [Google Scholar] [CrossRef]

- Wiegmann, D.A.; Shappell, S.A. Human error analysis of commercial aviation accidents: Application of the Human Factors Analysis and Classification System (HFACS). Aviat. Space Environ. Med. 2001, 72, 1006–1016. [Google Scholar]

- Wiegmann, D.A.; Shappell, S.A. A Human Error Approach to Aviation Accident Analysis: The 680 Human Factors Analysis and Classification System, 1st ed.; Ashgate: Aldershot, UK, 2003. [Google Scholar]

- Celik, M.; Cebi, S. Analytical HFACS for investigating human errors in shipping accidents. Accid. Anal. Prev. 2008, 41, 66–75. [Google Scholar] [CrossRef]

- Wróbel, K.; Gil, M.; Chae, C.J. On the influence of human factors on safety of remotely-controlled merchant vessels. Appl. Sci. 2021, 11, 1145. [Google Scholar] [CrossRef]

- Rasmussen, J. Human errors: Taxonomy for describing human malfunction in industrial installations. J. Occup. Accid. 1982, 4, 311–333. [Google Scholar] [CrossRef]

- Kaptan, M.; Sarıalïoğlu, S.; Uğurlu, Ö.; Wang, J. The evolution of the HFACS method used in analysis of marine accidents: A review. Int. J. Ind. Ergon. 2021, 86, 103225. [Google Scholar] [CrossRef]

- Hulme, A.; Stanton, N.A.; Walker, G.H.; Waterson, P.; Salmon, P.M. What do applications of systems thinking accident analysis methods tell us about accident causation? A systematic review of applications between 1990 and 2018. Saf. Sci. 2019, 117, 164–183. [Google Scholar] [CrossRef]

- Hulme, A.; Stanton, N.A.; Walker, G.H.; Waterson, P.; Salmon, P.M. Accident analysis in practice: A review of Human Factors Analysis and Classification System (HFACS) applications in the peer reviewed academic literature. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting, Seattle, WA, USA, 28 October–1 November 2019; SAGE Publications: Los Angeles, CA, USA, 2019; Volume 63, pp. 1849–1853. [Google Scholar]

- Hsieh, M.C.; Wang, E.M.Y.; Lee, W.C.; Li, L.W.; Hsieh, C.Y.; Tsai, W.; Wang, C.P.; Huang, J.L.; Liu, T.C. Application of HFACS, fuzzy TOPSIS, and AHP for identifying important human error factors in emergency departments in Taiwan. Int. J. Ind. Ergon. 2018, 67, 171–179. [Google Scholar] [CrossRef]

- Illankoon, P.; Tretten, P.; Kumar, U. 20 A prospective study of maintenance deviations using HFACS-ME. Int. J. Ind. Ergon. 2019, 74, 102852. [Google Scholar] [CrossRef]

- Omole, H.; Walker, G. Offshore transport accident analysis using HFACS. Procedia Manuf. 2015, 3, 1264–1272. [Google Scholar] [CrossRef]

- Liu, R.; Cheng, W.; Yu, Y.; Xu, Q.; Jiang, A.; Lv, T. An impacting factors analysis of miners’ unsafe acts based on HFACS-CM and SEM. Process Saf. Environ. Prot. 2019, 122, 221–231. [Google Scholar] [CrossRef]

- Chauvin, C.; Lardjane, S.; Morel, G.; Clostermann, J.-P.; Langard, B. Human and organisational factors in maritime accidents: Analysis of collisions at sea using the HFACS. Accid. Anal. Prev. 2013, 59, 26–37. [Google Scholar] [CrossRef]

- Wu, B.; Yip, T.L.; Yan, X.; Soares, C.G. Review of techniques and challenges of human and organizational factors analysis in maritime transportation. Reliab. Eng. Syst. Saf. 2022, 219, 108249. [Google Scholar] [CrossRef]

- Materna, M.; Maternová, A. Safety Management in Aviation, EDIS—Publisher of University of Zilina: Zilina, Slovakia, in press.

- Materna, M.; Galieriková, A.; Sosedová, J. Analysis of risks in aviation. In Proceedings of the 22nd International Scientific Conference, Trakai, Lithuania, 3–5 October 2018; Kauno Technologijos Universitetas: Kaunas, Lithuania. [Google Scholar]

- Maternová, A.; Materna, M.; Dávid, A. Revealing causal factors influencing sustainable and safe navigation in central Europe. Sustainability 2022, 14, 2231. [Google Scholar] [CrossRef]

- Gabrikova, B.; Svabova, L.; Kramarova, K. Machine Learning Ensemble Modelling for Predicting Unemployment Duration. Appl. Sci. 2023, 13, 10146. [Google Scholar] [CrossRef]

- Gajdosikova, D.; Lazaroiu, G.; Valaskova, K. How Particular Firm-Specific Features Influence Corporate Debt Level: A Case Study of Slovak Enterprises. Axioms 2023, 121, 183. [Google Scholar] [CrossRef]

- Agresti, A. Foundations of Linear and Generalized Linear Models, 2nd ed.; Wiley: Hoboken, NJ, USA, 2003; ISBN 978-1-118-73003-4. [Google Scholar]

- Marine Accident Investigation Branch (MAIB). Available online: https://www.gov.uk/government/organisations/marine-accident-investigation-branch (accessed on 3 July 2023).

- Transportation Safety Board of Canada (TSB). Available online: https://www.tsb.gc.ca/eng/index.html (accessed on 8 July 2023).

- Thai, V.V.; Grewal, D. The maritime safety management system (MSMS): A survey of the international shipping community. Marit. Econ. Logist. 2006, 8, 287–310. [Google Scholar] [CrossRef]

- International Maritime Organisation. International Convention on Tonnage Measurement of Ships. 1969. Available online: https://www.imo.org/en/About/Conventions/Pages/International-Convention-on-Tonnage-Measurement-of-Ships.aspx (accessed on 19 August 2023).

- Mrazova, L. The Influence of the Human Factor on Maritime Safety Using the Application of the HFACS Method. Master’s Thesis, EDIS, Publishing House of the University of Zilina, Žilina-Vlčince, Slovakia, 2022. [Google Scholar]

- Rawson, K.J.; Tupper, E.C. Basic Ship Theory. In Chapter 5—Hazards and Protection, 5th ed.; Butterworth-Heinemann: Oxford, UK, 2001; pp. 145–176. ISBN 9780750653985. [Google Scholar]

- Mitchell, J. Human Factors in the Chemical and Process Industries. In Chapter 21—Safety Critical Communication, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 417–434. ISBN 9780128038062. [Google Scholar]

- Schröder-Hinrichs, J.U.; Hollnagel, E.; Baldauf, M. From Titanic to Costa Concordia—A century of lessons not learned. WMU J. Marit. Aff. 2012, 11, 151–167. [Google Scholar] [CrossRef]

- Dalaklis, D. Shipping Operations Management. Chapter Safety and Security in Shipping Operations. In WMU Studies in Maritime Affairs, 4th ed.; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- International Maritime Organisation. International Convention for the Safety of Life at Sea (SOLAS); International Maritime Organisation: London, UK, 1974. [Google Scholar]

- Schroder-Hinrichs, J.-U.; Hollnagel, E.; Baldauf, M.; Hofmann, S. Maritime human factors and IMO policy. Marit. Policy Manag. 2013, 40, 243–260. [Google Scholar] [CrossRef]

- International Maritime Organisation. The International Convention for the Prevention of Pollution from Ships, 1973 as Modified by the Protocol of 1978, or “MARPOL 73/78”; International Maritime Organisation: London, UK, 1978. [Google Scholar]

- International Maritime Organisation. The International Safety Management (ISM) Code; International Maritime Organisation: London, UK, 1993. [Google Scholar]

- Psaraftis, H.N. Maritime safety: To be or not to be proactive. WMU J. Marit. Aff. 2003, 1, 3–16. [Google Scholar] [CrossRef]

- Galieriková, A.; Dávid, A.; Sosedová, J. Fatigue in maritime transport. Sci. J. Bielsko-Biala Sch. Financ. Law 2020, 24, 35–38. [Google Scholar] [CrossRef]

| Probability | Probability and Frequency of Occurrence | Value |

|---|---|---|

| Frequent | Likely to occur many times (has occurred frequently) Probability: 1 × 10−3 Frequency: more often than once a month | 5 |

| Occasional | Likely to occur sometimes (has occurred infrequently) Probability: 1 × 10−5–1 × 10−3 Frequency: more often than once in 1 year but not more often than once in 1 month | 4 |

| Remote | Unlikely, but possible to occur (has occurred rarely) Probability: 1 × 10−7–1 × 10−5 Frequency: more often than once in 5 years but not more often than once in 1 year | 3 |

| Improbable | Very unlikely to occur (not known to have occurred) Probability: 1 × 10−9–1 × 10−7 Frequency: more often than once in 5 years but not more often than once in 20 years | 2 |

| Extremely improbable | Almost inconceivable that the event will occur Probability: less than 1 × 10−9 Frequency: never (during lifetime of given system) | 1 |

| Severity of Consequences | Examples of Maritime Transport | Value |

|---|---|---|

| Catastrophic |

| A |

| Hazardous |

| B |

| Major |

| C |

| Minor |

| D |

| Negligible |

| E |

| Probability | Severity | ||||

|---|---|---|---|---|---|

| Catastrophic A | Hazardous B | Major C | Minor D | Negligible E | |

| Frequent 5 | 5A | 5B | 5C | 5D | 5E |

| Occasional 4 | 4A | 4B | 4C | 4D | 4E |

| Remote 3 | 3A | 3B | 3C | 3D | 3E |

| Improbable 2 | 2A | 2B | 2C | 2D | 2E |

| Extremely improbable 1 | 1A | 1B | 1C | 1D | 1E |

| Prediction | |||

|---|---|---|---|

| 0 | 1 | ||

| Actual | 0 | True Negative (TN) | False Positive (FP) |

| 1 | False Negative (FN) | True Positive (TP) | |

| Years | Number of Accidents | Causal Factors ∑ | Factors | |||

|---|---|---|---|---|---|---|

| Human | Meteorological | Technical | Other | |||

| 2015 | 27 | 54 | 42 | 3 | 9 | 2 unknowns |

| 2016 | 29 | 62 | 45 | 8 | 9 | 2 unknowns |

| 2017 | 19 | 36 | 27 | 2 | 7 | 1 unknown |

| 2018 | 20 | 41 | 30 | 6 | 5 | 1 unknown |

| 2019 | 19 | 35 | 28 | 2 | 5 | 3 unknowns |

| 2020 | 12 | 27 | 23 | 3 | 1 | 1 vis major |

| 2021 | 6 | 18 | 14 | 1 | 3 | 1 unknown |

| 2022 | 3 | 12 | 10 | 1 | 1 | - |

| ∑ | 135 | 295 | 219 | 26 | 40 | 11 |

| Years | Number of Accidents | Causal Factors ∑ | Factors | |||

|---|---|---|---|---|---|---|

| Human | Meteorological | Technical | Other | |||

| 2015 | 11 | 21 | 11 | 6 | 6 | 1 unknown |

| 2016 | 15 | 21 | 14 | 3 | 4 | 1 vis major |

| 2017 | 19 | 31 | 20 | 1 | 10 | 1 unknown |

| 2018 | 22 | 38 | 20 | 6 | 12 | 2 unknowns |

| 2019 | 14 | 24 | 16 | 3 | 5 | 4 unknowns |

| 2020 | 13 | 20 | 13 | 3 | 4 | 4 unknowns |

| 2021 | 8 1 | 8 | 5 | 2 | 1 | unknown (6 2) |

| 2022 | 11 | - | - | - | - | ongoing investigation (11) |

| ∑ | 112 | 160 | 99 | 23 | 42 | 30 |

| Category of Failure | Subcategories | MAIB | TSB | ∑ | % 1 |

|---|---|---|---|---|---|

| Unsafe acts | Decision Errors | 31 | 14 | 45 | 14.2% |

| Skill-Based Errors | 8 | 5 | 13 | 4.1% | |

| Perceptual Errors | 6 | 2 | 8 | 2.5% | |

| Routine Violations | 30 | 12 | 42 | 13.2% | |

| Exceptional Violations | 11 | 2 | 13 | 4.1% | |

| Preconditions for unsafe acts | Physical Environment | 7 | 2 | 9 | 2.8% |

| Technological Environment | 14 | 6 | 20 | 6.3% | |

| Adverse Mental State | 9 | 2 | 11 | 3.5% | |

| Adverse Physiological State | 4 | 3 | 7 | 2.2% | |

| Physical/Mental Limitations | 6 | 1 | 7 | 2.2% | |

| Crew Resource Management | 12 | 11 | 23 | 7.2% | |

| Personal Readiness | 10 | 5 | 15 | 4.7% | |

| Unsafe supervision | Inadequate Supervision | 23 | 14 | 37 | 11.6% |

| Planned Inappropriate Operations | 7 | 5 | 12 | 3.8% | |

| Failed to Correct a Known Problem | 7 | 4 | 11 | 3.5% | |

| Supervisory Violation | 6 | 5 | 11 | 3.5% | |

| Organisational influences | Resource Management | 7 | 1 | 8 | 2.5% |

| Organisational Climate | 2 | 0 | 2 | 0.6% | |

| Organisational Process | 19 | 5 | 24 | 7.5% | |

| ∑ | 219 | 99 | 318 | 100.0% |

| Category of Failure | INHERENT RISK 1 = Low/Acceptable, 5 = High/Unacceptable | ||

|---|---|---|---|

| Probability (1–5) | Severity (E–A) | Risk (P × S) | |

| Decision Errors | 5 | C | 5C |

| Skill-Based Errors | 3 | C | 3C |

| Perceptual Errors | 2 | C | 2C |

| Routine Violations | 5 | D | 5D |

| Exceptional Violations | 3 | B | 3B |

| Physical Environment | 2 | C | 2C |

| Technological Environment | 3 | C | 3C |

| Adverse Mental State | 2 | D | 2D |

| Adverse Physiological State | 2 | D | 2D |

| Physical/Mental Limitations | 2 | C | 2C |

| Crew Resource Management | 4 | B | 4B |

| Personal Readiness | 3 | A | 3A |

| Inadequate Supervision | 5 | C | 5C |

| Planned Inappropriate Operations | 2 | A | 2A |

| Failed to Correct a Known Problem | 2 | B | 2B |

| Supervisory violations | 2 | B | 2B |

| Resource Management | 2 | E | 2E |

| Organisational Climate | 1 | D | 1D |

| Organisational Process | 4 | C | 4C |

| Variable | B | S.E. | Wald | Sig. | Exp (B) |

|---|---|---|---|---|---|

| meteorological: ice | 42.477 | 18,364.78 | 5.35 × 10−6 | 0.998 | 2.80 × 1018 |

| meteorological: fog | 1.456 | 0.725 | 4.026 | 0.045 | 4.29 |

| meteorological: rain/precipitations | −1.016 | 0.858 | 1.403 | 0.236 | 0.36 |

| meteorological: waves/current | 21.644 | 12,791.1 | 2.86 × 10−6 | 0.999 | 2.51 × 109 |

| technical: propulsion | 0.384 | 0.528 | 0.53 | 0.467 | 1.47 |

| technical: ship construction | −0.437 | 2.035 | 0.046 | 0.830 | 0.65 |

| technical: equipment | 0.448 | 0.393 | 1.298 | 0.255 | 1.57 |

| technical: devices for navigation/communication | 2.538 | 1.422 | 3.184 | 0.074 | 12.65 |

| human: category unsafe acts (HFACS) | 0.219 | 0.318 | 0.475 | 0.491 | 1.24 |

| human: category preconditions (HFACS) | 0.368 | 0.323 | 1.3 | 0.254 | 1.44 |

| human: category supervision (HFACS) | 0.224 | 0.331 | 0.459 | 0.498 | 1.25 |

| human: category organisation (HFACS) | 0.375 | 0.387 | 0.943 | 0.332 | 1.45 |

| other: vis major | 0.356 | 1.048 | 0.115 | 0.734 | 1.43 |

| other: unknown | −0.897 | 0.518 | 2.997 | 0.083 | 0.41 |

| human: category Organisation (HFACS) + meteorological: waves/current | 0.842 | 1.927 | 0.191 | 0.662 | 2.32 |

| human: category Unsafe acts (HFACS) + technical: ship construction | 1.051 | 2.007 | 0.274 | 0.601 | 2.86 |

| human: category Organisation (HFACS) + technical: ship construction | 1.006 | 1.825 | 0.304 | 0.581 | 2.73 |

| human: category Preconditions (HFACS) + technical: ship construction | −2.151 | 1.853 | 1.348 | 0.246 | 0.12 |

| human: category Supervision (HFACS) + technical: devices | 21.3 | 11,801.51 | 3.26 × 10−6 | 0.999 | 1.78 × 109 |

| human: category Unsafe acts (HFACS) + technical: devices | 1.213 | 1.398 | 0.753 | 0.386 | 3.36 |

| human: category Preconditions (HFACS) + technical: devices | 2.77 | 1.416 | 3.828 | 0.05 | 15.96 |

| constant | 40.027 | 38,009.47 | 1.11 × 10−6 | 0.999 | 2.42 × 1017 |

| Prediction | |||

|---|---|---|---|

| 0 | 1 | ||

| Fatality | 0 | 52 | 93 |

| 1 | 11 | 132 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maternová, A.; Materna, M.; Dávid, A.; Török, A.; Švábová, L. Human Error Analysis and Fatality Prediction in Maritime Accidents. J. Mar. Sci. Eng. 2023, 11, 2287. https://doi.org/10.3390/jmse11122287

Maternová A, Materna M, Dávid A, Török A, Švábová L. Human Error Analysis and Fatality Prediction in Maritime Accidents. Journal of Marine Science and Engineering. 2023; 11(12):2287. https://doi.org/10.3390/jmse11122287

Chicago/Turabian StyleMaternová, Andrea, Matúš Materna, Andrej Dávid, Adam Török, and Lucia Švábová. 2023. "Human Error Analysis and Fatality Prediction in Maritime Accidents" Journal of Marine Science and Engineering 11, no. 12: 2287. https://doi.org/10.3390/jmse11122287

APA StyleMaternová, A., Materna, M., Dávid, A., Török, A., & Švábová, L. (2023). Human Error Analysis and Fatality Prediction in Maritime Accidents. Journal of Marine Science and Engineering, 11(12), 2287. https://doi.org/10.3390/jmse11122287